Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

212results about How to "Meet the needs of construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

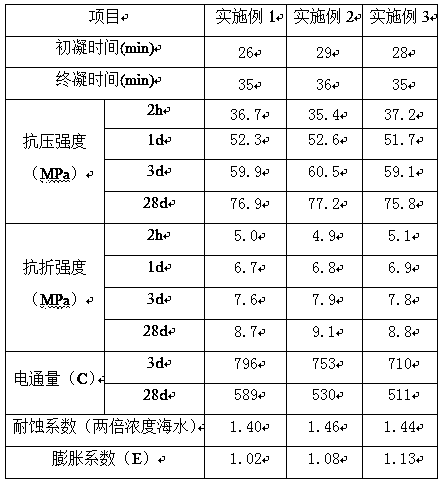

Sulphoaluminate maritime work cement and preparation method thereof

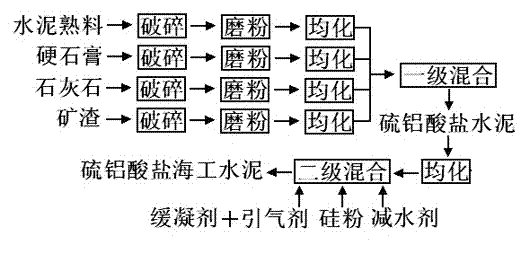

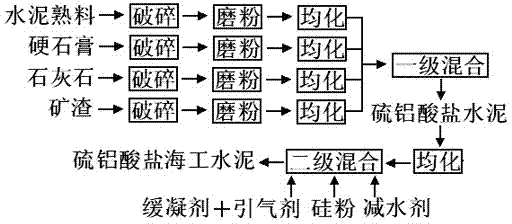

The invention discloses sulphoaluminate maritime work cement and a preparation method thereof. The sulphoaluminate maritime work cement comprises the following main raw materials in parts by weight: 50-80 parts of cement clinker, 8.0-20 parts of anhydrite, 0-30 parts of limestone, 0-30 parts of slag, 0.1-0.5 part of water reducing agent, 0.001-0.005 part of air entraining agent, 0.1-0.5 part of retarder and 2-5 parts of silicon powder. The preparation method comprises the following steps of: respectively smashing, grinding and homogenizing the sulphoaluminate cement clinker, the anhydrite, the limestone and the slag; then, burdening at a ratio, and evenly mixing; adding the water reducing agent, the air entraining agent, the retarder and the silicon powder; and mixing and homogenizing to obtain the product. The concrete mixed by the sulphoaluminate maritime work cement has the advantages of small bleeding rate and high slurry viscidity. The slurry has strong covering and supporting action on aggregate. The concrete keeps good homogeneity and has the advantages of hard and quick early strength, continuously-increased later strength, good slurry structure compactness and high volume stability and is convenient to use and operate for constructing.

Owner:广西云燕特种水泥建材有限公司

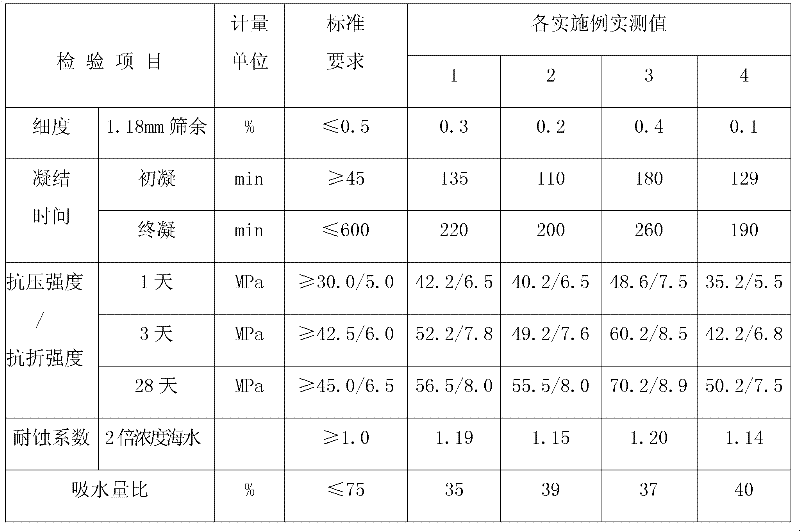

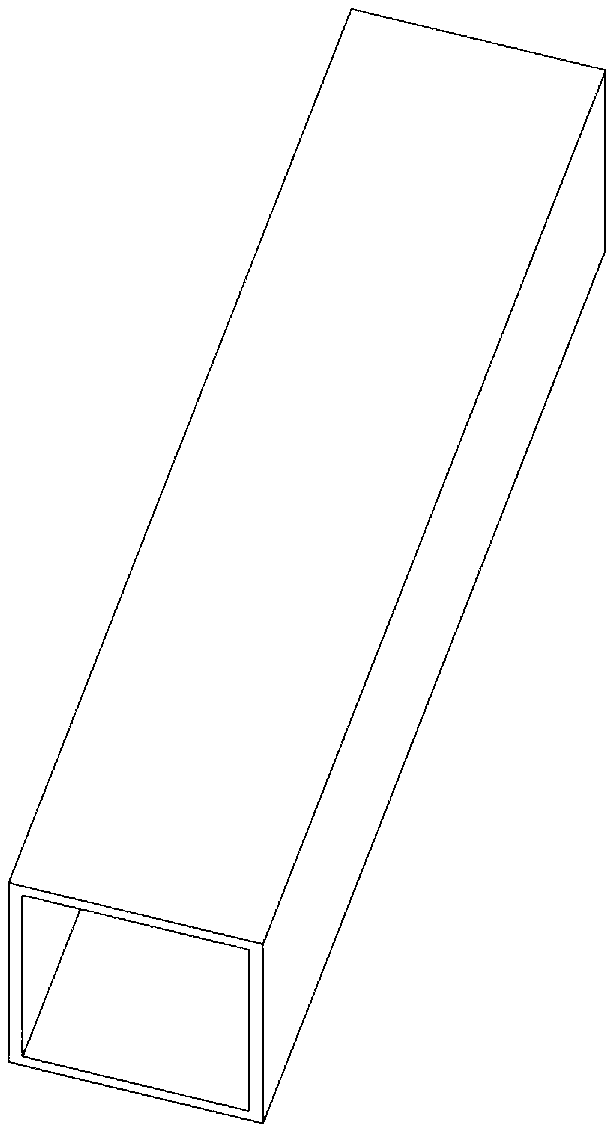

Abnormal shape box column and processing craft thereof

InactiveCN106884498ASimple structureGuaranteed sizeStrutsWelding apparatusEngineeringAbnormal shapes

The invention discloses an abnormal shape box column. The abnormal shape box column comprises a panel, partition plates, web plates and an upper flange plate, the partition plates are arranged on the panel, the web plates are arranged on the two sides of the partition plates and are fixedly connected with the panel, the upper flange plate is arranged at the upper parts of the two web plates, technical partition plates are arranged at the two ends of the panel, and the partition plates and the web plates are matched with the upper flange plate. According to the abnormal shape box column, the web plates are arranged on the panel to form a box body, the parathion plates are arranged in the box body, the upper flange plate is arranged at the upper part of the box body, and the technical partition plates are arranged at the two ends of the box body, so that the structure of the box column is improved, moreover, the size of the end part of the box body is effectively guaranteed, the processing of a large connector is facilitated on site, the supporting performance and the stability are also greatly improved, and the construction requirement is further better met.

