Solder alloy, solder ball and solder joint using same

A technology of solder joints and solder alloys, applied in the field of solder balls, solder joints, and solder alloys, can solve problems such as damage to joint strength, and achieve the effects of maintaining joint strength, maintaining connection reliability, and high connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

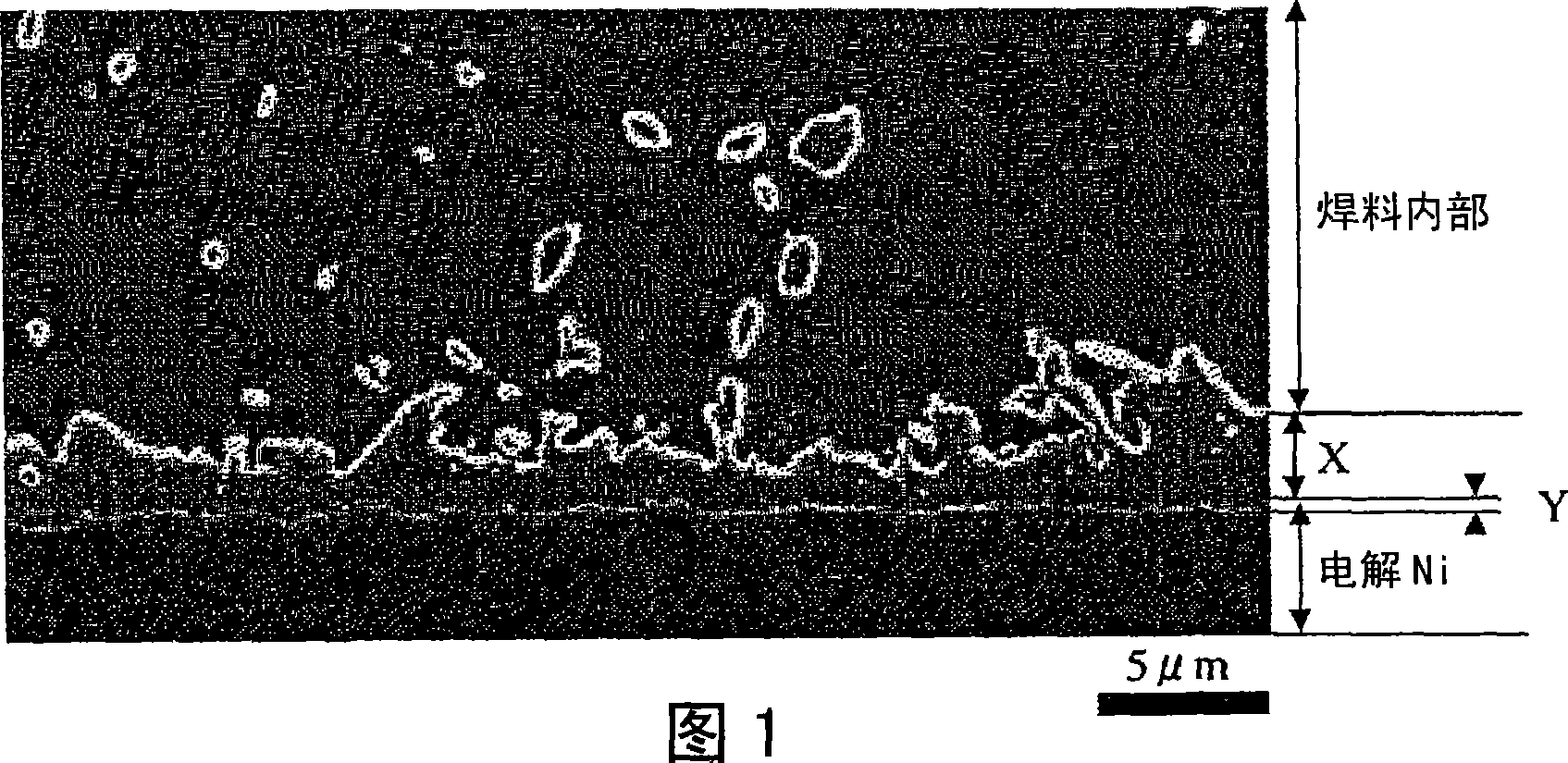

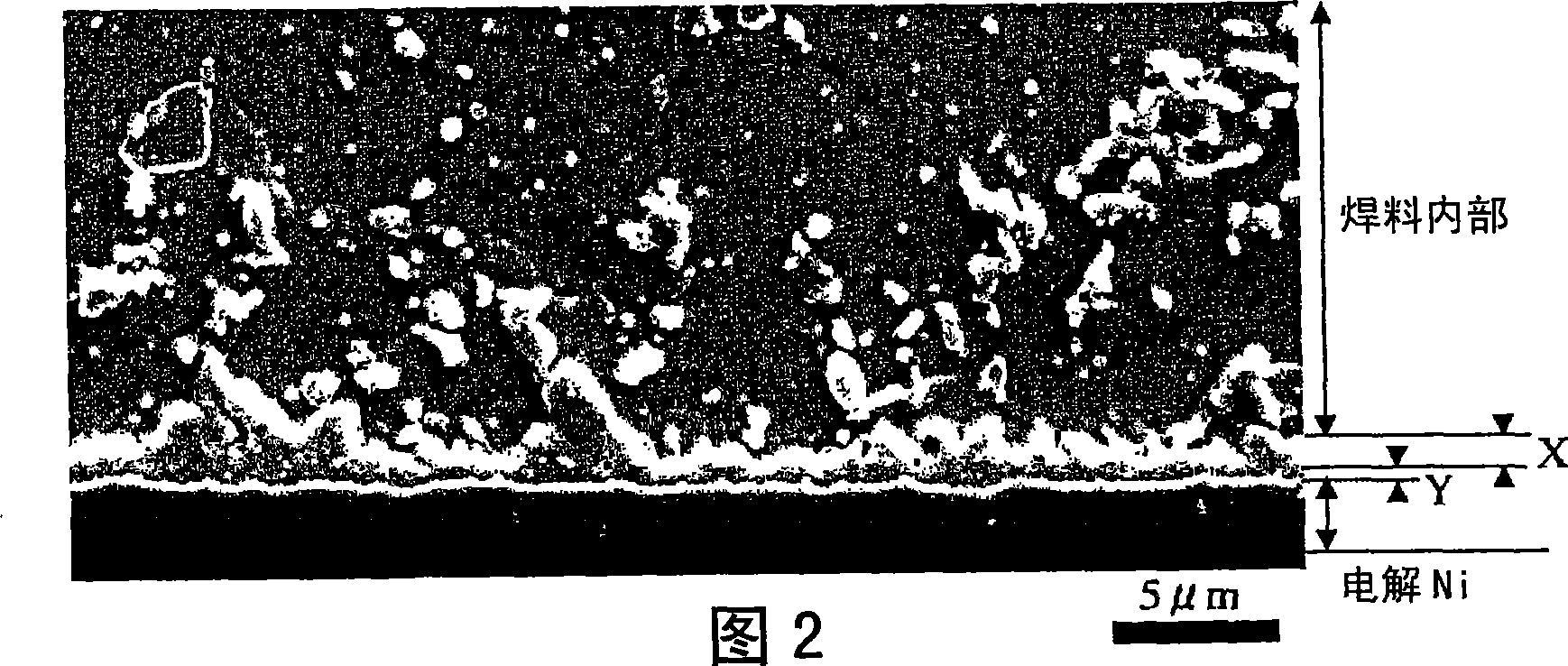

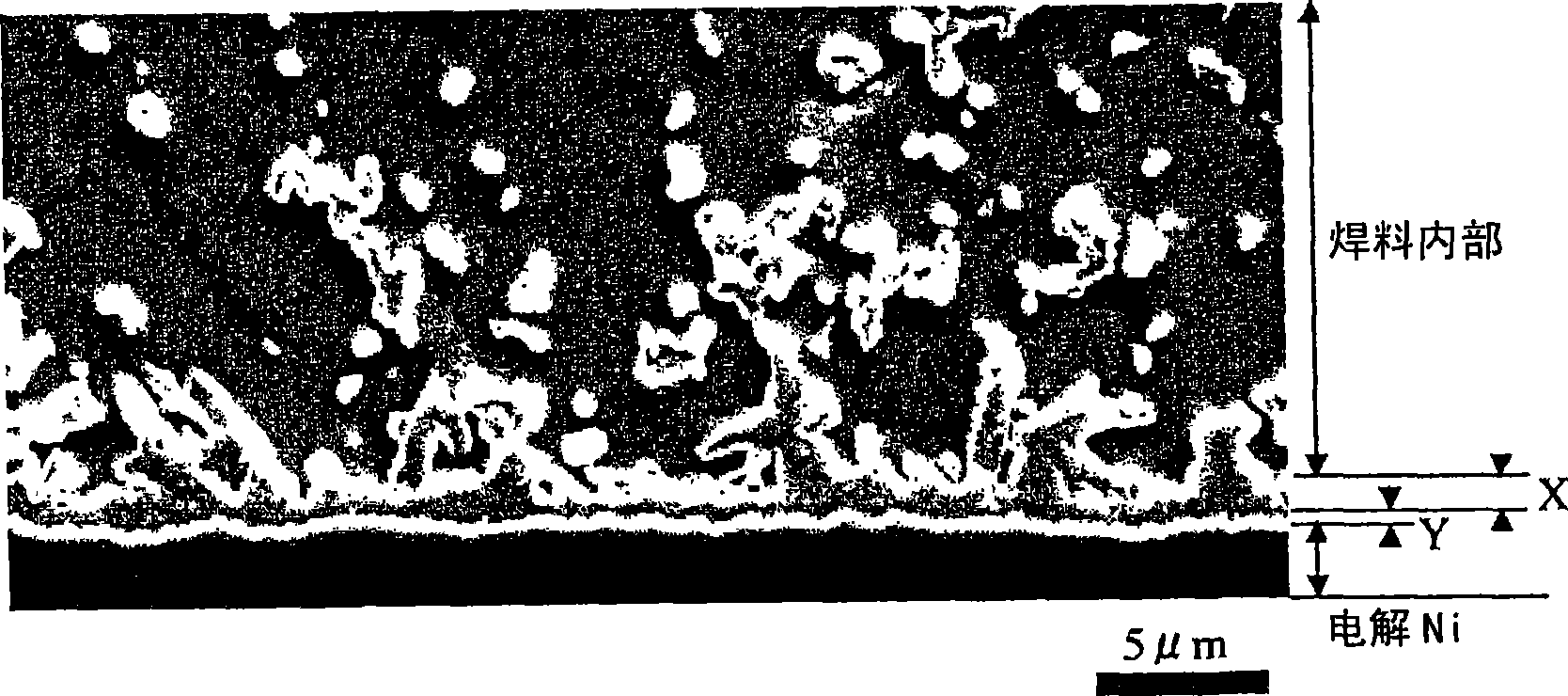

[0045] As mentioned above, the important feature of the solder alloy of the present invention is to optimize the addition amount of Ag and Ni so as not to hinder the impact resistance of the Sn—Cu alloy. Needless to say, the Cu electrode, even if it is applied to the Ni In the case of electrodes, the growth of (Cu, Ni) and Sn compounds formed at the joint interface can also be suppressed, and as long as possible, by forming only (Cu, Ni) 6 sn 5 compound, it is possible to maintain sufficient joint strength.

[0046] According to the research of the present inventors, in the Sn-Cu-Ag-Ni alloy, when the addition amount of Ni is too much, in a high-temperature environment, (Cu, Ni) tends to form on the joint interface. 6 sn 5 and (Ni, Cu) 3 sn 4 This two story compound. When the joint strength test is carried out on this solder joint, it can be seen that in (Cu, Ni) 6 sn 5 and (Ni, Cu) 3 sn 4 Delamination occurs at the interface, which will damage the bonding strength. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com