A preparing method for water permeable bricks by utilizing building waste

A construction waste and permeable brick technology is applied in the field of construction waste resource reuse and building materials, which can solve the problems of low strength and poor water retention performance, and achieve the effects of high strength, high water permeability and protection of cultivated land.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

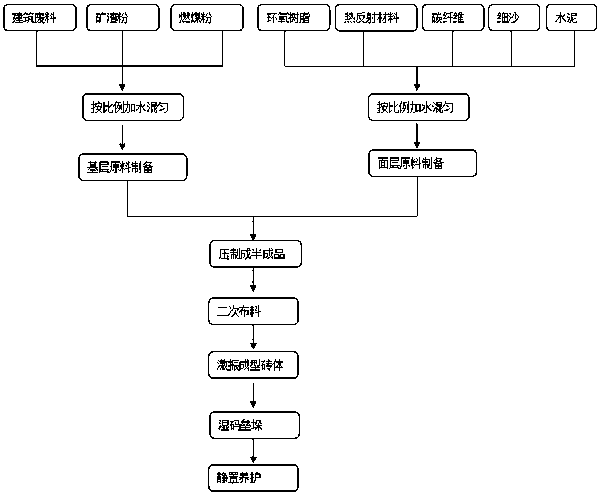

[0030] A method for making permeable bricks from construction waste, which specifically includes the following steps: Step 1: Base material preparation: add 3-5mm construction waste particles left after crushing and sieving, slag powder, and coal powder to the The mixer mixes evenly, automatically adds water according to the set ratio, and stirs evenly until the base material feeding hopper is ready for use.

[0031] Step 2 Preparation of raw materials for the surface layer: Add cement and ethylene oxide to a fixed mortar mixer in proportion. Do not use the same one as the base material. After mixing evenly, add other proportioning raw materials and mix evenly until the entire mixture surface Cover the slurry evenly, and put it in the fabric feeding hopper when finished.

[0032] Step 3: Transport the spare base materials and fabrics to the automatic brick making machine, and press them into semi-finished permeable bricks first;

[0033] Step 4: Pass the semi-finished permeab...

Embodiment 2

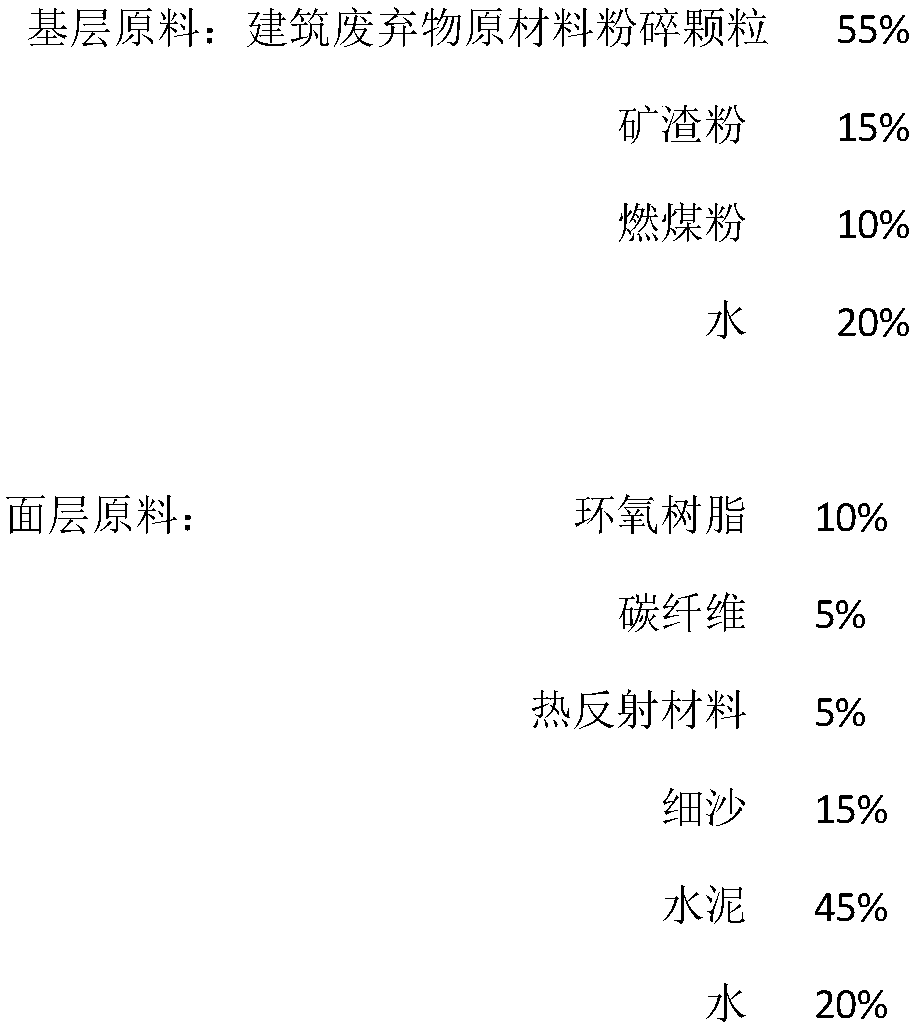

[0036] A permeable brick made of construction waste, composed of the following components by mass percentage:

[0037]

[0038] After the base and surface materials are prepared, the vibration-forming bricks are completed according to the production process described above. The ratio of the surface layer thickness to the base layer thickness of the finished permeable bricks prepared is 1:6, and the performance parameters are shown in Table 1.

Embodiment 3

[0040] A permeable brick made of construction waste, composed of the following components by mass percentage:

[0041]

[0042] After the base and surface materials are prepared, the vibration-forming bricks are completed according to the production process described above. The ratio of the surface layer thickness to the base layer thickness of the finished permeable bricks prepared is 1:6, and the performance parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com