Owner:JIANGSU HUNING STEEL MECHANISM

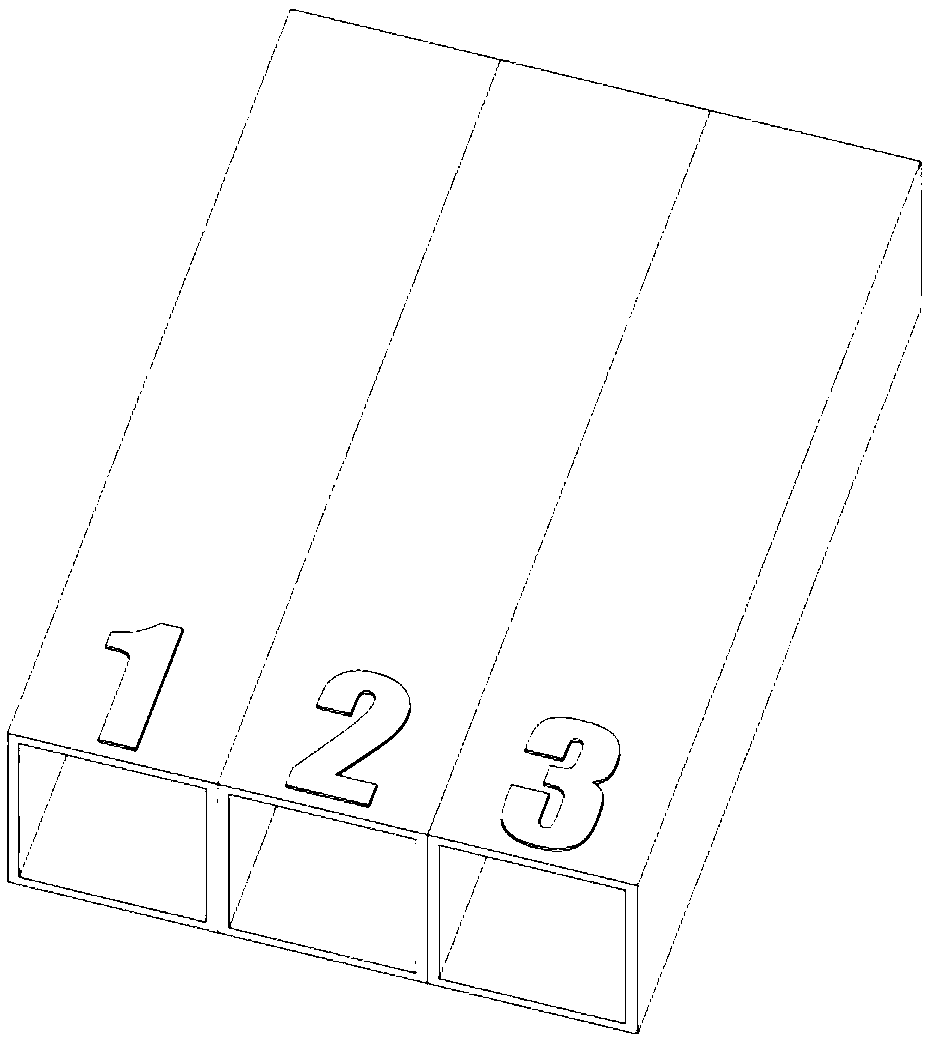

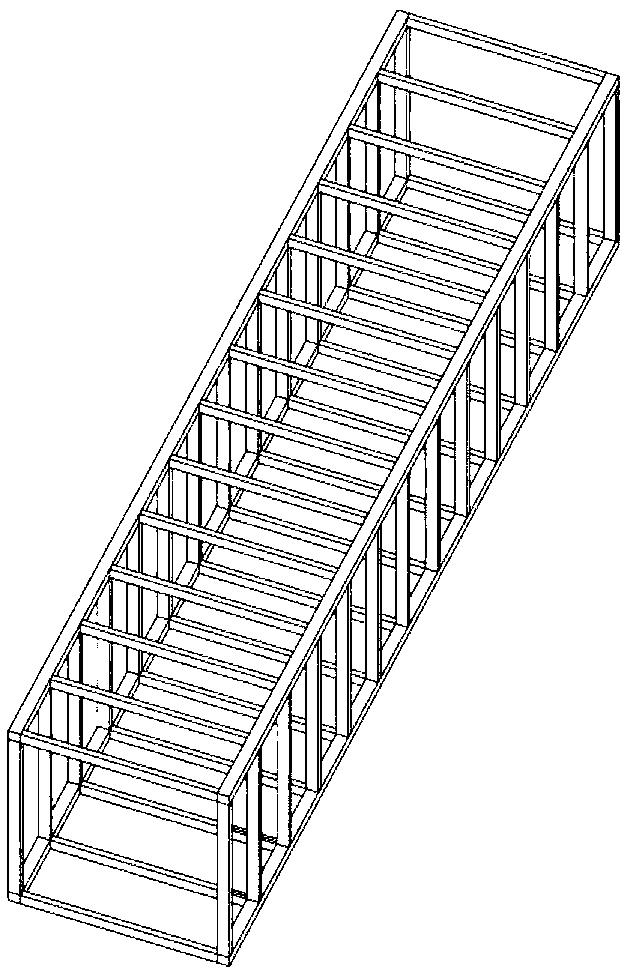

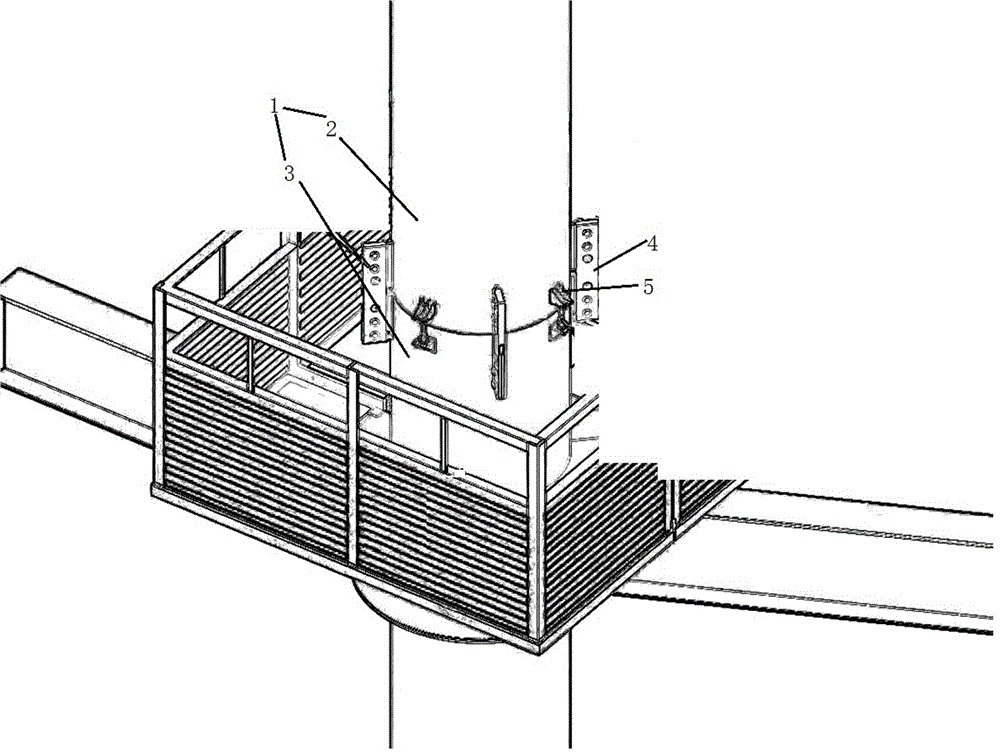

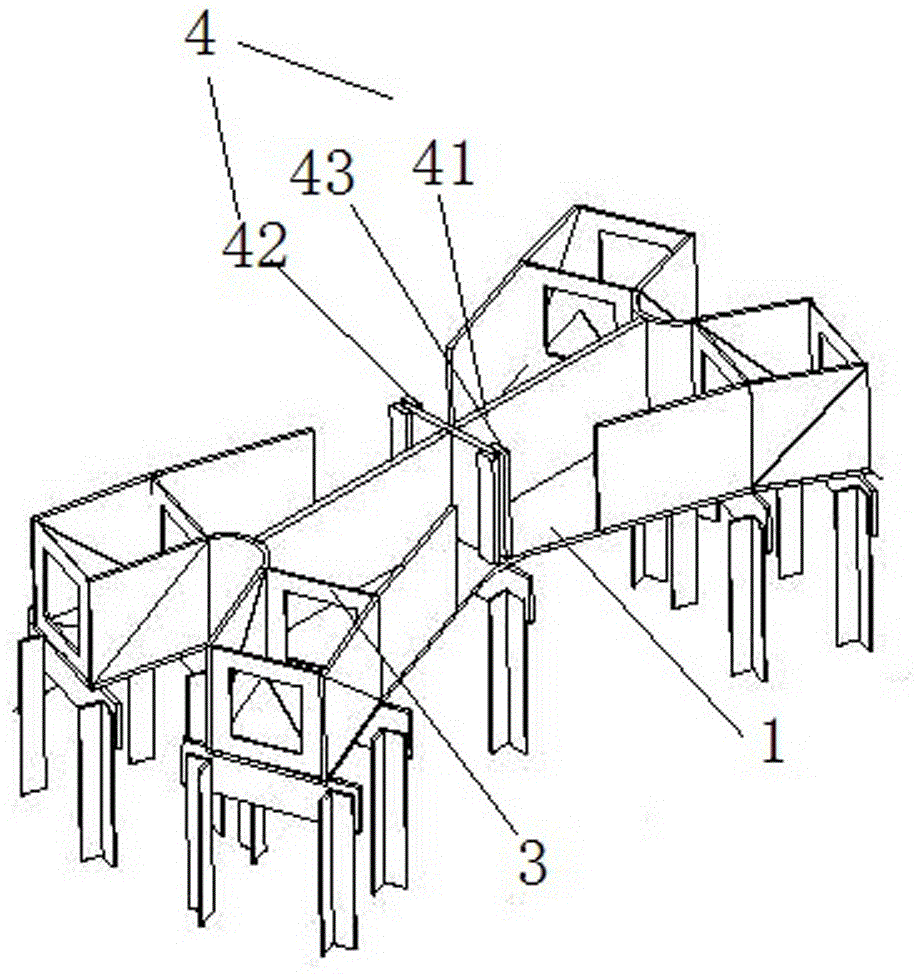

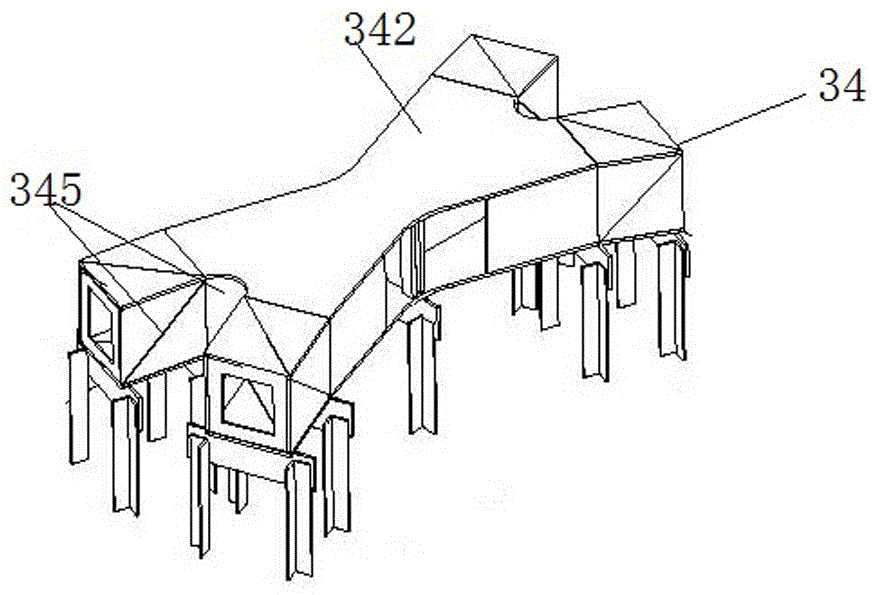

House construction building structure module, house and method for constructing same

InactiveCN108867875AGuaranteed StrengthDoes not affect structural strengthBuilding constructionsArchitectural engineeringPrefabrication

The invention relates to a house construction building structure module, a house and a method for constructing the same, and belongs to the technical field of prefabricated buildings. The house construction building structure module is of an integral structure formed by means of integral pouring prefabrication in factories and at least comprises a bottom surface, a left side surface, a top surfaceand a right side surface. The bottom surface, the left side surface, the top surface and the right side surface are sequentially connected with one another, and cavities are enclosed by the bottom surface, the left side surface, the top surface and the right side surface; the length of the house construction building structure module is the size of the house construction building structure modulealong the left-right directions, the width of the house construction building structure module is the size of the house construction building structure module along the front-rear directions, the height of the house construction building structure module is the size of the house construction building structure module along the up-down directions, and the length of the house construction buildingstructure module is larger than the width of the house construction building structure module; the design depth of the house is divided into a plurality of units in the width direction of the house construction building structure module according to restriction sizes not larger than the transport widths, and the sizes of the width of the house construction building structure module are the sizes of the widths of the divided units. The house construction building structure module, the house and the method have the advantages that use spaces of the house can be expanded by the house constructionbuilding structure module under the condition that the requirements of the transport sizes are met, and accordingly the limitation on the use spaces of the house due to the transport sizes can be broken.

Owner:张剑

Production process for grade II screw thread reinforced bar

InactiveCN101008065AReduce alloy consumptionReduce manufacturing costTemperature control deviceManufacturing convertersRebarNitrogen source

The invention discloses a process for preparing 20MnSi II grade thread reinforcement bar. It comprises: taking nitrogen source as strengthening element for said thread reinforcement bar; adding other microscale nitride; controlling manganese content in 20MnSi steel to be between 0.4 -1.2%, silicon content 0.20- 0.60%, and carbon 0.15- 0.25%; adding nitrogen- containing alloy during tapping process to make nitrogen content in steel be 0.5- 0.025%, adding nitrogen-containing compound of 0.1-3.0kg / t steel into ladle to form element alloy; sub argon areating or top argon areating to ladle after tapping, the argon areating strength is 0.01- 0.10 m3 / min. t steel, time is 3- 8 minutes, the rolling temperature is 1000- 1300 Deg. C, the coling speed after rolling is 1.0- 3.5 Deg. C / second. The yield strength is larger than 345 Mpa, strength for extension is larger than 500 Mpa, yield ratio is about 0.68, elongation is larger than 17%, and the comprehensive cost is reduced by 5- 10 yuan / t thread reinforcement bar.

