Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "No loss of adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

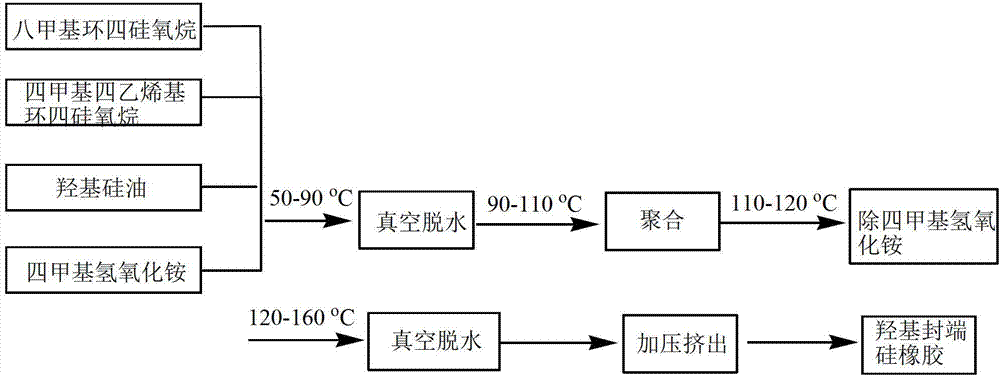

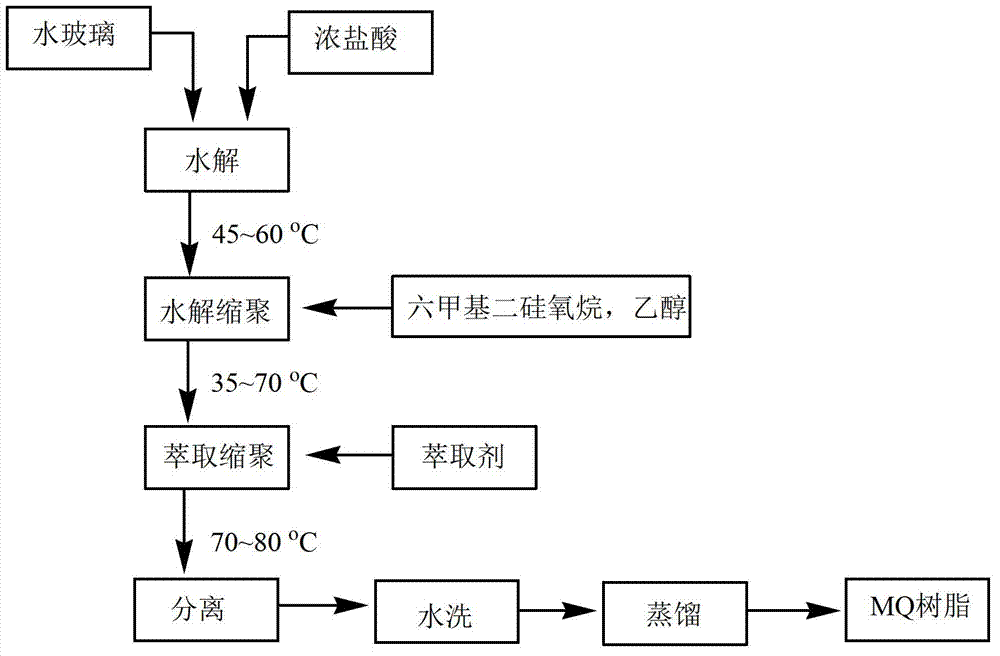

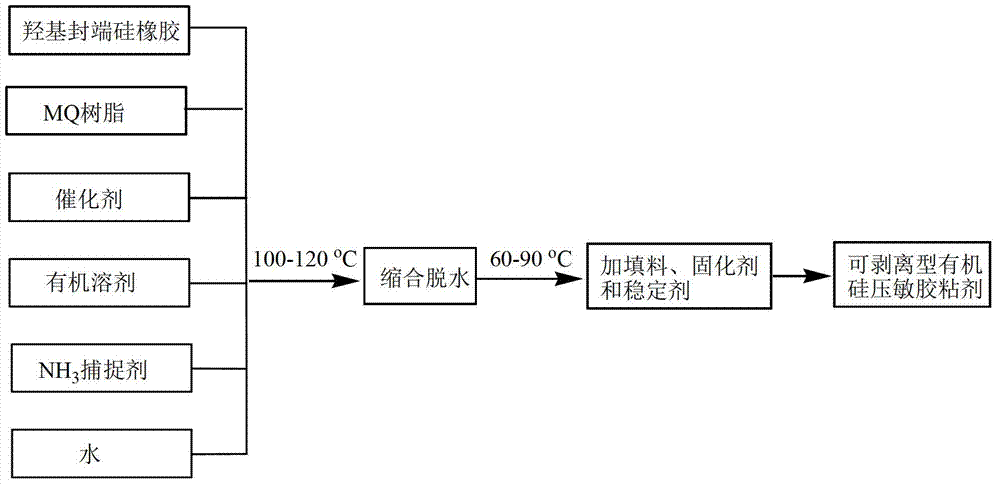

Preparation method of peelable type organosilicon pressure-sensitive adhesive

InactiveCN102876249AStir wellGood storage stabilityNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesive cementEndcapping

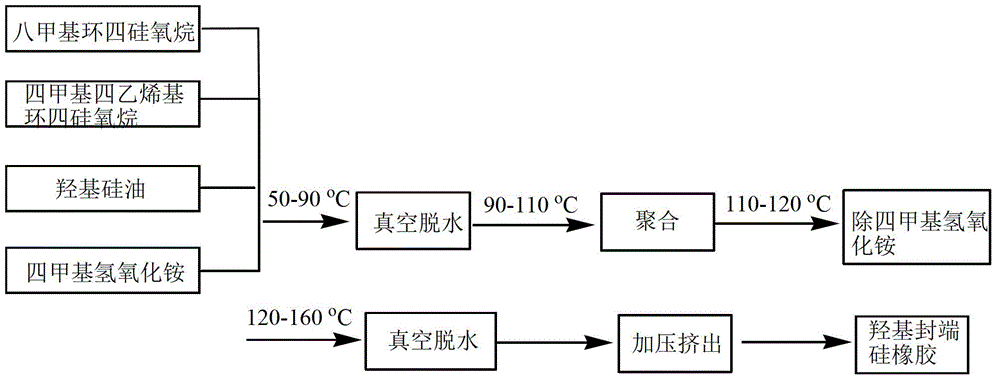

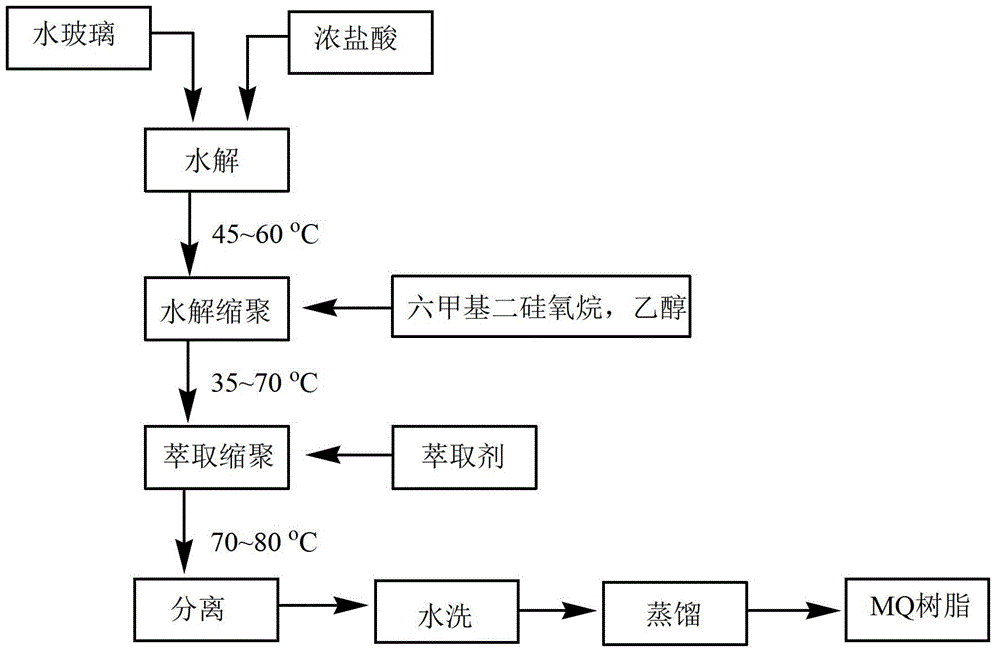

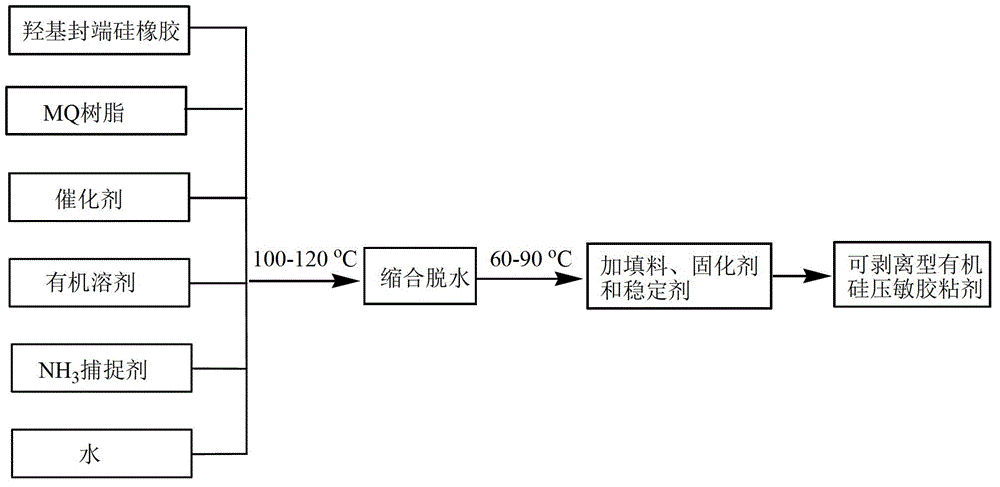

The invention provides a preparation method of a peelable type organosilicon pressure-sensitive adhesive. The preparation method comprises the following steps: firstly, synthesizing MQ resin by adopting a water glass method; secondly, synthesizing carboxyl-terminated silicone rubber by adopting a direct equilibrium copolymerization method; and finally, mixing the MQ resin, the carboxyl-terminated silicone rubber and an organic solvent in a certain proportion and stirring evenly, adding a certain amount of catalyst, a filling material, a curing agent and a stabilizing agent and stirring evenly, heating for reflux reaction for a certain time, and cooling and vacuumizing to remove the solvent as much as possible, so as to obtain the peelable type organosilicon pressure-sensitive adhesive. The method better solves the difficult problems of high coating fragility, bad peelability, poor durability and weatherability, higher cost and the like of the conventional peelable type organosilicon pressure-sensitive adhesive product. The peelable type organosilicon pressure-sensitive adhesive has excellent storage stability, film forming property, water resistance and peelability, leaves no mark after being peeled off a base material and can be reused without losing adhesiveness.

