Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

193results about How to "No bending deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

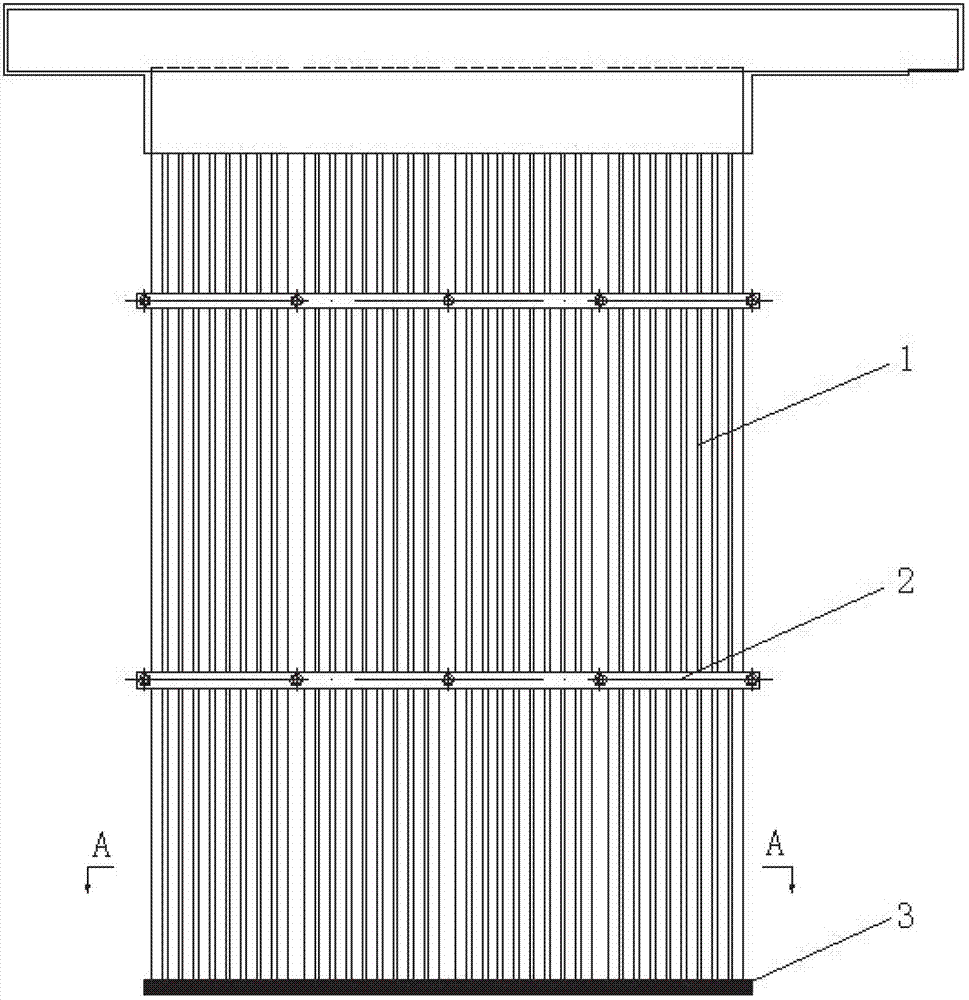

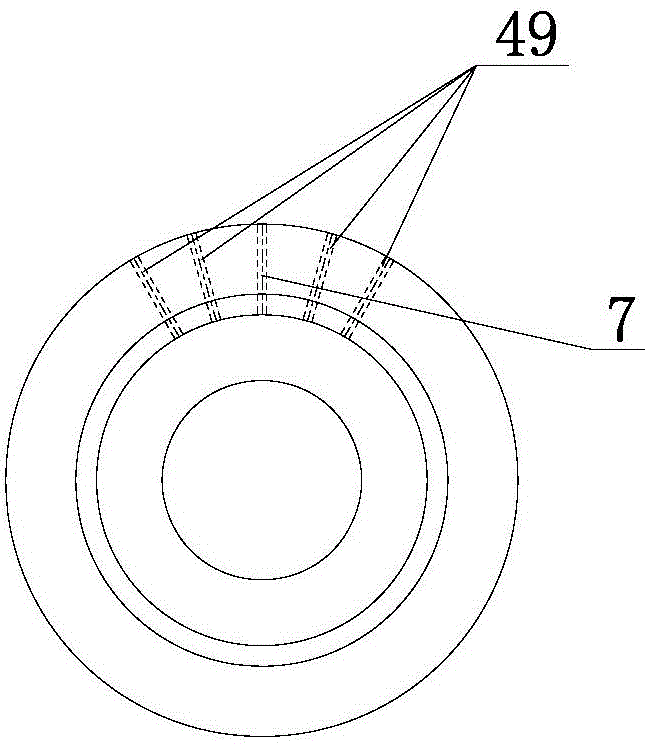

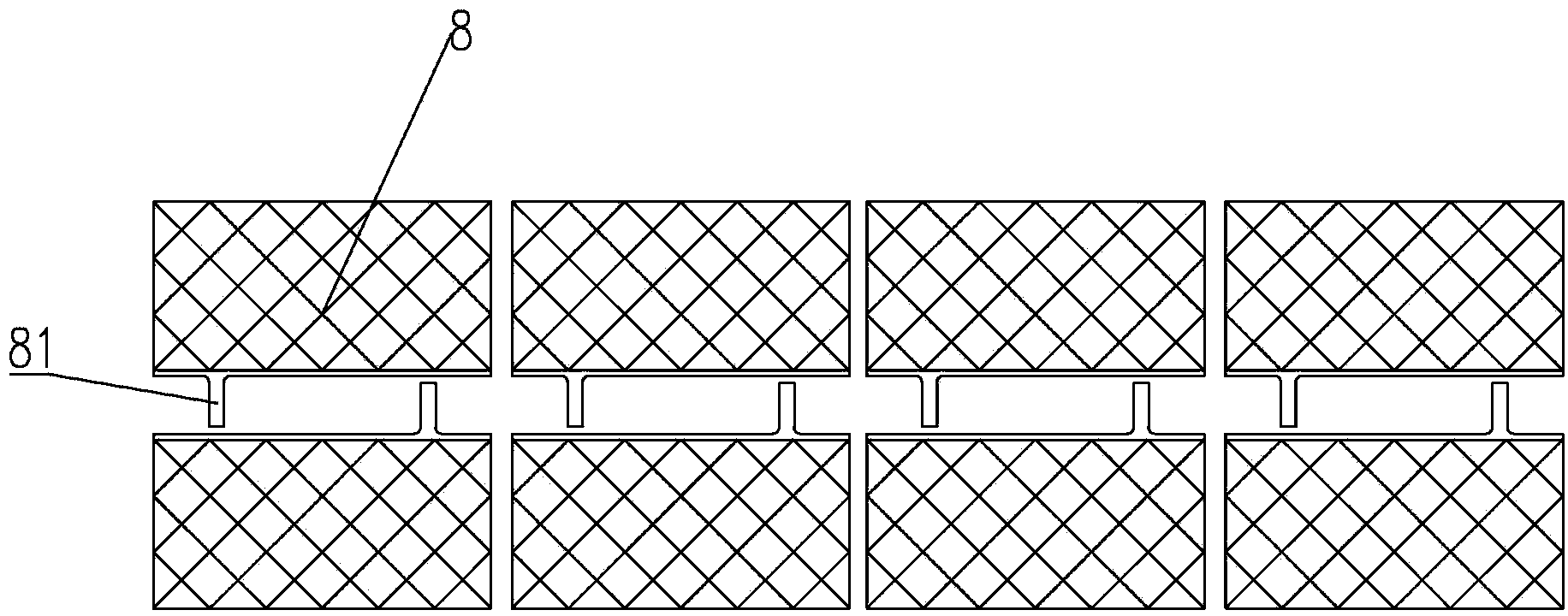

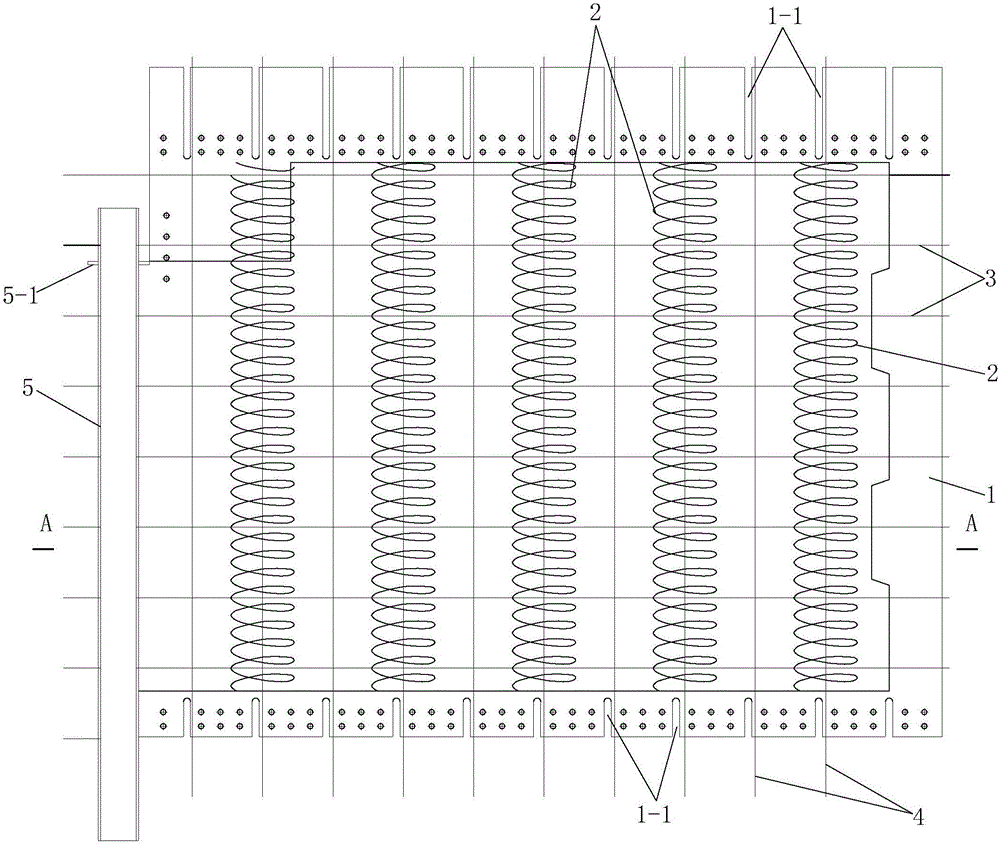

Fence type anode plate for electrodeposition of nonferrous metals

The invention discloses a fence type anode plate for electrodeposition of nonferrous metals. The fence type anode plate for electrodeposition of the nonferrous metals is characterized in that lead or lead-based complex alloy with the thickness of 2-10mm is compounded on the surface of a rod core to form a composite rod; a corrugated or sawtooth type pattern is drawn on the surface of the composite rod; a conductive ceramic composite coating layer is coated or electrodeposited on the surface of the composite rod; the fence type anode plate is formed by assembling a plurality of the composite rods; and the composite rods are fixed by insulation edge clamping strips and clamped by insulation rivets. By the fence type anode plate for electrodeposition of the nonferrous metals, fluidity of electrolyte solution is improved, concentration polarization of a cathode area is reduced, and deposition amount of cathode metals is increased, so that cathode current efficiency is improved; the fence type anode plate does not bend and deform, and therefore short circuit phenomenon of anode and cathode plates is prevented; and compared with the conventional lead-based alloy anode plate, the conductivity of the fence type anode plate is obviously improved, the tank voltage is reduced by 10%, the material cost is reduced by 20% and the current efficiency is increased by 2-5%.

Owner:KUNMING HENDERA SCI & TECH

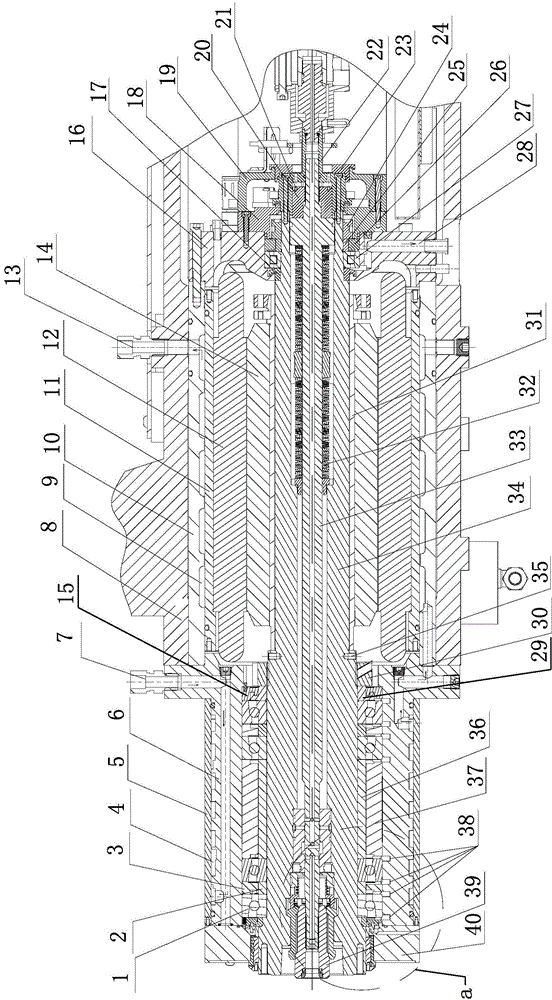

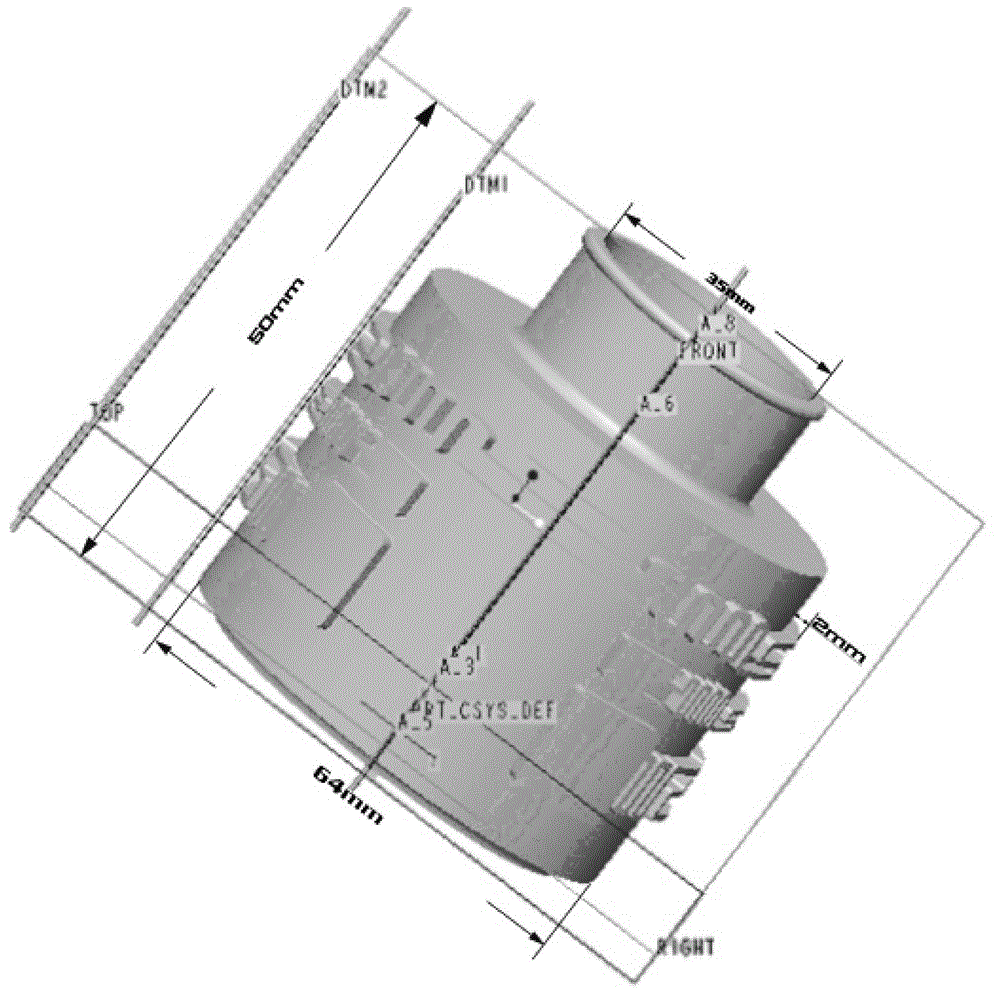

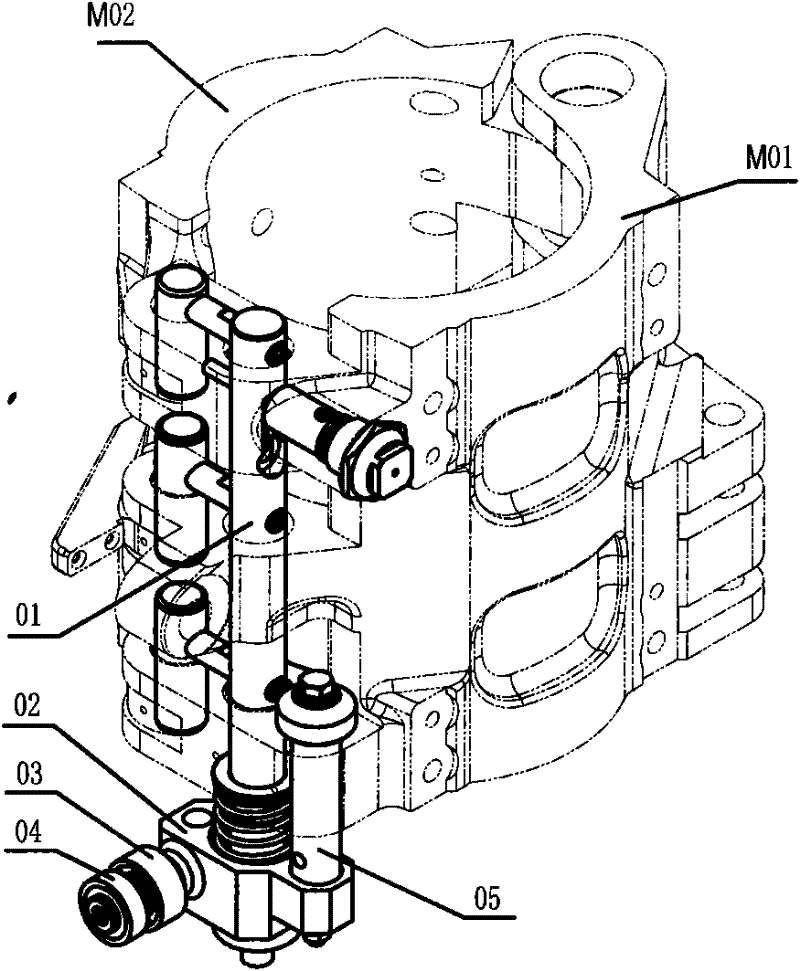

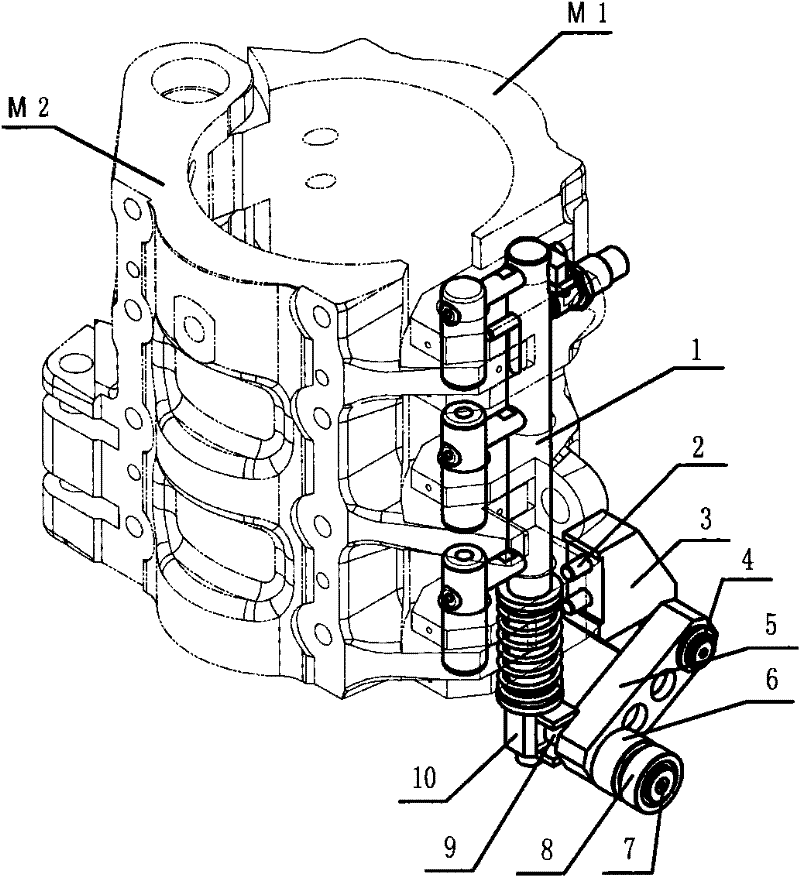

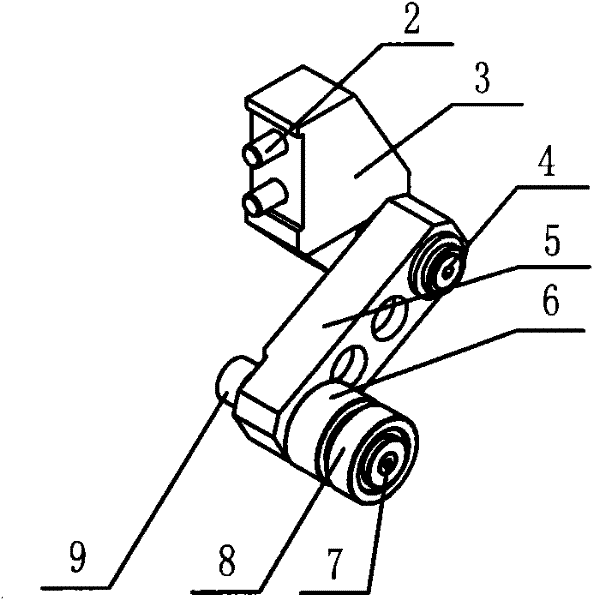

High speed spindle box structure

ActiveCN104889425ANo bending deformationGuaranteed rotation accuracyLarge fixed membersMaintainance and safety accessoriesBall bearingDynamic balance

The invention discloses a high speed spindle box structure, and belongs to the machine tool part device field. The high speed spindle box structure comprises a spindle box, a spindle device, a front bearing seat, a rear bearing seat, a spindle drive mechanism, a cooling system, a lubrication system and a dynamic balance regulating mechanism, wherein a spindle of the spindle device is supported by a front bearing component and a rear bearing component, and installed in a spindle hole in the spindle box, bearings of the front bearing component are two pairs of front ball bearings and rear ball bearings, which are arranged at a certain interval, bearings of the rear bearing component are roller bearings, the cooling system comprises a spindle cooling mechanism and a bearing cooling mechanism which respectively have functions of cooling the spindle and cooling the interiors of the bearings, and the lubrication system comprises a front bearing lubrication mechanism and a rear bearing lubrication mechanism, and respectively have functions of lubricating the front bearing component and lubricating the rear bearing component. The high speed spindle box structure solves the problems that an existing spindle box mechanism is poor in cooling effect, temperature of bearings of the existing spindle box mechanism easily rise, and then rotation speed and processing accuracy of the existing spindle box mechanism are influenced.

