Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Low print temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat transfer printing colored tape capable of being used on band-shaped or card-shaped label and preparation method thereof

The invention discloses a heat transfer printing colored tape capable of being used on a band-shaped or card-shaped label. The heat transfer printing colored tape comprises a tape base, one face of the tape base is coated with a printing ink layer, and the other face of the tape base is coated with a heat-resisting coating; the printing ink layer coats the tape base by using a heat melting way, and the printing ink layer comprises binders, coloring agents, filler and auxiliaries. A preparation method of the heat transfer printing colored tape comprises the steps that the binders, the coloring agents, the filler and the auxiliaries are fully mixed and dispersed, and then grinded to obtain printing ink layer coating liquid; the front face of the tape base is coated with the printing ink layer coating liquid by using a coating machine; the back face of the tape base are uniformly coated with organic silicone emulsion or a polyimide solution through the coating machine, and the heat-resisting coating is formed through drying the organic silicon emulsion or the polyimide solution. According to the heat transfer printing colored tape, the heat-resisting coating makes contact with a printing head, and the printing ink layer makes contact with the label, the printing head generates heat when is operated, and printing ink is dissolved and stamped on the label through the heat-resisting coating to form characters and images. The heat transfer printing colored tape can be used on the band-shaped or card-shaped label, and has better scratch resistance and durability.

Owner:POMA IND SHANGHAI

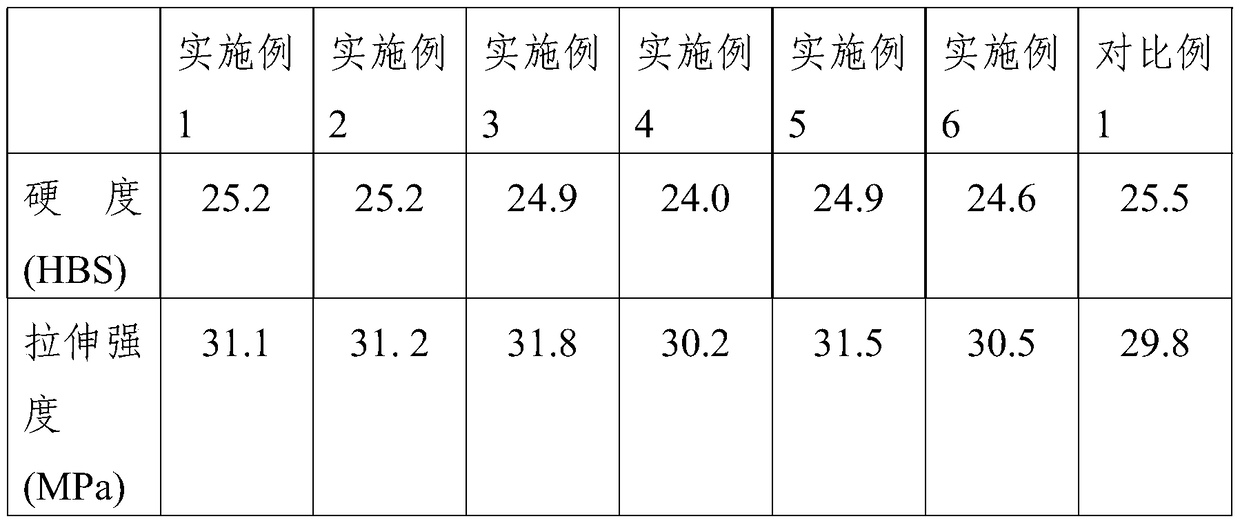

PBS (Poly Butylene Succinate)/carbon material composite wire for 3D (Three-dimensional) printing and preparation method thereof

ActiveCN105176020ALow print temperatureGood flexibility and tensile strengthPoly l lactic acidHeat stabilization

The invention discloses a PBS (Poly Butylene Succinate) / carbon material composite wire for 3D (Three-dimensional) printing and a preparation method thereof. The technical scheme is as follows: 1, a formula comprises 70 to 80 percent by weight of PBS, 2 to 50 percent by weight of a carbon material, 0.1 to 0.5 percent by weight of a chain expander, 0.1 to 0.5 percent by weight of a cross-linking agent, 0.1 to 2 percent by weight of a nucleating agent, 0.1 to 0.5 percent by weight of a heat stabilizer, 0.2 to 1 percent by weight of an antioxidant and 0.2 to 1 percent by weight of a lubricant; 2, the preparation method comprises the steps of (1) drying, (2) weighing, (3) high-speed kneading, (4) melt extrusion, (5) cooling drawing, and (6) rolling bundling. A high molecular material applicable to the 3D printing is prepared from completely-degraded biological materials namely the PBS and the carbon material. Compared with a conventional PLA (Poly Lactic Acid) wire, the high molecular material has lower printing temperature, higher tensile strength and flexibility, is applicable to multiple 3D forming technologies, and has a broad application prospect in the field of the 3D printing.