Owner:杭州材聚科技有限公司

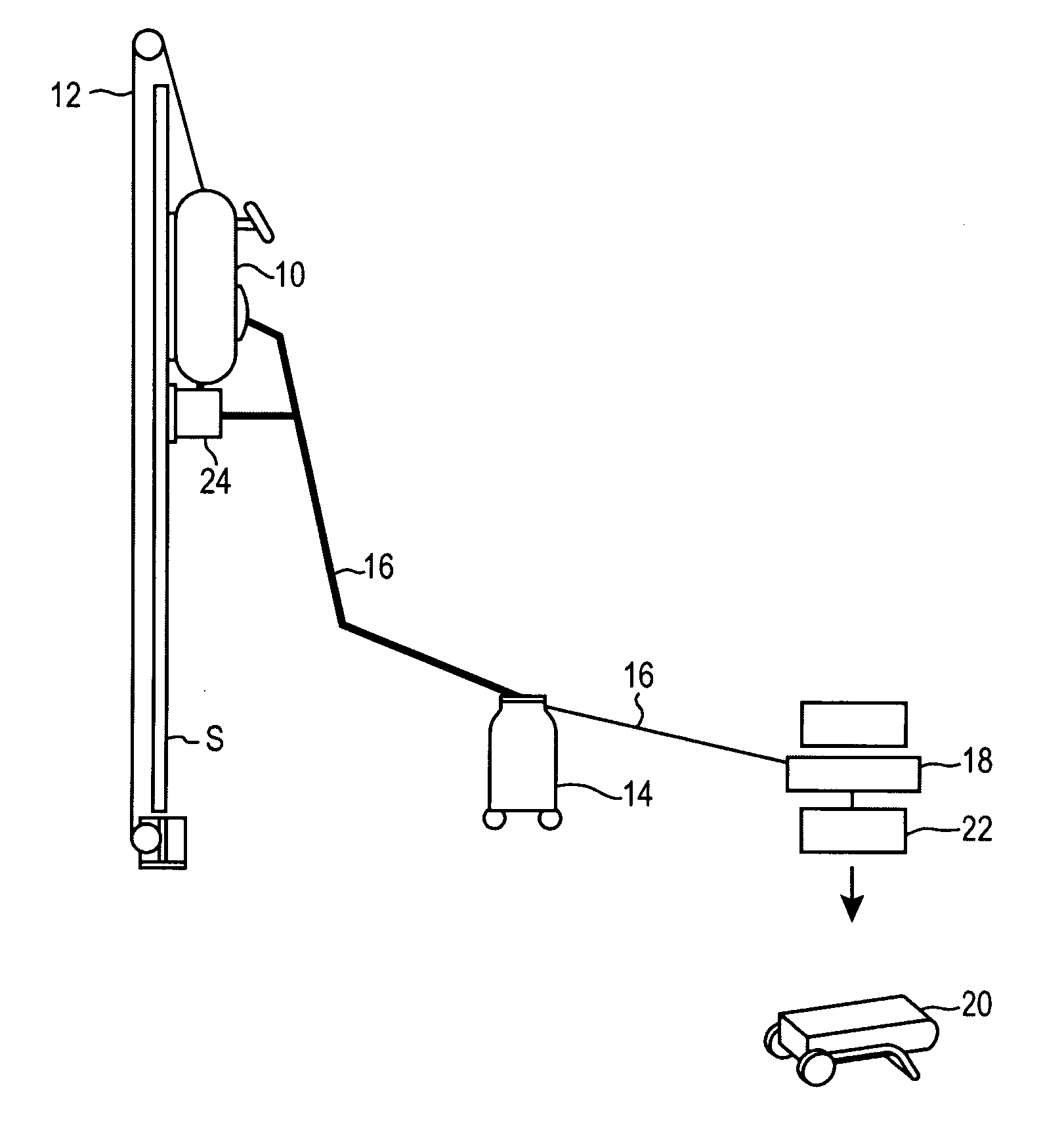

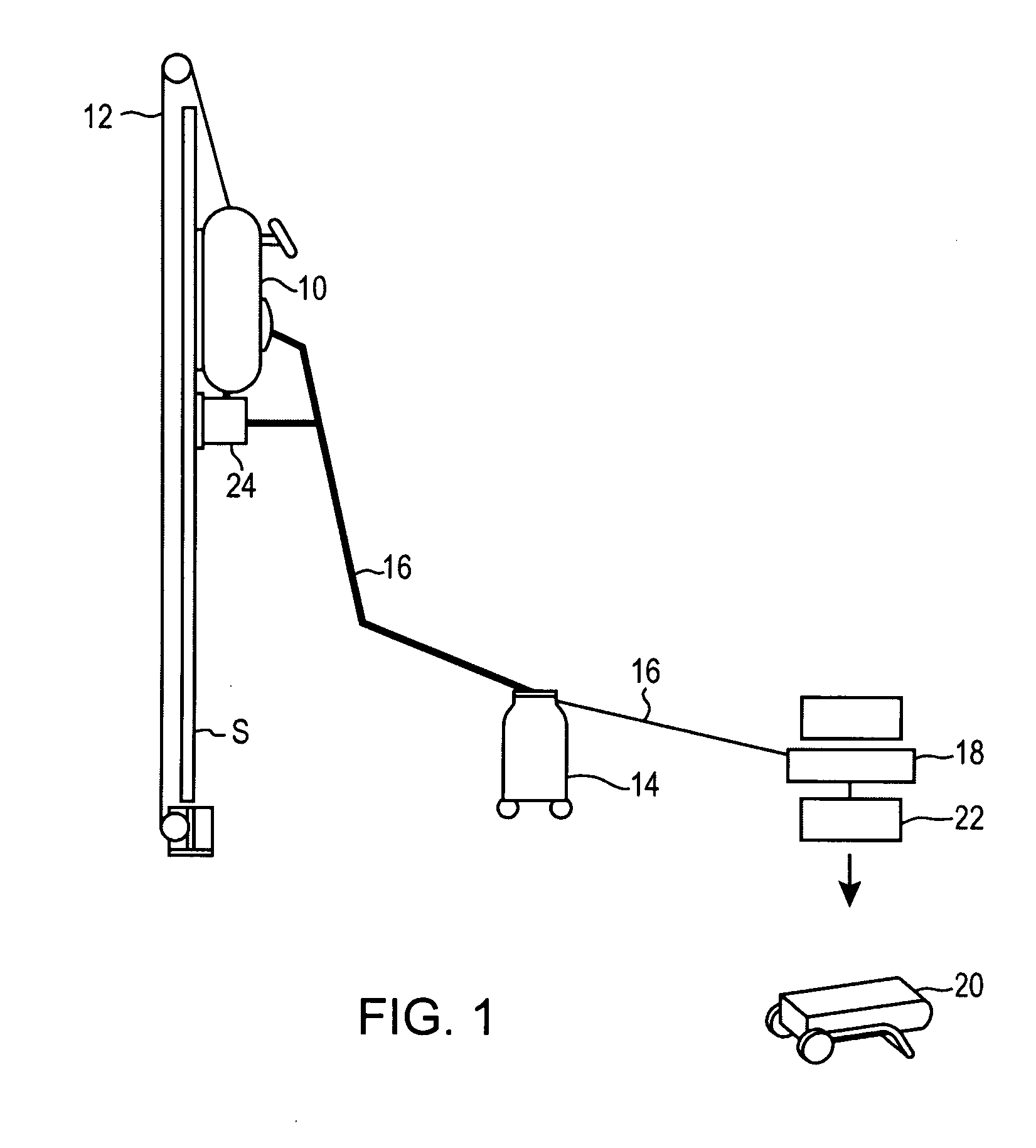

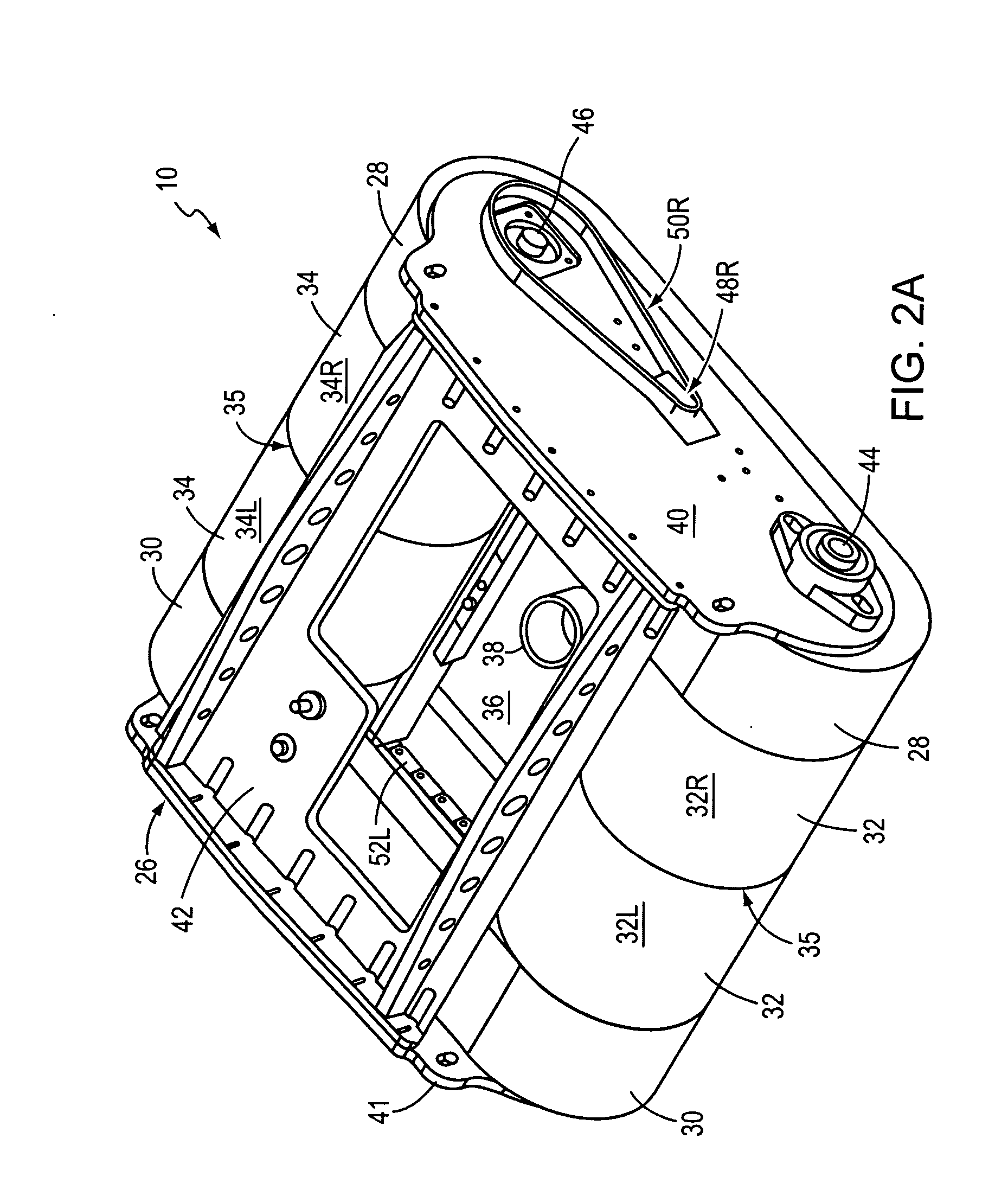

Surface traversing apparatus and method

ActiveUS20060278454A1No loss of adhesionIncreased durabilityVessel cleaningHullsEarth surfaceMechanical engineering

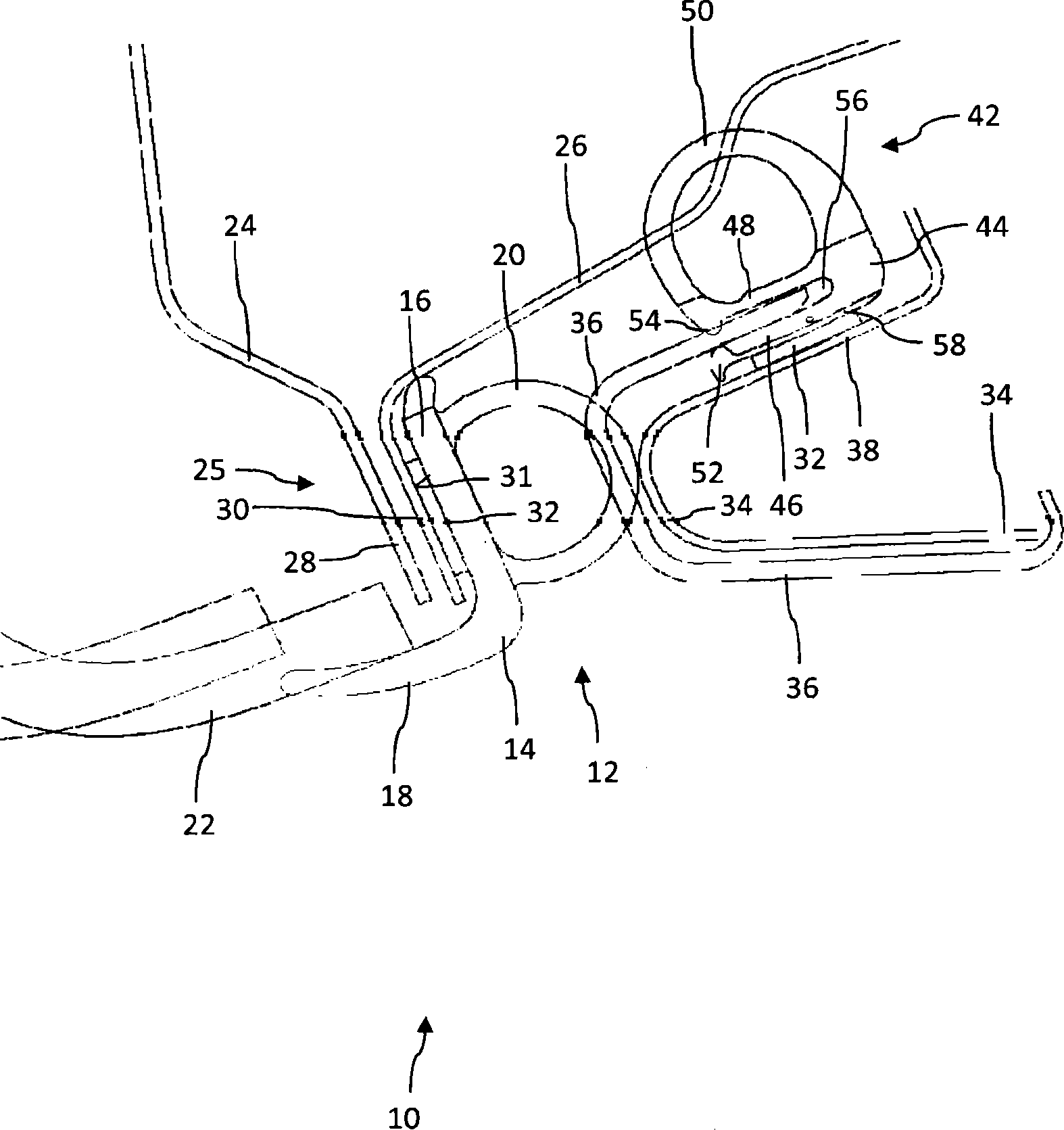

The invention concerns a surface traversing apparatus that includes a frame, a seal having a seal perimeter that is mounted to the frame, and a drive configured to move the apparatus relative to the surface. The seal perimeter is adapted substantially for rolling contact with the surface to be traversed. The device is capable of suction adhering and moving along horizontal, vertical, inverted surfaces and the like, and overcoming obstacles or surface irregularities while maintaining suction adhesion to the surface. The device can be propelled along the surface with a locomoting rolling seal assembly, which provides both a seal to affect the vacuum adhesion and the locomotion to drive the device across the surface.

Owner:INT CLIMBING MACHINES

Heavy-duty coating for prolonging life of sheet metals and preparation method thereof

ActiveCN102766388AImprove performanceGood adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxySalt spray test

The invention relates to a heavy-duty coating for prolonging life of sheet metals and a preparation method of the heavy-duty coating. The heavy-duty coating is obtained by mixing an epoxy component and a curing component according to the weight ratio of 4:1, wherein the raw materials of the epoxy component comprise resin, additive resin, an anti-rust material, a solvent and an auxiliary agent; and the raw materials of the curing component comprise an amine adduct, a curing auxiliary agent and a solvent. Compared with the prior art, the product obtained by the preparation method has the excellent performances as follows: the hardness is not less than 2H, the adhesion is 0-1 level, the corrosion resistance is improved by 7-10 times in comparison with the traditional surface treatment, and the heavy-duty coating can resist salt spray test for 1000h or more.

Owner:ZHANGZHOU XIN ZHAN WANG CHEM IND

High-temperature resistant ceramic fiber plate

The invention belongs to the technical field of ceramic fiber materials and in particular relates to a high-temperature resistant ceramic fiber plate. The high-temperature resistant ceramic fiber plate is prepared from the following raw materials in parts by weight: 95-96 parts of alumina silicate fiber, 1-2 parts of dispersing agent and 3-4 parts of zirconium latex, wherein the dispersing agent is a mixture of Na2SiO3 and CaCO3 and the zirconium latex is a mixture of ZrO2, Y2O3 and H2O2. The invention also provides a preparation method of the high-temperature resistant ceramic fiber plate. The preparation method comprises the following steps: mixing and stirring the raw materials, carrying out wet vacuum molding, drying and processing to obtain a product, wherein the drying time is 110-120 DEG C and the time is 22-24 hours. The high-temperature resistant ceramic fiber plate prepared by the preparation method can bear the high temperature being above 1100 DEG C and does not lose cohesive force.

Owner:山东红阳高温节能材料股份有限公司

Curable resins and curable resin compositions containing the same

There is provided a curable resin having an unsaturated group and a carboxyl group at the terminals of its side chains, such as a curable resin obtained by reacting an unsaturated group-containing monocarboxylic acid (d) with a reaction product (c) of a compound having three or more phenolic hydroxyl groups in its molecule (a) and an alkylene oxide (b) and further reacting a polybasic acid anhydride (f) with the resultant reaction product (e). By compounding such a curable resin with a photopolymerization initiator, a photosensitive (meth)acrylate compound, an epoxy compound, a diluent solvent, another curable resin which has a carboxyl group and an unsaturated group in its molecule and which is in the state of solid at room temperature, a flame-retardant, etc., there is obtained a photocurable and thermosetting resin composition which is useful for the formation of a solder resist of a printed circuit board, an interlaminar insulating layer of a multi-layer circuit board, or the like.

