Automatic arranging and conveying system for glass containers

A technology of automatic arrangement and conveying system, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low yield, poor quality, residual stress of glass bottles and cans, etc., to improve the yield, improve quality, Even heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

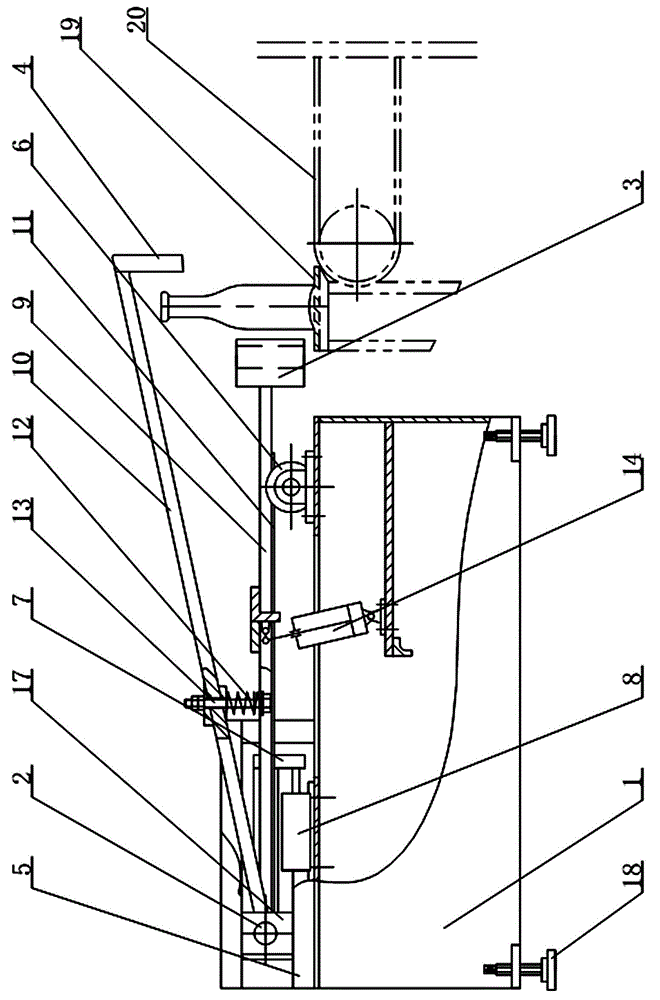

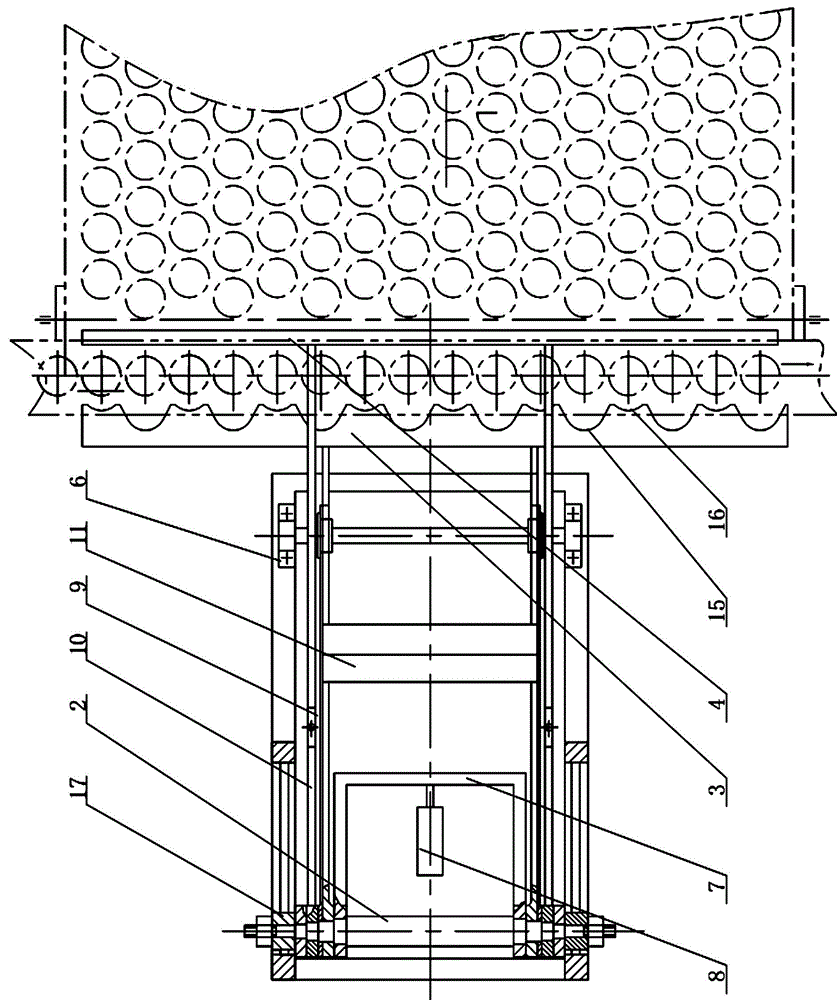

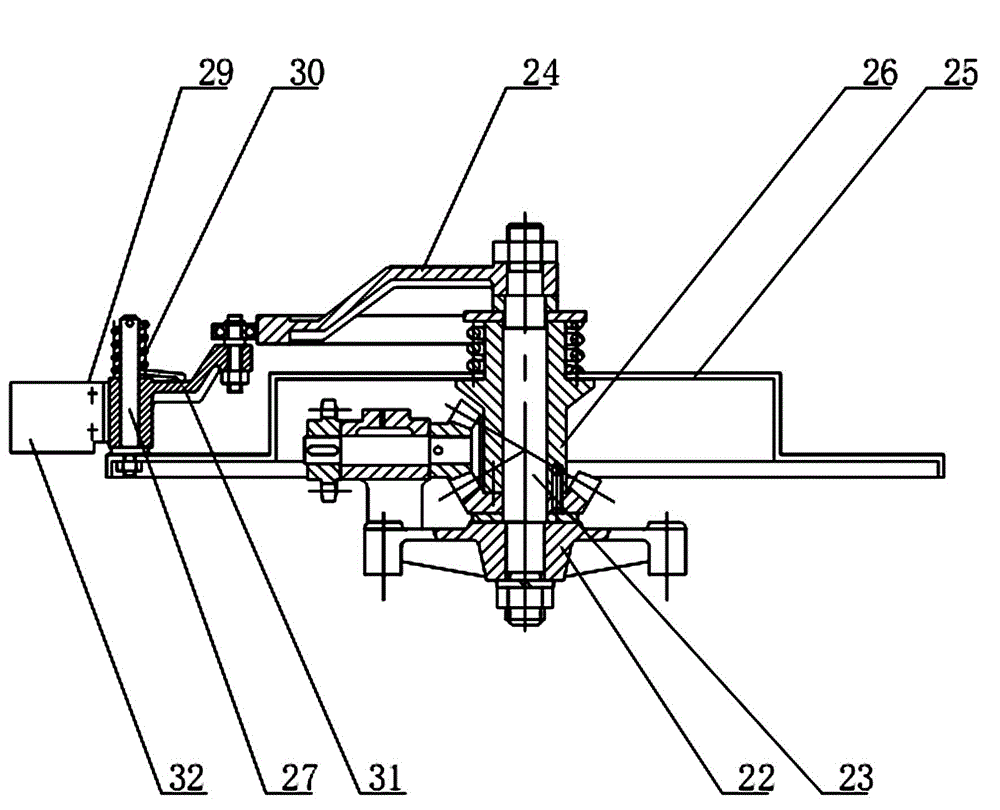

[0019] Depend on Figure 1 to Figure 6 As shown, an automatic arrangement conveying system for glass bottles and jars includes an automatic arrangement device, a pneumatic bottle pusher and a sequence control pneumatic valve. The automatic arrangement device is located between the output conveyor belt 21 and the transition conveyor belt 19 of the bottle forming machine. One end of the conveyor belt 19 is located at the annealing kiln mesh belt 20, and the pneumatic bottle pusher is placed on one side of the transition conveyor belt 9 and corresponds to the annealing kiln mesh belt 20. The pneumatic bottle pusher includes a frame 1, a central shaft 2. The push plate 3 and the guard plate 4 are provided with two slideways 5 and two rollers 6 above the frame 1. The two ends of the central shaft 2 are located in the slideway 5 and can slide along the slideway 5 in a straight li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com