Owner:湖南华菱涟源钢铁有限公司

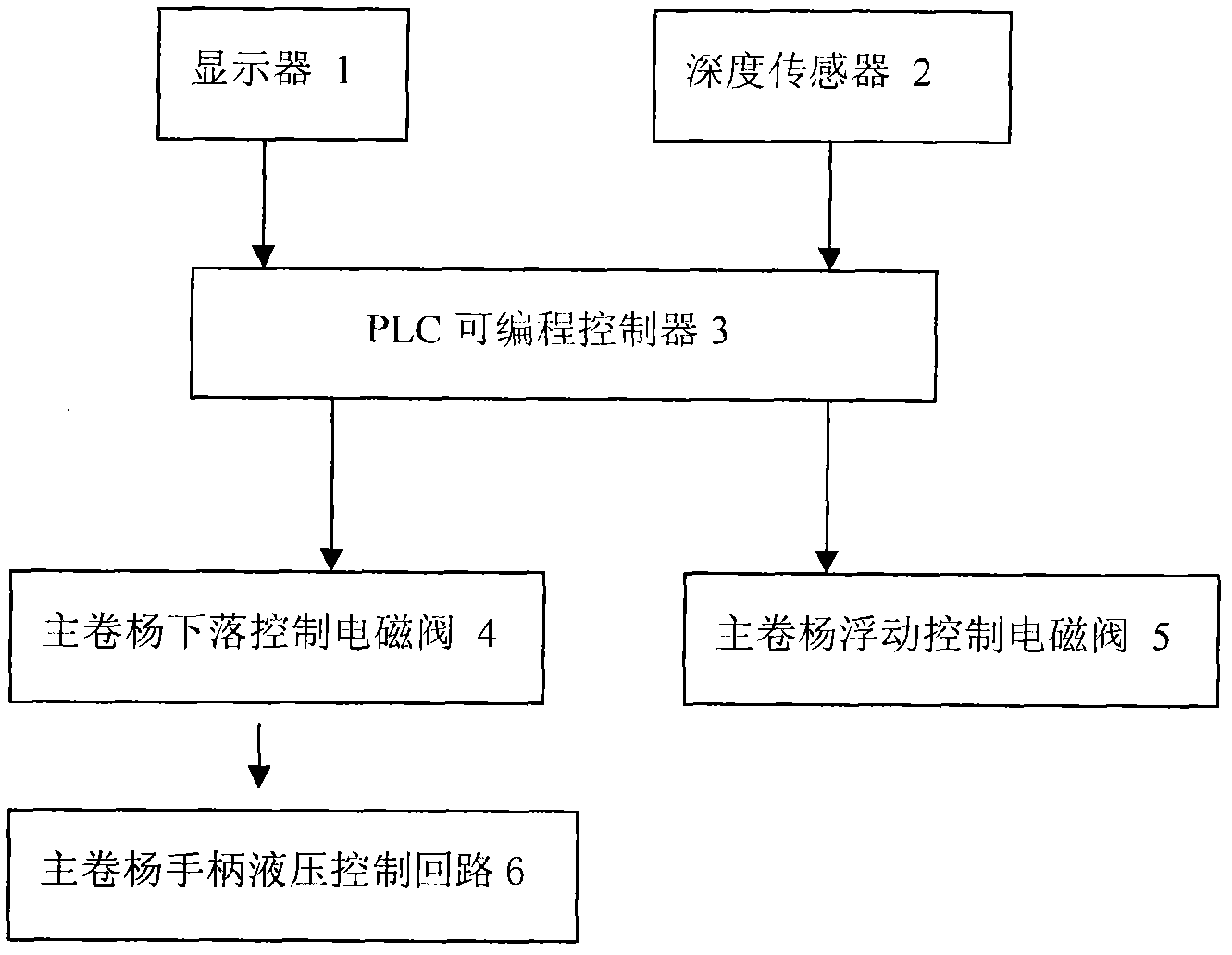

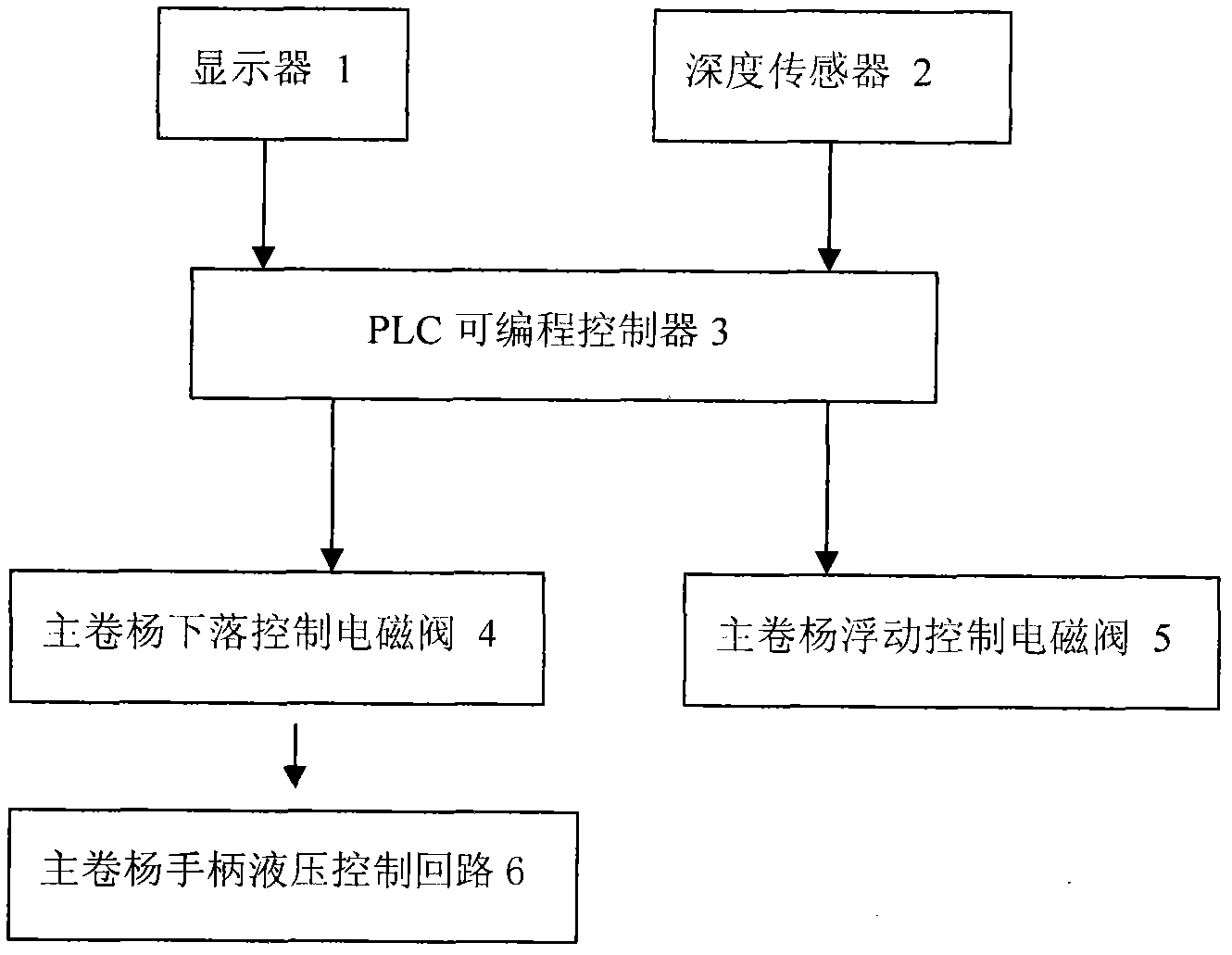

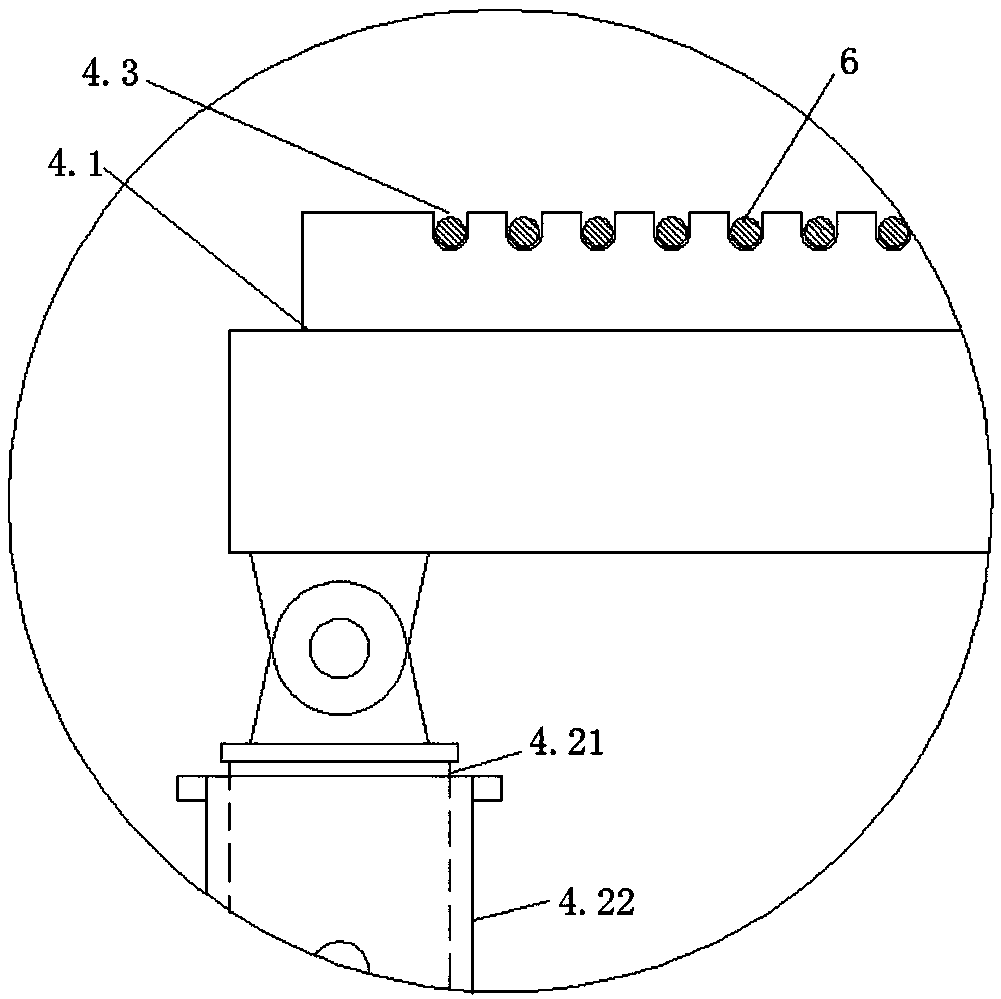

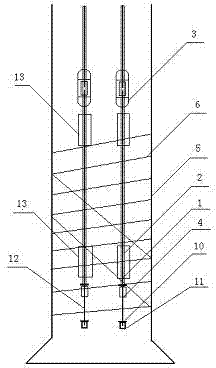

Interlocking control system for falling, floating and depth sounding of main winch of rotary drilling rig

InactiveCN102155210APhenomena that reduce service lifeReduce use costAutomatic control for drillingSolenoid valveControl signal

The invention discloses an interlocking control system for falling, floating and depth sounding of a main winch of a rotary drilling rig, and belongs to an electro-hydraulic interlocking control mechanism. The interlocking control system comprises a central processing unit (CPU), a display connected with the CPU, a depth sounding sensor and a main winch floating control solenoid valve; and a main winch falling control solenoid valve and the CPU which are connected together are serially connected on a hydraulic handle control circuit for main winch falling for the rotary drilling rig. In the invention, when lowering depth of a drill bit is close to depth of a bore hole, the CPU stops outputting a control signal to a switch solenoid valve so as to cut off a pressure control oil circuit which causes falling of the main winch, and meanwhile the CPU outputs a control signal to automatically control main winch floating, which prevents a steel wire rope from being loosen. The interlocking control system has the beneficial effects that application range of equipment is enlarged, construction risk of a user is lowered, and operating strength of a driver is greatly reduced; and the interlocking control system has the advantages of simple structure, reliable performance and low cost, and is convenient in operation.

Owner:徐州博汇东明机械制造有限公司

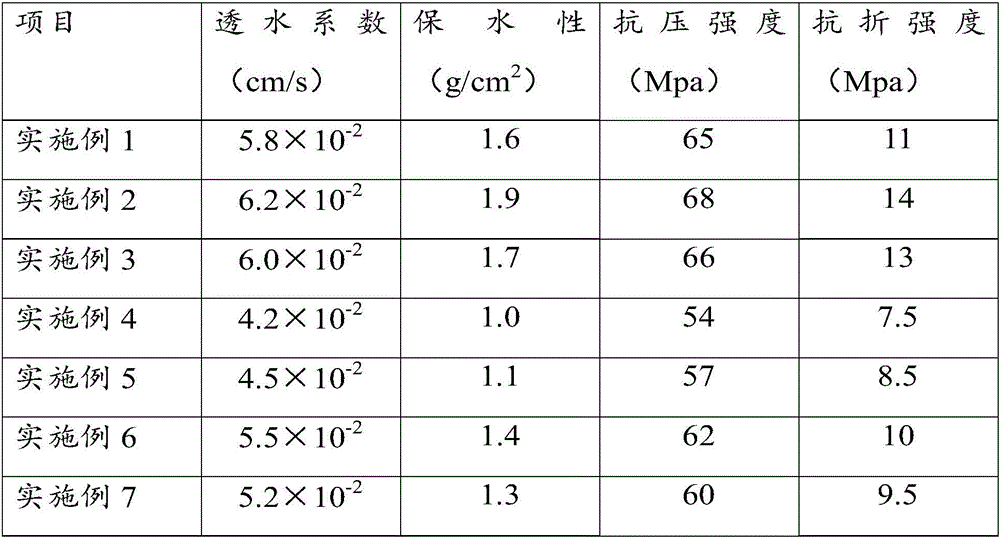

City sponge water permeable structure brick and production technology thereof

InactiveCN106747571AGood water permeabilityHigh water retentionSingle unit pavingsPaving gutters/kerbsBrickCrushed stone

The invention relates to the technical field of building materials, in particular to a city sponge water permeable structure brick and a production technology thereof. The city sponge water permeable structure brick comprises a bottom layer and a surface layer, wherein the surface layer is integrally formed at the upper surface of the bottom layer; the bottom layer is mainly prepared from the following raw materials in parts by weight: 80 to 120 parts of cement, 350 to 450 parts of fine sand, 400 to 550 parts of crushed stone, 50 to 100 parts of solid waste powder and 100 to 150 parts of water; the surface layer is mainly prepared from the following raw materials in parts by weight: 10 to 18 parts of cement, 25 to 45 parts of fine sand, 35 to 55 parts of crushed stone, 2 to 10 parts of white cement, 0.5 to 2 parts of pigment and 1 to 6 parts of water. The city sponge water permeable structure brick has the advantages that the problem of contradiction between mechanical property and water permeation rate of the water permeable brick is solved; the water permeable property, water retention rate and compressive strength are good, the utilization rate of wastes is effectively improved, and the production cost is reduced.

Owner:HENAN GUOLONG IND

Multi-function trolley and construction method thereof

The invention provides a multi-function trolley. The multi-function trolley comprises a door frame system, a rebar feeding system and a work platform assembly. The rebar feeding system comprises a rebar containing arch frame, a rotating member, a horizontally-moving member and a rebar falling-proof assembly, the rebar containing arch frame comprises a group of arch frame single piece or at least two groups of arch frame single pieces arranged in parallel; and the rotating member comprises at least one group of rotating single piece, and each rotating single piece comprises a power source and arotating connecting piece. The horizontally-moving member comprises a driving source and horizontally-moving single pieces arranged with the rotating single pieces in a one-to-one correspondence mode. The rebar falling-proof assembly comprises at least one group of rebar falling-proof single piece arranged correspondingly with the arch frame single pieces. The work platform assembly comprises a top platform and a side direction platform group. The multi-function trolley can realize quick feeding of circumferential rebar. The invention further discloses a construction method for the multi-function trolley. The construction method comprises the following steps of circumferential rebar construction, longitudinal rebar construction and waterproof material construction, one machine with multiple purposes is realized, and the practicality is high.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

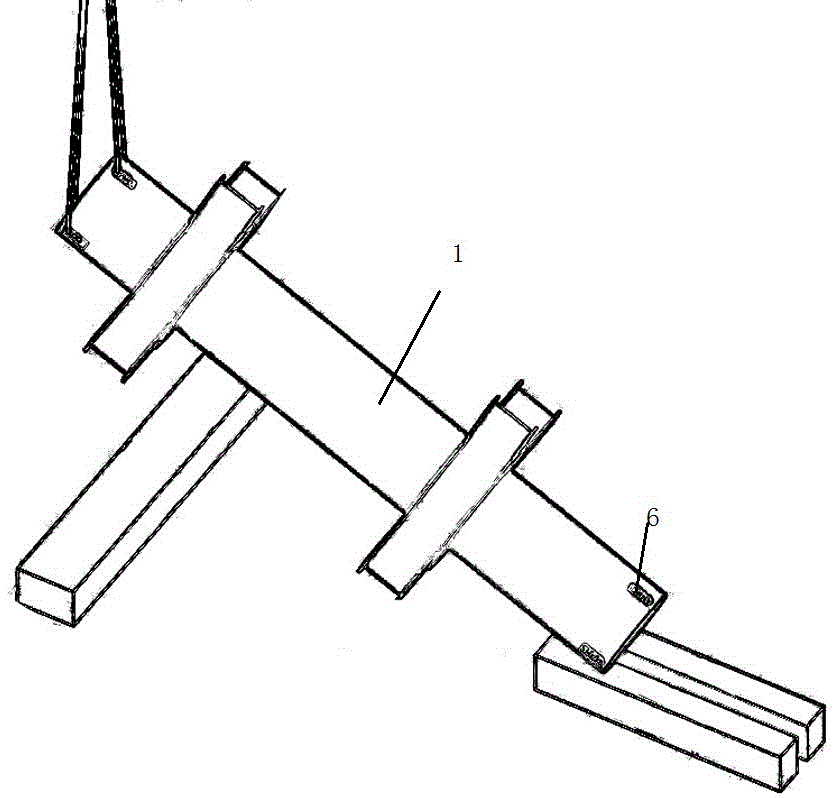

Steel column structure and method for controlling allowable misalignment thereof

ActiveCN106760197ASolve the problem of difficult liftingEasy to liftStrutsBuilding material handlingSteel columnsUpper segment

The invention discloses a steel column structure and a method for controlling allowable misalignment thereof. The steel column structure comprises a column body which is composed of an upper segment column and a lower segment column. The upper segment column and the lower segment column are connected through connecting plates. Jacks are arranged in the positions, located among the connecting plates, of the upper segment column and the lower segment column, and connecting ear plates are arranged at the two ends of the upper segment column. According to the steel column structure, the connecting ear plates are arranged at the two ends of the column body, so that hoisting is facilitated, the current problem of difficult hoisting of the steel column is well solved, and the safety of construction is improved. Meanwhile, the jacks are arranged between the upper and lower segment columns, errors between the upper segment column and the lower segment column are adjusted through the jacks in the process of the installation of the steel column structure, the installation is better finished, and accordingly, the construction requirement can be better met.

