Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

135results about How to "Predicted service life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

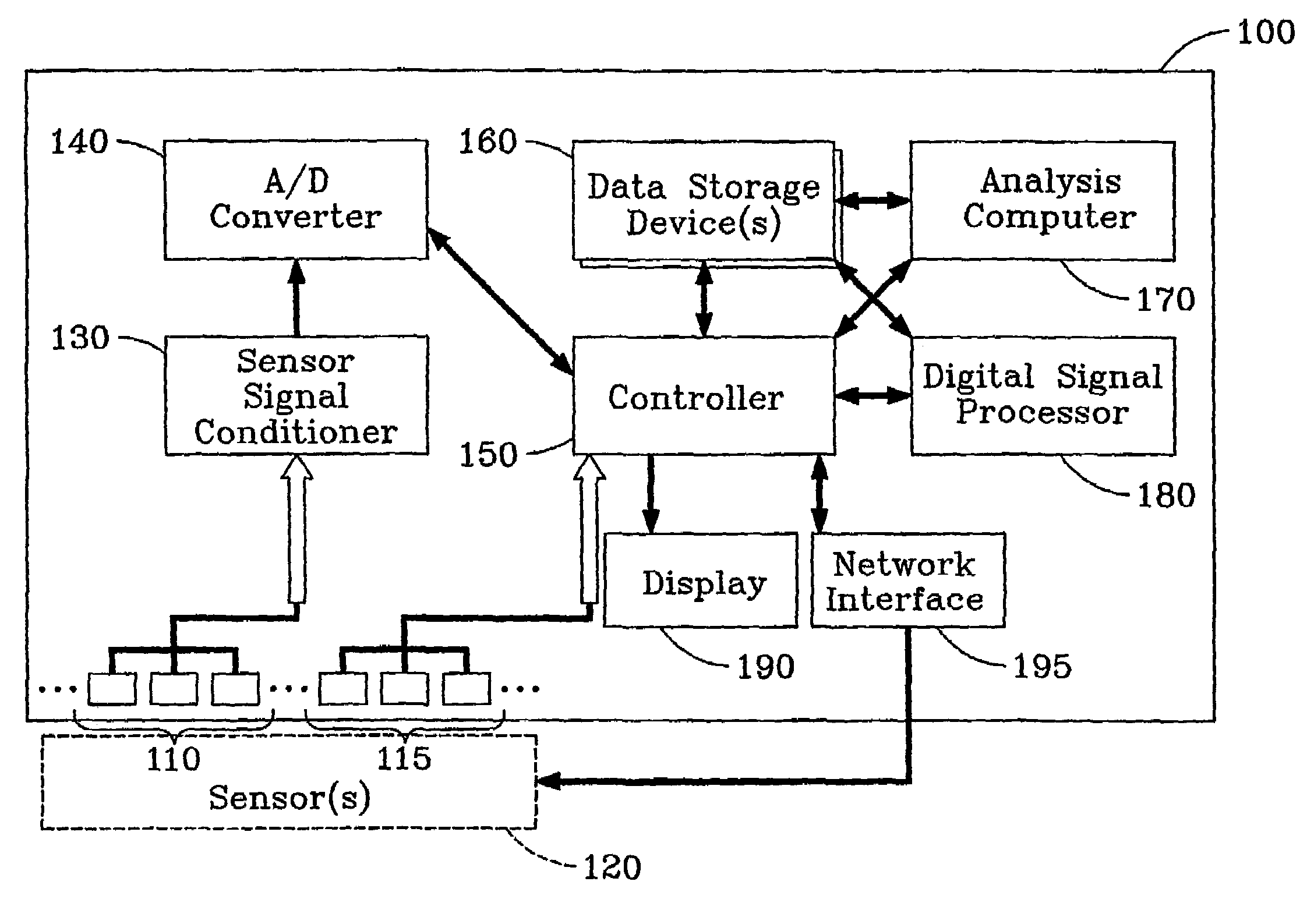

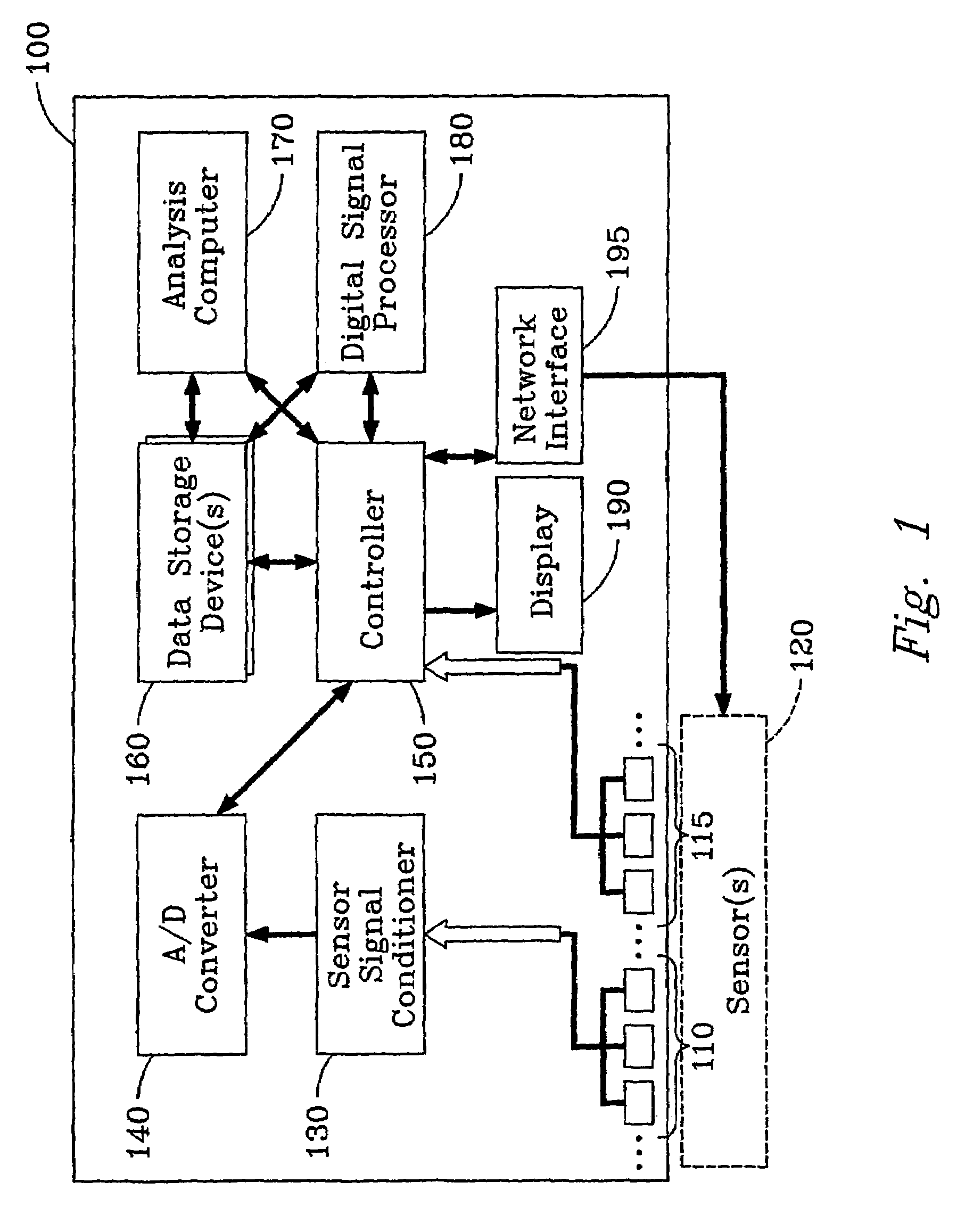

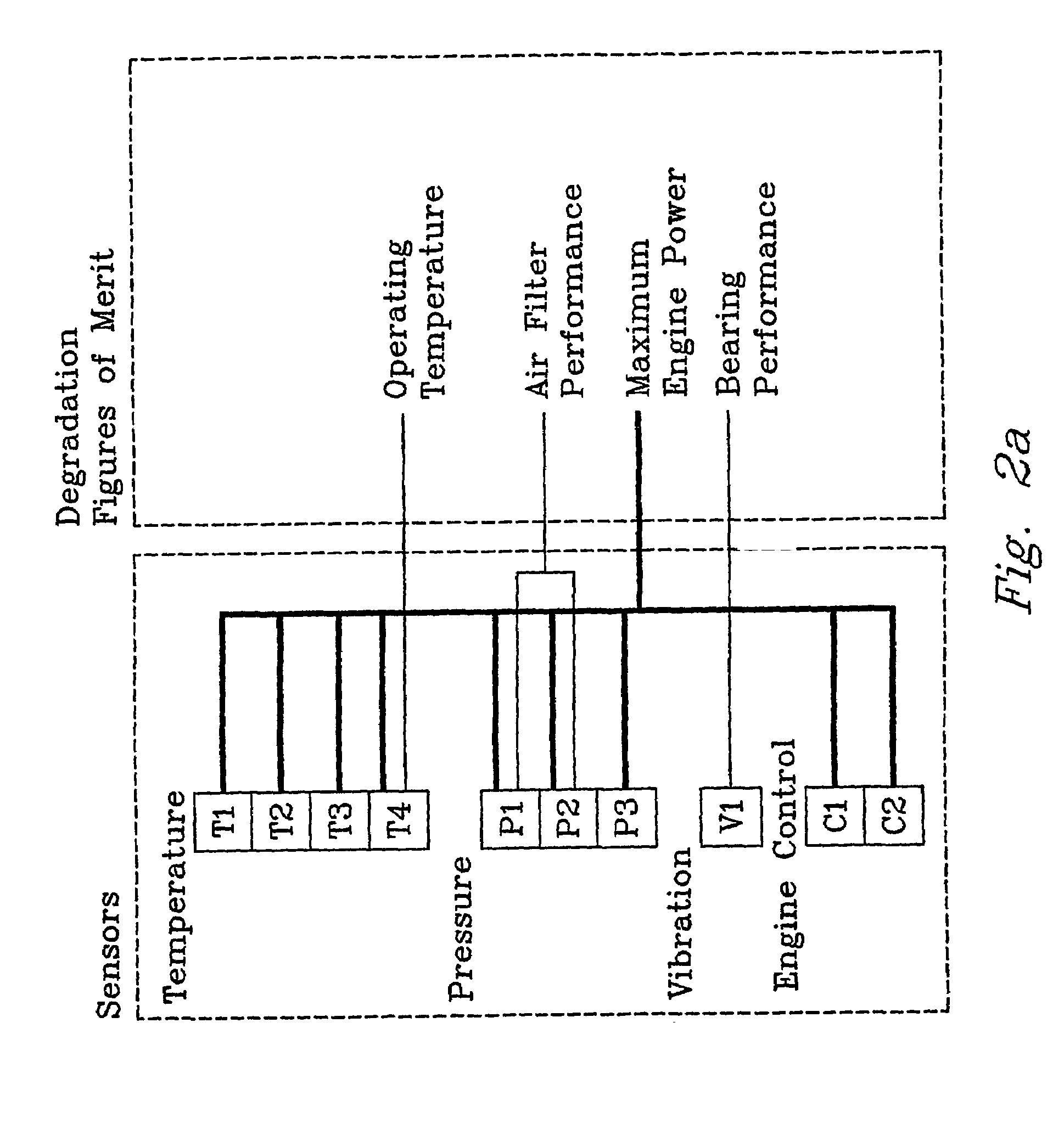

Method and apparatus to predict the remaining service life of an operating system

InactiveUS7457785B1Improve accuracy and reliabilityPredicted service lifeProgramme controlTesting/monitoring control systemsComputer basedResidual service life

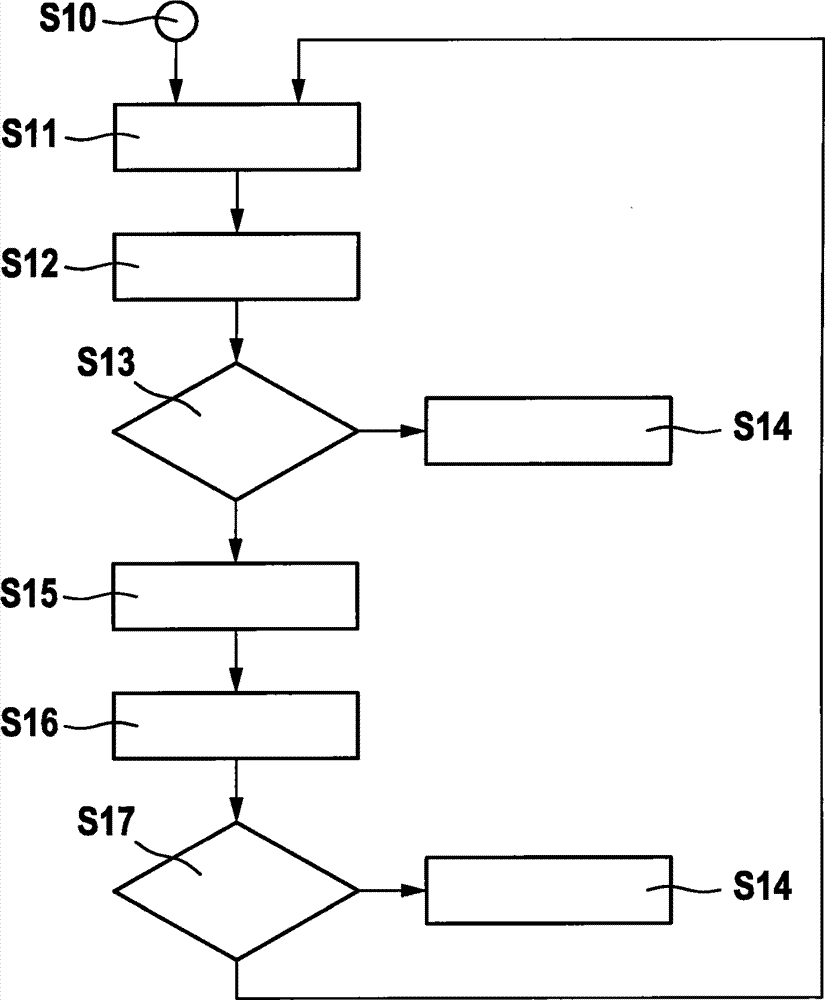

A method and computer-based apparatus for monitoring the degradation of, predicting the remaining service life of, and / or planning maintenance for, an operating system are disclosed. Diagnostic information on degradation of the operating system is obtained through measurement of one or more performance characteristics by one or more sensors onboard and / or proximate the operating system. Though not required, it is preferred that the sensor data are validated to improve the accuracy and reliability of the service life predictions. The condition or degree of degradation of the operating system is presented to a user by way of one or more calculated, numeric degradation figures of merit that are trended against one or more independent variables using one or more mathematical techniques. Furthermore, more than one trendline and uncertainty interval may be generated for a given degradation figure of merit / independent variable data set. The trendline(s) and uncertainty interval(s) are subsequently compared to one or more degradation figure of merit thresholds to predict the remaining service life of the operating system. The present invention enables multiple mathematical approaches in determining which trendline(s) to use to provide the best estimate of the remaining service life.

Owner:BATTELLE MEMORIAL INST

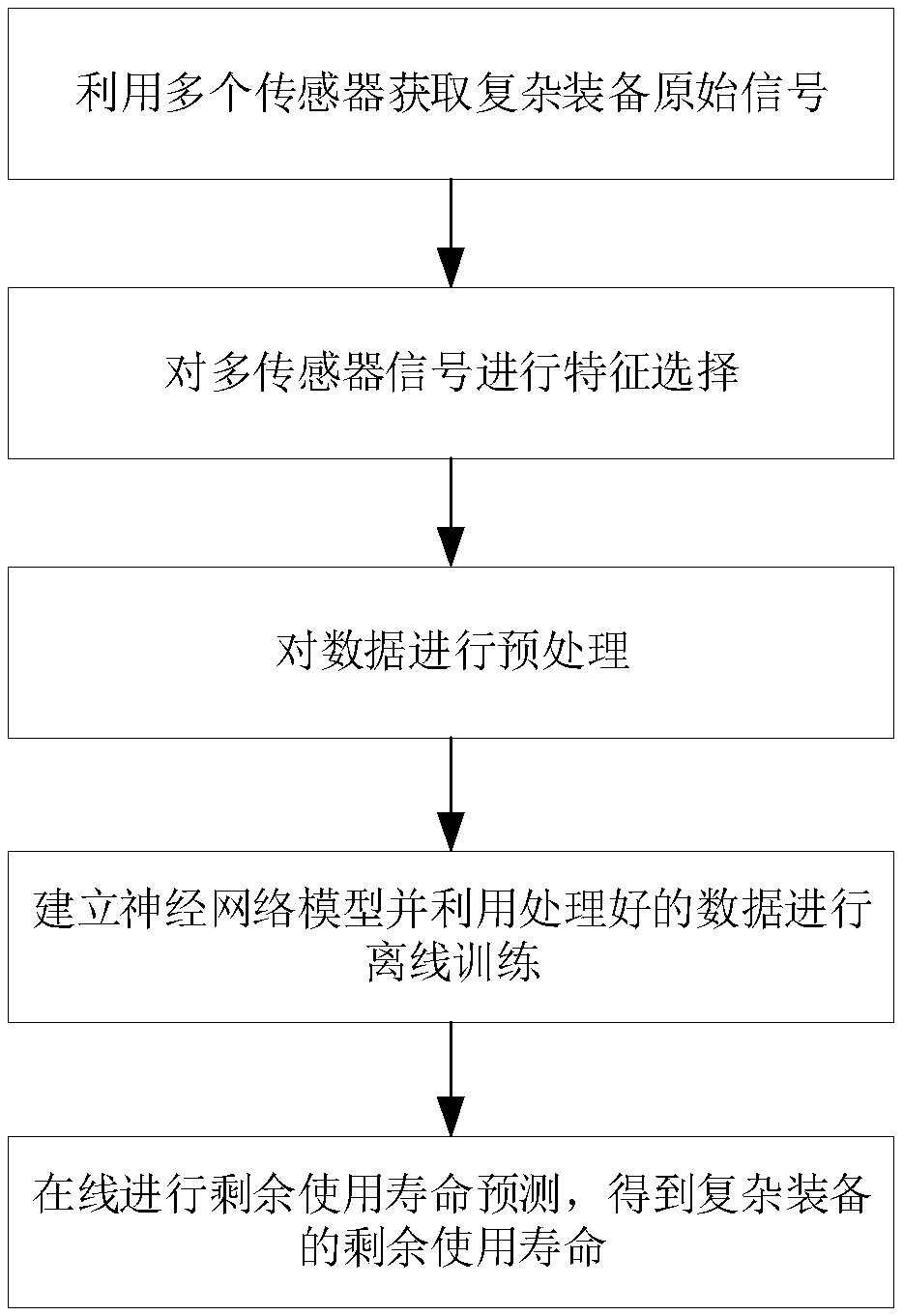

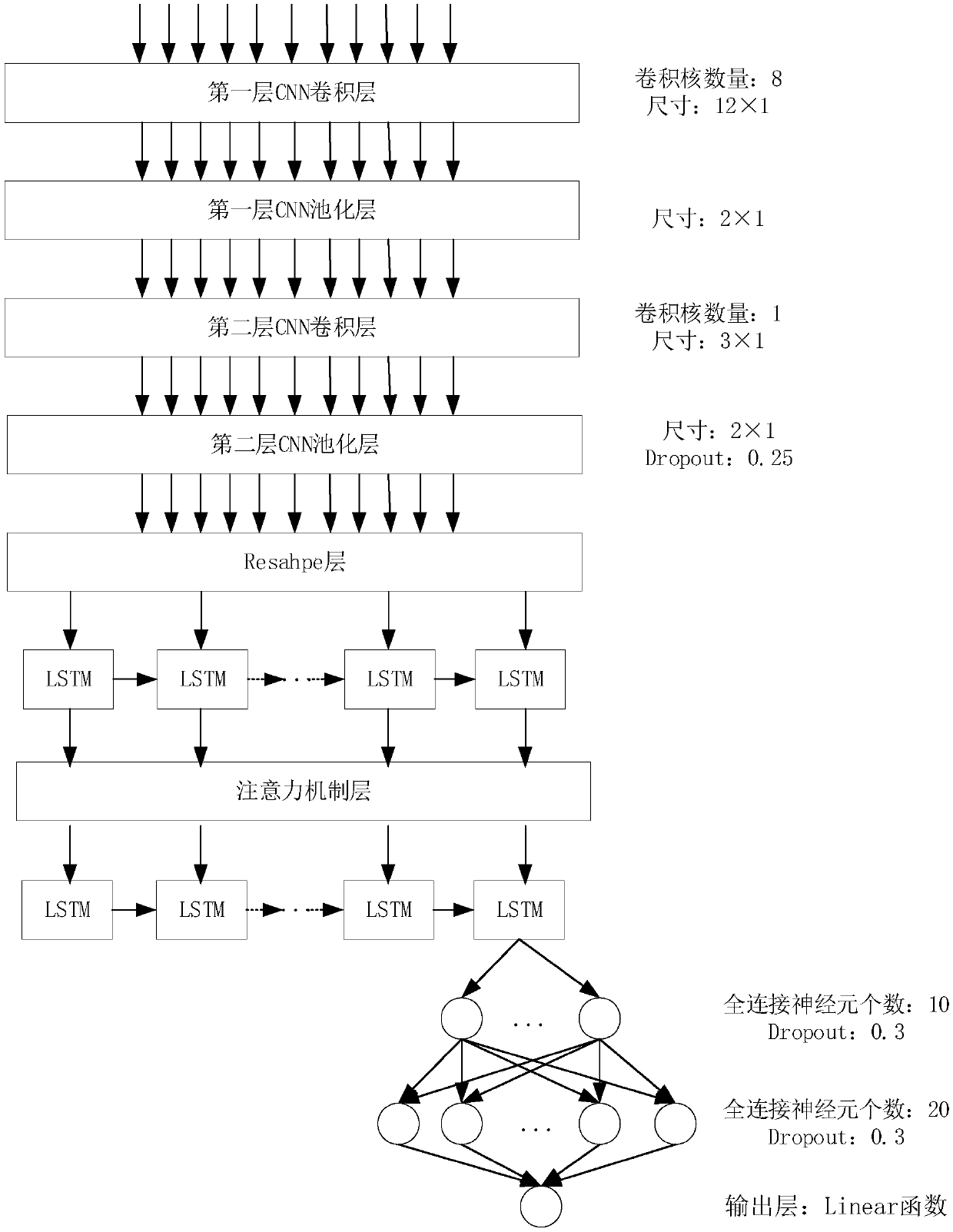

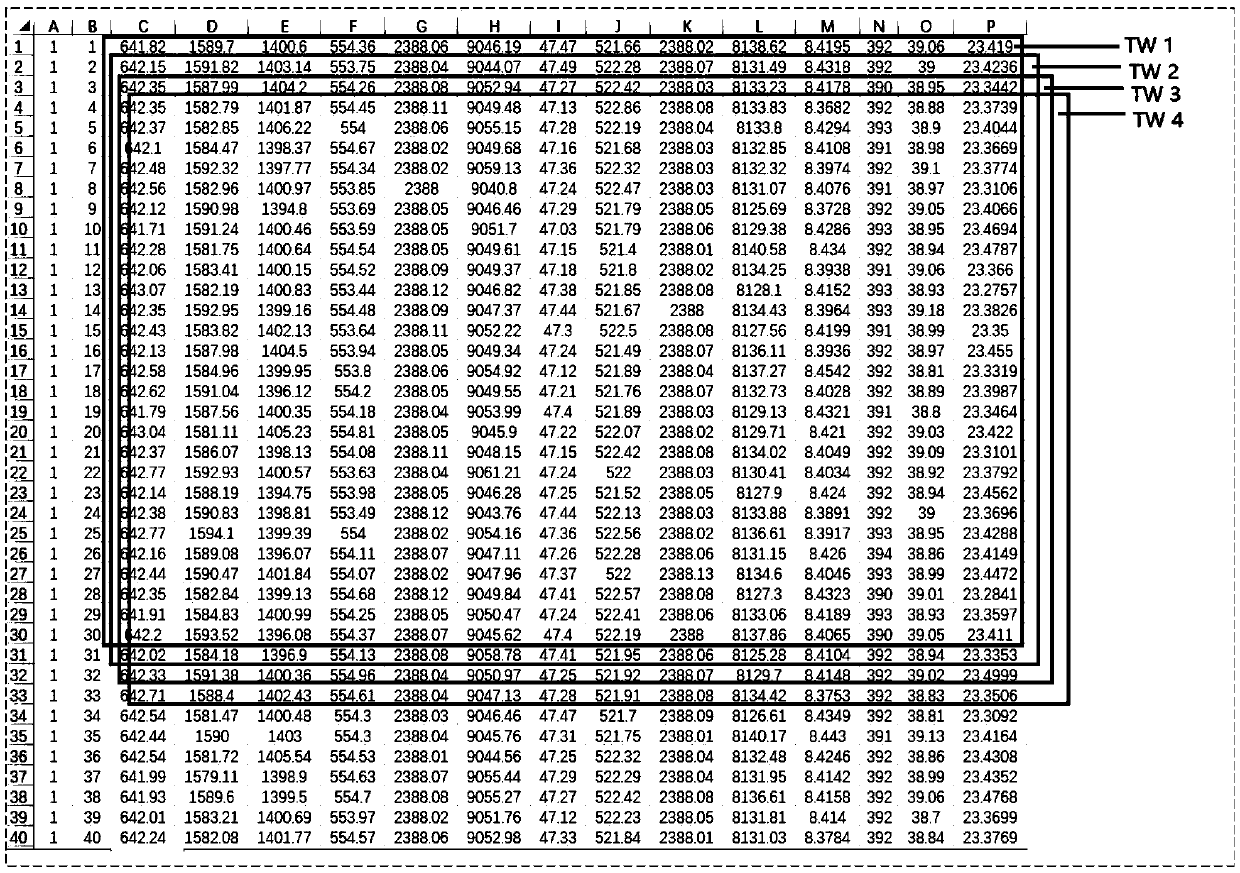

Residual service life prediction method of complex equipment based on combined depth neural network

ActiveCN109522600AStrong feature extraction abilitySimple structureGeometric CADCharacter and pattern recognitionFeature selectionSlice sampling

The invention discloses a method for predicting the remaining service life of complex equipment based on a combined depth neural network. The main steps are as follows: acquiring multi-sensor data ofcomplex equipment; Obtaining effective measurement data by feature selection; obtaining A plurality of slice samples by preprocessing; Establishing the neural network regression model which combines the attention mechanism and depth neural network; The slice samples and their corresponding labels are inputted into the neural network regression model to train the neural network regression model offline. inputting The slice samples of multi-sensor data to be predicted into the trained neural network regression model, and the remaining service life of complex equipment is obtained. Considering the data characteristics of the multi-sensor signal, the invention fully excavates the local characteristics and the time sequence information in the data, has high prediction accuracy and wide applicability, and can be widely applied to various pieces of complex equipment.