Owner:XIAMEN LUHAI ENVIRONMENT PROTECTION CO LTD

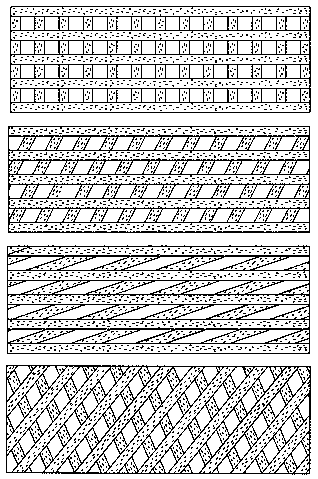

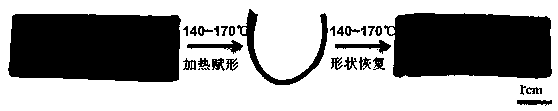

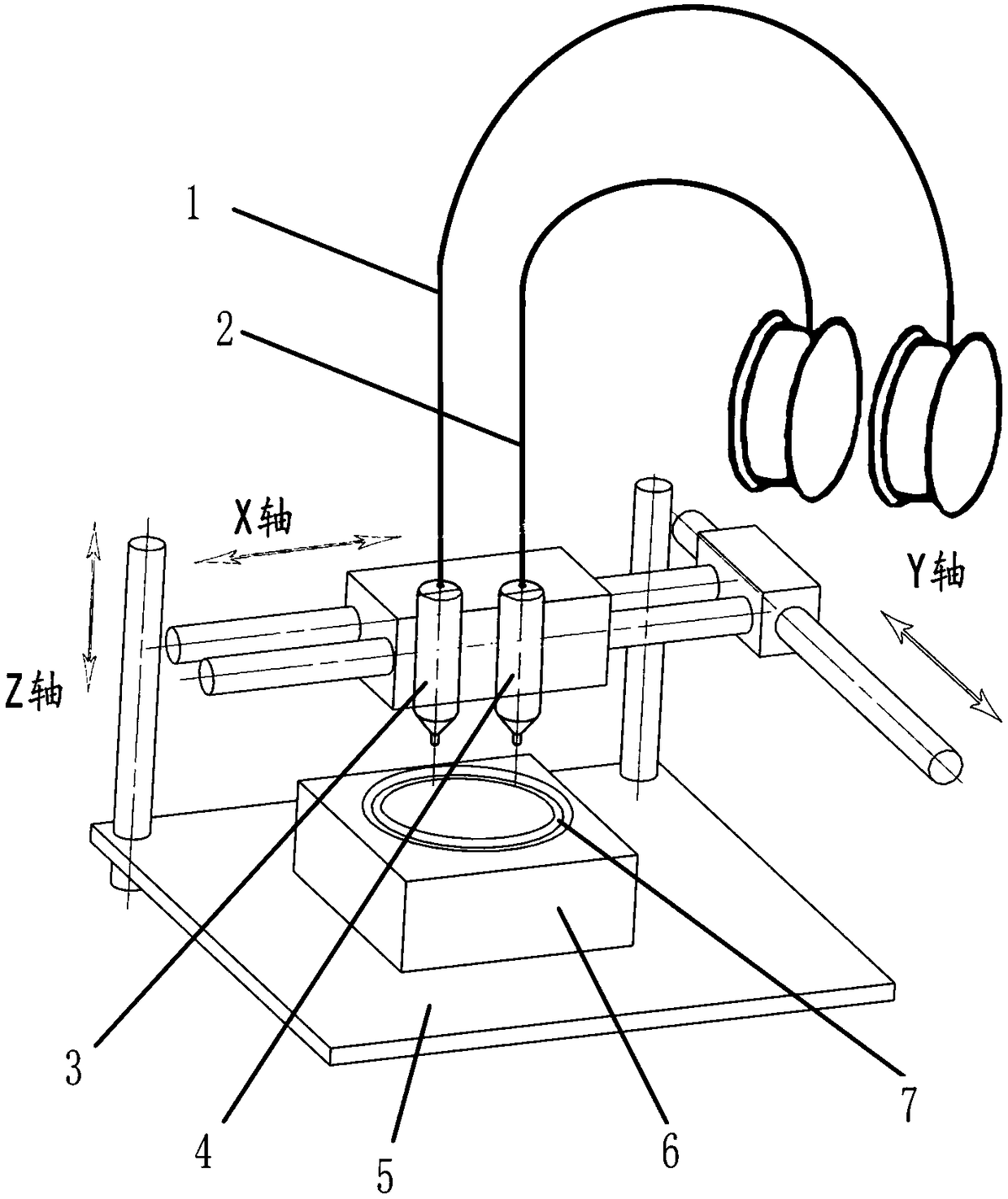

Preparing method of 3D printing intelligent deforming material

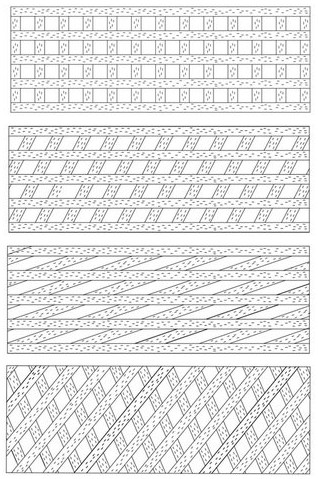

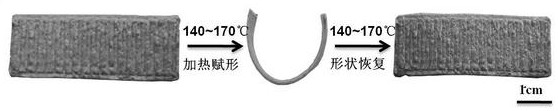

ActiveCN109648817AChange crossing angleThe pre-deformation structure is complex and diverseAdditive manufacturing apparatus3D object support structuresFiberCarbon fibers

The invention relates to a preparing method of a 3D printing intelligent deforming material. The method aims at printing complex irregular shapes such as a gradient structure, a biology structure, a spiral structure and a microstructure, the method is precise and efficient, simple and easy to implement, and the 3D printing intelligent deforming material of a complex structure and with large deforming is prepared, and the method comprises following steps of firstly, preparing of polymer wires, and secondly, 3D printing of the intelligent deforming material. On the basis of the 3D printing technology, polyether-ether-ketone powder and a carbon fiber serve as the main material, through control design of the printing shape in the 3D printing process, the path can be programmed, the crossed angle between layers can be changed, the pre-deformed structure is more complicated and diverse, deforming is benefited due to being parallel to the printing path, the larger deforming and the deformingrestore rate can be obtained, through the preparing method, the machining step is simplified, production cost is saved, and machining efficiency is improved.

