Numerical simulation method for crack propagation on pitting corrosion pit of RPV pipe based on extended finite element

An extended finite element and crack propagation technology, which is applied in the field of numerical simulation of crack propagation on pitting pits of RPV pipes, which can solve the problems of research, large volume of RPV, and difficulty in stress corrosion cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiment of the present invention will be further described in detail by describing the examples below with reference to the accompanying drawings. on its implementation.

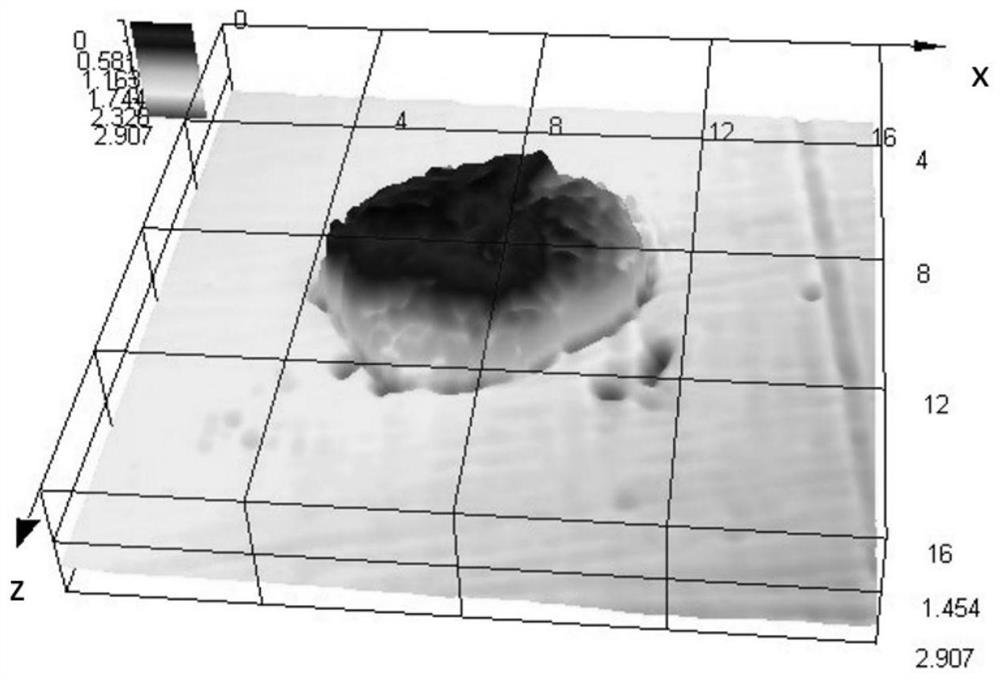

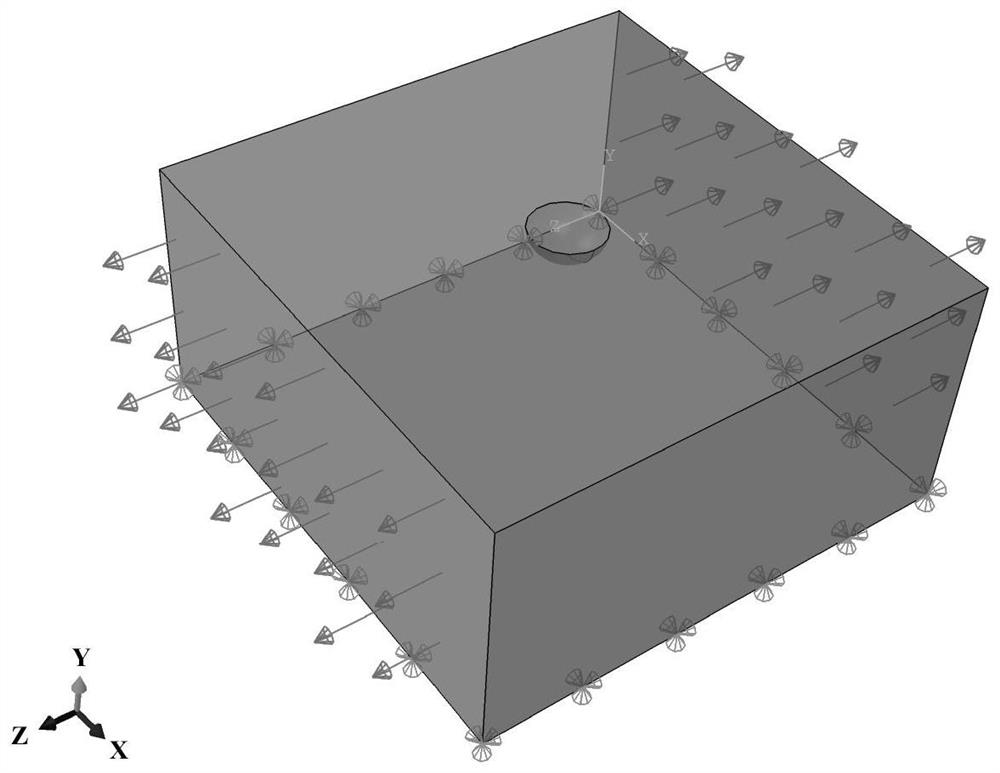

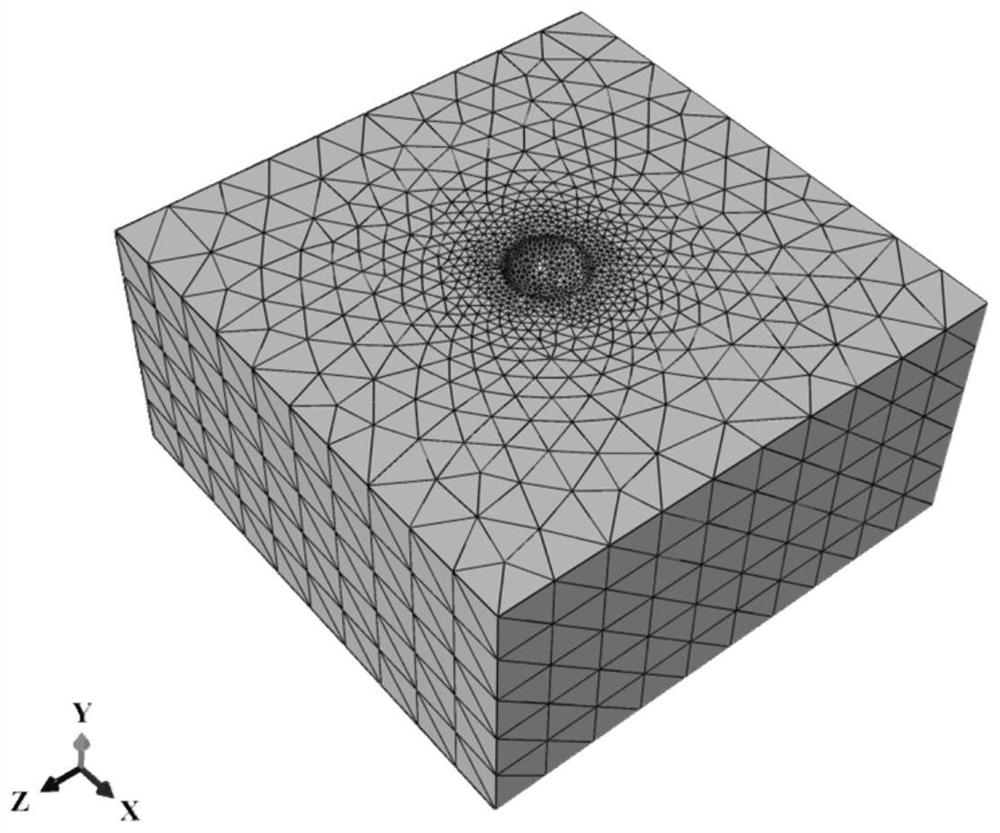

[0033] Based on the above-mentioned existing calculation results, the present invention proposes a research idea of calculating the stress distribution of pitting pits based on a three-dimensional model and further calculating the crack propagation behavior on pitting pits. Specifically, firstly, the morphology and size parameters of stainless steel pitting corrosion initiation stage were obtained through corrosion immersion test, based on which a three-dimensional model of pitting pits with different shapes was established, the stress distribution was calculated, and the stress concentration of different pitting pits was marked point. Furthermore, based on this, the XFEM enrichment unit area is set around the marked stress concentration point, and the crack initiation and propagati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com