Owner:ZHEJIANG UNIV

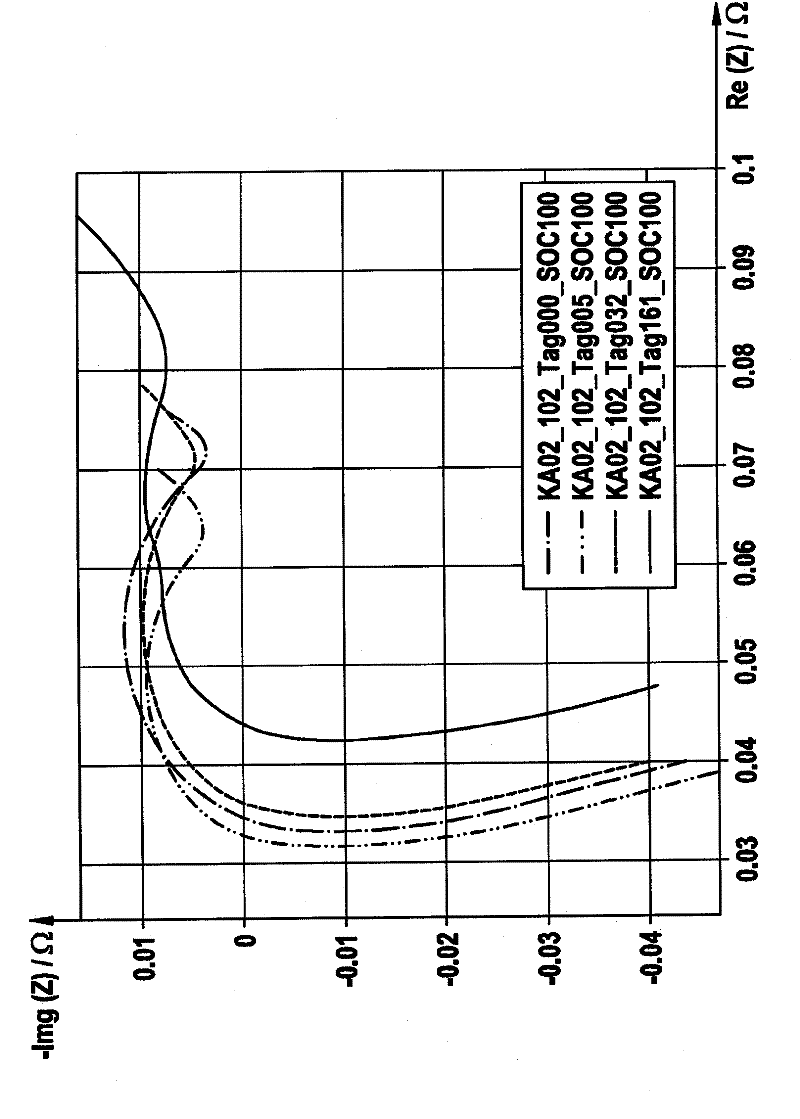

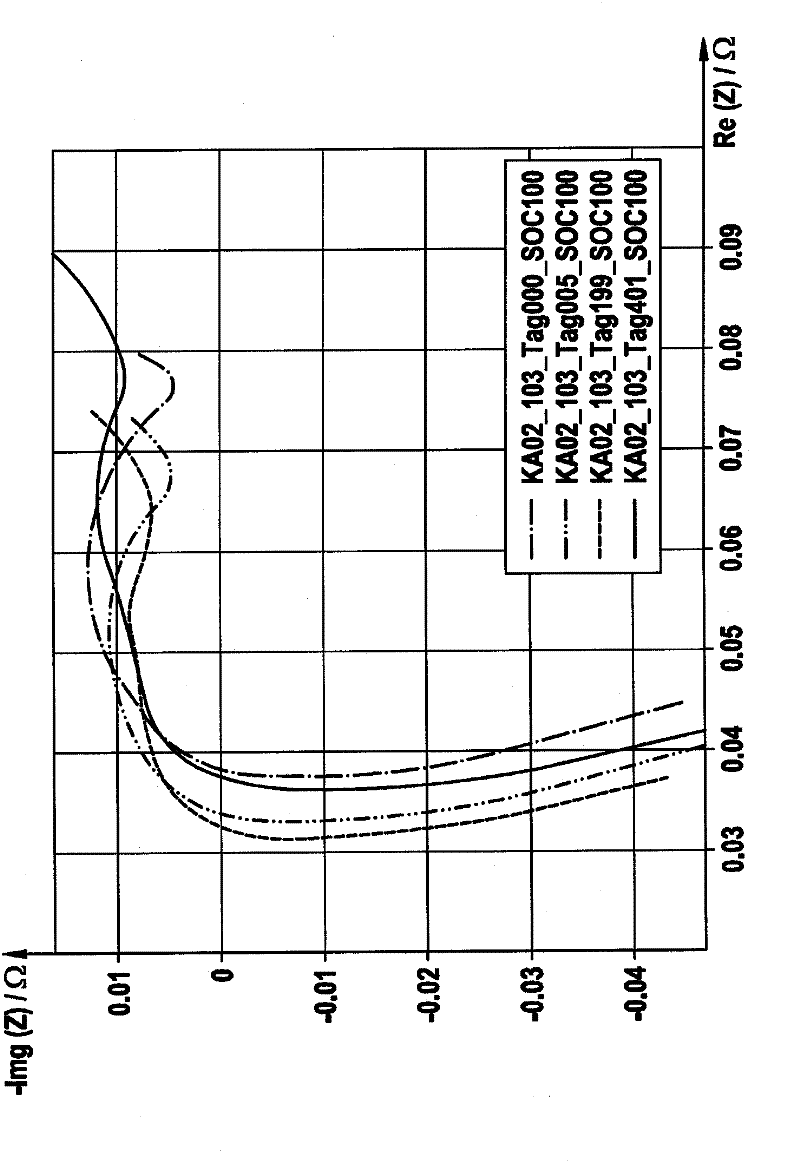

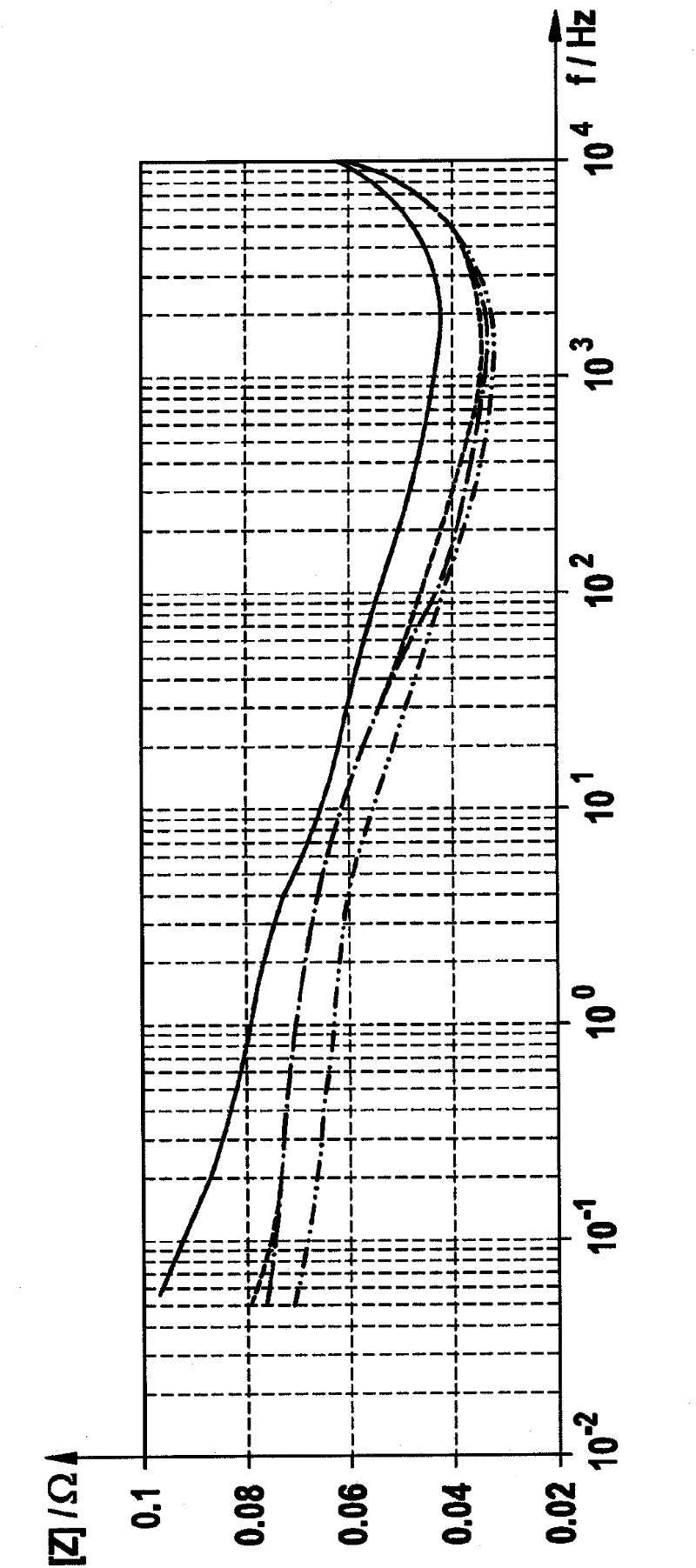

Method for determining the aging state of battery cells by means of impedance spectroscopy

InactiveCN102292864ADetermine aging statusPredicted service lifeSpectral/fourier analysisResistance/reactance/impedenceElectrical batteryPhysical chemistry

The invention relates to a method for determining an aging condition of a battery cell. The method has the following steps of a) providing a battery cell, b) recording an impedance spectrum of the battery cell, c) determining an evaluation quantity based on the measured impedance spectrum, and d) determining an aging condition of the battery cell based on a comparison of the evaluation quantity to a reference value.

Owner:ROBERT BOSCH GMBH

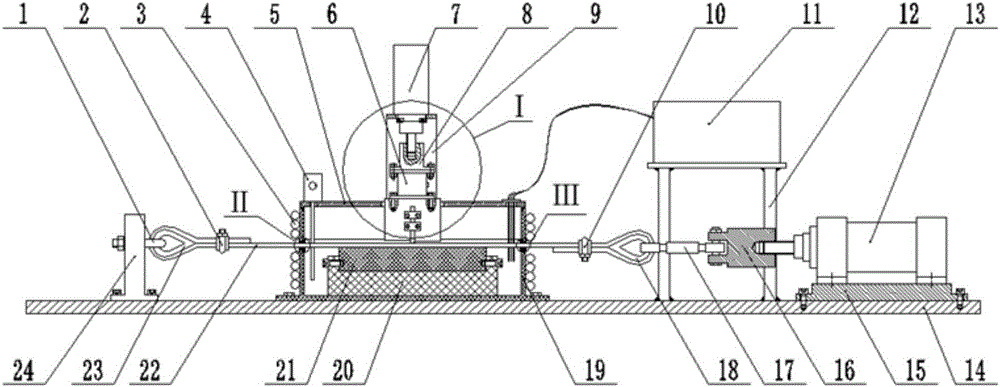

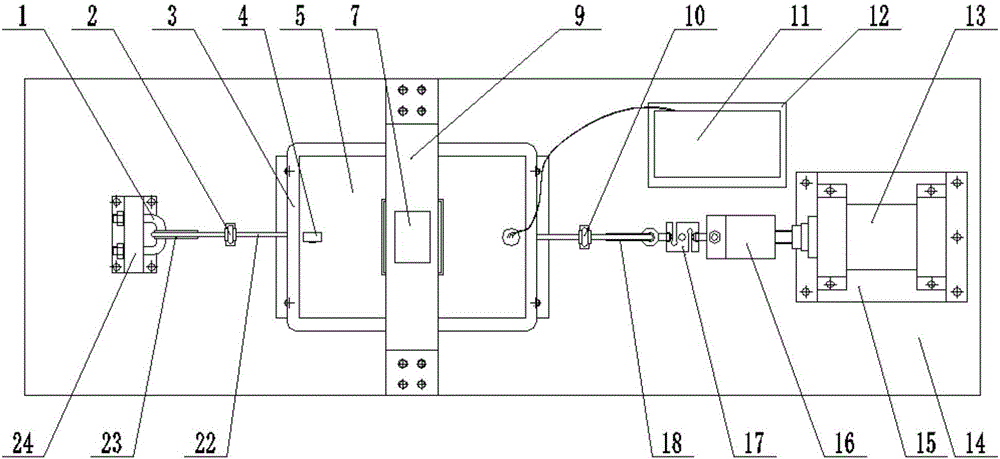

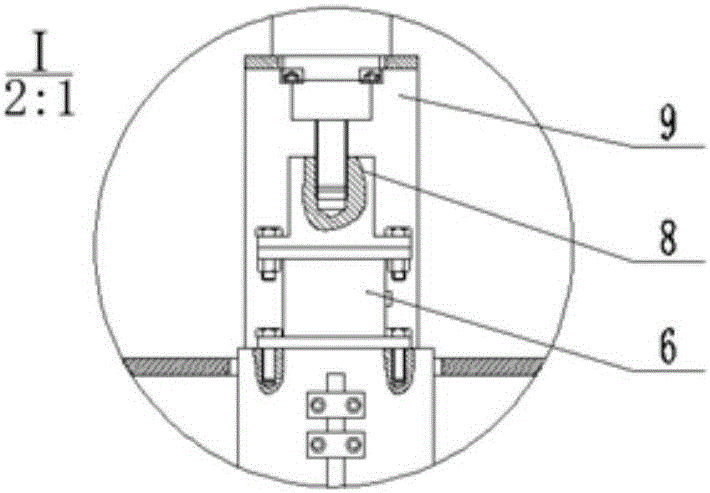

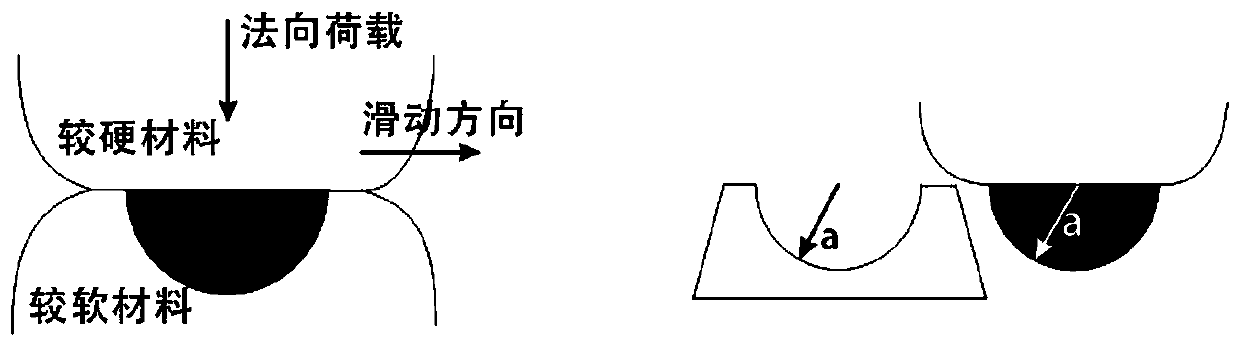

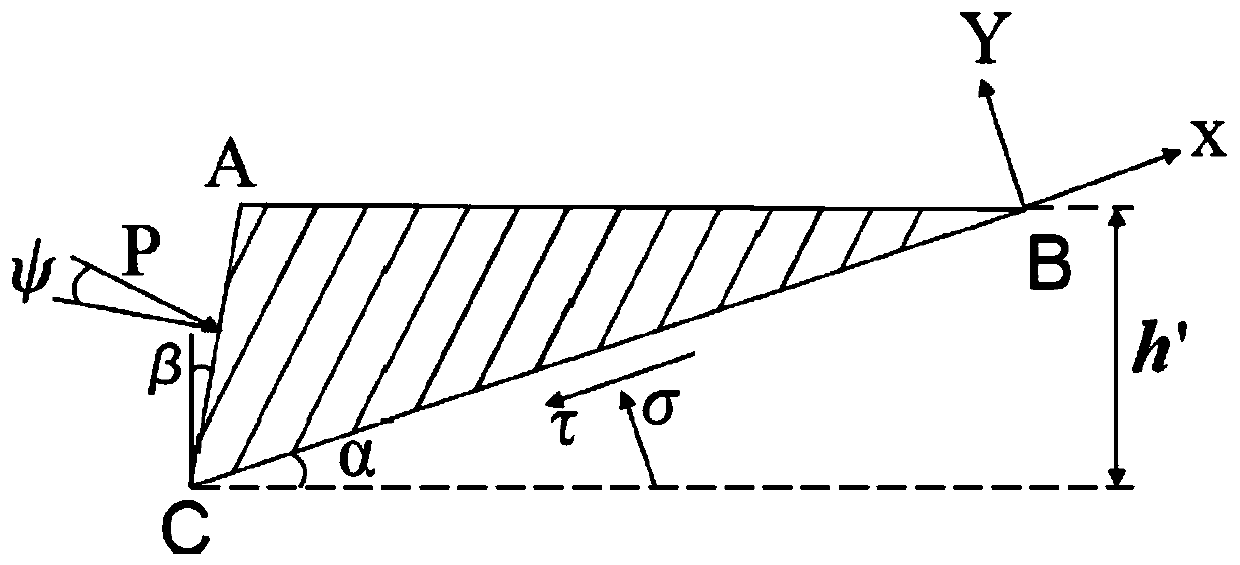

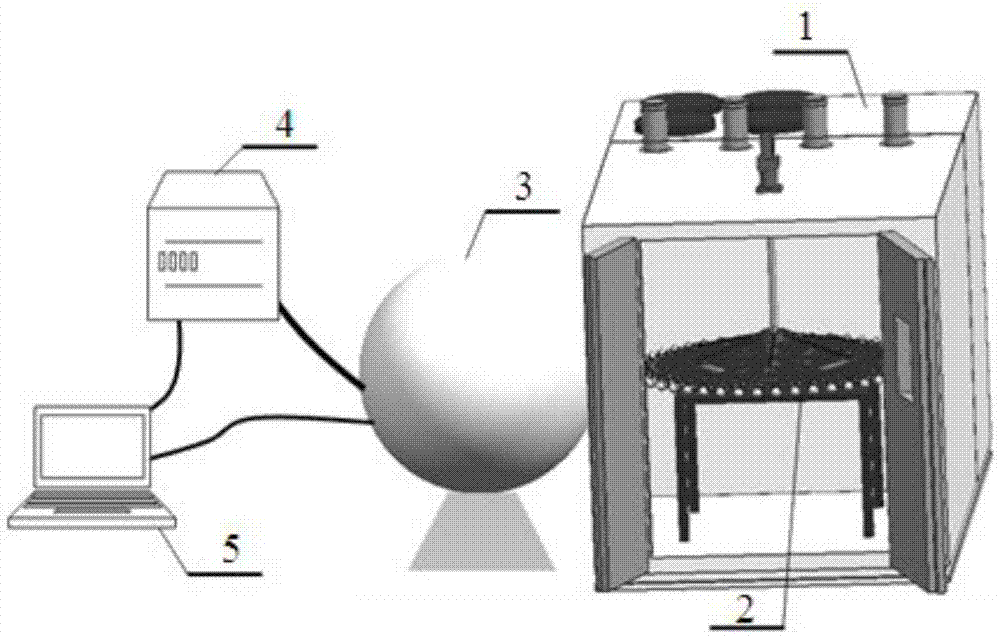

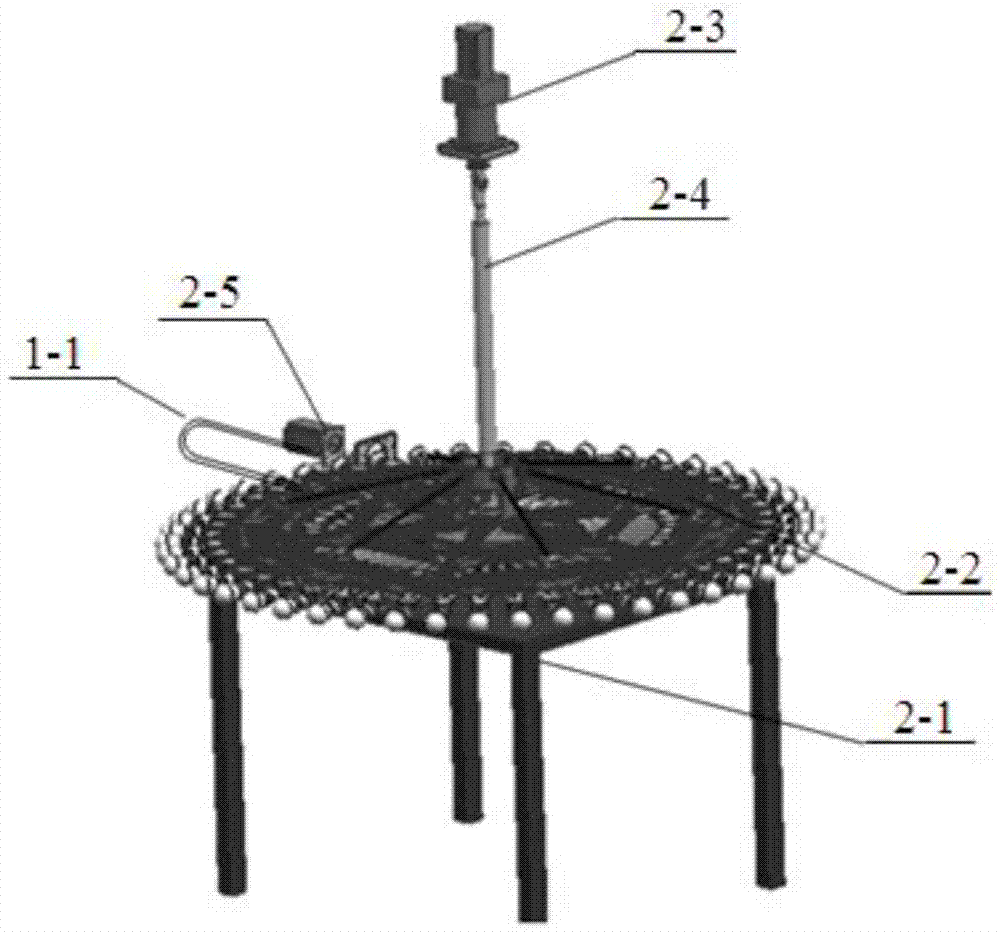

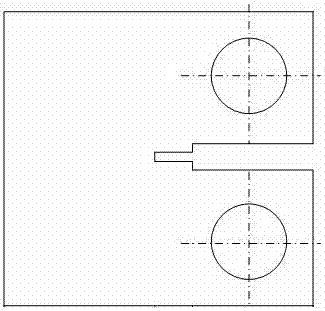

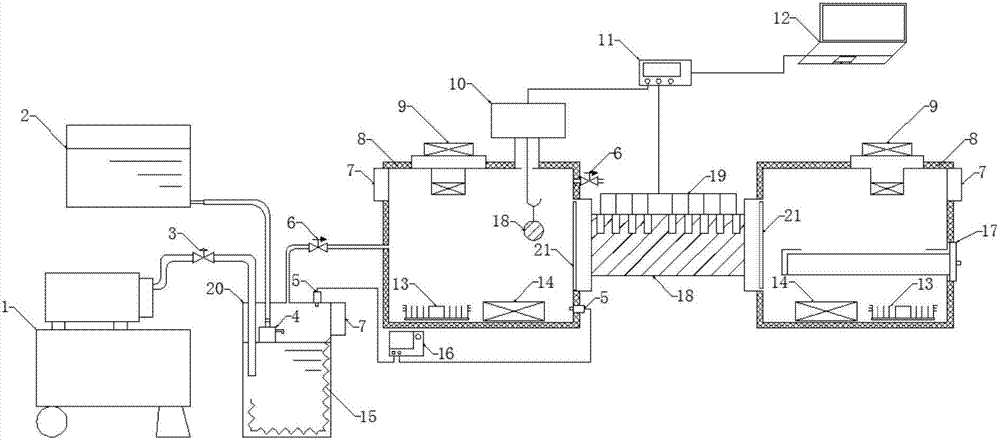

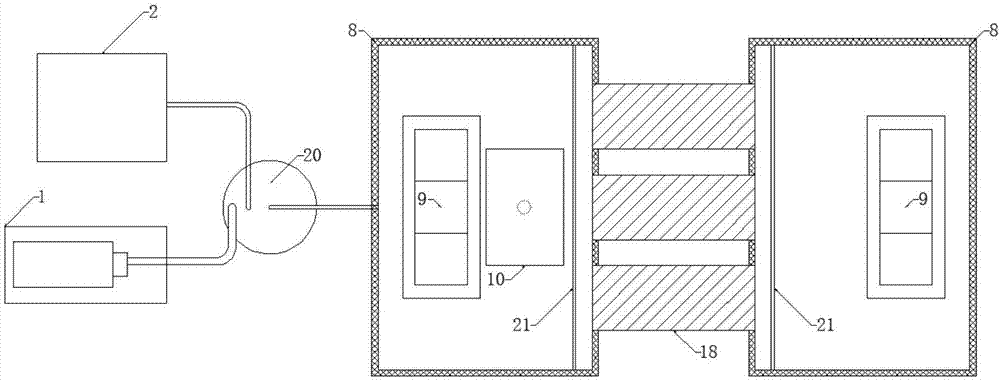

Device and method for monitoring friction and corrosion fatigue damage to twisted type lifting steel wire rope of super deep vertical shaft

ActiveCN106290035APredicted service lifeWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceSupporting systemMonitoring system

The invention discloses a device for monitoring friction and corrosion fatigue damage to a twisted type lifting steel wire rope of a super deep vertical shaft. The device comprises a supporting system, a tension-tension fatigue system, a constant-temperature corrosion system, a dynamic loading system and a monitoring system, wherein the supporting system supplies supporting to the tension-tension fatigue system, the constant-temperature corrosion system, the dynamic loading system and the monitoring system; the fatigue steel wire rope to be monitored is provided with a fatigue load supplied by the tension-tension fatigue test system in the horizontal direction, a dynamic contact load supplied by the dynamic loading system in the vertical direction, and a constant-temperature corrosion environment supplied by the constant-temperature corrosion system respectively; the monitoring system monitors the fatigue load, the dynamic contact load and a change of friction force on the fatigue steel wire rope. The device can realize the friction and corrosion fatigue damage to steel wire ropes on adjacent twisted layers of a twisted type lifting machine of the super deep vertical shaft under different temperatures, corrosion solutions, different dynamic tensile loads and different dynamic contact load parameters and dynamically monitor the damage.