Owner:浙江日发精密机床有限公司

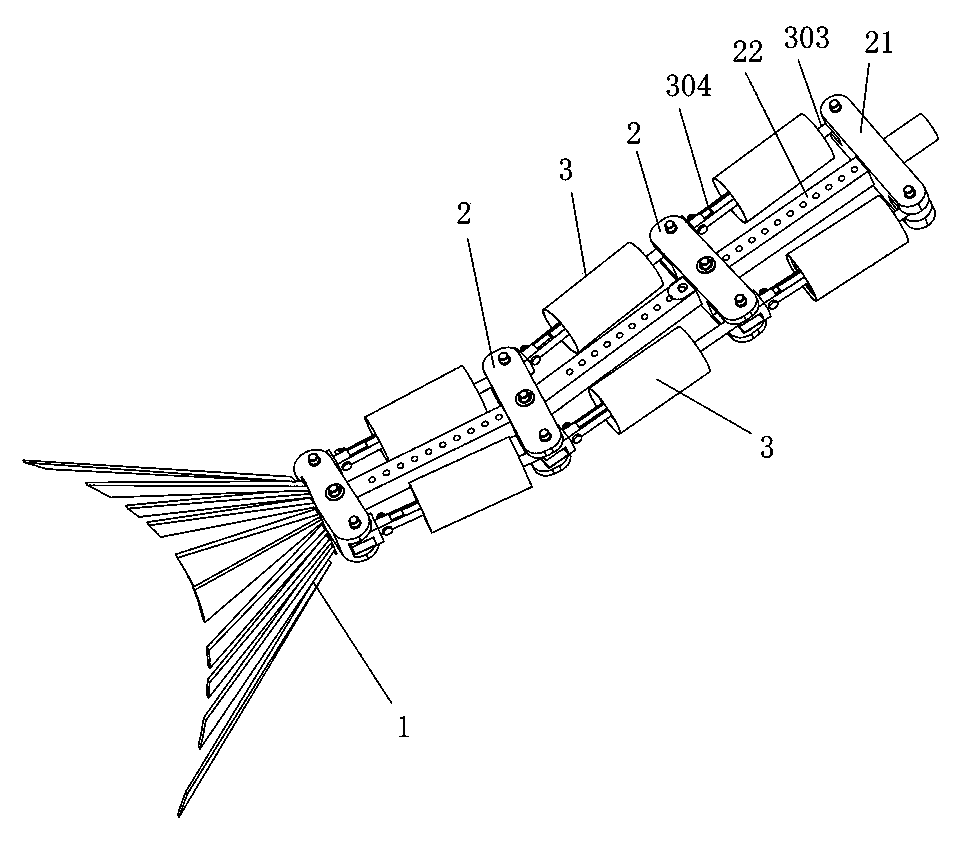

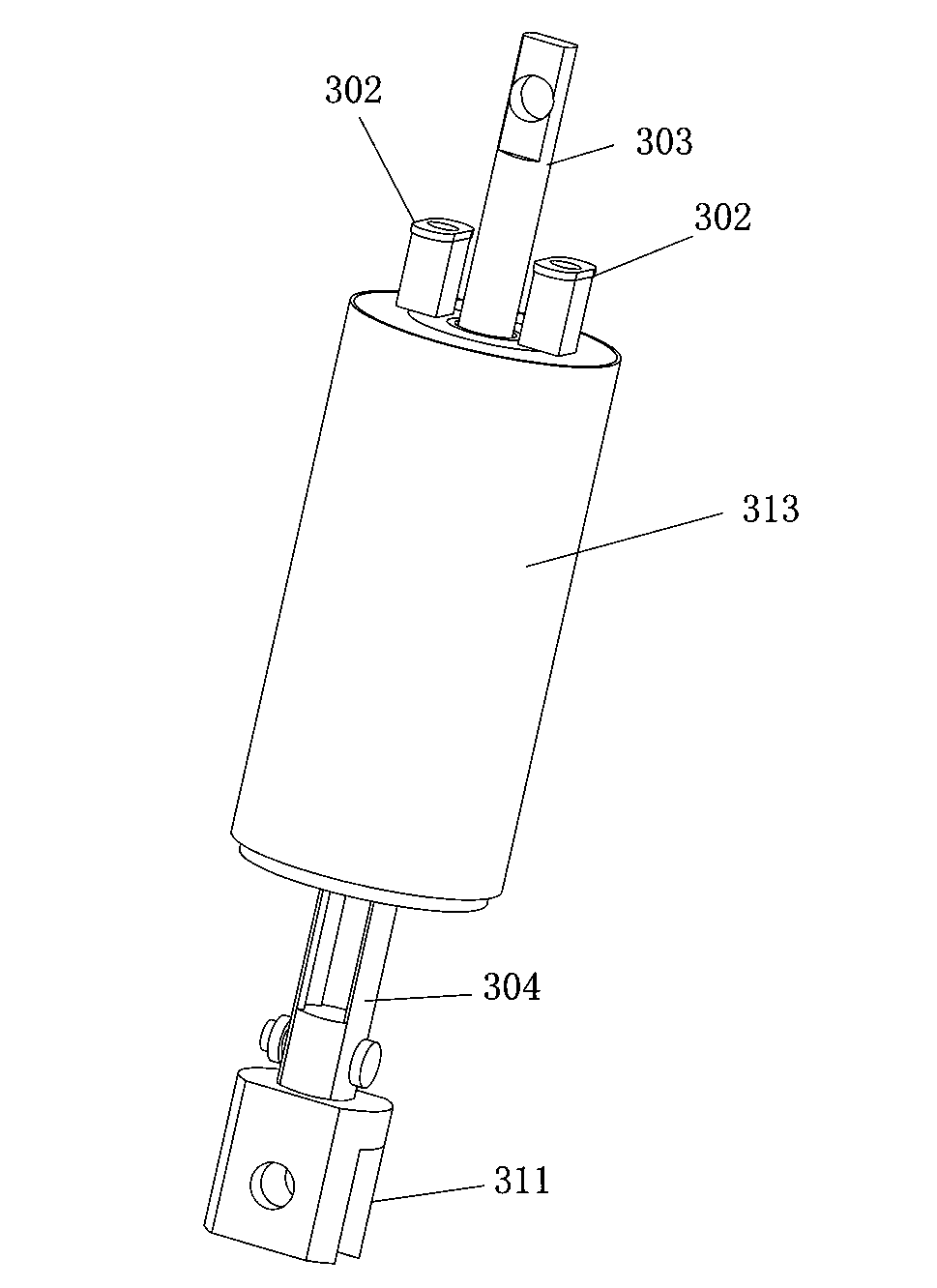

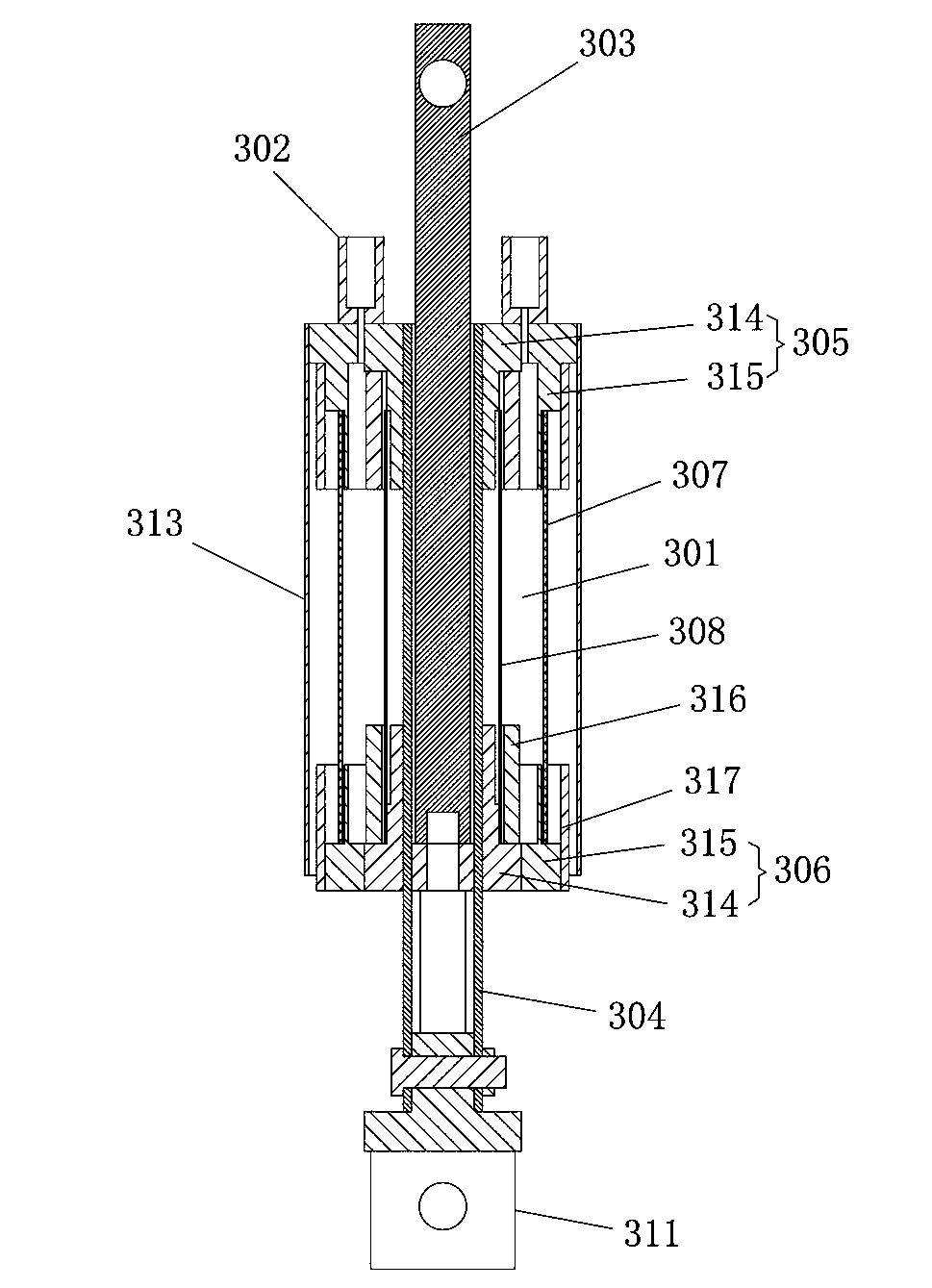

Bionic caudal fin underwater propeller based on hydraulic artificial muscles

ActiveCN103625625AImprove efficiencySimple controlPropulsive elements of non-rotary typePropellerHydraulic control unit

The invention discloses a bionic caudal fin underwater propeller based on hydraulic artificial muscles. The bionic caudal fin underwater propeller comprises more than two swinging devices, a caudal fin and a hydraulic control unit, wherein each swinging device comprises a T-shaped bracket and two artificial muscles which are symmetrically arranged on the T-shaped bracket; each artificial muscle comprises a telescopic assembly; each telescopic assembly is provided with an elastic hydraulic cavity and a connector which is connected with the elastic hydraulic cavity and the hydraulic control unit, and can linearly stretch and shrink through the liquid filling and drainage of the elastic hydraulic cavity; the T-shaped brackets of all the swinging devices are hinged end to end in sequence; one end of each telescopic assembly is hinged to the corresponding T-shaped bracket, and the other end of each telescopic assembly is hinged to the T-shaped bracket of the next swinging device; when one of the artificial muscles of each swinging device is in a stretching state in the same movement period, the other artificial muscle is in a shrinkage state, and the caudal fin is connected with the last swinging device. The bionic caudal fin underwater propeller has the advantages of simple structure, low cost, high efficiency, easiness in modeling and control, and the like.

Owner:NAT UNIV OF DEFENSE TECH

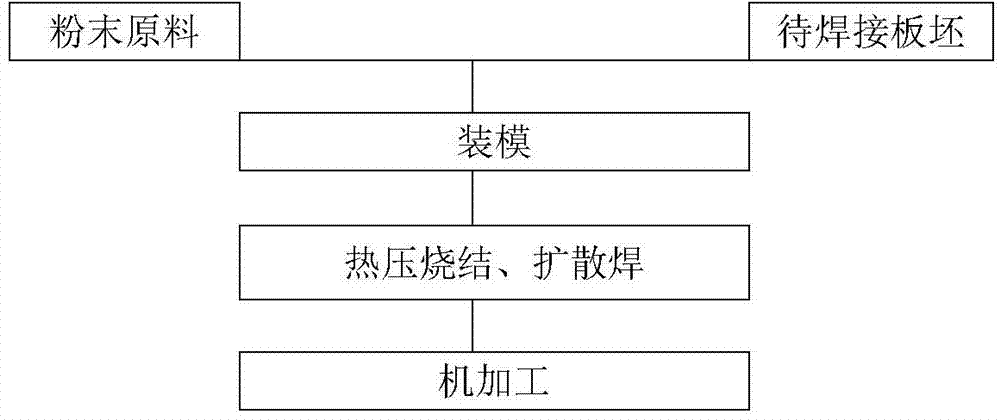

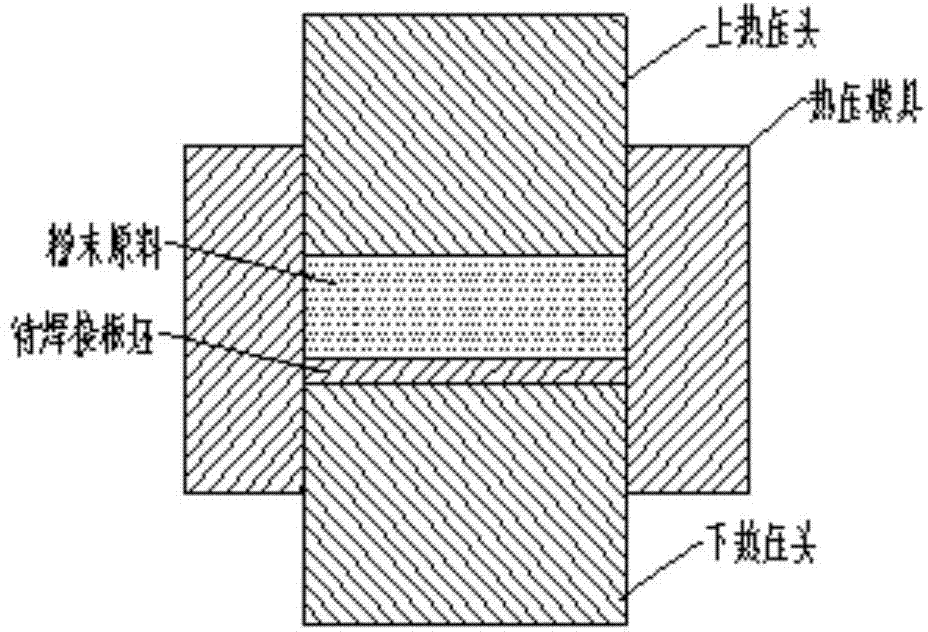

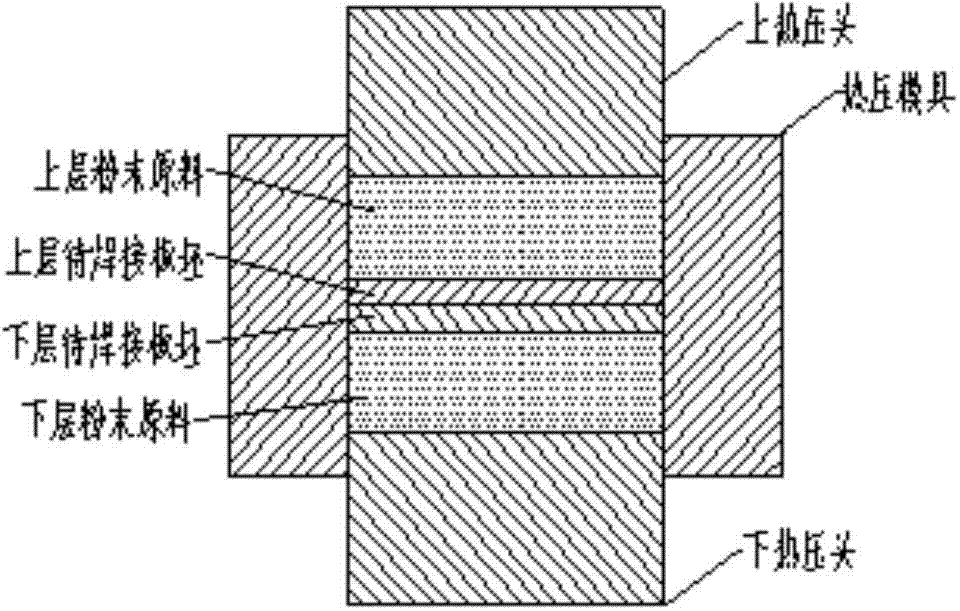

Diffusion welding method for W-Ti alloy target assembly

InactiveCN104708192AAdvantages of Diffusion Welding MethodImprove welding rateVacuum evaporation coatingSputtering coatingAlloyFilm-coated tablet

A method for diffusion welding a W-Ti alloy target material assembly for film coating, the method comprising: placing powdered raw material of W-Ti alloy target material and corresponding plate blank material to be welded and composited into a hot press mold and then into a hot press sintering furnace; synchronously conducting hot press sintering molding on the target blank and conducting diffusion welding on the target blank and plate blank to obtain a welded composite W-Ti alloy target material assembly; or utilizing the plate blank as a back plate or a transition layer to obtain the W-Ti alloy target material assembly or a composite three-layer structure of W-Ti alloy target material / transition layer / back plate. The method realizes synchronization between target blank hot press sintering molding and hot press diffusion welding of target blank and plate blank, with a welding tensile strength of greater than 50 MPa.