Owner:JILIN UNIV

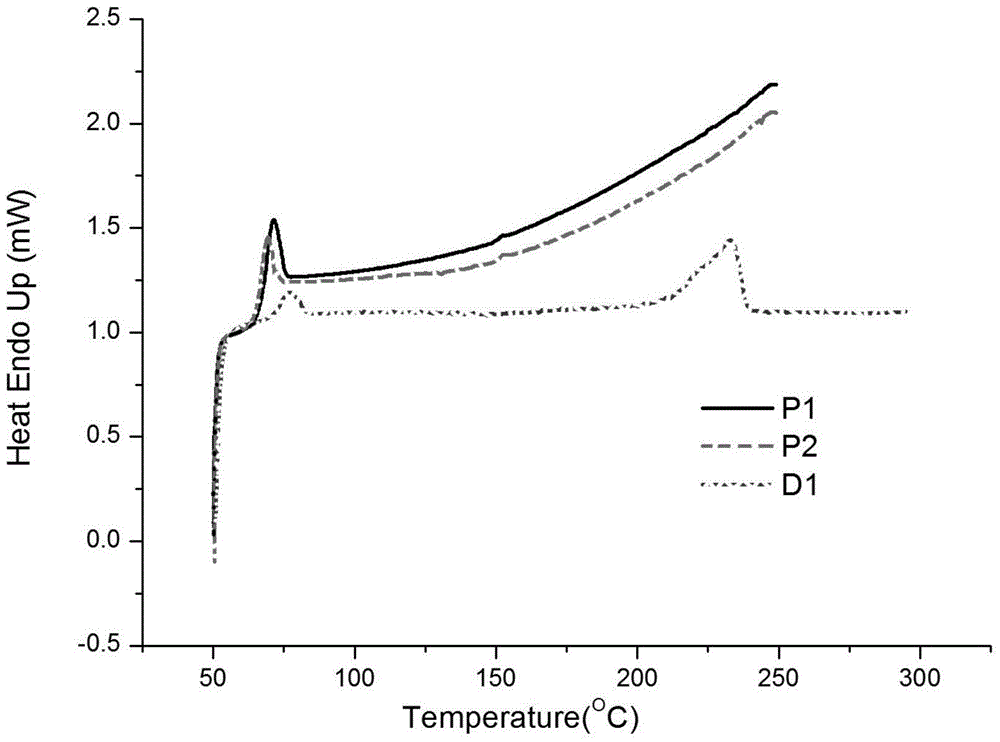

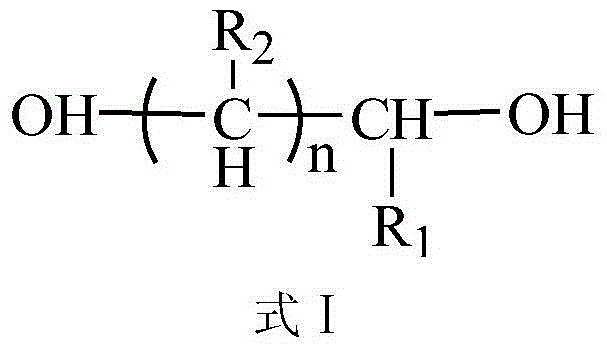

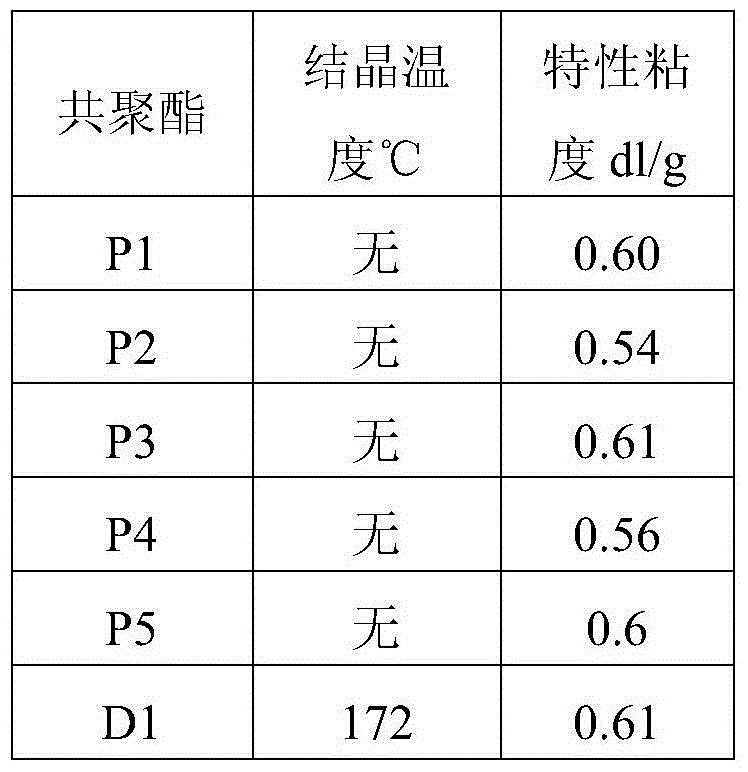

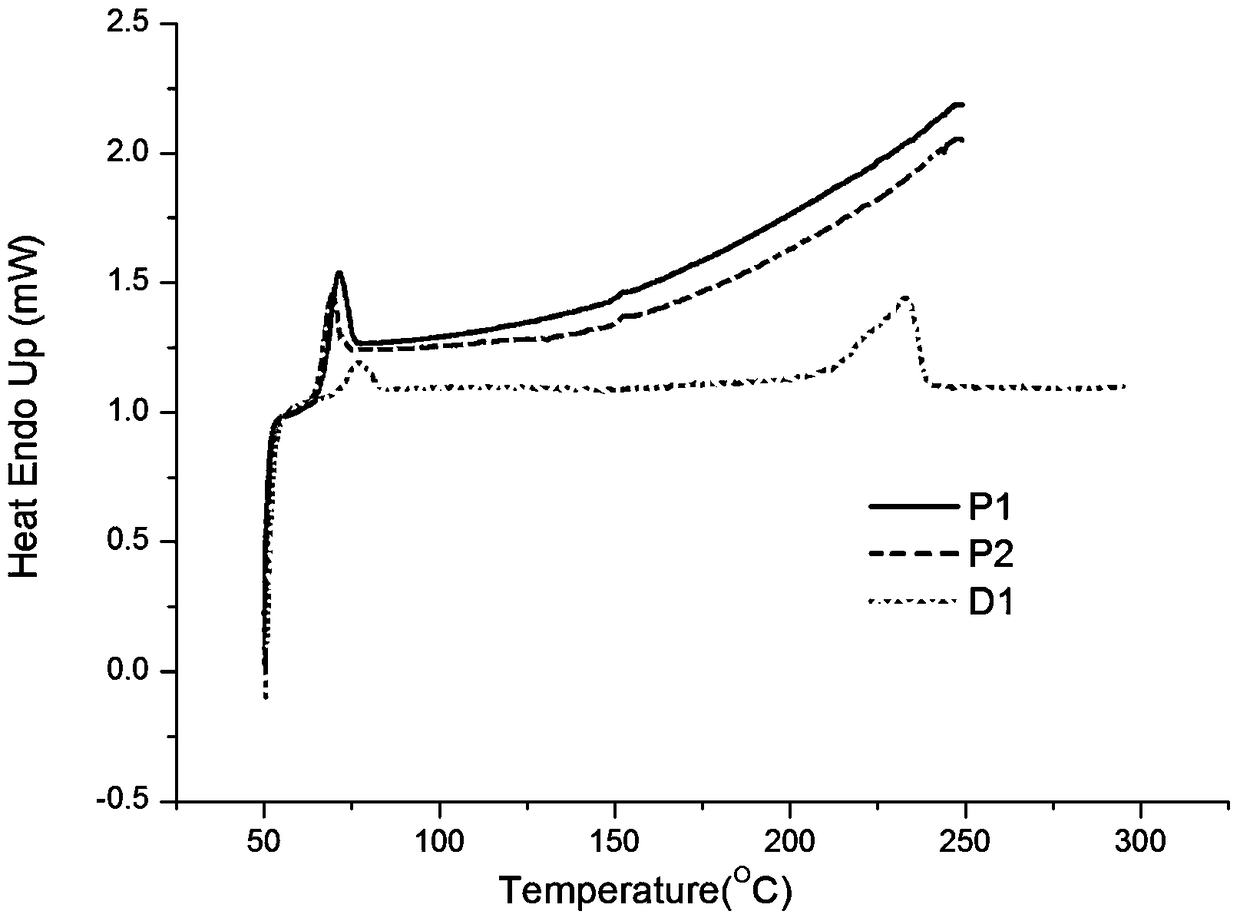

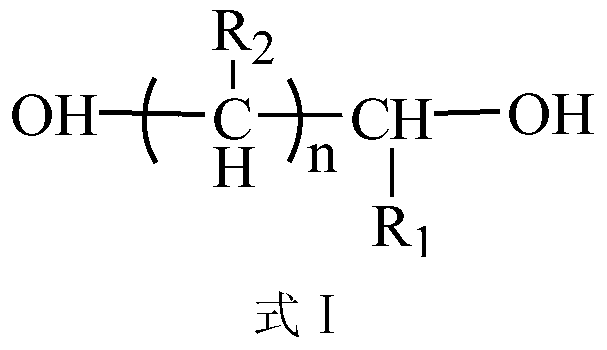

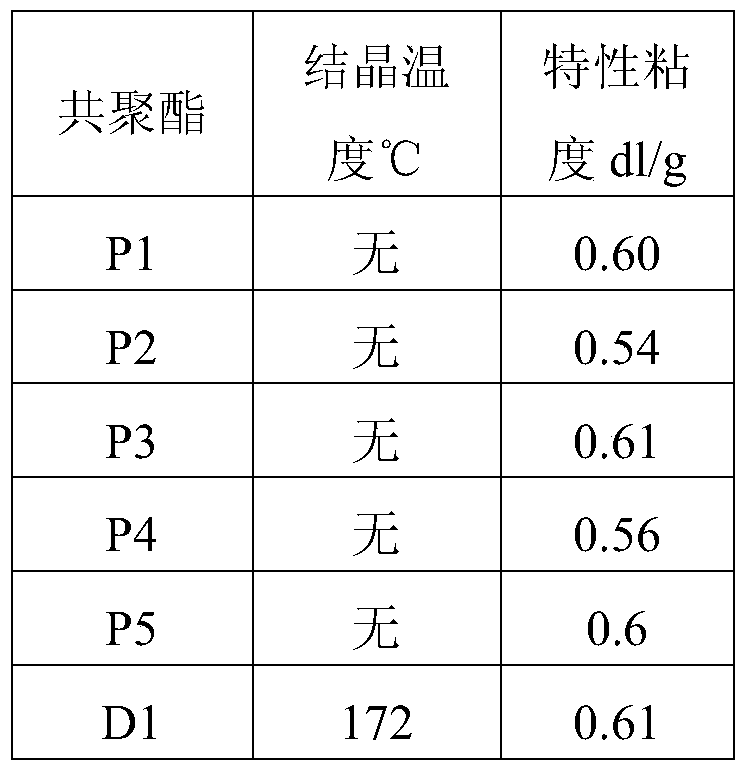

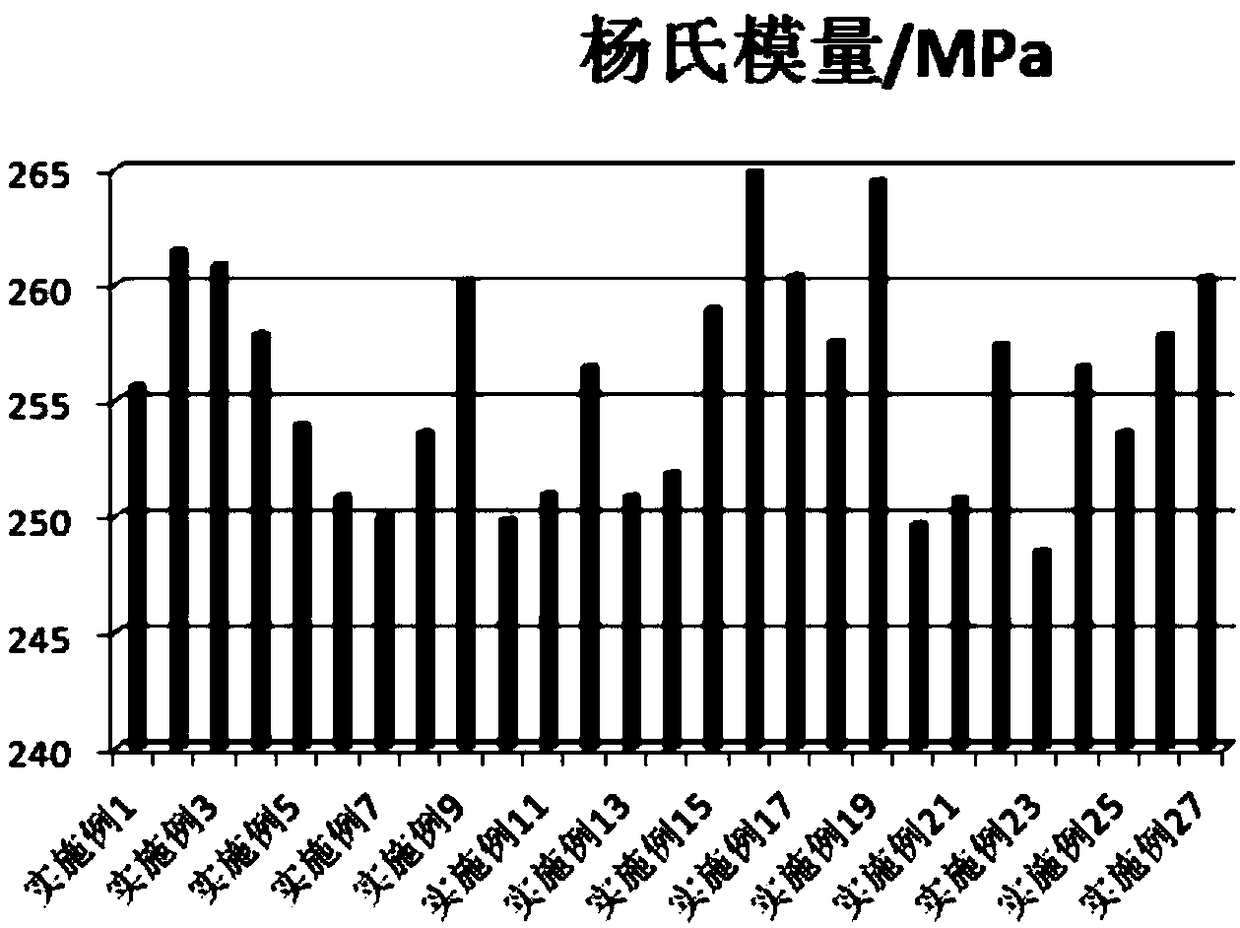

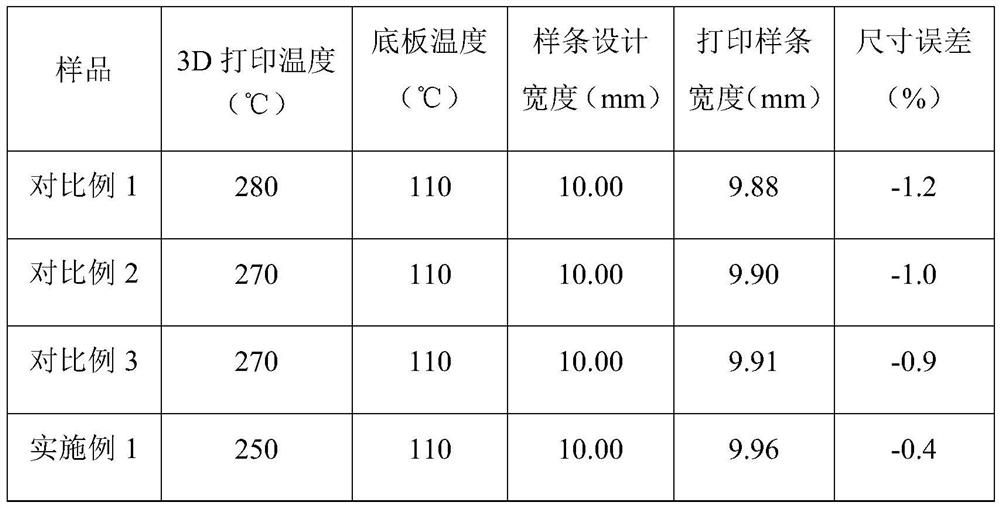

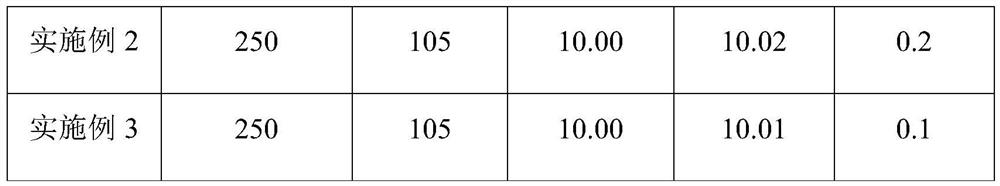

Copolyester preparation method and application of copolyester prepared thereby in 3 D printing

The present invention provides a copolyester preparation method comprising successive esterification and polycondensation of a dihydric alcohol, a fatty diacid and two or more aromatic diacid in the presence of a catalyst for preparation of an amorphous copolyester. The present invention also provides a method for using the copolyester material for preparation of a wire material and application of the wire material in 3D printing. The printing temperature of the wire material used in fused deposition method 3D printing is low, an obtained product is small in size deviation, and sample shrinkage rate is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