Owner:CHINA UNIV OF MINING & TECH

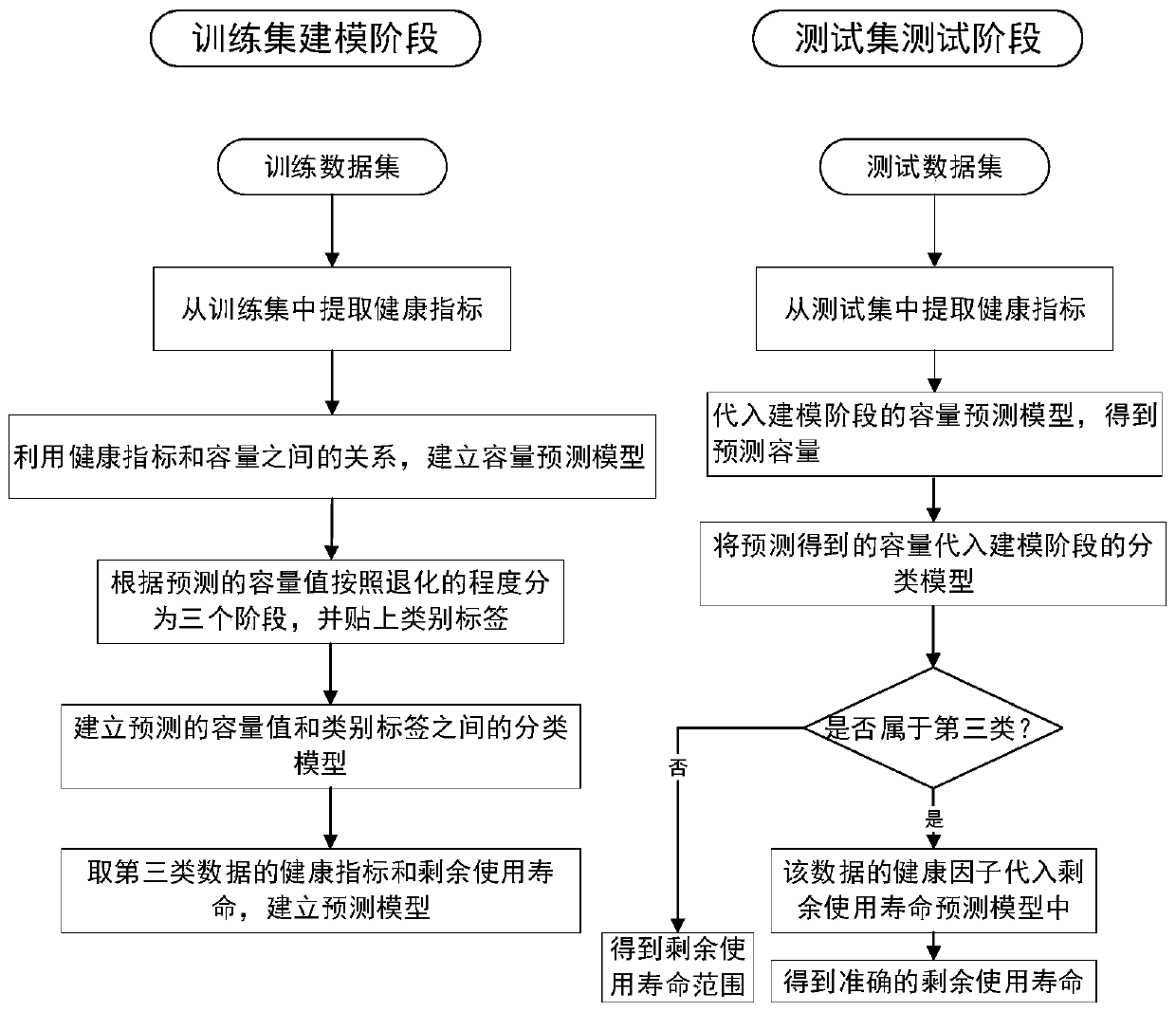

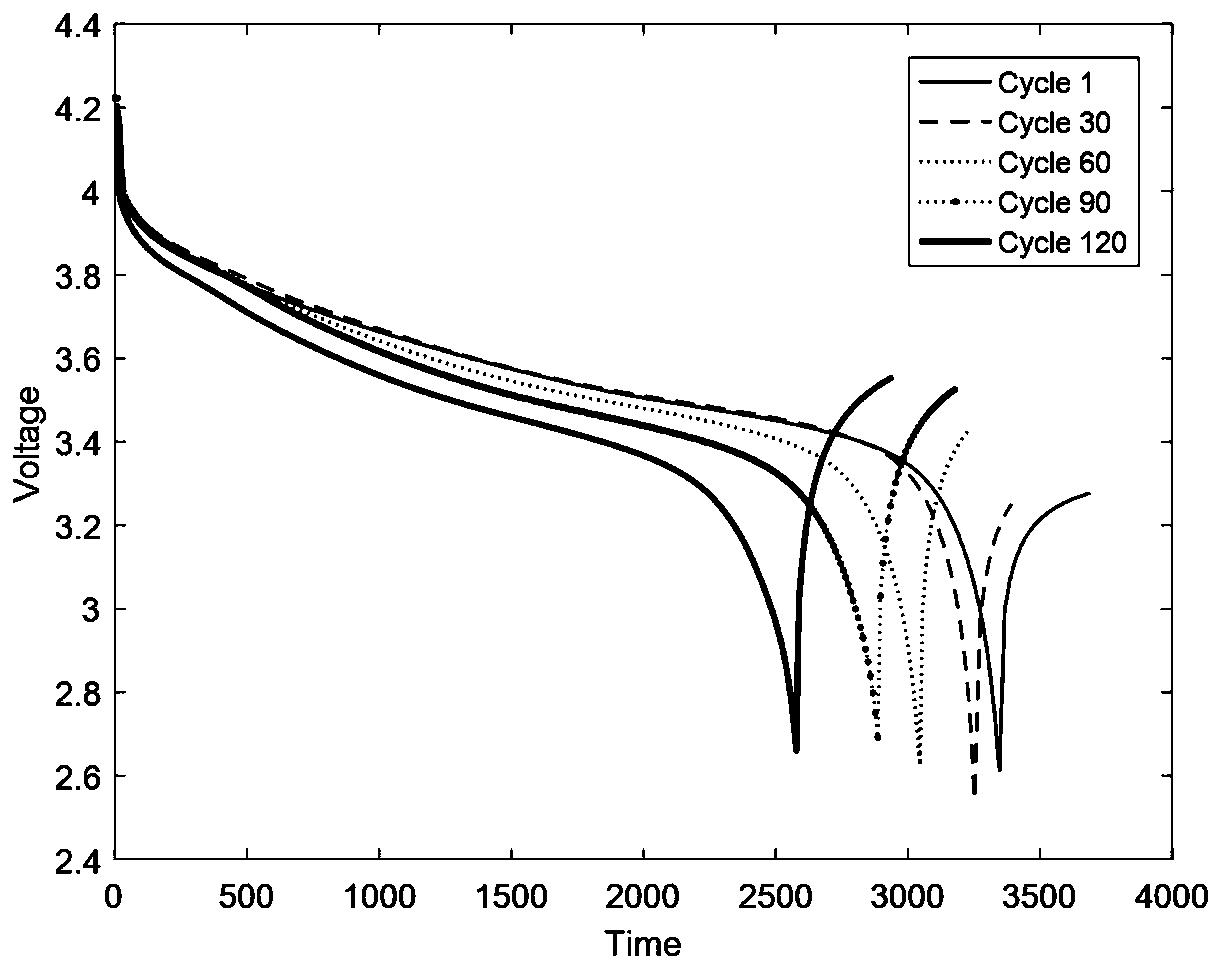

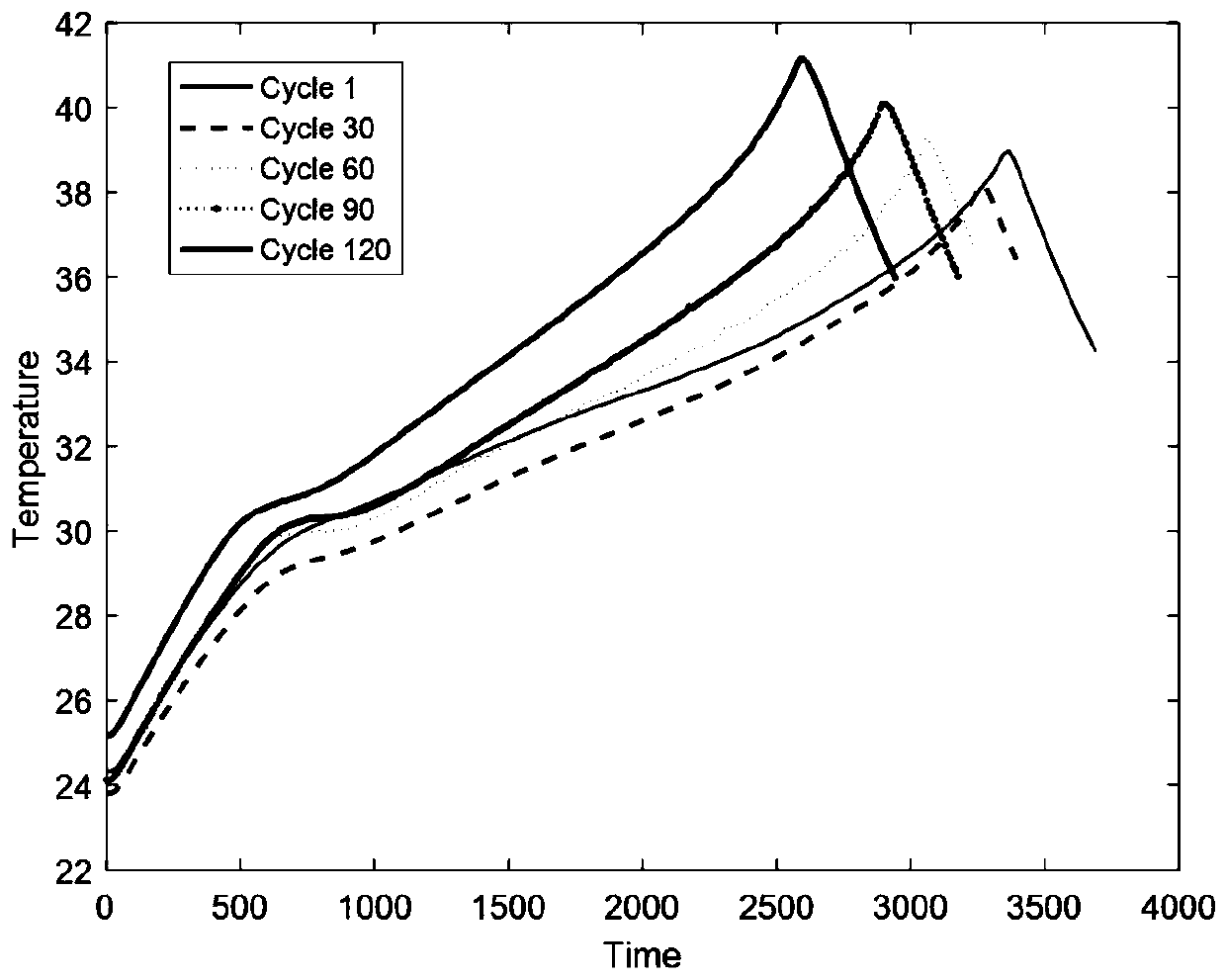

Prediction method of remaining useful life based on lithium battery degradation stage division

InactiveCN110161425APredicted service lifeAccurately Predict Service LifeElectrical testingHealth indexCapacity value

The invention discloses a prediction method of remaining useful life (RUL) based on lithium battery degradation stage division. The prediction method comprises the steps that according to the relationbetween health indexes and battery capacity values in a training set, a capacity prediction model is established; capacity values in a test set are predicted; the capacity values in the training setand the capacity values in the test set are divided into three stages, and a classification model is established; an RUL prediction model is established according to the health indexes and the corresponding RUL at the third stage; health indexes of a to-be-predicted RUL sample are collected, and a predicted capacity value is acquired; the predicted capacity value is input into the classification model to obtain a sample category; and if the sample is at the third stage, the health indexes of the sample are input into the RUL prediction model to obtain a predicted value of the RUL. Through theprediction method, the battery RUL at the third stage is accurately predicted according to the classification model and the RUL prediction model, and only the battery RUL at the third stage is predicted, so that the calculation amount is small.

Owner:HUAZHONG UNIV OF SCI & TECH

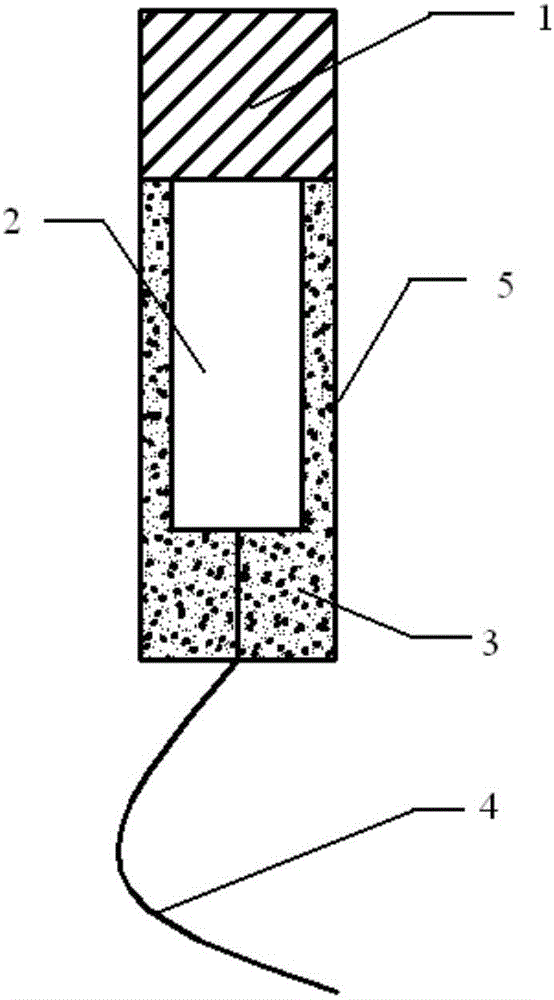

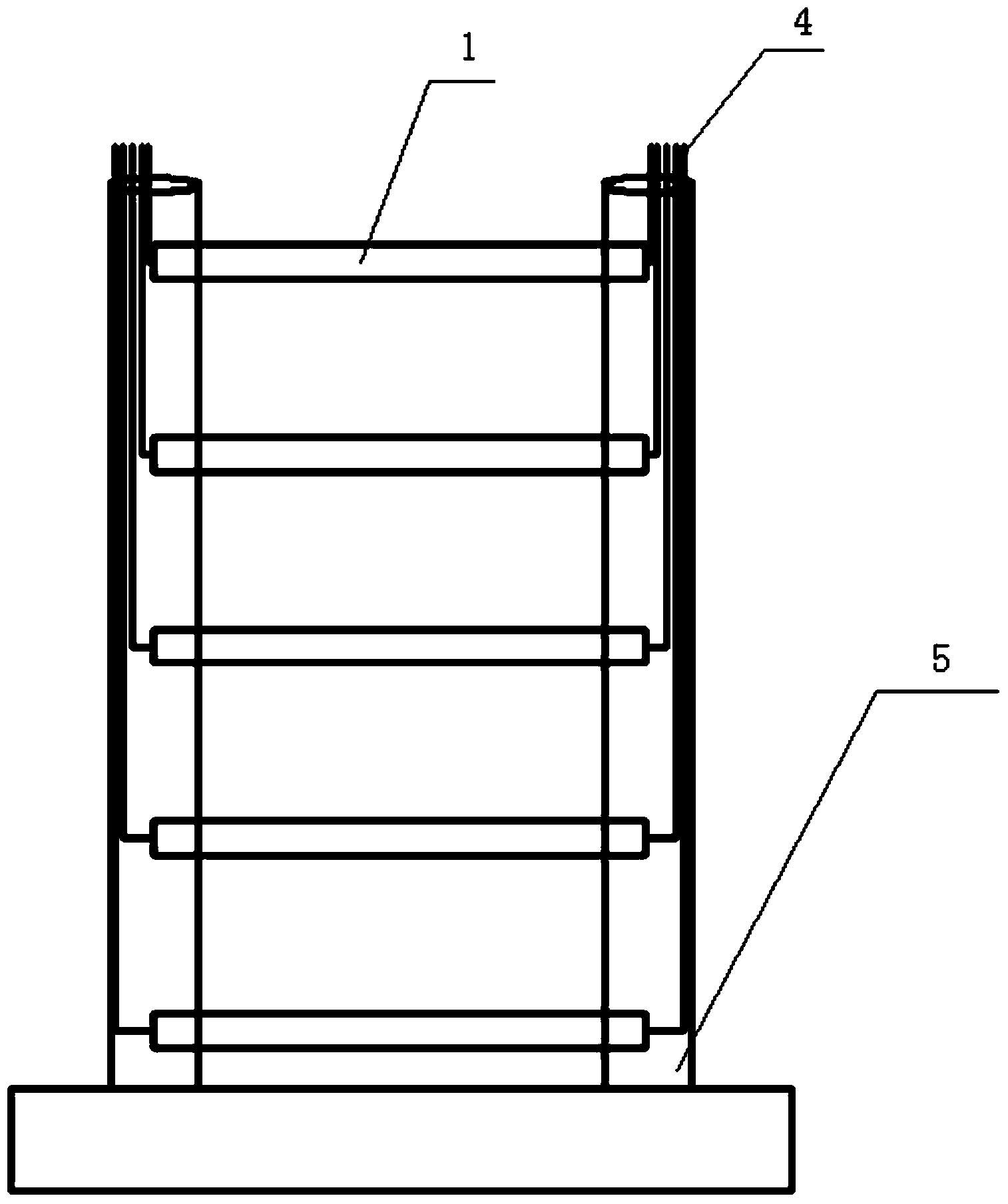

Monitoring system for monitoring durability deterioration evolution of reinforced concrete structure

InactiveCN106053326APredict the state of corrosionPredicted service lifeWeather/light/corrosion resistanceRebarRadio frequency

The invention provides a monitoring system for monitoring durability deterioration evolution of a reinforced concrete structure. The monitoring system comprises a temperature sensor for measuring the internal temperature of concrete, a humidity sensor for measuring the internal humidity of the concrete, a pH sensor for measuring the pH value of the interior of the concrete, a chloride ion sensor for measuring the chloride ion concentration in the concrete, an oxygen sensor for measuring the oxygen concentration in the concrete, noble electrodes, a steel bar electrode, a solid-state reference electrode, an RFID device for radio frequency monitoring, and a stainless steel tank for storing the sensors and the electrodes. The monitoring system can predict the corrosion state of steel bars and predict the service life of the reinforced concrete structure more accurately, and can position the sensors more easily.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for testing dynamic adhesion property of vulcanized rubber/steel wire cord

InactiveCN103033469ALess investmentPredicted service lifeUsing mechanical meansMaterial analysisEngineeringRepeatability

The invention relates to a method for testing the dynamic adhesion property of a vulcanized rubber / steel wire cord. The method can be used for determining the anti-fatigue property of a vulcanized rubber / steel wire cord composite material under different tensile deformations, reciprocating strokes, fatigue cycles, fatigue frequencies and temperatures, determining the change of the adhesion strength under different fatigue conditions via an electronic tension tester, and inspecting the evolvement rule of the dynamic adhesion property of the vulcanized rubber / steel wire cord. The method is simple and reliable, low in investment, high in efficiency and good in repeatability. The method disclosed by the invention is mainly applied to the field of the vulcanized rubber / steel wire cord composite material which are used for tires, conveying belts and the like, also can be used for evaluating the dynamic adhesion properties of a rubber / fibre cord and a rubber / single steel wire, and especially can be used for simulating the service environment of the tire carcass rubber / steel wire cord during the running process of a tire well, so that a reference for designing a safe, durable and high-performance tire and predicating the service life of the tire is provided.

Owner:QINGDAO UNIV OF SCI & TECH

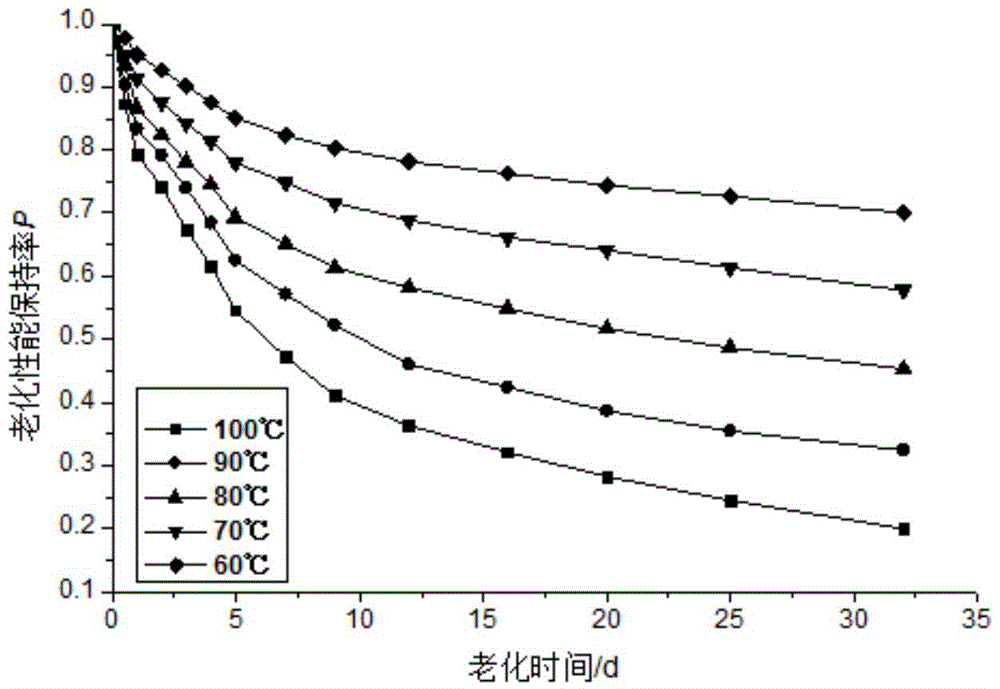

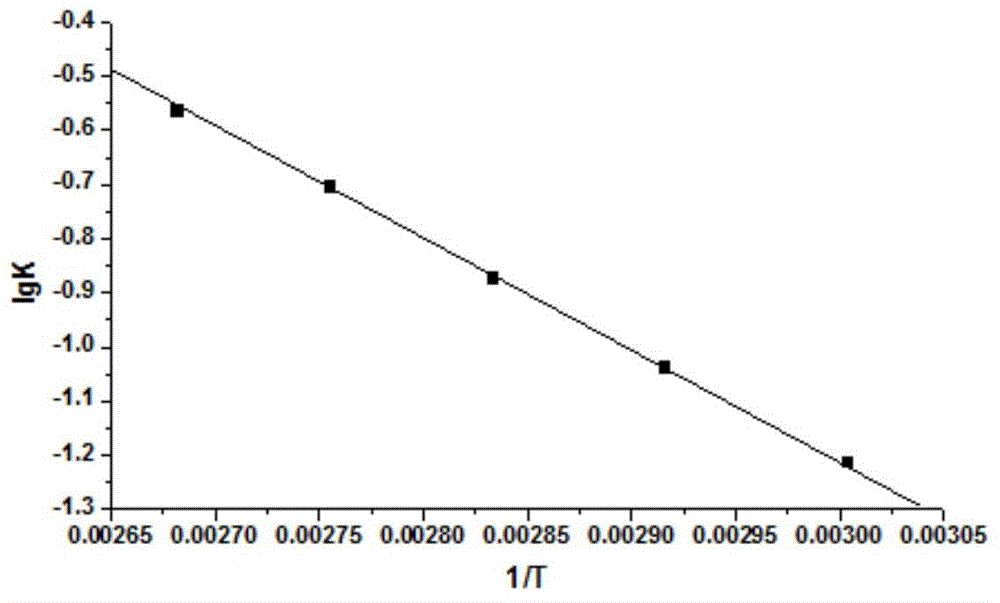

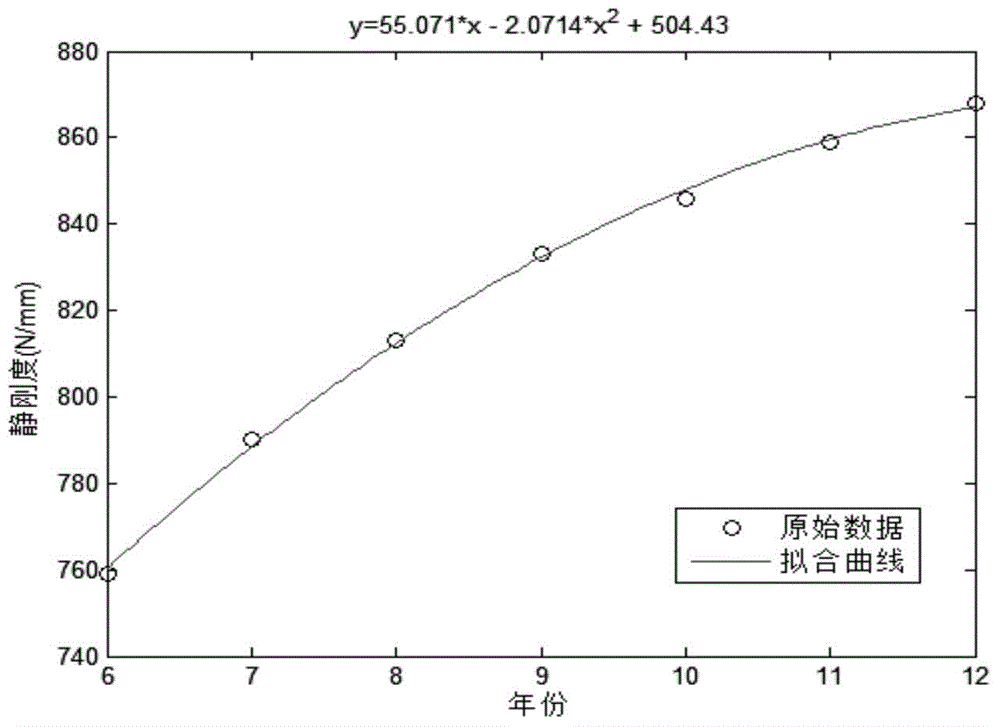

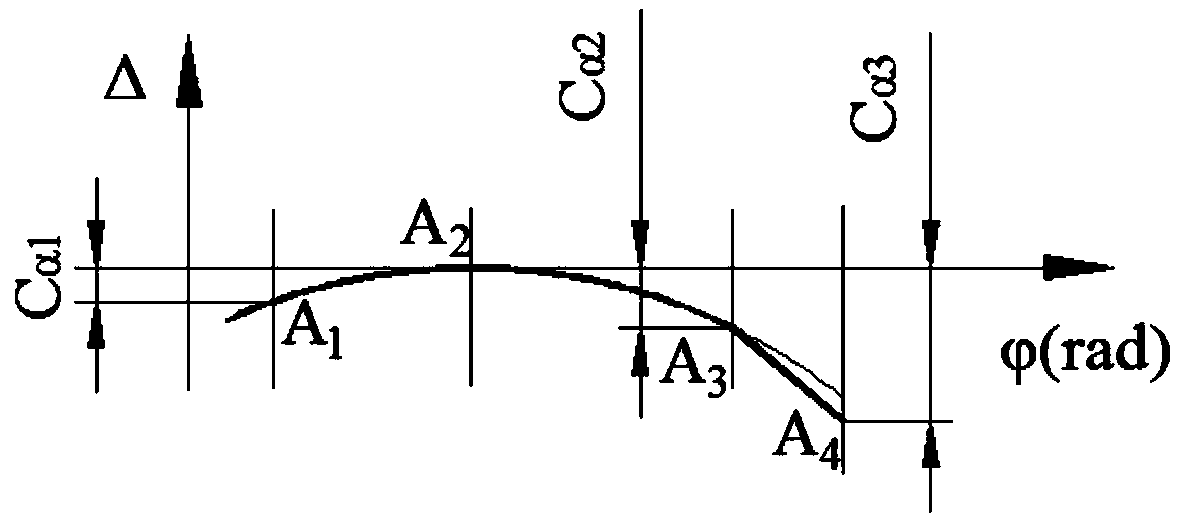

Method for predicting service life of rubber shock absorber

InactiveCN104697920ALife PredictionLifespan reflectionWeather/light/corrosion resistanceStrength propertiesEngineeringAge factor

The invention discloses a method for predicting a service life of a rubber shock absorber; the method comprises the steps: combining aging factors, influencing the use of the rubber shock absorber, and fatigue factors; firstly, establishing an aging service life prediction mathematic model of the rubber shock absorber in use of a hot air accelerated aging test; secondly, establishing a model relationship between static rigidity of a new absorber and fatigue times by means of the aging service life prediction model and the existing performance parameter of an old absorber; further, establishing a relation model between the static rigidity and the time and obtaining a service life prediction model of the rubber shock absorber, thereby realizing prediction of the service life of the rubber shock absorber. The aging factors and the fatigue factors are combined well to predict the service life of the rubber shock absorber, and the prediction precision is high.