Owner:GRIKIN ADVANCED MATERIALS

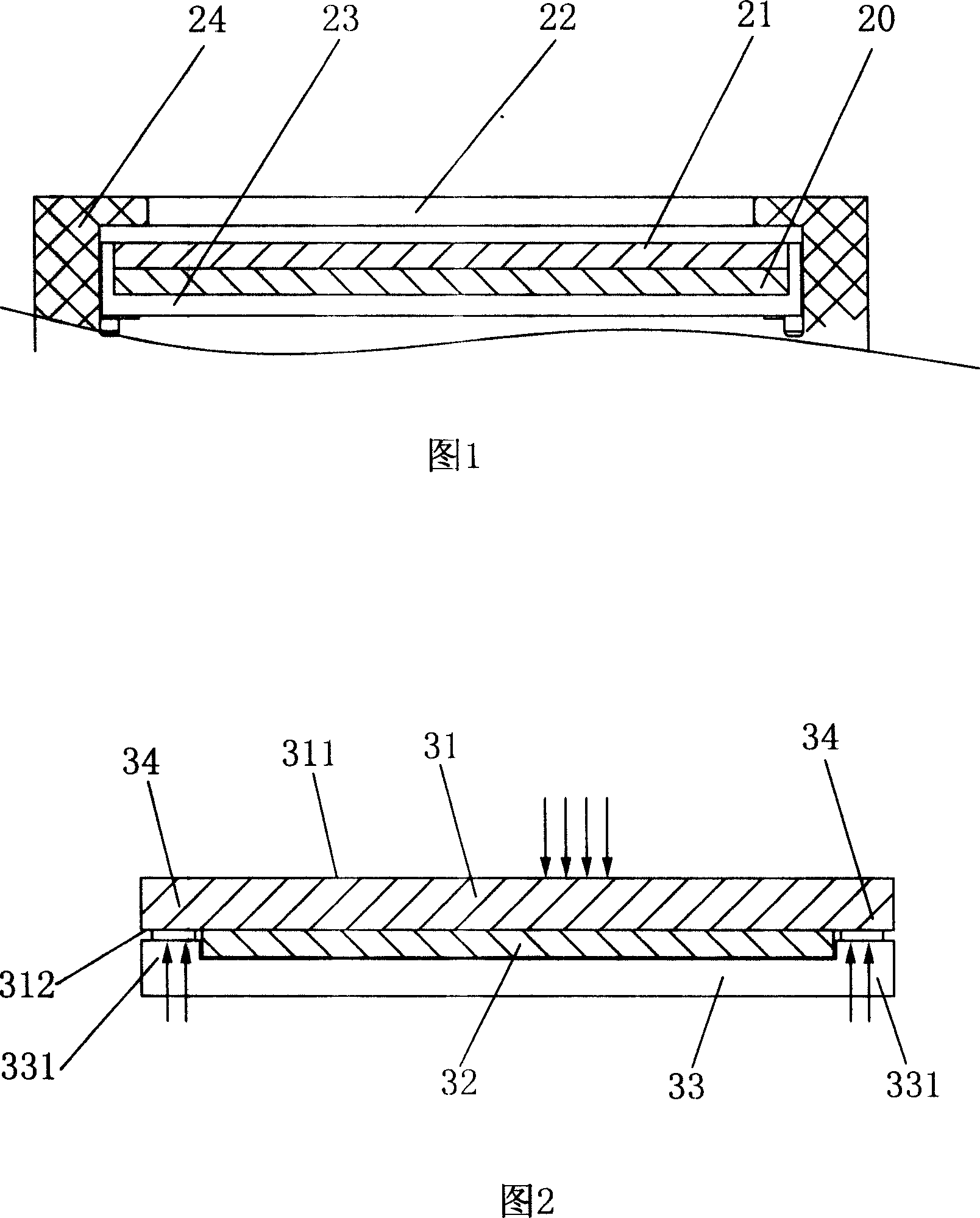

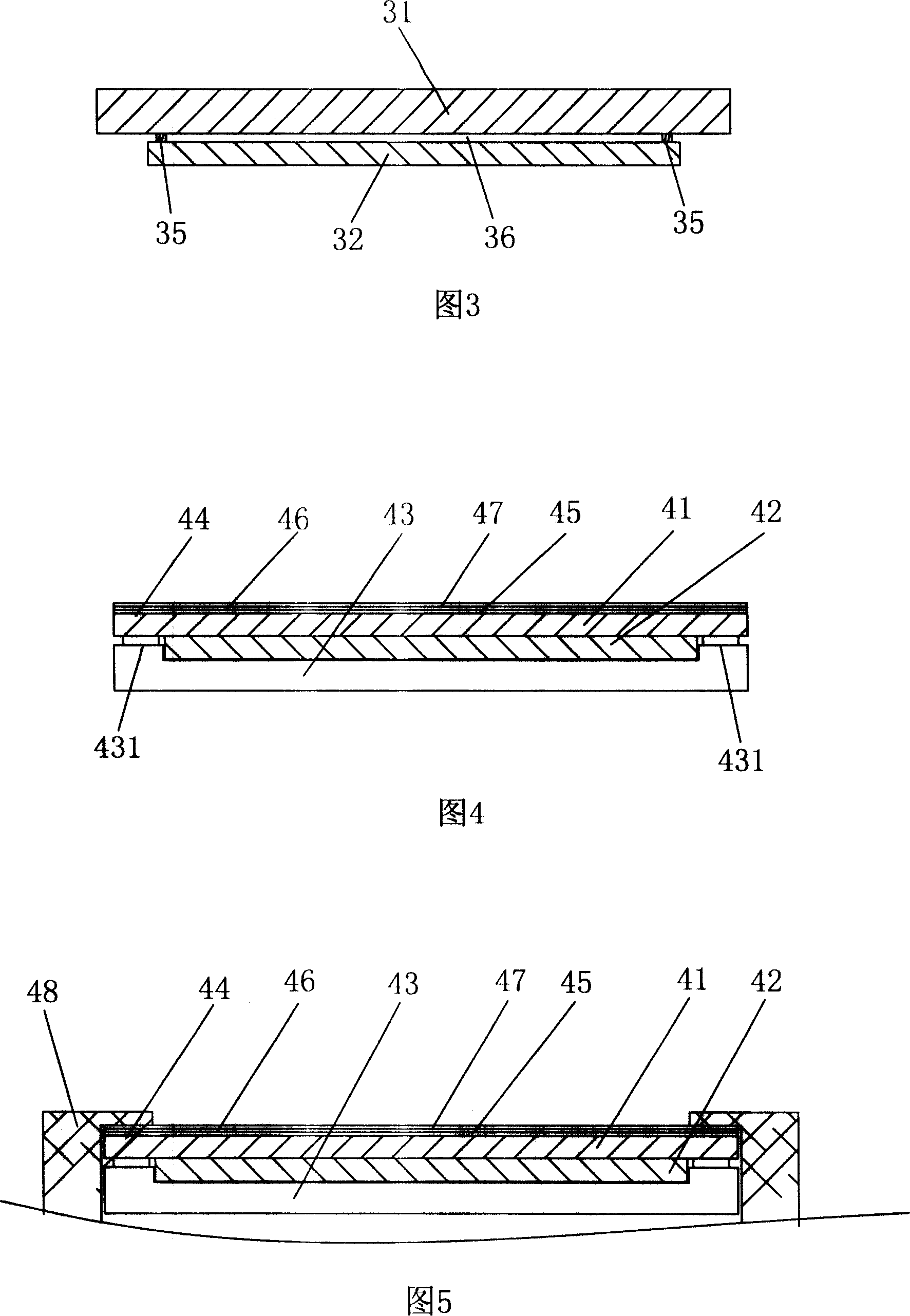

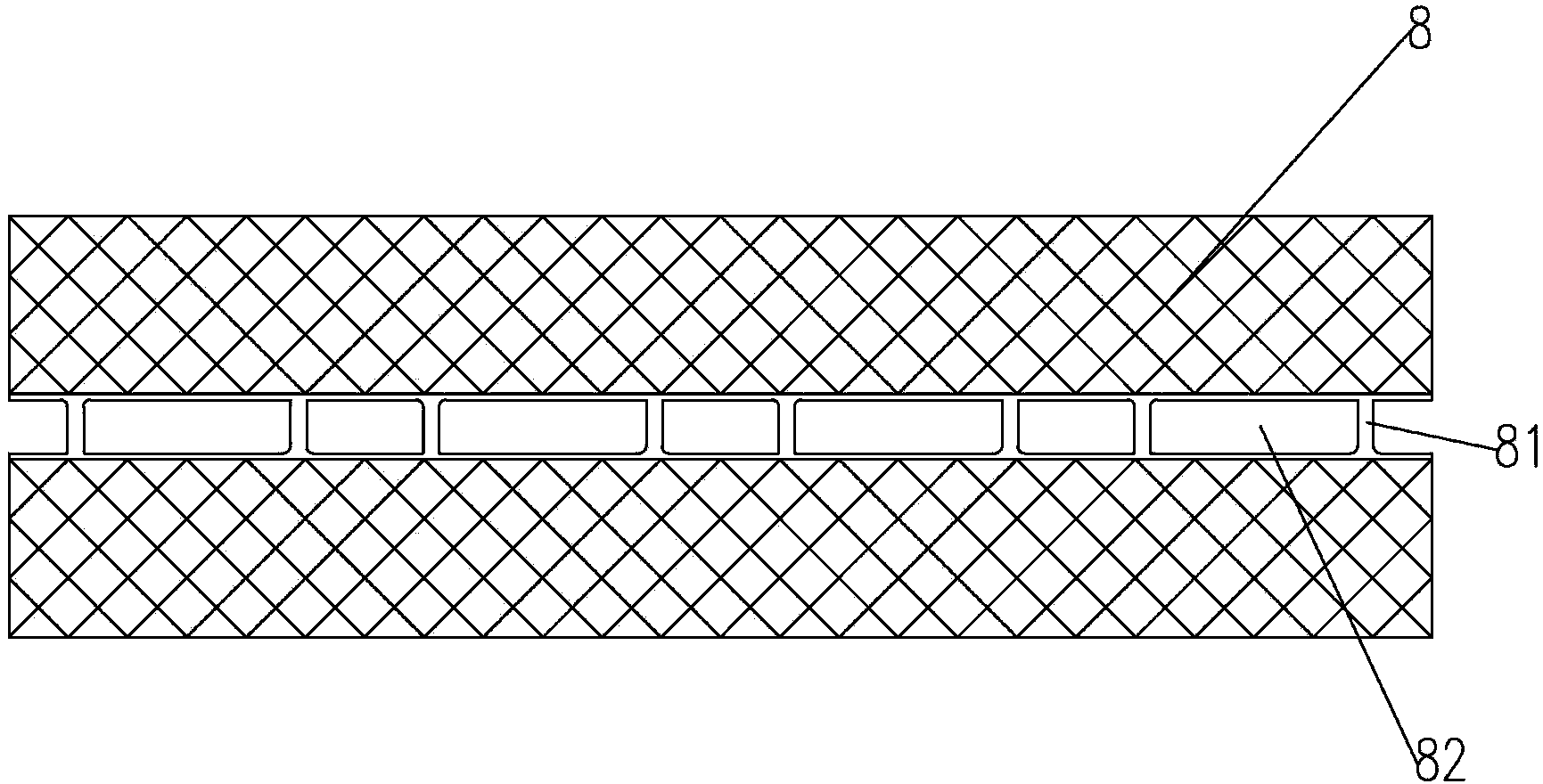

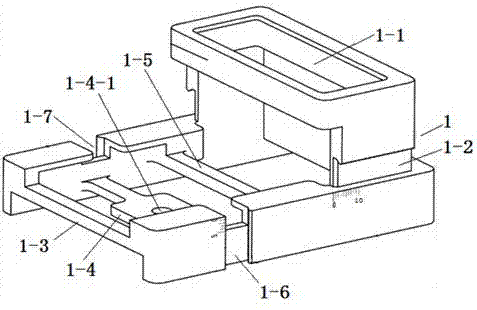

Liquid crystal box and liquid crystal display module group with liquid crystal box

The invention discloses a liquid display module which includes liquid box and negative module, the liquid box includes the first glass base board, the second glass base board and framework glue set between the first and second glass base board, in direction of width, two ends of the first glass base board extend the second glass base board, the glue framework of the negative module possesses supporting part for extending part of the first glass base board, the lower surface of the extended part of the first glass base board is pressed to the supporting part. The liquid box and negative module are packaged together and mounted on shell of electric equipment, when the first glass base board is forced, the force is supported by glue framework of negative module, force supported by the framework can be decreased greatly, and affect of liquid layer thickness can be decreased, at the same time because current protection glass is not needed, so weight and thickness of electric equipment is easy to be reduced.

Owner:深圳市合力泰光电有限公司

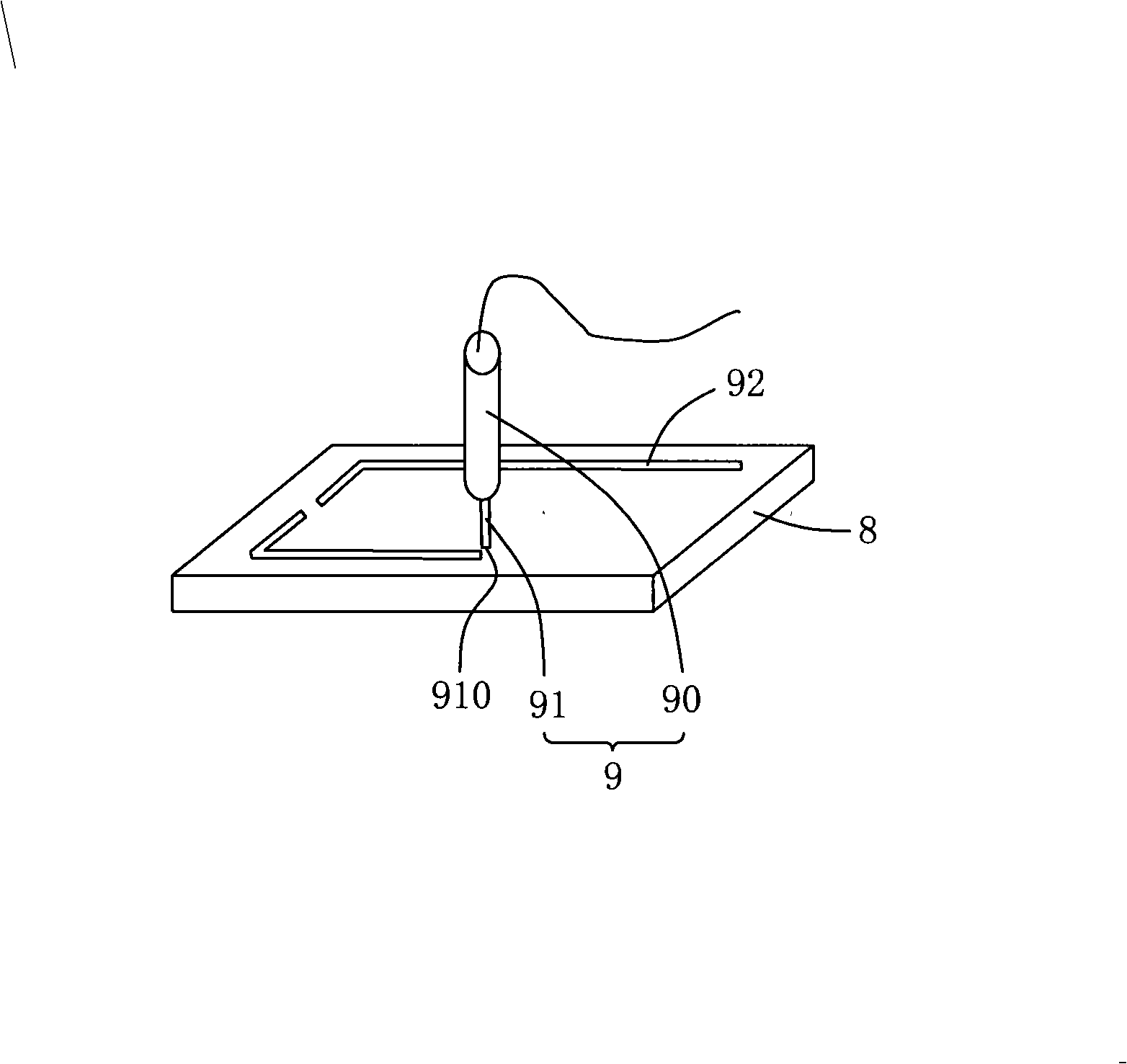

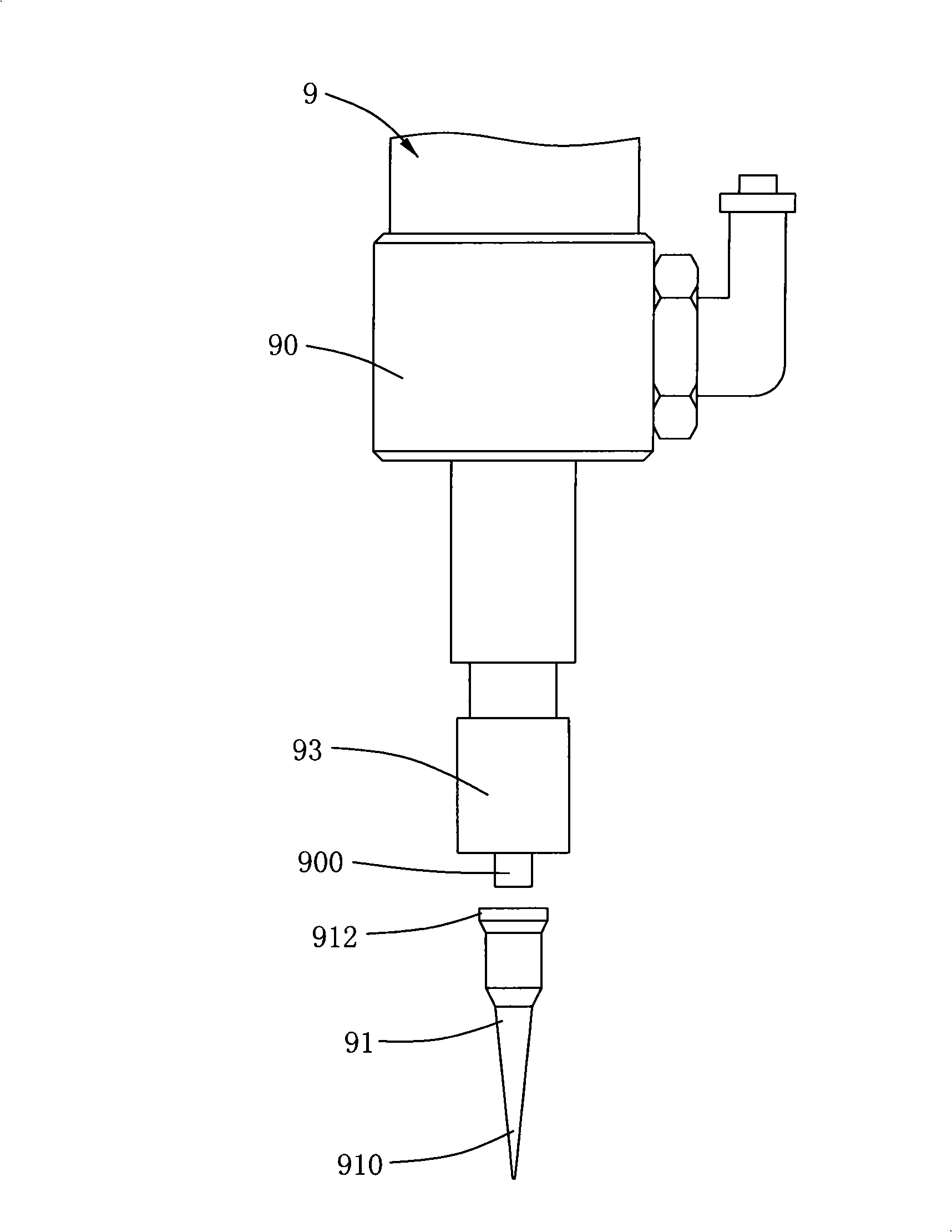

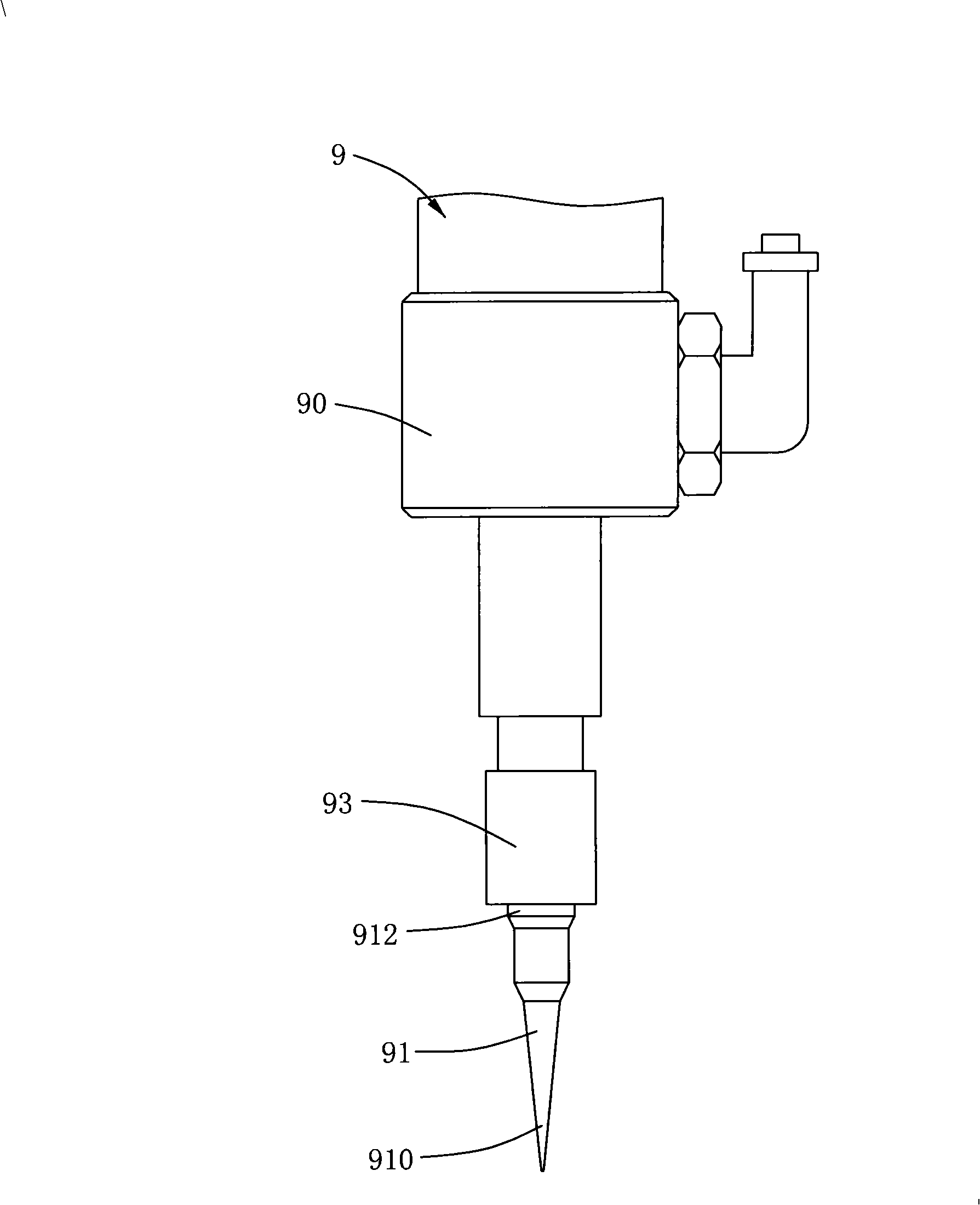

Glue spreading apparatus, using and maintaining method for the glue spreading apparatus

InactiveCN101318169AHigh strengthNo bending deformationLiquid surface applicatorsSpraying apparatusConical tubeMechanical engineering

The invention discloses a rubberizing device, comprising a base, a pin base, a rubberizing pin on the pin base, a fixing mechanism and a pin protecting mechanism. In an embodiment of the invention, the fixing mechanism comprises a slide block and a clamp; wherein the slide block can be arranged on a guide rail of the base in a sliding way, and drives the pin base and the rubberizing pin to lift up and down to adjust the distance between the fixing mechanism and the pin protecting mechanism; the clamp is connected with the slide block to clamp the pin base. The pin protecting mechanism comprises a conical tube; the conical tube can be separately sheathed on the outside of the rubberizing pin. During the use and maintenance of the rubberizing device, when the distance between the fixing mechanism and the pin protecting mechanism is increased, the rubberizing pin can be moved out of the pin protecting mechanism thus realizing quick replacement and improving the operation efficiency.