Owner:TAIYO INK MFG

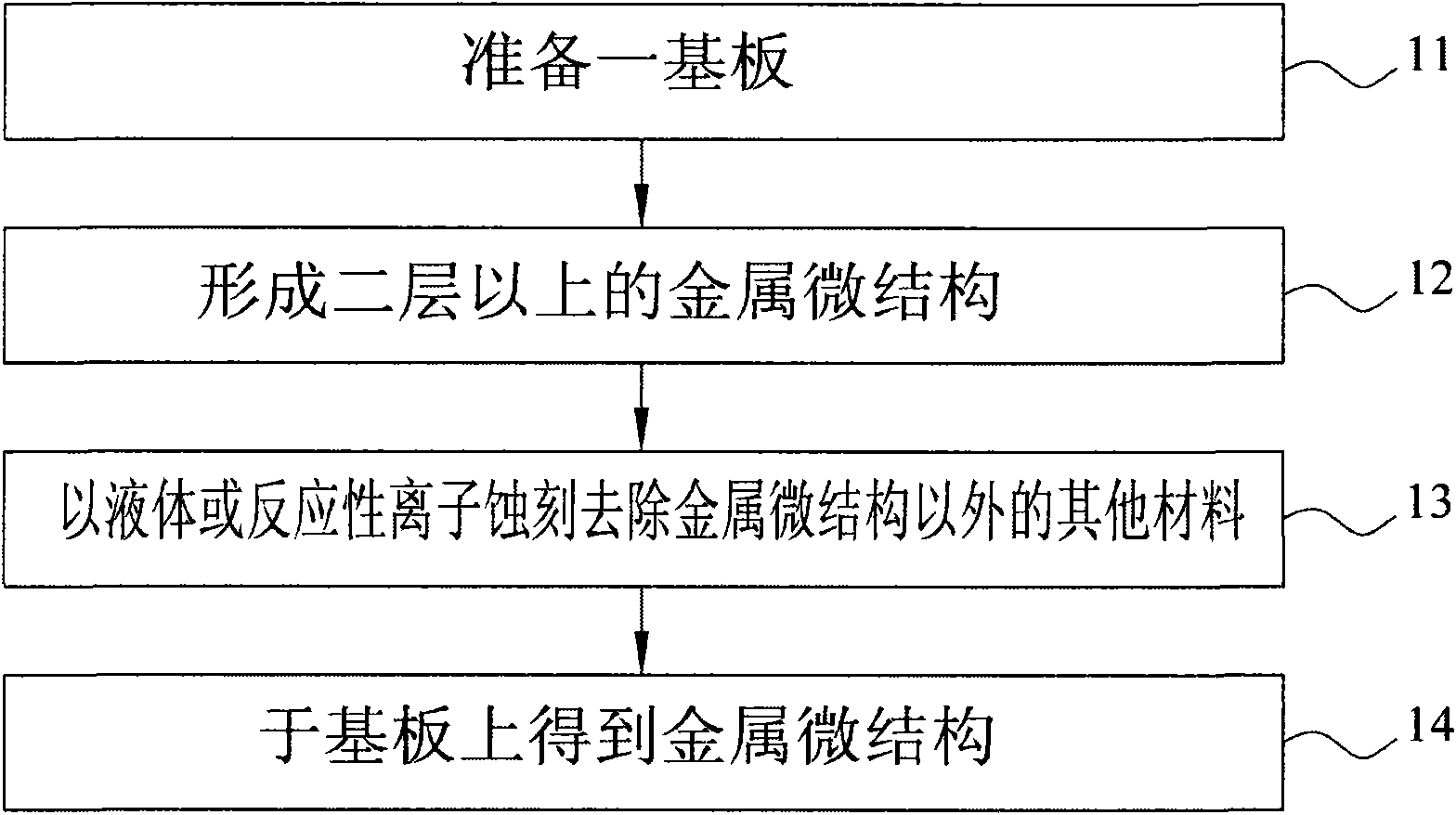

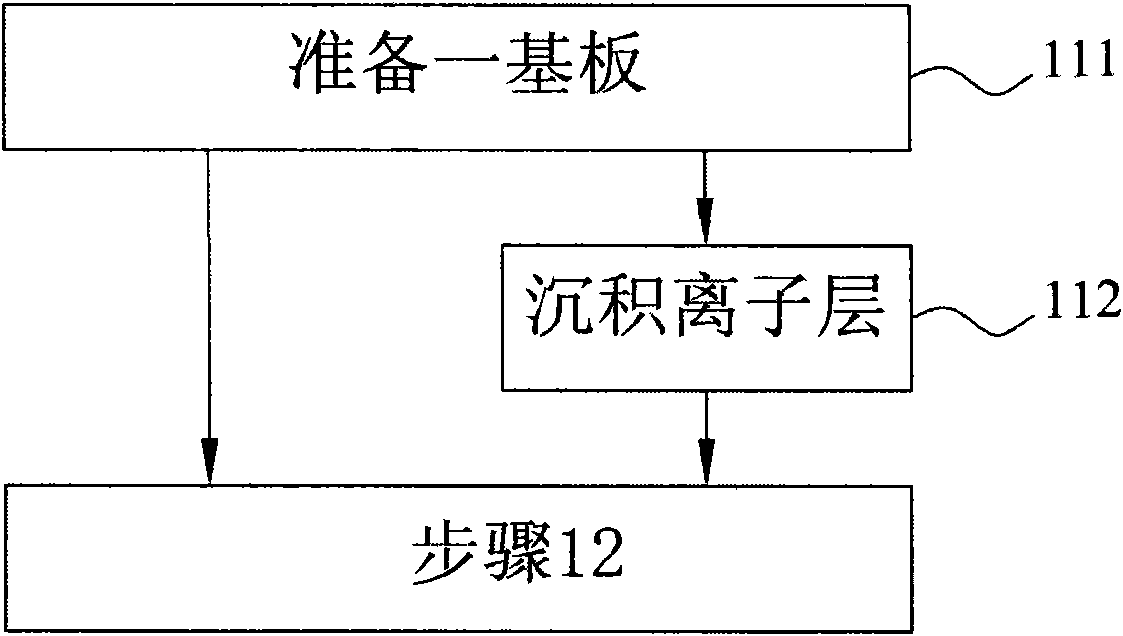

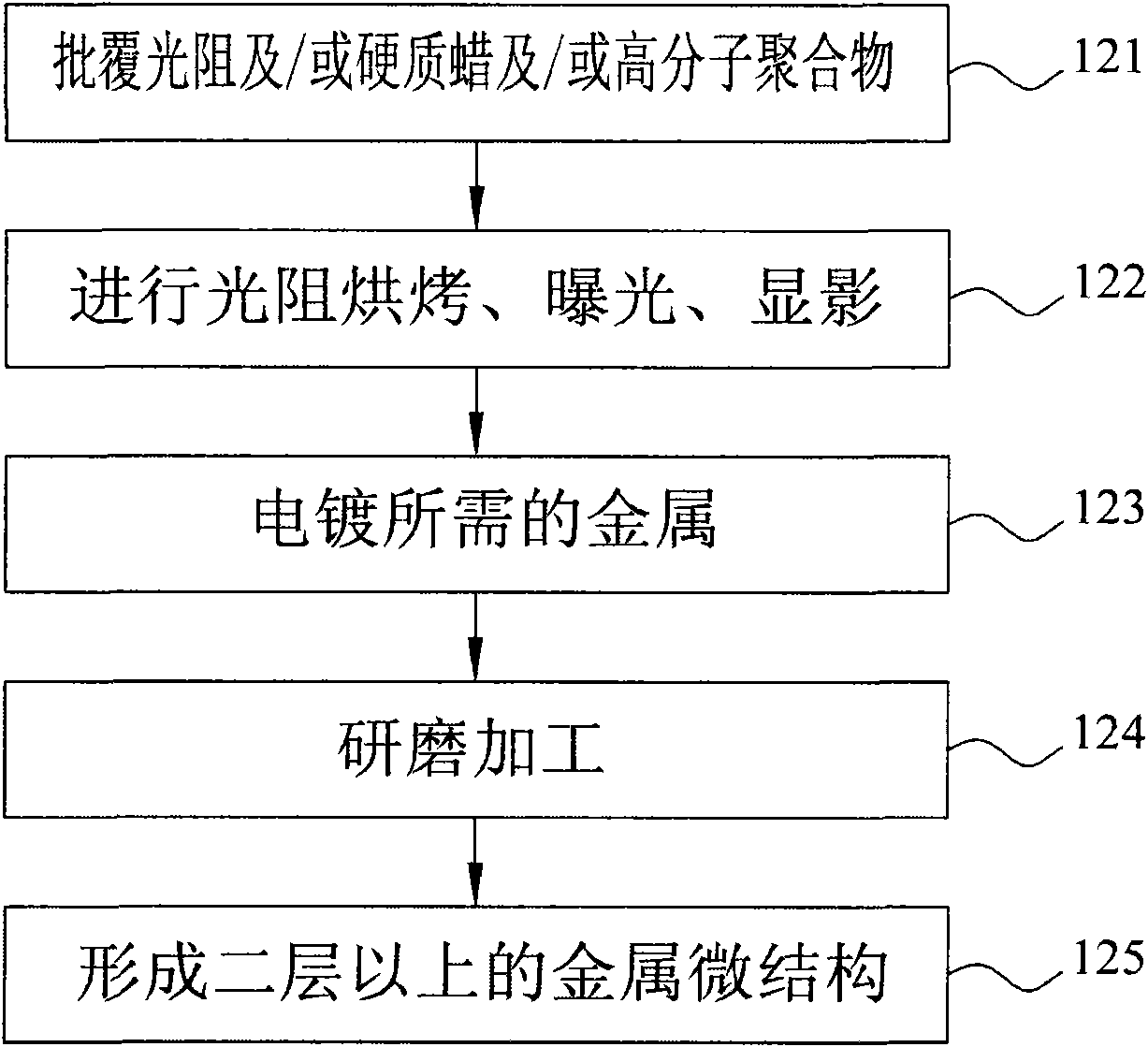

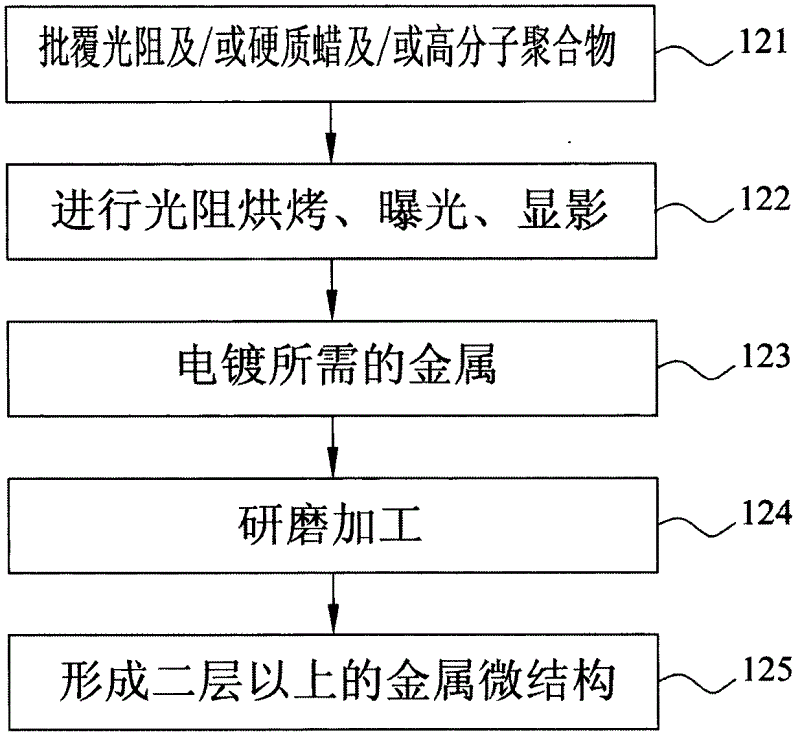

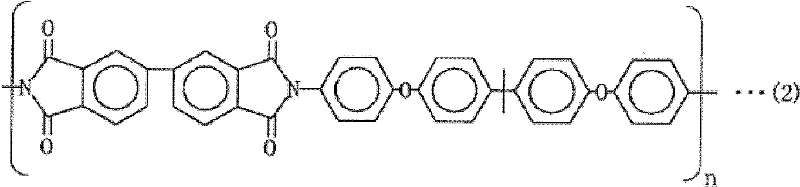

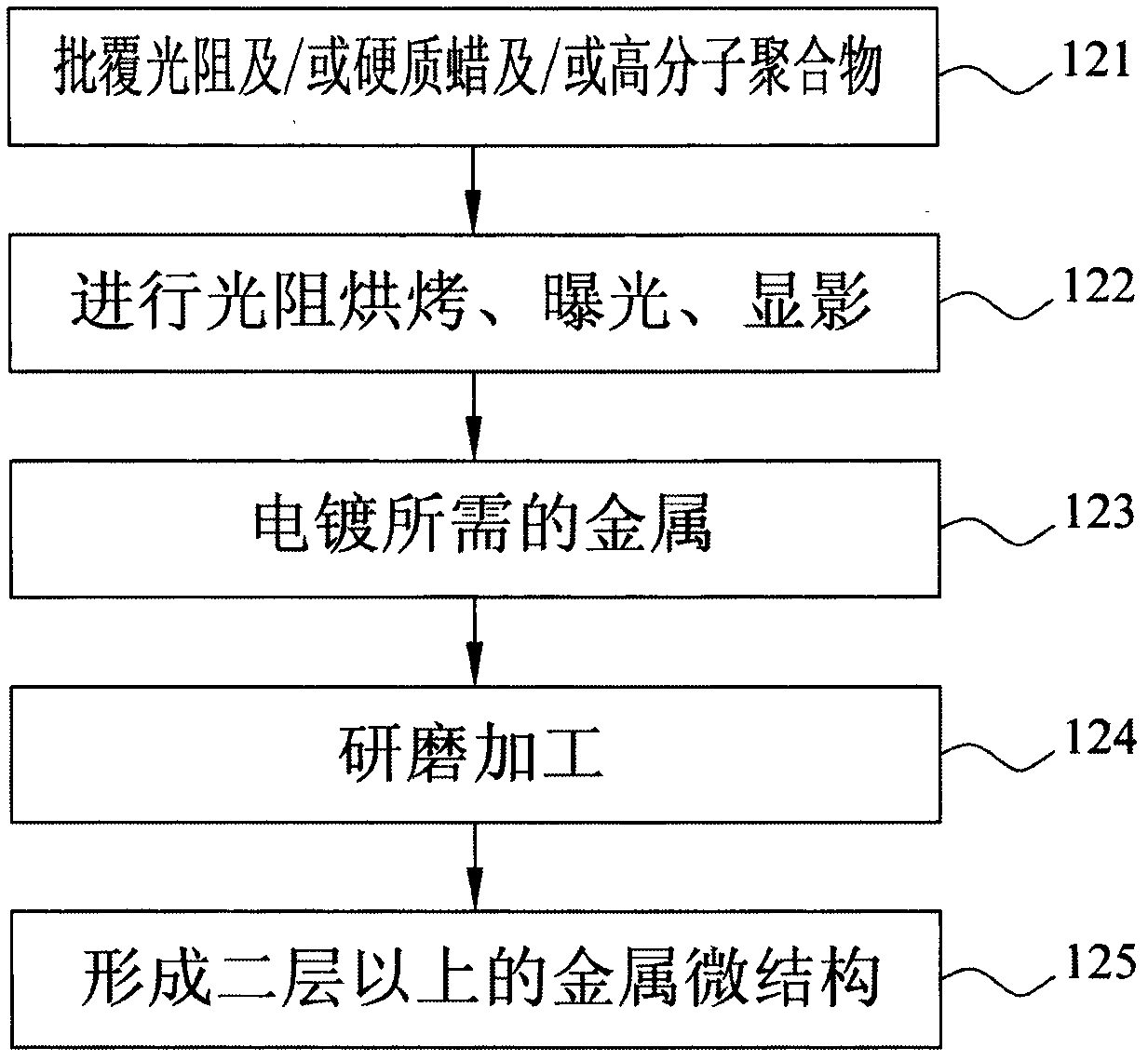

Metal microstructure forming method

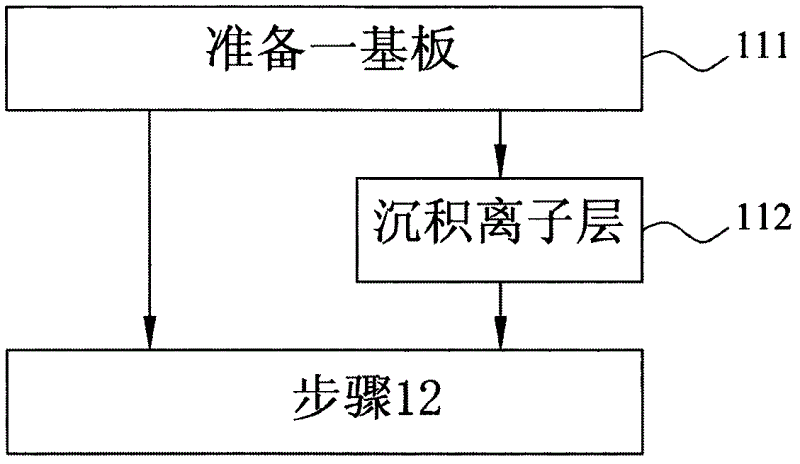

InactiveCN101995766ANo residual stressReduce residual stressPhotomechanical apparatusMetal microstructureElectroplating

The invention discloses a metal microstructure forming method which is applied to the manufacturing process of a microstructure component; by utilizing the metal microstructure forming method, a second type of metal is not needed to be electric-plated to surround the periphery of the metal and the second type of metal is not needed to be etched when a three-dimensional metal microstructure of the microstructure component is formed, therefore, the residual stress caused by electric-plating is reduced, no residual stress exists among the metal layers, a base plate attached by the metal is not deformed and the implementing of the follow-up manufacturing process of the microstructure component is not affected; in addition, as the second type of metal is not needed to be etched, the problem that etchants are permeated to the interface at each layer does not exist, adhesive force reduction at each layer can not caused, so as not to affect the functions of the microstructure component.

Owner:PREMTEK INT

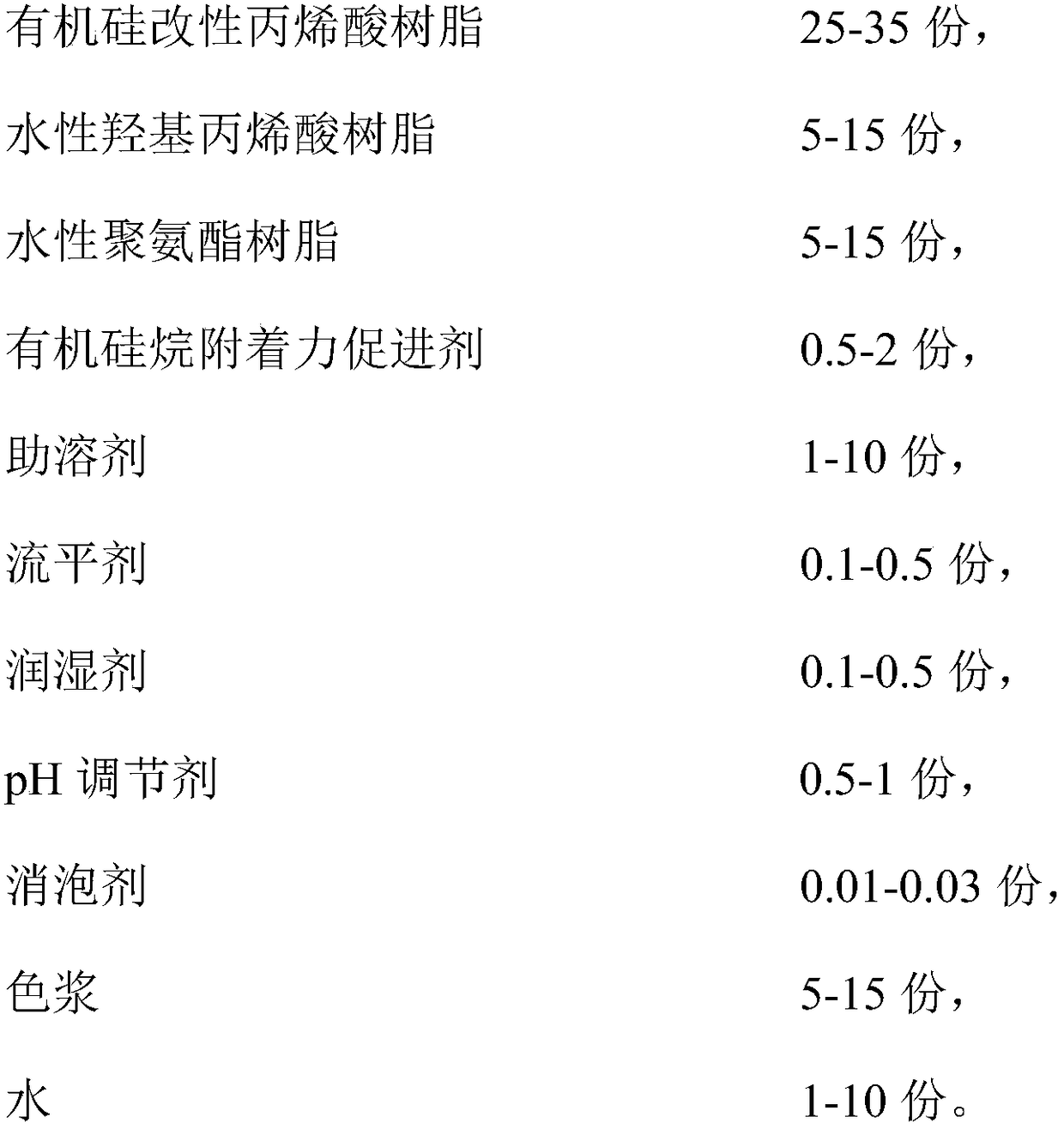

Novel environment-friendly type water-based glass baking paint and preparation method thereof

InactiveCN108976952AImprove adhesionImprove performancePolyurea/polyurethane coatingsWater basedAdhesion force

The invention relates to a novel environment-friendly type water-based glass baking paint. The novel environment-friendly type water-based glass baking paint is prepared from the following componentsaccording to a proportional ratio by weight: 25 to 35 parts of organosilicone modified acrylic resin, 5 to 15 parts of water-based hydroxy acrylic resin, 5 to 15 parts of water-based polyurethane resin, 0.5 to 2 parts of organosilane adhesion promoter, 1 to 10 parts of cosolvent, 0.1 to 0.5 part of flatting agent, 0.1 to 0.5 part of wetting agent, 0.5 to 1 part of pH (potential of hydrogen) regulator, 0.01 to 0.03 part of defoaming agent, 5 to 15 parts of color paste, and 1 to 10 parts of water. The invention also provides a preparation method of the novel environment-friendly type water-basedglass baking paint. The novel environment-friendly type water-based glass baking paint has the advantages that the adhesion force is high, and the wetting property, water-resistant property, weather-resistant property and other comprehensive properties are stronger; the preparation technology is simple, and is suitable for being widely popularized and applied.

