Metal microstructure forming method

A metal microstructure and metal structure technology, applied in optics, optomechanical equipment, instruments, etc., can solve the problems affecting the reliability of microstructure components, substrate deformation, and adhesion reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be described in more detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it after studying this specification.

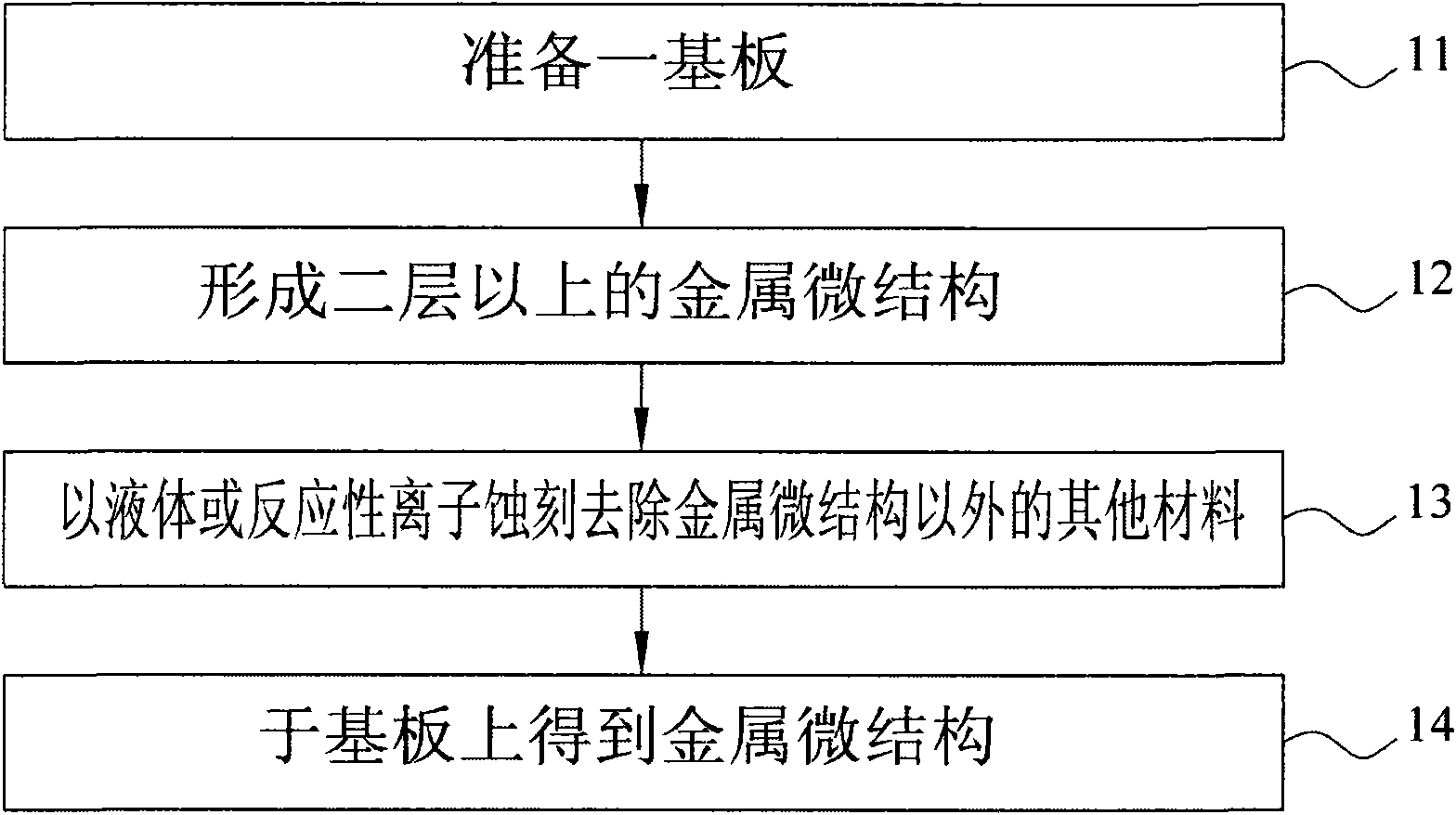

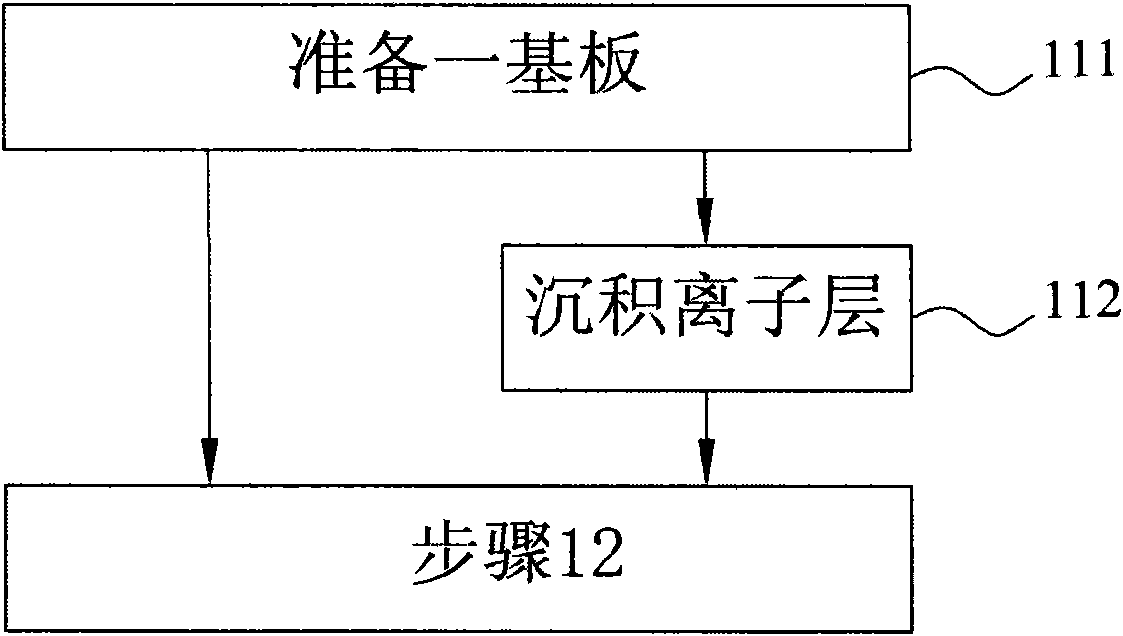

[0028] figure 1 It is a flowchart for illustrating the process steps of the metal microstructure forming method of the present invention. Such as figure 1 Shown in is