Owner:JIANGSU HUNING STEEL MECHANISM

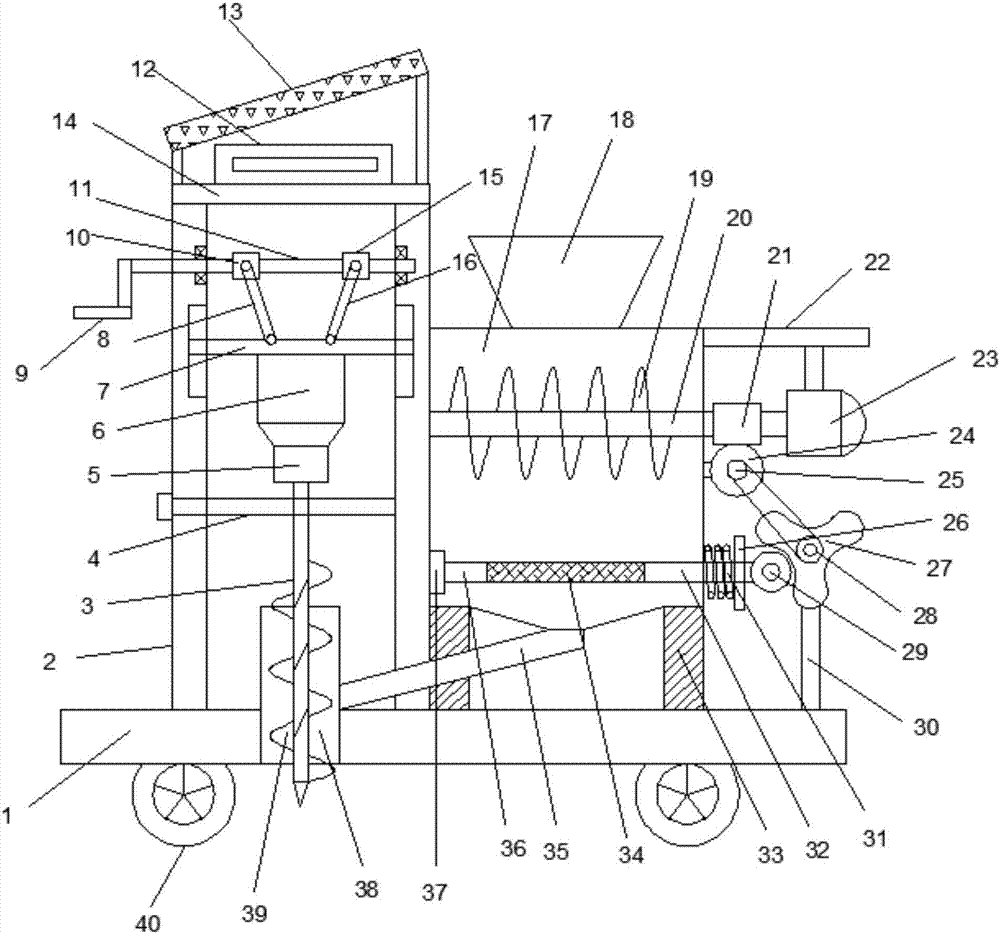

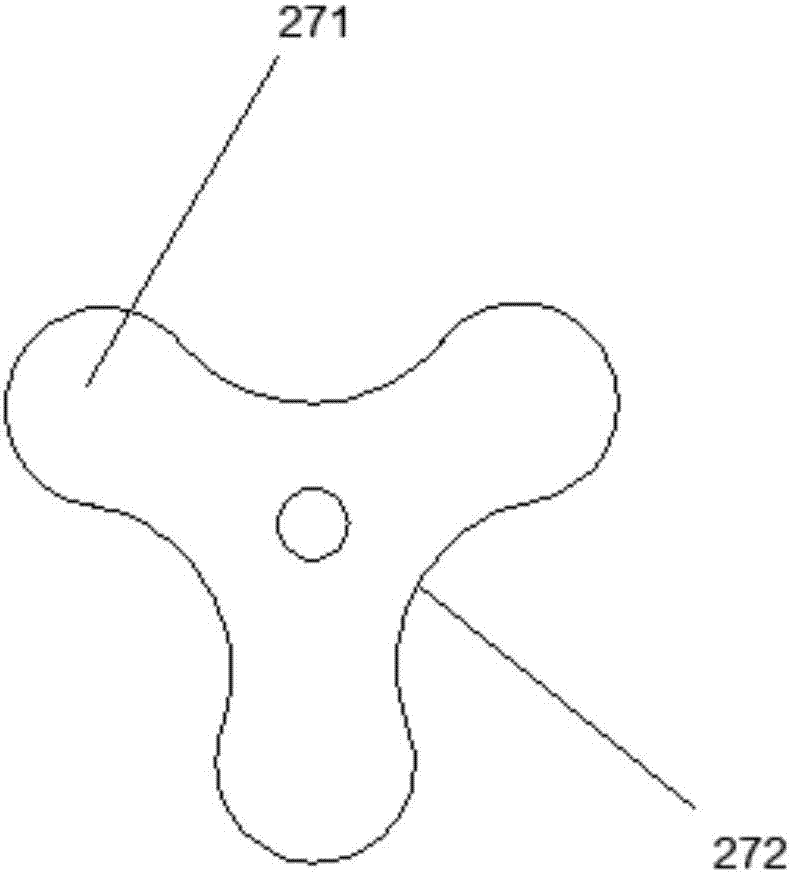

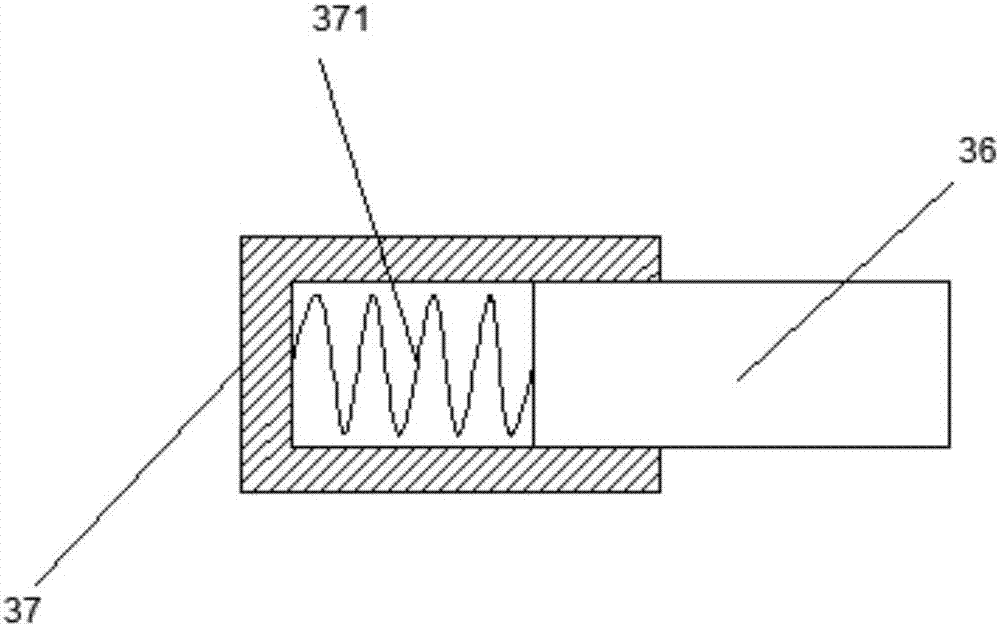

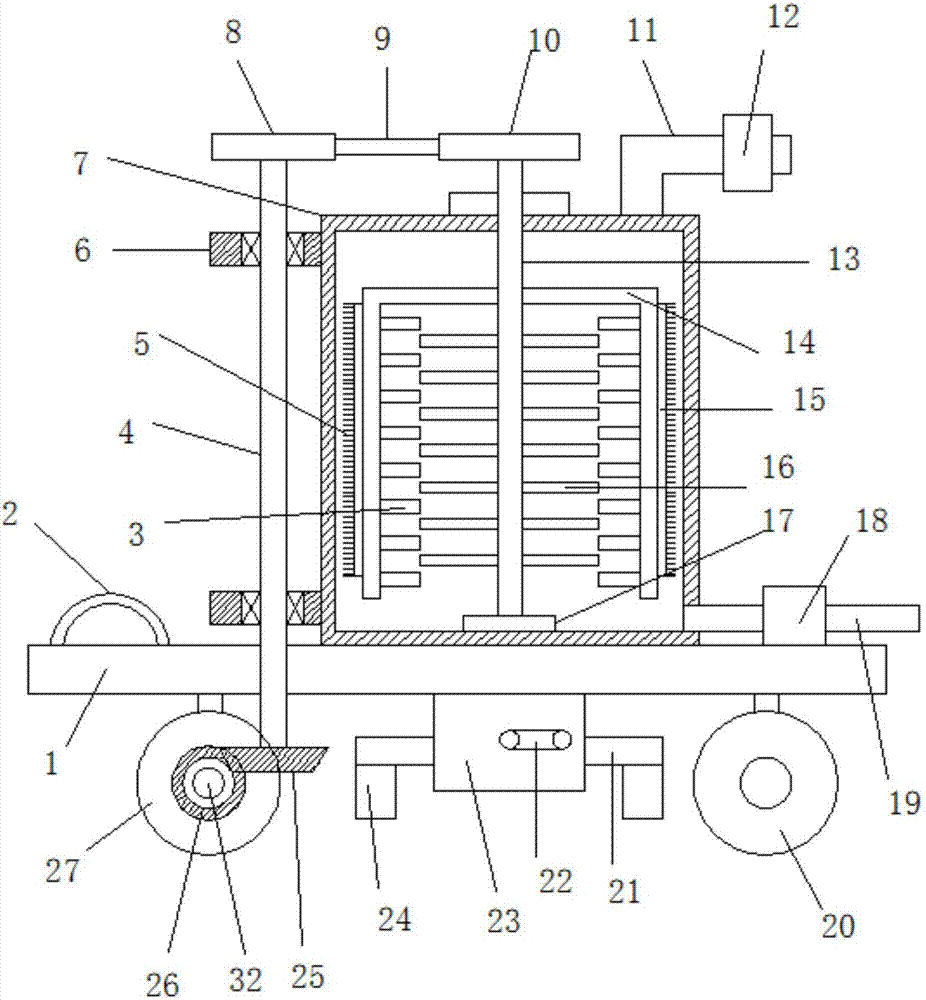

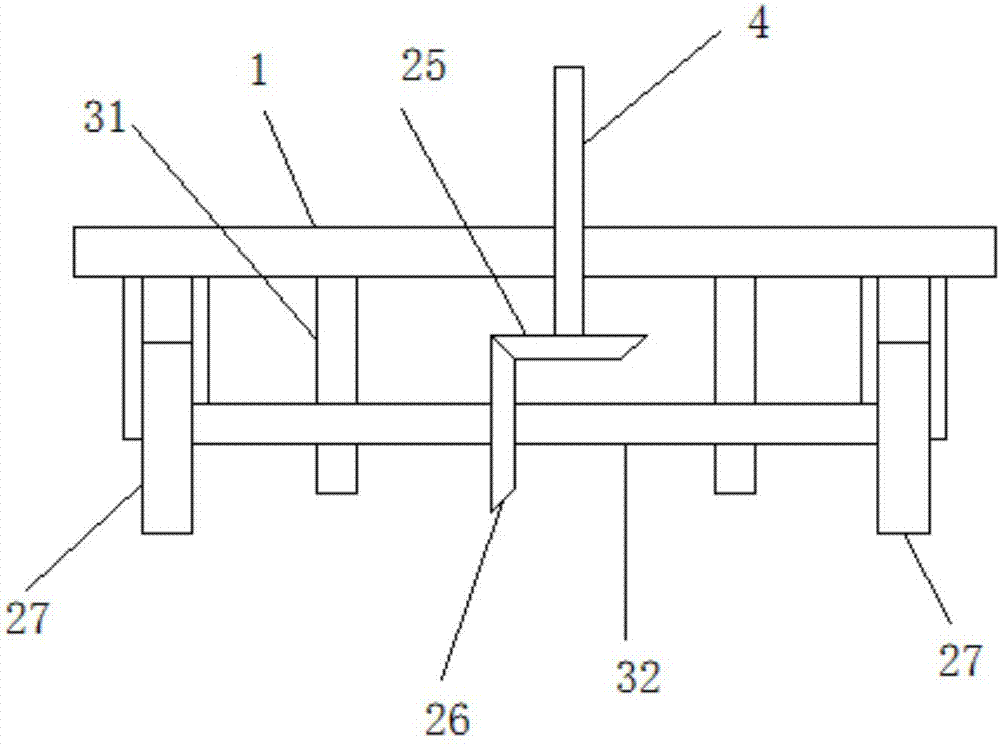

High-speed stirring-squeezing trolley

ActiveCN101352894AWell mixedQuality assuranceDischarging apparatusMixing operation control apparatusAutomatic controlVehicle frame

The invention discloses a high-speed stirring mud grouting trolley and is characterized in that: the high-speed stirring mud grouting trolley is provided with a frame, and the frame is equipped with a screw conveying mechanism, a high-speed stirring mechanism, a grout pump and a controller. The high-speed stirring mechanism is composed of a high-speed stirring drum, a bracket and a high-speed stirring motor. The inlet of the grout pump is communicated with the high-speed stirring drum by a pipeline. The bracket is provided with at least three pillars, and the lower ends of the pillars are fixed on a trolley board, while the upper ends thereof are connected with the bottom of the stirring drum by a weighting sensor. The output shaft of the high-speed stirring motor faces upwards and penetrates into the high-speed stirring drum, and the end of the output shaft is provided with blades. The screw conveying mechanism is fixed on the trolley board in an oblique manner in virtue of the bracket, the end of the the discharge hole of the screw conveying mechanism is communicated with the feeding hole of the high-speed stirring drum, and the feeding hole is provided with a feeding funnel. Automatic control of each part can be realized by the controller. The high-speed stirring mud grouting trolley of the invention not only can save time and improve production efficiency, but also can evenly mix grouting agents and can guarantee the quality of bridges. The high-speed stirring mud grouting trolley is suitable for preparing grouting agents and filling the grouting agents in pipelines.

Owner:贾铭铭 +1

Road surface casting machine of concrete for municipal engineering construction

InactiveCN107299584AReasonable structureInnovative designRoads maintainenceArchitectural engineeringRoad surface

The invention discloses a concrete pavement pouring machine for municipal engineering construction, which comprises a support seat, a support frame is fixedly connected to the left side of the upper end of the support seat, a screw rod is connected to the middle part of the upper end of the support frame, and a lifting plate is connected to the lower ends of the left tie rod and the right tie rod. The middle part of the lower end of the lifting plate is connected with a drive motor, the lower end of the drive motor is connected with a reducer, the reducer is connected with a pouring shaft, the upper end of the support seat is connected with a support leg, the upper end of the support leg is connected with a concrete box, and the upper end of the concrete box is connected with a stirring shaft , the right end of the stirring shaft is connected with a worm, the lower end of the worm is meshed with a worm wheel, the middle part of the worm wheel is connected with a driving pulley coaxially, the driving pulley is connected with a driven pulley through a belt, and the middle part of the driven pulley is connected with a Y-shaped cam at a coaxial position . The invention realizes the uniform feeding of the concrete in the concrete box, and also realizes the lifting type mixing of the concrete during the pouring process, and avoids the upper and lower stratification of the concrete.

Owner:丁家琪

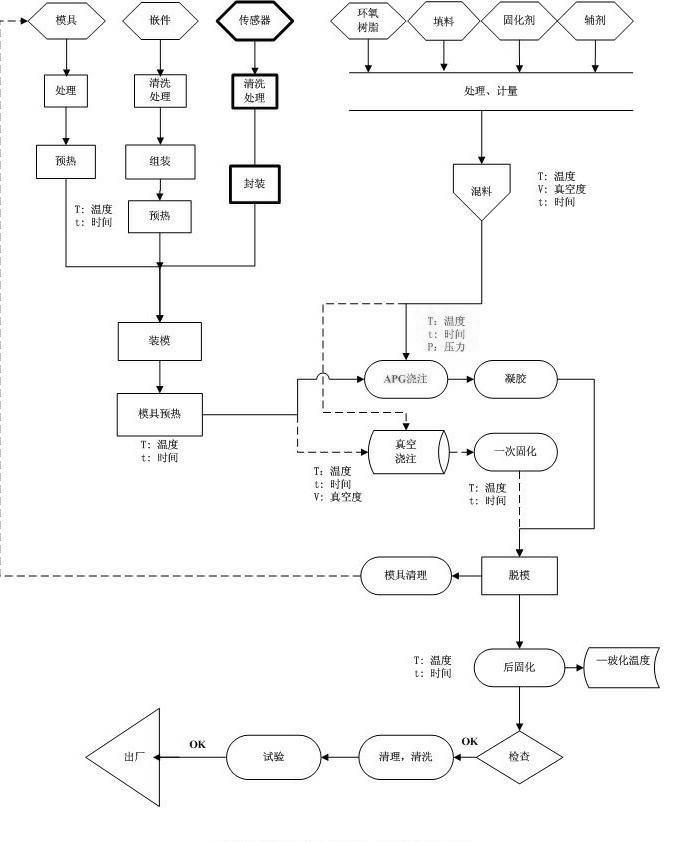

Method for producing insulator or contact box with temperature and/or voltage sensor

ActiveCN102211375AAccurate measurementAccurate measurement positionInsulatorsState of artCommunications system

The invention discloses a method for producing an insulator or a contact box with a temperature and / or voltage sensor. The method comprises the following steps of: a) loading an insert and the sensor into a mold, and preheating; b) mixing materials; c) pouring; d) demoulding; and e) post-curing. Compared with the prior art, the invention has the advantages that: 1) the voltage or / and temperature sensor is sealed inside the contact box or the insulator, so that the interference of outside dirty, light, heat, mechanical deformation and the like to signals is prevented; through an optical fiber transmission signal, the problem of high-voltage insulation is solved and the hidden danger that high voltage enters a low-voltage control system and a communication system is eliminated; 2) the temperature sensor is used to be directly contacted with a detected position, so that the method is accurate in measurement positions and measurement temperatures and high in reliability and safety, and has the characteristics of accurate detection temperature, low discreteness, no temperature upper limit and no temperature compensation simultaneously; and 3) an optical temperature sensor is not subjected to outside electromagnetic interference, so that the stability of a temperature signal is ensured.

