Preparation method of tubular chromium target material

A chromium target, tubular technology, applied in the field of tubular chromium target preparation, can solve the problems of chromium target density to be further improved, difficult to control straightness, existing process pollution, etc., to prevent bending deformation, combine Tight, pure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

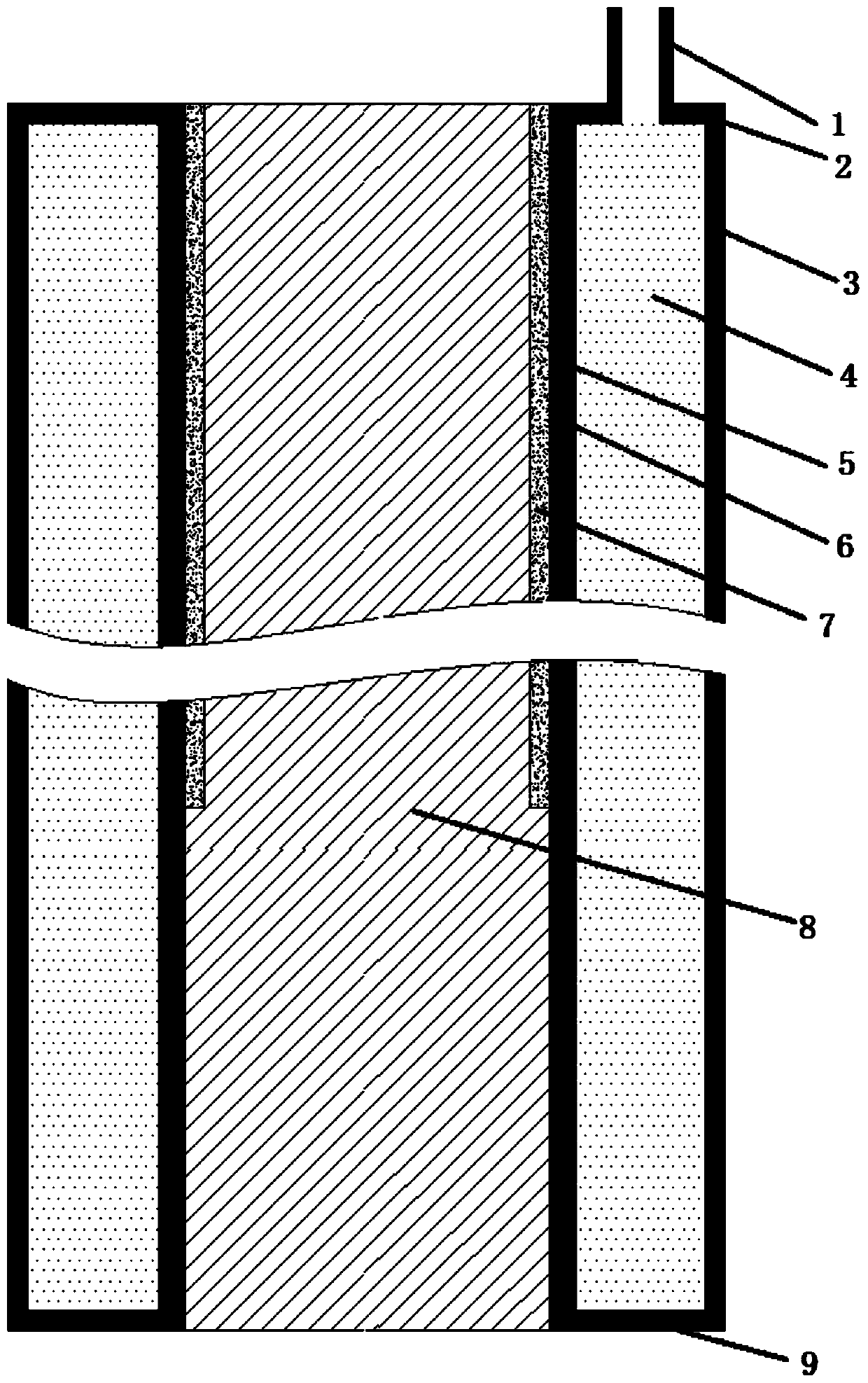

[0040] This embodiment provides a method for producing a tubular chromium target, such as figure 1 shown, including:

[0041] S1: A layer of NiCr alloy 6 is prepared by plasma spraying on the outer surface of the stainless steel back pipe 6, and the thickness of the alloy is 0.5mm. There is a 5mm long area at the two ends of the back pipe that is not sprayed, so as to facilitate the welding of the upper and lower covers in the next step.

[0042]S2: Stainless steel is used to make the outer casing 3, the upper cover 2, and the lower cover 9. At the same time, a degassing port 1 with an outer diameter of 8mm, an inner diameter of 4mm and a height of 300mm is welded on the upper cover 2 for powder loading and degassing.

[0043] S3: Weld the stainless steel back pipe 6, the outer sheath 3 and the upper and lower covers together to form a metal sheath with a cavity inside.

[0044] S4: fill the cavity inside the metal sheath with chromium powder 4 with a purity of 99.2% through...

Embodiment 2

[0053] This embodiment provides a method for producing a tubular chromium target, such as figure 1 shown, including:

[0054] S1: A layer of NiCr alloy is prepared by plasma spraying on the outer surface of the stainless steel back pipe, and the thickness of the alloy is 1 mm. There is a 5mm long area at the two ends of the back pipe that is not sprayed, so as to facilitate the welding of the upper and lower covers in the next step.

[0055] S2: Low-carbon steel is used as the outer cover and the upper and lower covers. At the same time, a degassing port with an outer diameter of 8mm, an inner diameter of 4mm and a height of 300mm is welded on the upper cover for powder loading and degassing.

[0056] S3: Weld the stainless steel back pipe, the outer sheath and the upper and lower covers together to form a metal sheath with a cavity inside.

[0057] S4: Fill the cavity inside the metal sheath with chromium powder with a purity of 99.5% through the powder loading and degassin...

Embodiment 3

[0066] This embodiment provides a method for producing a tubular chromium target, such as figure 1 shown, including:

[0067] S1: A layer of NiCr alloy is prepared by plasma spraying on the outer surface of the stainless steel back pipe, and the thickness of the alloy is 1.5mm. There is a 5mm long area at the two ends of the back pipe that is not sprayed, so as to facilitate the welding of the upper and lower covers in the next step.

[0068] S2: Low-carbon steel is used as the outer cover and the upper and lower covers. At the same time, a degassing port with an outer diameter of 8mm, an inner diameter of 4mm and a height of 300mm is welded on the upper cover for powder loading and degassing.

[0069] S3: Weld the stainless steel back pipe, the outer sheath and the upper and lower covers together to form a metal sheath with a cavity inside.

[0070] S4: Fill the cavity inside the metal sheath with chromium powder with a purity of 99.9% through the powder loading and degassi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com