Owner:AU OPTRONICS (XIAMEN) CORP +1

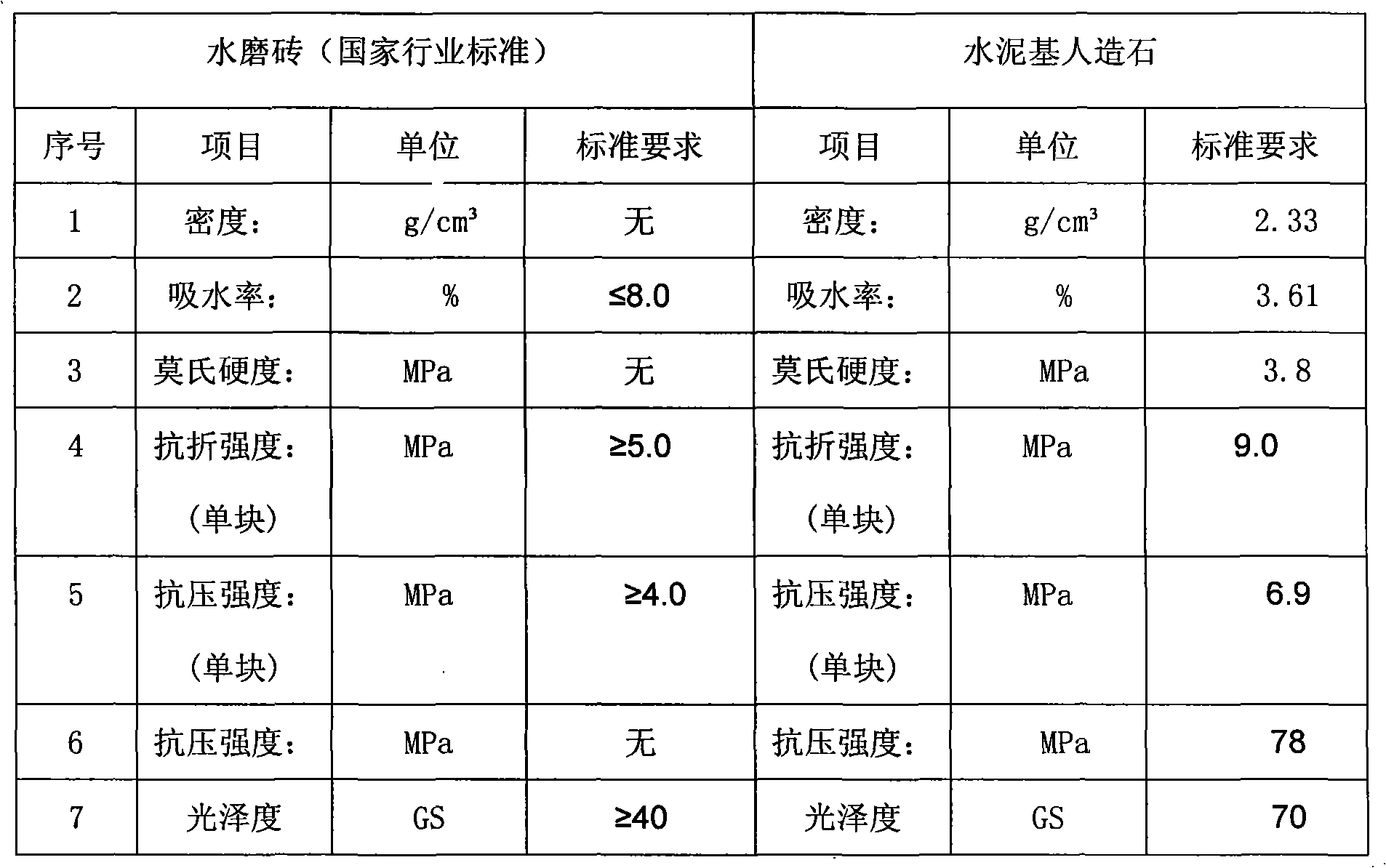

Cement-based artificial stone and production process thereof

The invention discloses a cement-based artificial stone and a production process thereof. The process comprises the following steps of: mixing cement and road metal with particle size of 0 to 15mm in a mass ratio of 1:1.5-2.5, adding an SM high-efficiency water reducing agent, namely SM1013P high-efficiency active powder in an amount which is 0.3 to 0.5 percent of the mass of the cement, and a brightening agent in an amount which is 0.3 to 0.5 percent of the mass of the cement, uniformly mixing to form an initial mixture; adding water in an amount which is 5 to 15 percent of the mass of the initial mixture and uniformly stirring to form a mixture; and injecting the mixture into a casting mold for pressure casting, vibrating under the conditions of vacuum and high pressure of 8.17*10<6> to 14.97*10<6>Pa, briquetting and curing with water to obtain the cement-based artificial stone. The cement-based artificial stone has the advantages of uniform patterns and colors, no deformation, fastness, skid resistance, wear resistance, rich third dimension, high level, elegant appearance, capability of manufacturing varieties with various colors and unequal large and small aggregates, simple curing (mopped by a wet mop for one time every day), and suitability to be paved on the indoor and outdoor ground and the ground of subway stations, market squares and the like.

Owner:云浮市泰利环保石材有限公司

Preparation method for antistatic UV (Ultraviolet) coating and film forming method of same

ActiveCN104263229AAntistatic performance is better thanEliminate pollution problemsPolyurea/polyurethane coatingsPrepolymerPhotoinitiator

The invention relates to a preparation method for an antistatic UV (Ultraviolet) coating and a film forming method of the same, wherein the preparation method for the antistatic UV coating comprises the following steps: firstly, adding an ether solvent into a polythiophene macro-molecular solution; after stirring for dispersing at a high speed, mixing with a UV prepolymer, an active diluent and a photoinitiator and stirring at a high speed till the mixture is uniformly dispersed; and finally adding a solvent. The film forming method of the antistatic UV coating comprises the following steps: coating an antistatic UV curing coating on a plastic thin film, and adopting a low-temperature vacuum drying or cooling, blowing and drying method to obtain a film which is 2-5 mu m thick; and then, firstly, curing for 2 seconds to 1 minute under the condition that the photocuring energy is 100-200mJ / cm<2> and then curing for 2 seconds to 1 minute under the condition that the photocuring energy is 600-1000mJ / cm<2>. The antistatic UV coating provided by the invention is good in stability and the prepared antistatic film further has the advantages of good antistatic property, high hardness, strong scratch resistance and the like.

Owner:GUANGZHOU SHENWEI NEW MATERIAL TECH

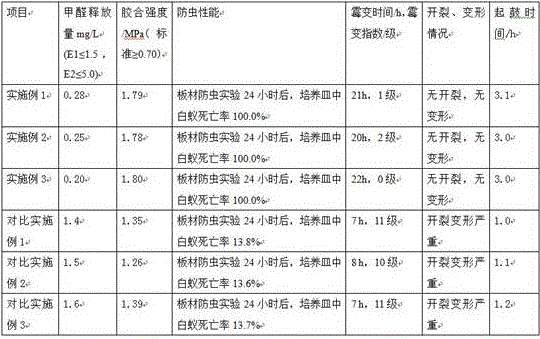

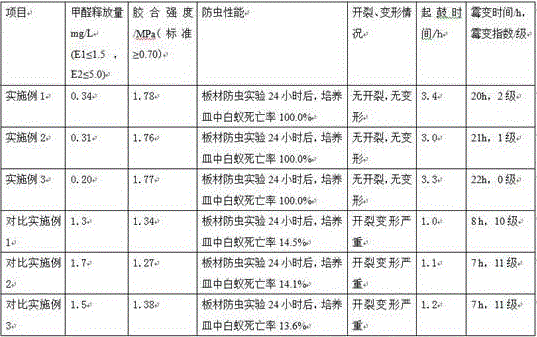

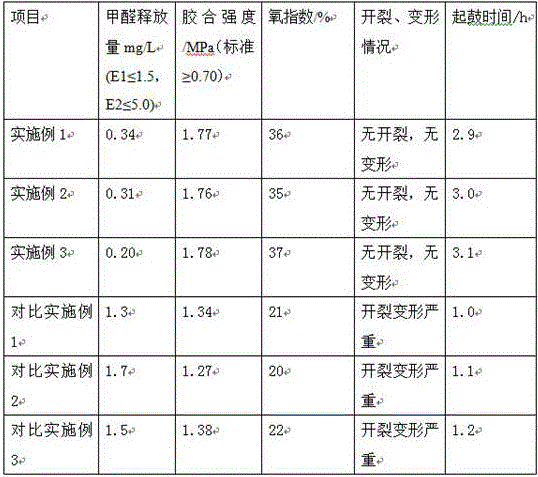

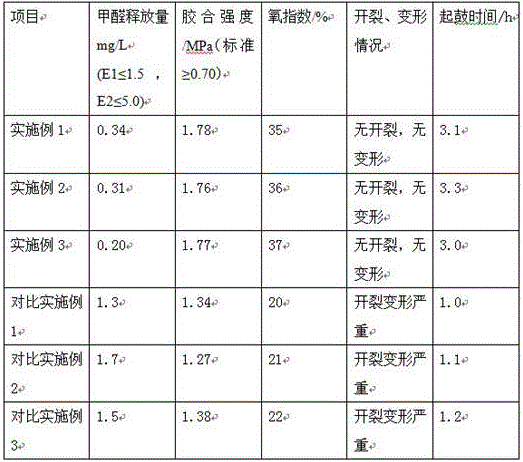

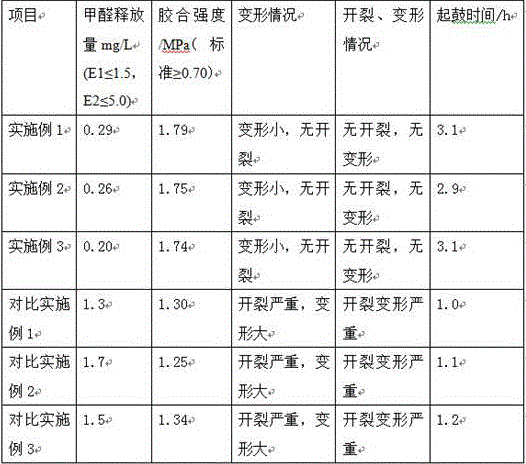

Method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin

ActiveCN106182218AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesStarch derivtive adhesivesAntioxidantAdditive ingredient

The invention discloses a method for producing eucalyptus wood plywood by adopting insect-proof and mildew-proof composite urea formaldehyde resin. The method comprises the following steps of: wood slab rotating, veneer drying, gluing, tertiary cold-pressing, standing and maintaining, tertiary hot-pressing, radiating and maintaining, and slab fixed-thickness sanding. The key point of the production method is that insect-proof and mildew-proof composite urea formaldehyde resin, which is prepared by taking melamine modified urea formaldehyde resin as an adhesive main ingredient, adding oxidized starch as a viscous complexing agent, taking polyvinyl alcohol as a flexibilizer, taking hydrogenated rosin as an antioxidant, taking polyisocyanate as a curing agent, taking triethoxyisobutylsilane as a bridging agent, taking phenolation lignin as a formaldehyde catching agent and adding an insect-proof and mildew-proof agent, is adopted. Solid wood composite floor produced by adopting the insect-proof and mildew-proof composite urea formaldehyde resin has the advantages of low formaldehyde residual amount and good insect-proof and mildew-proof effect, has relatively strong inhibiting effect on breeding of aspergillus, trichoderma and blue mould, and has instantaneous kill-down capacity and long-acting prevention effect on powder post beetles of wood slab.

Owner:广西横县正林木业有限公司

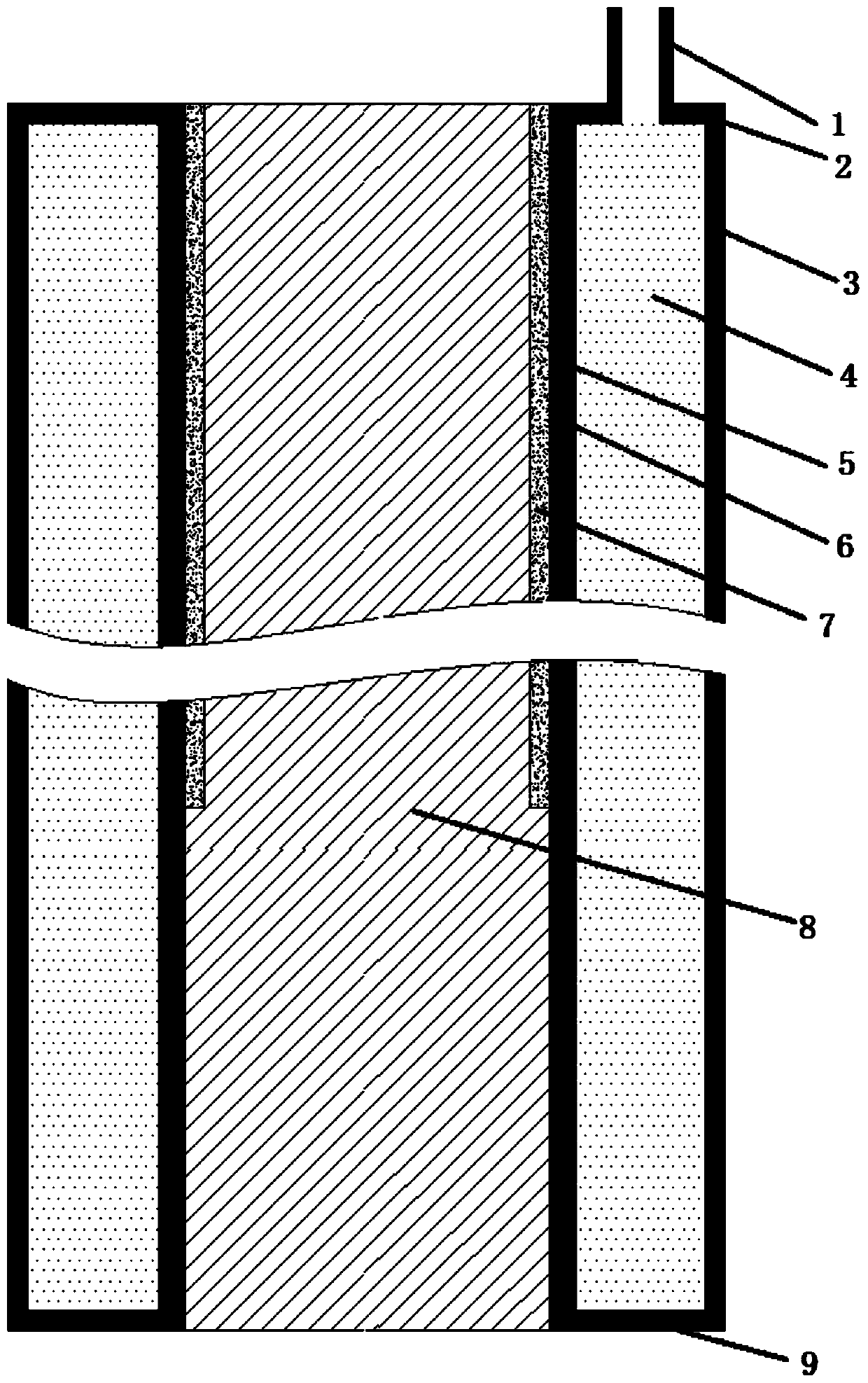

Method for producing cabinet board by adopting flame-retardant composite urea resin

InactiveCN106333530AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesBuilding materialUrea

The invention relates to home building materials, in particular to a method for producing a cabinet board by adopting flame-retardant composite urea resin. The cabinet board structurally comprises decorative paper, a cunninghamia lanceolata veneer, a shaving board and a back board from top to bottom, wherein the periphery of the cabinet board is edged with aluminium alloy; a flame-retardant composite urea resin adhesive is applied between the cunninghamia lanceolata veneer and the shaving board; a flame-retardant composite urea resin adhesive is applied between the shaving board and the back board; a flame-retardant composite urea resin adhesive is also adopted for the shaving board in the cabinet board. The cabinet board manufactured by the method has the advantages of strong water resistance, high bonding strength, low formaldehyde residue and a flame-retardant function. The shaving board in production of the cabinet board is made of waste materials and leftover materials which can not be utilized in the process of manufacturing a multilayered eucalyptus board after rotary cutting of eucalyptus boards, and the leftover materials are utilized, so that the woods can be saved and the production cost of an enterprise can be reduced.

Owner:广西横县正林木业有限公司

Printing plate and plate roller integrated flexible plate and 3D rapid molding printing type direct platemaking method and application

The invention provides a printing plate and plate roller integrated flexible plate and 3D rapid molding printing type direct platemaking method. The method comprises the following steps: designing a plate to be printed by utilizing a 3D printing plate making method by using three-dimensional software, and selecting a printing material; and spraying to obtain a printing plate material and images and texts on the printing plate material by using a 3D printing machine to obtain a printing plate and plate roller integrated flexible plate. According to the method, a printing plate and the images and texts in a 3D design image are designed into cylindrical shapes; mounting steps are omitted and troubles and labor are not wasted; the operability and the safety are improved; the bending deformation caused by installation does not occur, and the accuracy and the working efficiency are improved; meanwhile, a compensation step of pre-printing deformation amount is omitted; the antenna images and texts cover the printing plate so that the images and texts, and the printing plate are integrated, and the printing plate and a roller are integrated; the content of the images and texts on the printing plate is determined, and the image and text copying accuracy is improved; and the method can be used for creating a new chapter of a printing plate and plate roller integrated flexible plate platemaking technology, and fills up the national blank.

Owner:TIANJIN HAISHUN PRINTING & PACKAGING

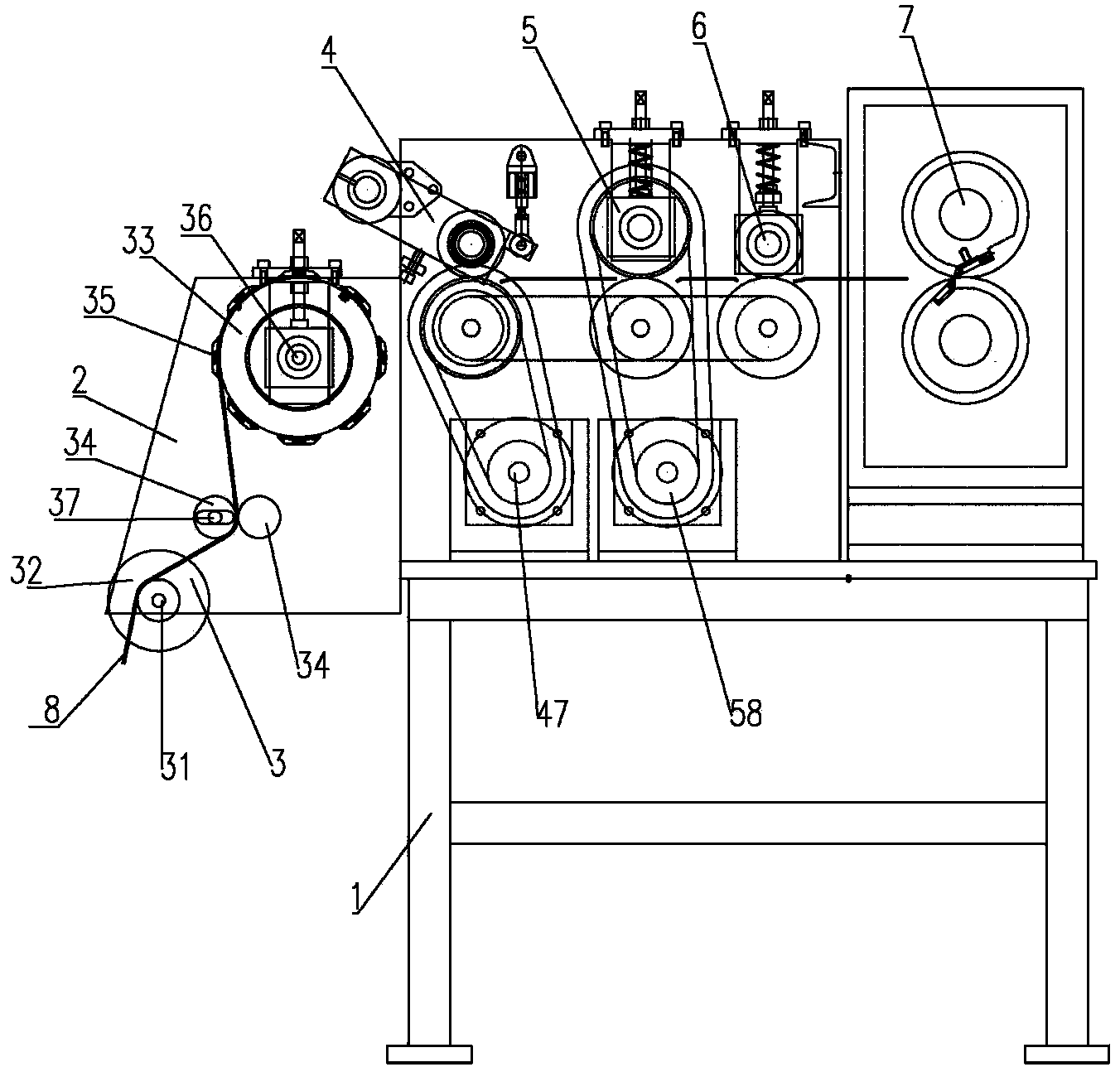

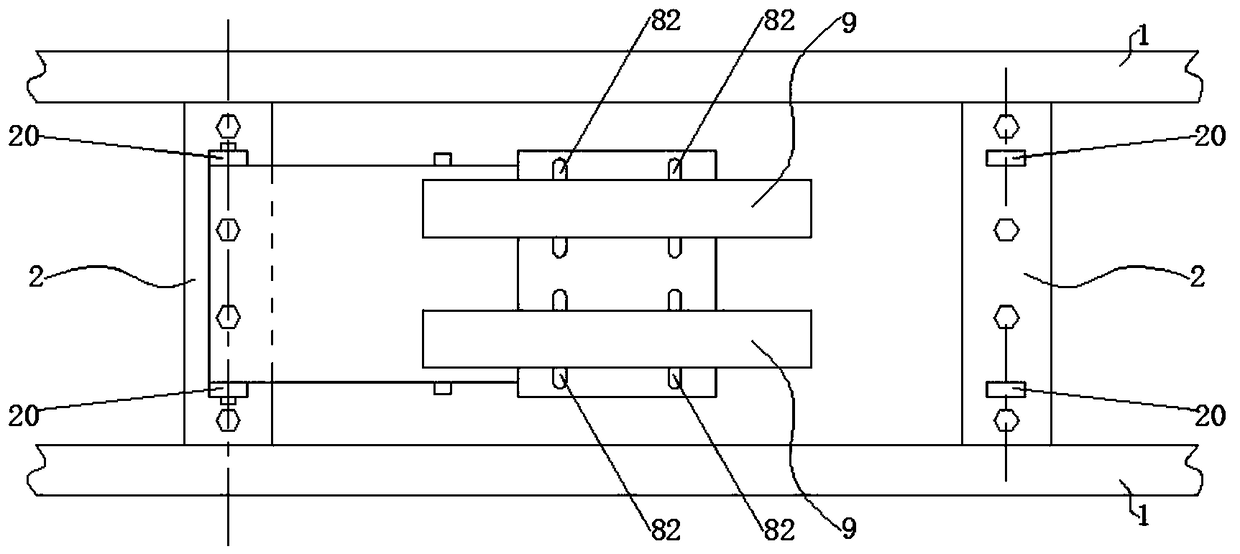

Continuous polar plate slitter machine and use method thereof

ActiveCN103962625AGuaranteed qualityGuaranteed cutting accuracyShearing machinesShearing control devicesMechanical engineeringAcceleration Unit

