Inulin-containing wet-mixed mortar admixture and application thereof

A wet-mix mortar and admixture technology, which is applied in the application field of inulin as a retarder in wet-mix mortar admixtures, can solve the problems of reduced strength, poor water retention, and increased mortar consistency, and achieve reduced shrinkage deformation, Wide range of sources, good water retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

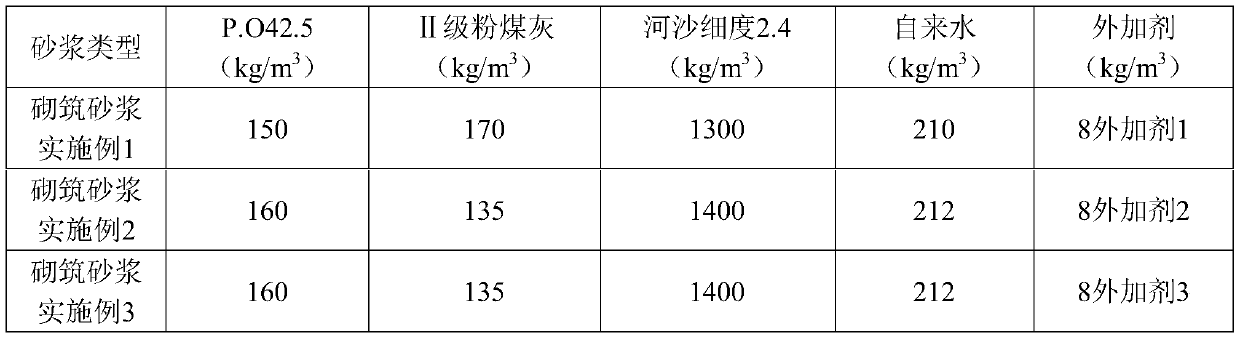

[0033] Configure the mortar cementitious material according to Table 1, and configure the admixture according to Table 2;

[0034] Test method: mix the admixture into the concrete;

[0035] Result detection: According to the methods in JGJ / T223-2010 and JG / T230-2007 standards, various performance tests are carried out, and the test results are shown in Table 3.

[0036] Table 1 The mix ratio of mortar gel material

[0037]

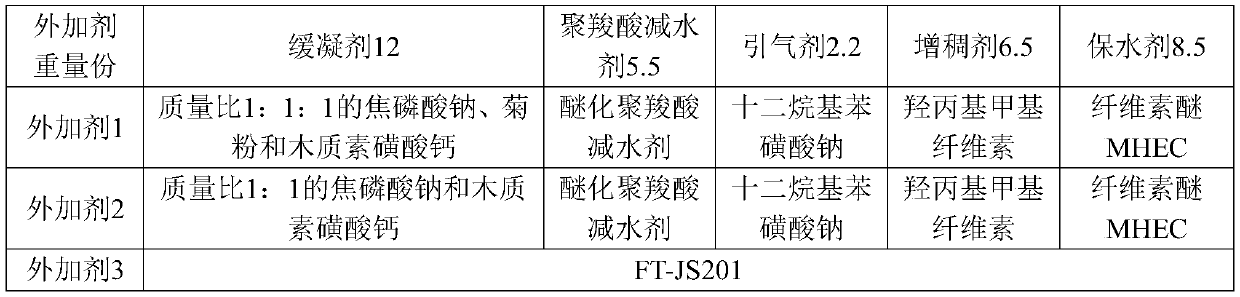

[0038] Table 2 admixture ratio

[0039]

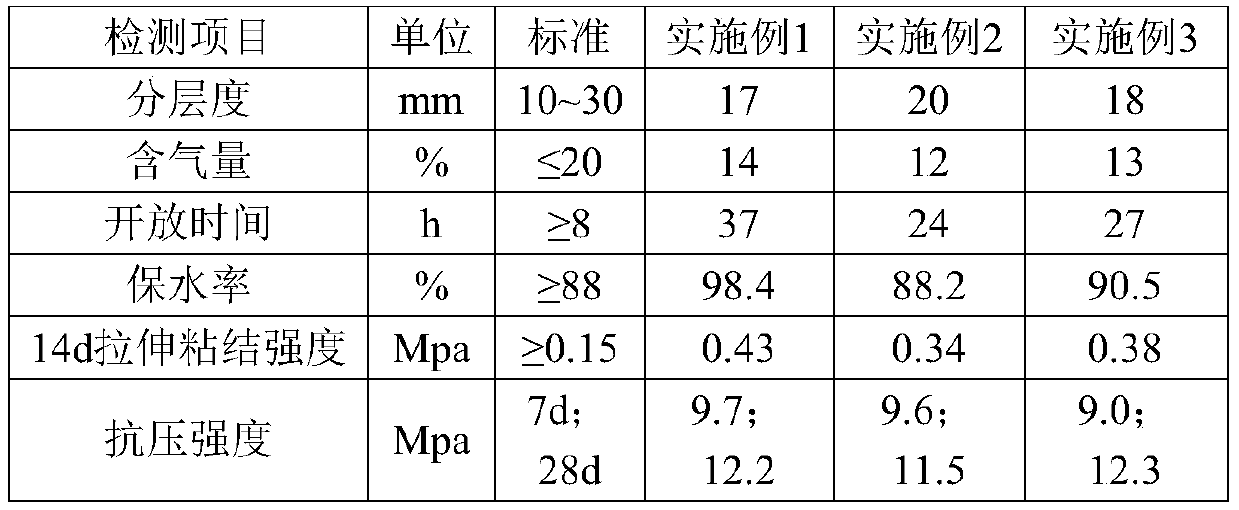

[0040] The above embodiment performance detection of table 3

[0041]

[0042] Table 3 shows that after adding inulin to the retarder, the operability is significantly enhanced, and the opening time is extended from 24 hours to 37 hours, which fully shows that inulin has strong water retention and stability. It can be seen that inulin can partially replace the retarder in the prior art and be used in wet-mixed concrete.

Embodiment 2

[0043] Example 2 In order to better prove the performance of the inulin of the present invention as a retarder, the retarder of the present invention is used in the patent embodiment 1 scheme whose application number is 201510551349.9, to replace the retarder therein, and then carry out detection. which is:

[0044] Take 100g of papermaking black liquor (Shandong Gaotang Kelin Environmental Protection Technology Co., Ltd.), adjust the pH to 9, heat to 55°C while stirring, add 1g of ferric sulfite, 2g of Russian wood sodium, after cooling, add 2g of dimethyl silicone oil , 10 g of guar gum, 24 g of retarder (sodium pyrophosphate, inulin and calcium lignosulfonate at a mass ratio of 1:1:1) were evenly mixed to obtain a tan lignin-based mortar admixture product. During construction, pour 240g of Portland cement, 218g of fly ash, 1928g of sand and 9g of the above-mentioned lignin-based mortar admixture into a clean mixer, add water while stirring, and follow the basic performance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com