Owner:ZHONGSHAN BRITE DAY COATING RAW MATERIALS

Refractory ceramic fiber board

The invention discloses a refractory ceramic fiber board. The refractory ceramic fiber board comprises, by weight, 20-60 parts of glass fibers, 30-50 parts of mineral fibers, 5-7 parts of aluminum oxide, 5-8 parts of chromic oxide, 6-10 parts of polyester fibers, 80-100 parts of linen fibers, 40-50 parts of carbon fibers, 3-8 parts of magnesium oxide, 5-10 parts of silicon oxide, 5-10 parts of polyethylene glycol, 3-5 parts of sodium hexametaphosphate, 5-8 parts of lauryl sodium sulfate, 10-15 parts of organic silicon defoaming agents, 3-8 parts of paraffin, 5-10 parts of rubber, 10-25 parts of resin, 12-20 parts of polybutadiene latex and 15-18 parts of butylbenzene latex. When at high temperature, the refractory ceramic fiber board can bear high temperature more than 1000 DEG C, and binding force is not lost; when at low temperature, the refractory ceramic fiber board has good binding and dispersing performance, fibers are evenly dispersed in the whole product manufacturing technological process, and service life is effectively prolonged.

Owner:陈欢娟

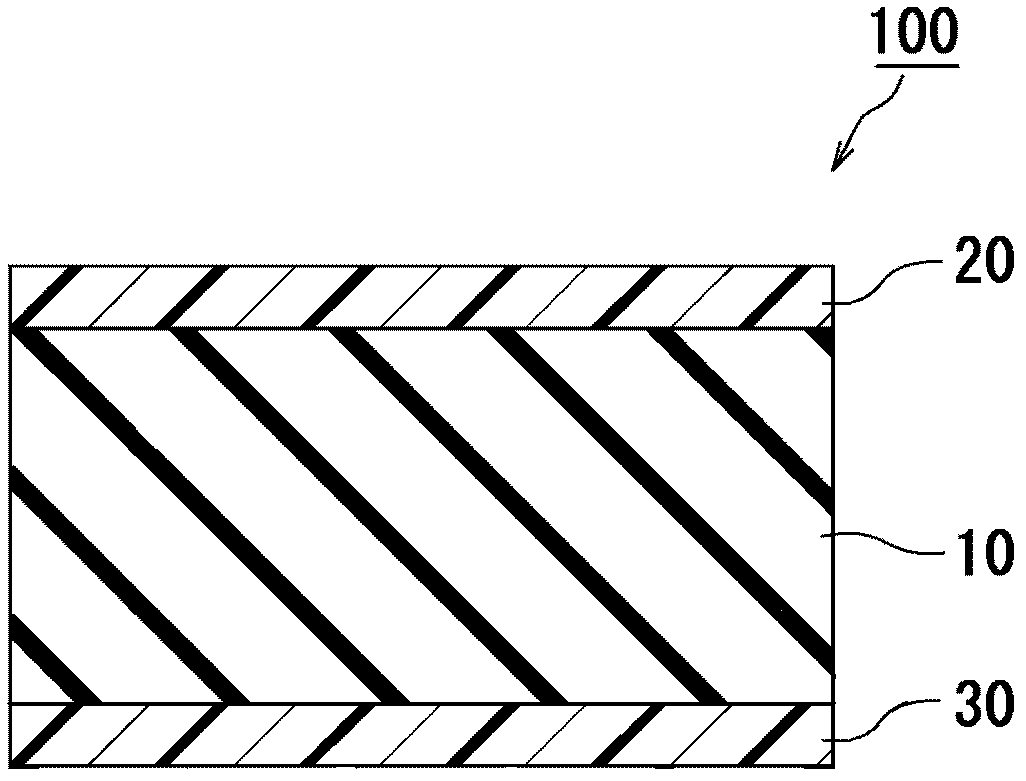

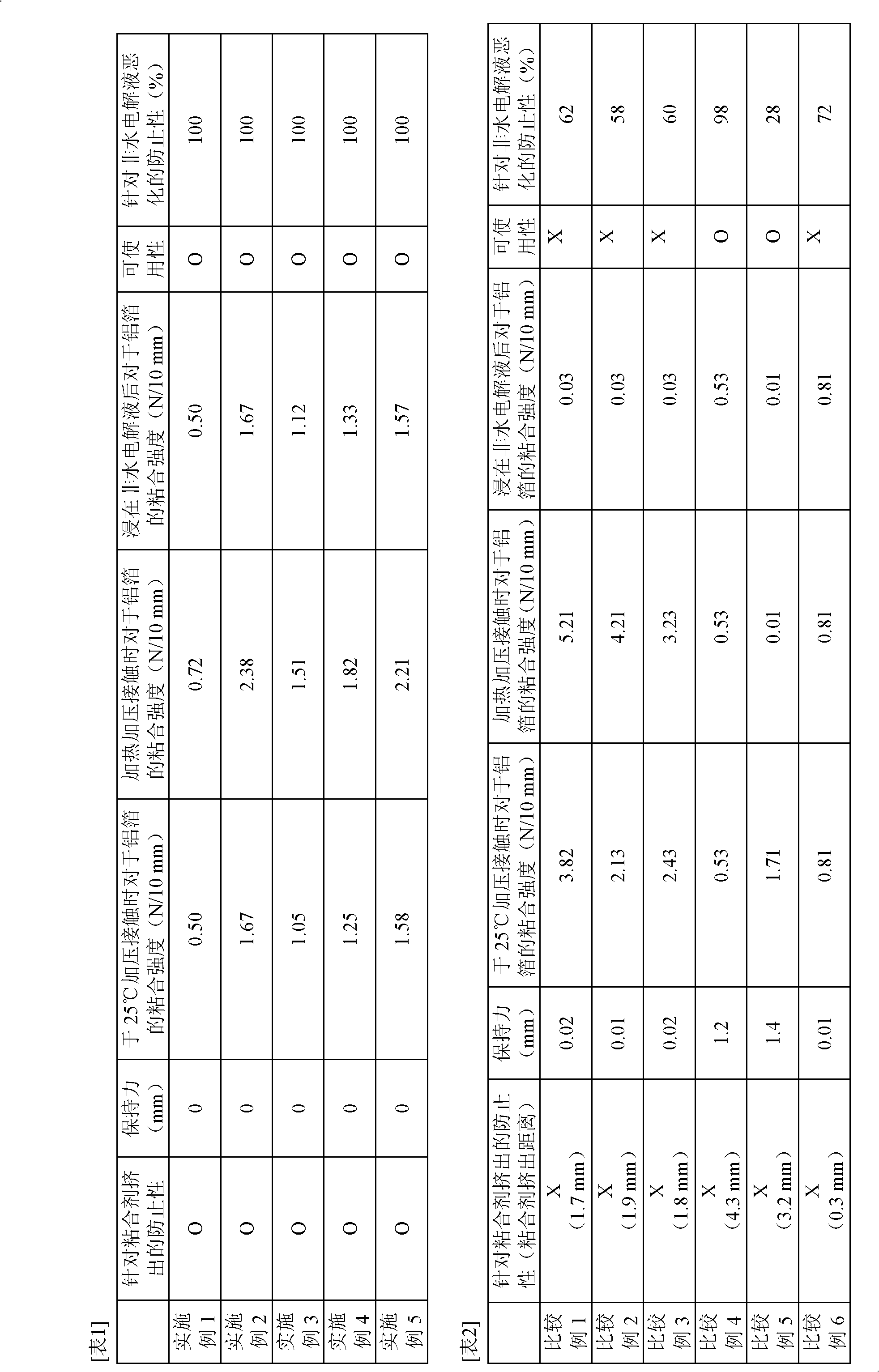

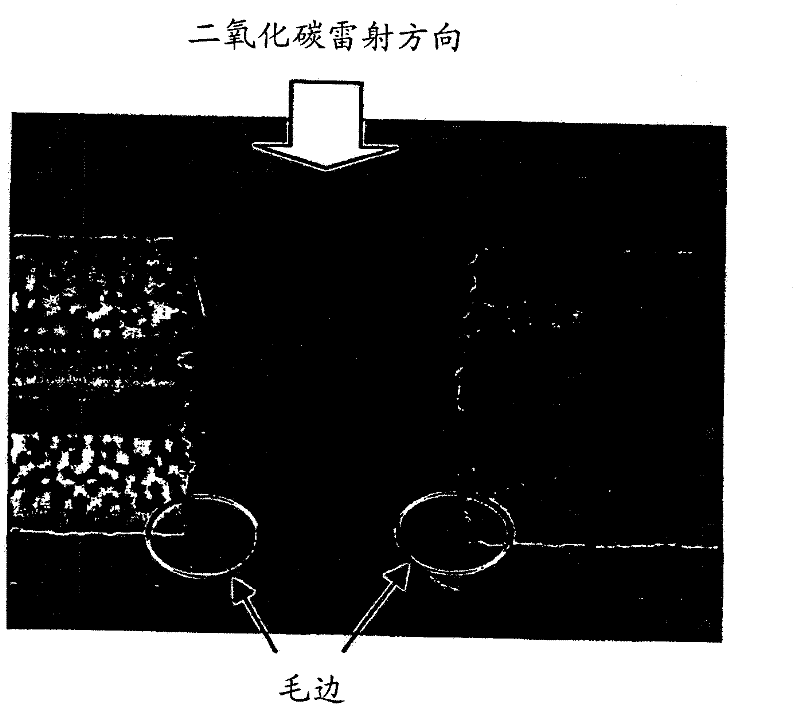

Laminate for nonaqueous battery

InactiveCN102618184AHas adhesive strengthInhibit deteriorationFinal product manufactureSecondary cellsPolyolefinCohesive strength

Provided is a laminate for a nonaqueous battery having moderate adhesion to be used in a nonaqueous battery in which a nonaqueous electrolytic solution is sealed, the laminate for a nonaqueous battery being capable of improving the suitability of electrodes to be packed into a battery case without causing a reduction in battery output, being capable of preventing a short circuit between the electrodes caused by the penetration of a burr or the like present on an electrode plate through a separator, being capable of suppressing the reduction of the adhesion in the nonaqueous electrolytic solution, being capable of suppressing the deterioration of the nonaqueous electrolytic solution, and having such a cohesive strength that when the laminate is used in the form of a tape, a pressure-sensitive adhesive layer does not squeeze out of a base material layer. The laminate for a nonaqueous battery is formed of at least two layers, including: a base material layer (A); and a pressure-sensitive adhesive layer (B) in the stated order, in which: the base material layer (A) contains a polyolefin-based thermoplastic resin; and the pressure-sensitive adhesive layer (B) contains Alpha--olefin-based thermoplastic resin.

Owner:NITTO DENKO CORP

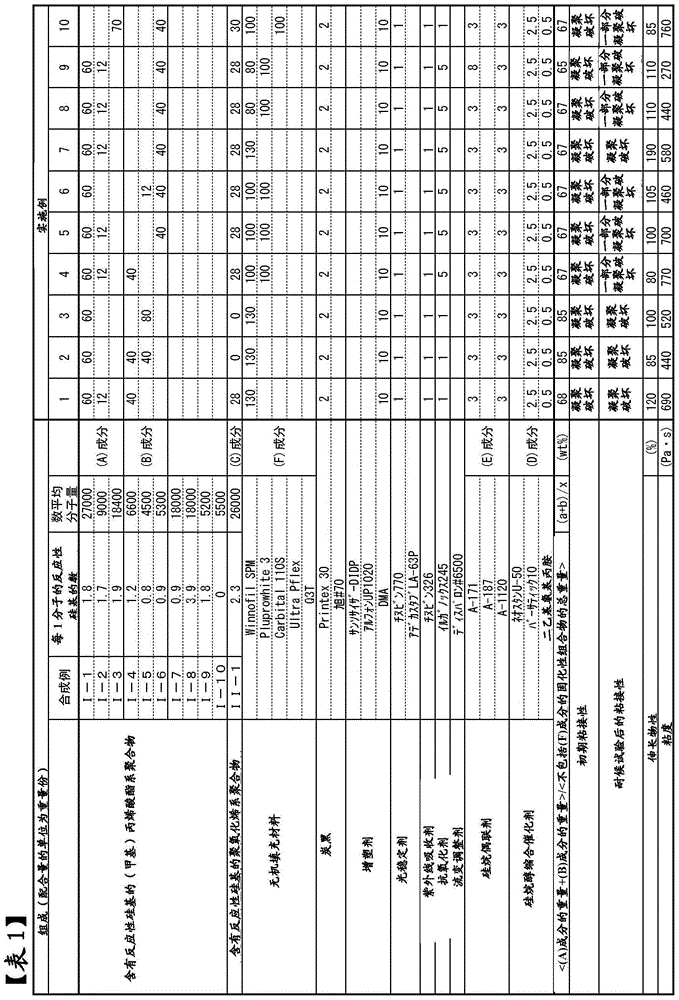

Structural body

InactiveCN104685022AImprove waterproof performanceImprove air tightnessOther chemical processesSynthetic resin layered productsCross-linkPolymer science

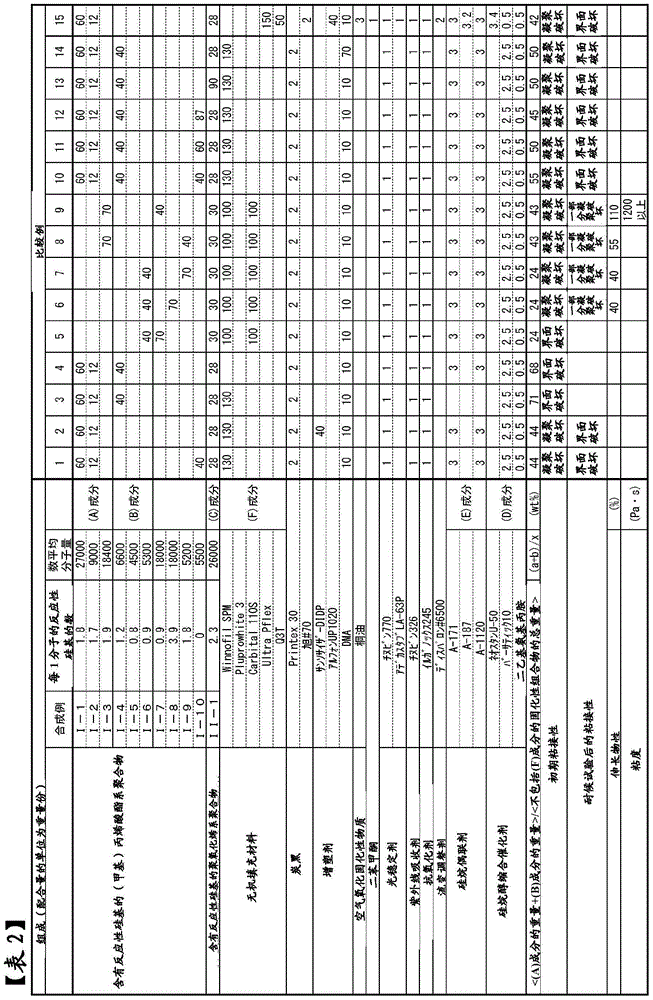

A structural body comprising a member that transmits light, a joint formed by the aforementioned member, and a solid object made of a hardening composition that is filled in the joint; wherein the hardening composition contains: (A) a (meth)acrylic acid ester polymer having in each molecule an average of 1.0 to 3.5 silicon-containing groups obtained by cross-linking by forming a siloxane bond, and having a number-average molecular weight of 8000 to 50,000; (B) a (meth)acrylic acid ester polymer having in each molecule an average of 0.5 to 1.5 silicon-containing groups obtained by forming a siloxane bond, and having a number-average molecular weight of 1000 to less than 8000; (D) a silanol condensation catalyst; (E) a silane coupling agent; and (F) an inorganic filler; the ratio between the sum of the weight (a) of component (A) and the weight (b) of component (B) in relation to the total weight (x) of the hardening composition excluding component (F) [(a+b) / x] being 60 to 99 weight%.