Owner:QINGDAO UNIV OF SCI & TECH

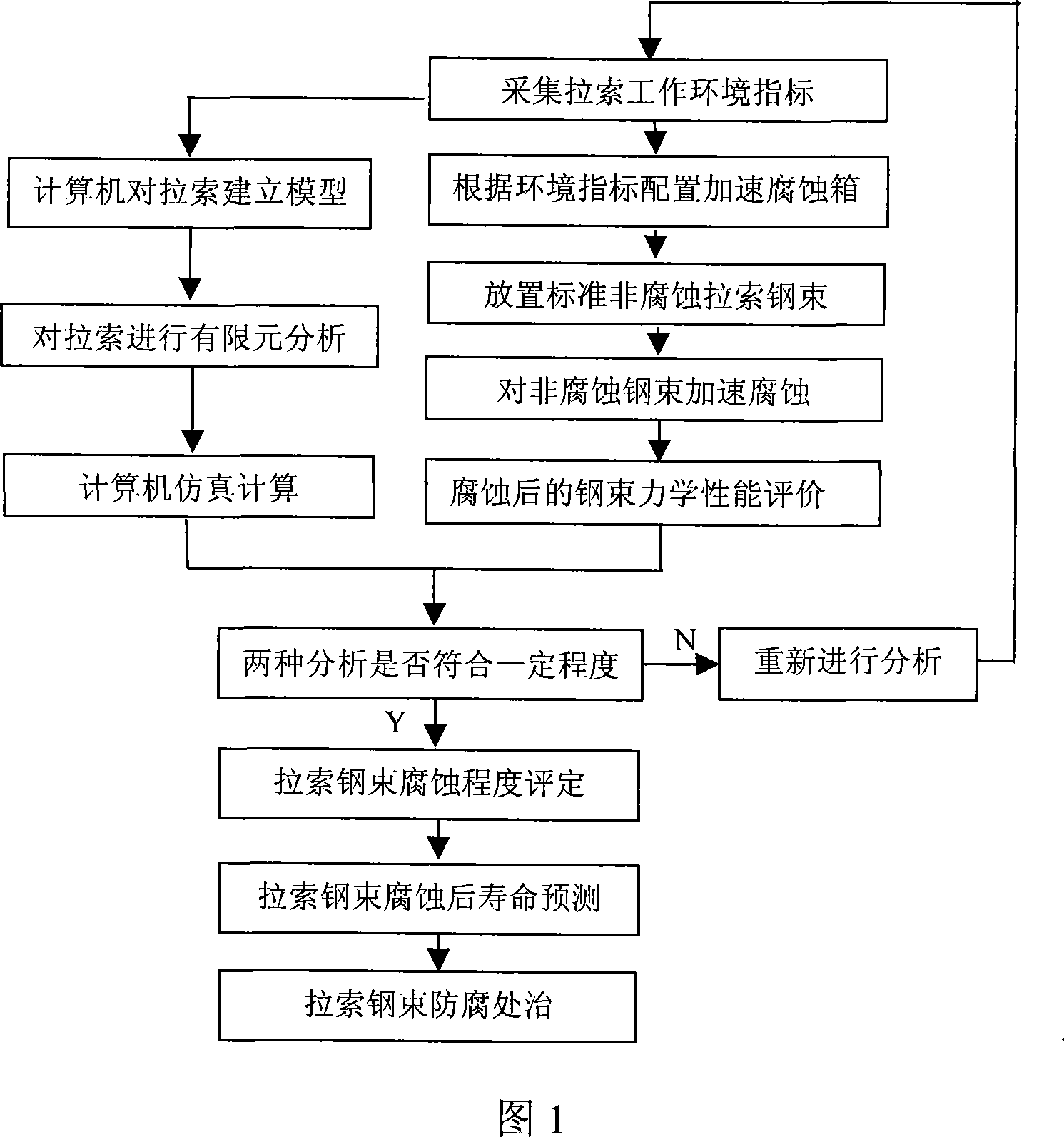

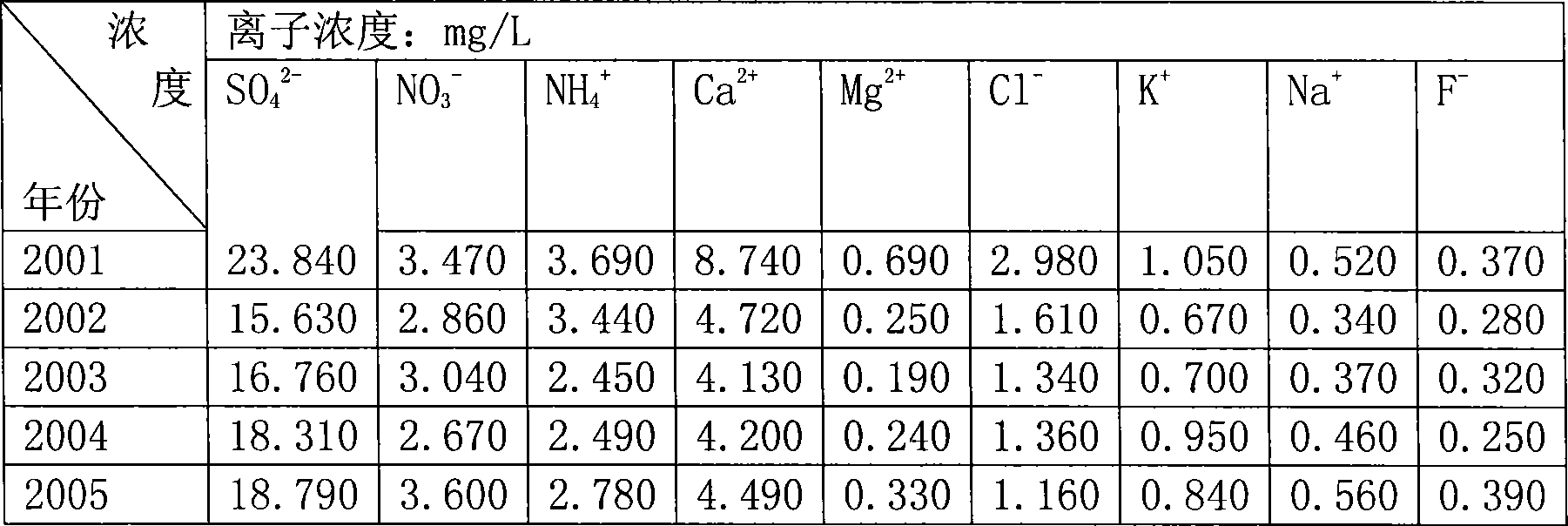

Stayed-cable bridge cable erosion state evaluation method

InactiveCN101059418APredicted service lifeEvaluate securityWeather/light/corrosion resistanceStrength propertiesSimulationTime effect

The invention discloses an evaluate method on the abrasion condition of the cable of stayed-cable bridge, comprising that (1) detecting the application condition of cable, (2), accelerating simulating test of cable, to obtain a time-abrasion time-effect curvature in special application condition, (3), based on the result of abrasion-safety simulation analysis, completing the cable abrasion evaluation and service life prediction. Based on prior art, the invention uses accelerated abrasion simulation test, to obtain the abrasion rule of cable, uses simulation analysis to evaluate the abrasion state and predict service life, and provides practical technique.

Owner:CHONGQING JIAOTONG UNIVERSITY

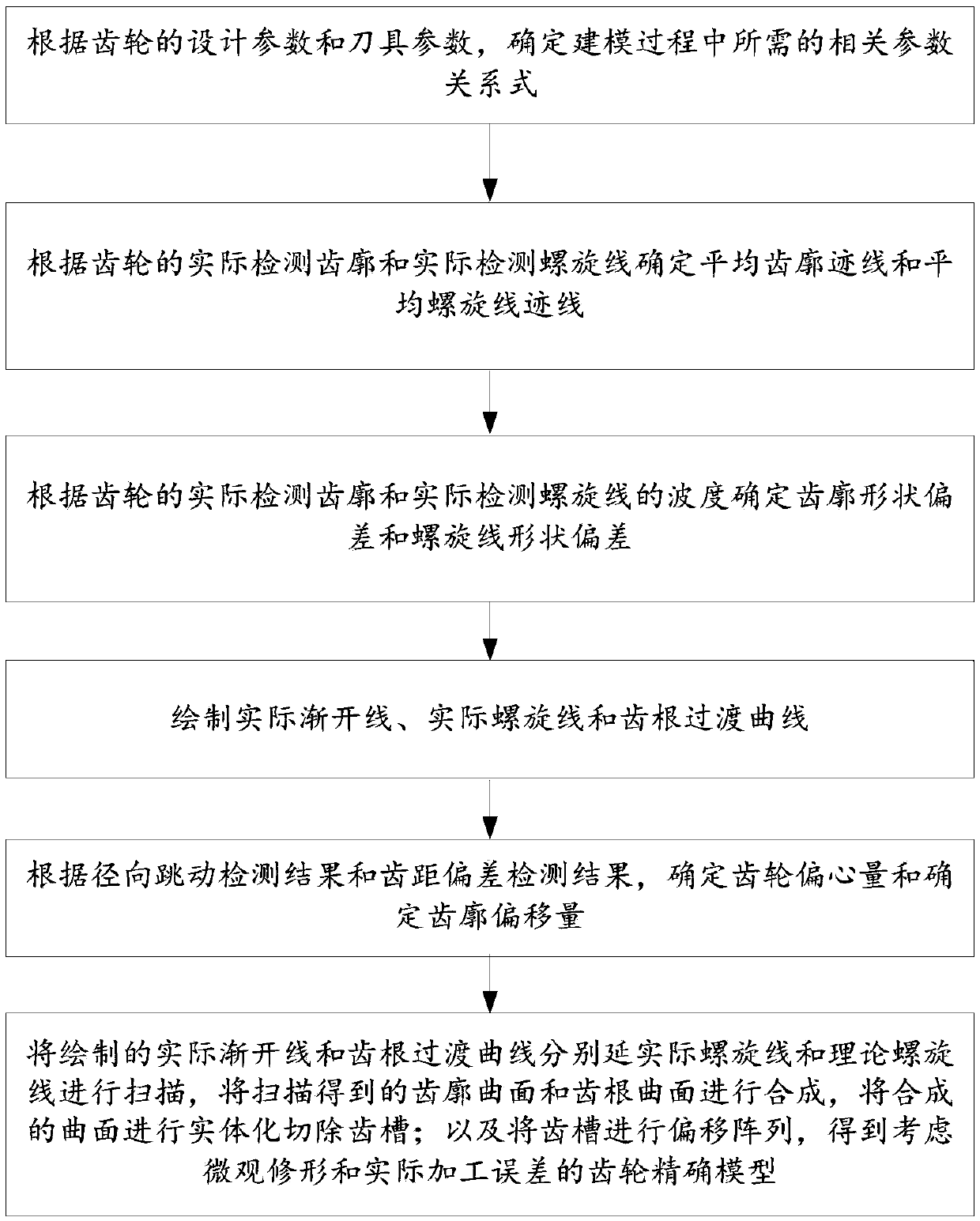

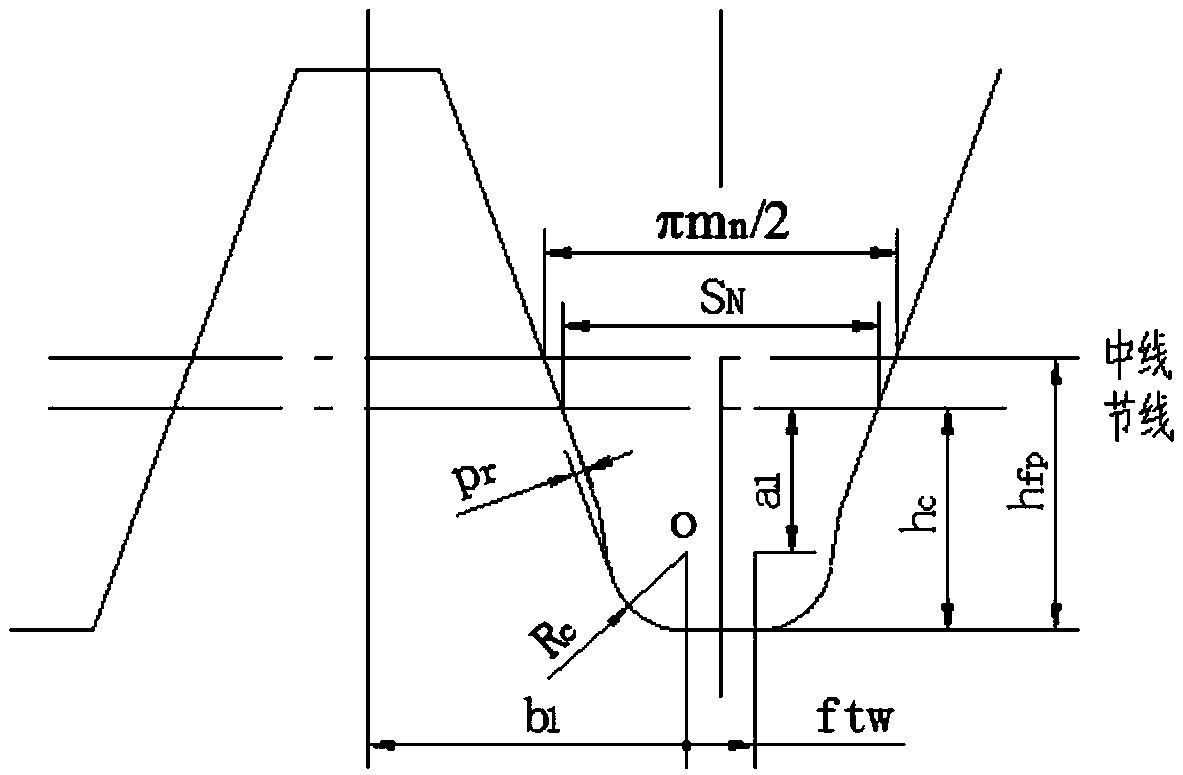

Precise modeling method of gear considering microcosmic modification and actual machining error

ActiveCN109063326APredicted service lifeReduce machining accuracyGeometric CADDesign optimisation/simulationThree dimensional modelBias detection

The invention provides an accurate modeling method of a gear considering microcosmic modification and actual machining error. The method firstly derives the necessary parameters of the gear and the cutter required in the modeling process. According to the actual detection of gear tooth profile and actual detection of helix, the average tooth profile trace and the average helix trace of gear are obtained. According to the actual detection of tooth profile and the actual detection of helix waviness, tooth profile shape deviation and helix shape deviation are obtained. According to the results ofradial runout and tooth pitch deviation detection, the eccentricity of the gear and the offset of the actual tooth profile are obtained. In three-dimensional software, the actual involute, the actualbase circle helix and the tooth root transition curve are plotted, and the tooth profile offset array is carried out. Finally, in the software, the surface is scanned, trimmed and merged, the tooth alveoli are removed, and the precise three-dimensional model is obtained after shifting the array. The gear model established by this method can simulate the meshing state of the actual machined gearsand predict the failure form and service life of the gears.

Owner:CHINA FIRST AUTOMOBILE

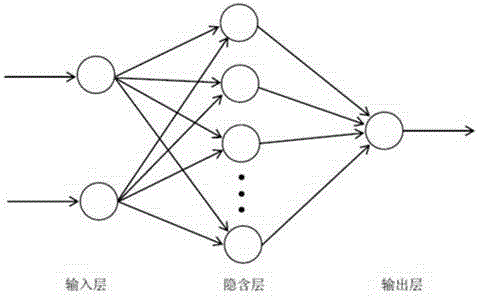

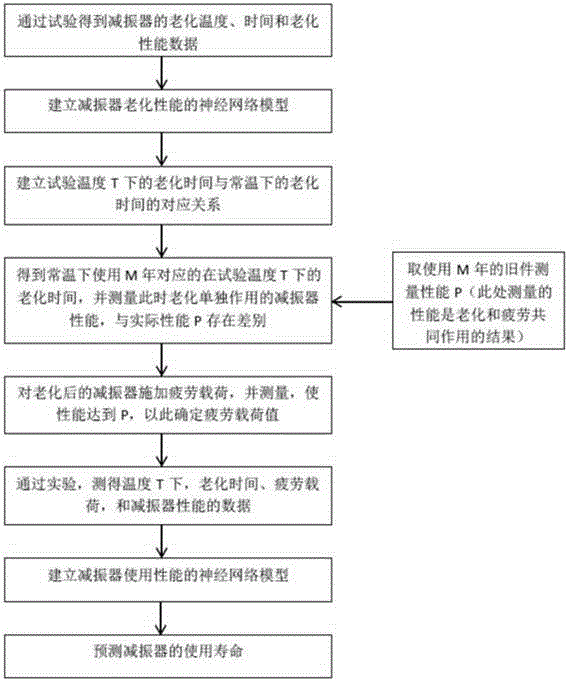

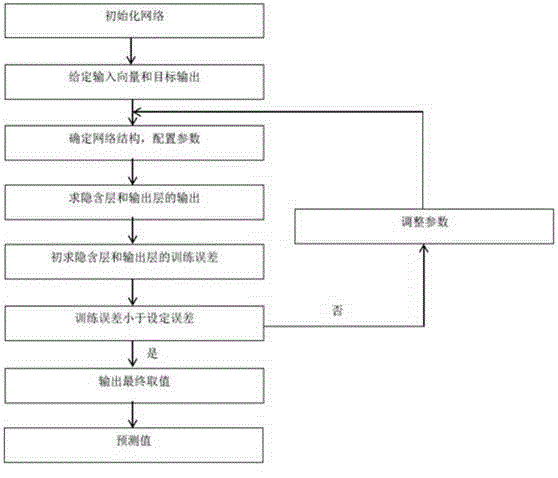

Back propagation (BP) neural network based method for predicting service life of rubber absorber

InactiveCN104834808APredicted service lifeOvercoming the disadvantage of inaccurate service life predictionSpecial data processing applicationsNetwork modelEngineering

The invention discloses a back propagation (BP) neural network based method for predicting service life of a rubber absorber. According to the method, a BP neural network model of aging life of the rubber absorber is created firstly; according to the created BP neural network model of the aging life of the rubber absorber as well as fatigue life, a BP neural network model of the service life of the rubber absorber is created; and finally, the service life of the rubber absorber is predicted through the BP neural network model of the service life. In the method, aging factors and fatigue factors affecting the use of the rubber absorber are combined, a service life prediction model of the rubber absorber is reasonably created, the service life of the rubber absorber affected by both aging and fatigue is accurately predicted, and the defect of inaccurate prediction of service life of the rubber absorber due to separate research of aging life and fatigue life is overcome.