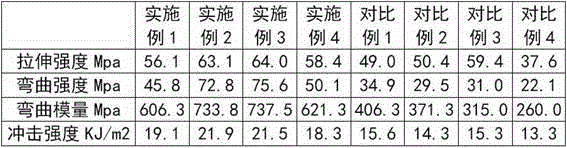

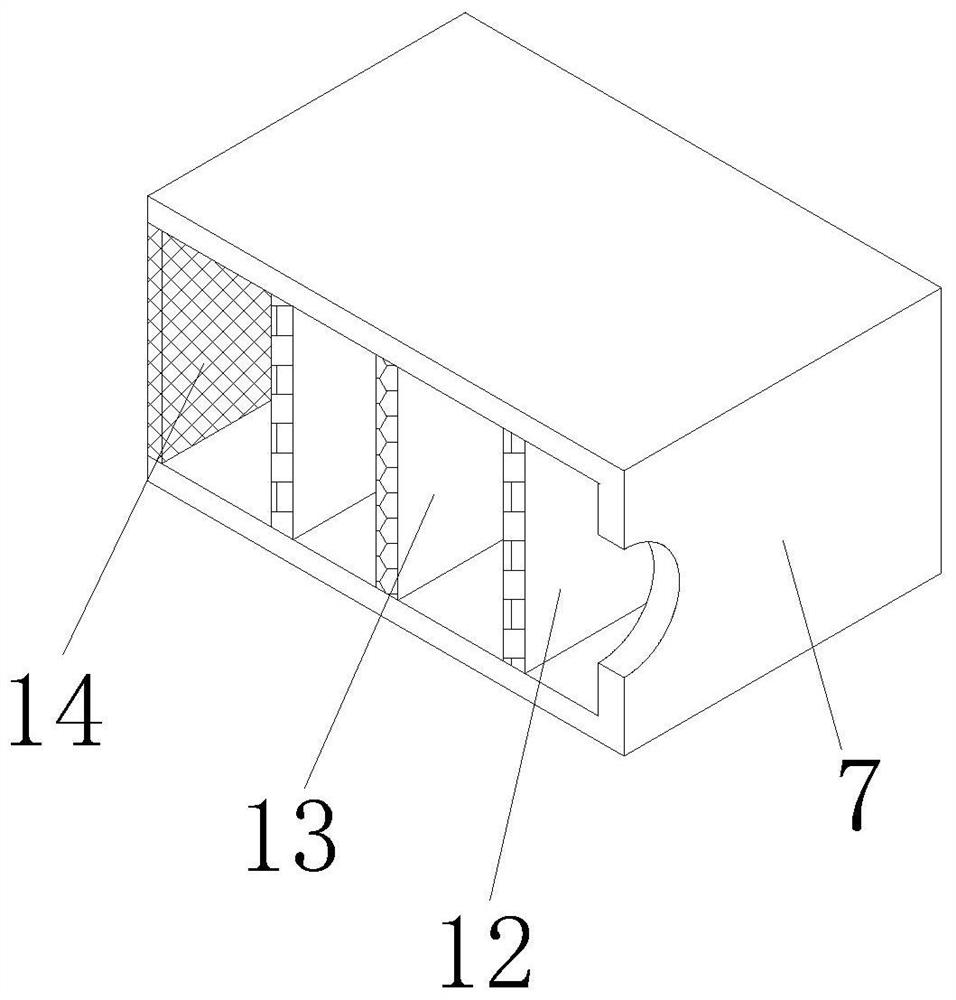

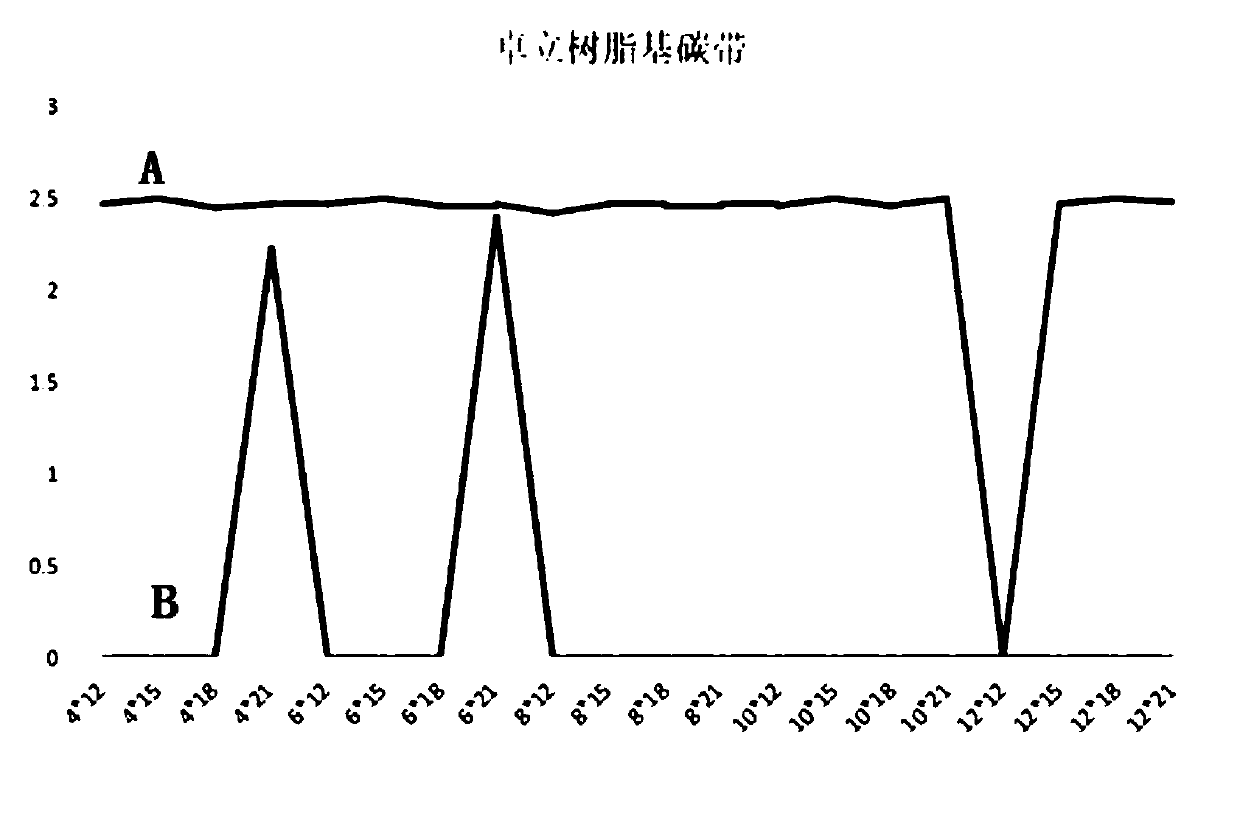

Resin-based thermal transfer printing ribbon high in universality and manufacture method thereof

PendingCN111703226ALow print temperatureVery good medium suitabilityInk ribbonsWax coatingsPrinting inkManufacturing engineering

The invention discloses a resin-based thermal transfer printing ribbon high in universality. The resin-based thermal transfer printing ribbon comprises a heat transfer printing layer and a heat-resistant printing ink layer. The front face and the rear face of a base ribbon are coated with the heat transfer printing layer and the heat-resistant printing ink layer. The heat transfer printing layer comprises a release layer correspondingly connected with the base ribbon. The release layer, a protection layer, a coloring layer and a bonding layer are sequentially and correspondingly connected. Theresin-based thermal transfer printing ribbon high in universality can be universal for flat pressing and edge pressing type bar code printers and is low in printing temperature, extremely good in medium applicability and wide in application.

Owner:福建鸣友新材料科技有限公司

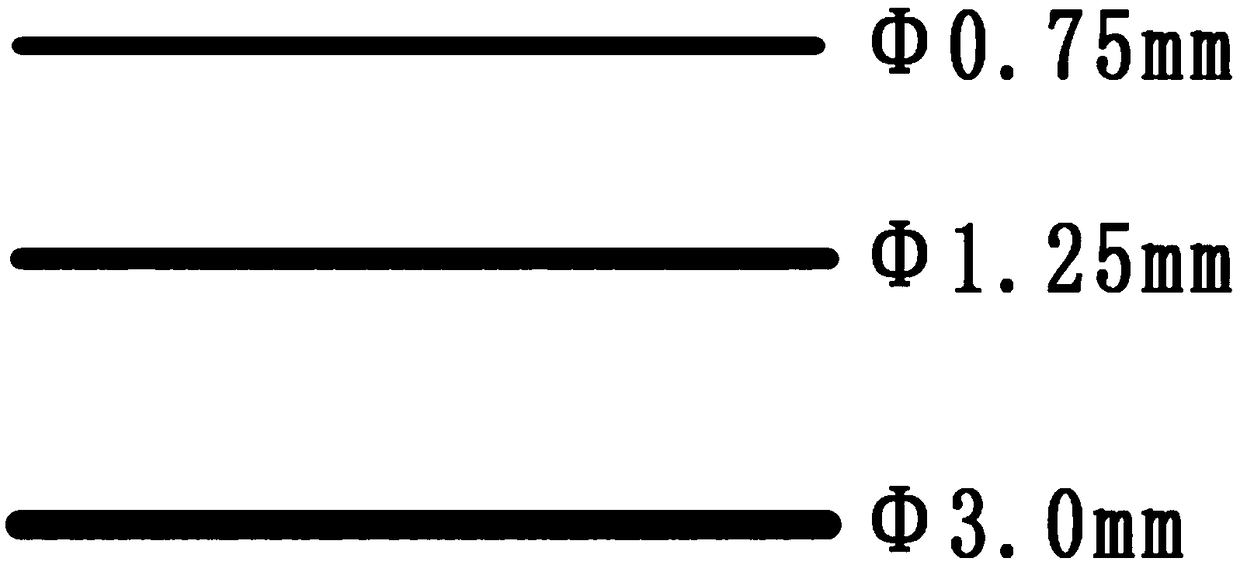

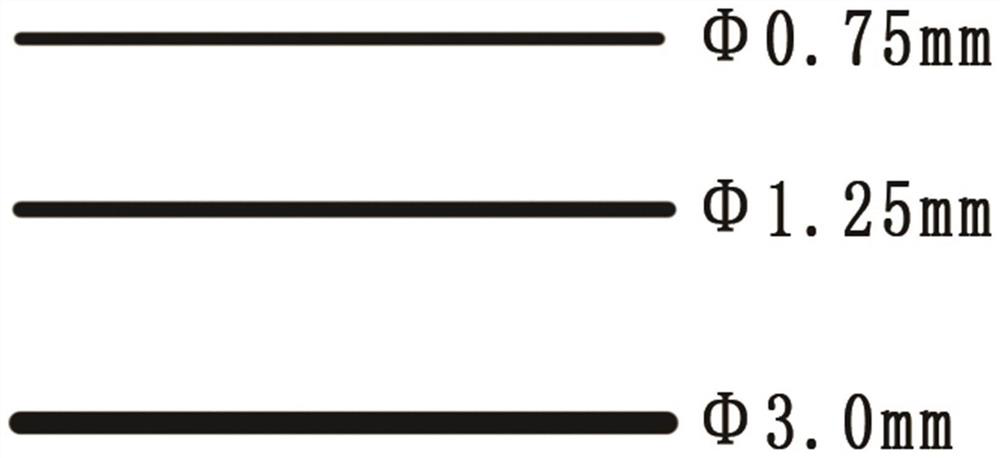

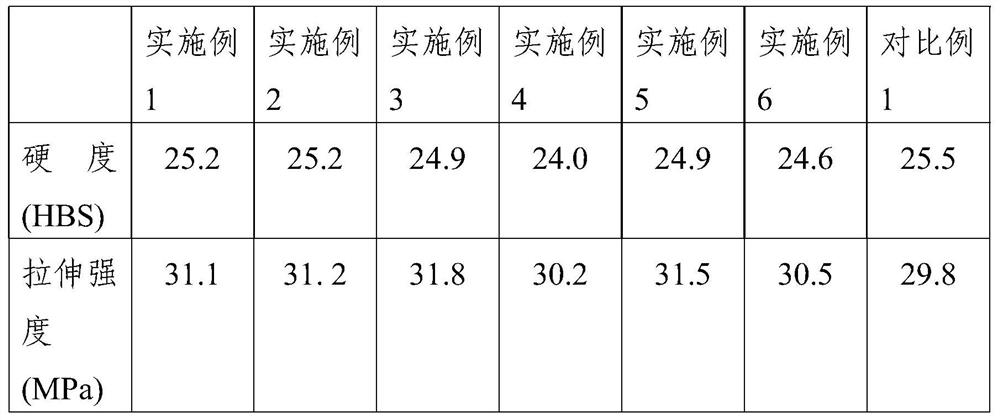

Low-melting-point metal wire for 3D printing

ActiveCN109047768AReduce the temperatureLow print temperatureAdditive manufacturing apparatus3D object support structuresHardnessMetal

