Micro angular swing control reflecting mirror followed by flexible auxiliary arm with superhigh angular sensitivity and high frequency response

A technology of auxiliary arms and mirrors, which is applied in the direction of optical components, optics, instruments, etc., can solve the problems of complex device manufacturing process, increase of liquid micro-wedge prism, increase of electrode plate voltage difference, etc., to ensure fast dynamic tracking response ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

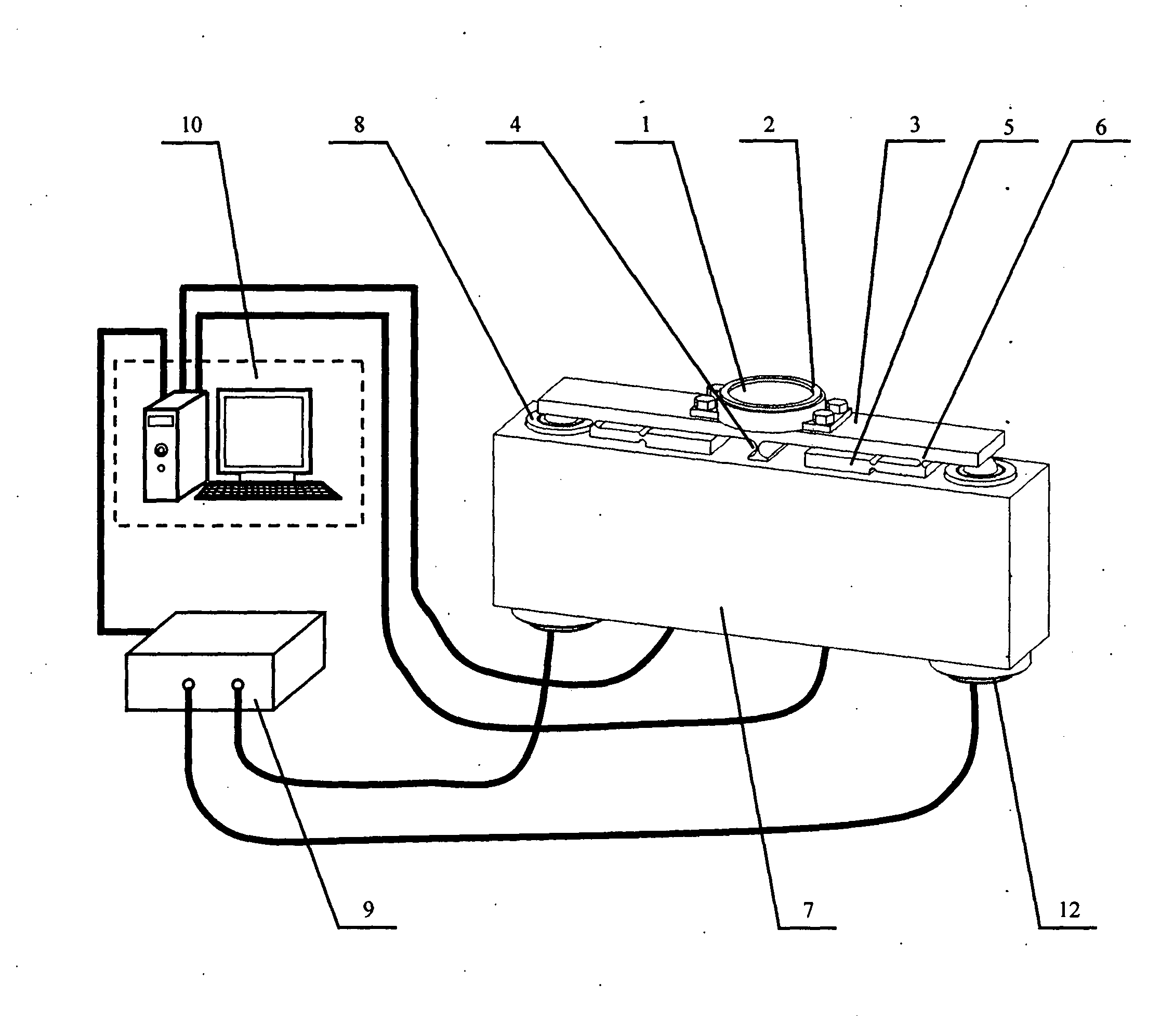

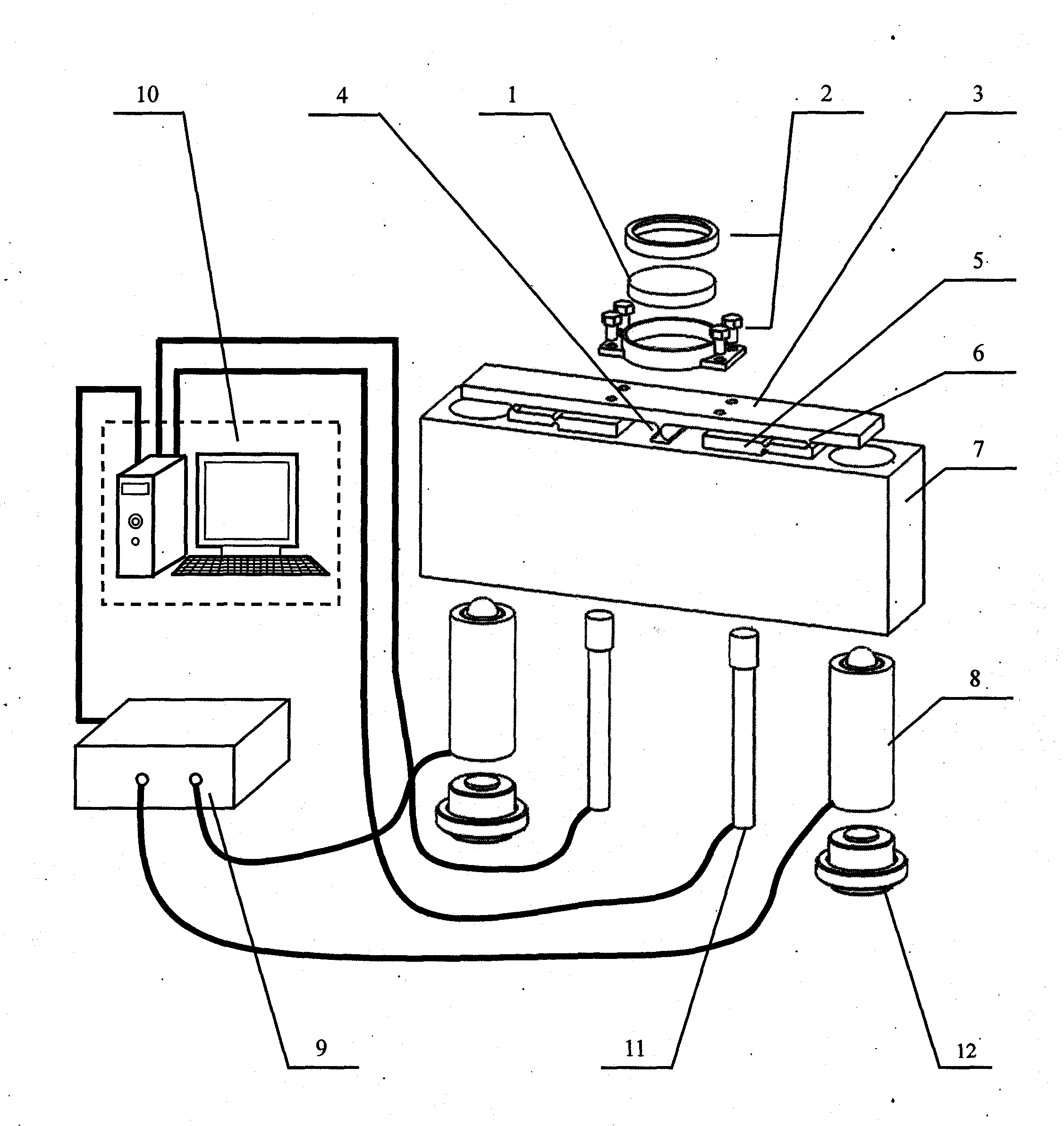

[0026] Such as figure 1 and figure 2 As shown, the flexible auxiliary arm tracking mirror of the present invention with ultra-high angular sensitivity and high frequency response micro-angular pendulum control includes: a mirror frame assembly, a flexible auxiliary arm following deflection mechanism, a driving mechanism, and a control system.

