Method for producing insulator or contact box with temperature and/or voltage sensor

A voltage sensor and production method technology, applied in the direction of insulators, circuits, electrical components, etc., can solve the problems of difficult flexible optical fiber layout, no consideration of high temperature effects, unsafe hidden dangers, etc., to eliminate high voltage from entering low-voltage control systems and communication systems Hidden dangers of the system, satisfying the effect of safe and reliable temperature online monitoring, high reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

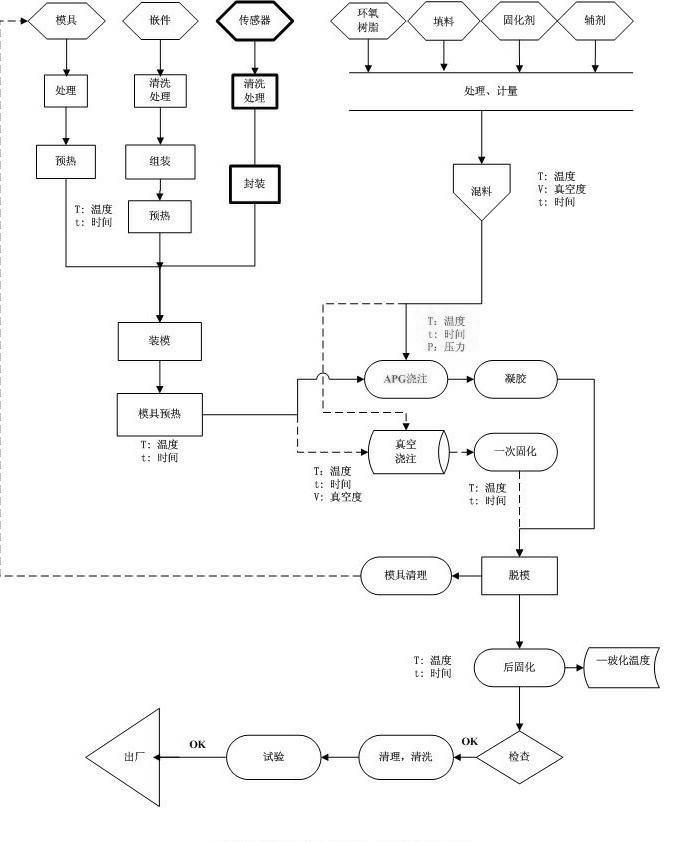

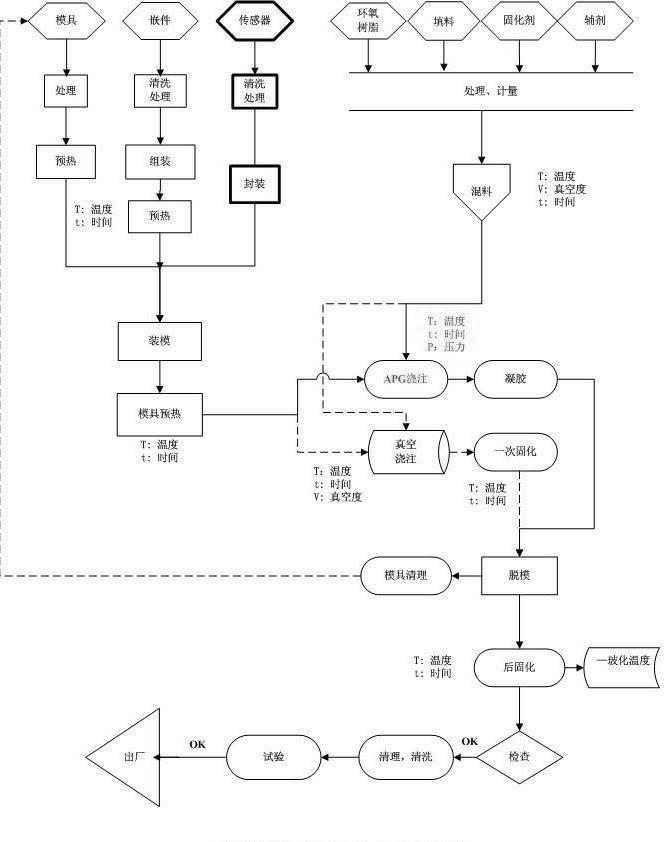

[0023] Below in conjunction with accompanying drawing embodiment, the present invention will be further described:

[0024] In the present invention, the temperature or / and voltage sensor is integrated into the insulator (insulator and contact box) through the APG or VC process in the post insulator (or capacitive post insulator) and the contact box for the switchgear. Insulators or contact boxes are combined into one, retaining the original structure and functions of insulators or contact boxes, without occupying additional space, without destroying the original structure of the switchgear, and without special assembly, debugging and fixing on site. The insulator with temperature and voltage sensor can be used not only as an ordinary insulator, but also as a sensor of a live display device, and can also measure the temperature of the conductive copper bar installed there.

[0025] like figure 1 Shown, the production method of the insulator or contact box with temperature or / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com