Owner:QINGDAO UNIV OF SCI & TECH

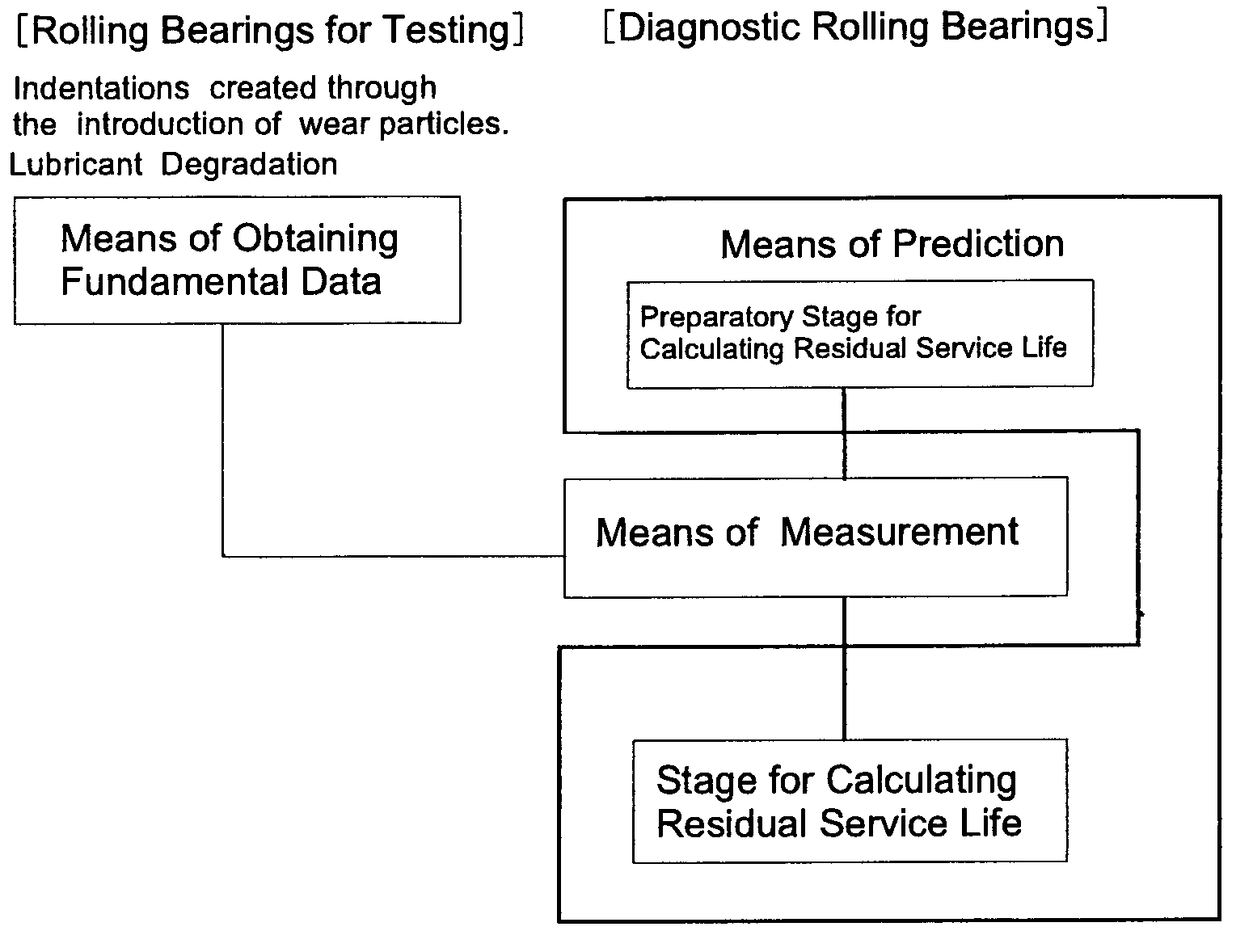

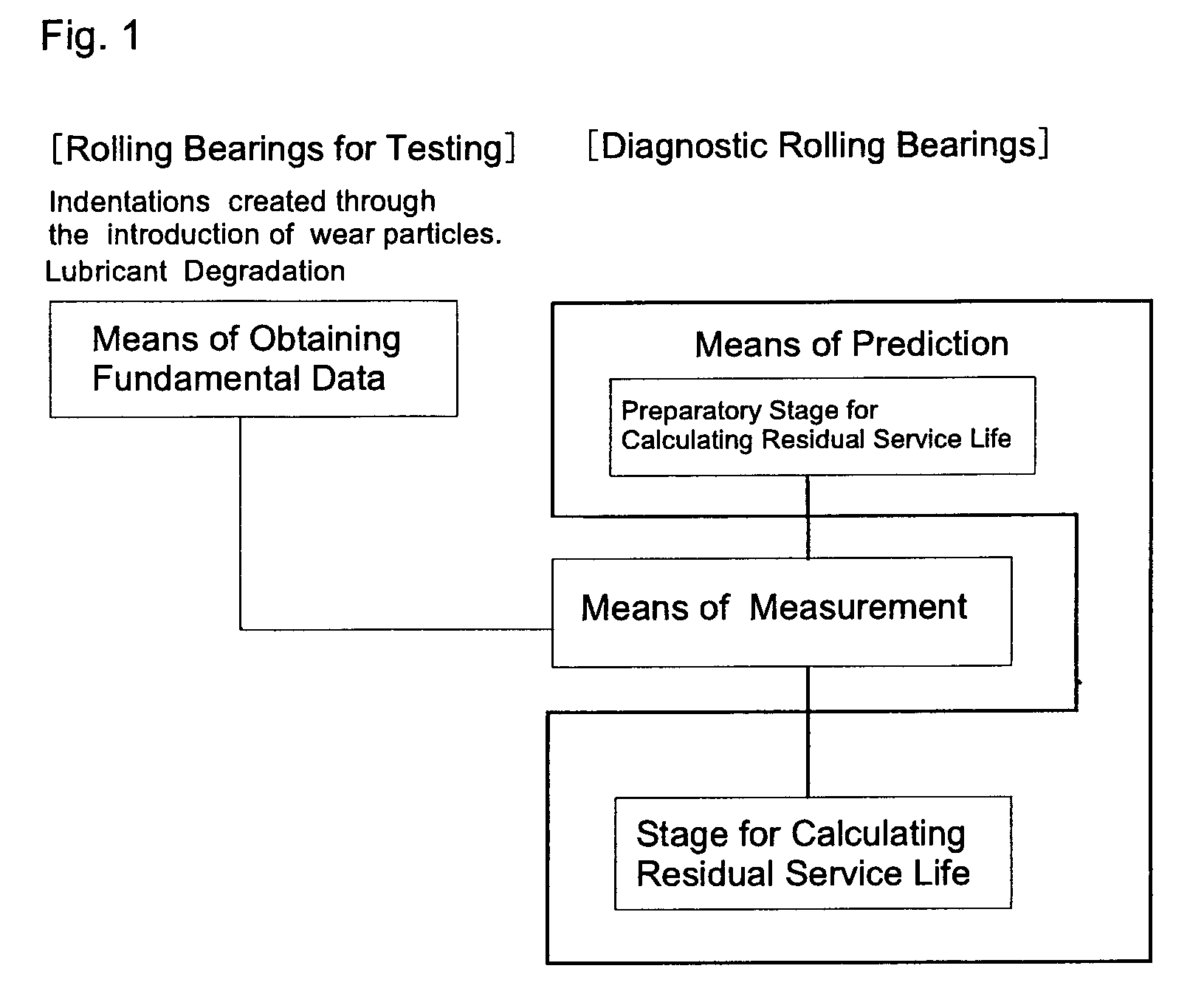

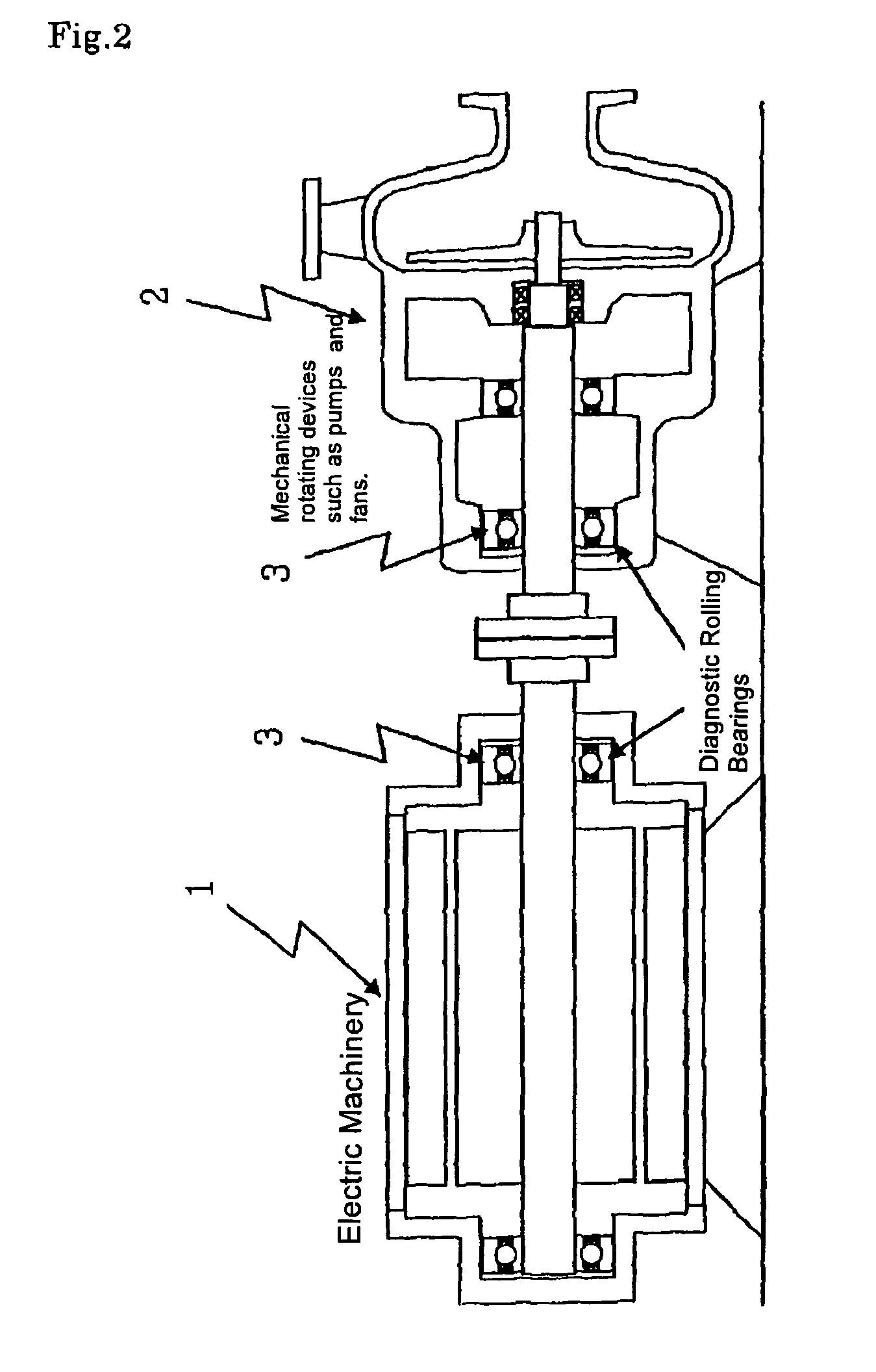

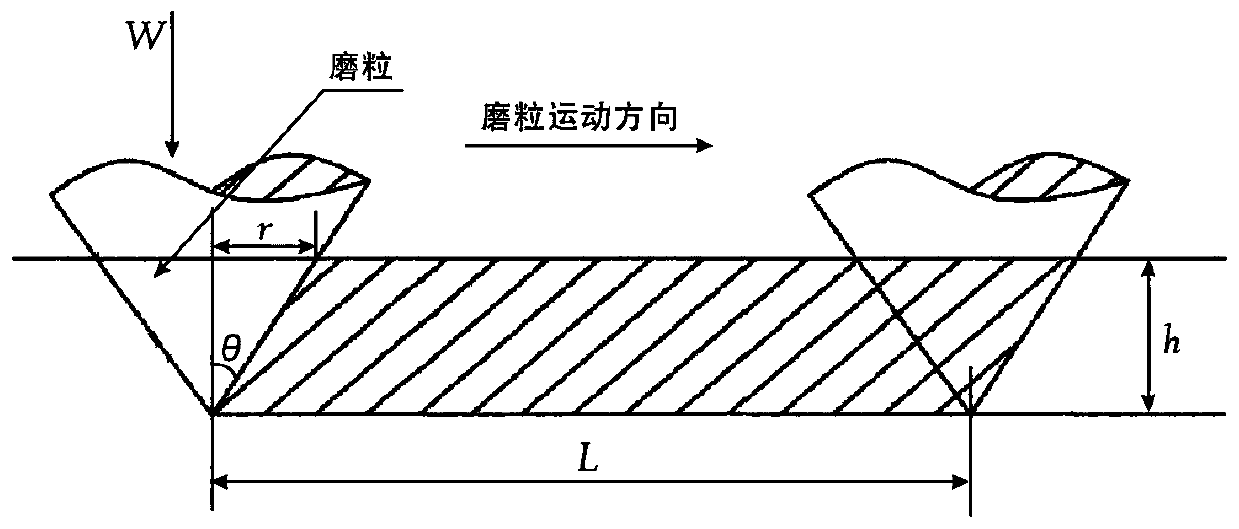

Method of predicting residual service life for rolling bearings and a device for predicting residual service life for rolling bearings

InactiveUS7813906B2Effective maintenanceImprove operating rateVibration measurement in solidsPump componentsAccelerometerRolling-element bearing

A method that utilizes signals from an accelerometer in resonant frequency bands or high frequency bands to, in a cost-effective manner, measure wear particle penetration of lubricant and lubricant degradation, both of which greatly affect prediction of residual service life; and, using as a basis these measurements of wear particle penetration and lubricant degradation, enables accurate estimation of residual service life for rolling bearings in the early stages.

Owner:THE CHUGOKU ELECTRIC POWER CO INC +1

Wear prediction method for shield tunneling hob

InactiveCN111005733APredicted service lifeData processing applicationsMining devicesEngineeringShield tunneling

The invention discloses a wear prediction method for a shield tunneling hob. The wear prediction method for the shield tunneling hob comprises the following steps that a unit displacement wear loss caused by a plastic removal mechanism, a unit displacement wear loss caused by a brittle fracture mechanism, a unit displacement wear loss caused by adhesive wear, a unit displacement wear loss caused by fatigue wear, a rock breaking arc length generated when a point on the front side of the hob rotates by one circle, a spatial rock breaking arc length generated when a point on the side face of thehob rotates by one circle, a normal cutting force of the hob, and a horizontal force borne by the hob are acquired; the radial wear and wear size of the front side of a hob ring caused when the hob rotates by one circle are worked out; the wear loss and wear size of the side face of the hob ring caused when the hob rotates by one circle are worked out; the four wear losses are multiplied by corresponding fitting coefficients, and the products are added to obtain the wear size of the front side and the wear size of the hob ring; and a wear prediction model is generated, and the wear is predicted. By the adoption of the wear prediction method, the service life of the shield tunneling hob can be predicted, the prediction precision can be improved, and the problems of severe wear of the hob and frequency opening of a bin are solved.

Owner:SOUTHWEST PETROLEUM UNIV

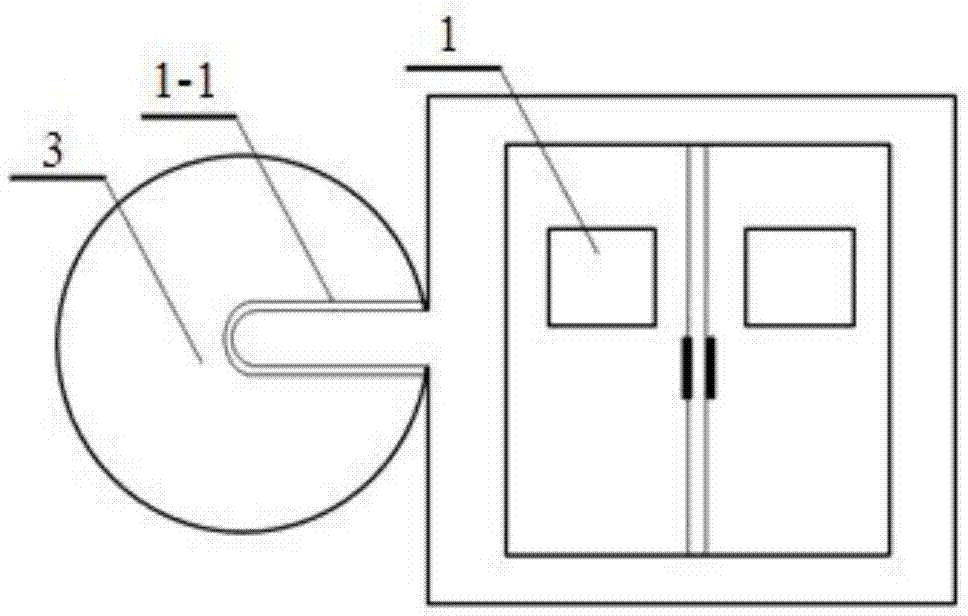

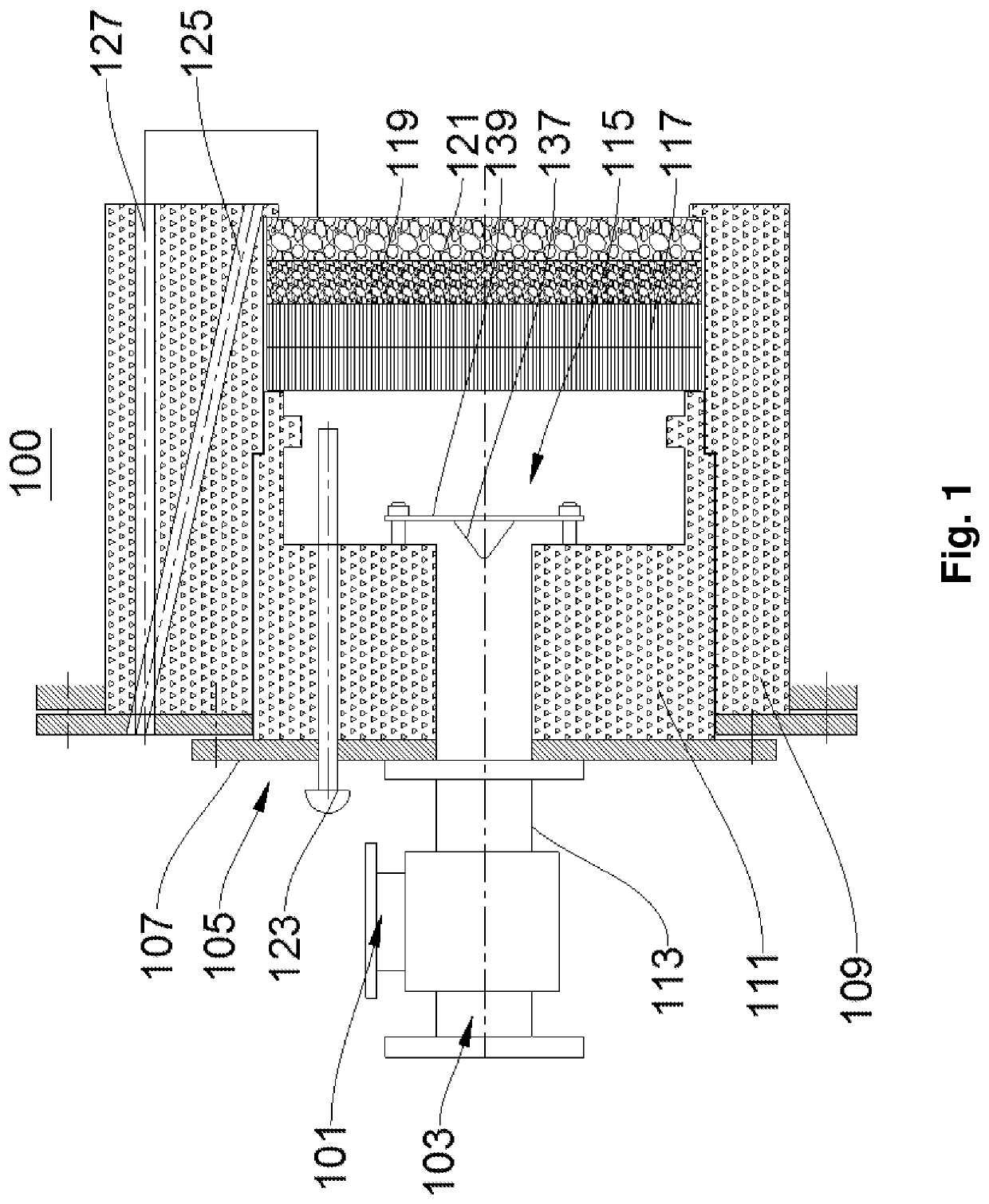

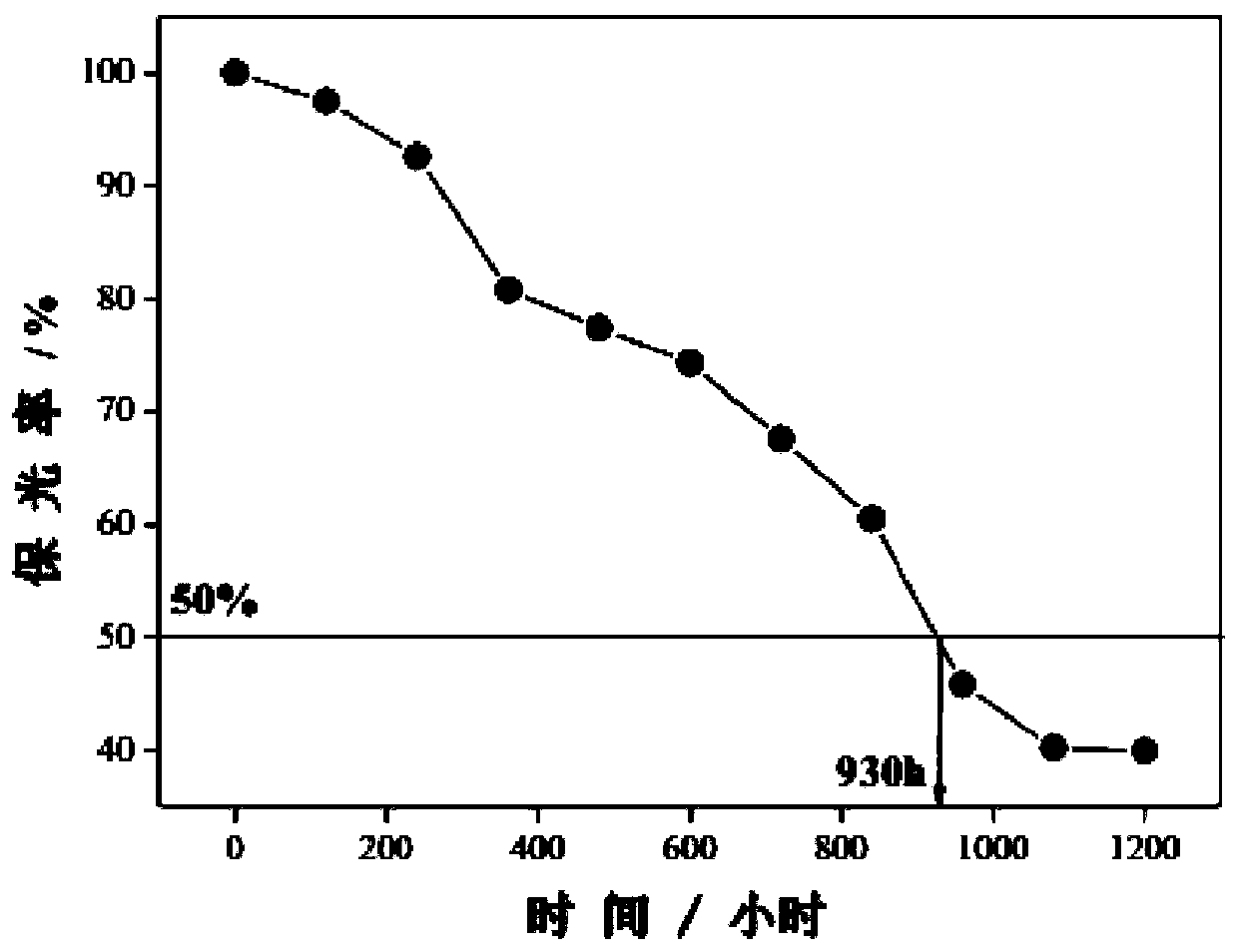

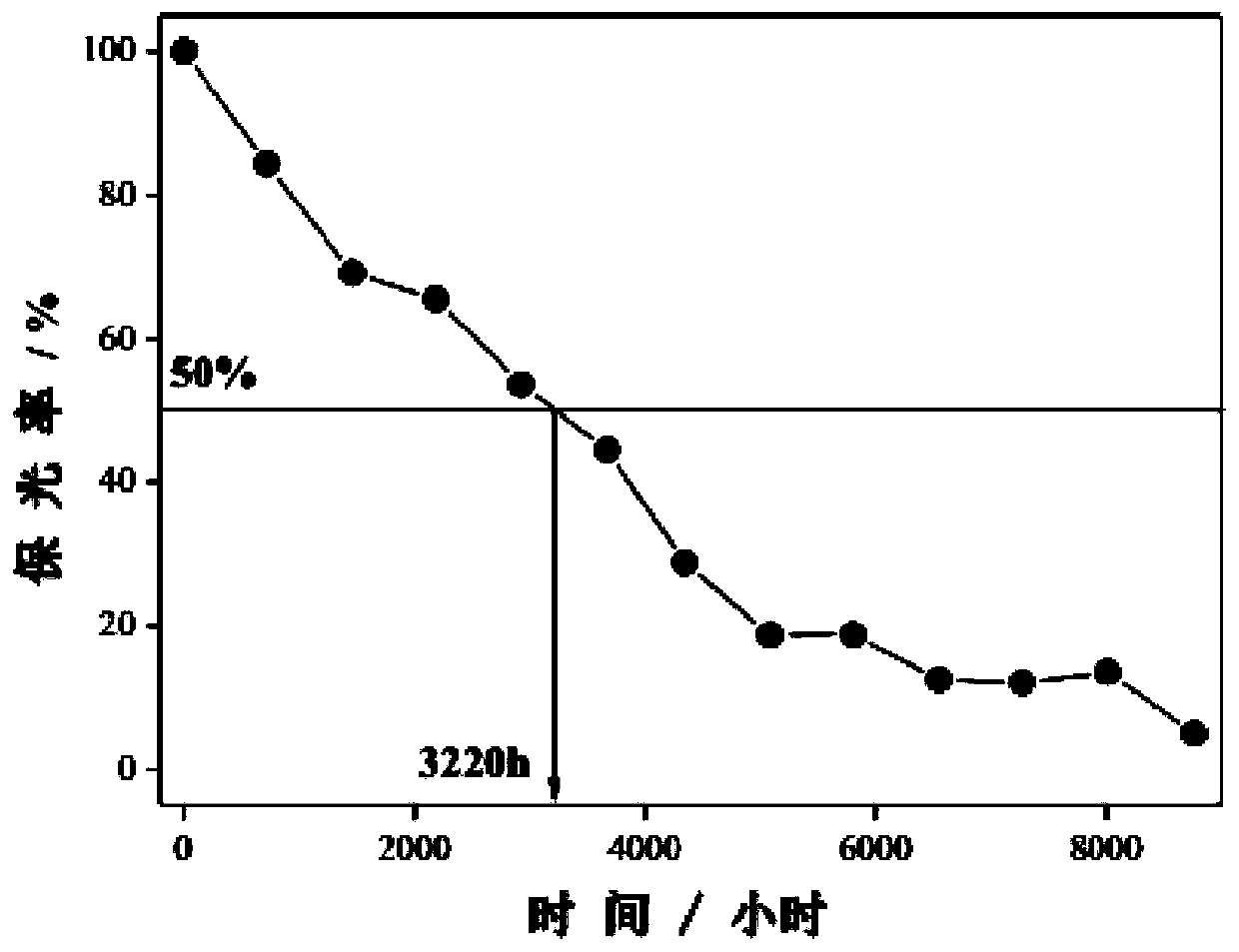

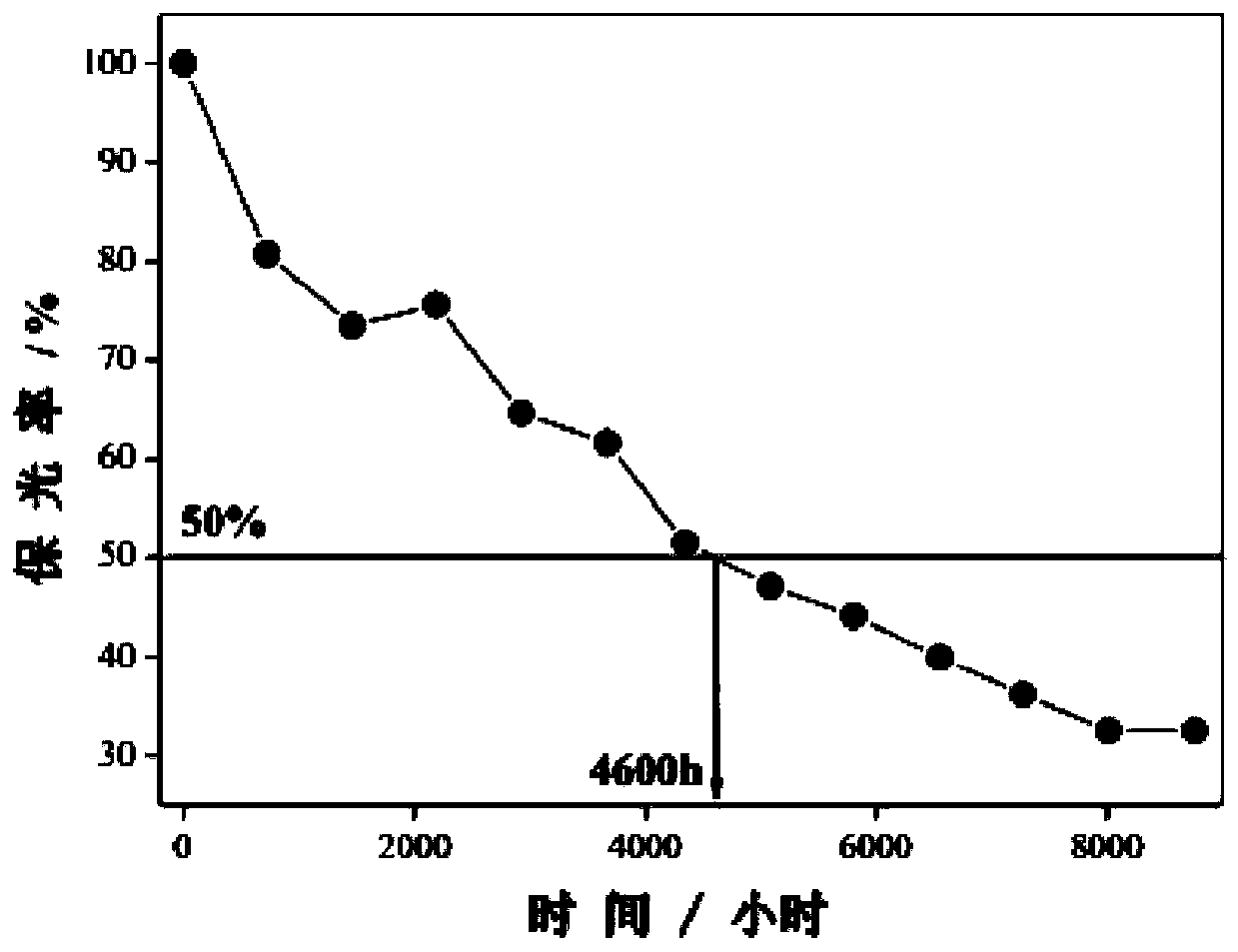

LED-lamp accelerated-life on-line detection equipment

InactiveCN105444995AQuick performanceAvoid environmental problemsTesting optical propertiesThermal insulationEngineering

LED-lamp accelerated-life on-line detection equipment belongs to the reliability detection field of a semiconductor device. In order to solve a problem in the prior art, the invention provides the equipment. The equipment comprises a test box body, a lamp clamp apparatus, an external connection integrating sphere system, a control host and a computer, wherein the test box body comprises an optical measurement channel and a temperature applying unit; the optical measurement channel is located at a connection position of the test box body and the external connection integrating sphere system; the lamp clamp apparatus is arranged in the test box body and is a positive-negative 360-degree rotary type multi-station independent lamp bracket; a detected LED lamp sample is installed on the lamp clamp apparatus; the external connection integrating sphere system is tightly connected to the test box body and there is no light leakage, and a thermal-insulation vacuum-pumping double-layer glass tube is arranged in the external connection integrating sphere system; the control host is connected to the test box body, the external connection integrating sphere system and the computer through a data line respectively and is used for controlling setting of an acceleration temperature of the test box body and setting of a test parameter of an external connection integrating sphere; and the computer is used for displaying on-line data of the control host in real time. By using the equipment, performance of a LED lamp product can be rapidly shown.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

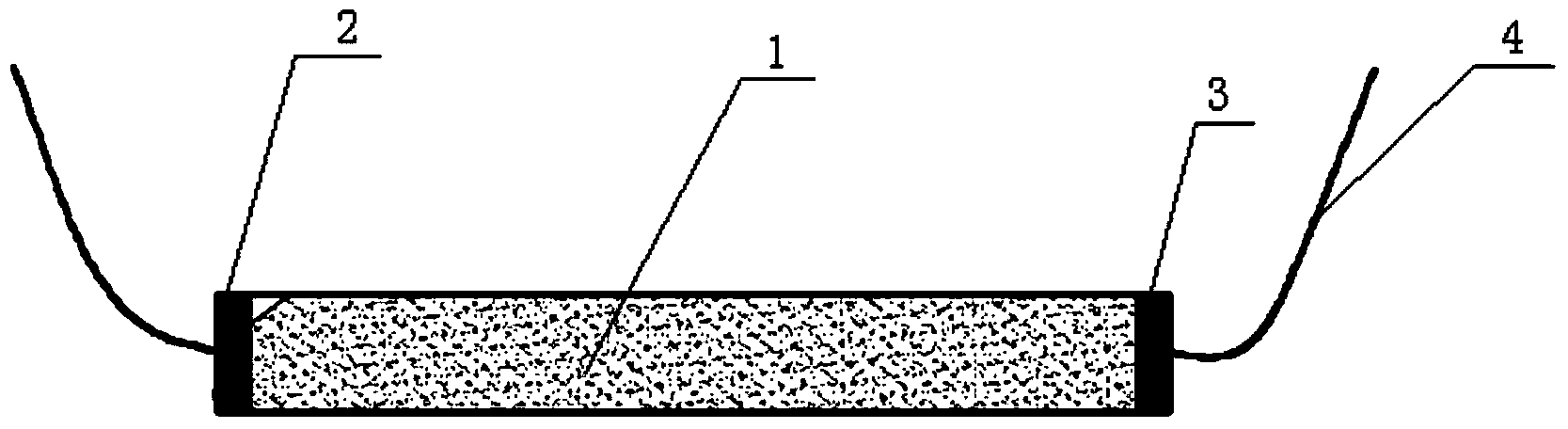

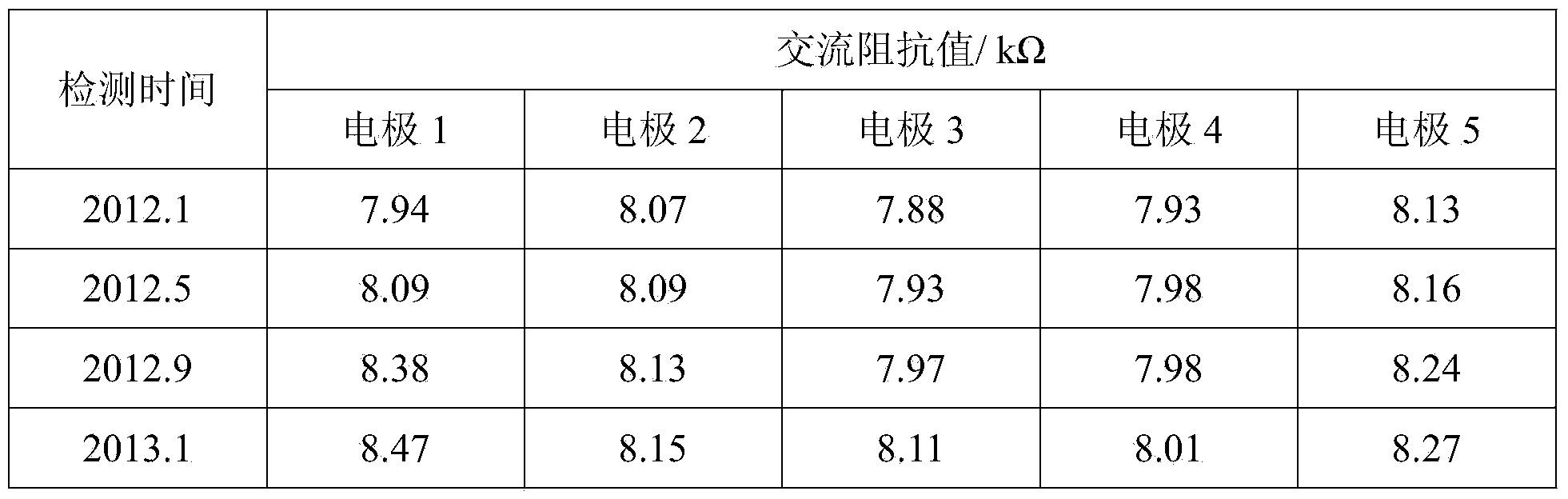

Cement-based mortar sensing electrode internally doped with nano-conductive material, as well as preparation method and application thereof

The invention provides a cement-based mortar sensing electrode internally doped with a nano-conductive material. The cement-based mortar sensing electrode comprises a cement base body, as well as graphene and nano-conductive carbon black which are dispersed in the cement base body. The invention further provides a preparation method of the electrode. The invention further provides a device for monitoring and sensing sulfate attack in concrete, which comprises the electrode. The electrode has the advantages of simple preparation process, low cost, stable performance, sensitivity in response and reliable detection data.