Owner:KANEKA CORP

Motor vehicle body with plasma-treated gluing surface for attachment of seal

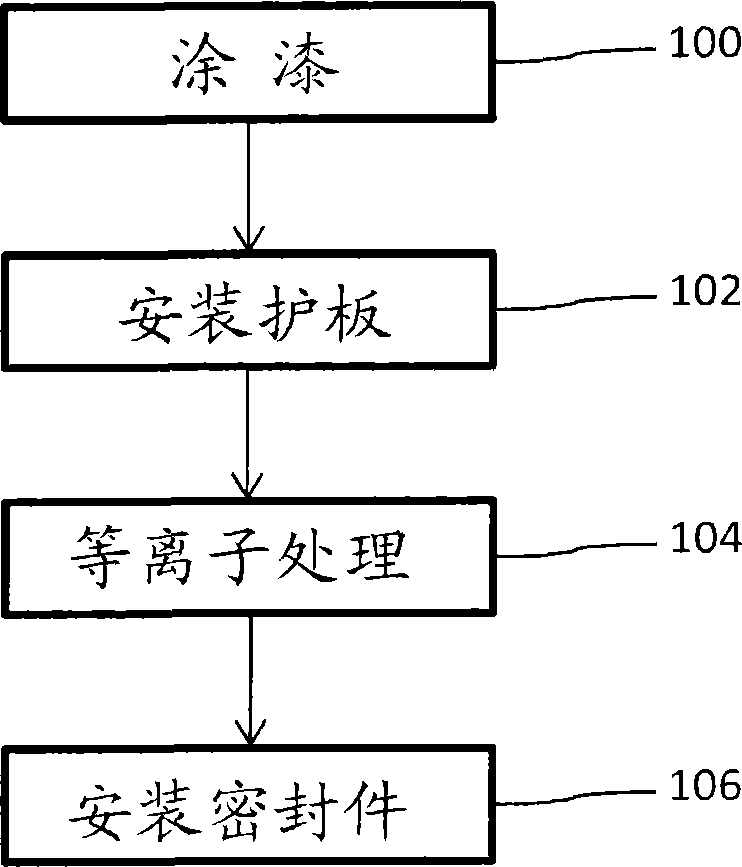

InactiveCN103072456AImprove adhesionEasy to fixEngine sealsLamination ancillary operationsEngineeringMechanical engineering

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for forming metal microstructure

InactiveCN102621804ANo residual stressReduce residual stressPhotomechanical apparatusMetal microstructureElectroplating

The invention discloses a method for forming a metal microstructure, which is applied to a process of manufacturing a microstructure component. By the method for forming the metal microstructure, a second metal is not required to be electroplated around the periphery of the metal and is not required to be etched in the process of forming a stereoscopic metal microstructure of the microstructure component, the residual stress caused by electroplating can be reduced, residual stress does not exist between metal layers, a substrate to which the metal is attached does not deform, and a subsequent process of manufacturing the microstructure component is not influenced; and moreover, because the second metal is not required to be etched, the problem that an etching solution penetrates each layer of interfaces is solved, the adhesive force on each layer cannot be reduced, and the function of the microstructure component is not influenced.

Owner:PREMTEK INT

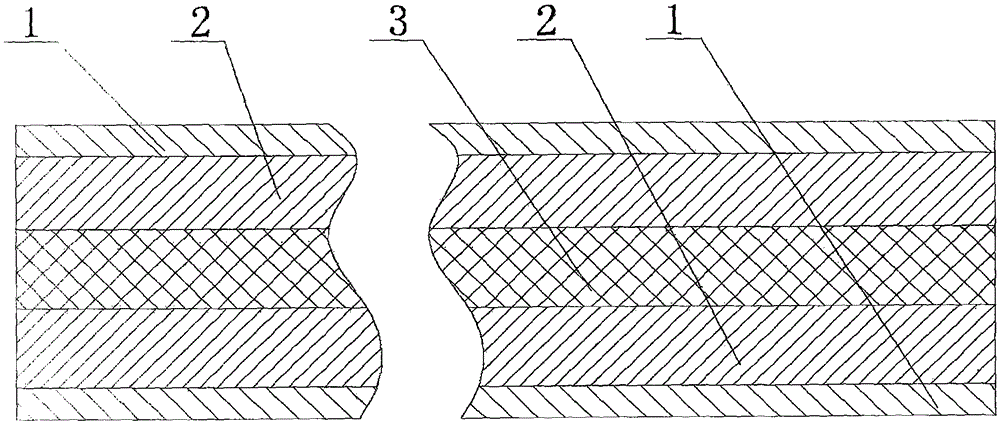

Low temperature and wetness bondable macromolecular self-adhesive waterproof coil material

InactiveCN105252839AReasonable structureGood adhesionNon-macromolecular adhesive additivesSynthetic resin layered productsCold areaChemical plant

The invention relates to a low temperature and wetness bondable macromolecular self-adhesive waterproof coil material, which comprises a base layer. The upper surface and lower surface of the base layer are provided with a self-adhesive layer, and the outer surface of the self-adhesive layer is provided with a covering layer. The coil material provided by the invention has the advantages of reasonable structure, good adhesion at low temperature, nondecreasing adhesion when encountering water, great tensile strength and large elongation, and is especially suitable for waterproof construction in cold areas and in winter. The self-adhesive coil material construction is cold operation, has no need for naked flame, does not produce pollution, and does not cause energy waste, and is especially suitable for waterproof engineering at granaries, oil depots, chemical plants and the like not easy for naked flame operation. The coil material is convenient to maintain, can save a lot of maintenance cost, and has high tensile strength, good dimensional stability, and lasting and stable waterproof effect.

Owner:LIAONING BENTENAI TECH DEV

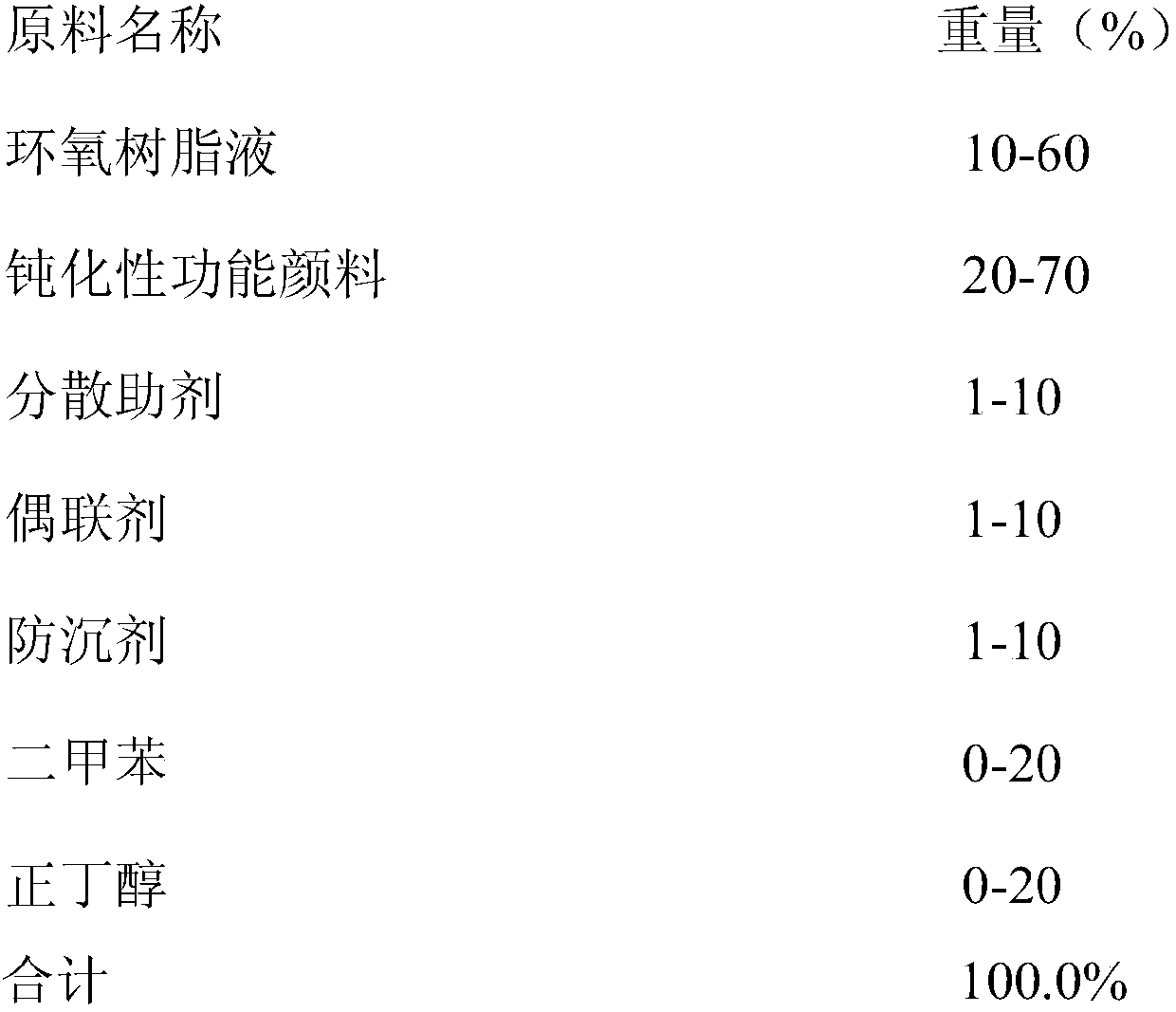

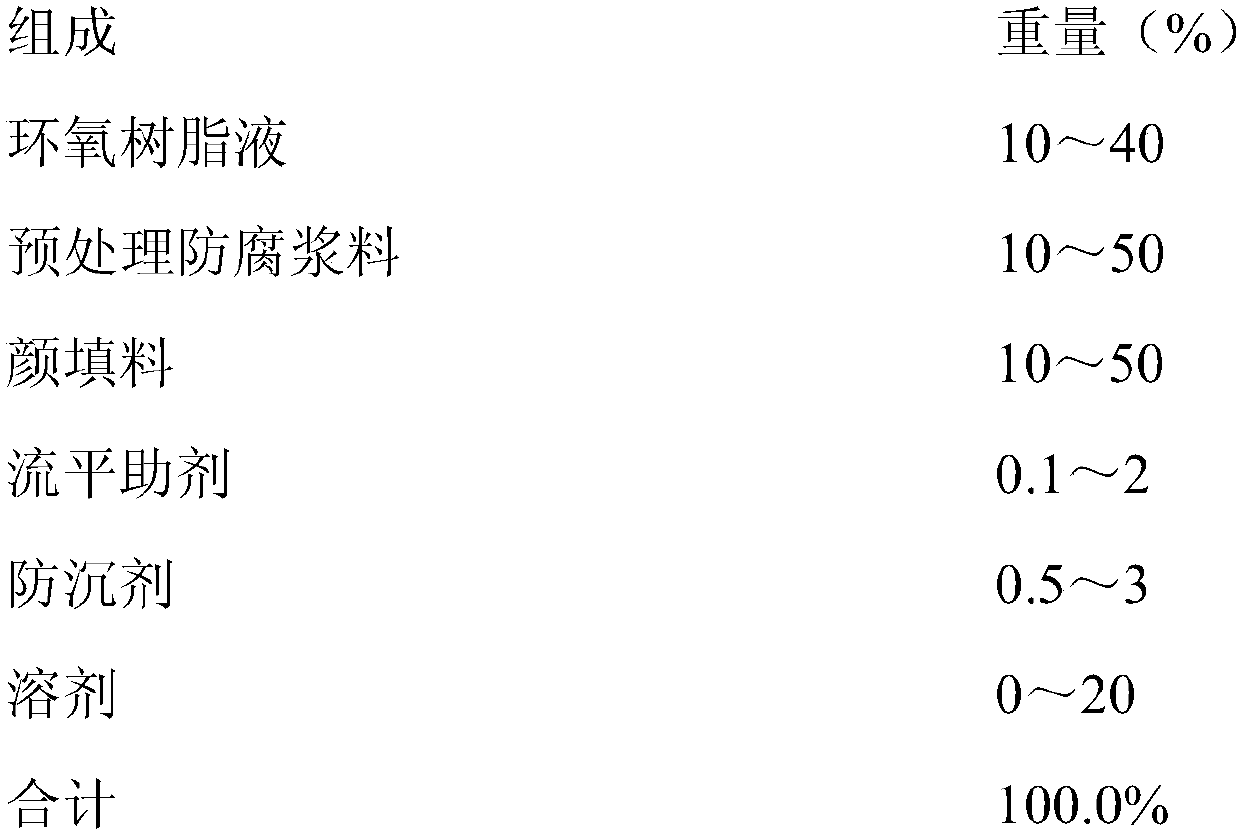

Organic protective coating used for low-treatment aluminum alloy surfaces

InactiveCN109868029AInhibit migrationEffective combinationAnti-corrosive paintsEpoxy resin coatingsXylylenePolyamide

The invention relates to a high-adhesion normal-temperature curing organic protective coating suitable for surfaces of a plurality of types of low-treatment aluminum alloy. A method for preparing thecoating firstly comprises the step of preparing pretreatment anticorrosive slurry: adding a passivating functional pigment, a resin liquid, a coupling agent and an auxiliary agent into a mixed solventunder stirring to obtain the stable slurry; and the normal-temperature curable organic protective coating used for the low-treatment aluminum alloy surfaces is composed of an A component and a B component, and the A component and the B component are used cooperatively, wherein the A component mainly comprises the above pretreatment anticorrosive slurry, and further comprises an epoxy resin liquid, a pigment filler, an auxiliary agent and an appropriate amount of solvent, and the B component is a mixture of a polyamide-based curing agent and a mixture of xylene and n-butanol. The special coating for the low-treatment aluminum alloy provided by the invention not only has excellent comprehensive performance on the aluminum substrate, but also eliminates a complicated and cumbersome processing technology to a substrate before coating of a traditional coating, meets novel trend of saving energy and reducing consumption, and has broad application prospects.

Owner:MARINE CHEM RES INST

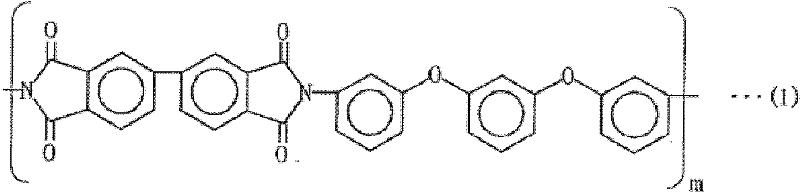

Resin composite copper foil

ActiveCN102264539AImprove practicalityNo loss of adhesionPrinted circuit aspectsPrinted circuit manufacturePolymer scienceCopper foil

Owner:MITSUBISHI GAS CHEM CO INC +1

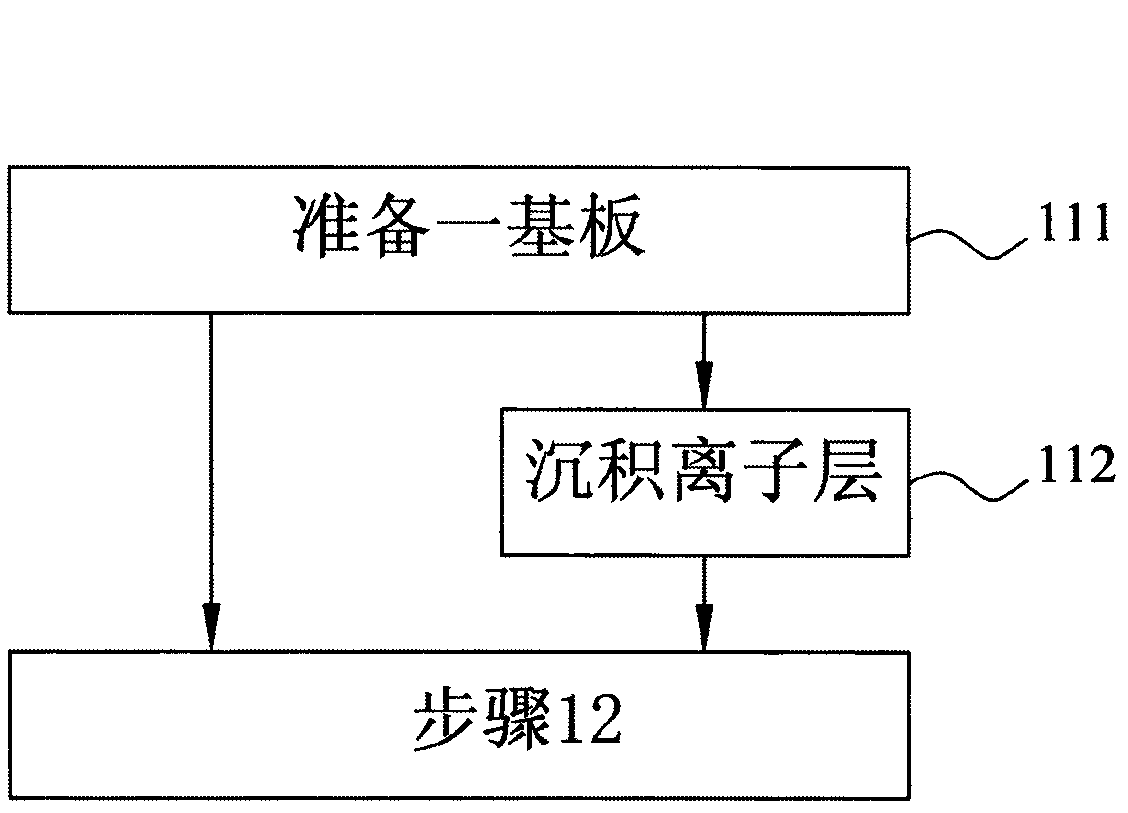

Metal microstructure formation method

InactiveCN102591144ANo residual stressReduce residual stressPhotomechanical apparatusEtchingBaseboard

The invention discloses a metal microstructure formation method, which is applied to the manufacturing process of a microstructure assembly. By utilizing the metal microstructure formation method of the invention, the stereo metal microstructure of the microstructure assembly can be formed without electroplating a second metal for surrounding the periphery of the metal and without etching the second metal, so residual stress caused by the electroplating can be reduced, there is no residual stress between metal layers, and a baseboard adhered by the metal is not deformed, thereby subsequent manufacturing processes of the microstructure assembly are not influenced; and the etching of the second metal is not needed, so a problem that an etching liquid penetrates into each layer interface does not generate, and the adhesion of each layer does not decrease, thereby functions of the microstructure assembly are not influenced.

