Wear prediction method for shield tunneling hob

A tool wear and prediction method technology, which is applied in the direction of earth drilling, mining equipment, instruments, etc., can solve the problems of tool wear and tear, frequent opening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

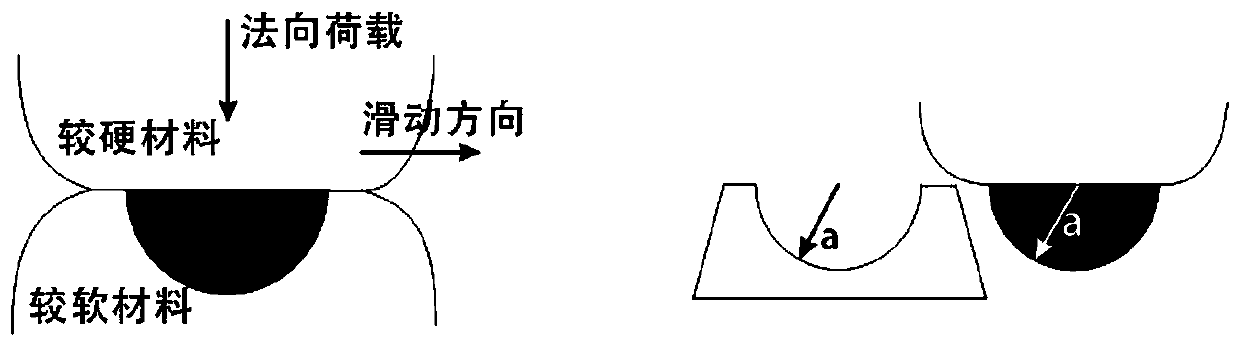

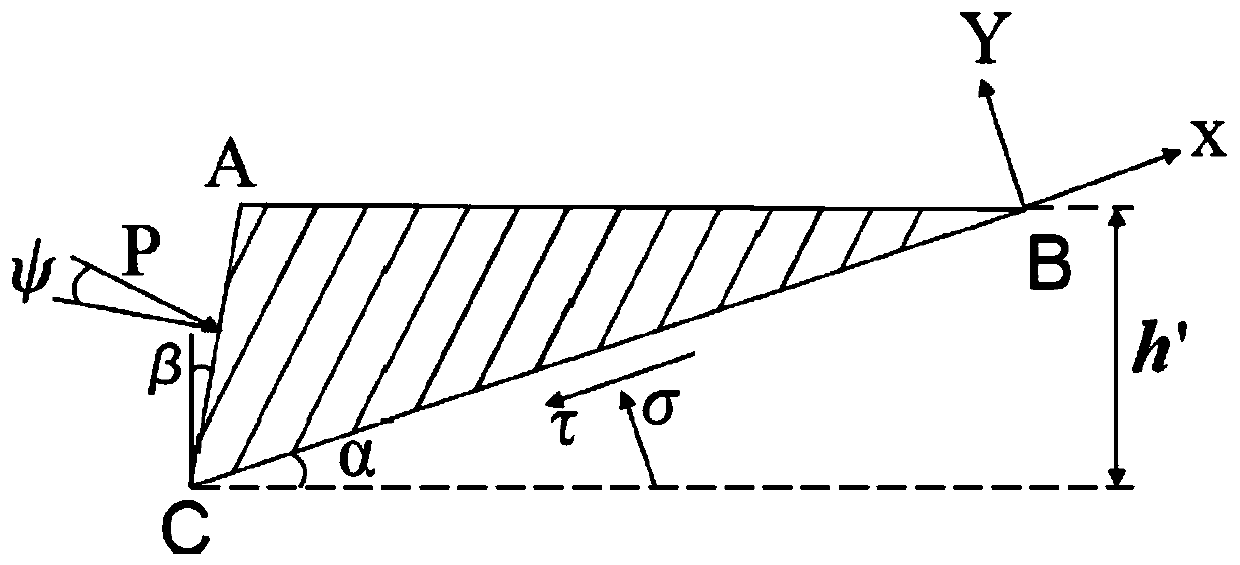

[0090] The main forms of hob wear include plastic removal, brittle fracture, adhesive wear and fatigue wear. In this embodiment, a hob wear prediction model including four different wear mechanisms is established by combining specific hob parameters and geological condition parameters.

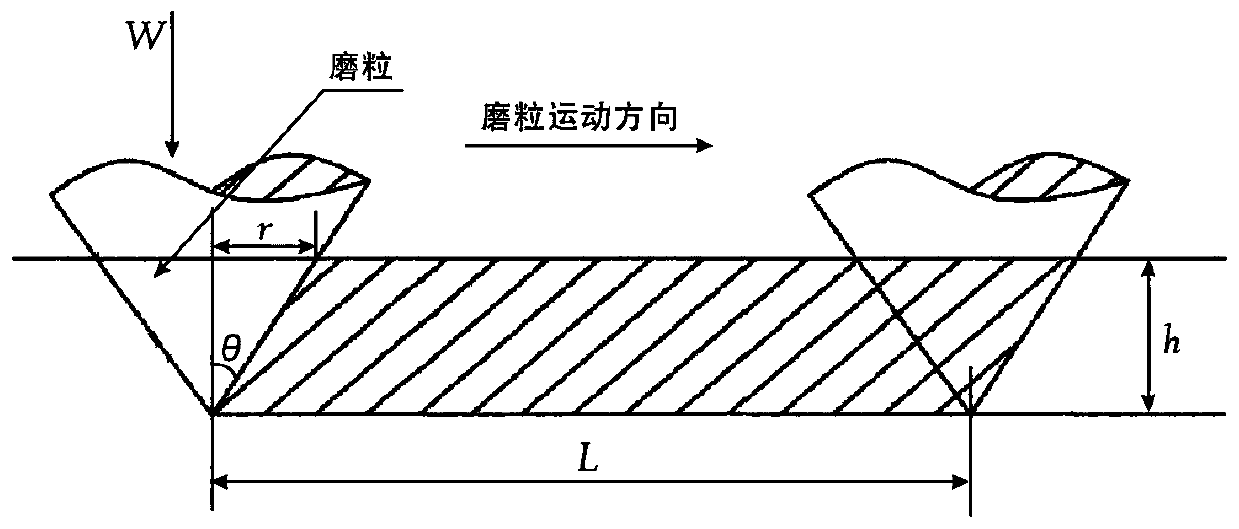

[0091] The calculation method of hob wear based on plastic removal mechanism is: figure 1 It is a simplified model of abrasive wear based on the theory of micro-cutting. This model assumes that the abrasive particles are hard particle cones plowing grooves in softer materials, and the wear process is regarded as the normal load pressed into the micro-cutting and sliding of the friction surface. furrow shear action. Among them, the projected area A of the pressed-in part of a single cone is:

[0092] A=πr 2 (1)

[0093] In the formula, r is the radius of the cone base.

[0094] If the normal load on each abrasive particle is W, assuming that there are n cones on the contact surface, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com