The invention relates to a low-melting-point metal wire for 3D printing. The low-melting-point metal wire is prepared from raw materials comprising the following contents of, by weight, 20-45% of Bi,25-40% of Sn, and the balance In complemented to 100%. The melting point of the metal wire is 75-100 DEG C, by adjusting the relative content of Bi, Sn and In, the hardness and the tensile strength ofthe metal wire can be effectively improved, the demands of circuit printing, three-dimensional metal structural part printing and functional structural part printing combined with plastic can be met,and the low-melting-point metal wire has wide application prospects and high commercial promotion value.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

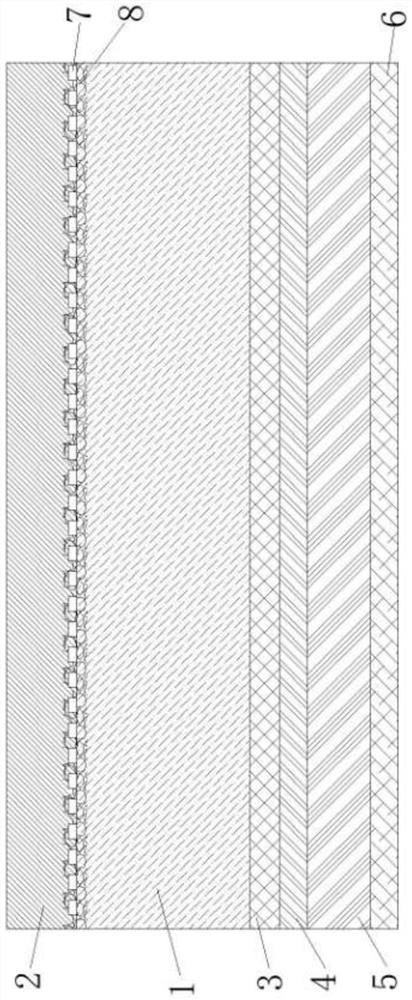

Preparation method for compounded thermal transfer ribbon

InactiveCN105172409AScratch resistantDurable toolSynthetic resin layered productsLaminationEngineeringSolvent

The invention discloses a preparation method for a compounded thermal transfer ribbon. The compounded thermal transfer ribbon comprises a ribbon base, wherein one surface of the ribbon base is coated with an ink layer; the other surface of the ribbon base is coated with a heat-resistant coating; a bonding material, a coloring agent, a filling material and an auxiliary are fully mixed and dispersed, so that an ink layer coating solution is obtained; the front surface of the ribbon base is coated with the ink layer coating solution through a coating machine; the back surface of the ribbon base is coated with the raw materials of the heat-resistant coating through the coating machine; the surface, to which the heat-resistant coating is attached, is in contact with a printing head; the ink layer is in contact with a label; and during operation, the printing head generates heat, and the ink layer is molten and stamped onto the strip-shaped or card-shaped label through the heat-resistant coating, so that clear characters and images are formed. Compared with the prior art, the compounded thermal transfer ribbon has higher scratch resistance, durability and solvent resistance, and in addition, can be well applied to strip-shaped or card-shaped labels with small areas, and the printing temperature is low by adopting the compounded thermal transfer ribbon disclosed by the invention, so that equipment is protected effectively.

Owner:POMA IND SHANGHAI

Low-temperature FDM (fused deposition modeling) 3D printing material and preparation and application thereof

InactiveCN107641303ALow print temperatureHigh precisionAdditive manufacturing apparatusManufacturing data aquisition/processingWire rodMasterbatch

The invention belongs to the field of FDM ((fused deposition modeling) 3D printing and discloses a low-temperature FDM 3D printing material and preparation and application thereof. The material is prepared from PCL (polycaprolactone), graphite, EBS, SiO2 and magnesium stearate. A preparation method includes steps: subjecting PCL masterbatch to melt mixing with filler such as graphite, EBS, SiO2 and magnesium stearate according to a certain proportion through double screws, crushing, granulating, extruding through a single screw, and stretching to obtain wires uniform and appropriate in size. By adoption of the process, the problem of failure in 3D printing of PCL according to an FDM method is solved, and simplicity, feasibility, low preparation cost and high printing precision are realized. Due to high selectivity and low 3D printing equipment requirements, the low-temperature FDM 3D printing material can be applied to normal domestic FDM 3D printers and has important values and significances in the field of FDM 3D printing.

Owner:BEIJING UNIV OF CHEM TECH

PBS (poly butylenes succinate)/halloysite nanotubes composite wire for 3D printing and preparation method of PBS/halloysite nanotubes composite wire

InactiveCN105199340ALow print temperatureGood flexibility and tensile strengthPolymer chemistryPolylactic acid

The invention discloses a preparation method of a PBS (poly butylenes succinate) / halloysite nanotubes composite wire for 3D printing. The technical scheme is that the halloysite nanotubes composite wire is prepared from the following raw materials by weight percent: 70-95 percent of PBS, 0.1-20 percent of halloysite nanotubes, 0.1-10 percent of a coupling agent, 0.1-2 percent of a nucleating agent, 0.1-1 percent of a chain extendor, 0.1-1 percent of a cross-linking agent, 0.2-1 percent of an anti-oxidant and 0.2-1.2 percent of a lubricant. The preparation method comprises the following steps: (1) drying, (2) material weighing, (3) high-speed kneading, (4) melt extrusion, (5) cooling and drawing, and (6) winding and bundling. According to the preparation method, the two completely biodegradable materials, PBS and the halloysite nanotubes, are adopted to prepare a polymer material suitable for 3D printing, and compared with a traditional polylactic acid (PLA) wire, the PBS / halloysite nanotubes composite wire is relatively low in printing temperature and relatively good in tensile strength and flexibility.

Owner:FUJIAN NORMAL UNIV

PBS/carbon material composite wire material for 3D printing

InactiveCN107151423ALow print temperatureHigh tensile strengthAdditive manufacturing apparatusAntioxidantBiological materials

The invention discloses a PBS / carbon material composite wire material for 3D printing, and a preparation method thereof. The technical scheme of the invention is that the components of the formula comprise, by weight, 70-80 parts of PBS, 2-50 parts of a carbon material 0.1-0.5 part of a chain extender, 0.1-0.5 part of a cross-linking agent, 0.1-2 parts of a nucleating agent, 0.1-0.5 part of a heat stabilizer, 0.2-1 part of an antioxidant, and 0.2-1 part of a lubricant. According to the present invention, the polymer material for 3D printing is prepared by using the completely degraded biological material poly(butylene succinate) (PBS), has advantages of low printing temperature, good tensile strength and good flexibility compared to the traditional polylactic acid (PLA) wire material, is suitable for a variety of 3D molding technologies, and has wide application prospects in the 3D printing field.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

A kind of preparation method of copolyester and the application of obtained copolyester in 3D printing

The present invention provides a copolyester preparation method comprising successive esterification and polycondensation of a dihydric alcohol, a fatty diacid and two or more aromatic diacid in the presence of a catalyst for preparation of an amorphous copolyester. The present invention also provides a method for using the copolyester material for preparation of a wire material and application of the wire material in 3D printing. The printing temperature of the wire material used in fused deposition method 3D printing is low, an obtained product is small in size deviation, and sample shrinkage rate is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Artificial bone material and preparation method thereof

The invention discloses a preparation method of an artificial bone material. The preparation method comprises providing raw materials including hydroxyapatite, collagen and nano-crystalline cellulose. The preparation method comprises: step (S1100). dropping a solution containing PO4<3-> of 0.05-0.5 mol / L into a collagen solution with a mass percent concentration of 0.1-1%, stirring to keep in reserve; step (S1200). preparing a nano-crystalline cellulose solution with a mass percent concentration of 0.5-10%, and mixing the nano-crystalline cellulose solution and the collagen PO4<3-> solution prepared by the step (S1100), stirring and homogenizing; step (S1300). adding a solution containing Ca<2+> of 0.2-0.8 mol / L into the collgen / nano-crystalline cellulose composite solution prepared by the step (S1200), setting the mol ratio of Ca to P as 1.67, adjusting the pH to 7-9 with an alkaline solution and precipitating, freeze-drying the precipitation to obtain the artificial bone material.