The invention discloses a continuous polar plate slitter machine which comprises a machine base, two machine frames, a material guide mechanism, a front conveying roller mechanism, a speed measuring device, a detection switch device, a longitudinal cutting mechanism, a rear conveying roller mechanism, a transverse cutting mechanism and a servo system, wherein the two machine frames are fixed to opposite sides of the machine base respectively, the material guide mechanism, the front conveying roller mechanism, the speed measuring device, the detection switch device, the longitudinal cutting mechanism, the rear conveying roller mechanism and the transverse cutting mechanism are sequentially arranged between the two machine frames, and the servo system is connected with the longitudinal cutting mechanism and the transverse cutting mechanism and is used for controlling the longitudinal cutting mechanism and the transverse cutting mechanism. The speed measuring device and the detection switch device feed back detected speed and lug position signals to the servo system. The servo system carries out compensation operation on the detected signals and preset parameters through a servo controller, and adjusts a slitter variable acceleration curve for compensation and modification. The invention further discloses a use method of the continuous polar plate slitter machine. The servo controller outputs corresponding execution instructions by changing input parameters, a slitter mechanism executes the variable acceleration curve and carries out compensation and modification according to the instructions, and accordingly the situation that continuous polar plates of different specifications are automatically switched for splitting is achieved.

Owner:SHENZHEN CENT POWER TECH

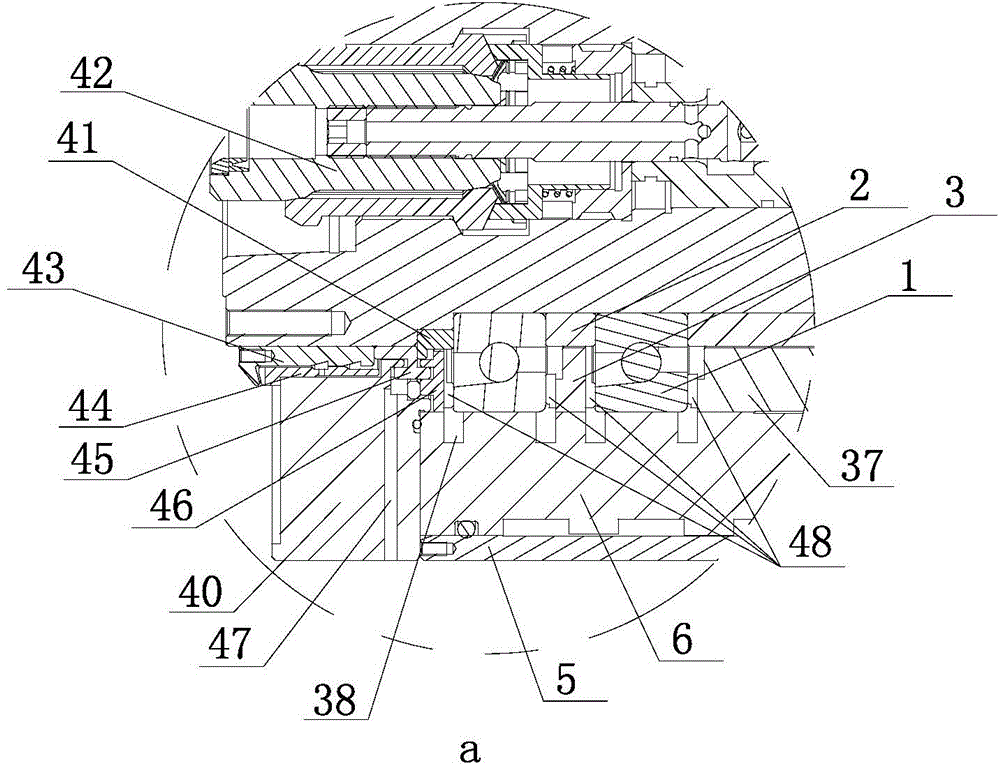

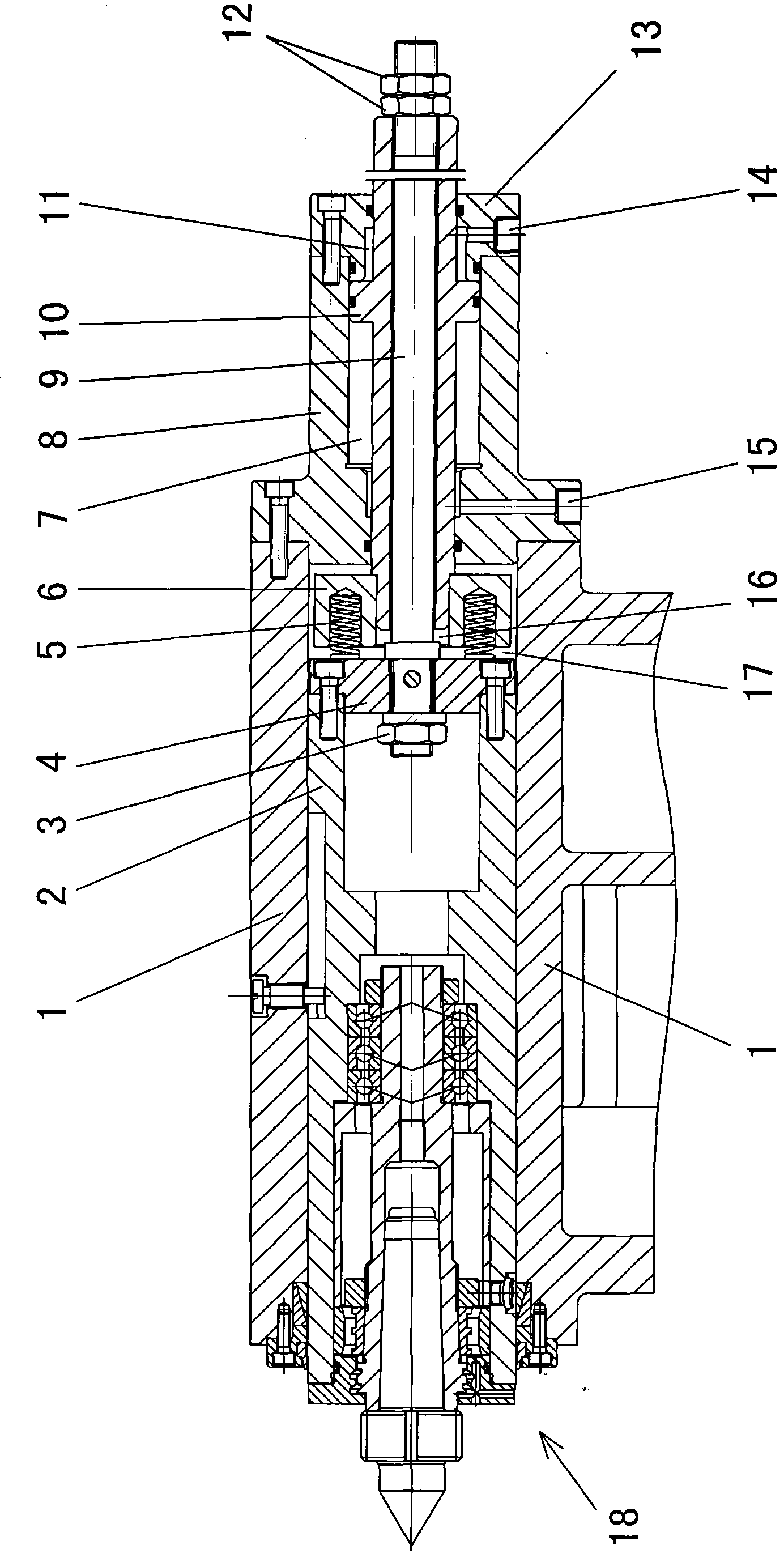

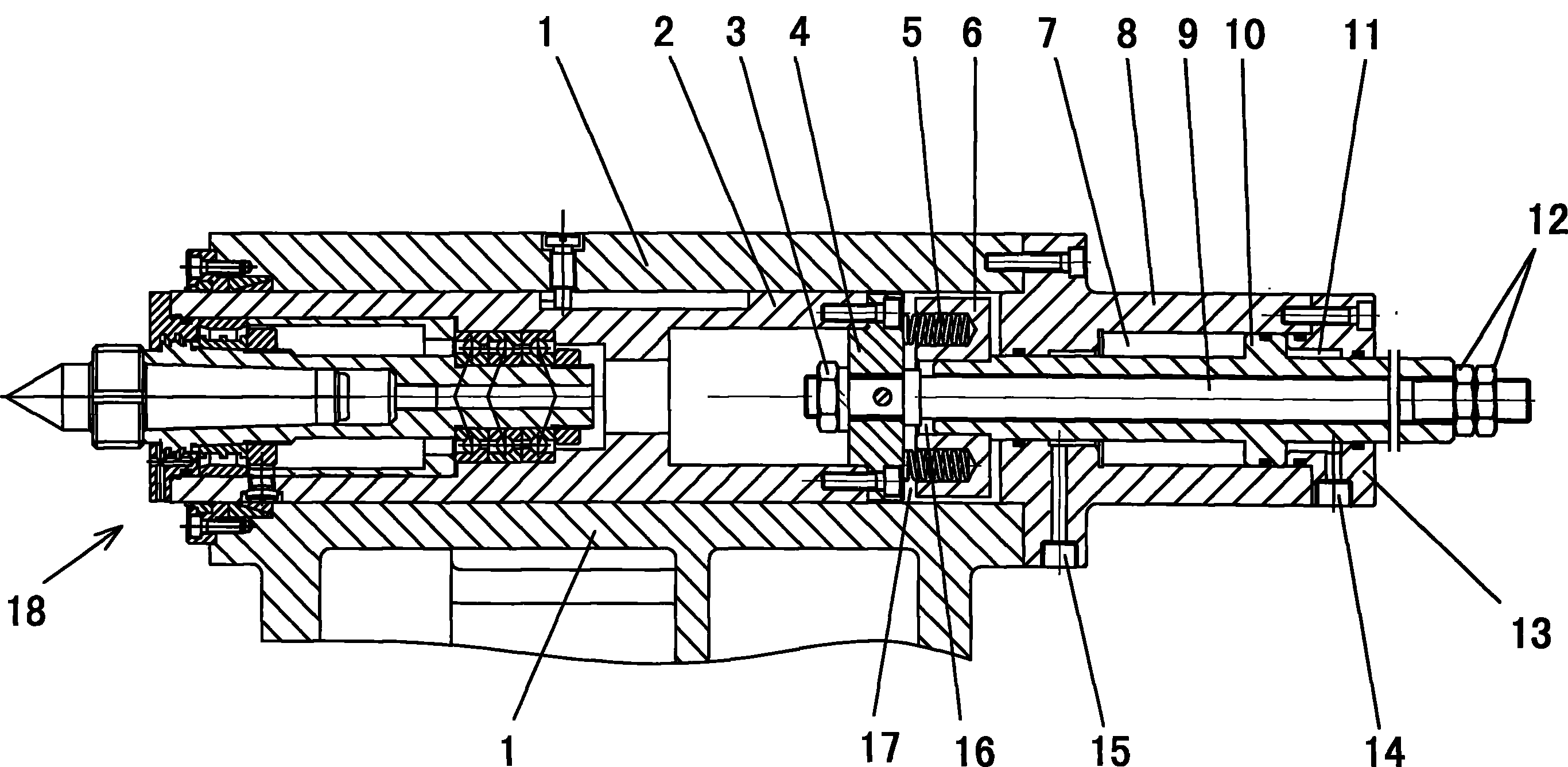

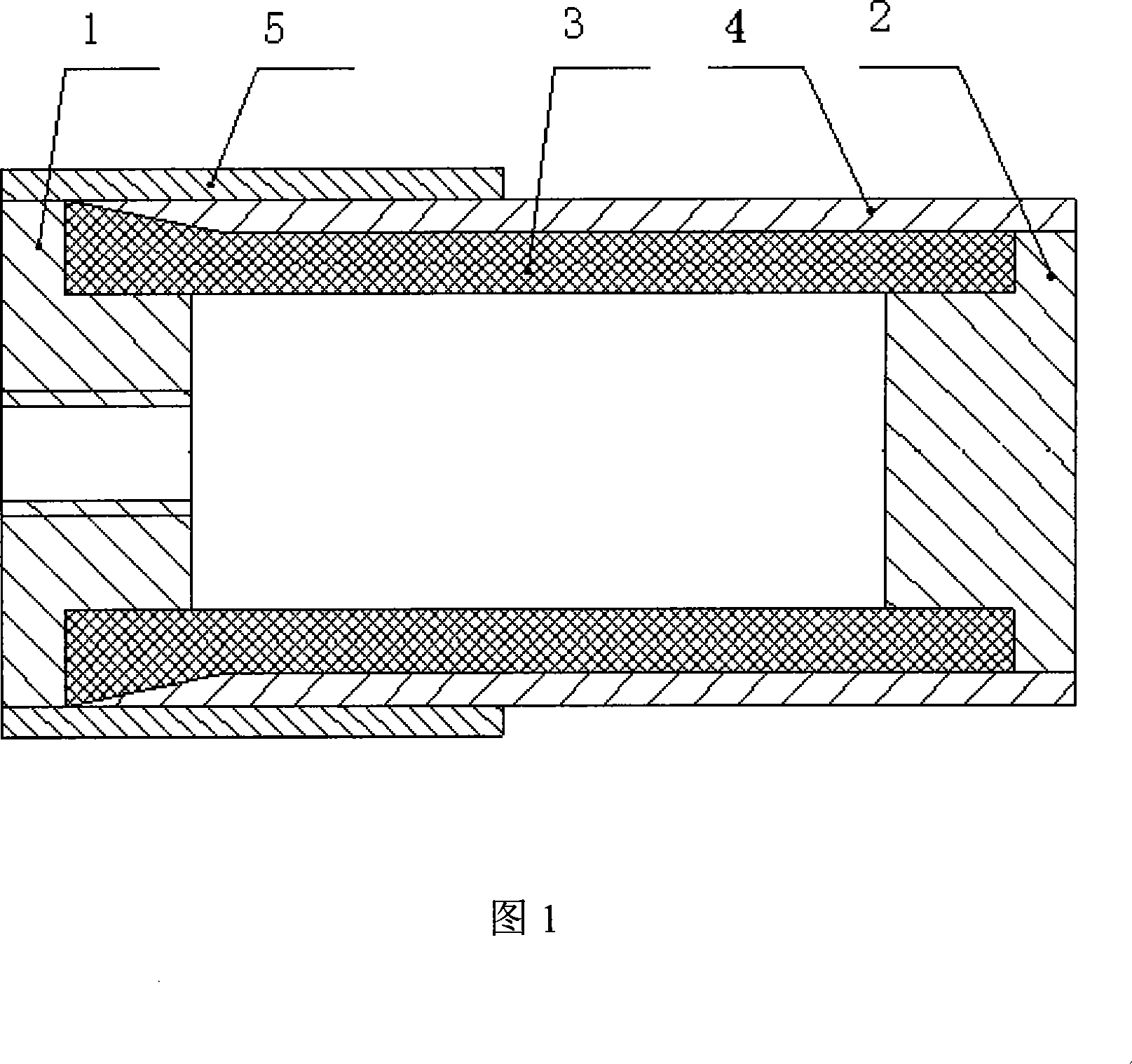

Spring pre-tightening type hydraulic floating tailstock

InactiveCN102019440AEliminate deformation and bendingNo bending deformationTailstocks/centresTailstockDistortion

The present invention provides a spring pre-tightening type hydraulic floating tailstock which comprises: a tailstock body with a sleeve disposed inside, a core clamper mechanism mounted on the front of the sleeve inner side, an oil cylinder connected on the rear end of the tailstock body, a rear cover fixedly connected with the tailstock inner side at the rear end of the sleeve, a piston with a center aperture, and a pull bar disposed in the center aperture. The front end of the pull bar is fixedly connected with the rear cover; the front end of the piston is protruded through the oil cylinder to the outside and is suited with a spring seat which lies on the step of the piston; between the spring seat and the bonnet, springs are provided and leaves spring seat gap; between the front end face of the piston and the boss of the pull bar, a piston gap is kept; the rear end of the pull bar is protruded through the center aperture of the piston and is in thread connection with double fastening nuts. The invention can prevent a heated workpiece from buckling distortion, therefore guarantees processing precision and raises workpiece quality.

Owner:大连机床(数控)股份有限公司

H-shaped steel production process

The invention discloses an H-shaped steel production process. The production process includes the following steps that (1) feeding is performed, specifically, coiled materials are put in an uncoiler through a feeding trolley; (2) material guiding is performed; (3) flattening is performed, specifically, strip steel is flattened and delivered to the next procedure through a clamping delivery flattening machine; (4) shearing and butt welding are performed, specifically, the tail of the former coil of strip steel and the head of the latter coil of strip steel are parallelly shorn firstly, and then the two sections of strip steel are welded together; (5) a loop material storage machine is provided; (6) clamping delivery is performed; (7) web S tackling is performed, specifically, the strip steel coming out of a clamping delivery device is rotated by 90 degrees from the horizontal position to form a vertical plate; (8) combined clamping delivery is performed; (9) welding fixing is performed, specifically, a welding fixing device is composed of a wing plate guiding device, a web upsetting device, a welding pressure device, a web limiting roller device and a bending correcting device; (10) welding is performed; (11) cooling is performed; (12) correcting is performed; (13) a pull-out rack is provided; and (14) flying sawing is performed. The H-shaped steel production process has the beneficial effects and advantages that the production efficiency is high, and the product quality is also high.

Owner:滁州南钢盛达实业有限公司

Method for producing whole eucalyptus parquet from anti-insect and anti-mildew composite urea-formaldehyde resin

ActiveCN106335120AReduce formaldehyde contentGood gluing propertiesOther plywood/veneer working apparatusNon-macromolecular adhesive additivesLacquerSurface layer

A method for producing whole eucalyptus parquet from anti-insect and anti-mildew composite urea-formaldehyde resin comprises steps as follows: rotary cutting of a board to form pieces; single plate drying; adhesive coating; three times of cold pressing; leaving to stand for reconditioning; three times of hot pressing; heat dissipation for reconditioning; fixed-thickness sanding of plate blanks; adhesive coating of base material surface layers; reconditioning and grooving; paint coating, drying and setting. The key of the production method is that melamine modified urea-formaldehyde resin is used as a main adhesive material; oxidized starch is added as a viscous compound; polyvinyl alcohol is added as a toughening agent; hydrogenated rosin is added as an anti-oxidant; polyisocyanate is added as a curing agent; isobutyltriethoxysilane is added as a bridging agent; phenolated lignin is added as a formaldehyde catching agent; an anti-insect and anti-mildew agent is added; anti-insect and anti-mildew composite urea-formaldehyde resin is prepared; and the parquet prepared from anti-insect and anti-mildew composite urea-formaldehyde resin has the advantages of being low in formaldehyde residual amount and good in anti-insect and anti-mildew effect, has the relatively high inhibition effect on breeding of Aspergillus, Trichoderma and Penicillium and has the instant killing force and the long-acting preventive effect on board powder-pest beetles.

