Chip engagement device and chip engagement method

A chip bonding and jointing technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of lengthening manufacturing process and hindering cost reduction, so as to ensure the bonding strength and reduce the amount of hydrogen used , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

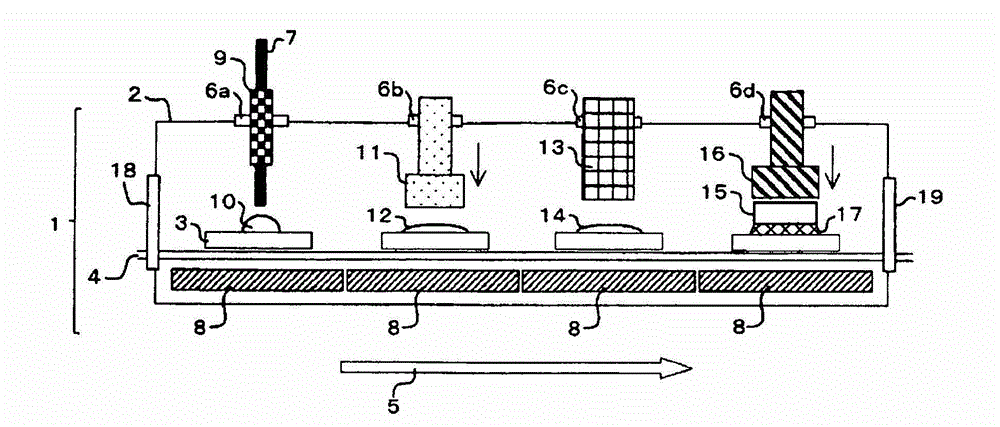

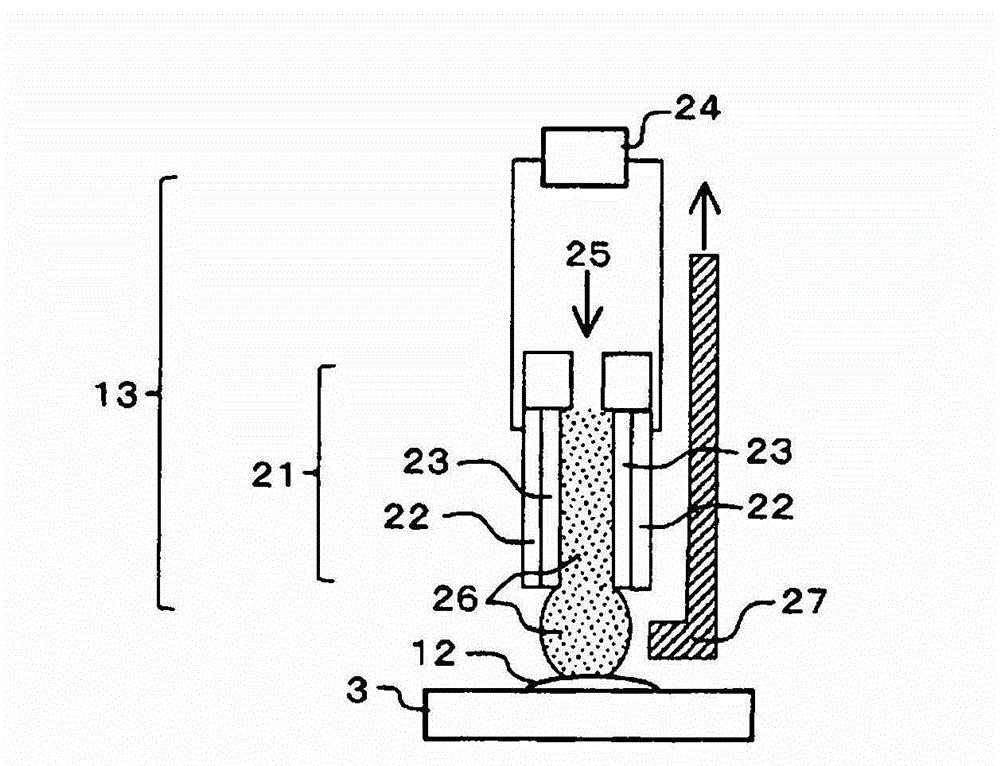

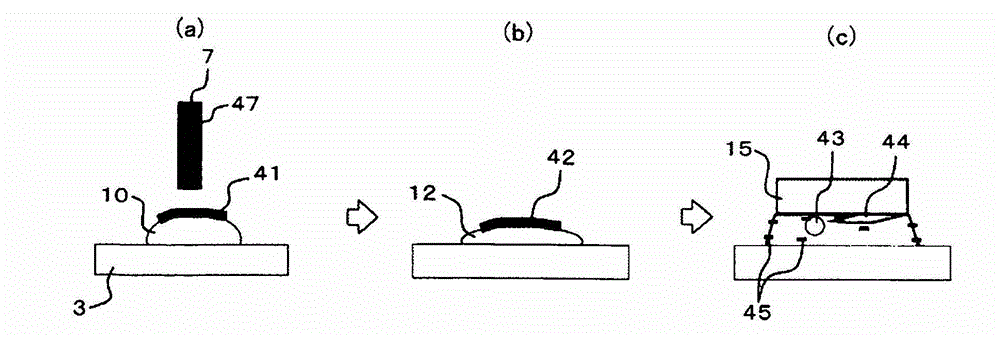

[0045] figure 1 It is an enlarged view of a main part of the die bonder having a solder surface cleaning unit according to the present invention. This die bonding machine 1 is in a furnace covered by a cover 2 to isolate the outside air, and has a guide rail 4 for intermittently moving a lead frame or a substrate 3, which is a member to be bonded, along a moving direction 5 of the lead frame or substrate 3, Four opening windows 6 a , 6 b , 6 c , and 6 d are provided at predetermined positions on the top surface of the cover (furnace) 2 . When described in terms of the die bonding process, the first step is a solder supply step of supplying the elongated solder wire 7 to the lead frame or the substrate 3 through the opening window 6 a. If this step is described in detail, the solder wire 7 sent from the solder supply nozzle 9 contacts the lead frame or the substrate 3 whose bottom surface is heated by the heater 8, and the front end of the solder wire 7 melts and wets the lead...

Embodiment 2

[0074] An example of other solder surface cleaning unit 13 Figure 10 As shown, the surface of the molten solder 12 on the lead frame or substrate 3 is plasma treated using a torch nozzle 31 at atmospheric pressure. In the torch nozzle 31, the center electrode 33 is arranged in the center