Owner:麦克奥迪(厦门)智能电气有限公司

Sea fracturing method

InactiveCN104234681ASolve small spaceSolve the difficulty of moving equipmentFluid removalLine tubingFracturing fluid

The invention relates to a sea fracturing method. The method includes firstly performing fracturing geological design; mounting a fracturing wellhead, and mounting a fracturing wellhead high-pressure pipeline and connecting to a high pressure hose; loading fracturing equipment, suspending the fracturing equipment to a deck and fixing, concentrating the fluid container area, arranging a fluid feeding pump, a sand container, a sand mixing pump pry, a high-pressure injecting pump unit, a high pressure pipeline assembly and the like sequentially behind, preparing water, feeding material and preparing fracturing fluid; after a fracture construction ship arrives at a platform, adopting a tail laying manner, mooring, connecting to the high pressure hose at the gunwale of the platform, starting all high pressure injection pumps, inspecting circularly, and performing the pipeline pressure test; performing fracture construction according to the designed pump injection progress after the pressure test is qualified. The high pressure pipeline assembly is an assembly connected the high pressure injection pumps and high pressure injection pipeline, and the high pressure injection pumps are power equipment injecting fracture fluid into oil pipes through the high pressure pipeline assembly and the high pressure pipeline. The method is applied to oil testing and fracturing construction of sea exploration and development wells.

Owner:PETROCHINA CO LTD

Plastic expanding agent for settlement resistance of high flow state cement based cementing material and preparation method thereof

The invention provides a plastic expanding agent for settlement resistance of high flow state cement based cementing materials and a preparation method thereof. The raw materials include, by weight, 30-50 portions of an azo compound, 10-30 portions of a stabilizing agent, 5-20 portions of a catalyst and 20-40 portions of a rheological additive. The plastic expanding agent provided by the invention can be compounded with efficient water reducer and other additives, and can assist auxiliary additive to realize the flow properties of cement based cementing material, effectively improve the workability, wrapping performance and durability of the cement based materials, has certain compensating shrinkage effect on early age shrinkage of cement based cementing material, and shows anti-settlement and anti-segregation effects while maintaining the high flow state of cement based cementing material.

Owner:武汉品泰新型建材有限公司

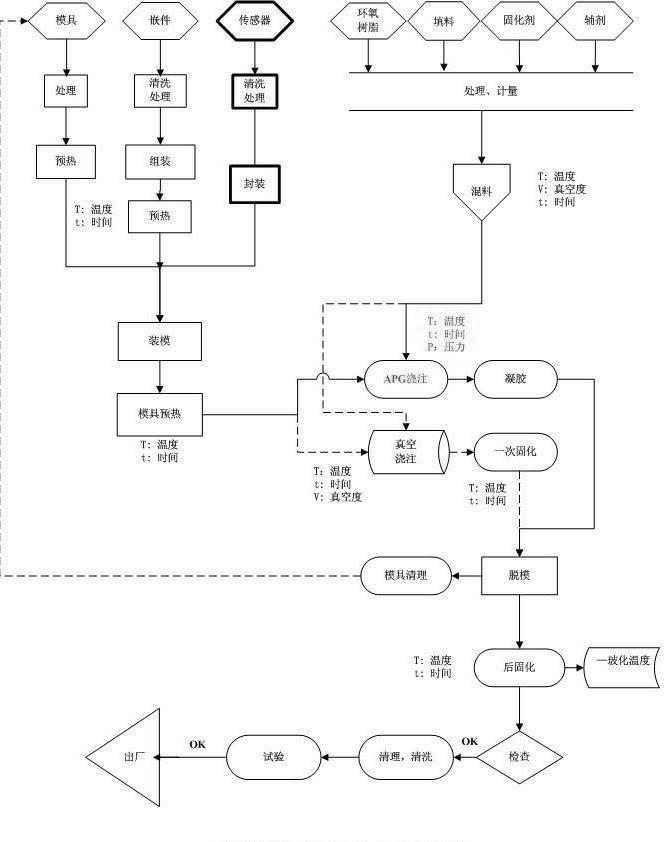

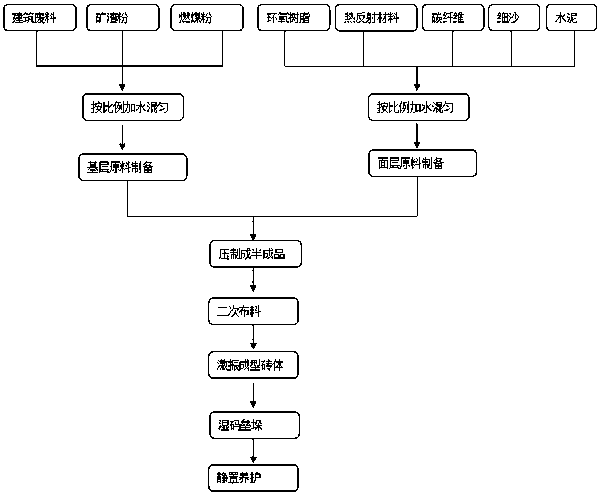

A preparing method for water permeable bricks by utilizing building waste

InactiveCN108484003AMitigate the heat island effectSolve processing problemsSolid waste managementClimate change adaptationFiberEnvironmental resistance

The invention belongs to the field of the reutilization for building waste resource and building material and provides a preparing method for water permeable bricks by utilizing building waste. The water permeable brick comprises a base and surface layer. The raw material of the base layer comprises, by weight: 50-60% of waste raw material crushing particles, 10-20% of slag powder, 5-15% of fire coal powder, and 20-30% of water. The raw material of the surface layer comprises, by weight: 10-20% of epoxy resin, 5-15% of carbon fiber, 10-20% of fine sand, 5-10% of heat reflection material, 30-50% of cement, and 10-20% of water. After the semi-finished product water permeable brick is prepared by mixing and optimizing the configuration, the semi-finished product water permeable brick is shaped by secondary material distribution and once excitation through the intelligentized device. The building water permeable brick has advantages of high permeability, permeation coefficient >= 1.0 * 10<-2 > cm / s, high strength, flexural quality which reaches the national standard of the quality of the brick, ecology, environmental protection, non-radiation, alleviating the city heat island effect,effectively reducing the temperature of the pavement by 3-7DEG C, the texture of natural stone, alkali resistance, and changing building waste into valuables and protecting the ecology environment.

Owner:四川内师检验检测有限责任公司

Emulsified asphalt special for spraying rubber asphalt paint and preparation method of emulsified asphalt

ActiveCN105949480AImprove liquidityWide range of temperature adaptationBituminous coatingsEmulsionBituminous waterproofing

The invention discloses emulsified asphalt special for spraying rubber asphalt paint and a preparation method of the emulsified asphalt. The emulsified asphalt is composed of, by mass, 80-120 parts of asphalt, 40-80 parts of water, 2-5 parts of an anionic asphalt emulsifier, 0-3 parts of a pH agent and 0.1-1 part of a stabilizer, wherein the adding amount of the pH agent is not zero, and the anionic asphalt emulsifier is prepared by mixing at least two of a sulfonate surfactant, a carboxylate surfactant and a sulfate surfactant. The emulsified asphalt can be used for preparing the spraying rubber asphalt paint, can be mixed with a rubber emulsion at any proportion, is stable in storage below minus 10 DEG C and can be matched with the rubber emulsion for spraying construction at minus 5 DEG C. The spraying rubber asphalt waterproof paint prepared by using the emulsified asphalt is high in fluidity, long in working time, wide in temperature adaptation range, less prone to segregation and laying and excellent in physical and mechanical performance; during construction spraying, a coating is quick to solidify and better in performance index, and construction needs can be met fully.

Owner:CHINA OFFSHORE BITUMEN

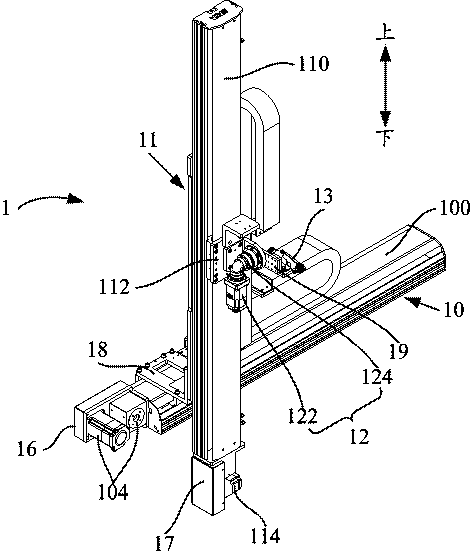

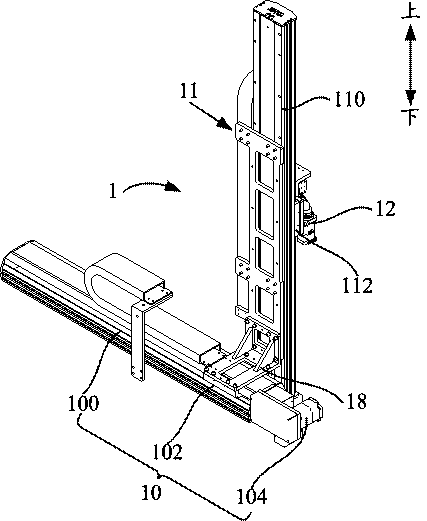

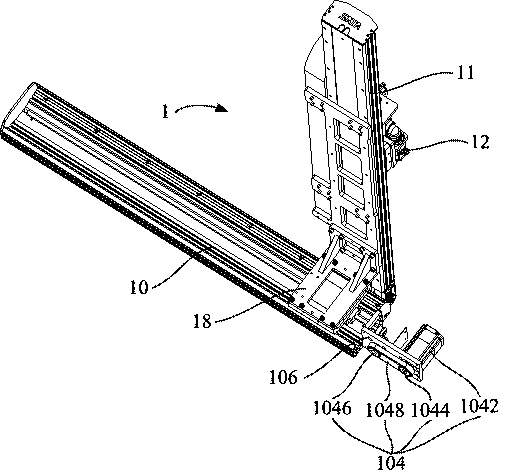

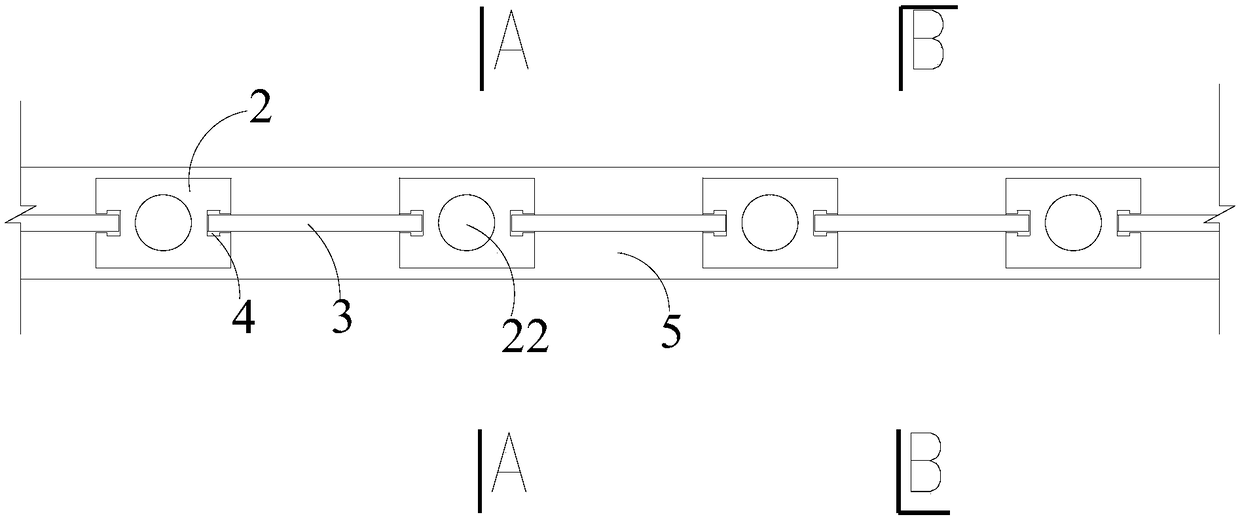

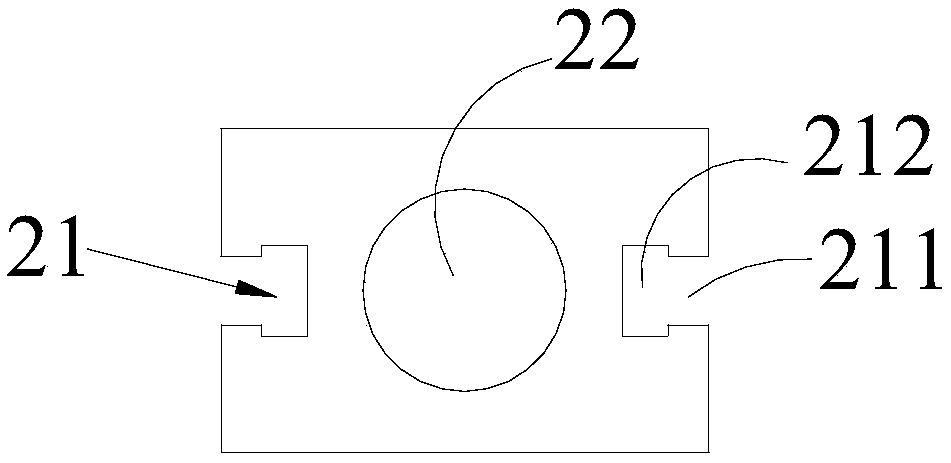

Spray gun assembly and spraying robot

InactiveCN109881872AGuaranteed reliabilityPrevent slippingCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention provides a spray gun assembly and a spraying robot. The spray gun assembly comprises a first guide rail assembly, a second guide rail assembly, a rotating driving part, and a spray gun,wherein the first guide rail assembly comprises a first guide rail mounted on a frame body, a first slide block slidably mounted on the first guide rail and a first slide driving part for driving thefirst slide block to slide, and the first guide rail is arranged in the transverse direction of the working surface; the second guide rail assembly comprises a second guide rail, a second slide block,and a second slide driving part, wherein the second guide rail is mounted on the first slide block and is arranged in the longitudinal direction of the working surface, the second slide block is slidably mounted on the second guide rail, and the second slide driving part is used for driving the second slide block to slide; the rotating driving part is mounted on the second slide block and is provided with a rotating driving shaft; the spray gun is mounted on the rotating driving shaft; and the first slide driving part and / or the second slide driving part are / is connected with the first slideblock and / or the second slide block through a belt transmission assembly. According to the spray gun assembly, slide of the first slide block and the second slide block drives the spray gun to slide in the longitudinal direction and the transverse direction of the working surface, and at the same time, the rotating driving part can drive the spray gun to rotate.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

