Cylinder device and method for manufacturing the same

A manufacturing method and cylinder block technology, applied in the direction of manufacturing tools, liquid shock absorbers, resistance welding equipment, etc., can solve problems such as increased manufacturing costs, and achieve the effects of reduced manufacturing costs, safe manufacturing, and pollution suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings.

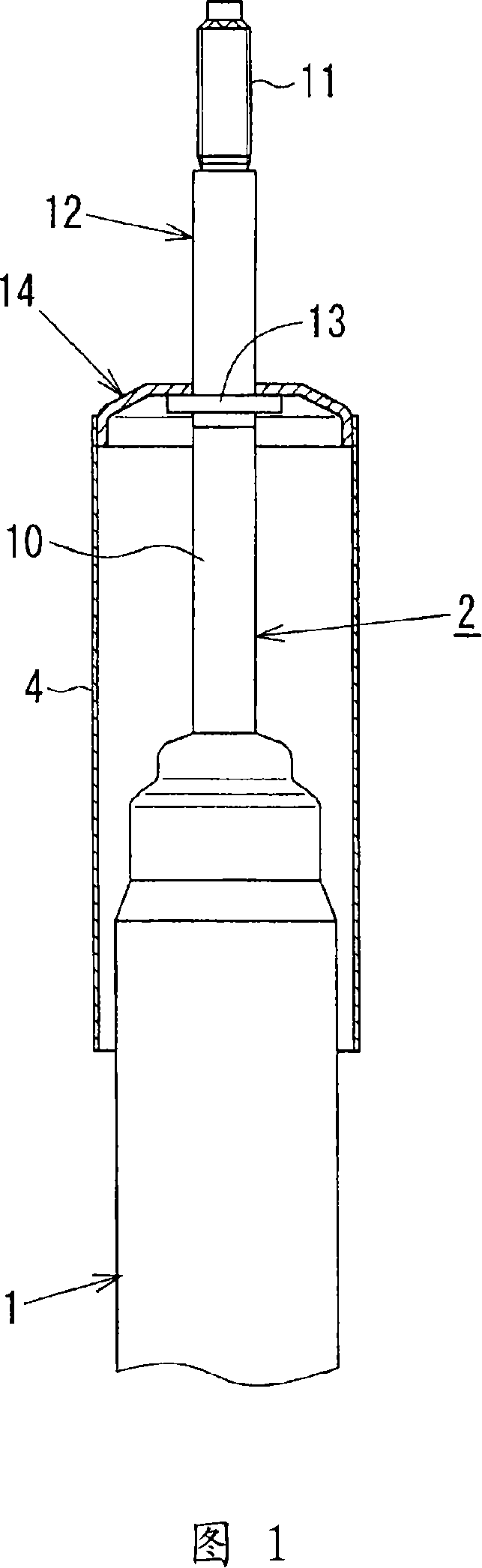

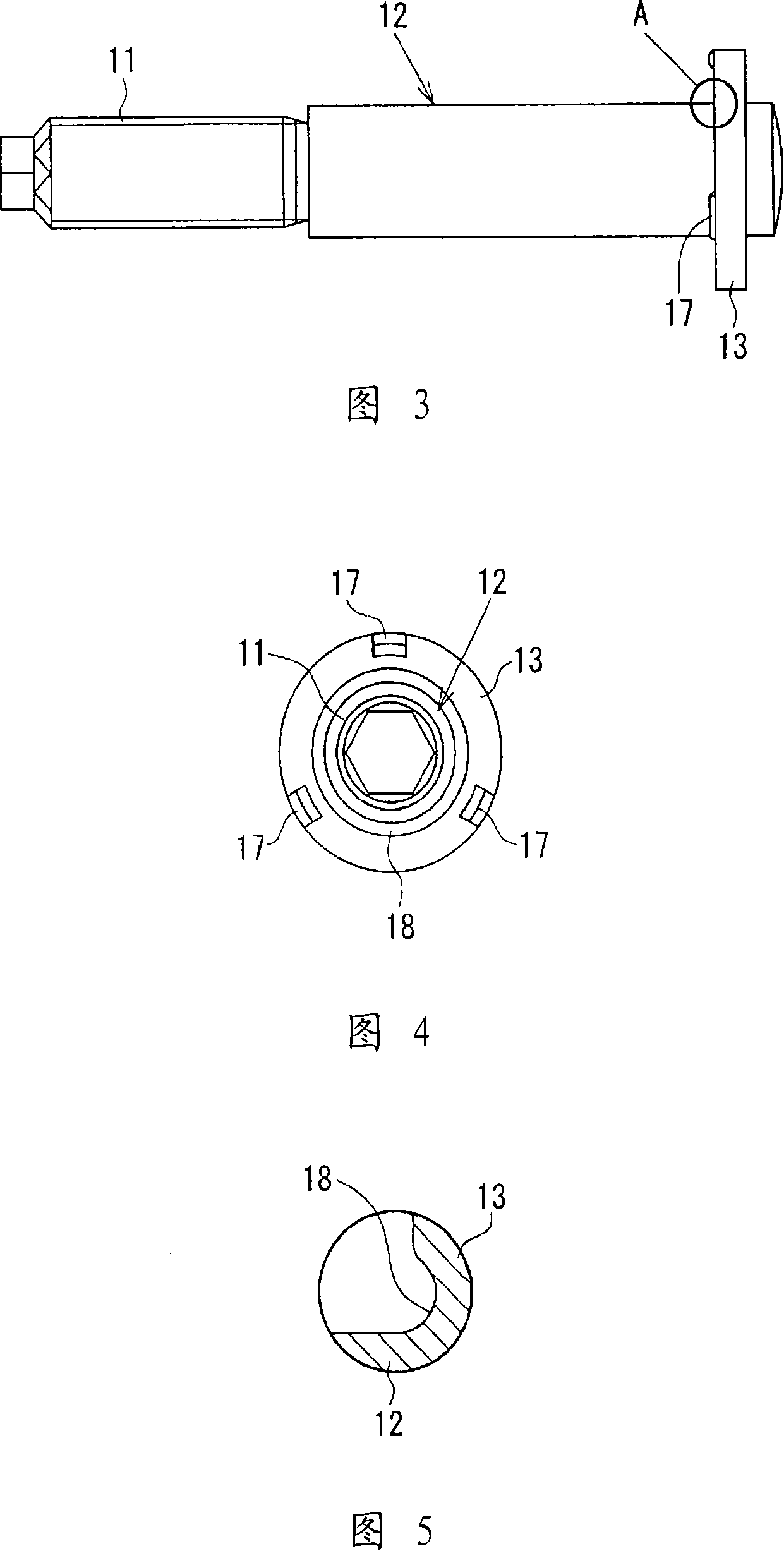

[0038] Fig. 1 shows a hydraulic shock absorber as an embodiment of the present invention. This hydraulic shock absorber is equipped on the suspension of an automobile, and its basic configuration is the same as that shown in FIG. 6 above, so the same symbols are used for the same parts here. In this embodiment, the connecting rod 2 telescopically extending from the cylinder 1 is constructed by butt-joining the connecting rod main body 10 extending from the cylinder 1 and the mounting member 12 having a bolt-shaped portion 11 at the front end as in the conventional art. Then, as shown in FIG. 2 , a flange portion 13 is integrally formed on the end side of the mounting member 12 that abuts with the connecting rod body 10 , and a cover 14 for mounting the above-mentioned protective rod is superimposed on the flange portion 13 .

[0039] In this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com