Owner:PREMTEK INT

Pressure-sensitive adhesive tape or sheet for application to skin, and process for producing the same

InactiveCN101711889AEasy to fixWon't peel offSynthetic resin layered productsAdhesive dressingsLong chain fatty acidCross-link

The present invention provides a pressure-sensitive adhesive tape or sheet for application to skin, which contains: a stretch fabric, and a pressure-sensitive adhesive layer provided on one surface of the stretch fabric, in which the pressure-sensitive adhesive layer contains: an acrylic copolymer obtained from a monomer mixture including an alkyl (meth)acrylate of from 40 to 80% by weight, an alkoxy (meth)acrylate of from 10 to 50% by weight and a (meth)acrylic acid of from 1 to 10% by weight; a long-chain fatty acid glycerin ester in an amount of from 20 to 100 parts by weight relative to 100 parts by weight of the acrylic copolymer, and a cross linking agent, the pressure-sensitive adhesive layer being crosslinked with the crosslinking agent; and also provides a process for producing the tape or sheet.

Owner:NITTO DENKO CORP

High temperature resistant ceramic fiber board

Owner:山东红阳高温节能材料股份有限公司

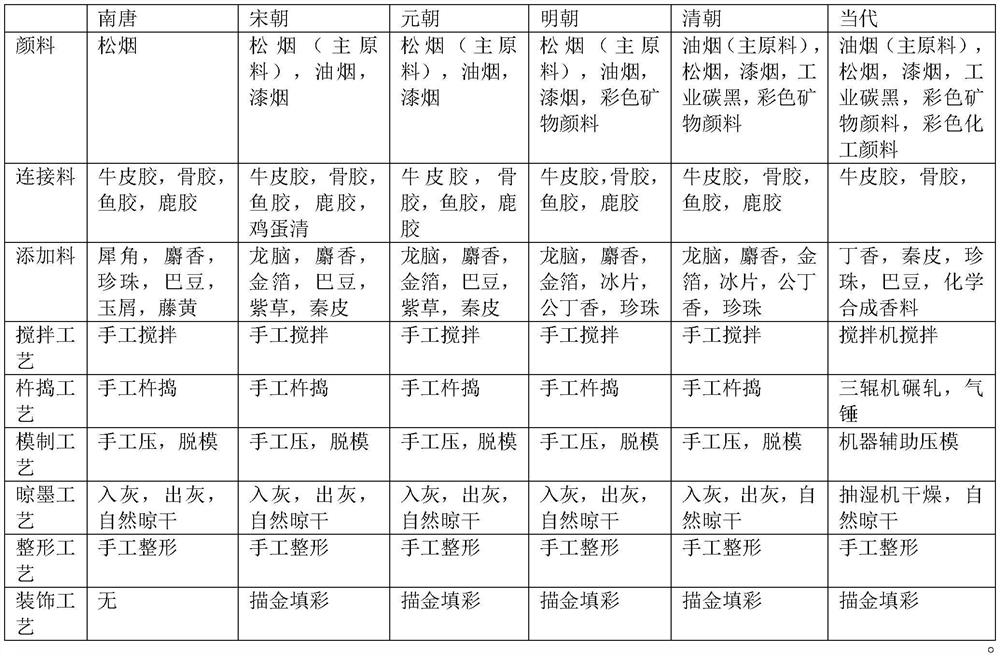

Pine smoke Huizhou ink and preparation method thereof

The invention relates to pine soot Huizhou ink and a preparation method thereof. According to the preparation method, a nano preparation process is introduced into the preparation of the Huizhou ink for the first time, sodium cholate in a specific proportion is added into the pine smoke, a nano-scale pine smoke mixture is prepared by a high-pressure homogenization process, and the pine smoke Huizhou ink is further prepared. The pine smoke Huizhou ink prepared by the technology can neglect the influence of the proportion of added glue to a certain extent. Even if a large proportion of glue is added, the writing is also smooth, and the adhesive force is not reduced under the condition that a low proportion of glue is added. The process is suitable for industrial production.

Owner:黄山市歙县徽韵工艺品厂(普通合伙)

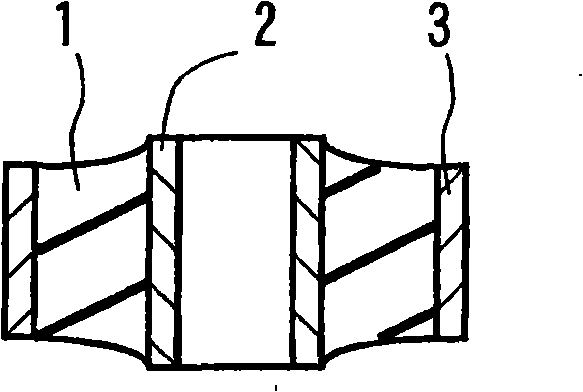

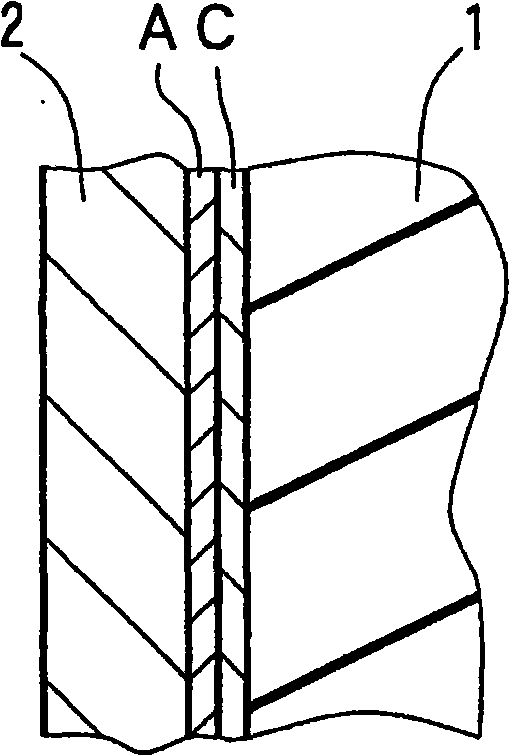

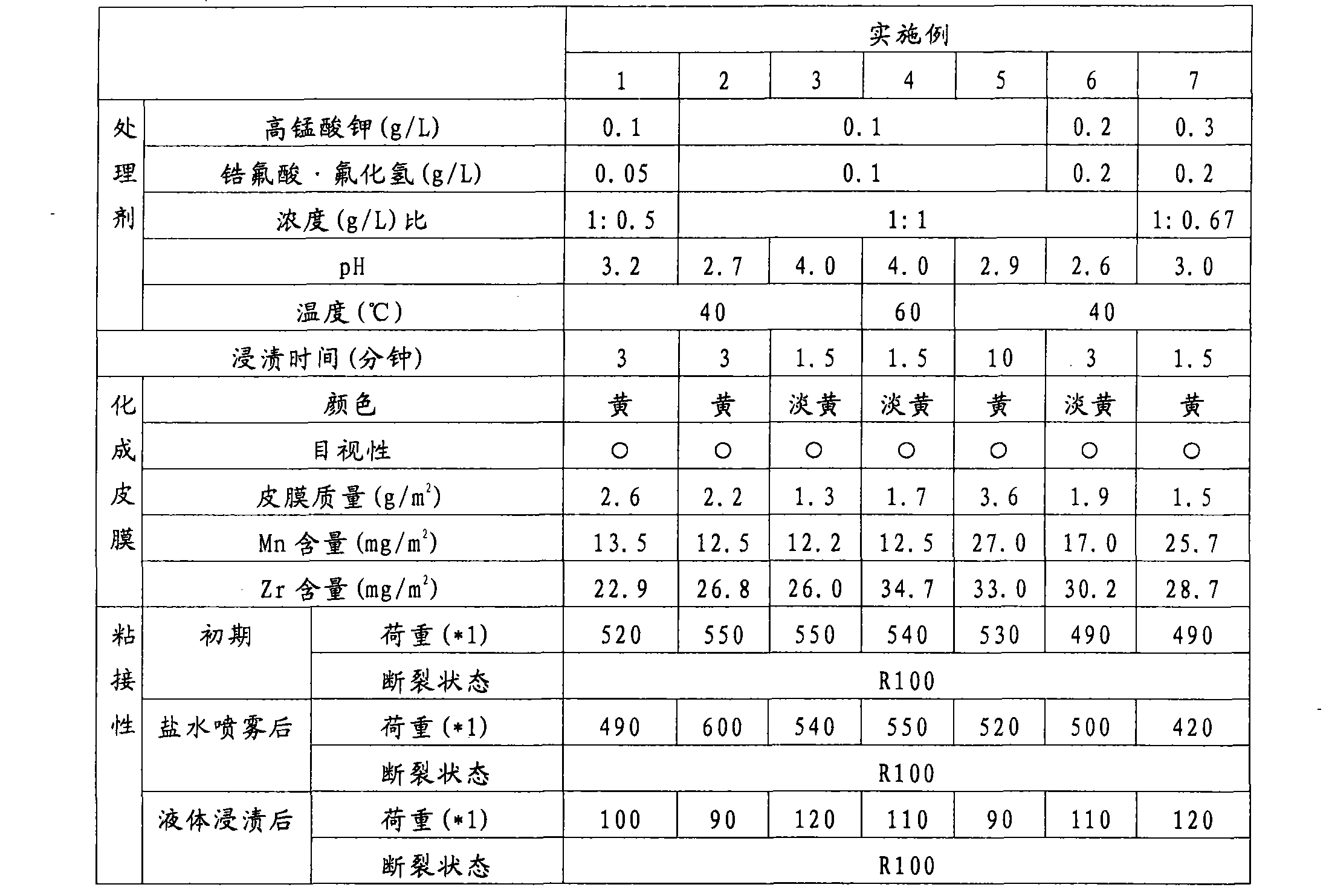

Rubber member including aluminum-based metal component, and production method for the same

InactiveCN101275226AGood followabilityNo loss of adhesionEfficient propulsion technologiesMetallic material coating processesRubber materialVulcanization

A rubber member is provided which includes an aluminum-based inner metal tube (2) (aluminum-based metal component), a film (A) chemically formed on an outer peripheral surface of the inner metal tube (2), an adhesive layer (C) provided on an outer surface of the film (A), and a vibration damping rubber (1) provided on an outer surface of the adhesive layer (C). The film (A) contains manganese oxide and zirconium oxide. In the film (A), manganese from the manganese oxide is present in a content of 10 to 30 mg / m 2 on a manganese atom weight basis, and zirconium from the zirconium oxide is present in a content of 5 to 40 mg / m 2 on a zirconium atom weight basis. The film (A) is free from deterioration in, adhesion to the aluminum-base metal component which may otherwise occur due to heat applied for vulcanization of a rubber material, and is excellent in followability to deformation of the aluminum-based metal component. Further, it is easy to visually check the presence of the film (A) on the surface of the aluminum-based metal component.

Owner:SUMITOMO RIKO CO LTD

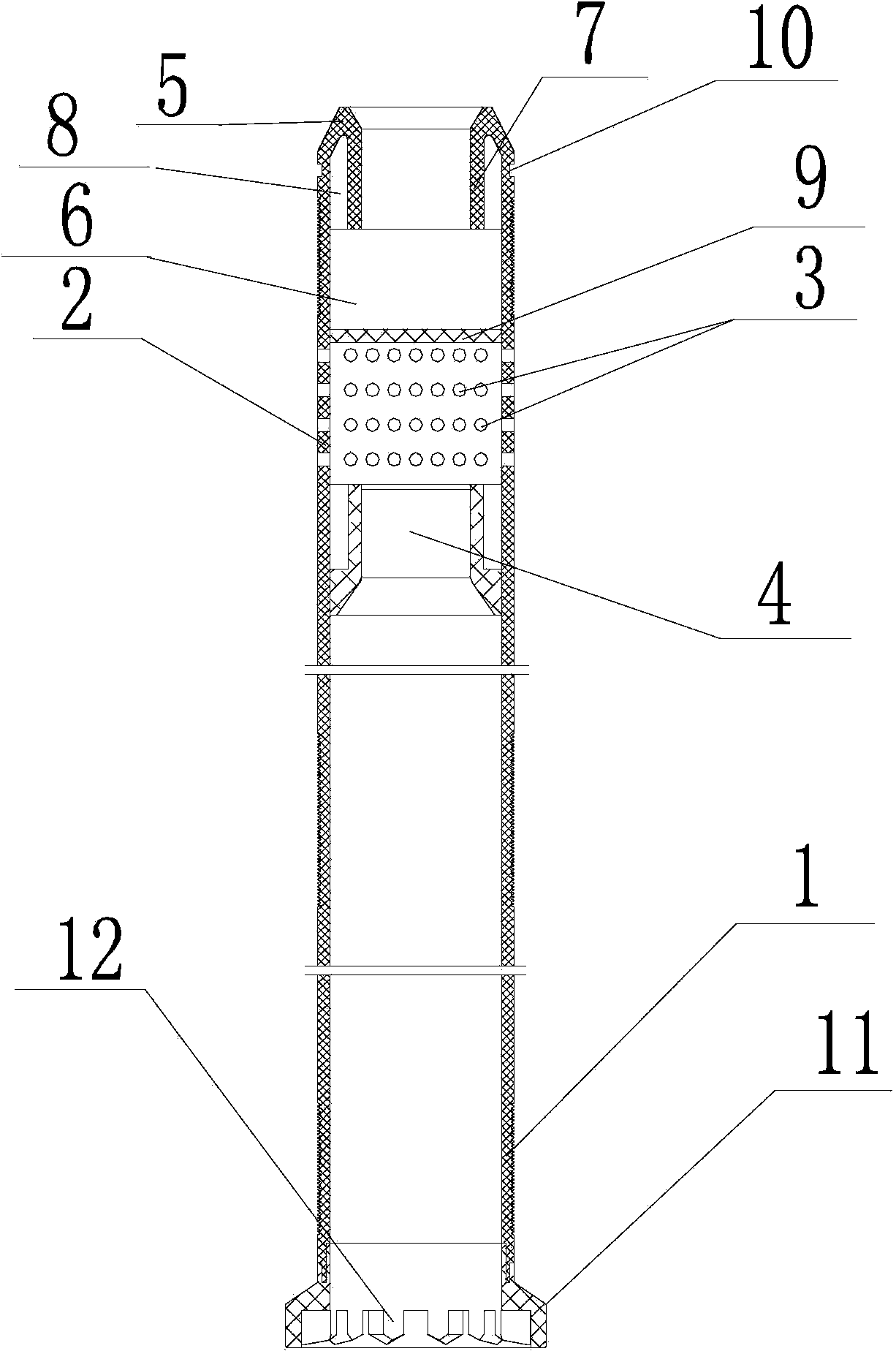

Negative-pressure jointing bobbin

The invention discloses a negative-pressure jointing bobbin comprising a bobbin body. A plurality of negative-pressure holes are uniformly formed in an annular jointing area of the bobbin body. A negative-pressure cavity is formed inside the bobbin body in correspondence to the annular jointing area and is communicated with the negative-pressure holes. Air in the negative-pressure cavity is sucked to form negative pressure. A negative-pressure adsorption area is formed in the annular jointing area. Yarns are adsorbed in the annular jointing area under negative pressure. Negative pressure is formed in the negative-pressure cavity by a suction fan, and the negative-pressure holes in the wall of the bobbin body are used for adsorbing the yarns so as to facilitate automatic doffing jointing, so that the automatic doffing jointing rate is up to 100%, labor intensity is reduced, no yarns are left, and utilization rate of roving yarns is greatly increased.

