Prestress uplift pile and construction method thereof

A construction method and technology of uplift piles, which are applied in sheet pile walls, manufacturing tools, infrastructure engineering, etc., can solve the problems of different connection strengths of uplift piles with different lengths, difficulties in prefabricating and connecting pipe piles, poor durability of piles, etc. Achieve the effect of enhancing the overall tensile strength and pullout resistance, saving production costs, improving service life and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

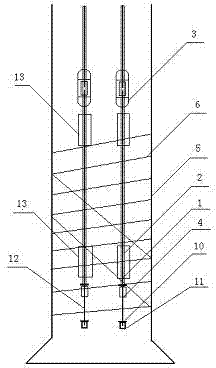

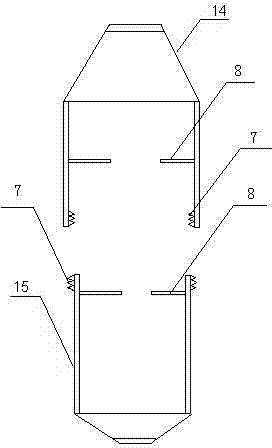

[0038] This embodiment provides a kind of prestressed uplift pile, see Figure 1-2 , including concrete and steel cage frames, but also unbonded prestressed steel bars.

[0039] The two ends of the unbonded prestressed steel bar are respectively provided with a first thread tooth end and a second thread tooth end, the length of the first thread tooth end is equal to or greater than the second thread tooth end, and the length of the second thread tooth end is the length of the steel bar connector half the length. Both ends of the tendon body of the unbonded prestressed reinforcement are respectively fixed with sleeves 13 matching the external dimensions, and the length of the sleeve 13 is shorter than the length of the unbonded prestressed reinforcement. The reinforcement cage frame is composed of at least two sections of reinforcement cages connected. Each section of the reinforcement cage is composed of stirrups 6 and high-strength reinforcements 5. The high-strength reinfor...

Embodiment 2

[0042] This embodiment provides a kind of prestressed uplift pile, see Figure 1-2 , including concrete and steel cage frames, but also unbonded prestressed steel bars.

[0043] The two ends of the unbonded prestressed steel bar are respectively provided with a first thread tooth end and a second thread tooth end, the length of the first thread tooth end is equal to or greater than the second thread tooth end, and the length of the second thread tooth end is the length of the steel bar connector half the length. Both ends of the tendon body of the unbonded prestressed reinforcement are respectively fixed with sleeves 13 matching the external dimensions, and the length of the sleeve 13 is shorter than the length of the unbonded prestressed reinforcement. The reinforcement cage frame is composed of at least two sections of reinforcement cages, and each section of the reinforcement cage is composed of stirrups 6 and unbonded prestressed reinforcement. The unbonded prestressed re...

Embodiment 3

[0047] This embodiment is a construction method of prestressed uplift piles, including the following steps.

[0048] Firstly, in the factory, the smooth round prestressed steel bar 1 is cut according to the length required by the project, and the two ends are rolled into the required thread teeth by a thread rolling machine, wherein the length of one end of the thread teeth is equal to or greater than the other end, and the rolled Good smooth round prestressed steel bars are coated with anti-corrosion oil and wrapped with plastic sleeves 2 by an injection molding machine to make unbonded prestressed steel bars.

[0049] The steel bar connector 4, the anchor plate 11, the locking nut 10 and the node 3 are manufactured according to the size, thread teeth and strength requirements of the prestressed steel bar 1.

[0050] Transport the processed unbonded prestressed steel bar to the construction site, cut and remove the plastic wrapped in the thread teeth, and screw the steel bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com