Owner:广西横县正林木业有限公司

Striking device for elevating of mode locked shaft component

InactiveCN102205626AReduce weightReduce centrifugal forceBlowing machine gearingsHollow articlesEngineeringMoment of inertia

The invention discloses a striking device used for smoothly elevating of a mode locked shaft component on a full-automatic rotary type high speed bottle blowing machine. The shape of the device comprises a set of swing components capable of rotating around a swing arm shaft, and a prodding block which is controlled by the set of swing components as well as possesses a raceway on its side surface. A set of guiding shaft mechanism can be omitted after installing the device, so the weight of machine is reduced, rotational inertia and centrifugal force can be reduced as well as the interference effect generated by a dual-shaft movement can be avoided. Because a prodding wheel is rolled in the raceway of the prodding block, so that a reaction force from a mode locked guide rail can be eliminated, the bending deformation of the mode locked shaft can be avoided, the abrasive wear of the mode locked shaft can be mitigated as well as the service life of the mode locked shaft can be prolonged, the smooth elevating of the mode locked shaft component can be guaranteed, thereby a screwing type mold base enables a rapid opening or closing, a more smooth opening or closing of the mold base can be ensured, and the present invention establishes a powerful foundation for development of high speed operation of the full-automatic rotary type bottle blowing machine.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

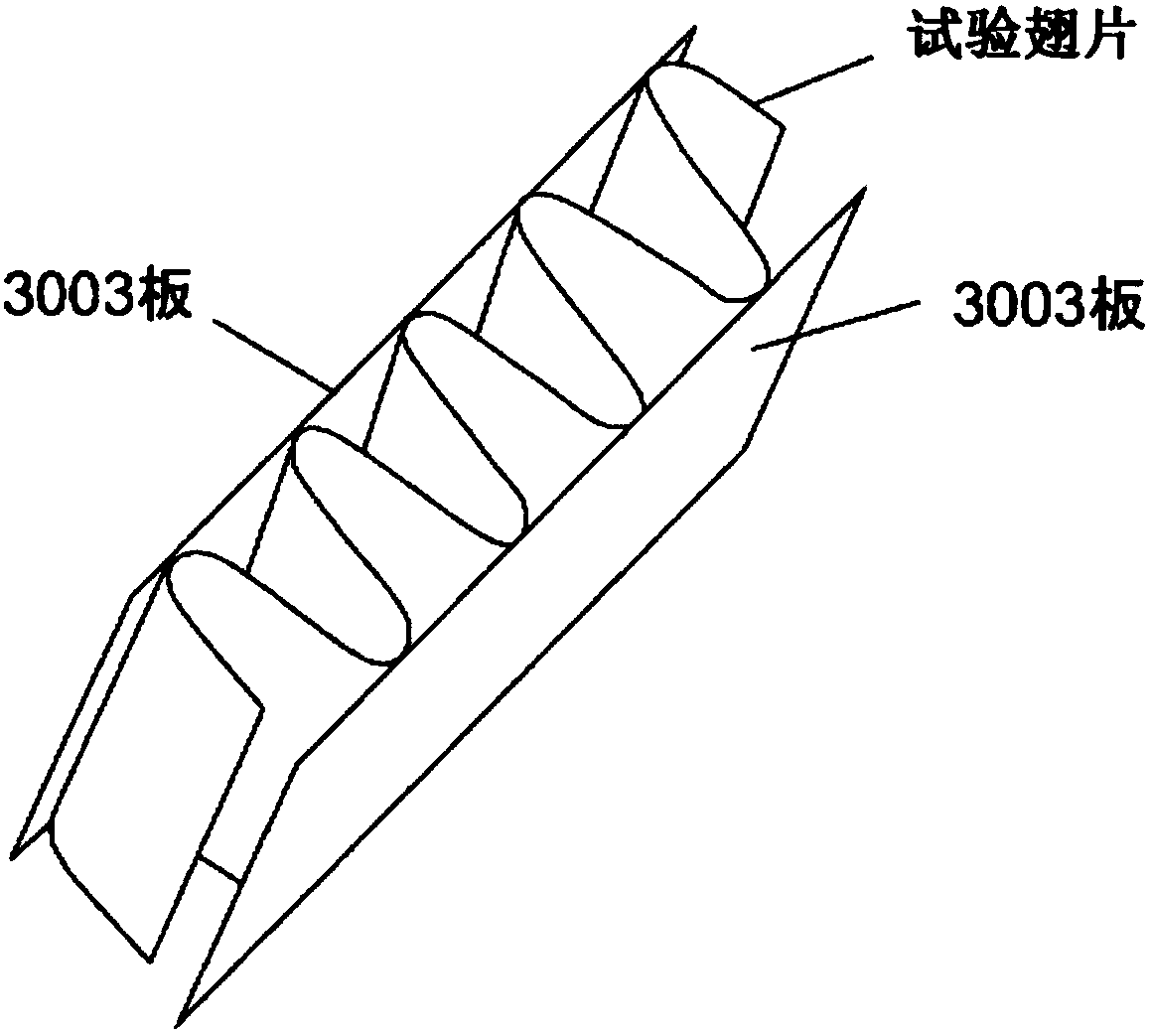

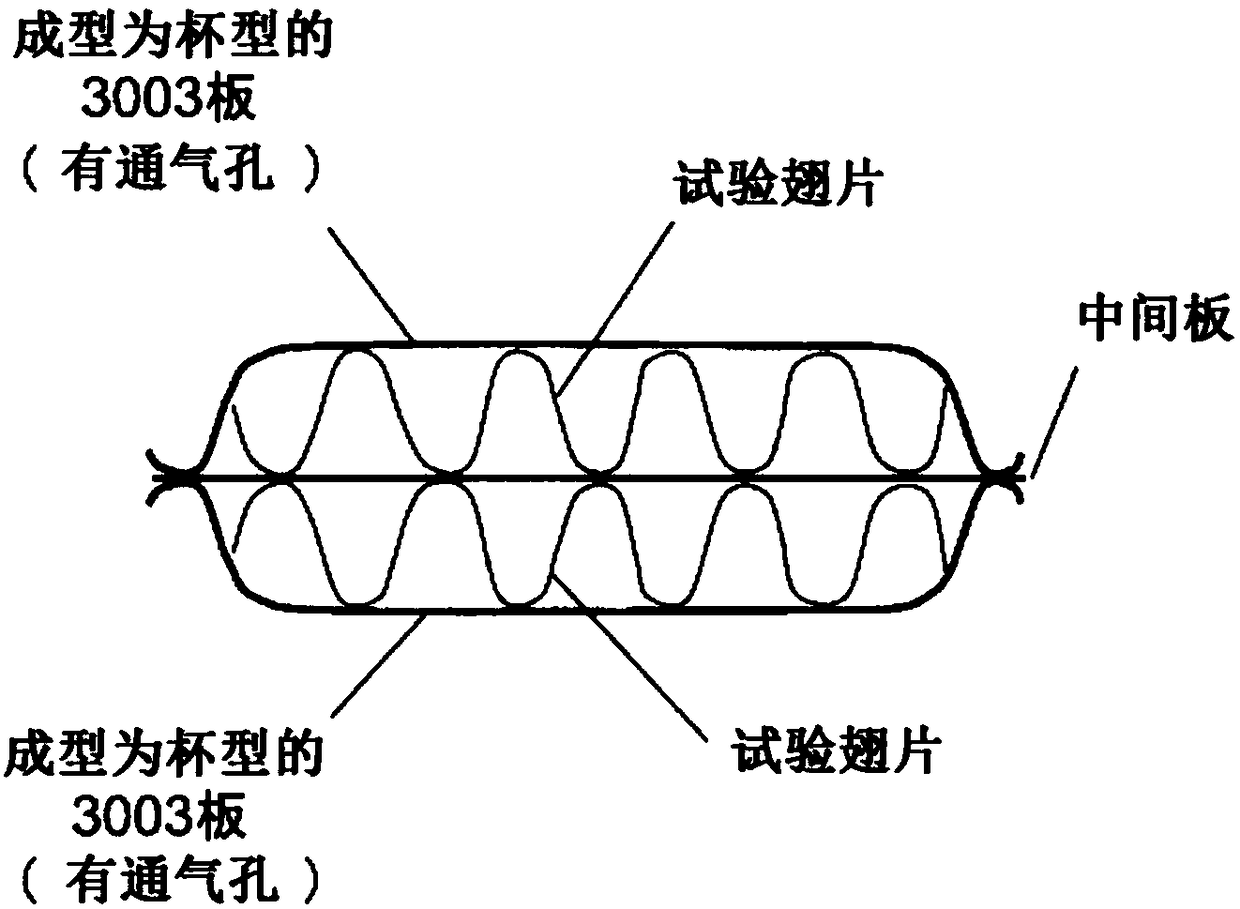

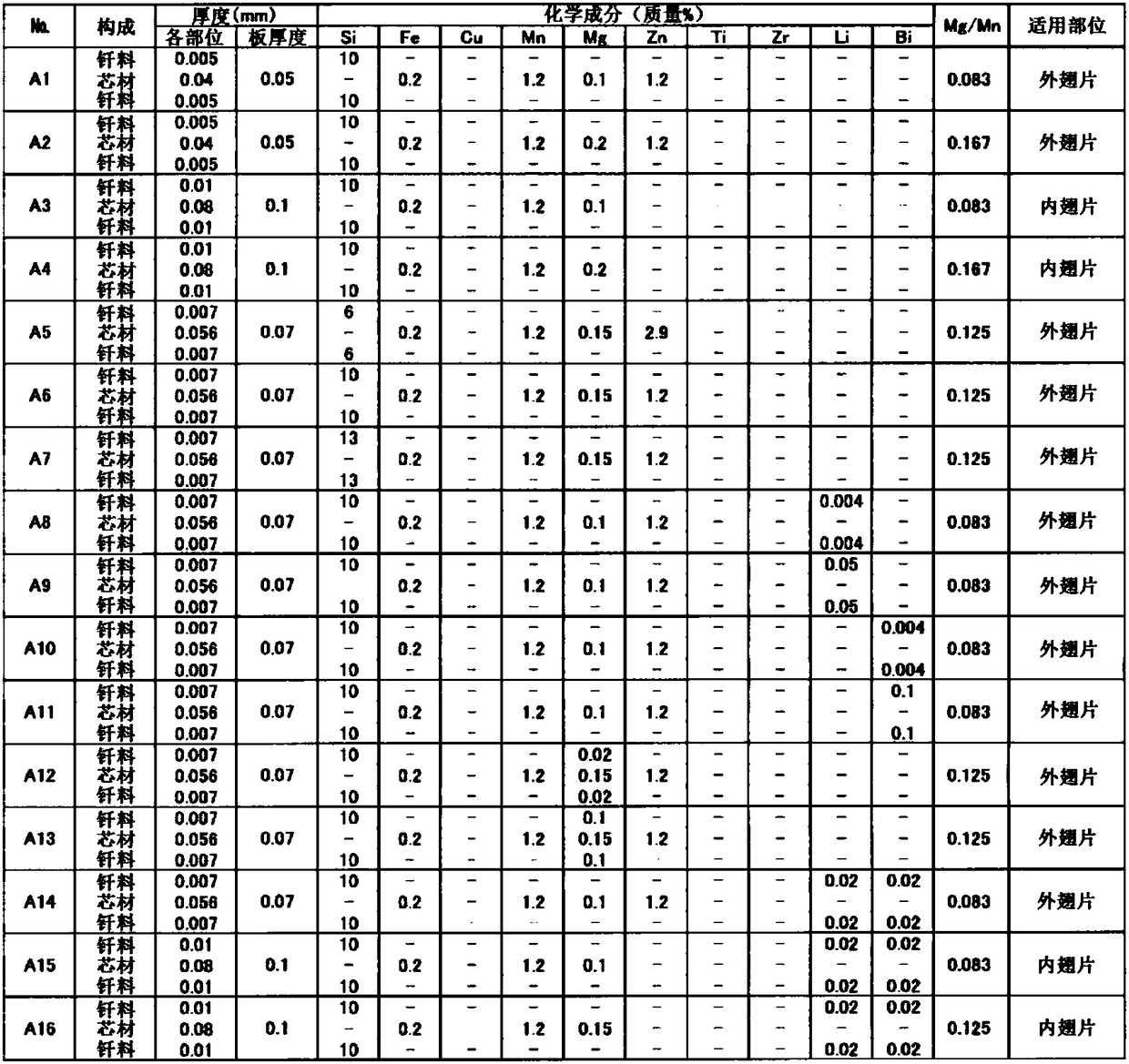

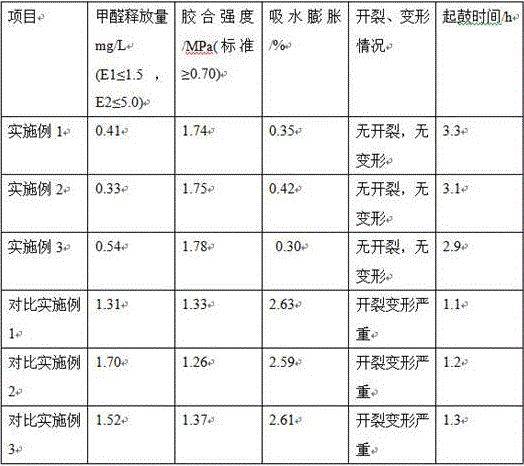

Aluminum alloy brazing sheet, and method for producing heat exchanger made from aluminum alloy

ActiveCN108431260ANo bending deformationWelding/cutting media/materialsWelding/soldering/cutting articlesBrazingHeat exchanger

An aluminum alloy brazing sheet which can be used for brazing in an inert gas atmosphere without using any flux, said aluminum alloy brazing sheet being characterized by comprising an aluminum alloy core material and an aluminum alloy brazing material, wherein one surface or both surfaces of the aluminum alloy core material is / are cladded with the aluminum alloy brazing material, the aluminum alloy core material contains 0.8 to 1.8% by mass of Mn, 0.05 to 0.20% by mass of Mg and a remainder made up by aluminum and unavoidable impurities, the aluminum alloy brazing material contains 6 to 13% bymass of Si and a remainder made up by aluminum and unavoidable impurities, the thickness of the brazing sheet is 0.12 mm or less, and the thickness of the brazing material is 0.012 mm or less. According to the present invention, an aluminum alloy brazing sheet for fluxless brazing use can be provided, which does not undergo the problem of the buckling deformation of a tip part of a fin or the problem of a defect in the formation of a fillet during brazing by heating despite the sheet thickness of as small as 0.12 mm or less of the brazing sheet.

Owner:FURUKAWA SKY ALUMINUM CORP +1

Method for producing total-eucalyptus plywood by adopting moisture-proof composite urea resin

InactiveCN106313203ALow residual formaldehydeImprove water resistanceNon-macromolecular adhesive additivesVeneer manufactureSilanesAdhesive

The invention discloses a method for producing total-eucalyptus plywood by adopting moisture-proof composite urea resin. The method comprises the following steps: rotatably cutting wood boards; drying each board; gluing; performing cold pressing for three times; stewing and conditioning; performing hot pressing for three times; cooling and conditioning; determining the thickness of a board blank and sanding the board blank. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, magnesium oxide is taken as an antiaging agent, hexamine and triglycidyl isocyanurate are taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and aliphatic polyurethane acrylate is taken as a moisture-proof agent to prepare the composite urea resin; the composite urea resin has the advantages of being low in formaldehyde residual volume, good in water resistance and good in moisture resistance; therefore, the produced total-eucalyptus plywood is low in formaldehyde residual volume, hard to expand after absorbing water and hard to arch and deform, and a wear-resistant layer is hard to damage.

Owner:南宁市创锦胶合板有限责任公司

Method for producing full-eucalyptus plywood with flame-retardant composite urea-formaldehyde resin

InactiveCN106346568AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesScavengerAdditive ingredient

The invention relates to a method for producing full-eucalyptus plywood with flame-retardant composite urea-formaldehyde resin, comprising the steps of wood board peeling->veneer drying -> gluing -> three times of cold pressing -> standing for curing->three times of hot pressing ->heat dissipation for curing->slab calibrating and sanding. The method is characterized in that the melamine modified urea-formaldehyde resin is used as the main ingredient in the adhesive; the oxidized starch as adhesive compound, the polyving akohol as toughening agent, the hydrogenated rosin as antioxidant, the polyisocyanate as curing agent, i-butyltriethoxanesilane as bridging agent, phenolic lignin as formaldehyde scavenger and flame retardant agent are added together to produce the flame-retardant composite urea-formaldehyde resin. The flame-retardant composite urea-formaldehyde resin has such advantages as littleformaldehyde residue, perfect flame resistance and lowering combustion temperature by internal endothermic reaction so that the full-eucalyptus parquet contains little formaldehyde residue and has good flame-retardant effectin case of fire disasters.

