Hydraulic steel reinforcement cage unloading device for steel bar framework seam welder

A steel frame and roll welding machine technology, which is applied in the direction of roller electrode welding, welding equipment, resistance welding equipment, etc., can solve the problems of large equipment cost investment, large floor area occupied by mobile crane equipment, bending deformation of steel cages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The steel bar frame roll welding machine uses a steel cage hydraulic unloading device. Before the two ends of the prepared steel cage are disassembled from the fixed plate and the movable plate, the hydraulic cylinder 5 is first started, and the piston rod of the hydraulic cylinder 5 is stretched out. The supporting force of the piston rod of the cylinder 5 acts on the hinge shaft 2 7, and the hinge shaft 2 7 takes the rotating plate 3 to rotate counterclockwise around the axis hinged with the hinge seat 1 20, while the connecting rod 4 rotates around the hinge shaft 1 6 The axis rotates counterclockwise synchronously, then the platform board 8 is raised by the hinge seat 2 80 and the hinge seat 81, and the support baffle 9 rises with the platform board 8, so that the steel cage falls between the two support baffles 9, and is Support the baffle plate 9 to support it, and then disassemble the two ends of the prepared reinforcement cage from the fixed plate and the moving ...

Embodiment 2

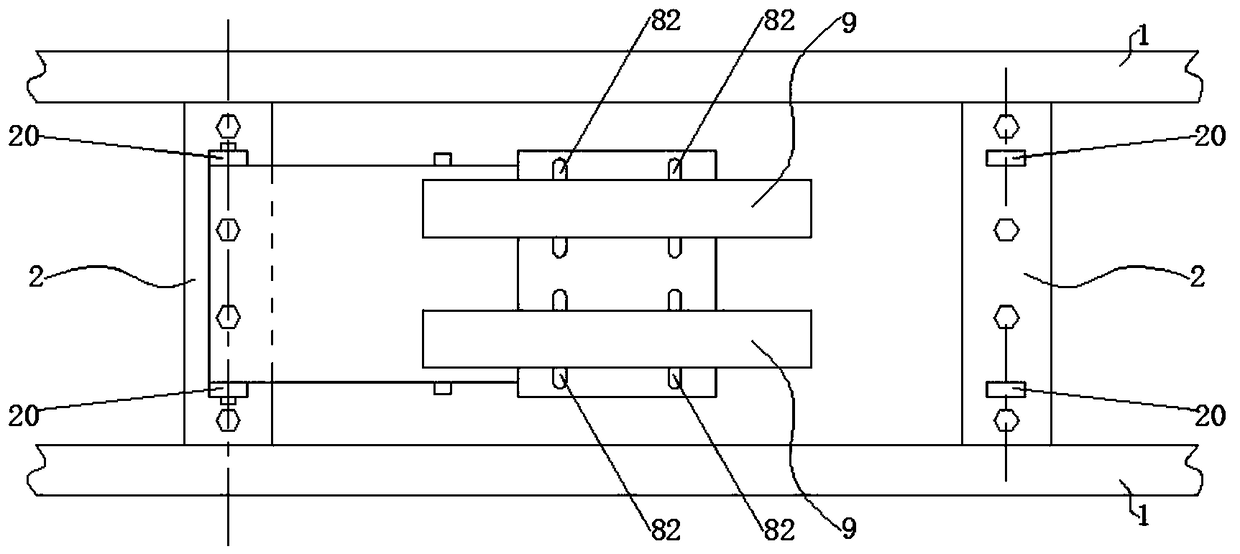

[0025] On the basis of Example 1, the platform board 8 is symmetrically provided with long grooves 82, the lower end of the support baffle 9 is provided with a screw 90, and the support baffle 9 passes through the long groove 82 through the screw 90 and passes through the nut. Locking realizes the adjustment of the distance between the two support baffles 9, and can support the reinforcement cages of different diameters. The reinforcement cage with a large diameter can increase the distance between the two support baffles 9, and the reinforcement cage with a small diameter , the distance between the two support baffles 9 can be reduced to avoid rolling of the reinforcement cage; there are two support baffles 9, which are symmetrical with respect to the platform board 8, so that the support to the reinforcement cage is stable.

Embodiment 3

[0027] On the basis of Embodiment 1, the vertical distance between the rotating plate 3, the connecting rod 4, the center of hinge seat 20 and the axis of hinge shaft 16, the center of hinge seat 2 80 and the center of hinge seat 3 81 form a parallel The quadrilateral mechanism keeps the support baffle 9 horizontal all the time during the lifting process of the hydraulic cylinder 5 driving the platform plate 8 and the support baffle 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com