Owner:HOHAI UNIV

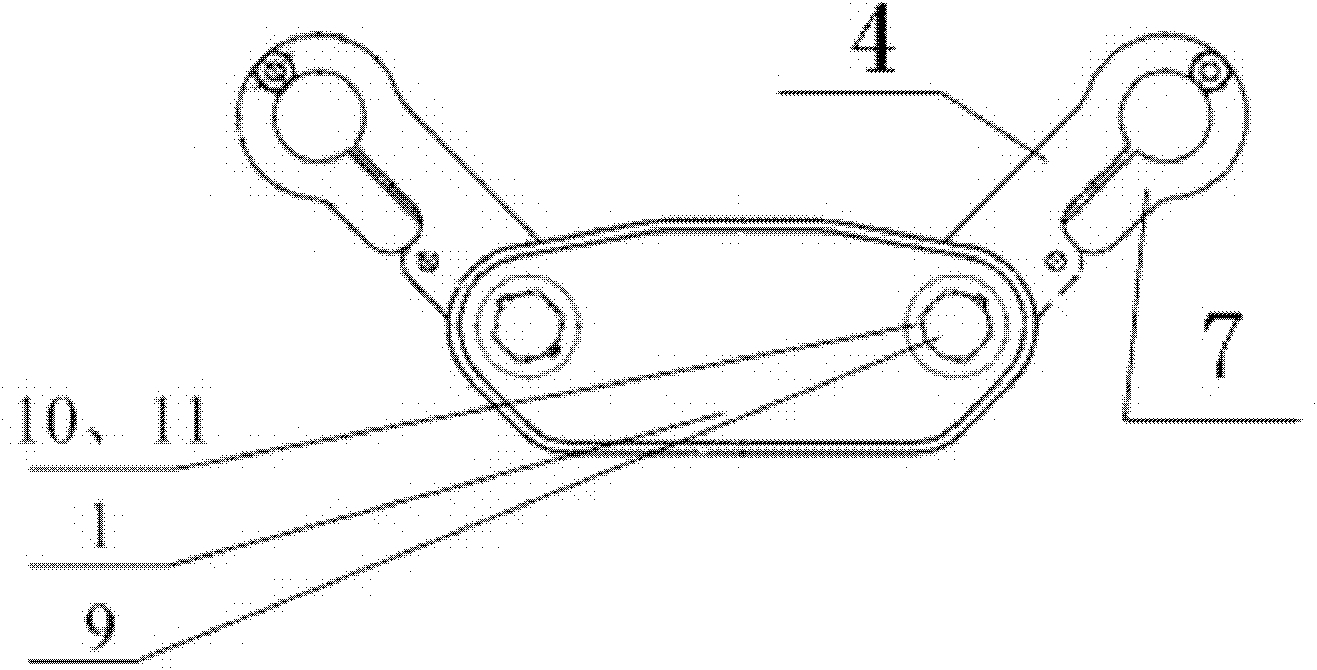

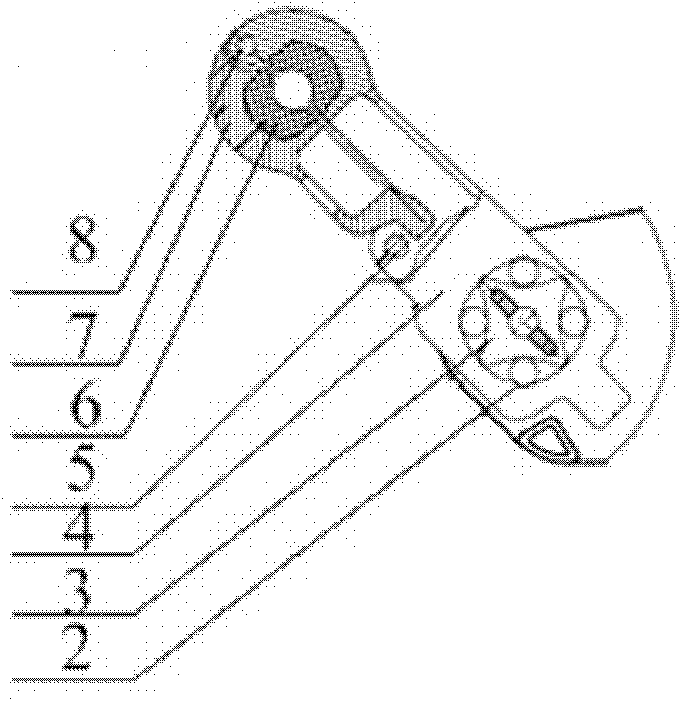

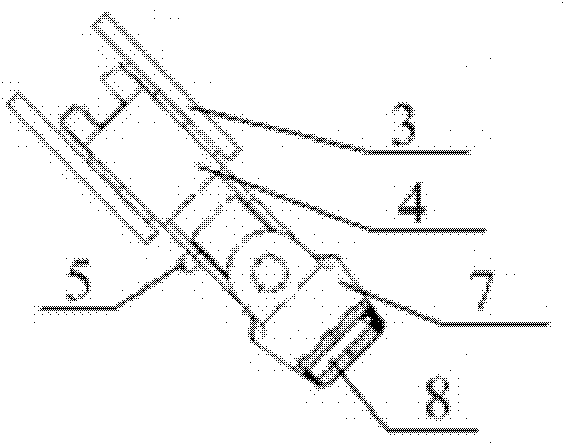

Composite material light energy-saving conductor spacer

InactiveCN102545123ANo power lossGood value for moneyMaintaining distance between parallel conductorsHysteresisLight energy

The invention discloses a composite material combination type light energy-saving conductor spacer, which is formed in the way that a frame (1), a cross shaft sleeve (3), a wire clip body (4) and a cover plate (7) are all made of fiber composite materials on the basis of a common conductor spacer. The conductor spacer adopts the fiber composite materials and a specially optimized structure, does not generate hysteresis lag or eddy-current loss, does not generate corona, is free of corona noise and electromagnetic energy loss, and is obvious in energy saving effects. The conductor spacer is high in mechanical strength, stable in grip power, waving resistant and small in maintenance cost. By means of special optimized structure design, the conductor spacer effectively prevents abrasion caused of connection of different materials of connection joints, improves abrasion resistance, prolongs service life, is light in weight and convenient to construct and install, saves electric energy and is remarkable in economical and social benefits.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +1

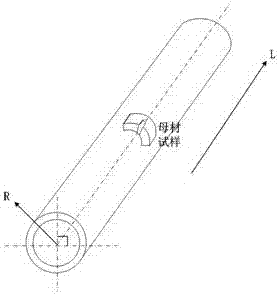

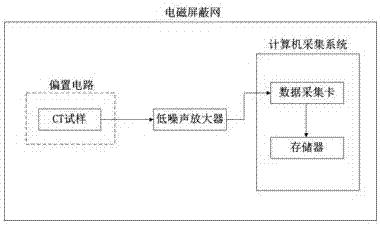

Fractal dimension representation method for expansion trend of corrosion fatigue crack of gas pipeline

InactiveCN107084899APredicted service lifeLow costInvestigating abrasion/wear resistanceCorrosion fatigueFatigue testing

The invention discloses a fractal dimension representation method for an expansion trend of a corrosion fatigue crack of a gas pipeline. The method comprises the steps of firstly cutting an L360 pipe wall material and preparing a CT sample; secondly, carrying out pre-fatigue noise testing and fractal dimension calculation on the pipe crack; thirdly, carrying out corrosion fatigue testing on the CT sample on a fatigue machine; finally carrying out noise testing on the corrosion fatigue crack and calculating a fractal dimension, wherein the expansion trend of the fatigue crack of the gas pipeline can be reflected according to the fractal dimension change of the crack noise calculated before and after the fatigue. Low-frequency noise testing and calculation are carried out on the sample, and the sample is not destroyed by the behavior, so that the method is a nondestructive testing means, and furthermore, the test can be carried out on most of metal pipes, and has relatively wide applicability.

Owner:XIAN UNIV OF POSTS & TELECOMM

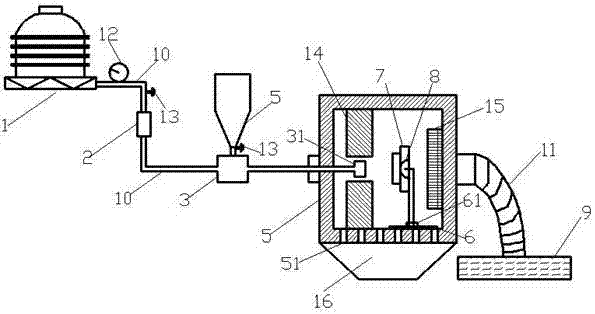

Experimental device applied to simulating high-temperature fused salt washout environment

InactiveCN107228806APredicted service lifeFast heating rateInvestigating abrasion/wear resistanceThermal insulationEngineering

The invention discloses an experimental device applied to simulating a high-temperature fused salt washout environment. The experimental device comprises an air compressor, a rotor flow meter, a spray gun, a material storage tank, a sand blasting box, a test sample frame, an electromagnetic heater, an angle gauge and a water tank, wherein the air compressor is connected with the rotor flow meter through a pressure-resistant flexible pipe, the rotor flow meter is connected with the spray gun through a pressure-resistant flexible pipe, the material storage tank is arranged above the spray gun and communicated with the spray gun, a nozzle integrally connected with the spray gun is arranged in the sand blasting box and close to the front end of an inlet of the sand blasting box, the test sample frame, the electromagnetic heater and the angle gauge are all arranged in the sand blasting box, the test sample frame is fixedly arranged in the middle position of the sand blasting box, the test sample frame is provided with a movable guide rail, the electromagnetic heater and the angle gauge are arranged above the test sample frame, a test sample is placed on the electromagnetic heater, the angle gauge is used for adjusting the angle direction of the test sample, and the water tank is communicated with the sand blasting box through a water pipe. The experimental device disclosed by the invention has quick temperature rise speed and good thermal insulation effect; furthermore, adjustable variables can be used for predicting service life of a coating layer by accelerating corrosion.

Owner:GUANGXI UNIV

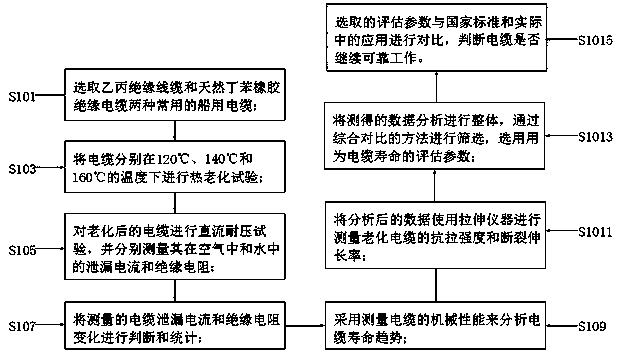

Marine cable aging performance testing method

InactiveCN110297147ARun fastAvoid accidentsTesting dielectric strengthVery high resistance measurementsElectrical resistance and conductancePower flow

The invention discloses a marine cable aging performance testing method. The marine cable aging performance testing method comprises the following steps: selecting two common marine cables, namely, anethylene propylene rubber insulation cable and a natural butadiene styrene rubber insulation cable; carrying out a thermal aging test on the cables at the temperatures of 120 DEG C, 140 DEG C and 160DEG C; carrying out a direct-current voltage-withstand test on the aged cable, and measuring the leakage currents and the insulation resistance of the cable in air and water; carrying out judgment and statistics on the changes of the measured leakage currents and insulation resistance of the cable; analyzing the service life trend of the cable by measuring the mechanical performance of the cable;measuring the tensile strength and the breaking elongation rate of the aged cable by using a stretching instrument according to analyzed data; analyzing and arranging measured data, carrying out screening through a comprehensive comparison method, selecting the change trend with the high breaking elongation rate, and selecting and using an evaluation parameter which serves as the service life ofthe cable; and comparing the selected evaluation parameter with the national standard and the actual application, thereby judging whether the cable can continue to work continuously or not.

Owner:南京荣港电气技术有限公司

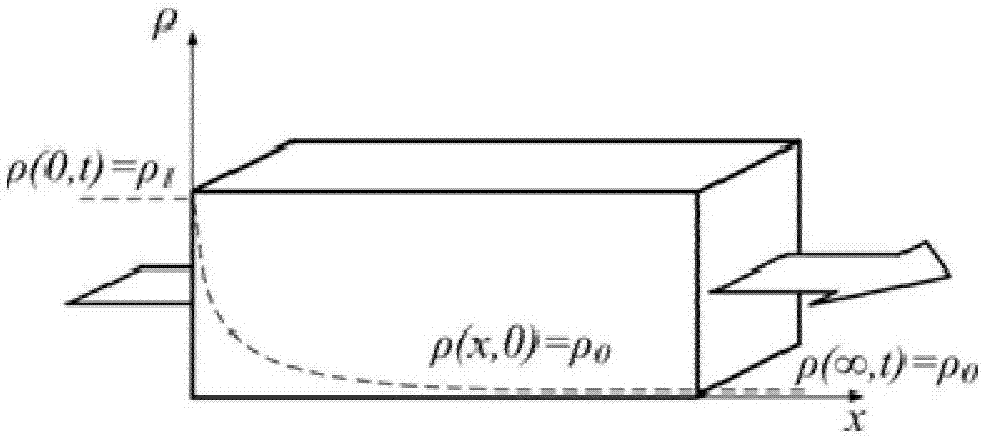

Device and method for measuring humidity physical properties of porous materials

PendingCN107132174AImplement usage estimatesPredicted service lifePermeability/surface area analysisTemperature controlHigh humidity

The invention discloses a device and a method for measuring humidity physical properties of porous materials. The device comprises a high-humidity test cabinet, a low-humidity test cabinet, a saturation system, a temperature control system and a data acquisition system. The device and the method have the advantages that the problems of deterioration of the heat-insulation performance of existing porous materials and diversified adverse effects due to accumulation of moisture in service procedures can be solved by the aid of the device and the method; the device for measuring the humidity physical properties of the porous materials comprises a system for testing water vapor effective diffusion coefficients and isothermal moisture absorption curves of the porous materials under the conditions of different temperatures and different types of relative humidity, accordingly, the water vapor effective diffusion coefficients and the isothermal moisture absorption curves of the porous materials under the conditions of the different temperatures and the different types of relative humidity can be obtained, the humidity physical properties and heat and moisture coupled transfer conditions of the porous materials can be comprehended, service conditions of the porous materials under different working conditions can be ultimately estimated, the service lives of the materials can be predicted, and unfavorable effects due to excessively high humidity can be prevented.

Owner:CHINA JILIANG UNIV

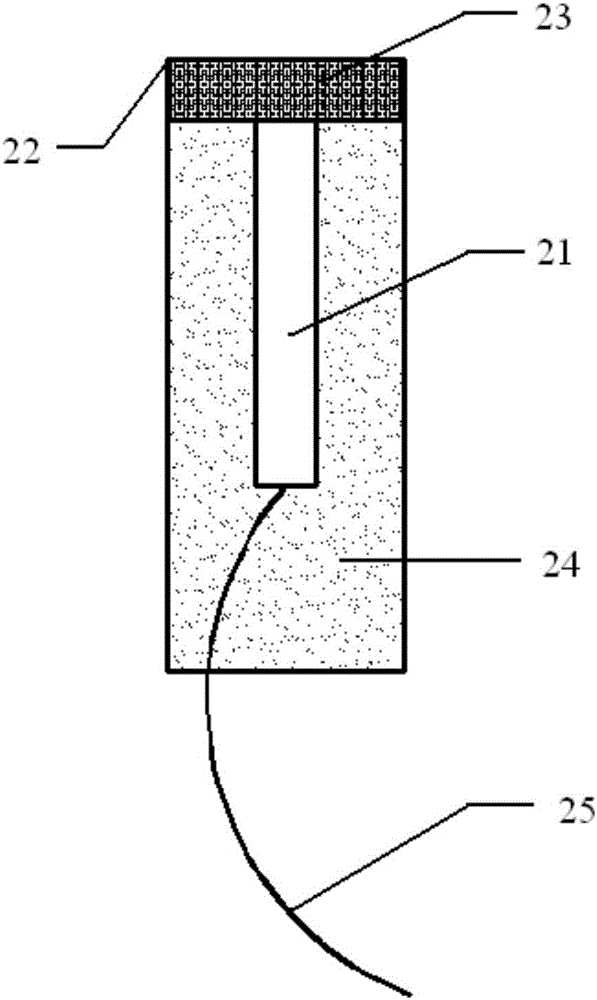

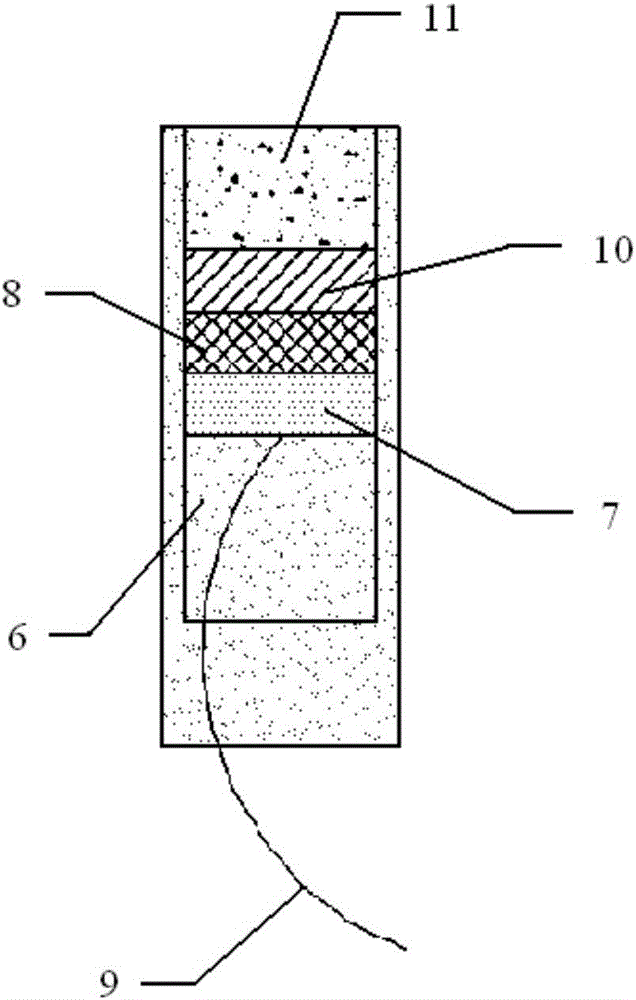

Porous Medium Premixing Combustor

ActiveUS20190353346A1Effectively avoid occurrenceAvoid it happening againFlow mixersTransportation and packagingCombustorPorous medium

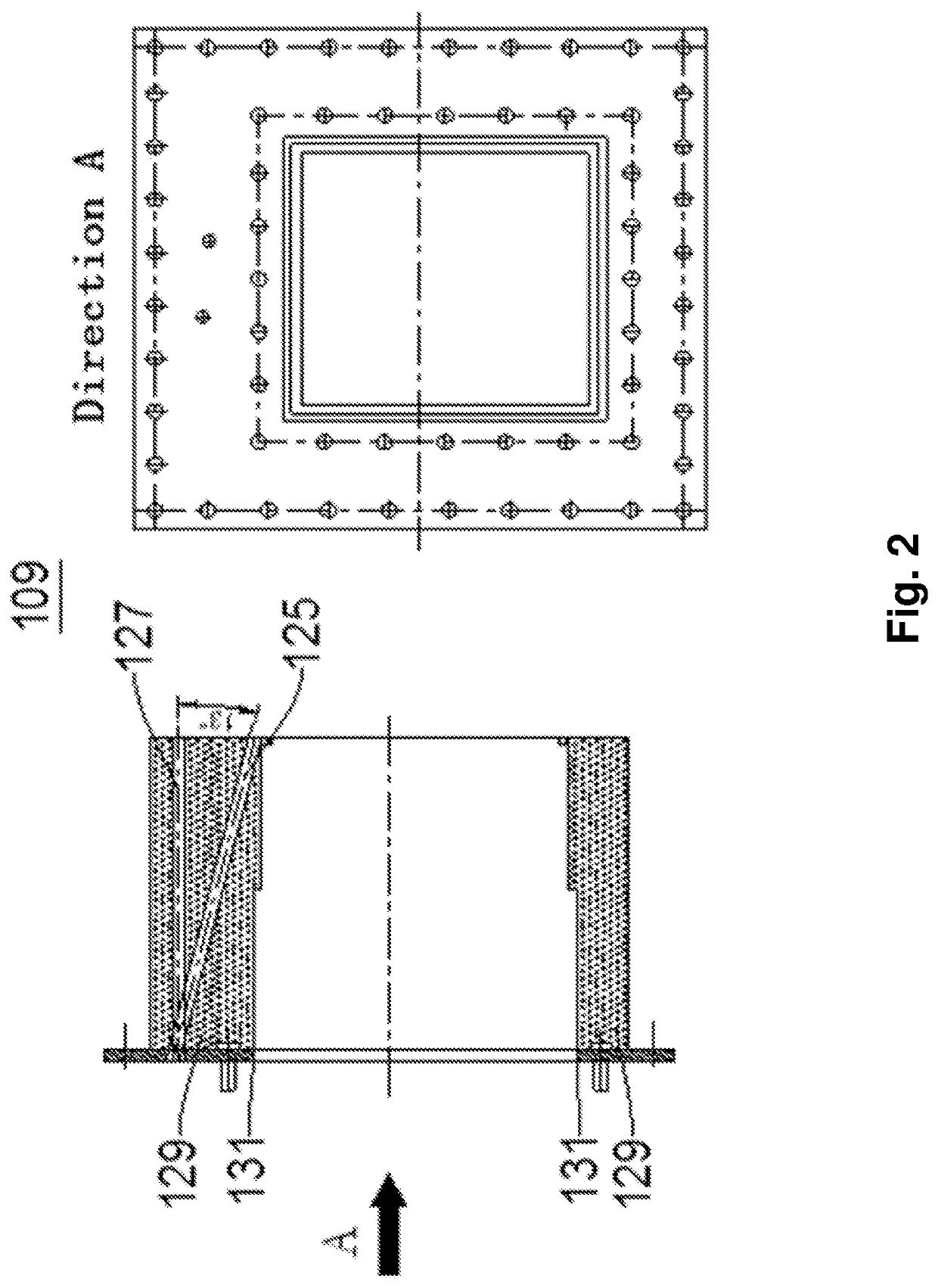

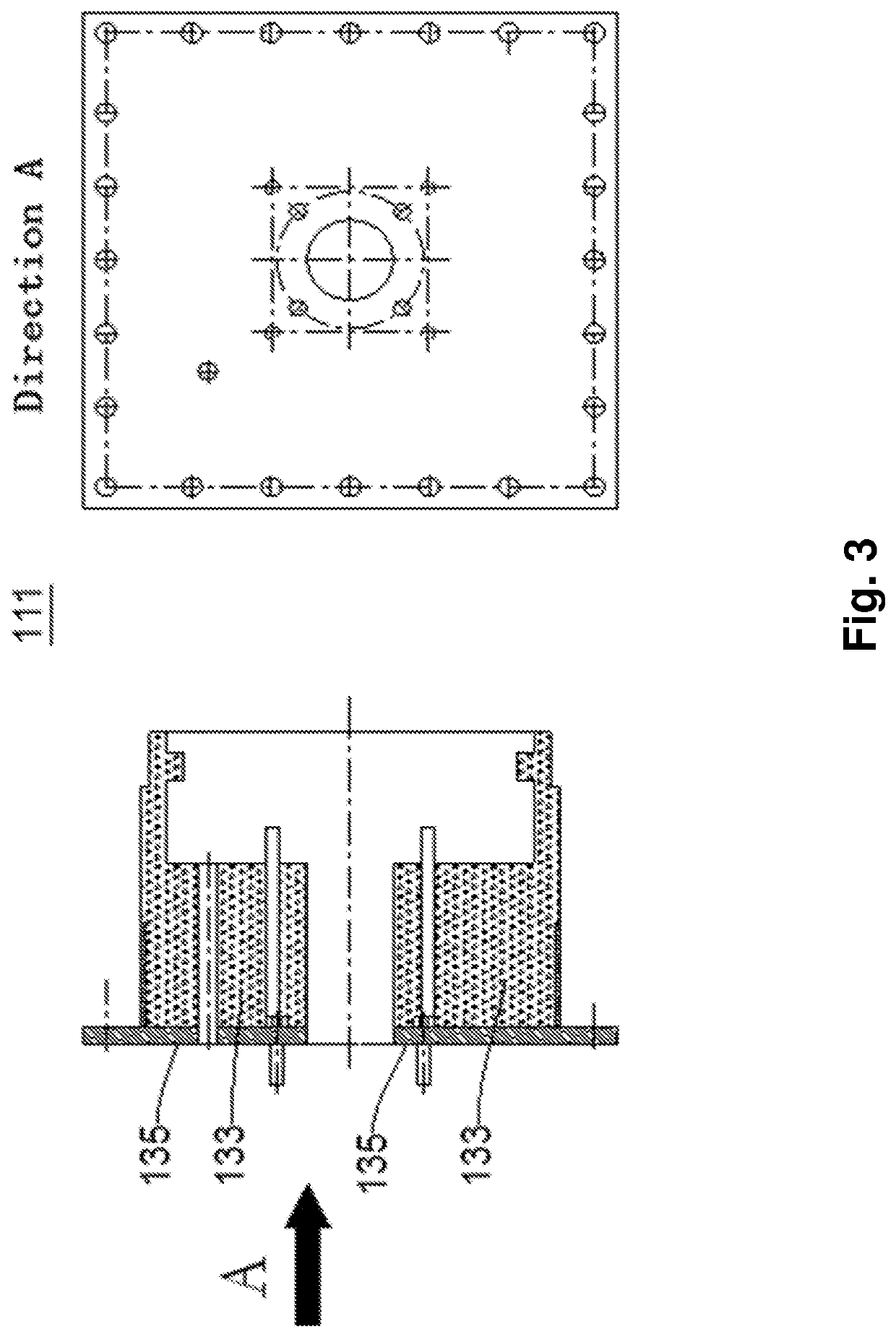

A porous-medium premixing combustor is provided, which includes: an air-fuel gas mixer, a combustor body, a thermocouple, an ignition electrode, and a detecting electrode. The combustor body includes a casing connected to the air-fuel gas mixer; an outer and an inner burner-block, wherein the outer burner-block and the casing are connected, forming a square chamber, and the inner burner-block is provided inside the square chamber, with a via hole communicating with a pipe; and a mixed gas distributing plate, an ordered porous plate, a small-pore foamed ceramic plate, and a big-pore foamed-ceramic plate sequentially provided along an axis direction of the via hole of the inner burner-block. The thermocouple is provided at the casing and extends into the square chamber. The ignition electrode is provided close to an end of the big-pore foamed-ceramic plate. The detecting electrode is provided close to an exit end of the big-pore foamed-ceramic plate.

