Interlocking control system for falling, floating and depth sounding of main winch of rotary drilling rig

A technology of rotary drilling rig and control system, which is applied to the automatic control system of drilling, drilling equipment, earth-moving drilling, etc. Operation Intensity, Effect of Reducing Operation Intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

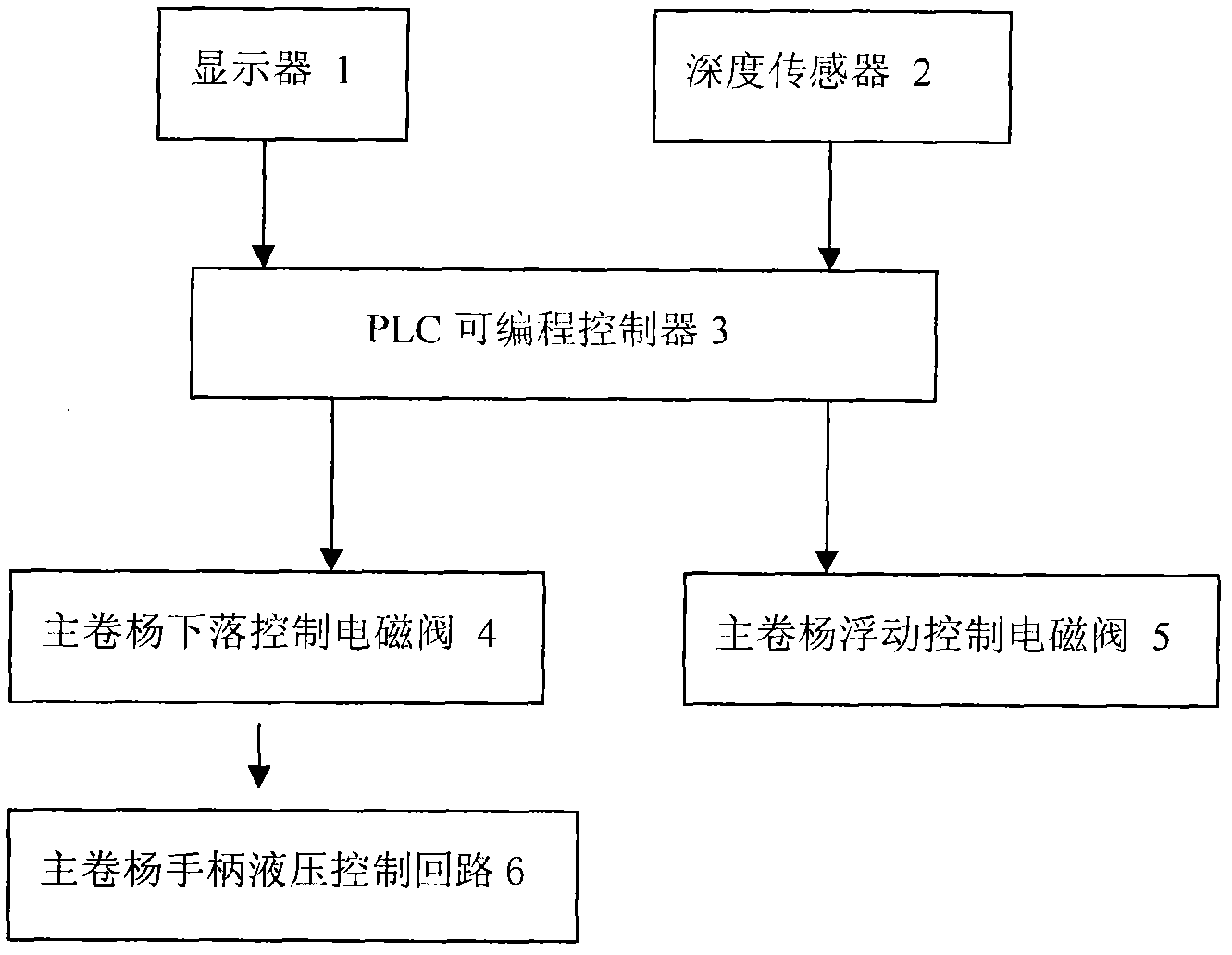

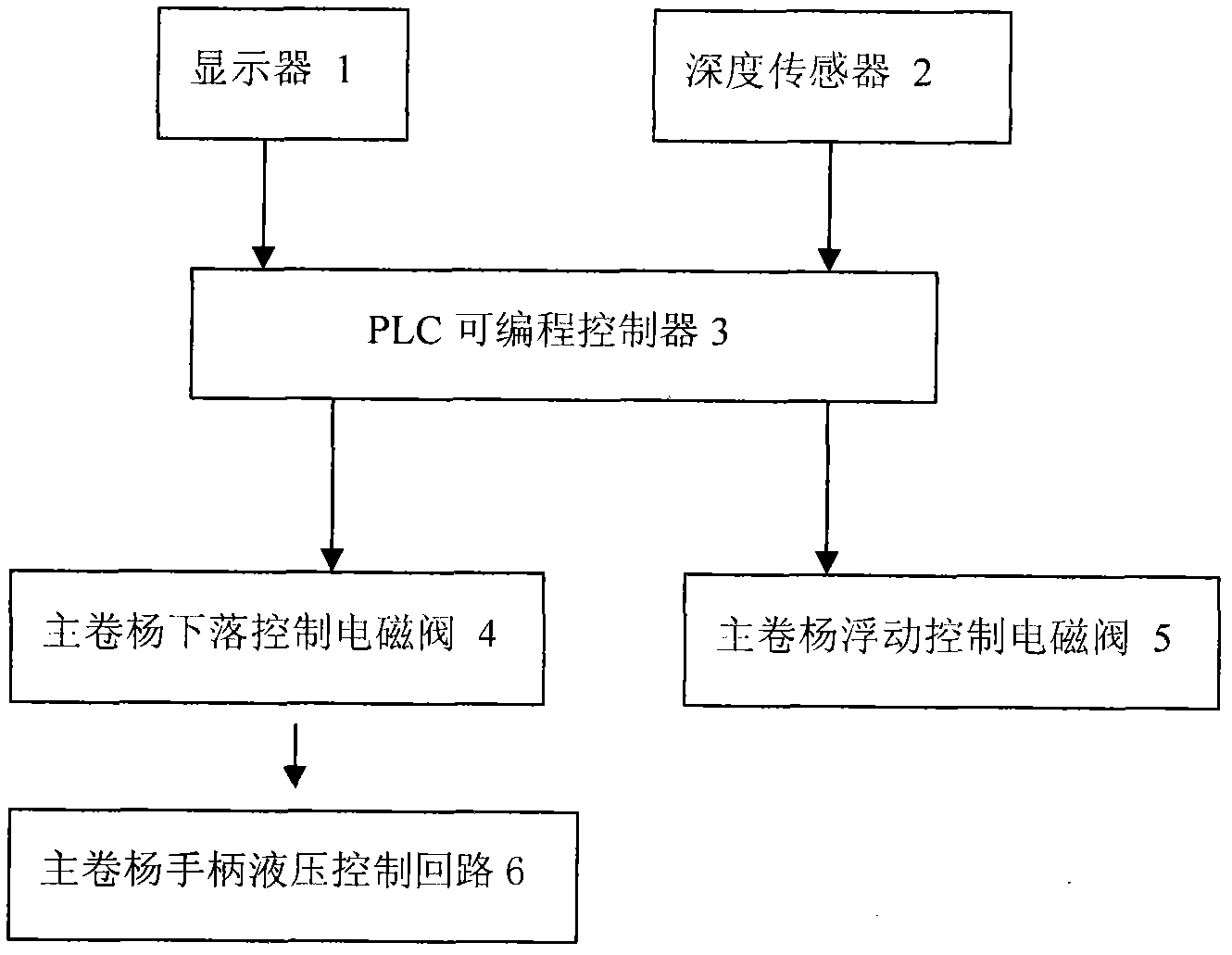

[0011] Such as figure 1 As shown, the control system of the main winch falling, main winch floating and sounding interlocking of the rotary drilling rig includes a central processing unit 3 on the rotary drilling rig for receiving and processing data and output control, and the central processing unit 3 adopts PLC Programmable Controllers. It is connected with the central processing unit 3 and is used for real-time online display of the drilling depth and the display 1 of various prompt information. The display 1 adopts a color display and is installed in the cab; the display 1 and the PLC programmable controller 3 are connected through the CANBUS bus. The depth-sounding sensor 2 that detects the change of the depth of the drill bit is connected with the central processing unit 3; the depth-sounding sensor 2 adopts an encoder or a proximity switch. The main coil floating control solenoid valve 5 connected with the central processing unit 3; the main coil falling control solen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com