Cement-based artificial stone and production process thereof

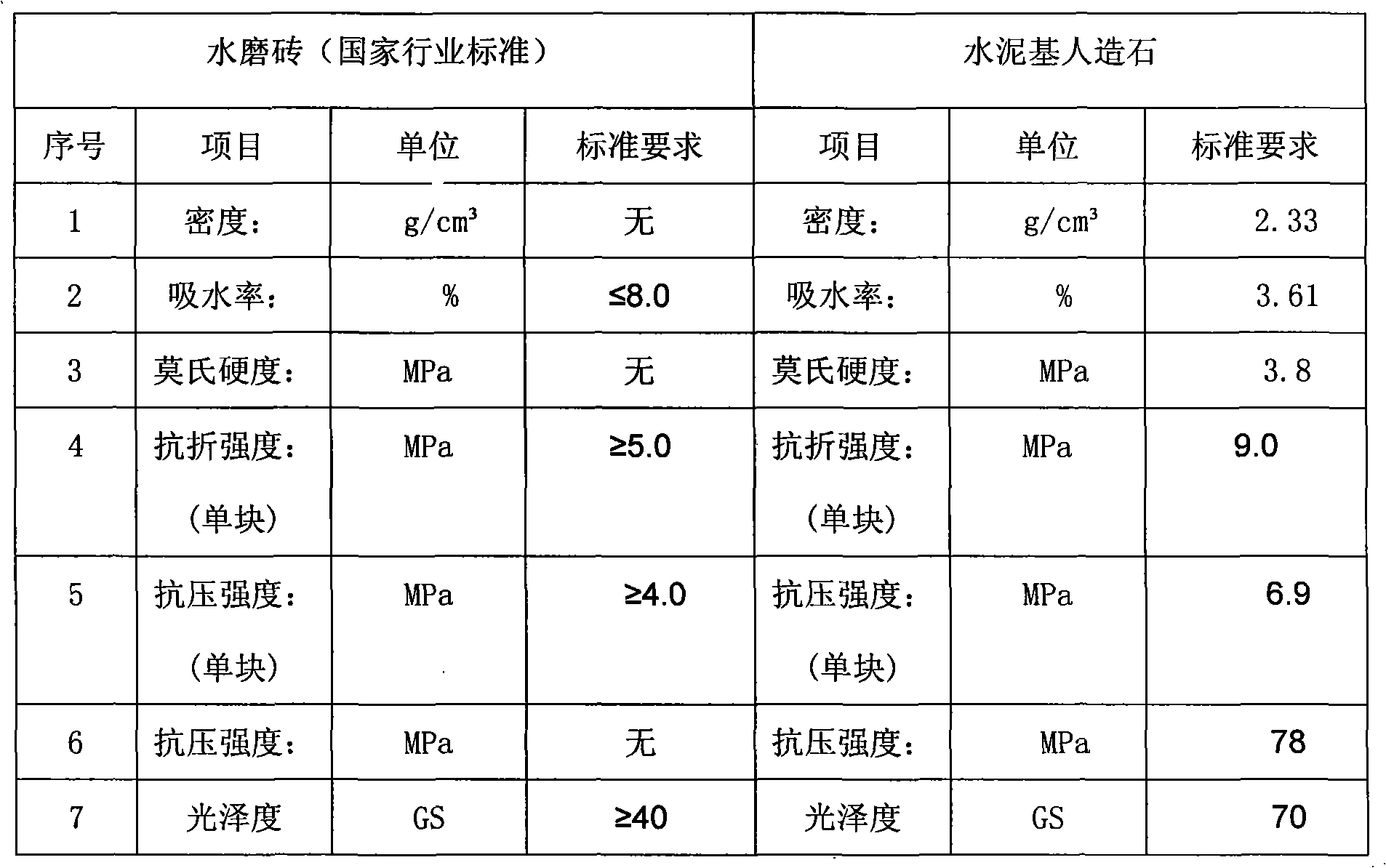

A production process and artificial stone technology, applied in the field of artificial stone and its production process, can solve the problems of not meeting the physical and mechanical performance requirements of construction engineering, poor physical and mechanical properties, dull colors and varieties, etc., and achieve good comfort and water absorption. Low, soft and soft effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Use a crusher to crush the scraps and corners of natural marble into silt with a particle size of 0-15mm, and divide them into various specifications and models of 80 mesh, 60 mesh, 40 mesh, 20 mesh, 10 mesh and 5 mesh. s material. Based on the total mass fraction of 100%, 80 mesh accounts for 40%, 10 mesh accounts for 30%, and 5 mesh accounts for 30%. The above materials are mixed evenly. Mix white cement No. 525 with the above-mentioned mixed materials according to the mass ratio of 1:1.5, and then add water reducing agent, the amount of which is 0.3% of the cement mass; SM 1013 P high-efficiency active powder (manufacturer: Suzhou Xingbang Chemical Building Materials Co., Ltd.), its consumption is 0.5% of cement quality, brightener, its consumption is 0.4% of cement quality, mix and stir evenly, form initial mixture; Add water according to 8% of initial mixture quality, stir, Form the mixed material; inject the above mixed material into the mold for die-casting, pre...

Embodiment 2

[0026] Use a crusher to crush the scraps and corners of natural marble into silt with a particle size of 0-15mm, and divide them into various specifications and models of 80 mesh, 60 mesh, 40 mesh, 20 mesh, 10 mesh and 5 mesh. s material. Based on the total mass fraction of 100%, 80 mesh accounts for 5%, 10 mesh accounts for 30%, and 60 mesh accounts for 65%. The above materials are mixed evenly. Mix white cement No. 625 with the above-mentioned mixed materials according to the mass ratio of 1:2.5, and then add melamine formaldehyde resin water reducer, the amount of which is 0.5% of the cement mass; SM 1013P high-efficiency active powder (manufacturer: Suzhou City Xingbang Chemical Building Materials Co., Ltd.), its consumption is 0.3% of cement quality, brightener, its consumption is 0.5% of cement quality, mix and stir evenly, form initial mixture; Add water according to 15% of initial mixture quality, Then stir evenly to form a mixture; inject the above mixture into the m...

Embodiment 3

[0029] Use a crusher to crush the scraps and corners of natural marble into silt with a particle size of 0-15mm, and divide them into various specifications and models of 80 mesh, 60 mesh, 40 mesh, 20 mesh, 10 mesh and 5 mesh. s material. Based on the total mass fraction of 100%, 80 mesh accounts for 5%, 10 mesh accounts for 30%, and 60 mesh accounts for 65%. The above materials are mixed evenly. Mix the colored cement with the above-mentioned mixed materials according to the mass ratio of 1:2, and then add the water reducer, the amount of which is 0.4% of the cement mass; SM 1013 P high-efficiency active powder (manufacturer: Suzhou Xingbang Chemical Building Materials Co., Ltd.), its dosage is 0.4% of the cement mass, brightener, its dosage is 0.3% of the cement mass, mix and stir evenly to form the initial mixture; add water according to 10% of the initial mixture quality, and then stir evenly to form Mixed material; inject the above mixed material into the mold for die-ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com