Owner:WUHAN UNIV OF SCI & TECH

Method for predicting service life of polystyrene material by using sun tracking condensation accelerated aging test

ActiveCN110927050AShorten test timeGood correlationWeather/light/corrosion resistanceDesign optimisation/simulationSun trackingChemistry

The invention discloses a method for predicting the service life of a polystyrene material by using a solar tracking condensation accelerated aging test. The method comprises the following steps: carrying out a sun tracking condensation accelerated aging test on a polystyrene material in any selected region; and establishing an environment severity model, and calculating the acceleration multiplying power of the sun tracking condensation accelerated aging test relative to the natural aging of the PS in the actual use area based on the environment severity model so as to predict the service life of the PS material in the natural environment of the actual use area. According to the method, an environment severity model is adopted; the accelerated multiplying power of the accelerated aging test relative to any region can be calculated, the service life of the PS material in any region can be predicted through one-time sun tracking condensation accelerated aging test of the PS material inany selected region, the test workload can be effectively reduced, and the accuracy of service life prediction can be improved.

Owner:CHINA NAT ELECTRIC APP RES INST

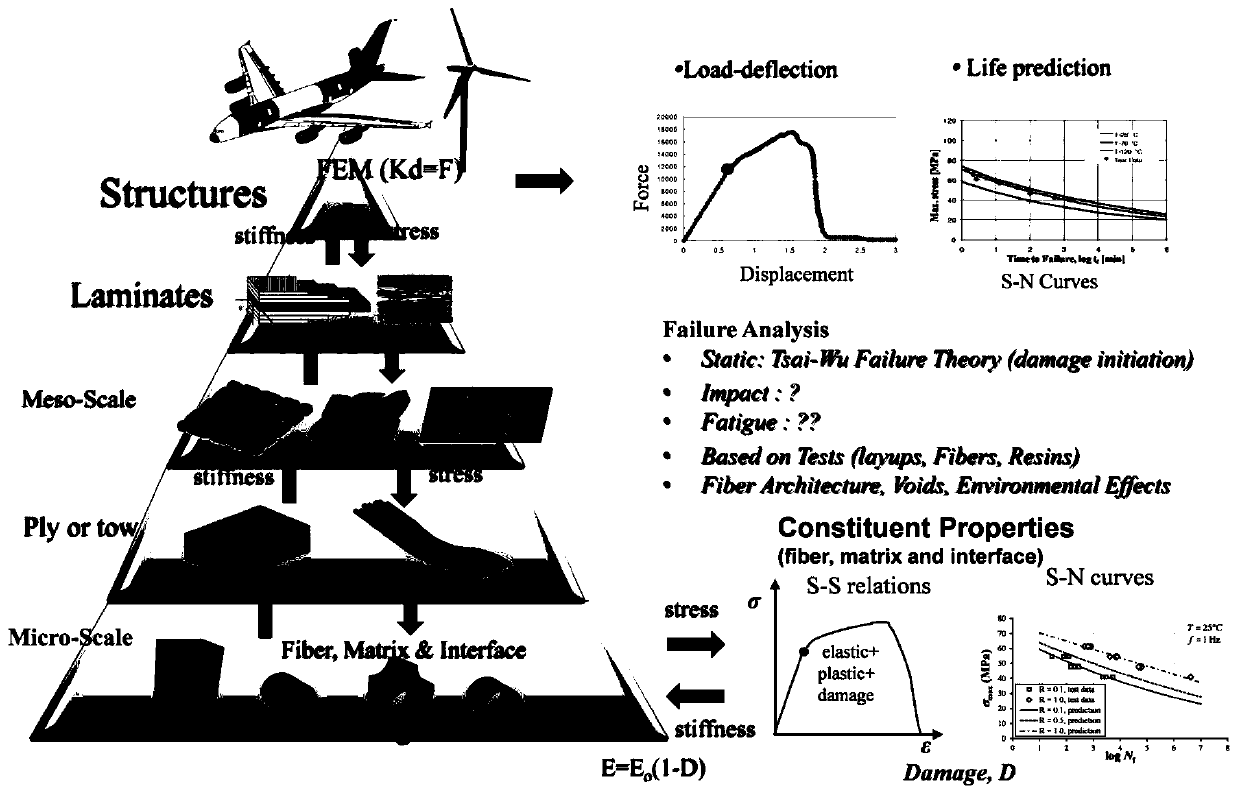

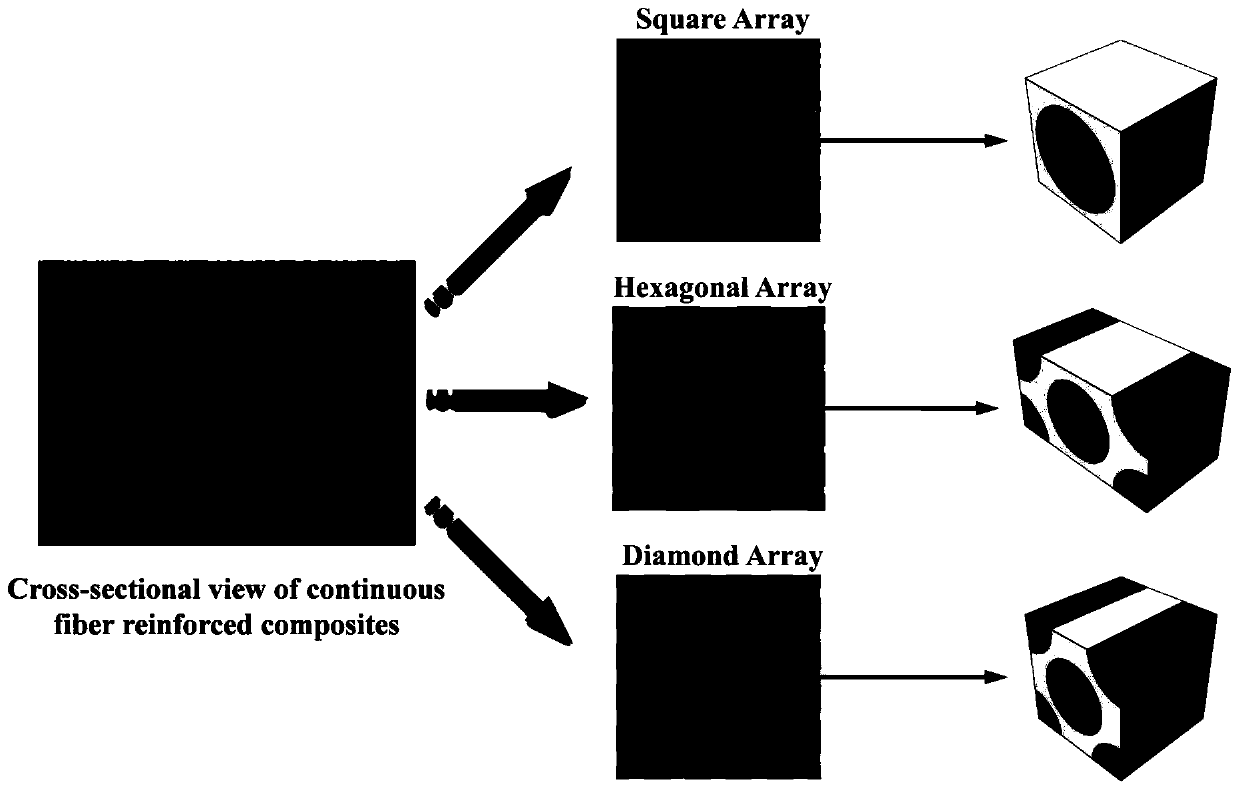

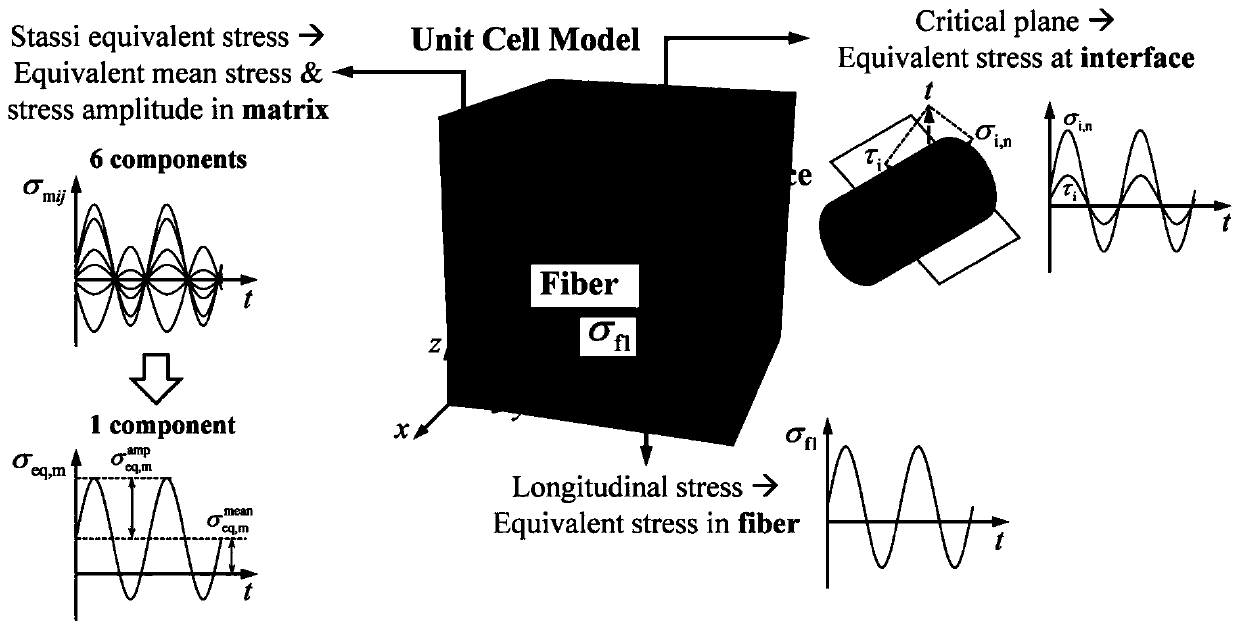

Polymer-based composite fatigue life prediction method based on mesomechanics

InactiveCN111198141AEasy to usePredicted service lifeMaterial strength using repeated/pulsating forcesFiberFatigue loading

The invention discloses a polymer-based composite fatigue life prediction method based on mesomechanics. The performance research object of a polymer-based composite is determined, and the performanceresearch object comprises fibers, a base and a fiber-base interface; according to the constitutive relation and the S-N curve of the performance research object, an equivalent volume unit model is repeatedly stacked to construct an equivalent regular fiber array; the multi-axis time-varying mesoscopic stress of the polymer-based composite laminate under the action of the static load and the fatigue load is determined by utilizing the unit body model; the given mesoscopic stress of each performance research object is converted into an equivalent average stress and an equivalent stress amplitude; according to the equivalent average stress and the equivalent stress amplitude, the cycle index of fatigue failure is obtained in combination with a creep rupture kinetic model, and an equivalent life diagram is established for predicting the creep / fatigue life. The method is beneficial for people to effectively predict the service life of the equipment made of the polymer-based composite, so that the method has guiding significance for normal and efficient use of the equipment.

Owner:烟台宏远氧业股份有限公司

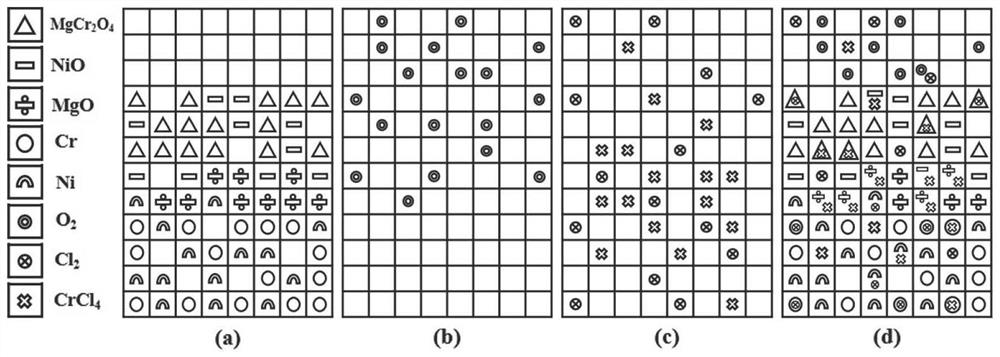

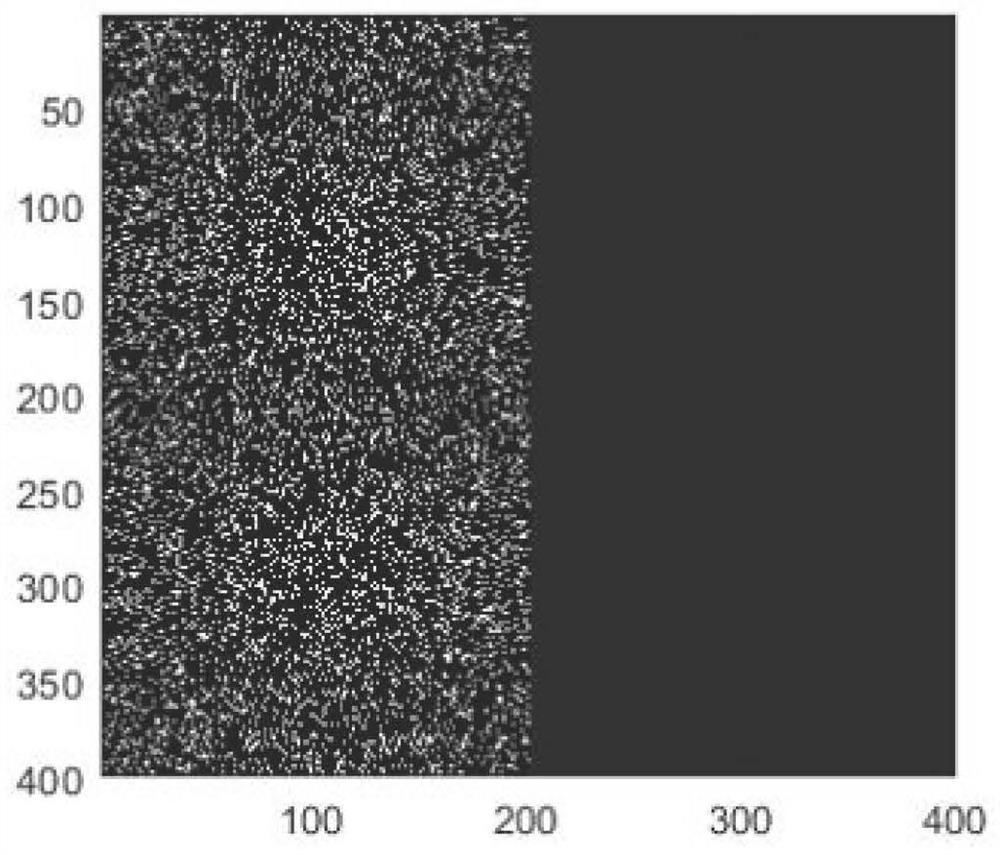

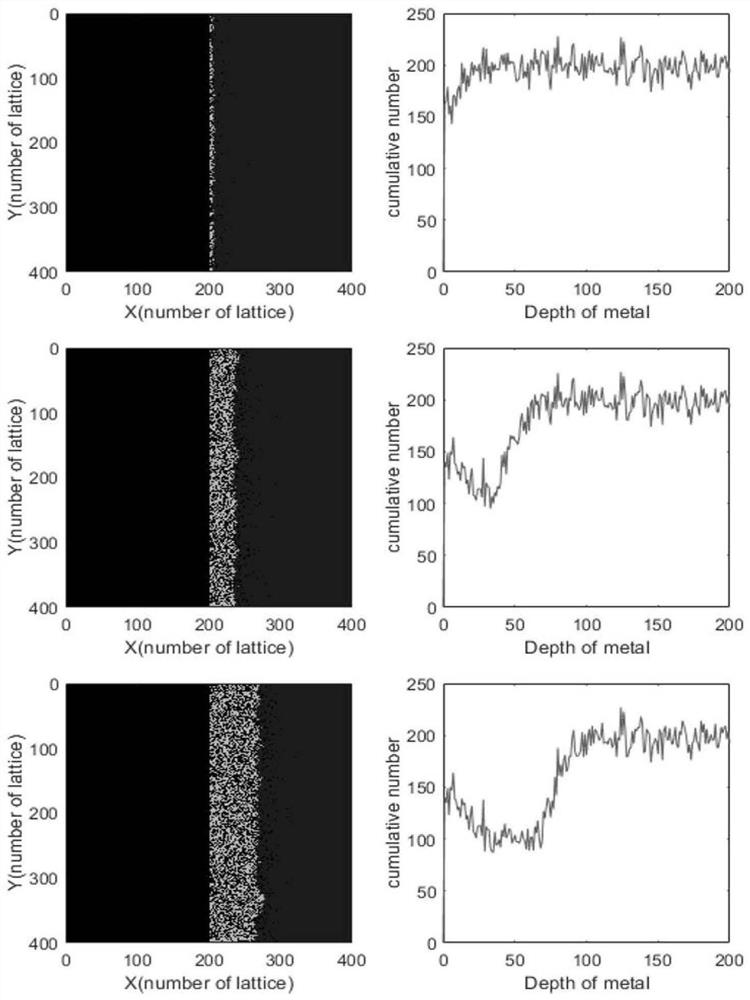

Nickel-based alloy corrosion layer dynamic evolution analysis method based on cellular automaton

PendingCN112800612AHigh degree of fitClear corrosion processChemical processes analysis/designDesign optimisation/simulationCellular automationChemical reaction

The invention discloses a nickel-based alloy corrosion layer dynamic evolution analysis method based on a cellular automaton. Each step of chemical reaction is converted into a corresponding programming language for expression, so that a model is more consistent with an actual situation; meanwhile, a change curve of the thicknesses of a total corrosion layer, an outer corrosion layer and an inner corrosion layer can be obtained, and the corrosion layer thickness change condition of the alloy under long-term corrosion can be predicted. The mass loss trend of the alloy can be predicted through the change trend of the total corrosion layer thickness, and the two are combined, so that the purpose of predicting the service life of a metal structure pipeline and a container can be achieved.

Owner:SUN YAT SEN UNIV

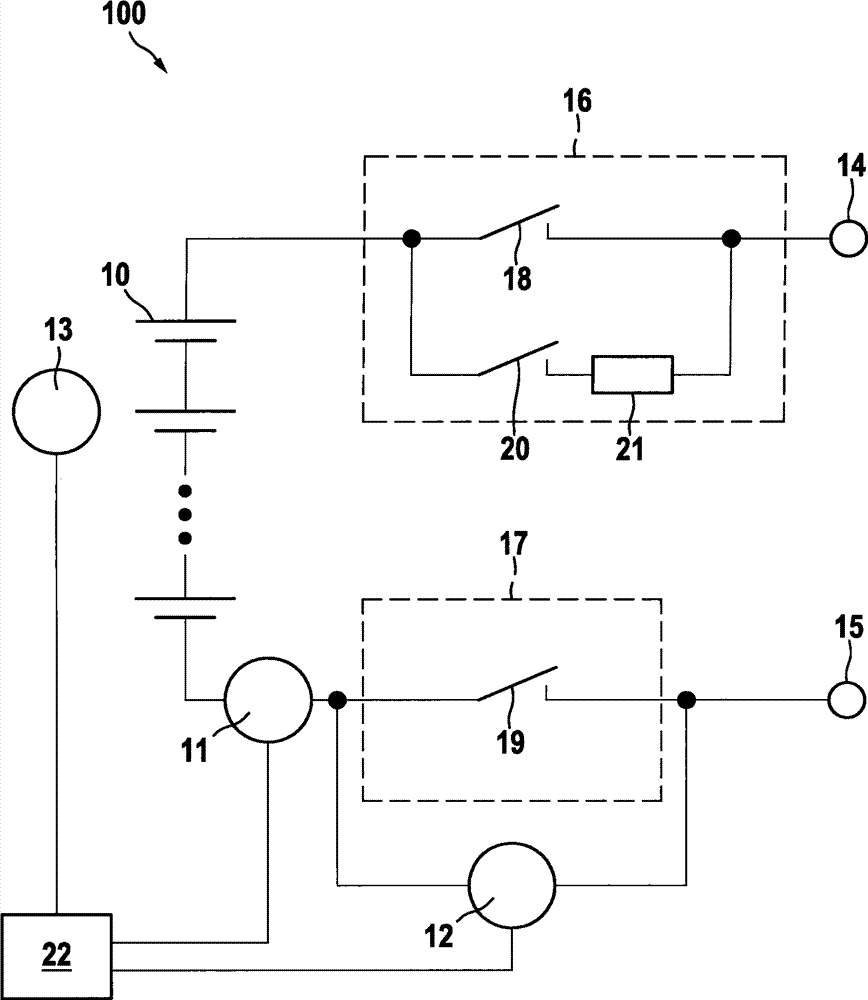

Method for predicting the usability of a relay or a contactor

ActiveCN104854466ARedundancy is beneficialAvoid stickingProtective switch detailsElectric devicesPower flowObservation unit

A method for predicting the usability of a relay or a contactor is described herein. A current flowing through the relay or the contactor and / or a voltage applied to the relay or the contactor is measured repeatedly, and the measured values are transmitted to an observation unit. The observation unit makes a prediction relating to the usability of the relay or of the contactor on the basis of the measured values and a model. Furthermore described are an observation unit and a battery which are configured to carry out the method according to the disclosure.

