A kind of highly adhesive conductive self-healing hydrogel and its preparation method and application

A self-healing, hydrogel technology, applied in adhesive types, starch adhesives, ester copolymer adhesives, etc., can solve the problems of insufficient adhesive force, high energy consumption in the preparation process, and poor production process Difficult to control and other problems, to achieve the effect of easy control of conditions, simple preparation method and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, preparation cationic monomer

[0041]

[0042] Add 250mL of acetone to a 500mL round bottom flask, add dimethylaminoethyl methacrylate (0.21mol) and n-bromobutane (0.28mol) to the system respectively, pump and change the gas 3 times, and replace the solution system with a nitrogen atmosphere , under full stirring, reflux at 50°C for 6 hours. Most of the acetone solvent was removed, and anhydrous ether was added to precipitate the product. After suction filtration, it was fully dried in an oven at 40°C to obtain a white powder product (N-(2-(methacrylic acid acyloxy)ethyl)- N,N-dimethylbutane-1-ammonium bromide, about 90% yield).

Embodiment 2

[0043] Embodiment 2, preparation graphene oxide dispersion liquid

[0044] 15 mg of graphene oxide was added to 5 mL of purified water, and after stirring for 30 minutes, the cell crusher was crushed for 2 hours to obtain a uniformly dispersed graphene oxide aqueous dispersion.

Embodiment 3

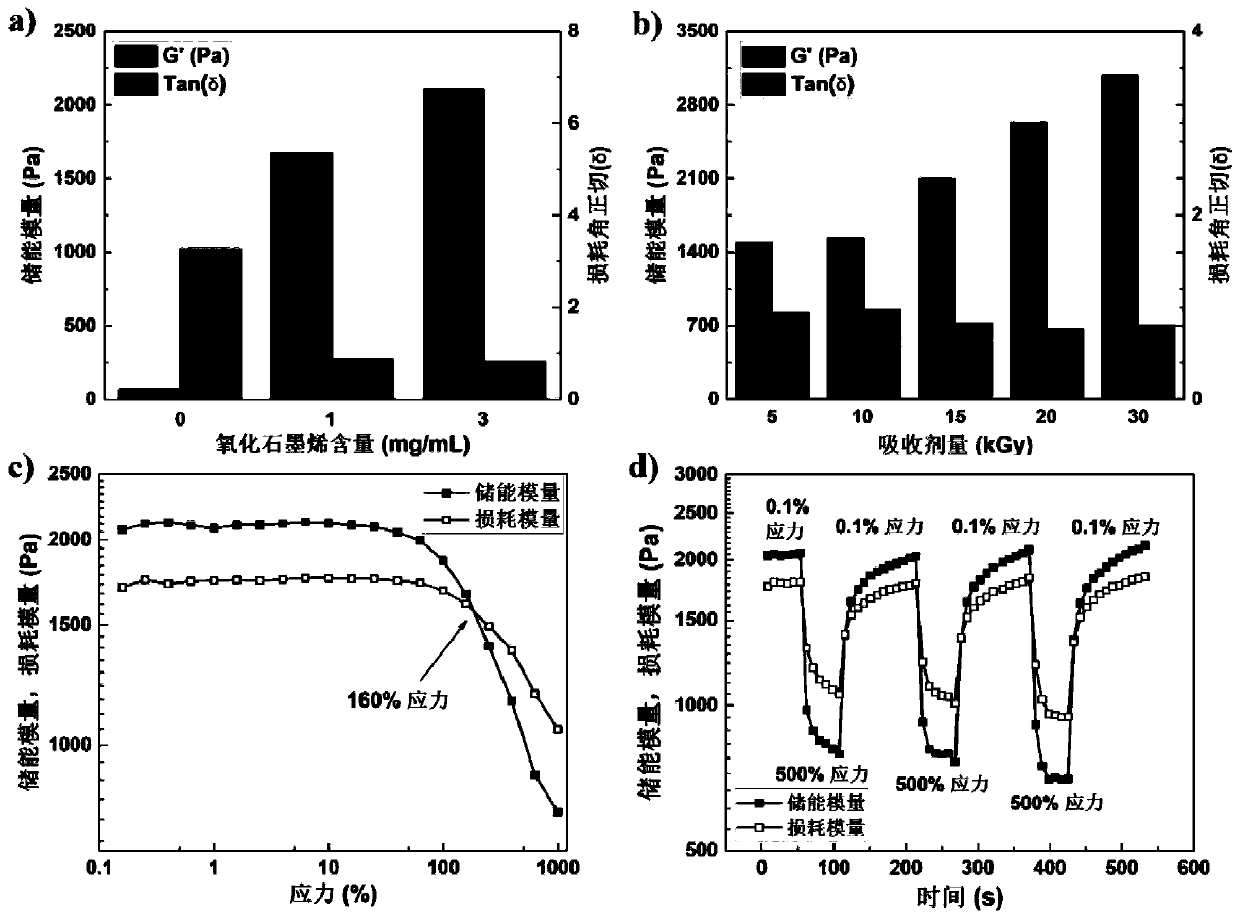

[0045] Embodiment 3, preparation self-healing hydrogel

[0046] Self-healing hydrogels (3GO-P(NaSS-co-MOBAB)-15kGy) were prepared by γ-ray irradiation technique. The details are as follows: 100 mg of soluble starch, 1 mol / L of sodium styrene sulfonate and 1 mol / L of (N-( 2-(methacrylic acid acyloxy)ethyl)-N,N-dimethylbutane-1-ammonium bromide, after mixing evenly, a black viscous solution is formed. After γ-ray irradiation, at the dose rate Under the conditions of 80Gy / min and an absorbed dose of 15kGy, the polymerization of the system was initiated to form a self-healing hydrogel (3GO-P(NaSS-co-MOBAB)-15kGy).

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com