Concrete structure self-compacting waterproofing agent and preparation method and application thereof

A concrete structure and self-compacting technology, which is applied in the field of waterproofing agent, can solve the problems of building water leakage, single function, inability to cover concrete waterproof performance and construction requirements, etc., to achieve reduced cement consumption, excellent comprehensive performance, and efficient water reduction The effect of water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

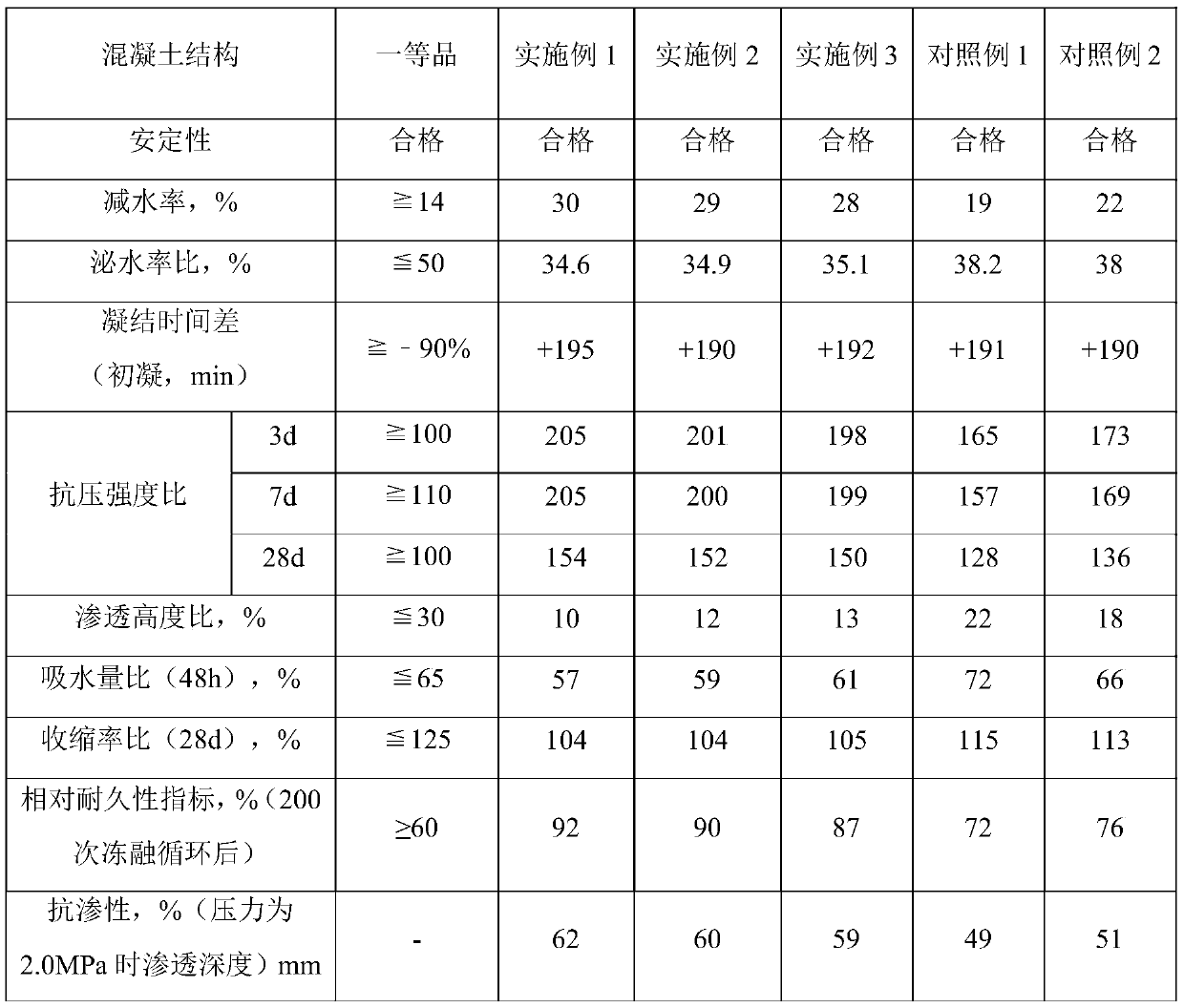

Examples

Embodiment 1

[0043]Weigh 17.5 parts of sodium methyl silicate, 16.5 parts of potassium fluorosilicate and 30 parts of tap water, put them in a container and stir for 1 hour, then raise the temperature to 62°C and keep stirring for 1 hour to form a dispersion liquid, and stand for 3 hours for use. That is the first component.

[0044] Weigh 5 parts of sodium pyrophosphate, 3 parts of electrolytic aluminum solution and 9 parts of tap water, put them into a container and stir for 2 hours, then raise the temperature to 65°C and keep stirring for 1 hour, and let stand for 1 hour to be used, which is the second component.

[0045] Weigh 5.5 parts of polycarboxylate superplasticizer, 3.5 parts of slump retaining agent and 10 parts of tap water, put them into a container and stir for 1 hour, and let stand for use, namely the third component.

[0046] Put the above-mentioned first component, second component and third component into a container and stir for 1 hour, let it stand for 3 hours, then fi...

Embodiment 2

[0054] Weigh 19 parts of sodium methyl silicate, 15 parts of potassium fluorosilicate and 28 parts of tap water, put them into a container and stir for 0.5 hours, then raise the temperature to 65°C and keep stirring for 1.5 hours to form a dispersion, and stand for 3 hours for use. That is the first component.

[0055] Weigh 3 parts of sodium pyrophosphate, 4 parts of electrolytic aluminum solution and 10 parts of tap water, put them into a container and stir for 2 hours, then raise the temperature to 68°C and keep stirring for 1.5 hours, and let stand for 1 hour for use, which is the second component.

[0056] Weigh 7 parts of polycarboxylate superplasticizer, 3 parts of slump retaining agent and 15 parts of tap water, put them into a container and stir for 1.5 hours, and let stand for use, namely the third component.

[0057] Put the above-mentioned first component, second component and third component into a container and stir for 1 hour, let it stand for 3 hours, then filt...

Embodiment 3

[0060] Weigh 16 parts of potassium ethyl silicate, 18 parts of sodium fluorosilicate and 35 parts of tap water, put them in a container and stir for 1 hour, then raise the temperature to 65°C and keep stirring for 1.5 hours to form a dispersion, and let it stand for 5 hours before use. That is the first component.

[0061] Weigh 7 parts of sodium gluconate, 2 parts of electrolytic aluminum solution and 6 parts of tap water, put them into a container and stir for 1.5 hours, then raise the temperature to 68°C and keep stirring for 1.5 hours, and let stand for 2 hours for use, which is the second component.

[0062] Weigh 4 parts of sodium naphthalenesulfonate superplasticizer, 5 parts of slump retaining agent and 12 parts of tap water, put them into a container and stir for 1 hour, and let stand for use, which is the third component.

[0063] Put the above-mentioned first component, second component and third component into a container and stir for 1 hour, let it stand for 3 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com