Owner:珠海市红旌发展有限公司

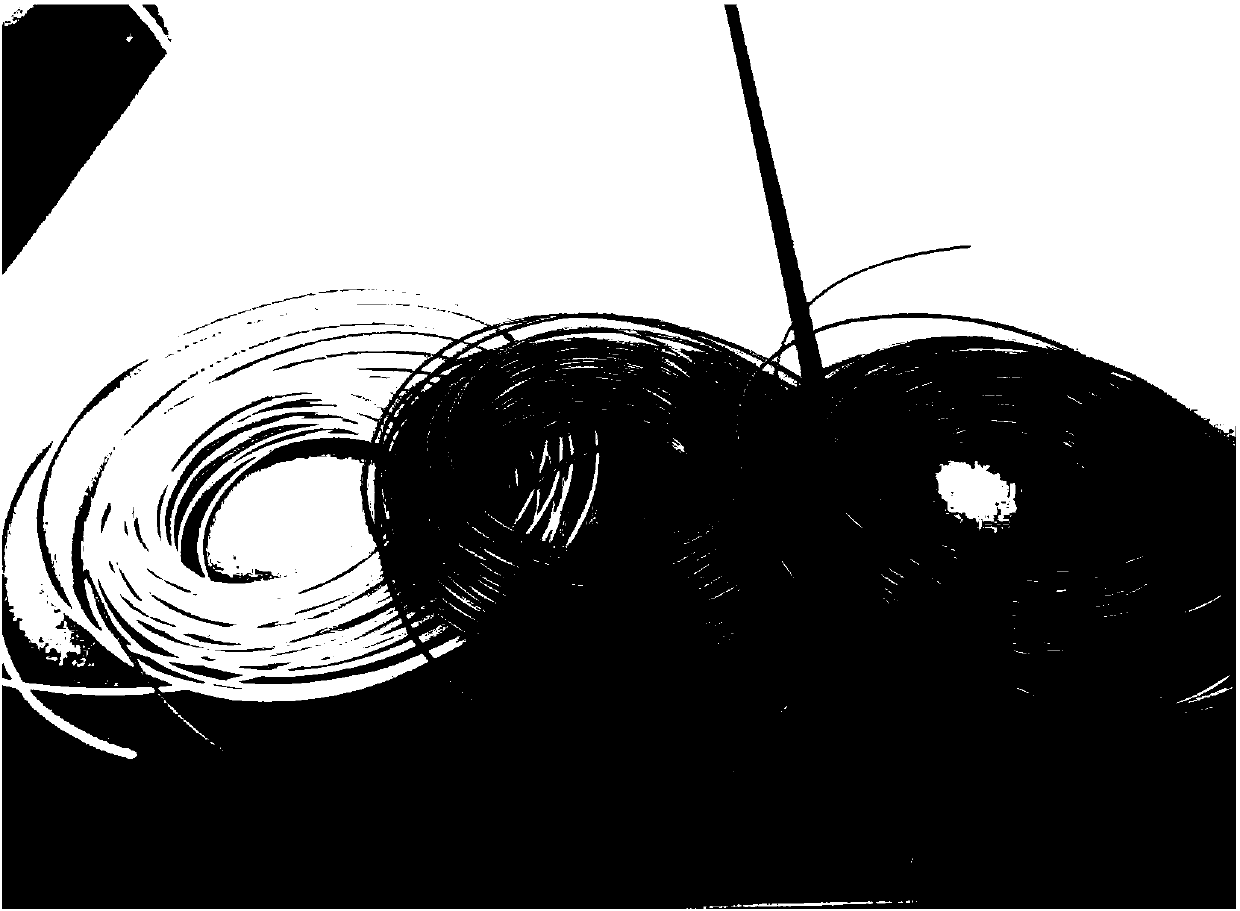

Anion PBS (poly butylenes succinate) composite wire for 3D (three-dimensional) printing

The invention discloses an anion PBS (poly butylenes succinate) composite wire for 3D (three-dimensional) printing, which is prepared from the following raw materials in parts by weight: 75 to 85 parts of PBS, 0 to 2 parts of PHA (polyhydroxyalkanoate), 0 to 5 parts of compatilizer, 0.1 to 0.5 part of chain extender, 0.1 to 0.5 part of cross-linking agent, 0.1 to 2 parts of nucleating agent, 0.2 to 1 part of antioxidant, 0.2 to 2 parts of lubricant, 0.5 to 2 parts of multiwalled carbon nanotube / ZnO composite powder and 1 to 4 parts of anion powder. According to the anion PBS composite wire for 3D printing, the anion powder can release anions, anion concentration can be improved, air quality can be improved, harmful gas can be reduced, and the anion PBS composite wire for 3D printing has wide application prospect in the field of 3D printing.

Owner:佛山市高明区诚睿基科技有限公司

A kind of coated matte pp carbon ribbon printing synthetic paper and preparation method thereof

ActiveCN111087639BImprove printing effectHigh printing densityPolyurea/polyurethane coatingsThermographyPolymer scienceInsulation layer

A coated matte PP carbon ribbon printing synthetic paper, the synthetic paper comprises a PP synthetic paper base material and a coating layer coated on the surface of the base material, the coating layer comprises the following raw materials in parts by weight: The solid parts by weight of the layer are taken as the reference parts, the others are measured in parts by solid content, the moisture of the solution property is counted in the parts of water, 100 parts of heat insulation layer, 80-180 parts of adhesive, 0.08- of water-retaining agent 0.15 part, lubricant 0.5-1.0 part, defoamer 0.2-0.8 part, and water 500-1300 part. The thermal insulation layer is used in the coating of the present invention, which effectively reduces the energy transmission loss of the print head, thereby preventing the poor transfer caused by the temperature reduction of the printed carbon ribbon, and reducing the energy level of the print head.

Owner:河北方大新材料股份有限公司

Degradable flexible 3D printing material as well as preparation method and application thereof

ActiveCN113150510AReduce swelling ratioInhibition of crystallinityAdditive manufacturing apparatusPolymer sciencePolymer chemistry

The invention provides a degradable flexible 3D printing material as well as a preparation method and application thereof. The degradable flexible 3D printing material is prepared from the following raw materials in parts by weight: 40 to 90 parts of PBAT, 5 to 15 parts of polylactic acid, 3 to 8 parts of polycaprolactone, 5 to 15 parts of modified starch, 0.1 to 2 parts of maleic anhydride grafted polylactic acid, 3 to 5 parts of PEG and 1 to 3 parts of compatibilizer. The flexible 3D printing material has the advantages of being capable of being completely degraded, good in compatibility, low in thermal expansion rate, good in flexibility and the like, the printing temperature is low and the printing precision and the printing success rate are high during 3D printing, the 3D printing requirements of FDM equipment can be well met, printed products have good flexibility and rebound resilience, and the application range is wide.