Owner:ROBERT BOSCH GMBH +1

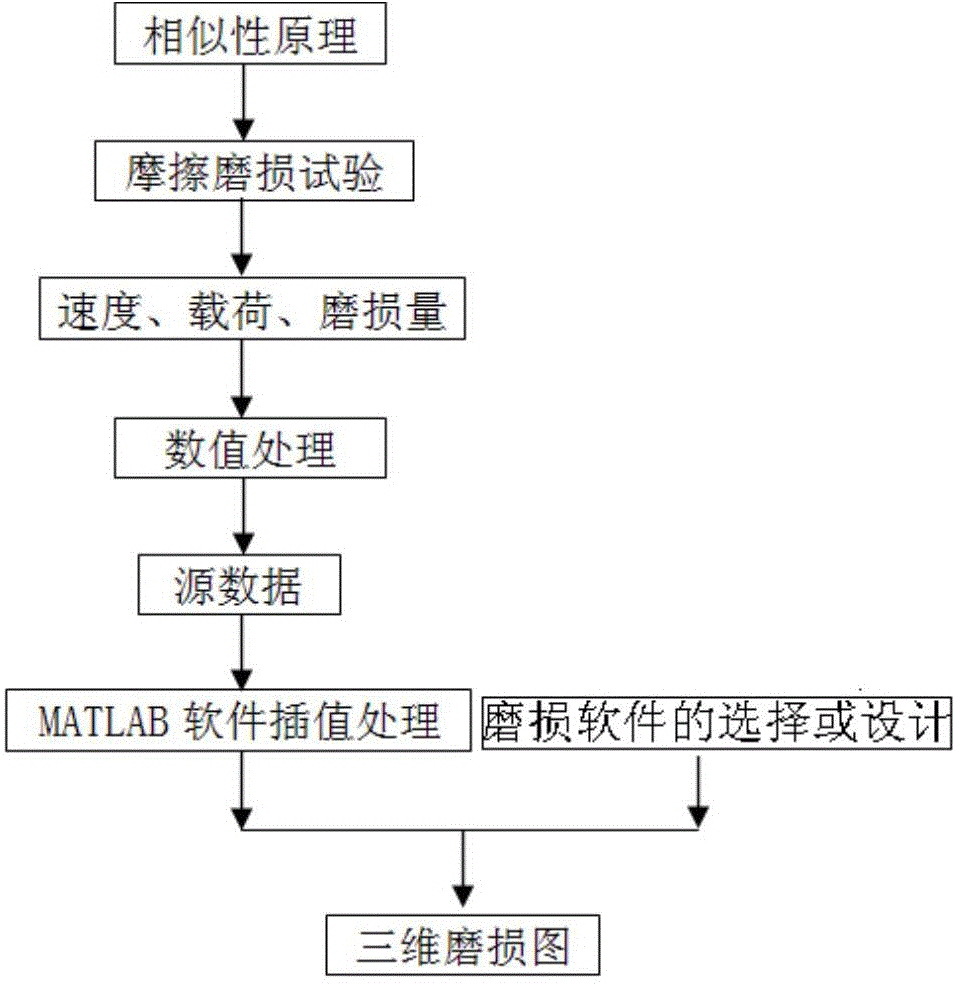

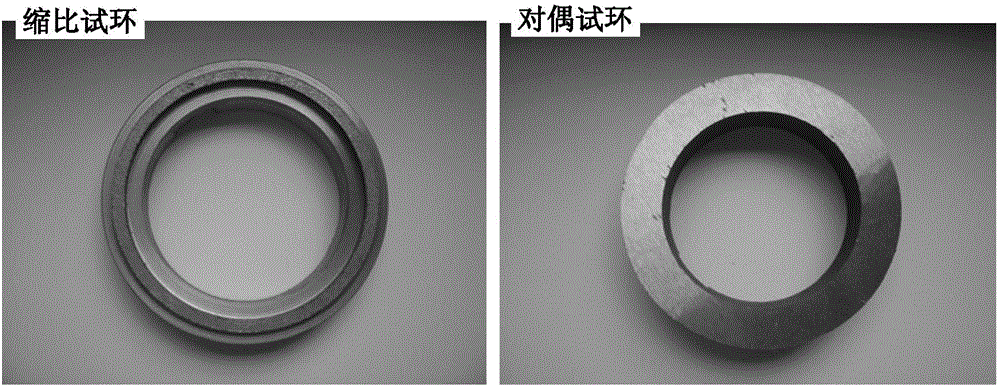

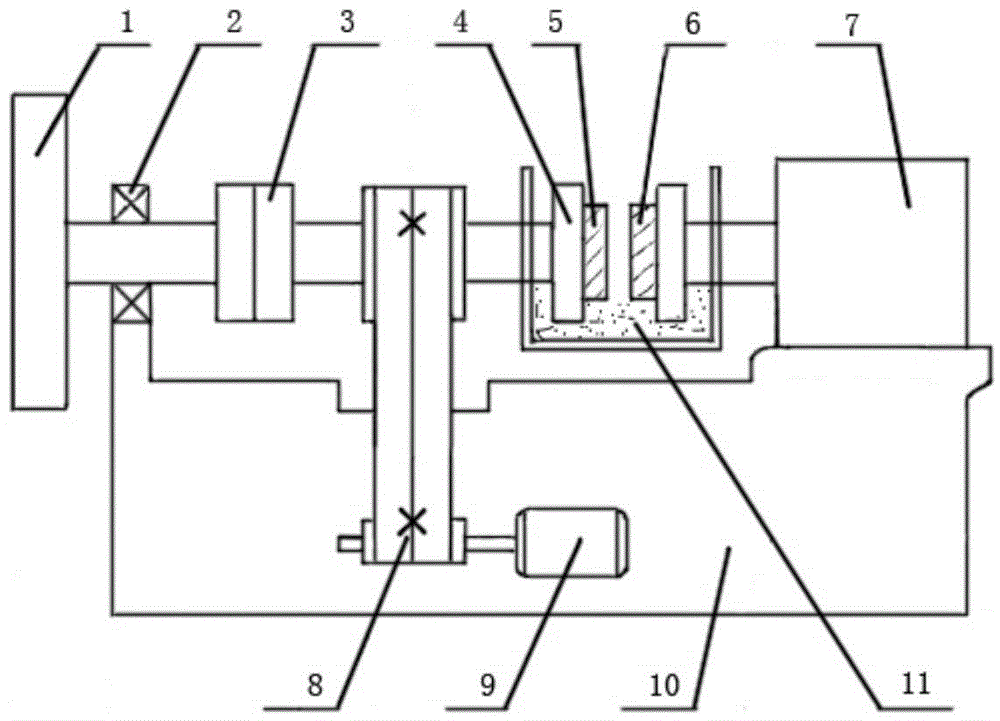

Method for constructing three-dimensional abrasion map of copper-based powder metallurgy wet friction material

InactiveCN104655508AReduce CooldownShorten the test cycleInvestigating abrasion/wear resistanceWear testingCopper

The invention relates to the technical field of a friction material for a clutch and in particular provides a method for constructing a three-dimensional abrasion map of a copper-based powder metallurgy wet friction material. The method comprises the following steps: (1) carrying out friction-wear testing on the copper-based powder metallurgy wet friction material processed into a narrow band by use of a disc-to-disc friction braking testing machine according to the similarity principle to acquire the primary data of the material; (2) performing numerical treatment on the primary data to obtain source data for constructing the three-dimensional abrasion map; (3) carrying out interpolation processing on the source data by use of MATLAB software to construct the three-dimensional abrasion map of the copper-based powder metallurgy wet friction material by use of the speed, the load and the abrasion loss as coordinate parameters. According to the method, the change rule of the abrasion loss of the copper-based powder metallurgy wet friction material along with the speed and the load can be acquired based on the constructed abrasion map, the abrasion loss and the service life of the copper-based powder metallurgy wet friction material can be predicted under different working conditions and the method has important engineering application value and the theoretical guiding significance.

Owner:CENT SOUTH UNIV

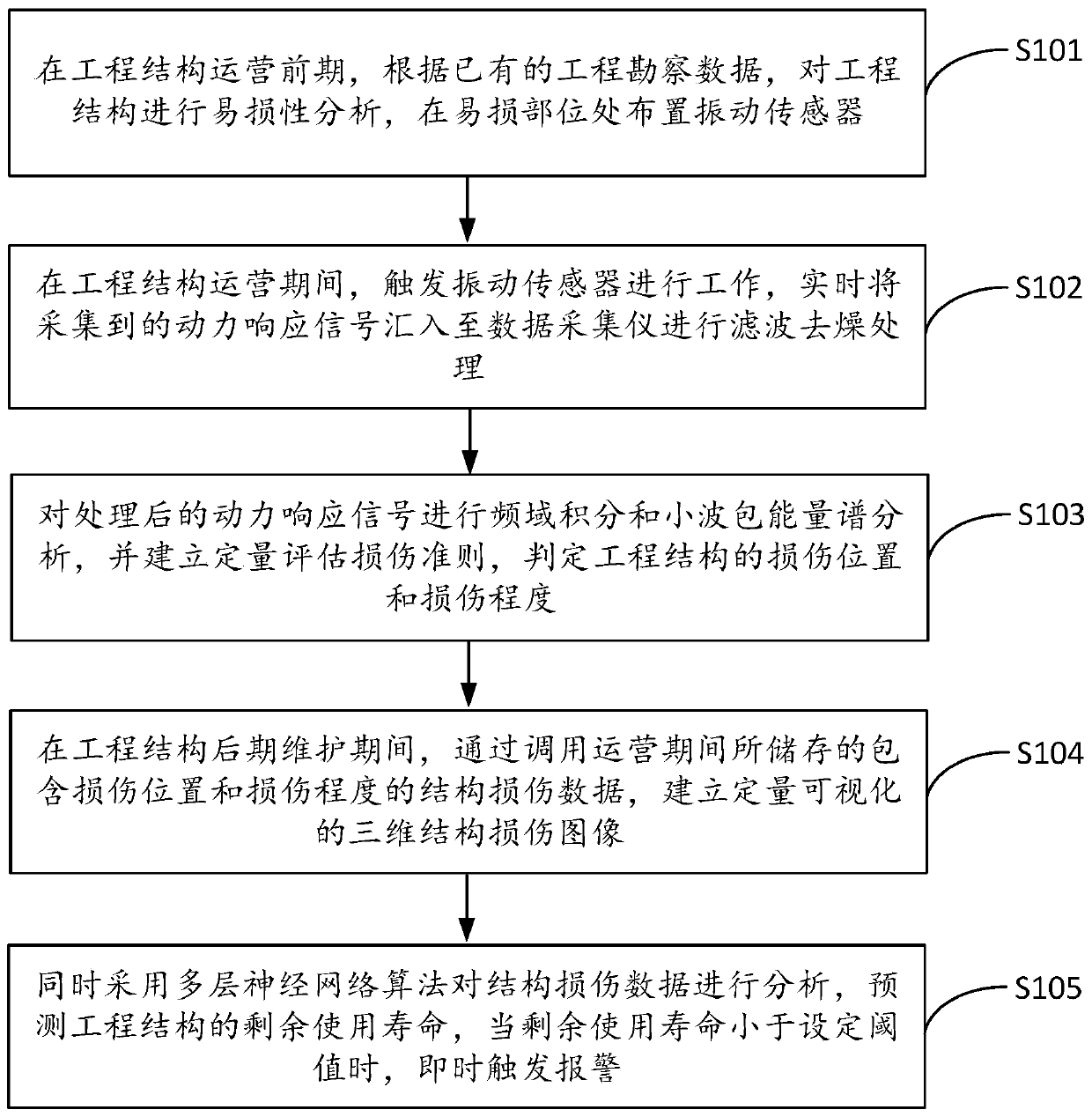

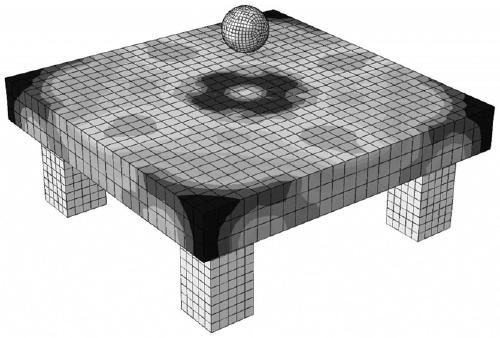

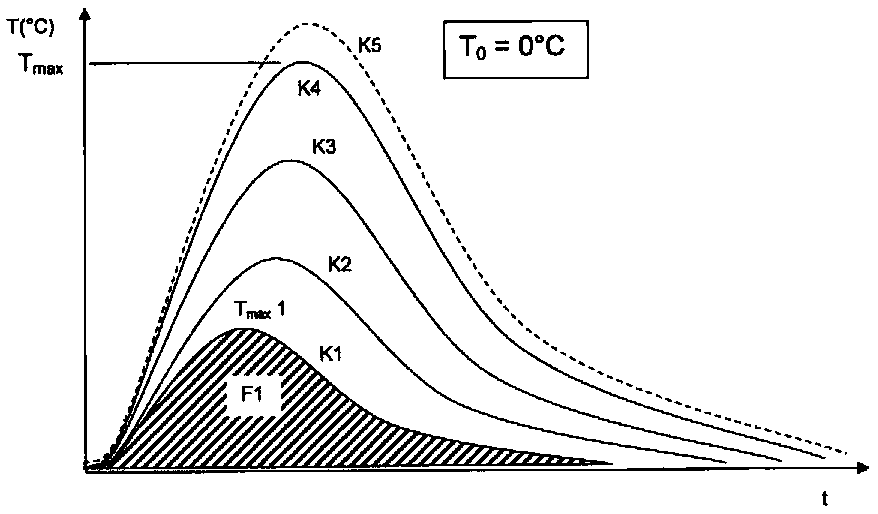

Engineering structure damage remote monitoring and early warning method and system

PendingCN111581865APredicted service lifePosition determination is accurateSubsonic/sonic/ultrasonic wave measurementCharacter and pattern recognitionFrequency domainResidual service life

The invention discloses an engineering structure damage remote monitoring and early warning method and system, and the method comprises the steps: carrying out the vulnerability analysis of an engineering structure according to the existing engineering investigation data at the early stage of the operation of the engineering structure, and arranging a vibration sensor at a vulnerable part; duringoperation, collecting a power response signal; performing frequency domain integration and wavelet packet energy spectrum analysis on the dynamic response signal, establishing a quantitative evaluation damage criterion, and judging a structural damage position and a damage degree; in the later maintenance period, establishing a quantitative visual three-dimensional structure damage image by calling the structure damage data stored in the operation period; and meanwhile, adopting a multi-layer neural network algorithm to analyze the structural damage data, predicting the remaining service lifeof the engineering structure, and when the remaining service life is smaller than a set threshold value, triggering an alarm immediately. Therefore, accurate dynamic real-time monitoring of the damagedegree of the structure and instant early warning before failure of the engineering structure are realized, and theoretical and technical guarantee is provided for operation and maintenance of the engineering structure.

Owner:CHENGDU SHANDI HUANAN DISASTER PREVENTION AND DAMAGE REDUCTION TECHNOLOGY CO LTD

Lightning arrester device with aging determination unit

InactiveCN111416316APredicted service lifeSpark gap detailsDischarge by conduction/dissipationThermodynamicsThermal state

The present invention relates to a lightning arrester device with an aging determination unit (1), comprising a lightning arrester (VAR) and an aging determination unit (1), the aging determination unit (1) has a first temperature measurement unit (S1) that detects the thermal state of the arrester (VAR), the aging determination unit (1) also has a storage unit (MEM) and an evaluation unit (CPU),the storage unit (MEM) stores aging data corresponding to the relationship between energy input and temperature characteristics of the arrester type, the first temperature measuring unit (S1) measuresthe temperature characteristics of the arrester (VAR) corresponding to the energy input, and the evaluation unit (CPU) obtains relevant aging data according to the measured temperature characteristics corresponding to the energy input, and then determines the aging degree of the lightning arrester (VAR).

Owner:PHOENIX CONTACT GMBH & CO KG

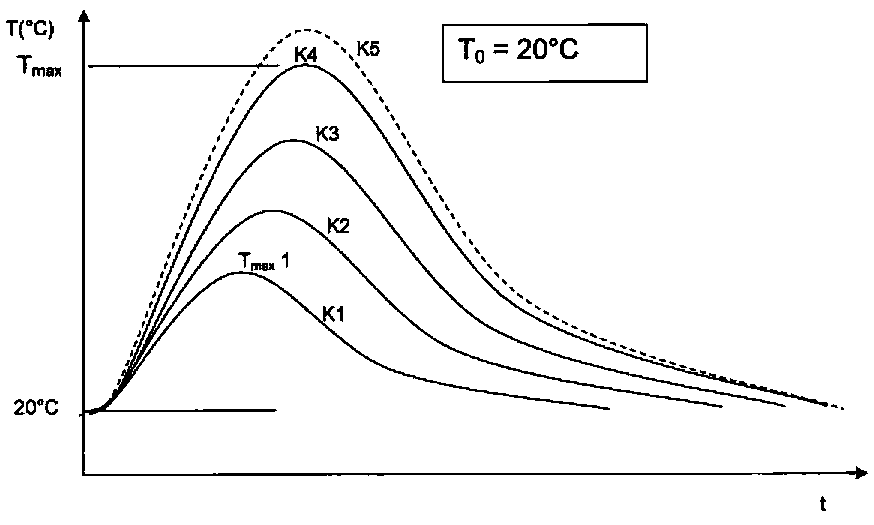

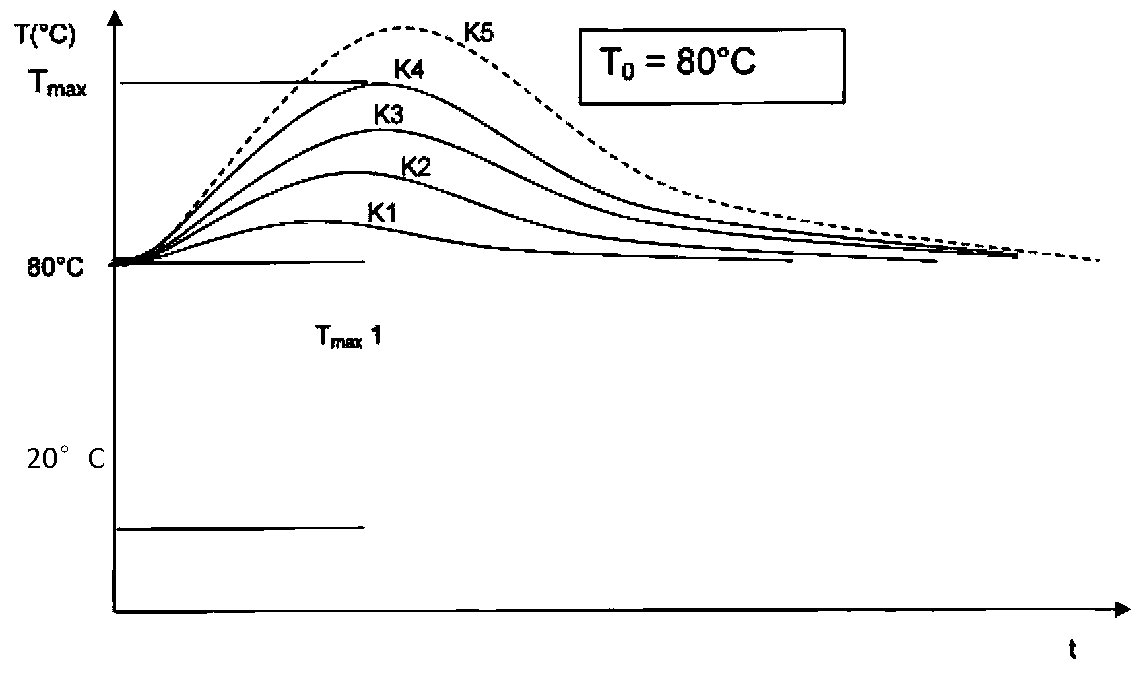

Method for evaluating friction and wear performance of valve and predicting service life under simulating working conditions

InactiveCN110411737AAccurate evaluationPredictive performanceMachine valve testingMaterial strength using repeated/pulsating forcesTorque sensorEngineering

The invention relates to a method for evaluating the friction and wear performance of a valve and predicting the service life under simulating working conditions. By simulating the actual working condition environment in combination with the mature sensing technology, the variation conditions of the operation torque are monitored through a torque sensor, and then the wear conditions of the valve are reflected; the pressure intensity variation of a closed containing cavity is monitored through a pressure sensor, and the static sealing performance of the valve is reflected; by recording the revolutions of a driver through a counter, through the relationship between the revolutions of the driver and the switching on and off frequency of the valve, the switching on and off frequency of the valve is calculated, and then the service life of the valve is predicted. By placing the practical use valve in an artificially-set working condition environment, the effect of simulating actual workingconditions is realized, the friction and wear performance of the valve is evaluated through torque and pressure intensity indexes, the service life of the valve is predicted according to the switchingon and off frequency index, the evaluating result and the predicting result are closer to the actual working condition results, and the accurate guiding effect on actual production is realized.

Owner:WUZHONG INSTR

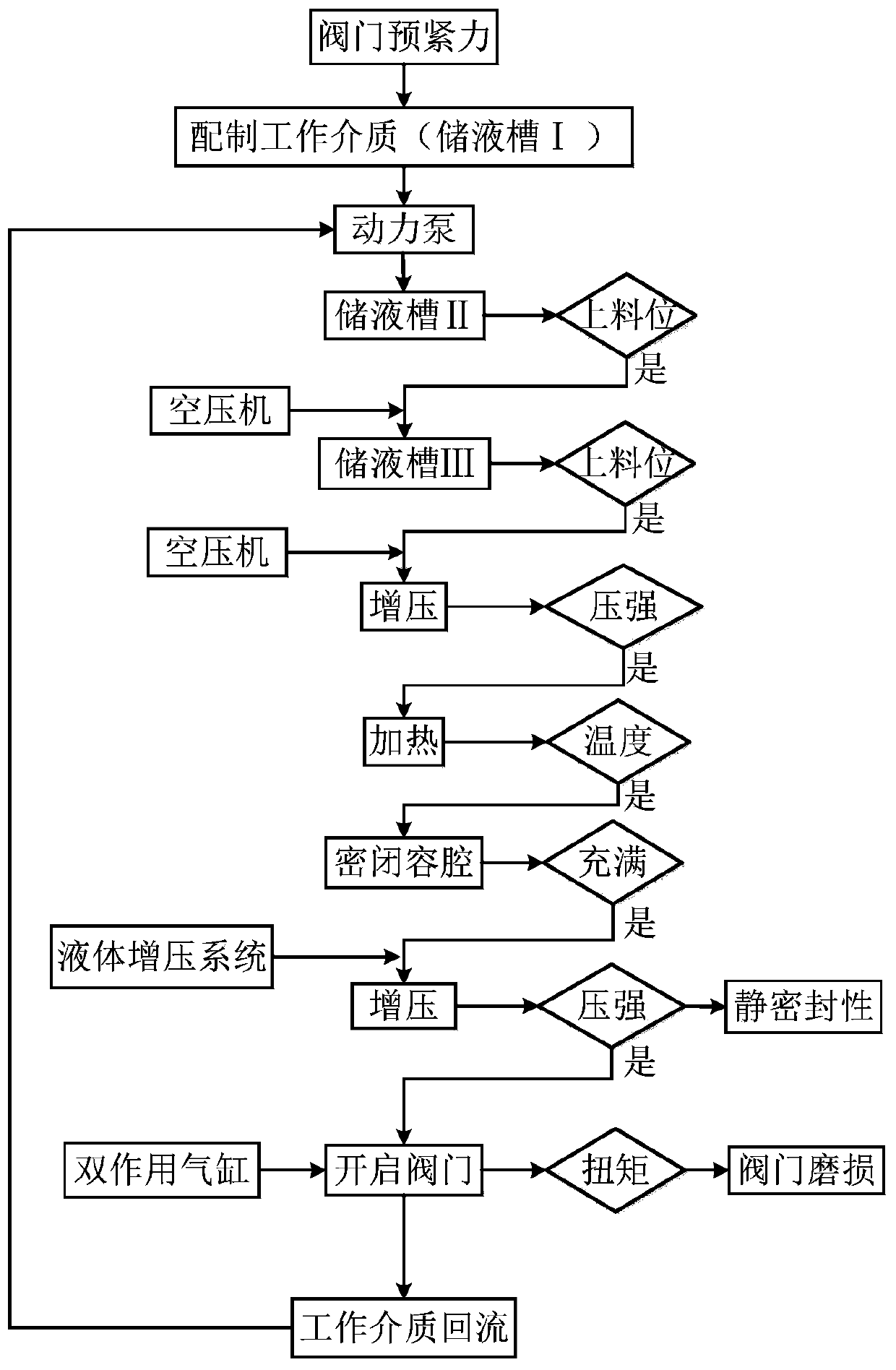

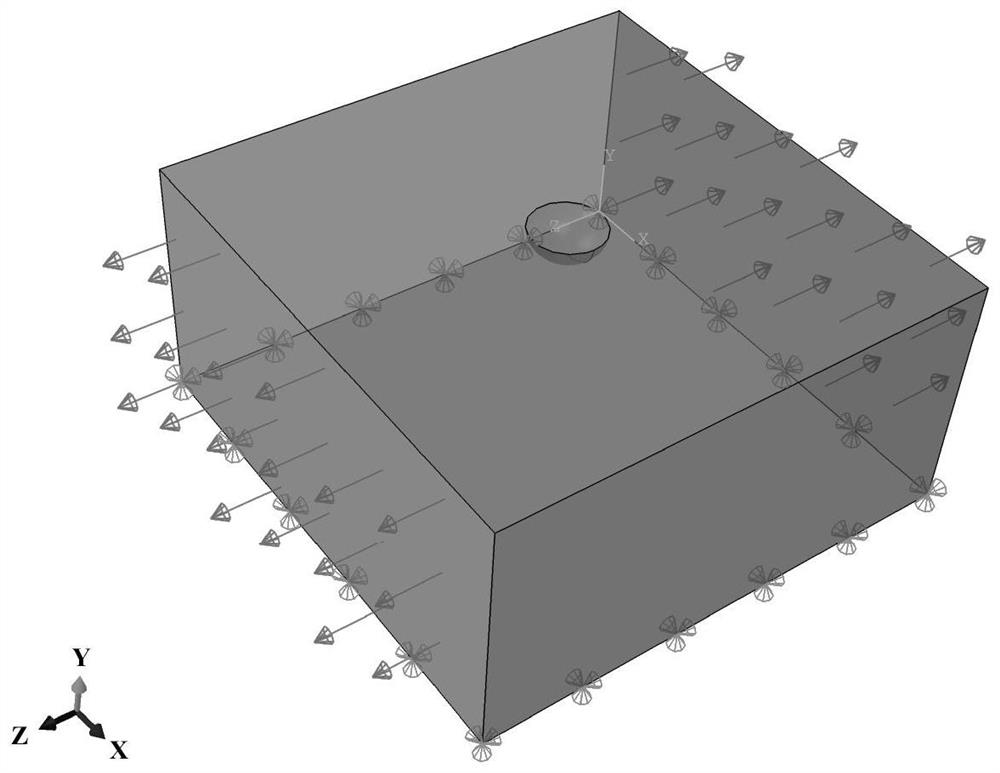

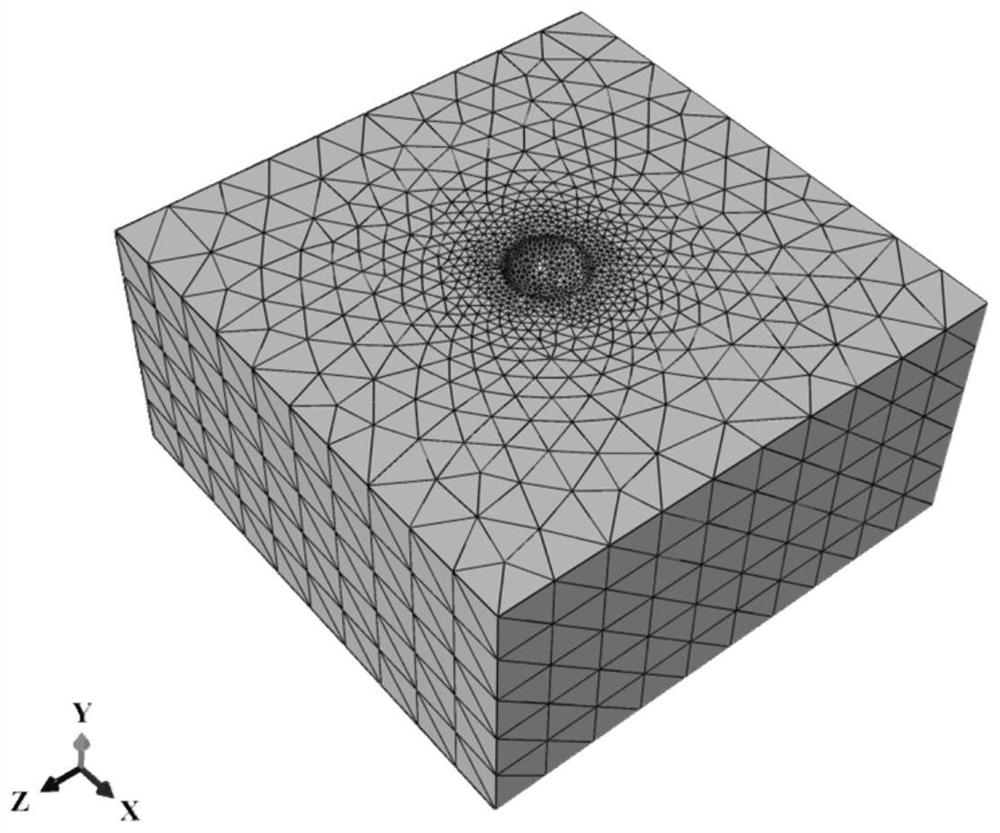

Numerical simulation method for crack propagation on pitting corrosion pit of RPV pipe based on extended finite element

ActiveCN113378432APredicted service lifeDesign optimisation/simulationSpecial data processing applicationsStress distributionStructural engineering

The invention discloses a numerical simulation method for crack propagation on a pitting corrosion pit of an RPV pipe based on an extended finite element. The method comprises the following steps: determining the morphology and size parameters of the pitting corrosion pit generated by an RPV pipe material under an actual working condition through a test; establishing a pitting-pit-containing damage model suitable for the RPV pipeline material; defining load and boundary conditions; setting an XFEM unit enrichment area by calculating stress distribution; and simulating a crack cracking process on the pitting corrosion pit model. According to the method, the influence of the morphology and size of the pitting corrosion pit on the crack initiation position is considered, no prefabricated crack is added in simulation, damage accumulation-cracking whole-process simulation of cracks around the pitting corrosion pit from nothing to nothing under the approximate RPV pipeline working condition is achieved, and the service life of the RPV pipe can be effectively and accurately predicted.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com