Owner:南宁市创锦胶合板有限责任公司

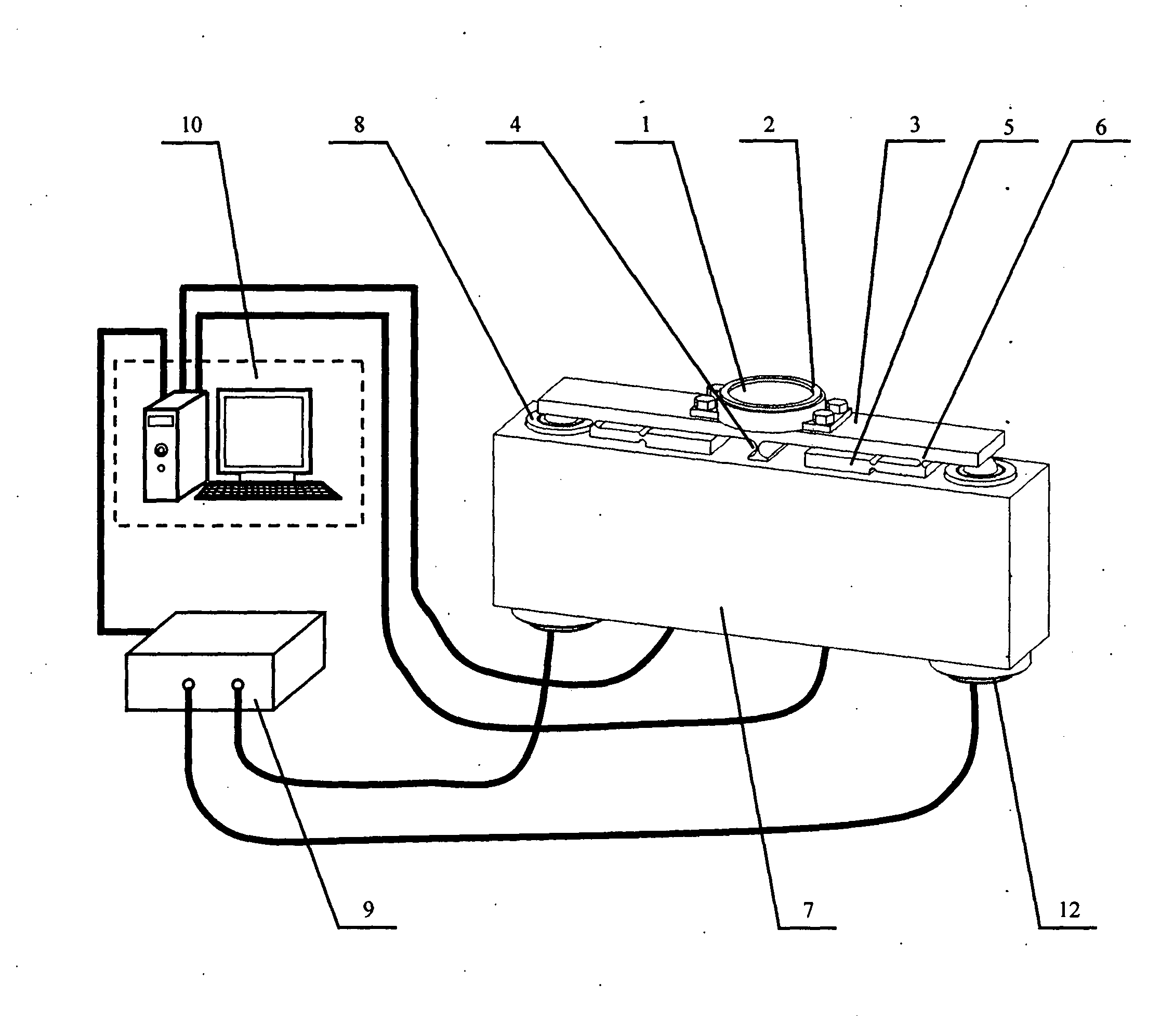

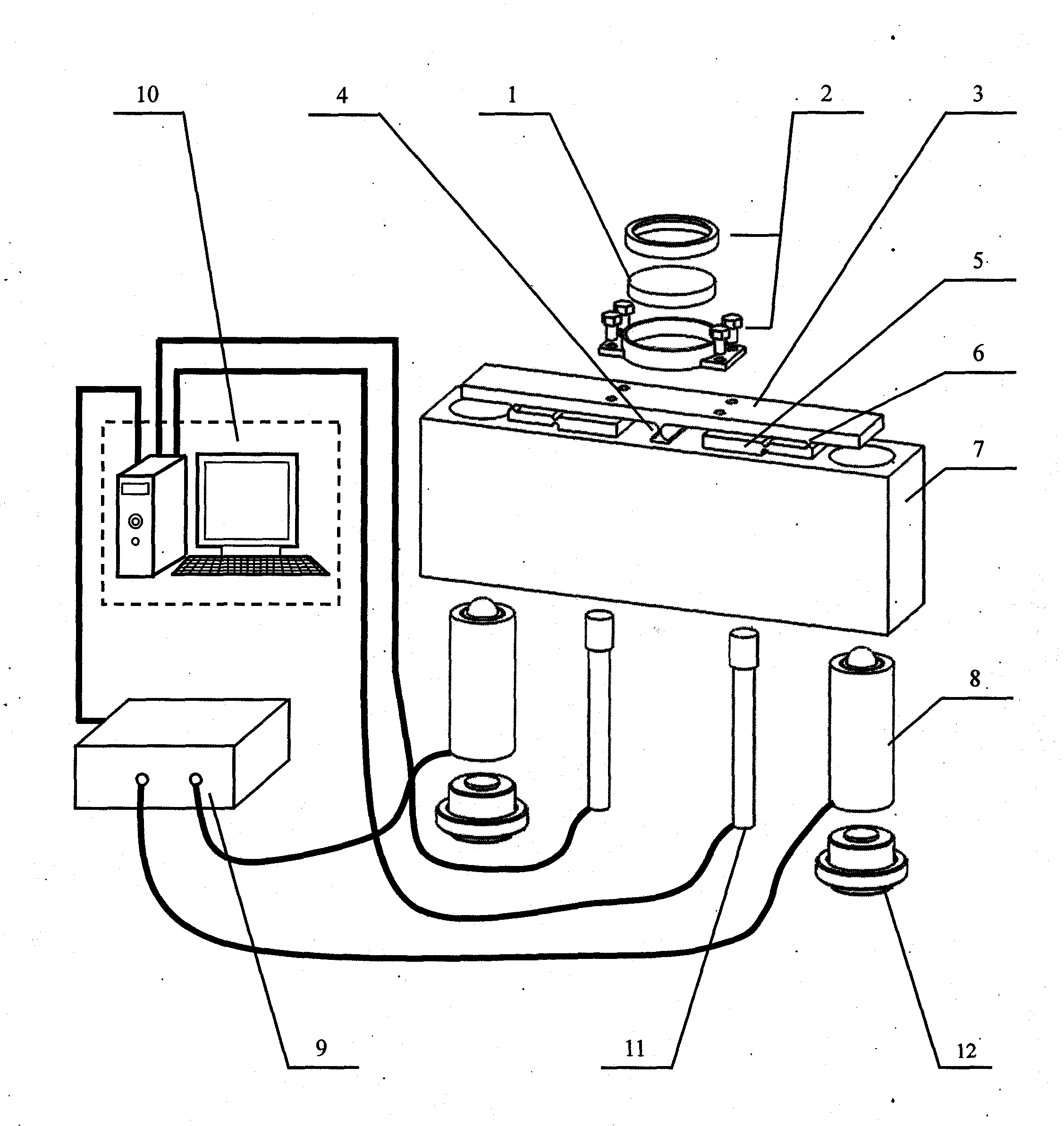

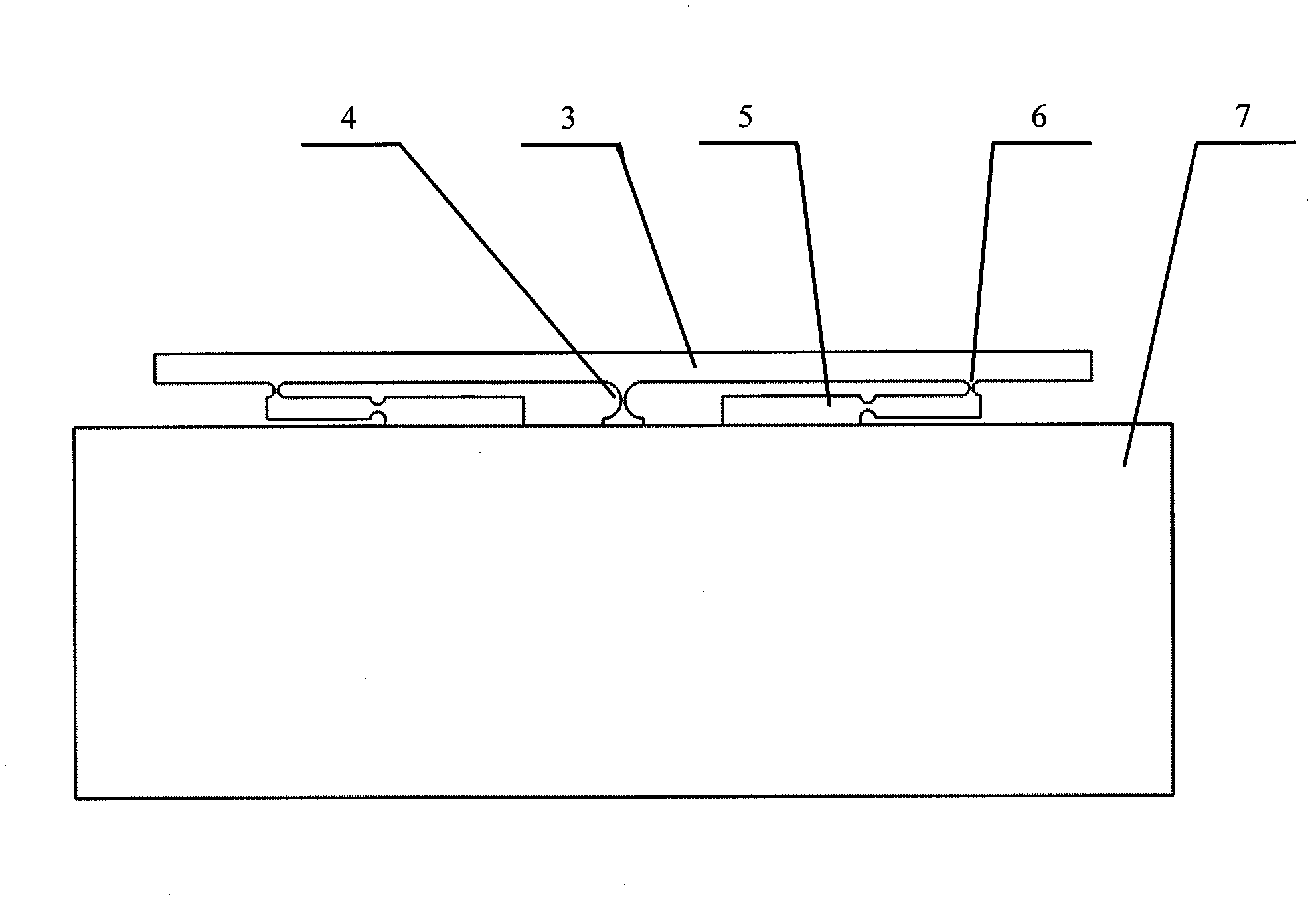

Micro angular swing control reflecting mirror followed by flexible auxiliary arm with superhigh angular sensitivity and high frequency response

InactiveCN102354050ANo bending deformationAchieve ultra-high angular displacement sensitivityOptical elementsElectricityControl system

The invention discloses a micro angular swing control reflecting mirror followed by flexible auxiliary arms with superhigh angular sensitivity and high frequency response and belongs to a light beam control device. The micro angular swing control reflecting mirror comprises a mirror frame assembly, a flexible auxiliary arm followed deflection mechanism, a driving mechanism and a control system, wherein the mirror frame assembly is fixedly arranged on a rigid cross beam of the flexible auxiliary arm followed deflection mechanism; an incident light beam is emerged through a reflecting mirror inthe mirror frame assembly; the control system is used for controlling the driving mechanism to push the rigid cross beam, so that an angle of the reflecting mirror is deflected and the control over the direction of an emergent light beam is realized; a displacement sensor is used for feeding back corner information of the reflecting mirror to the control system; the flexible auxiliary arms are additionally arranged at the positions close to a piezoelectric ceramic driving point and are connected with the rigid cross beam through a pivot hinge; the pivot hinge is used for ensuring no deformityof the cross beam during deflection so as to realize the superhigh angular sensitivity; and the flexible auxiliary arms are used for providing a large auxiliary restoring force for the rigid cross beam during deflection to improve the dynamic response speed. The micro angular swing control reflecting mirror has the characteristics of high angular sensitivity and high dynamic track response speed.

Owner:HARBIN INST OF TECH

Method for producing full-eucalyptus parquet with flame-retardant composite urea-formaldehyde resin

InactiveCN106346584AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesLaminationScavengerToughening

The invention relates to a method for producing full-eucalyptus parquet with flame-retardant composite urea-formaldehyde resin, comprising the steps of wood board peeling->veneer drying -> gluing -> three times of cold pressing -> standing for curing->three times of hot pressing ->heat dissipation for curing->slab calibrating and sanding-> substrate surface gluing -> curing and slotting-> leaching paint, drying and shaping. The method is characterized in that the melamine modified urea-formaldehyde resin is used as the main ingredient in the adhesive; the oxidized starch as adhesive compound, the polyving akohol as toughening agent, the hydrogenated rosin as antioxidant, the polyisocyanate as curing agent, i-butyltriethoxanesilane as bridging agent, phenolic lignin as formaldehyde scavenger and flame retardant agent are added together to produce the flame-retardant composite urea-formaldehyde resin. The flame-retardant composite urea-formaldehyde resin has such advantages as little formaldehyde residue, perfect flame resistance and lowering combustion temperature by internal endothermic reaction so that the full-eucalyptus parquet contains little formaldehyde residue and has good flame-retardant effect in case of fire disasters.

Owner:南宁市林润木业有限公司

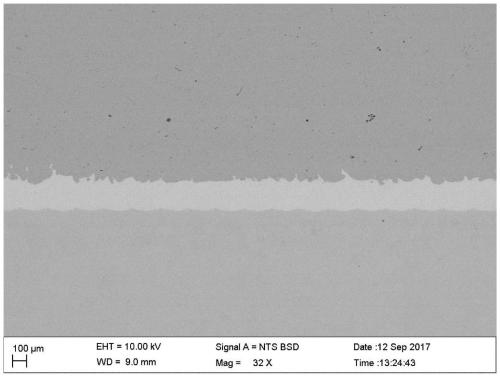

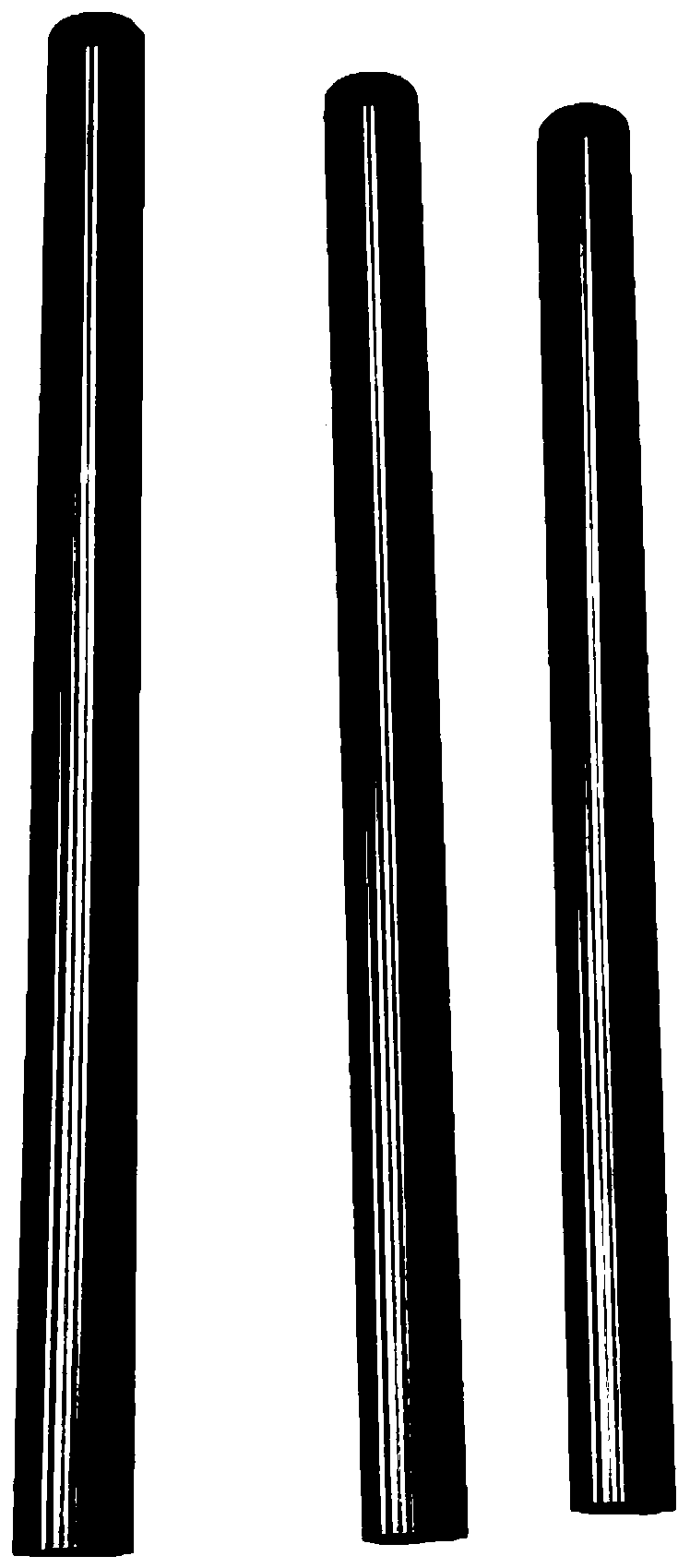

Preparation method of tubular chromium target material

ActiveCN109972100AAvoid crackingNo bending deformationVacuum evaporation coatingSputtering coatingManufacturing technologyVolumetric Mass Density

The invention belongs to the technical field of target material manufacturing and in particular relates to a preparation method of a tubular chromium target material. The preparation method comprisesthe following steps: preparing a transitional layer; preparing a package sheathing; degassing the package sheathing; carrying out hot isostatic pressuring; carrying out annealing treatment; carrying out machining and the like. The tubular chromium target material prepared by the method is free of cracks and bending deflection and high in purity, the density is greater than 99%, and the percent ofpass of products is increased greatly.

Owner:无锡飞而康新材料科技有限公司

Fabricated structural system of steel plate reinforced concrete shear walls and construction method of fabricated structural system

ActiveCN106639052AReduce section loss rateOvercome the technical difficulty of being unable to fix on the vertical steel plateWallsLoad-supporting elementsFloor slabSheet steel

The invention discloses a fabricated structural system of steel plate reinforced concrete shear walls. The fabricated structural system comprises a beam member, the steel plate reinforced concrete shear walls, a floor and a sleeve connecting piece. Each steel plate reinforced concrete shear wall comprises vertical steel plates and continuous spiral stirrups. The structural system is high in assembling rate. The invention further discloses a construction method of the fabricated structural system of the steel plate reinforced concrete shear walls. The construction method comprises the steps that firstly, one prefabricated steel plate reinforced concrete shear wall is manufactured; secondly, the steel plate reinforced concrete shear wall on the lower layer is assembled; thirdly, the sleeve connecting piece is assembled on the steel plate reinforced concrete shear wall on the lower layer; fourthly, the beam member is assembled, and the floor is installed; fifthly, the floor and the beam member as well as the floor and the steel plate reinforced concrete shear wall on the lower layer are connected by pouring concrete, and concrete is poured to the junction of the beam member and the steel plate reinforced concrete shear wall on the lower layer; and sixthly, the steel plate reinforced concrete shear wall on the upper layer is hoisted, and finally concrete is poured to the junction of the steel plate reinforced concrete shear walls on the upper layer and the lower layer in situ. By adoption of the fabricated structural system of steel plate reinforced concrete shear walls and the construction method of the fabricated structural system, construction can be completed with the high assembling rate.

Owner:陕西省建筑设计研究院(集团)有限公司

Pneumatic driving device

InactiveCN101104273ASimple preparation processIncrease elasticityFluid-pressure actuatorsManipulatorEngineering

Disclosed is an aerodynamic driver, comprising a left end cover and a right end cover, wherein an inflation hole is arranged on the left end cover and the two ends of a rubber tube are respectively in sealed connection with the left end cover and the right end cover. The invention is characterized in that the outer side of the right end cover is fixedly connected with a rigid inner neck bush, which is nested on the outside of the rubber tube and can be clung glidingly on the outer wall of the rubble tube; the outer side of the left end cover is fixedly connected with a rigid outer neck bush, which is nested on the outside of the inner neck bush and can be clung glidingly on the outer wall of the inner neck bush.

Owner:ZHEJIANG UNIV OF TECH

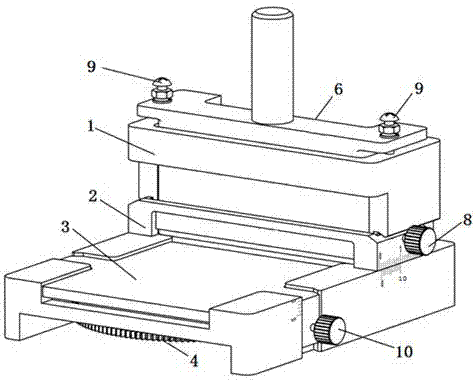

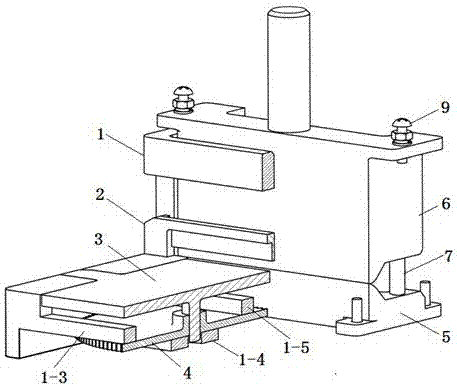

Multifunctional device pin tailoring tool and application method

The invention relates to a multifunctional device pin tailoring tool and an application method. The smallest gap between an upper cutter edge and a lower cutter edge is adjusted to enable the upper cutter edge to just contact with the lower cutter edge; a positioning plate is fixed on a base frame; a lifting table is adjusted to fix on the base frame; a cutter shank on an adjusted tool is mountedon a manual press, and an upper cutter is upwards lifted; devices are placed on the surface of the lifting table, and pins are supported on the lower cutter edge, so that packing surfaces on pin tailoring sides are tightly bonded on a transverse belt III surface of the positioning plate; the press is operated to enable the upper cutter to downwards move along a guide column; and through cooperation between the upper cutter edge and the lower cutter edge, pins of the devices are tailored off. The positioning plate is designed by using a principle of a vernier caliper to control the pin tailoring size precision of the devices; the tailoring precision can reach 0.1 mm; the tailored devices are high in consistency and low in scrap rate; and the welding quality of the devices is improved.