of the counter electrode 32, and the insulator 34 is provided on the surface of each electrode. A high-frequency power source 35 is connected to the center electrode 33 . In addition, a processing gas is supplied from the gas inlet 36 , plasma is generated in the discharge space 37 , and nozzle-shaped plasma 39 is irradiated from the gas outlet 38 . As the processing gas, a mixed gas of nitrogen and hydrogen used as the ambient gas of the plasma apparatus was used. Thereby, hydrogen plasma is generated, and the oxide film on the surface of the molten solder 12 existing on the lead frame or the substrate 3 can be reduced.

[0075] At this time, reaction products are generated, and if left u...

Embodiment 3

[0078] An example of other solder surface cleaning units Figure 11 shown. This method is a method of irradiating laser beams. Laser beam 102 generated from laser oscillator 101 is irradiated on the surface of molten solder 14 on lead frame or substrate 3 via optical fiber 103, optical lens 104 system, and the like. The furnace is an ambient gas with a low oxygen concentration, and there is also reducing hydrogen, so the oxide film on the surface of the solder can be effectively removed. Here, as laser light, pulsed laser light of YAG laser or excimer laser is used, but not limited thereto. In addition, not only a nozzle shape but also a line shape can be used.

[0079] In addition, when the area of solder to be processed is wide, the laser beam irradiation is not irradiated so that the output is high in the center (convex shape), but is irradiated in a ring shape so that the output is substantially the same as a whole. By irradiating a laser beam, it is also possible to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com