Owner:CMT HICORP MACHINERY QINGDAO

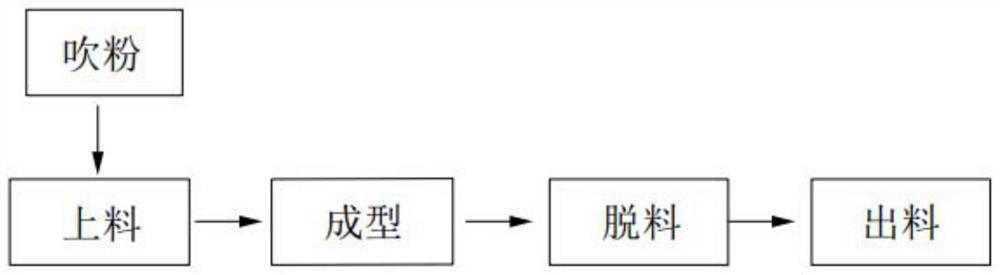

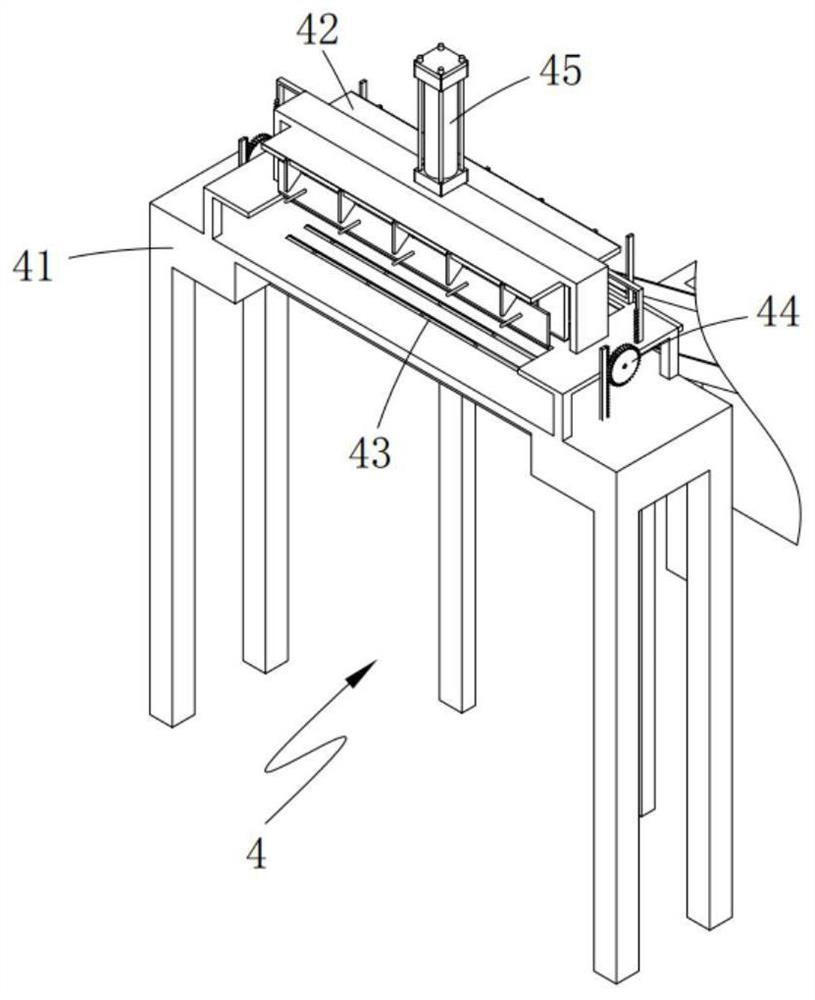

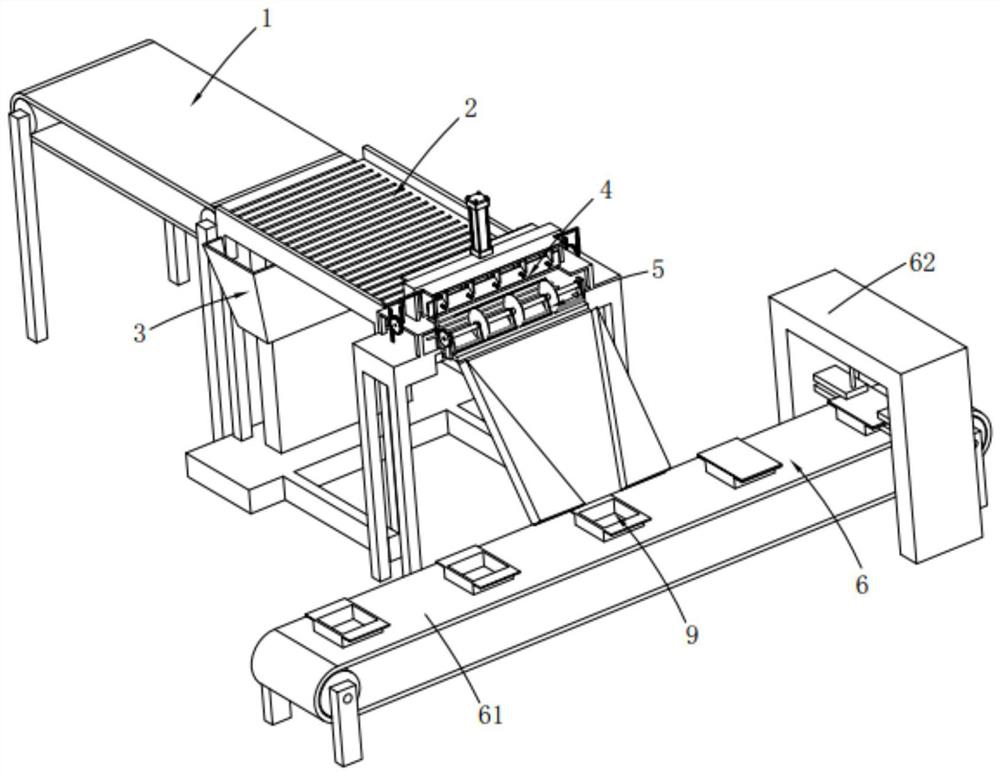

Processing and production method of dough sheets

InactiveCN112042699AIncrease profitImprove product qualityDough shaping and cutting apparatusDough processingProcess engineeringMechanical engineering

The invention relates to the technical field of food processing equipment, and particularly relates to a processing and production method of dough sheets. The processing and production method comprises the following steps of step 1, a loading working procedure: conveying dough sheets by a first conveying mechanism in the conveying direction; step 2, a powder blowing working procedure: performing powder blowing on the bottoms of the dough sheets by a powder blowing device under a second conveying mechanism; step 3, a shaping working procedure: conveying the dough sheets to a first base by the second conveying mechanism; step 4, a material stripping working procedure: driving a first shaping piece and a second shaping piece to move downwards by a driving piece, so that the shaped dough sheets are separated from the first shaping piece and the second shaping piece; and step 5, a discharging working procedure: cutting off the shaped dough sheets by a second cutter to obtain a butterfly shape. According to the processing and production method disclosed by the invention, the first shaping piece and the second shaping piece are matched, so that the dough sheets are pressed until side edges are in M shapes, besides, through mutual movement of shaping rods, the dough sheets at a first notch and a second notch are mutually adhered, and then the dough sheets on a discharging mechanism arecut and discharged.

Owner:马胜男

Karaya gum-based hydrophilic gel system for skin care

InactiveCN101115460ANo loss of adhesionCosmetic preparationsToilet preparationsKaraya GumPolymer chemistry

The invention relates to a hydrophilic gel system for cosmetic and / or skin care applications. Said gel system comprises a detachable carrier film and a hydrogel which contains at least 15 percent by weight of karaya gum and whose water concentration is less than 5 percent by weight.

Owner:LTS LOHMANN THERAPIE-SYST AG

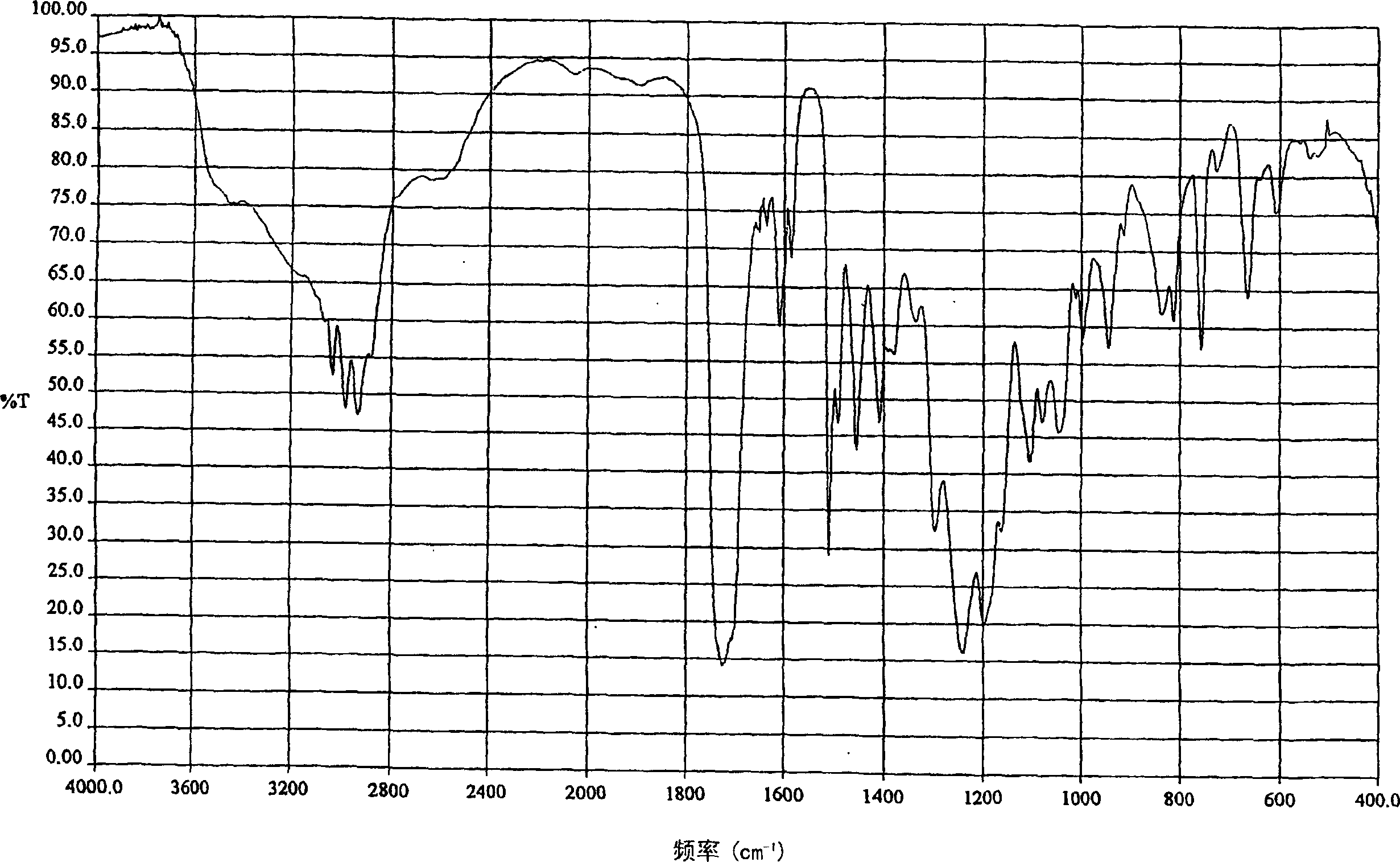

Preparation method of peelable type organosilicon pressure-sensitive adhesive

InactiveCN102876249BStir wellGood storage stabilityNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesive cementEndcapping

The invention provides a preparation method of a peelable type organosilicon pressure-sensitive adhesive. The preparation method comprises the following steps: firstly, synthesizing MQ resin by adopting a water glass method; secondly, synthesizing carboxyl-terminated silicone rubber by adopting a direct equilibrium copolymerization method; and finally, mixing the MQ resin, the carboxyl-terminated silicone rubber and an organic solvent in a certain proportion and stirring evenly, adding a certain amount of catalyst, a filling material, a curing agent and a stabilizing agent and stirring evenly, heating for reflux reaction for a certain time, and cooling and vacuumizing to remove the solvent as much as possible, so as to obtain the peelable type organosilicon pressure-sensitive adhesive. The method better solves the difficult problems of high coating fragility, bad peelability, poor durability and weatherability, higher cost and the like of the conventional peelable type organosilicon pressure-sensitive adhesive product. The peelable type organosilicon pressure-sensitive adhesive has excellent storage stability, film forming property, water resistance and peelability, leaves no mark after being peeled off a base material and can be reused without losing adhesiveness.

Owner:杭州材聚科技有限公司

Weighing apparatus and method for liquid crystal display glass raw materials

InactiveCN1850669AGuaranteed accuracyAvoid Weighing FluctuationsLiquid-crystal displayMaterials science

The invention relates to a high-accuracy weighing device and method for raw materials for liquid crystal display glass. And the device comprises a high accuracy electric scale for accurately weighing smaller numbers of raw materials and an electric scale for weighing larger numbers of raw materials, where the material outlet of the former is connected through the lower paddle with the material inlet of the latter, and the material outlet of the latter is connected with a material mixer; firstly the smaller numbers of raw materials are added in sequence to the high accuracy electronic scale for accurate weighing and after this, they enter through the other electronic scale into the material mixer, thus able to assure the weighing accuracy of the smaller numbers of raw materials and further improve the preparing quality of the auxiliary materials.

Owner:HENAN ANCAI HI-TECH +1

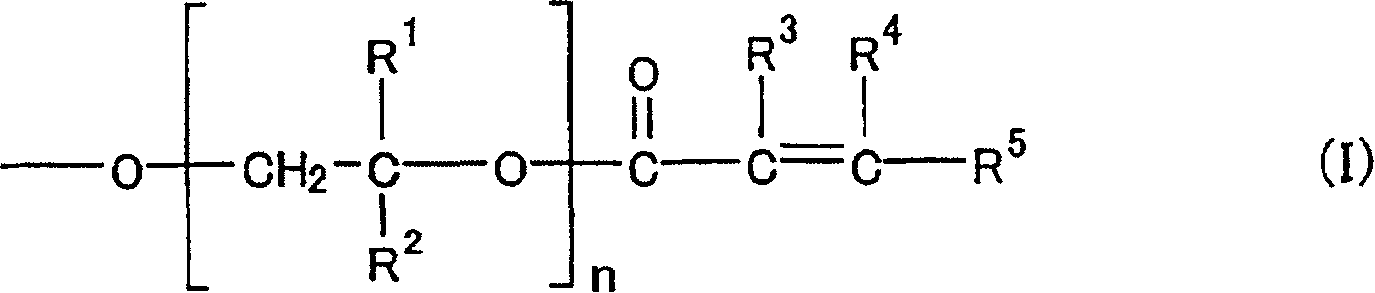

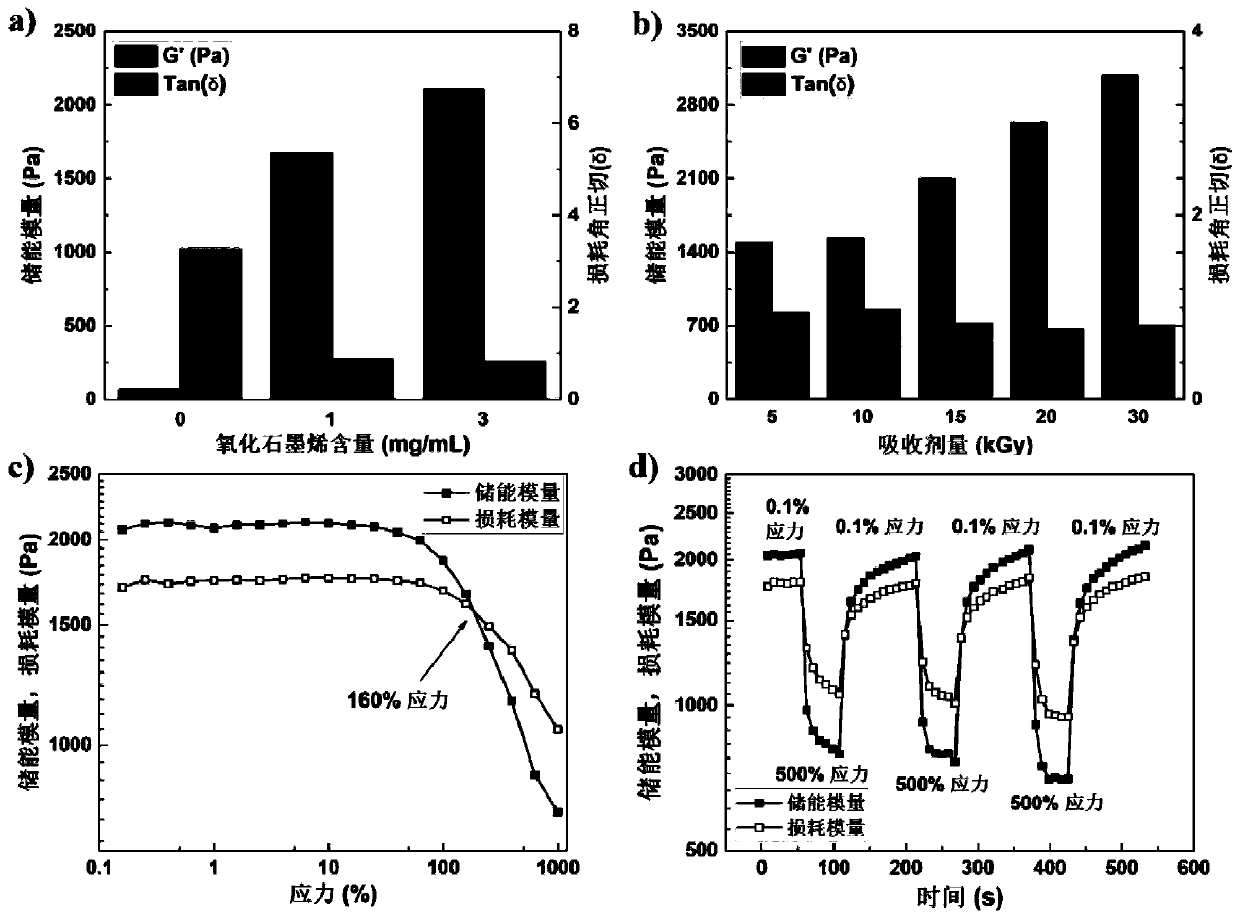

A kind of highly adhesive conductive self-healing hydrogel and its preparation method and application

ActiveCN107973874BImprove ionic conductivityImprove adhesionStarch adhesivesEster polymer adhesivesTissue repairBiocompatibility

The invention discloses high-adhesiveness conducting self-healing hydrogel as well as a preparation method and application thereof. A gamma ray or electron beam initiation polymerization method is used; cationic monomers shown as a formula I and polymerizable hydrophilic anion monomers are polymerized in an inorganic filler aqueous dispersion dissolved with polysaccharides; the physical crosslinking self-healing hydrogel is obtained. The self-healing hydrogel has the excellent characteristics of high response and self healing capability; the repeated use can be realized; high ionic conductivity, good biocompatibility and high adhesiveness are realized; the adhesive force on a conducting copper sheet can reach 60.5MPa. The gamma ray or electron beam irradiation method is used, so that the preparation method is simpler; safety and environment protection are realized; the energy consumption is low; the preparation method is very suitable for industrial production. The high-adhesiveness conducting self-healing hydrogel related by the invention is hopeful to be used in the fields of electronic device bonding agents, medical device bonding agents, tissue repair and the like.