the metal microstructure forming method of the present invention. Firstly, in step 11 , a substrate is prepared for subsequent metal microstructure formation on the substrate, and the process proceeds to step 12 .

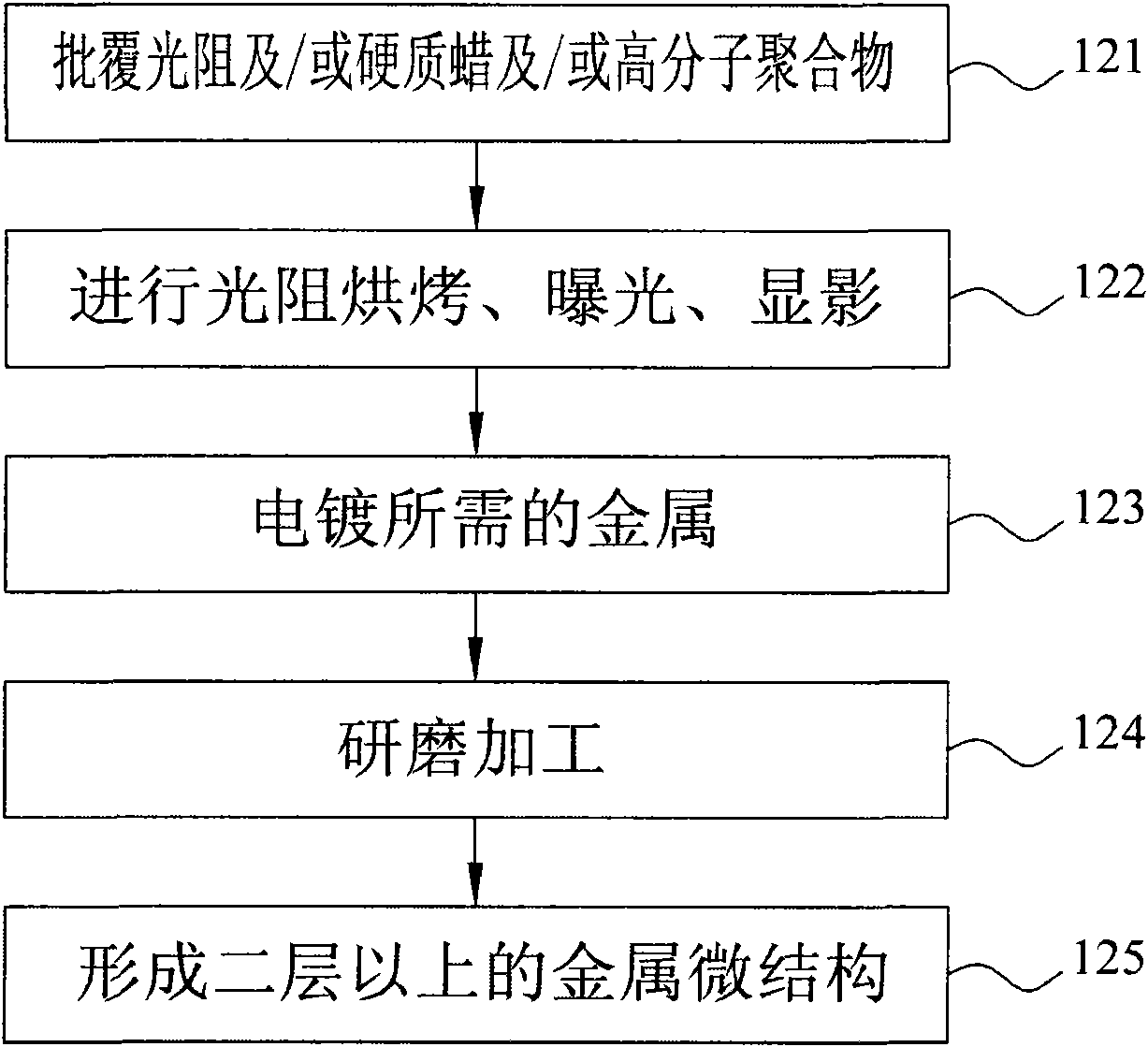

[0029] In step 12, two or more layers of metal microstructures are successively formed on the surface of the substrate, where each layer of metal microstructures is composed of a material, and the two or more layers of metal microstructures can be made of the same material and / or consist of different materials, and go to step 13.

[0030] In step 13, liquid or reactive ion etch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com