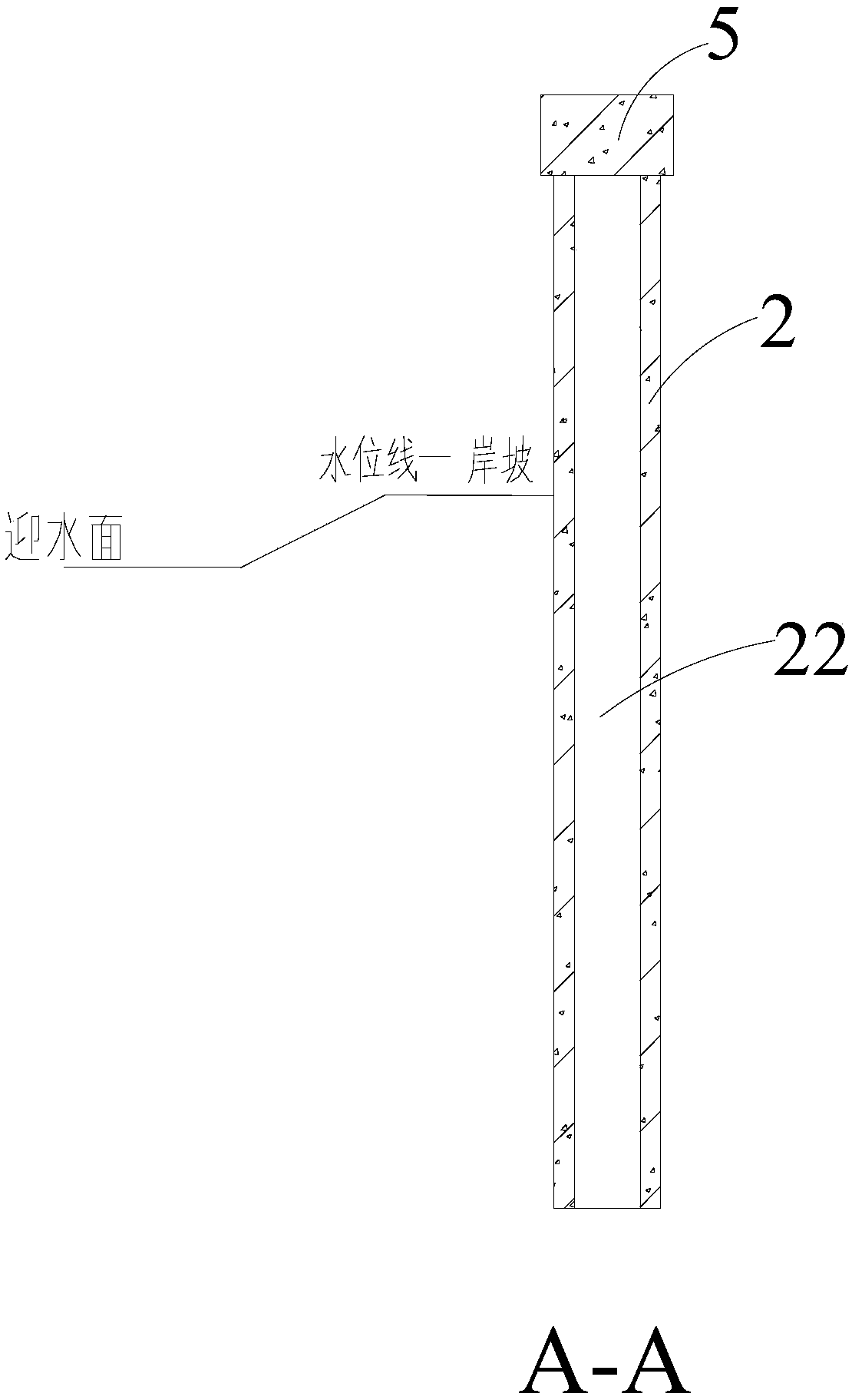

Prefabricated sheet pile combined bank revetment and construction method thereof

PendingCN109056650ASimple and fast constructionPrevent soil leakageClimate change adaptationCoastlines protectionEngineeringRevetment

The invention relates to a prefabricated sheet pile combined bank revetment and a construction method thereof. The prefabricated sheet pile combined bank revetment comprises a plurality of PC wall body piles, a plurality of groups of prefabricated slabs, grouting material and top beams, wherein the PC wall body piles are arranged at intervals along a bank slope; grooves are formed in opposite sidefaces of every two adjacent PC wall body piles; the two ends of each group of prefabricated slab are inserted in the grooves of every two adjacent PC wall body piles; the grouting material is filledbetween the two end parts of each prefabricated slab and the grooves; the top beams are formed at the tops of the PC wall body piles and the prefabricated slabs; each of the prefabricated slabs is formed through assembling a plurality of splice plates; a splice groove is formed in the upper side face of each of the splice plates; and a splice bulge is formed on the lower side face of each of the splice plates. The prefabricated sheet pile combined bank revetment is simple and fast in construction, saves investment, is environmentally-friendly, effectively protects the bank revetment from the soil leakage phenomenon and meets the demand of non-excavation type bank revetment construction.

Owner:无锡市水利设计研究院有限公司

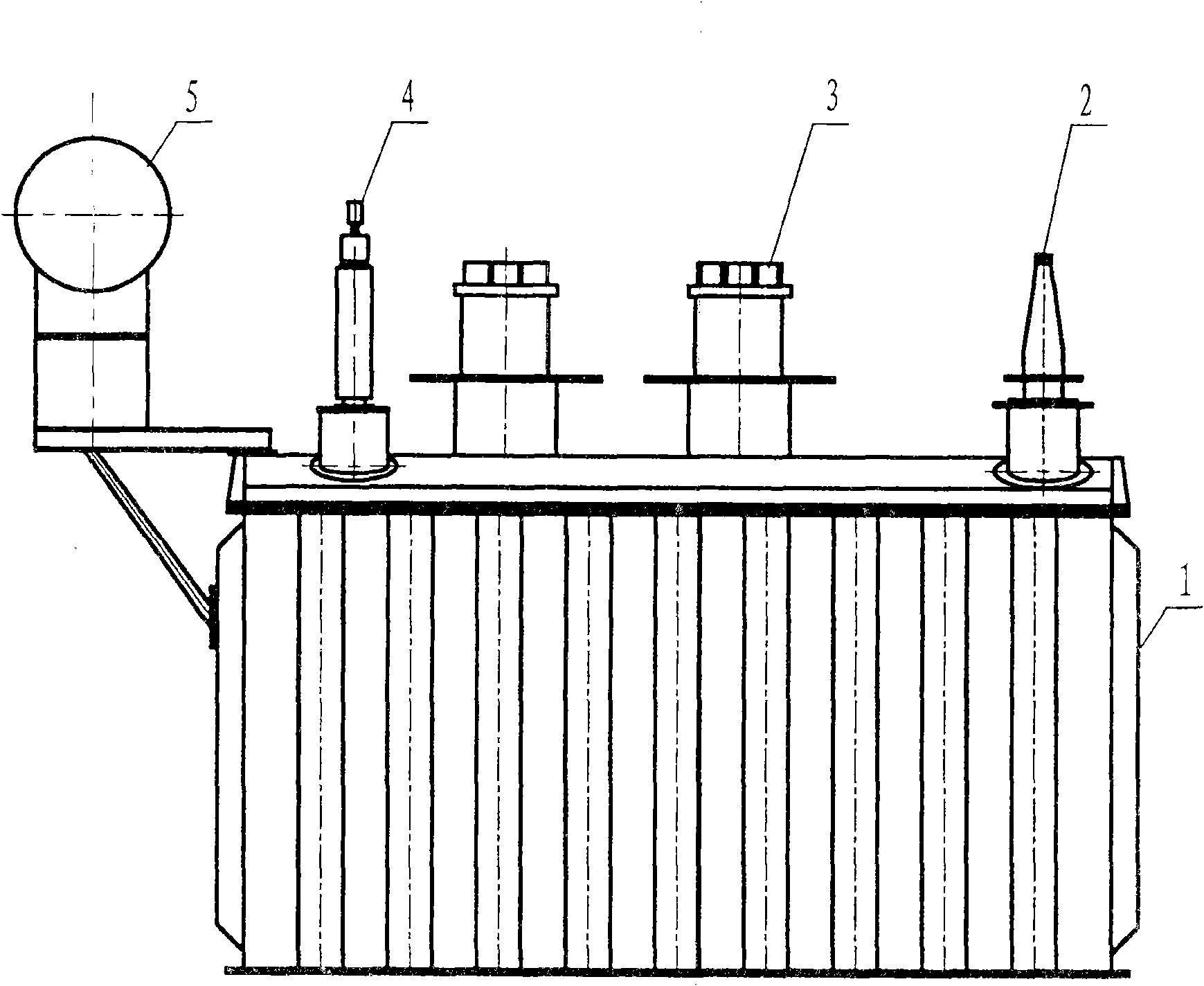

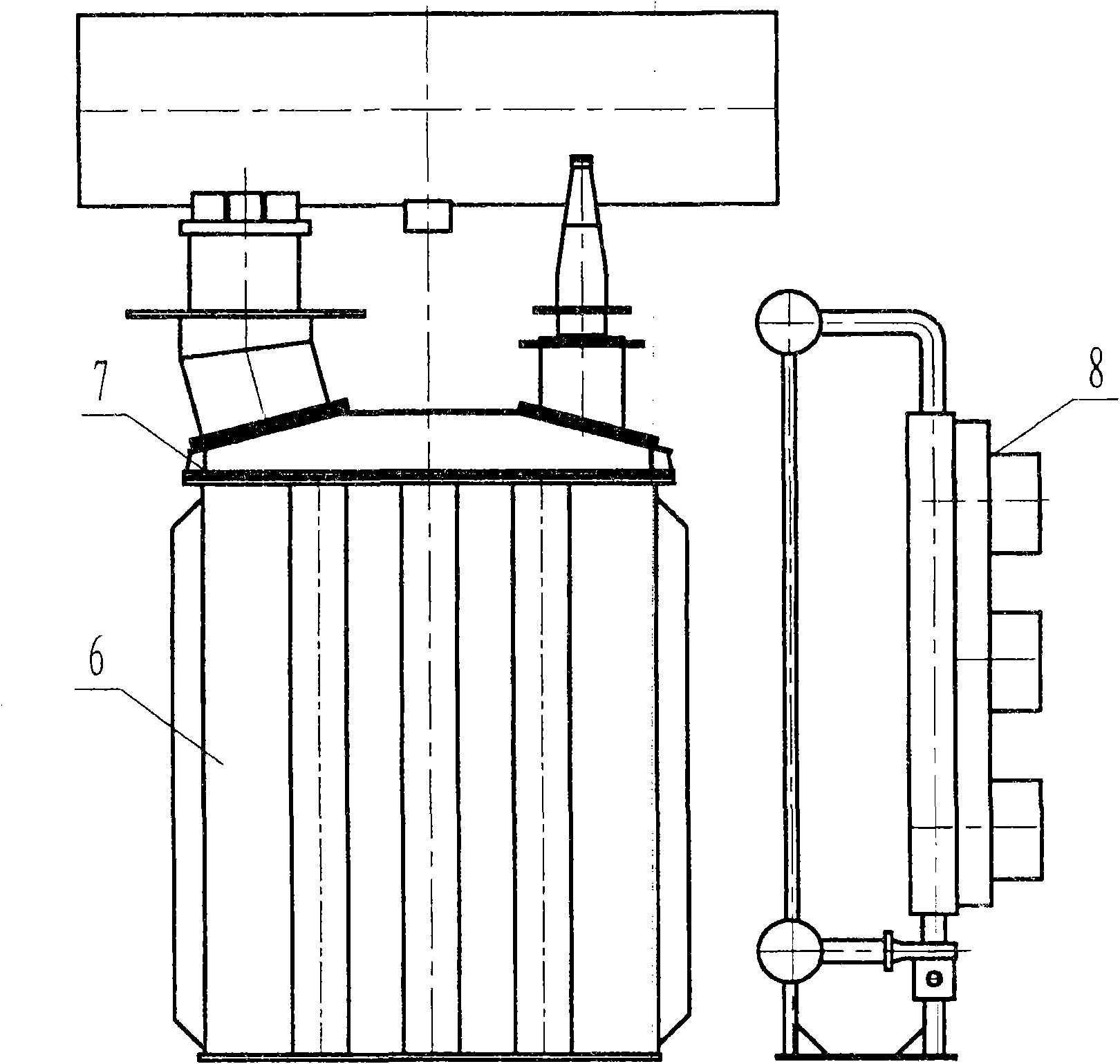

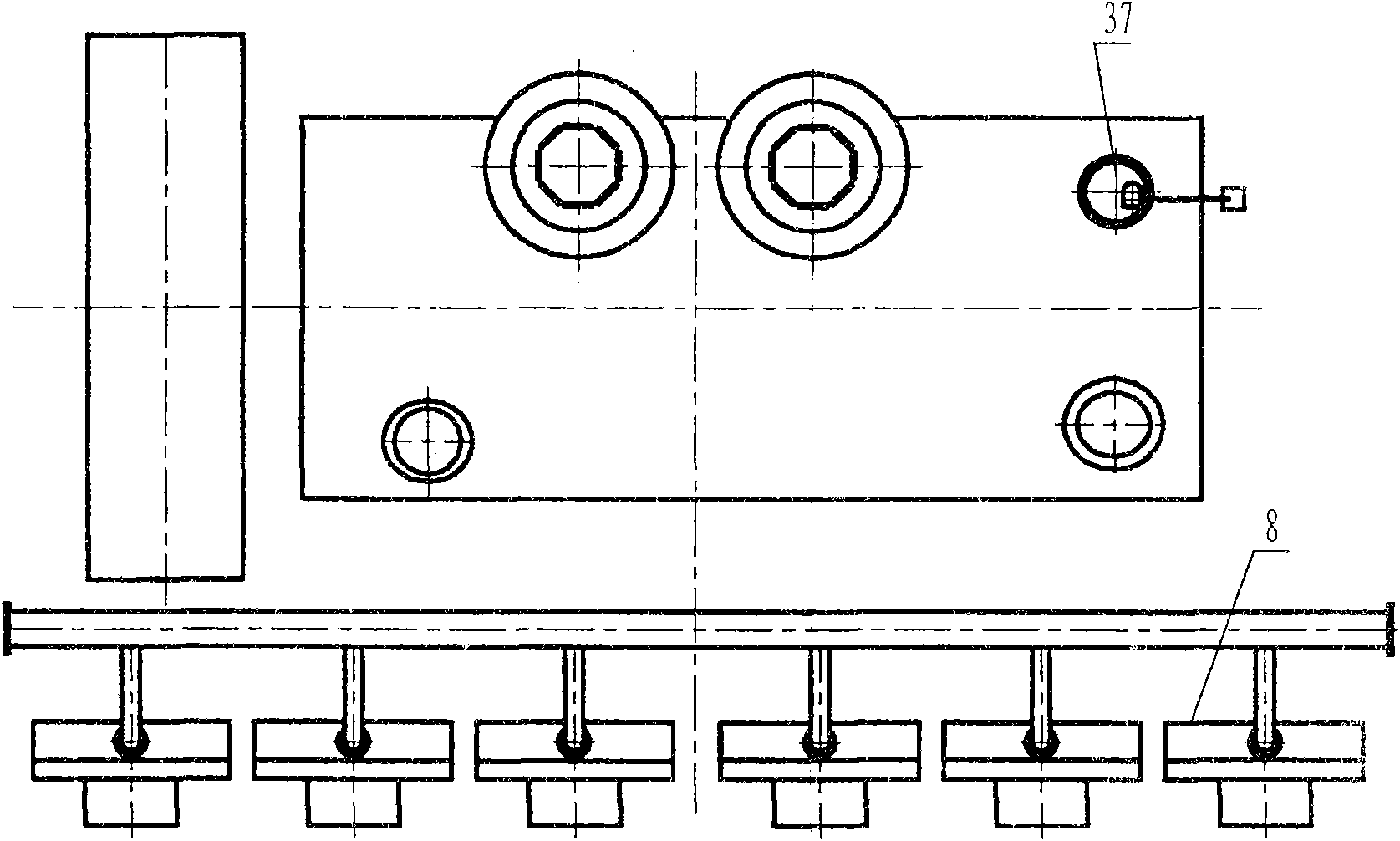

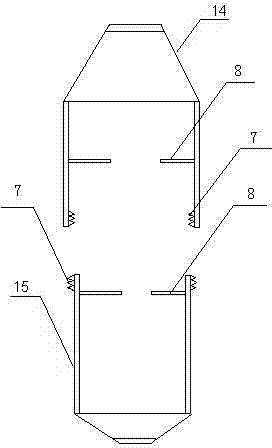

Single-phase ultra-high-capacity nuclear power station transformer

ActiveCN102315007AIncrease the distance to the groundGuaranteed outer insulation distanceTransformers/inductances coolingTransformers/inductances coils/windings/connectionsSingle phaseDynamo

