Electrically operated valve

An electric valve, valve chamber technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of cumbersome process, failure, stress concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

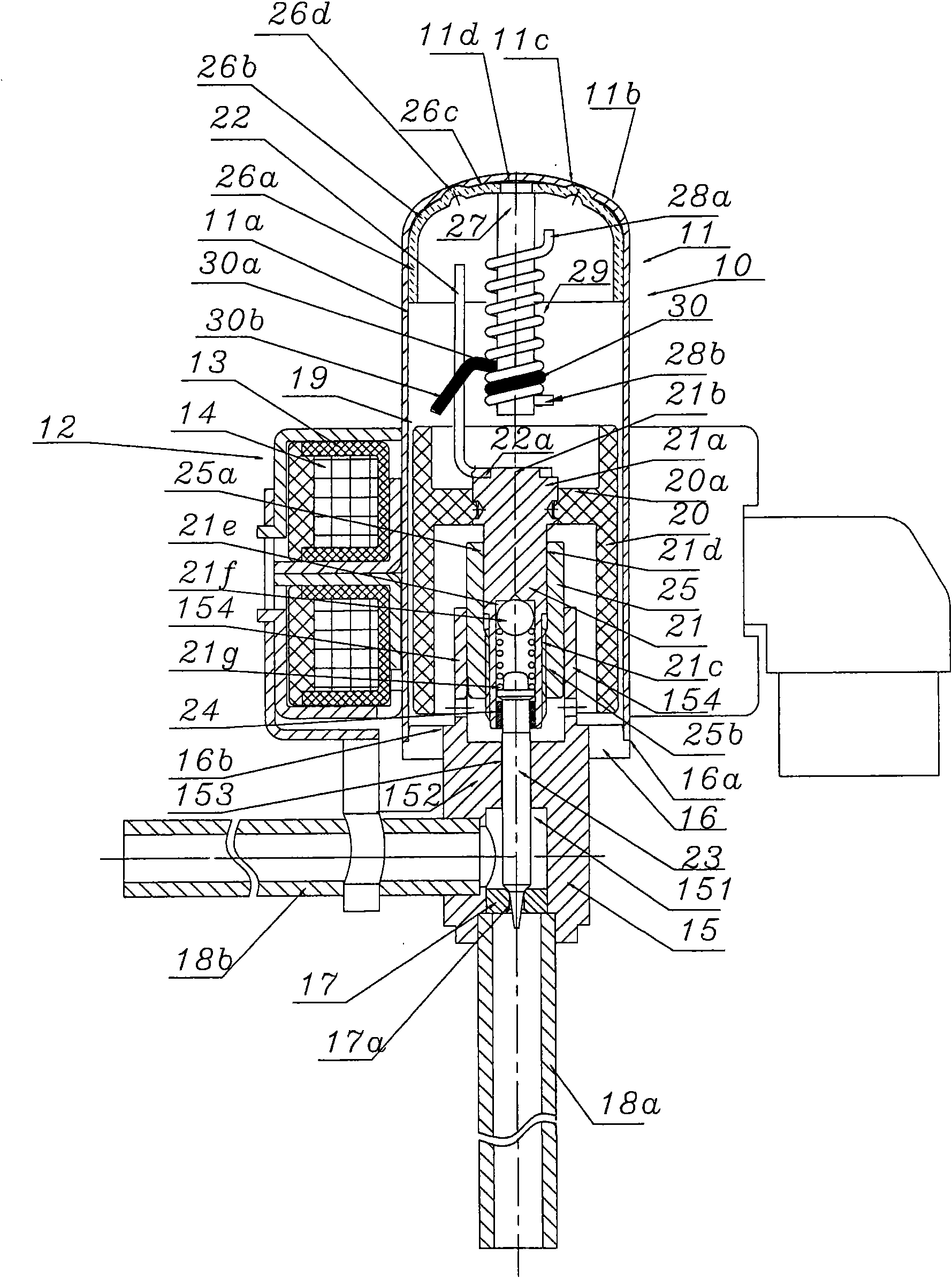

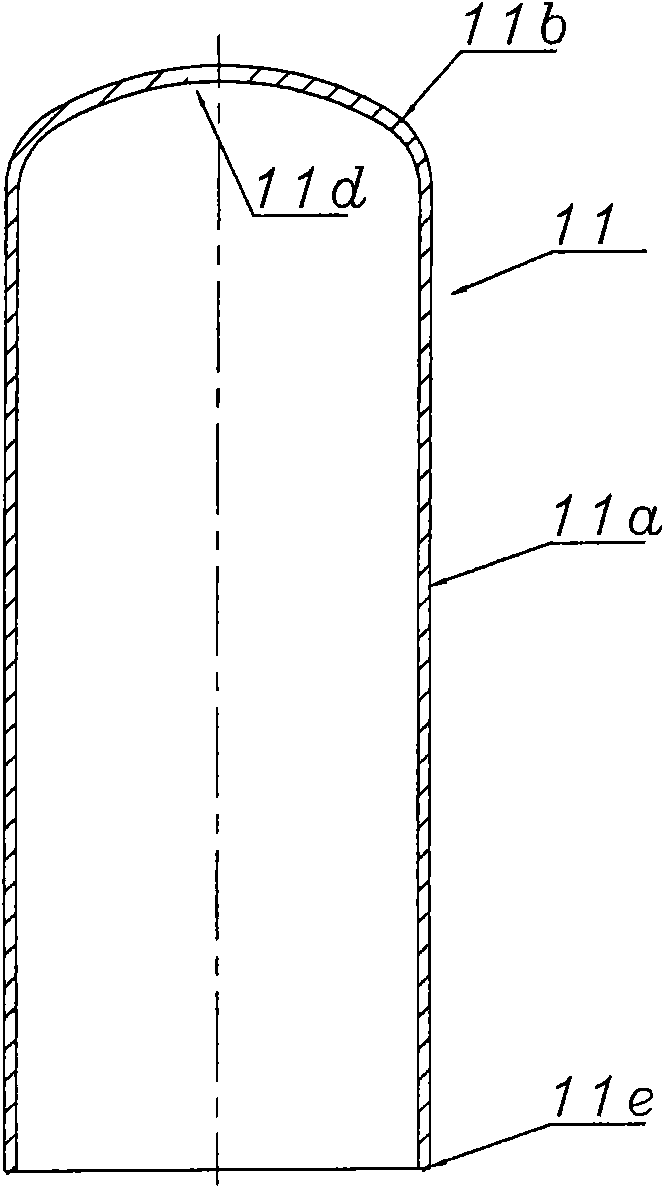

[0069] Below, refer to Figure 1A , Figure 1B , Figure 1C , Figure 1D , Figure 1E as well as Figure 1F A specific embodiment of the electric valve of the present invention will be described.

[0070] Figure 1A It is an overall structural diagram of an electric valve related to a specific embodiment of the present invention. Figure 1A The electric valve indicated by reference numeral 10 in its entirety has a cylindrical airtight housing 11 made of a stamped metal such as stainless steel, and a stator portion 12 disposed on the outer periphery of the housing 11 . The stator part 12 has a coil 14 arranged in the stator yoke 13, and since the electric valve with this configuration is basically the same as the conventional electric valve, detailed description thereof will be omitted. Therefore, only for Figure 1A The differences between the illustrated embodiment and the conventional electric valve, that is, the airtight housing 11 and the stopper mechanism provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com