Owner:PEKING UNIV

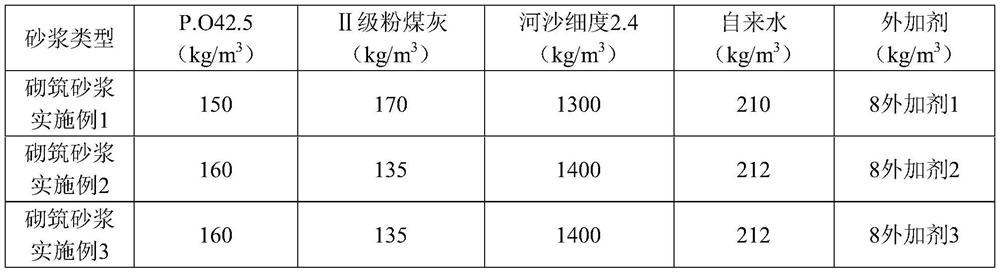

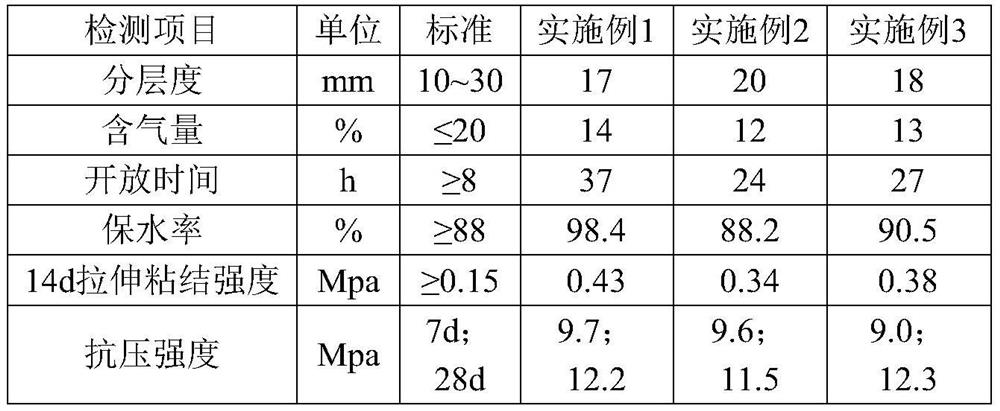

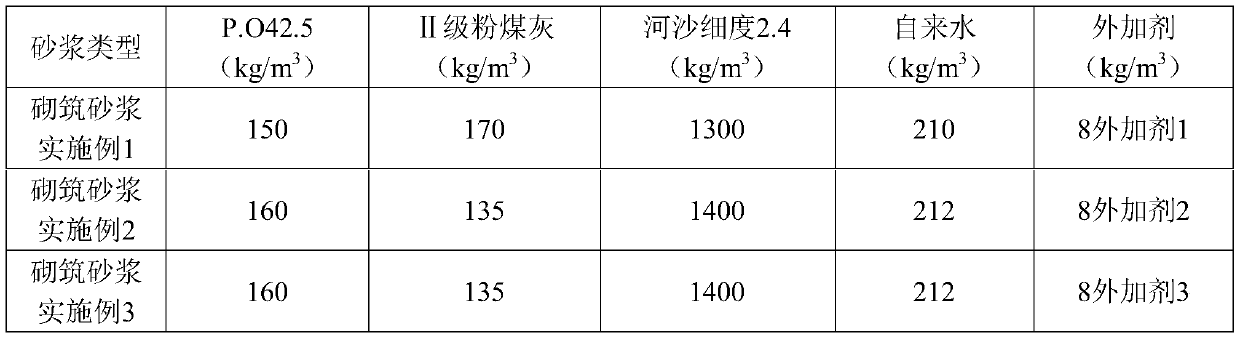

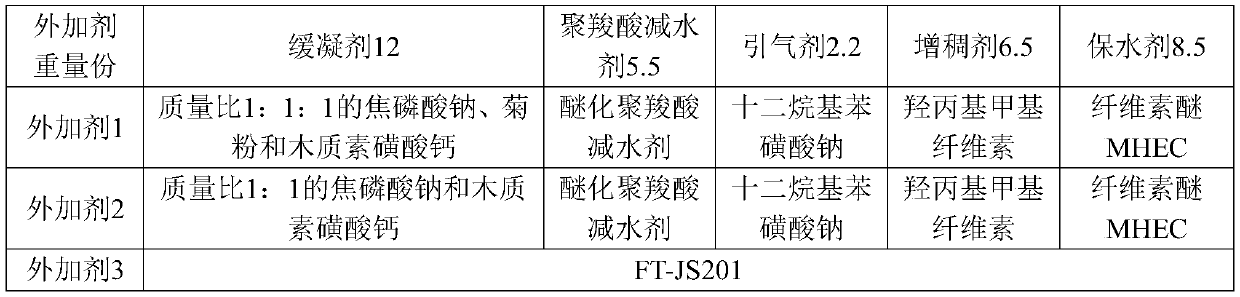

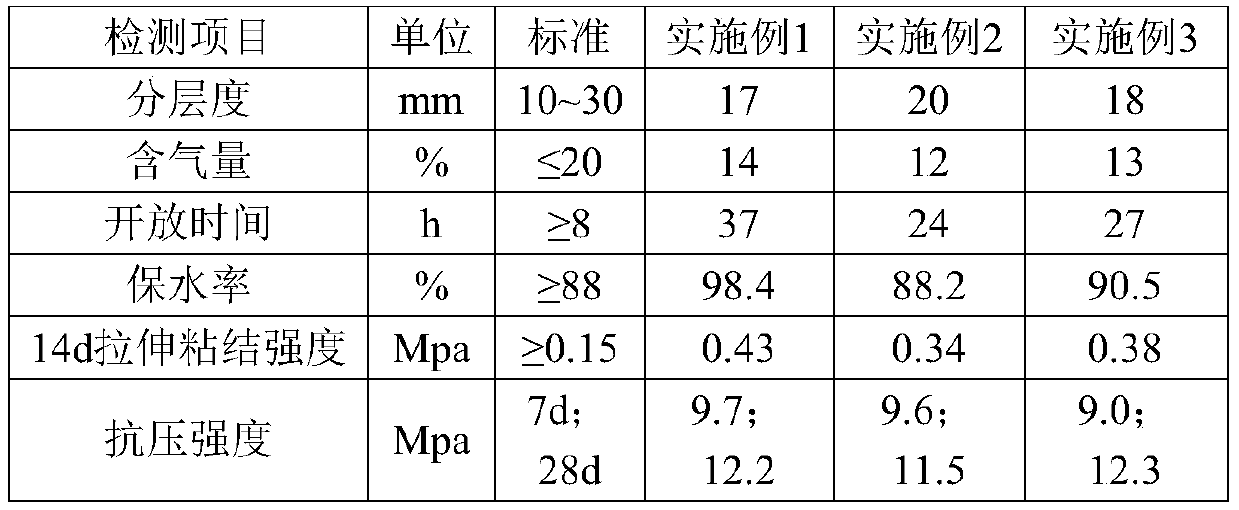

A kind of wet-mix mortar additive containing inulin and its application

The invention discloses an inulin-containing wet-mixed mortar admixture and application thereof, and relates to wet-mixed mortar admixtures. The admixture comprises a retarder, wherein the retarder comprises inulin. It is shown through experimental results that the inulin-added wet-mixed mortar has an operation time of up to 37 hours, needs of the wet-mixed mortar for long-term storage at a construction site are met, and the early strength is not reduced; and prepared mortar is loose and soft, and has good water retention properties, and the water retention rate can reach 98.4%.

Owner:山东翰辰石油科技有限公司

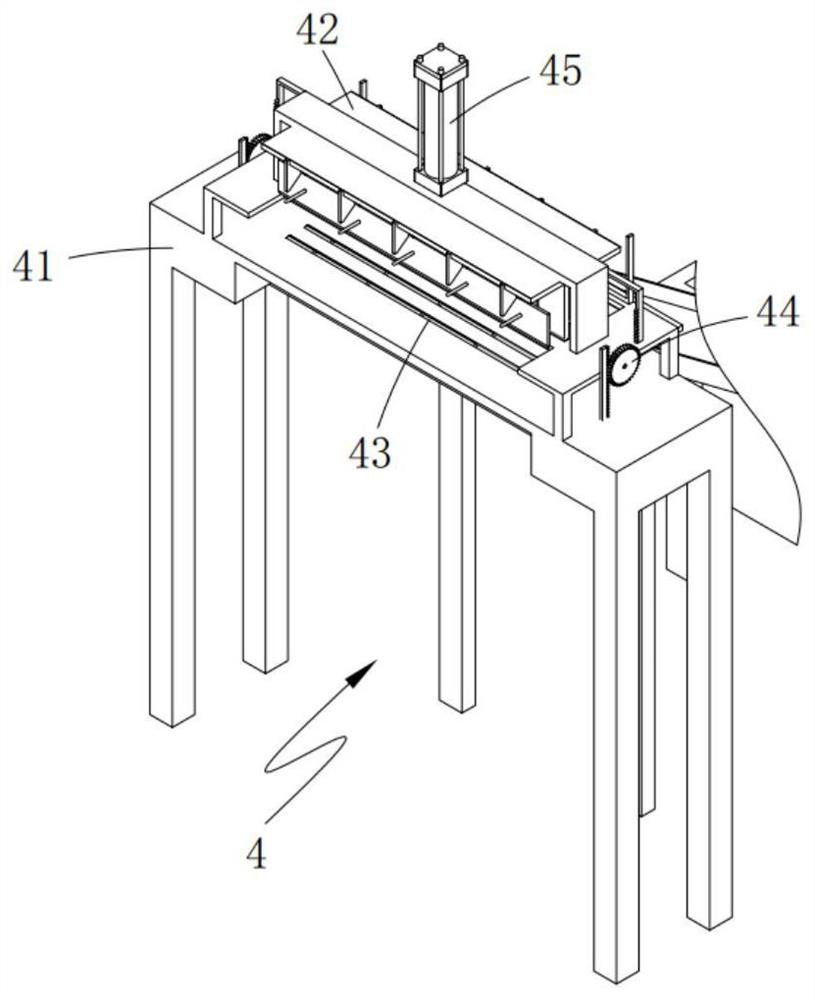

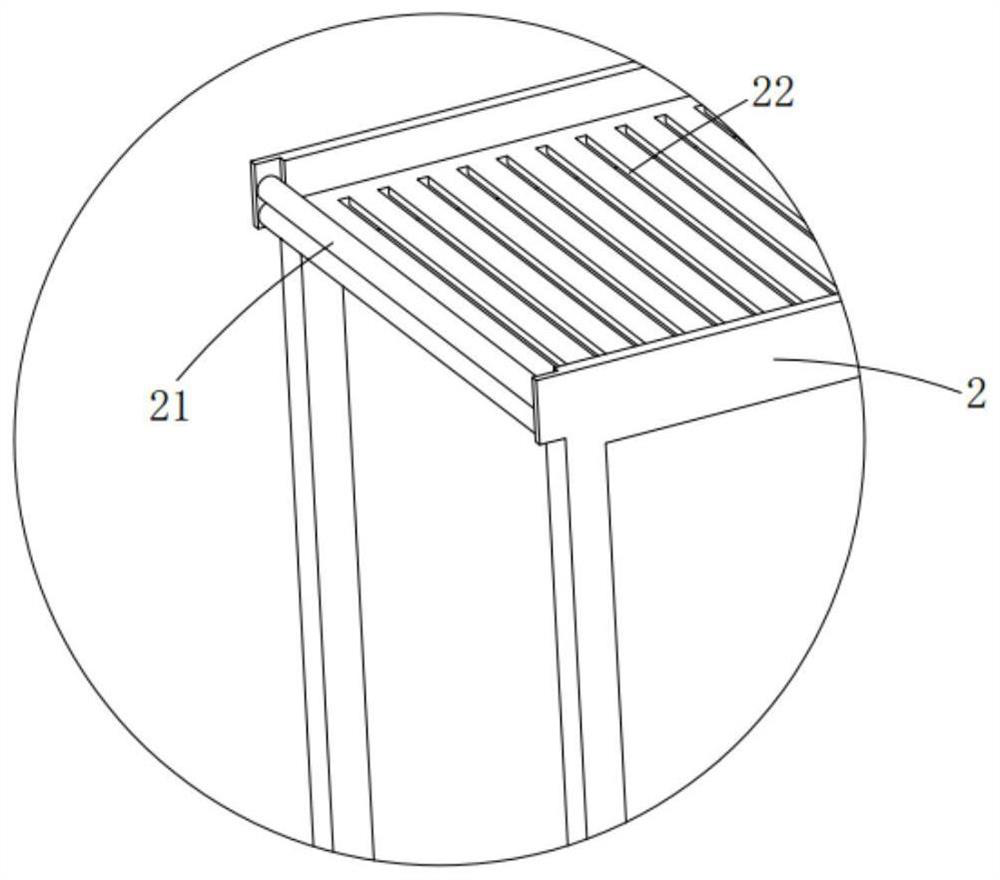

Automatic processing and forming production device of farfalle

InactiveCN112056339ARealize automatic production packagingIncrease profitWrapper twisting/gatheringSolid materialWaste materialIndustrial engineering

The present invention relates to the technical field of food processing devices and particularly to an automatic processing and forming production device of farfalle. The automatic processing and forming production device of farfalle comprises a first conveying mechanism, a second conveying mechanism arranged at an output end of the first conveying mechanism, a forming mechanism arranged at an output end of the second conveying mechanism in a conveying direction of the second conveying mechanism, a discharging mechanism arranged at an output end of the forming mechanism, and a packaging mechanism arranged at an output end of a material chute. Through cooperation of a first forming part and a second forming part, dough skins are pressed into side-edge M shapes, meanwhile, the dough skins atfirst notches and second notches are bonded through mutual movements of forming rods, then the formed farfalle enters packaging boxes through the material chute, the packaging boxes and box covers are nailed together through a stapling assembly after the box covers are additionally arranged on the packaging boxes through an external mechanical arm, packaging is finished, automatic production andpackaging of the farfalle are achieved, and production quality and a utilization rate of waste materials are improved.

Owner:马胜男

Inulin-containing wet-mixed mortar admixture and application thereof

The invention discloses an inulin-containing wet-mixed mortar admixture and application thereof, and relates to wet-mixed mortar admixtures. The admixture comprises a retarder, wherein the retarder comprises inulin. It is shown through experimental results that the inulin-added wet-mixed mortar has an operation time of up to 37 hours, needs of the wet-mixed mortar for long-term storage at a construction site are met, and the early strength is not reduced; and prepared mortar is loose and soft, and has good water retention properties, and the water retention rate can reach 98.4%.

Owner:山东翰辰石油科技有限公司

A kind of negative pressure spinning bobbin

The invention discloses a negative-pressure jointing bobbin comprising a bobbin body. A plurality of negative-pressure holes are uniformly formed in an annular jointing area of the bobbin body. A negative-pressure cavity is formed inside the bobbin body in correspondence to the annular jointing area and is communicated with the negative-pressure holes. Air in the negative-pressure cavity is sucked to form negative pressure. A negative-pressure adsorption area is formed in the annular jointing area. Yarns are adsorbed in the annular jointing area under negative pressure. Negative pressure is formed in the negative-pressure cavity by a suction fan, and the negative-pressure holes in the wall of the bobbin body are used for adsorbing the yarns so as to facilitate automatic doffing jointing, so that the automatic doffing jointing rate is up to 100%, labor intensity is reduced, no yarns are left, and utilization rate of roving yarns is greatly increased.

Owner:CMT HICORP MACHINERY QINGDAO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com