The invention relates to a single-phase ultra-high-capacity generator transformer. The single-phase ultra-high-capacity generator transformer is provided with high-voltage bushings, low-voltage bushings, high-voltage neutral point bushings, an oil storage cabinet, an upper oil-saving tank, a lower oil-saving tank, cooling devices and a no-load switch; each of the upper oil-saving tank and the lower oil-saving tank is internally provided with a single-phase four-column iron core structure; a high-voltage winding and a low-voltage winding are respectively sheathed on two main column iron cores of each single-phase four-column iron core, and the high-voltage winding and the low-voltage winding of two main columns of the iron core are connected in parallel; the outlet heads of the low-voltagewindings of the two main columns are arranged at the upper ends and are connected by copper bars to form a low-voltage dual-column parallel connection structure; the oil storage cabinet is arranged above the upper oil-saving tank at the side opposite to the high-voltage bushings; the cooling devices are arranged at the outer sides of one sides of the upper oil-saving tank and the lower oil-savingtank, which are provided with the high-voltage bushings and the high-voltage neutral point bushings, and are parallel to the direction of the long axis of the transformer; and the no-load switch is arranged at the low-voltage side of the transformer. The single-phase ultra-high-capacity generator transformer provided by the invention has the advantages of compact whole structure, reduced outer limit size, low loss, low noise and good shielding effect, and the partial overheat is prevented effectively; meanwhile, the support structure of the oil storage cabinet is more reasonable.

Owner:TBEA SHENYANG TRANSFORMER GRP CO LTD

Asphalt cement mortar

ActiveCN101186477AMeet the needs of constructionGood weather resistanceWeather resistanceCement mortar

The invention discloses an asphalt cement mortar, which is a compound synthesized by dry materials, emulsified asphalt, water-reducing agent, defoaming agent and water pro rata. Each component in the mixture is calculated in portions by weight: 70-80 portions of the dry materials, 10-20 portions of the emulsified asphalt, 0.1-0.4 portion of the water-reducing agent, 0.005-0.01 portion of the defoaming agent and 8-15 portions of the water. The dry materials consist of cement, aggregate and expansion agent. Each component in the dry materials is calculated in portions by weight: 35-42 portions of the cement, 58-65 portions of the aggregate and 0.0015-0.0025 portion of the expansion agent. The component proportion of the asphalt cement mortar of the invention is proved by a great number of experiments and can lead each component to be fully used and generate synergistic effect. The invention has appropriate intensity and elasticity, good weather resistance and construction ability and can completely meet the need of plate-typed unballasted track construction in railways or in cities. Furthermore, the raw materials of the components of the invention are all produced in domestic, thus greatly saving cost.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Electric power on-site monitoring equipment

InactiveCN101800443AMeet the needs of constructionMeet the needs of monitoring effectivenessBatteries circuit arrangementsEmergency protective circuit arrangementsDistributed structureElectric power system

The invention relates to electric power on-site monitoring equipment which adopts a pluggable distributed structure. The electric power on-site monitoring equipment comprises one or more chassises and chassis backboard circuit board(s) and communication connectors among the chassises, wherein each chassis comprises a communication processing board based on an ARM (Advanced RISC Machine) processor, one or more analog quantity processing boards based on a DSP ( Digital Signal Processor), one or more state quantity and switching quantity processing boards based on the DSP, one or more interface boards matched with the current signal or the voltage signal conversion and isolation of the analog quantity processing board, one or more interface boards matched with the isolation state and the switching of the state quantity and switching quantity processing board(s) and a power panel which supplies power for the chassis equipment and can charge and discharge storage batteries. According to the electric power on-site monitoring equipment, the requirements on railway construction in China are sufficiently satisfied; multi-CPU (Central Processing Unit) distributed computation and high-density acquisition satisfy the demands of the on-site capacity; the electric power on-site monitoring equipment has a fault recording function and effectively distinguishes fault properties; and multi-stage isolation access satisfies the requirements on the on-site strong electromagnetic field environment and is safe and reliable.

Owner:北京南凯自动化系统工程有限公司

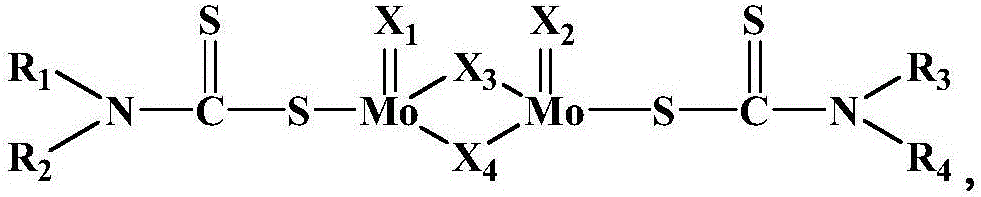

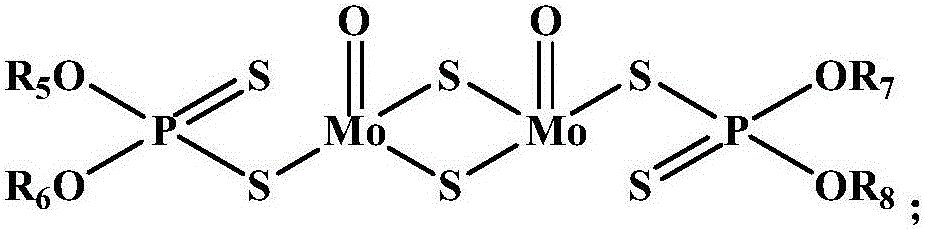

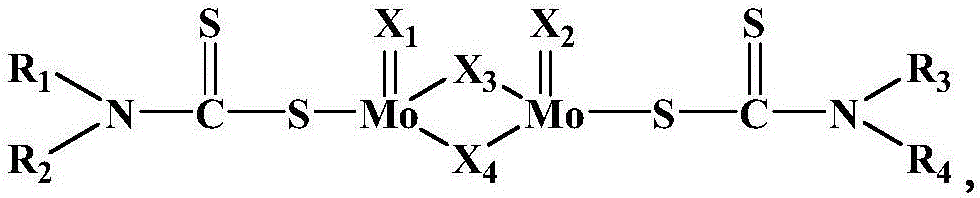

Drilling fluid lubricant and drilling fluid

InactiveCN106010480AImprove the lubrication effectImprove temperature resistanceDrilling compositionWell drillingFresh water

The invention relates to a drilling fluid lubricant and drilling fluid used in oil drilling construction. The drilling fluid lubricant components include: base oil, surfactant, carbon black, molybdenum dialkyl dithiocarbamate and molybdenum dialkyl dithiophosphate; the parts by weight of each component are: base oil 51-86 2-6 parts of surfactant, 0-3 parts of carbon black, 5%-20 parts of molybdenum dialkyldithiocarbamate, 5-20 parts of molybdenum dialkyldithiophosphate. The invention has good lubricating effect in fresh water drilling fluid and composite brine drilling fluid, and has good temperature resistance, oxygen resistance and corrosion resistance.

Owner:中石化石油工程技术服务有限公司

Marine sulphoaluminate cement for rapid construction and preparation method thereof

The invention discloses marine sulphoaluminate cement for rapid construction and a preparation method thereof. The marine sulphoaluminate cement is prepared from the following raw materials in parts by weight: 40-60 parts of sulphoaluminate cement clinker, 5-10 parts of modified nano calcium carbonate, 0.05-0.2 part of an efficient water reducing agent, 0-4 parts of a setting accelerator, 6-8 parts of an anti-cracking waterproof expanding agent, 3-5 parts of redispersible latex powder, 10-15 parts of clinker sea sand, 2-5 parts of silica fume, 6-10 parts of granulated blast furnace slag powderand 0.01-0.1 part of modified graphene. Concrete prepared from the marine sulphoaluminate cement can be quickly cured, has high early strength, can reach the demolding strength earlier, can be widelyapplied to ocean engineering buildings, and meets the requirement of quick construction in an ocean environment.

Owner:广西云燕特种水泥建材有限公司

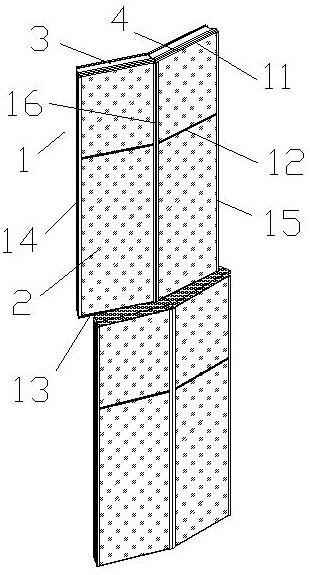

Special-shaped space staggered distorted curtain wall unit body

The invention discloses a special-shaped space staggered distorted curtain wall unit body. The curtain wall unit body comprises a frame composed of a transverse frame, a middle cross beam, a lower cross beam, a left male stand column and a right female stand column, wherein a wall face plate is arranged in the frame; the curtain wall unit body further comprises an upper cross beam, and the upper cross beam is arranged on the top face of the transverse frame through a connecting piece; and the middle part of the frame is parted vertically through a vertical column, the upper cross beam, the transverse frame, the middle cross beam and the lower cross beam are arranged at included angles with the stand column as joints, and the upper cross beam of a curtain wall unit body at the lower layer and the lower cross beam of a curtain wall unit body at the upper layer are oppositely inserted and connected up and down to achieve splicing of the curtain wall unit body piece at the upper layer andthe curtain wall unit body piece at the lower layer. The unit body overcomes the defects of a traditional unit body curtain wall flat plate structure, meets the requirement for building a curtain wallfor distorted in-out staggered-shaped building facade, is simple in structure and convenient to install, and effectively improves the attractiveness of a building outer wall.

Owner:上海金冠幕墙科技有限公司

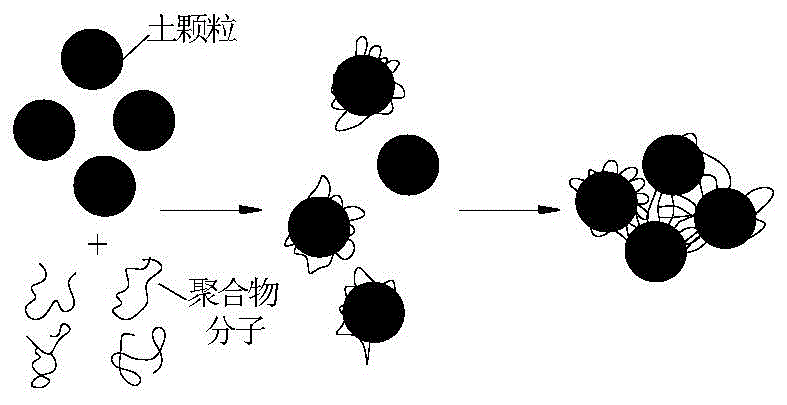

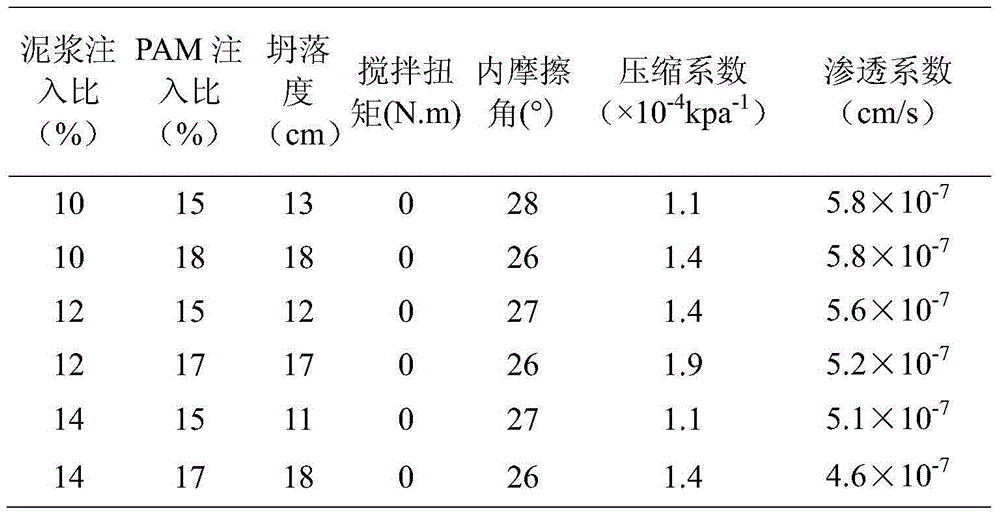

Soil improving method for rectangular-pipe jacking construction in gravel soil layer

InactiveCN104674786AReduce cohesionShort stabilization timeTunnelsSoil preservationSodium BentoniteSoil science

The invention relates to a soil improving method for rectangular-pipe jacking construction in a gravel soil layer. The soil improving method specially includes that a PAM (polyacrylamide) solution and a bentonite mud solution are added to a working surface and the soil body of a soil pressure bin, content of the PAM in the PAM solution ranges from 1g / L to 4g / L, and the mass concentration of the bentonite mud solution ranges from 7% to 11%. The soil body cut with the soil improving method is improved to have the advantages of good fluidity, low frictional angle, middle compressibility, lower adhesivity, low permeability and the like, the full-tank jacking and jacking construction speed are ensured, problems about uneasiness in soil pressure balance construction, severe abrasion of a nose cutter, easiness in 'caking', proneness to 'water gushing' when the nose cutter passes through the water-baring layer and the like can be solved, requirements of the rectangular-pipe jacking construction with the soil pressure balance can be met, and technical support is provided for establishment of dynamic soil pressure balance of the soil-pressure-balance rectangular-pipe jacking working surface of a multicutter in the gravel soil layer.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Asphalt concrete still-standing-proof transporting device for municipal road construction

The invention discloses an asphalt concrete still-standing-proof transporting device for municipal road construction. The asphalt concrete still-standing-proof transporting device comprises a base, atransporting tank is mounted in the middle of the upper end of the base, a rotating shaft is mounted in the middle of the transporting tank, and a stirring rod is mounted in the middle of the upper end of the rotating shaft; a steel brush seat is mounted on the outer side of the stirring rod, a driven belt wheel is mounted in the middle of the upper end of the rotating shaft, and a driving belt wheel is connected with the left end of the driven belt wheel through a belt; a transmission shaft is mounted at the lower end of the driving belt wheel, and a driven gear is mounted at the lower end ofthe transmission shaft; the lower end of the driven gear is connected with a driving gear in an engaged mode, a travelling shaft is mounted in the middle of the driving gear, and travelling wheels are mounted at the two ends of the travelling shaft; and limiting frames are mounted in the middle of the lower end of the base, a screw rod is mounted between the limiting frames, a sliding block is mounted in the middle of the screw rod, a sliding rod is hinged to the lower end of the sliding block, and a lifting plate is hinged to the lower end of the sliding rod. According to the asphalt concrete still-standing-proof transporting device for municipal road construction, whole asphalt concrete can further be stirred in the transporting process, still standing of the asphalt concrete is avoided, and the using quality of the asphalt concrete is improved.