Owner:TIANJIN 712 COMM & BROADCASTING CO LTD

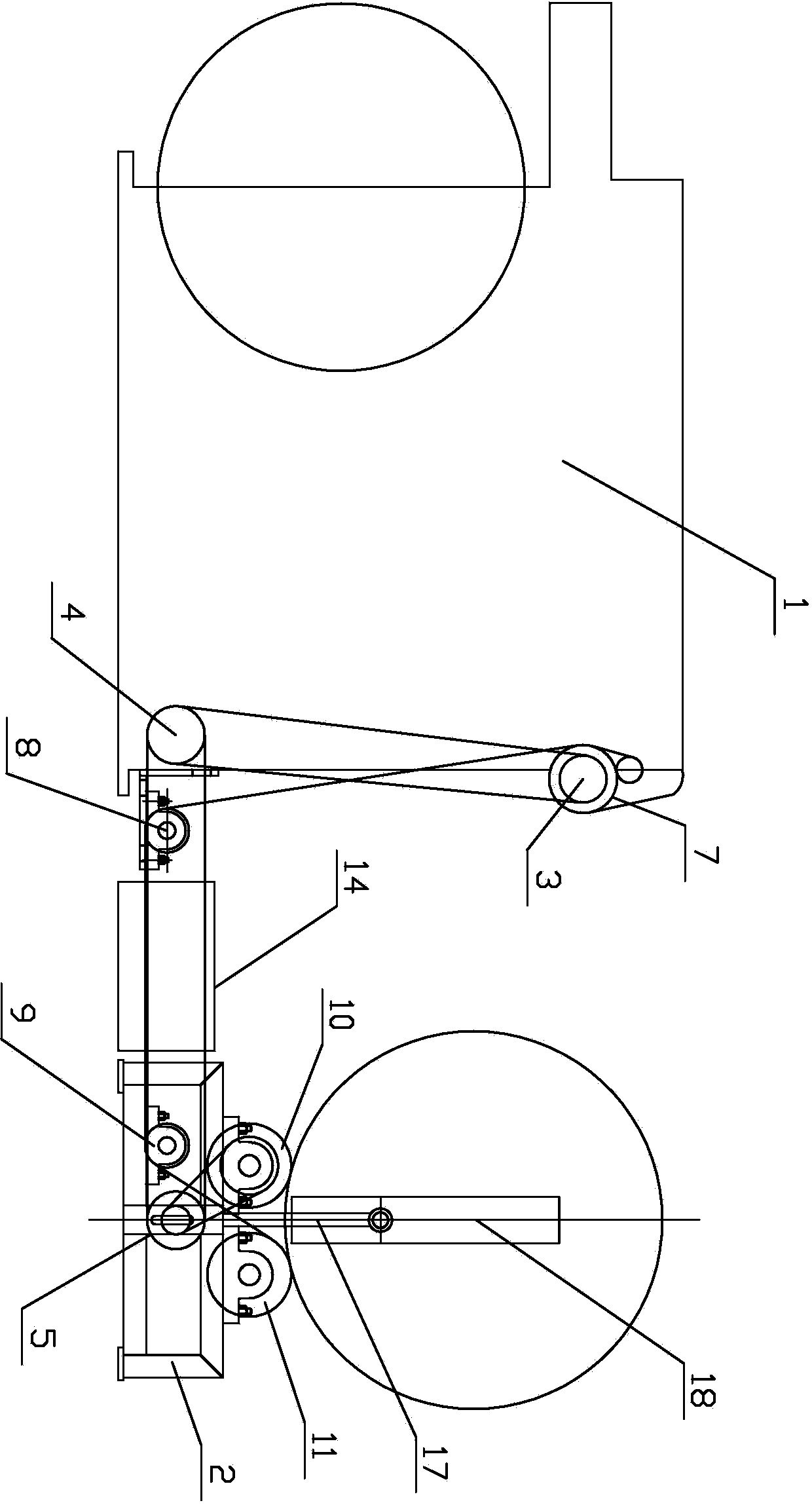

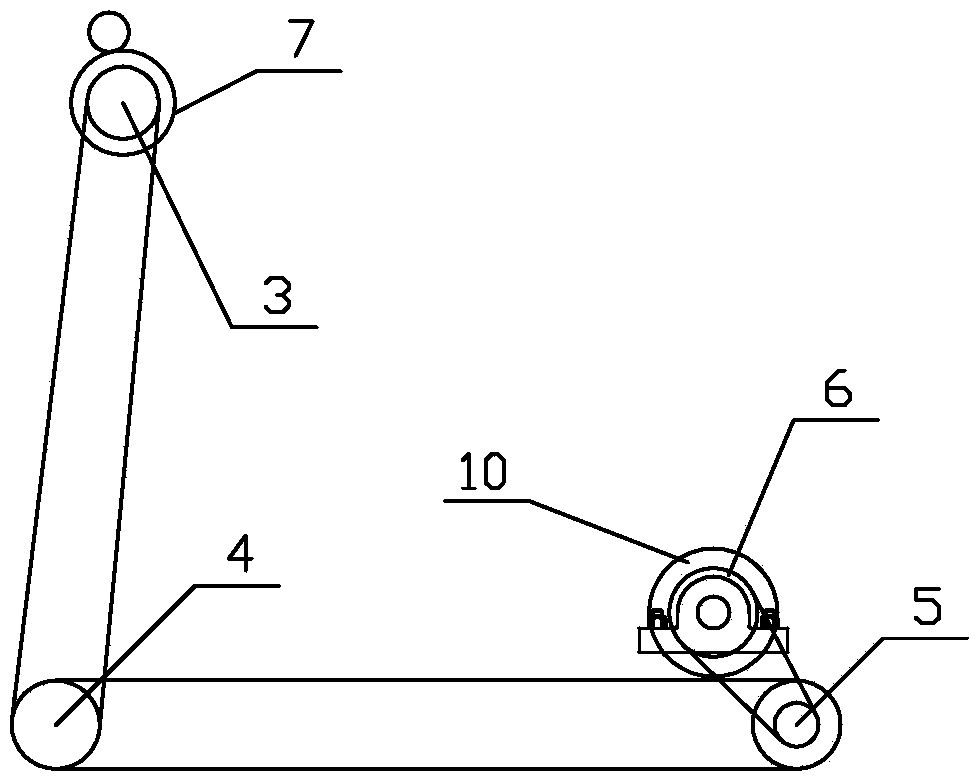

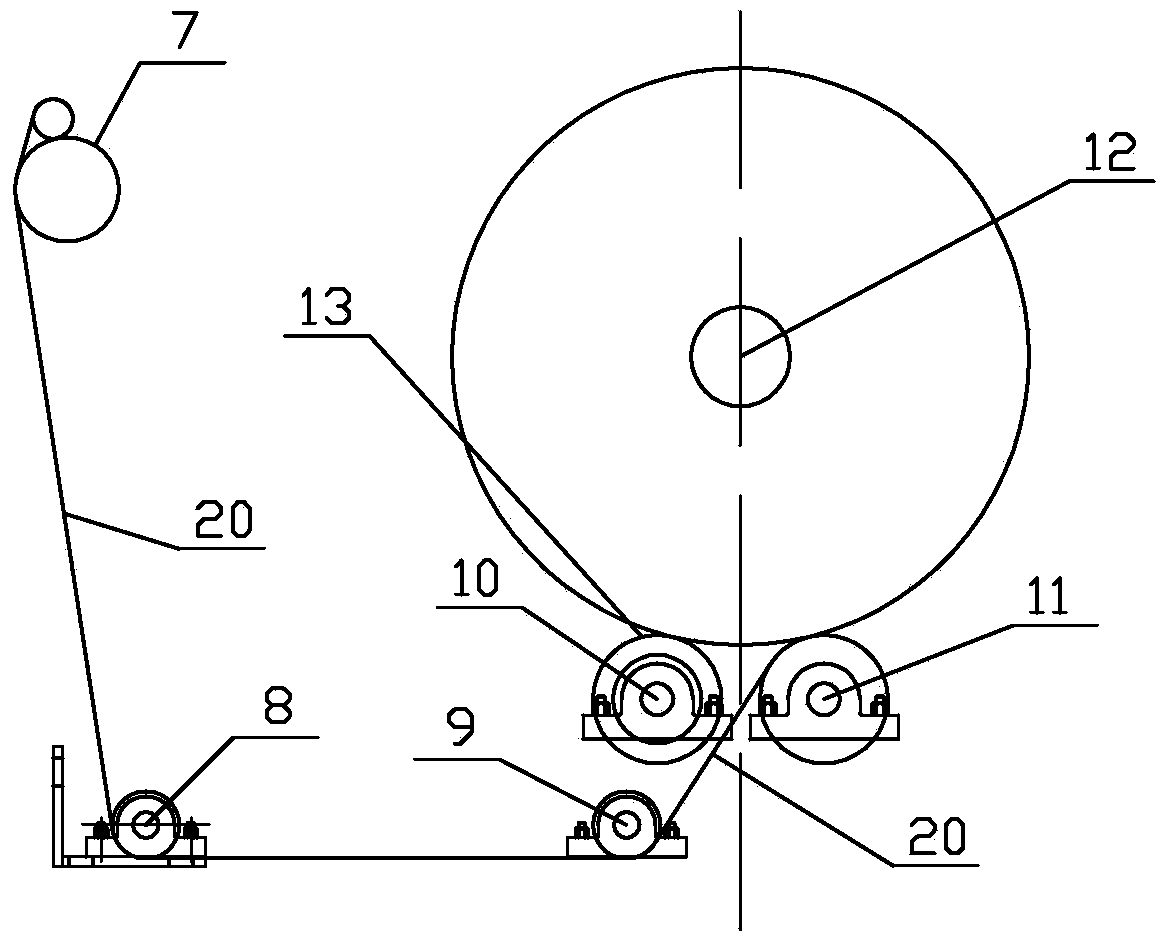

Device for batching gray fabric of loom

The invention discloses a device for batching a gray fabric of a loom. The device is characterized in that the device includes a machine base (2) arranged outside the loom, a batching mechanism arranged on the machine base (2) and a transmission mechanism for connecting the loom (1) with a batching mechanism, the transmission mechanism is a multi-stage chain transmission mechanism, and the transmission mechanism is connected with an original loom batching taker (7) on the loom. The device for batching the gray fabric of the loom has the advantages of simple structure, convenient, safe and reliable operation, low equipment failure rate and low cost; a driving shaft is capable of producing a batch, thereby reducing the number of fittings during the post processing of finished products.

Owner:ZHEJIANG SHUANGDUN TEXTILE TECH CO LTD

Method for producing total-eucalyptus plywood by adopting weather-resistant composite urea resin

InactiveCN106313200AWhite colorGood film formingOther plywood/veneer working apparatusNon-macromolecular adhesive additivesAntioxidantAdhesive

The invention discloses a method for producing total-eucalyptus plywood by adopting weather-resistant composite urea resin. The method comprises the following steps: rotatably cutting wood boards; drying each board; gluing; performing cold pressing for three times; stewing and conditioning; performing hot pressing for three times; cooling and conditioning; determining the thickness of a board blank and sanding the board blank. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, polyisocyanate is taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher, and moreover an antioxidant and an ultraviolet absorbent are also added to prepare the weather-resistant composite urea resin; the composite urea resin has the advantages of low formaldehyde residual volume and good weather resistance. The total-eucalyptus plywood produced by the method disclosed by the invention is excellent in weather resistance and is relatively high in environmental disruption tolerance.

Owner:南宁市林润木业有限公司

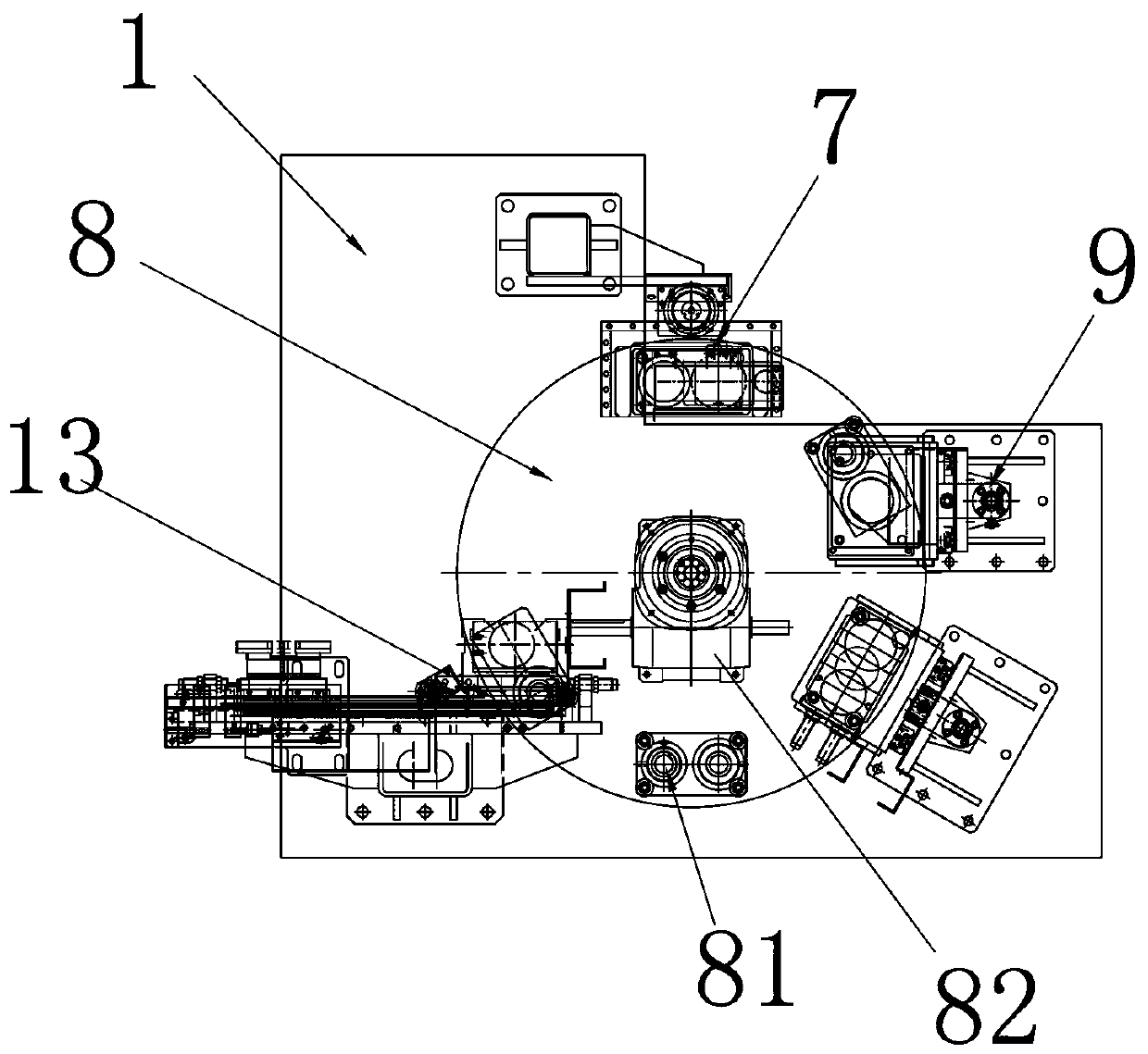

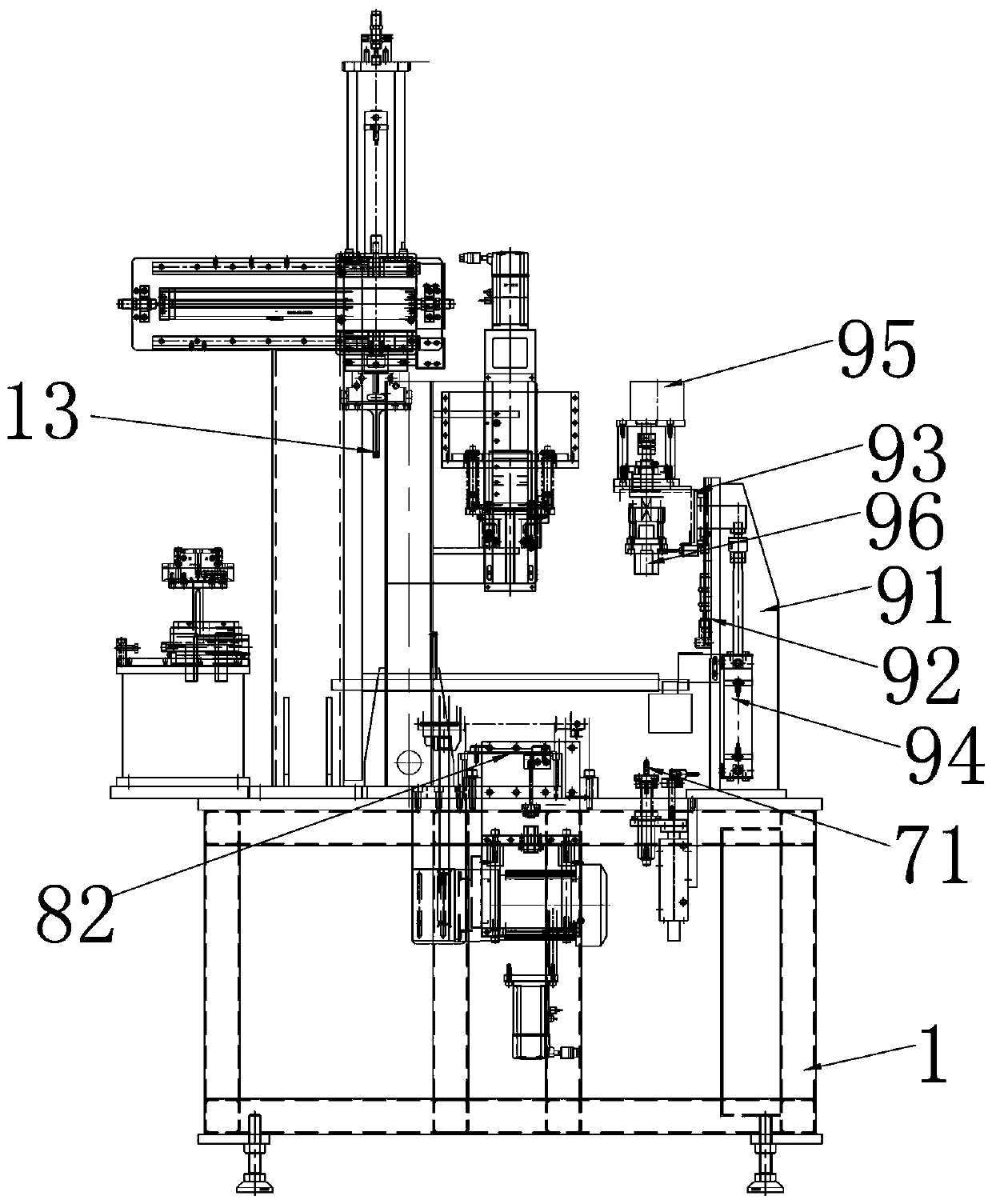

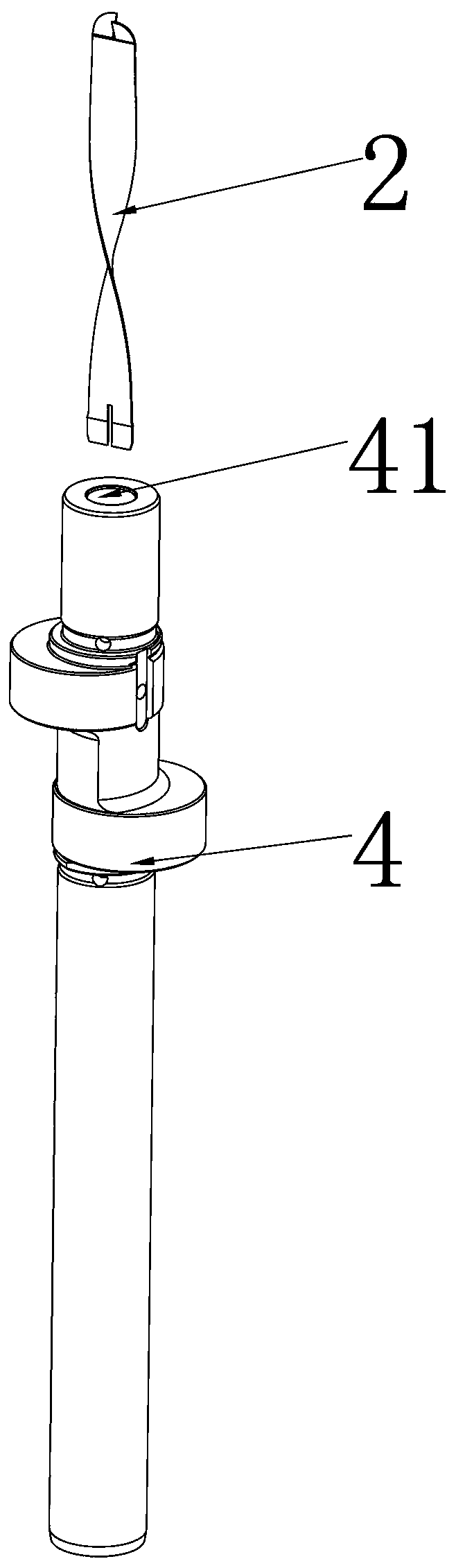

Compressor crankshaft fitting assembling and thrust surface grinding production line

PendingCN110842499AUnified standardNo bending deformationGrinding carriagesAssembly machinesProduction lineMachine

The invention relates to a compressor crankshaft fitting assembling and thrust surface grinding production line. The production line is characterized by involving the following components of a machineframe, wherein a rotating disc is arranged on the machine frame through a rotating mechanism, a plurality of crankshaft positioning seats are distributed in a circumferential array on the rotating disc, and a compressor oil liquid sheet automatic assembly manipulator, a spring oil plug automatic assembly manipulator and a thrust surface grinding manipulator, corresponding to the positions of thecrankshaft positioning seats, are sequentially arranged on the machine frame. The production line has the beneficial effects that an oil liquid sheet is installed in a crankshaft by an oil liquid sheet feeding manipulator, and the installation parameters of the oil liquid sheet can be set through a system, so that installation of each oil liquid sheet is guaranteed to be standard and unified, andthe quality is guaranteed to be stable; and automatic operation in the whole process is realized, no manual intervention is needed, the production efficiency is high, and the quality is stable.

Owner:广东顺德蕴洋智能科技有限公司

Hydraulic steel reinforcement cage unloading device for steel bar framework seam welder

InactiveCN108817632AAvoid bending deformationNo bending deformationWelding with roller electrodesHydraulic cylinderArchitectural engineering

The invention discloses a hydraulic steel reinforcement cage unloading device for a steel bar framework seam welder. The hydraulic steel reinforcement cage unloading device comprises guide rails, stayarms, a rotating plate, a connecting rod, a hydraulic cylinder, a first hinge shaft, a second hinge shaft, a platform plate and supporting baffles, wherein the number of the guide rails is two, moreover, the two guide rails are arranged in parallel, the two ends of each stay arm are correspondingly connected with the inner walls of the guide rails through bolts, and the stay arms are connected with the ground through bolts; first hinge seats are arranged on the stay arms, one side of the lower end of the platform plate is provided with second hinge seats, and the other side of the lower end of the platform plate is provided with third hinge seats; the lower end of the rotating plate is hinged to the first hinge seats, and the upper end of the rotating plate is hinged to the second hinge seats; the lower end of the connecting rod is hinged to the guide rails through the first hinge shaft, and the upper end of the connecting rod is hinged to the third hinge seats; and the cylinder barrel end of the hydraulic cylinder is hinged to the first hinge shaft, the piston rod end of the hydraulic cylinder is hinged to the middle of the rotating plate through the second hinge shaft, and the supporting baffles are connected with the platform plate. Therefore, bending deformation of a welded steel reinforcement cage during unloading cannot be caused.

Owner:ANHUI YUTE CONCRETE STRUCTURE TECH

Rotation body type composite material component forming method

The invention relates to a rotation body type composite material component forming method. The forming method comprises the following steps that the surface of a forming tool is coated with a demoulding material; secondly, manual pavement and pasting of prepreg are conducted on the surface of the forming tool coated with the demoulding material, in the pavement and pasting process, pavement and pasting positioning is conducted, and a vacuum bag pressing method is used for conducting pre-compaction on the paved and pasted prepreg; thirdly, after pavement and pasting are finished, the paved andpasted prepreg is overturned, and rotation type prepreg is formed through overturning; and fourthly, an inflated cylindrical vacuum bag or air bag is used for packaging the rotation type prepreg, thencuring is conducted, and a rotation body type composite material component is obtained. According to the rotation body type composite material component forming method, fiber winding equipment is notneeded, and the production cost is reduced; and material sheet paving and pasting of a rigidity core die are not needed, and fiber wrinkling and deformation caused by the too long rigidity core die are avoided.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com