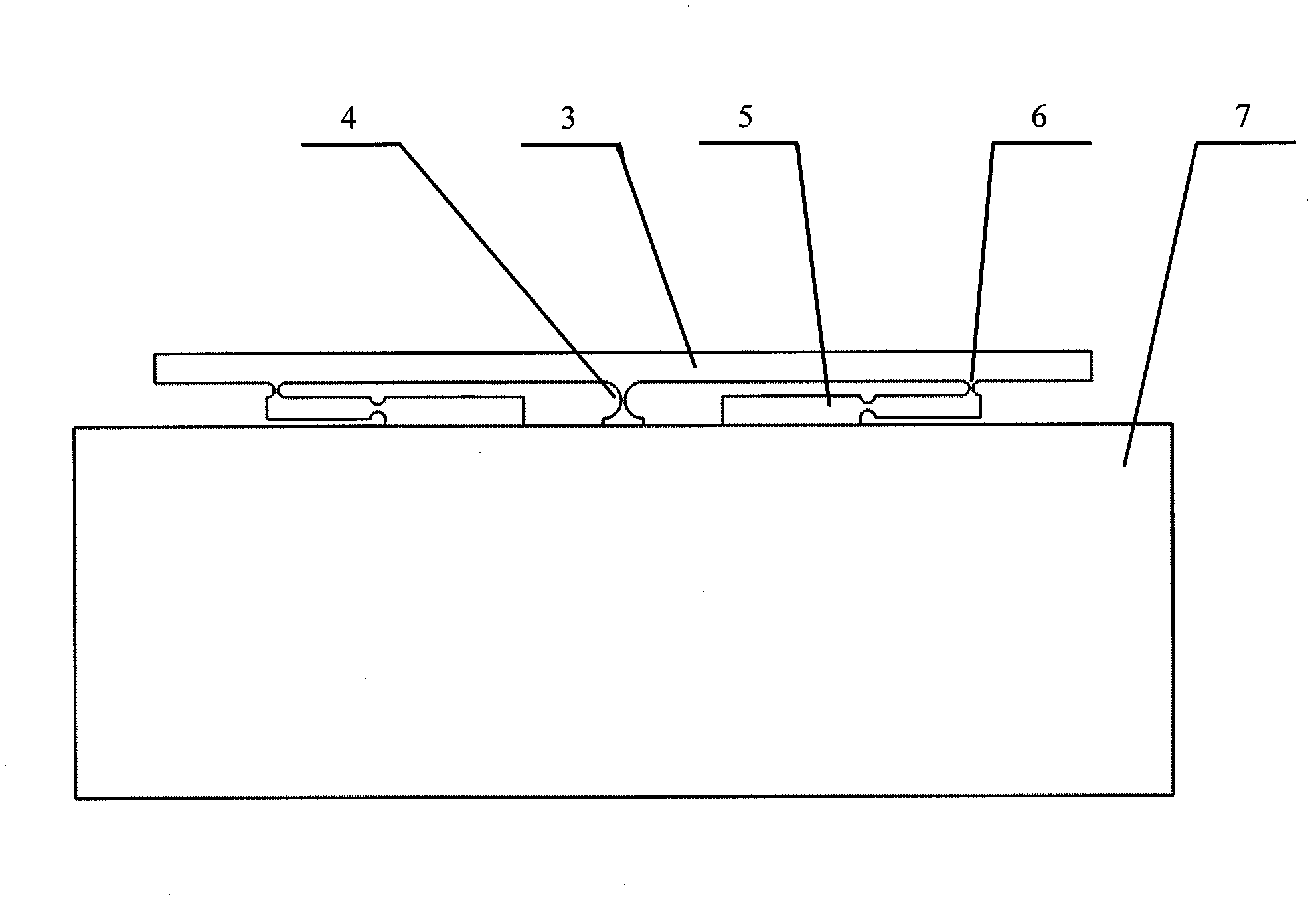

[0027] Mirror frame assembly: including reflector 1 and fixing part 2. Fixing part 2 fixes reflector 1 on the flexible auxiliary arm following deflection mechanism, and the angle deflection occurs with the deflection of the flexible auxiliary arm following the deflection mechanism, and the incident beam passes through reflector 1 After reflection, the angle deflection of the mirror 1 is controlled by controlling the flexible auxiliary arm to follow the deflection mechanism, so as to realize the directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com