Owner:李厚兵

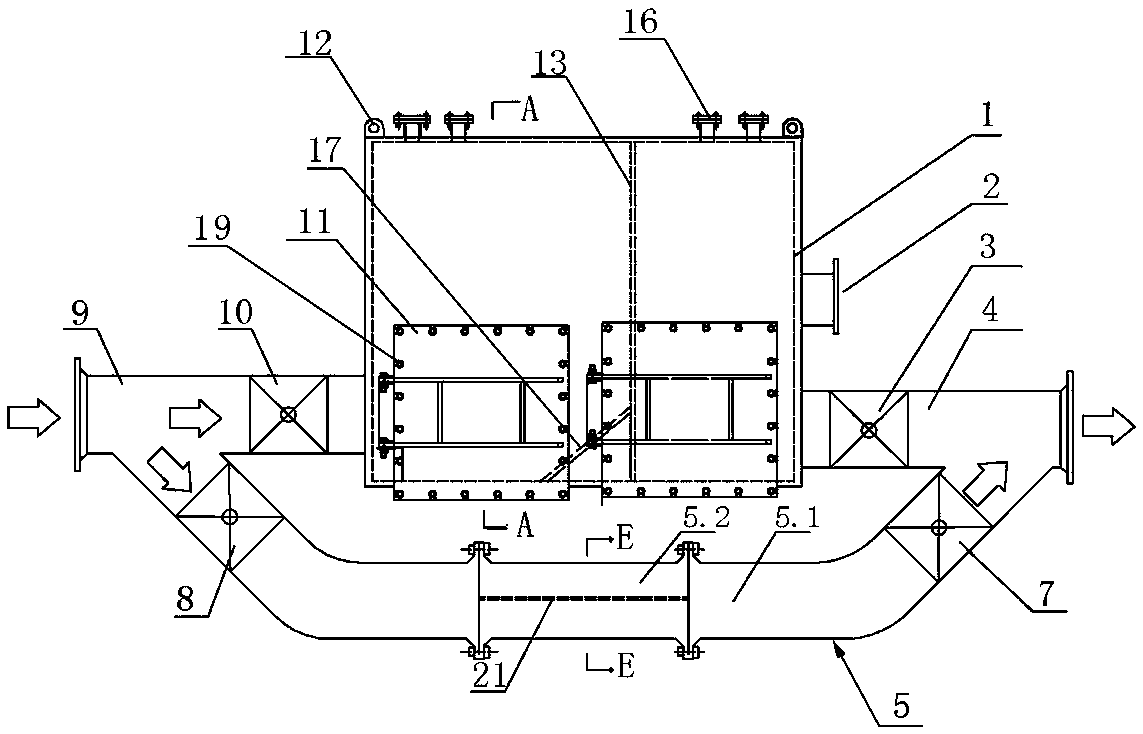

Tunneling method of slurry shield passing through anchor cable zone in long distance

A tunneling method of a slurry shield passing through an anchor cable zone in a long distance comprises the following steps that 1, reinforcing is conducted on soil masses within the range of 5 m-6 mon the two sides of the central line of a to-be-excavated tunnel; 2, drilling and anchor distributing are conducted on the reinforcing areas; 3, a manual gate valve is mounted between a quarrying boxof a shield mechanism and a slurry discharging gate valve of a soil bin; 4, the quarrying box of the shield mechanism is transformed; 5, a slurry parameter used by the shield mechanism is set; and 6,a shield tunneling parameter is set, till excavation of a designed shield route is completed, and construction is ended. The tunneling method solves the technical problems that a slurry discharging pipe and the quarrying box are clamped deadly or blocked by an anchor cable, a cutter disc is wound, the aperture ratio of the cutter disc is decreased, and a cutter tool is damaged in the long distanceanchor cable zone passing through construction process of a traditional slurry shield.

Owner:CHINA CONSTR COMM ENG GRP UNITED

Garland X joint for steel structure building and mounting process of joint

PendingCN106759887AGood for decorationImproves stability and firmnessBuilding constructionsEngineeringFlange

The invention discloses a garland X joint for a steel structure building. The garland X joint comprises a lower flange plate and an upper flange plate arranged above the lower flange plate, a stiffening plate is arranged between the upper flange plate and the lower flange plate, a partition plate is arranged in the middle of the stiffening plate, and edges of the upper flange plate and the lower flange plate are connected through a web plate. According to the garland X joint for the steel structure building, the partition plate and the stiffening plate are arranged between the lower flange plate and the upper flange plate to effectively connect the lower flange plate and the upper flange plate, excellent decoration functions are achieved as for the building industry, aesthetic effects are achieved, use firmness and stability of the X joint are greatly improved, deformation can be effectively prevented, and double functions can be further achieved.

Owner:JIANGSU HUNING STEEL MECHANISM

Strong-support elliptical column and assembly and welding technology thereof

InactiveCN110761489ASimple structureImprove the support bearing capacityStrutsWelding apparatusPipeColumn structure

The invention discloses a strong-support elliptical column. The strong-support elliptical column comprises a pipe column, a column bottom plate and a sealing plate, the column bottom plate is arrangedat the bottom of the pipe column, and the sealing plate is arranged at the top of the pipe column, wherein the interior of the pipe column is provided with a set of partition plates and a set of longitudinal stiffening plates, the partition plates are distributed in an inner cavity of the pipe column, the longitudinal stiffening plates are arranged to be perpendicular to the partition plates andarranged on the partition plates in penetrating and inserted modes, and the partition plates are matched with the pipe column. According to the strong-support elliptical column, the whole structure ofthe elliptical column is optimized, the strong-support elliptical column is simple in structure and reasonable in design, the bottom plate is arranged at the bottom of the pipe column, the partitionplates and the longitudinal stiffening plates are arranged inside the pipe column, and thus the supporting bearing performance and structural stability of the elliptical column structure are greatly improved; and the invention further relates to a assembly and welding technology of the elliptical column, machining precision is greatly improved, the machining quality of the product is ensured, andthe safety of the elliptical column during later use is further ensured.

Owner:JIANGSU HUNING STEEL MECHANISM

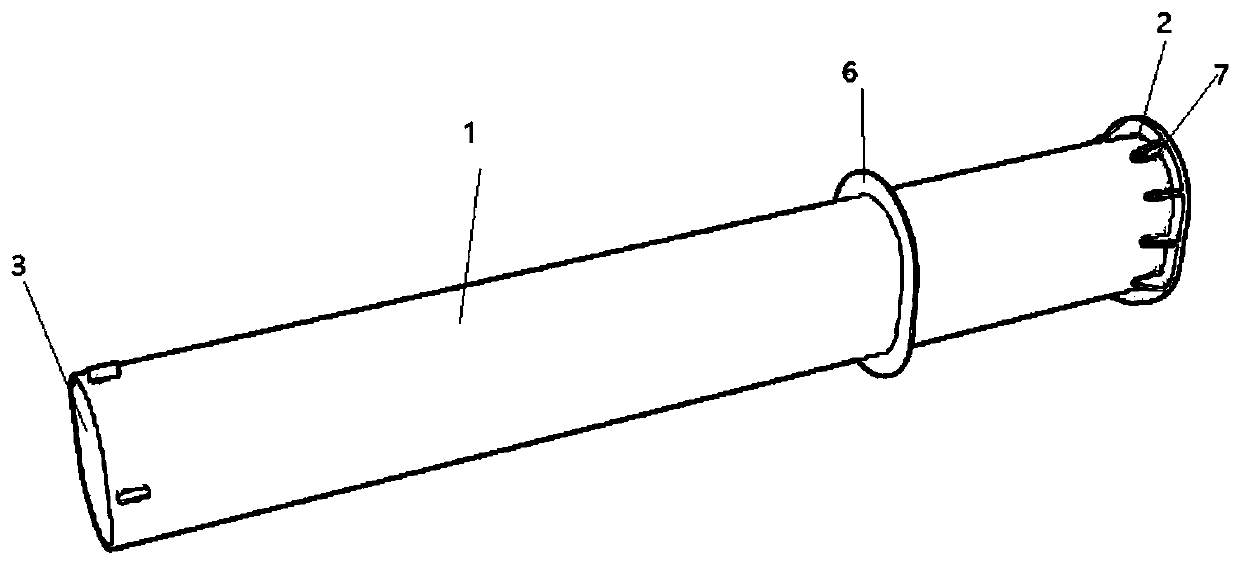

Prestress uplift pile and construction method thereof

ActiveCN103485338AReduce manufacturing costReduce dosageCeramic shaping apparatusBulkheads/pilesPre stressArchitectural engineering

The invention discloses a prestress uplift pile and a construction method of the prestress uplift pile. The prestress uplift pile is composed of a reinforcing cage and a small number of unbonded prestressed reinforcement bars. Long and short thread teeth are arranged on the unbonded prestressed reinforcement bars, casing pipes are fixed in the reinforcing cage, meanwhile, the connected unbonded prestressed reinforcement bars are fixed through pitch points, and rapid locating is conducted. The prestress uplift pile satisfies the requirements for prestressed reinforcement bar construction in the post-tensioning method, enables the prestressing force of the reinforcement bars to be transmitted conveniently, enhances the overall tensile resistance and pulling resistance, saves the manufacturing cost, simplifies the construction procedure and enables the manual operation to be convenient.

Owner:江苏森林建筑新材料股份有限公司

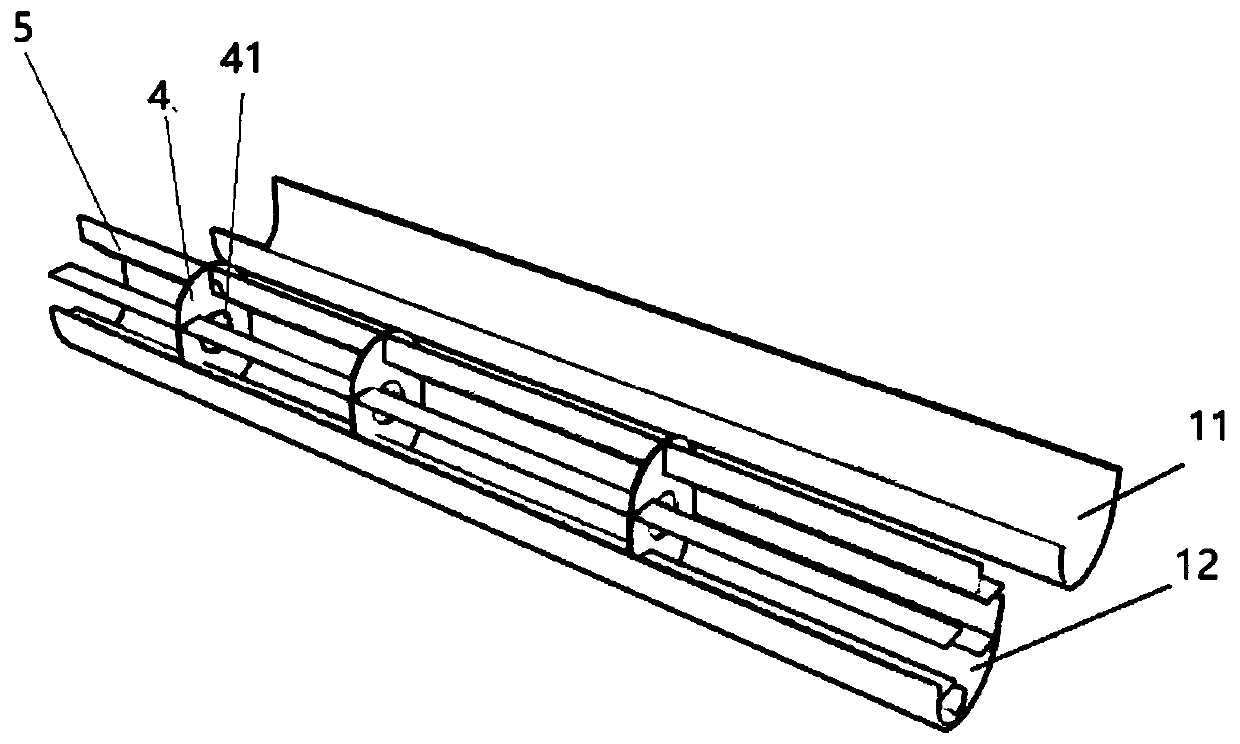

Prestressed concrete supporting pile wall

ActiveCN102605765AEasy to transportReduce shipping costsExcavationsBulkheads/pilesReinforced concretePre stress

The invention discloses a prestressed concrete supporting pile wall, which comprises a cement-soil wall consisting of a plurality of cement-soil stirring piles. The cement-soil wall is provided with an outwards protruded or staggered structure, prefabricated piles are continuously or intermittently inserted in the cement-soil stirring piles, each prefabricated pile comprises multiple sections of reinforced concrete members, a plurality of through holes are arranged on each reinforced concrete member along an axis direction, the reinforced concrete members of each prefabricated pile are serially connected together via an anti-bending rope penetrating through the through holes of the prefabricated pile, after being tensioned, each anti-bending rope is respectively fixedly connected with two ends of the corresponding prefabricated pile, and a reinforcing anti-shear plate is fixedly mounted at a joint of each two adjacent reinforced concrete members. Due to the mode, the prestressed concrete supporting pile wall not only guarantees safety and reliability of a foundation pit supporting structure, but also has a good economic benefit, is convenient in construction and low in influence to environments, and further meets requirements of foundation pit engineering construction.

Owner:JIANGSU DINGDA BUILDING NEW TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com