Owner:张晓军

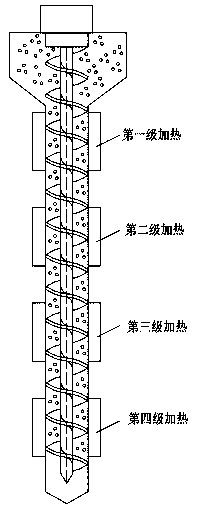

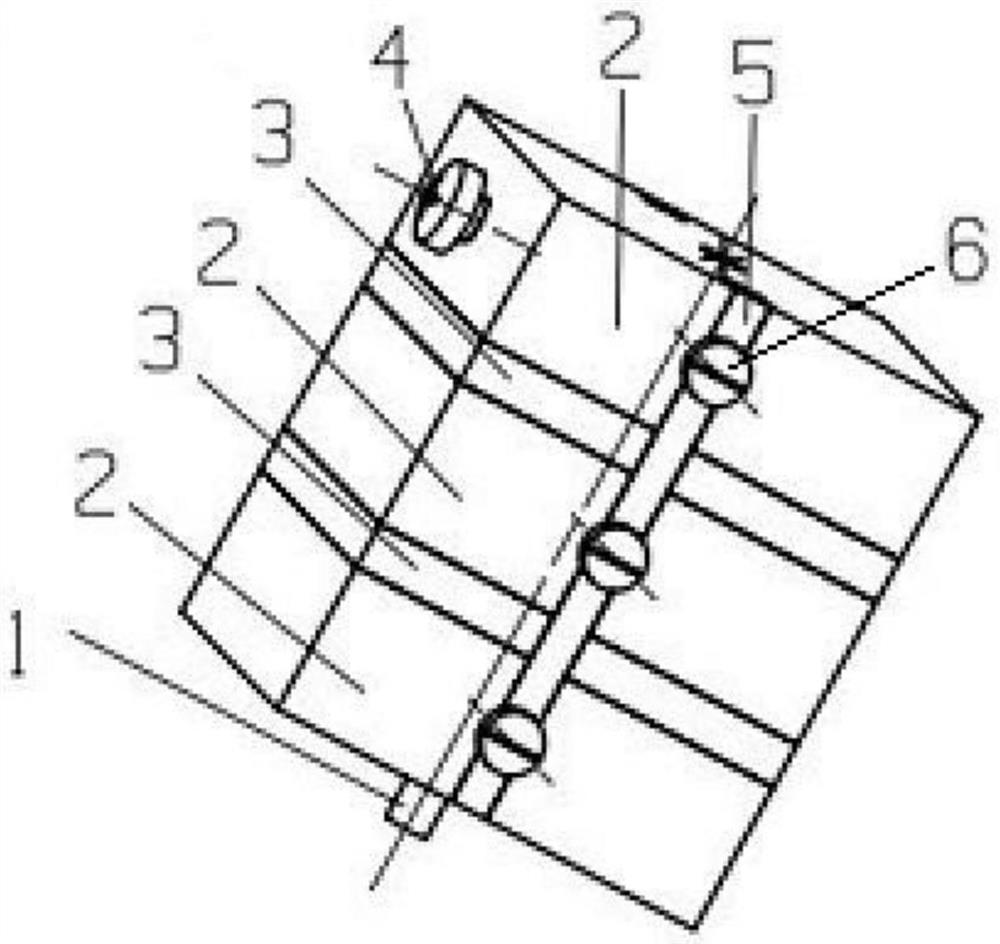

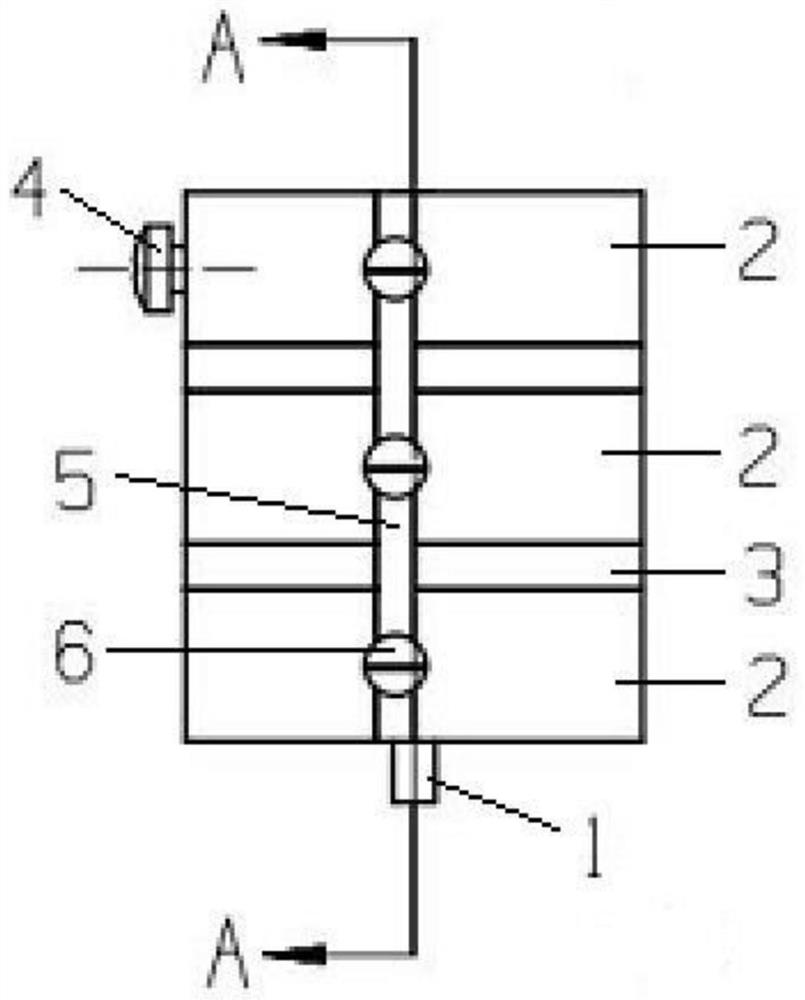

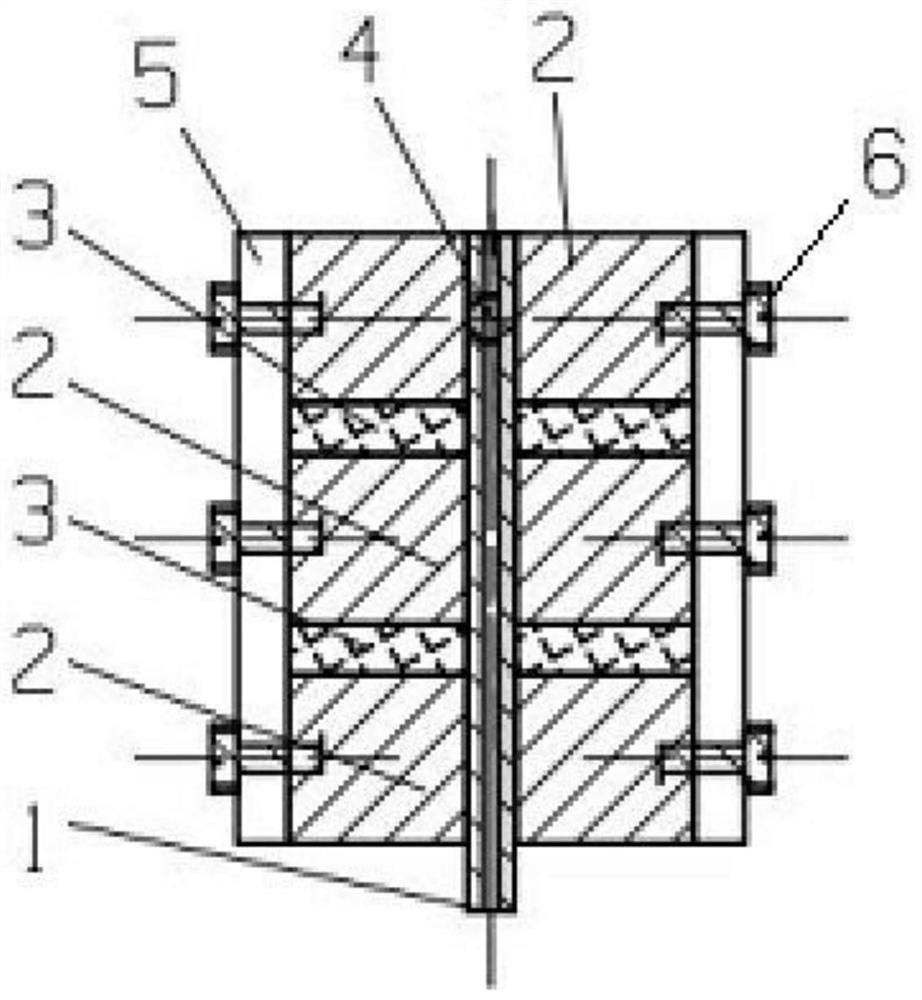

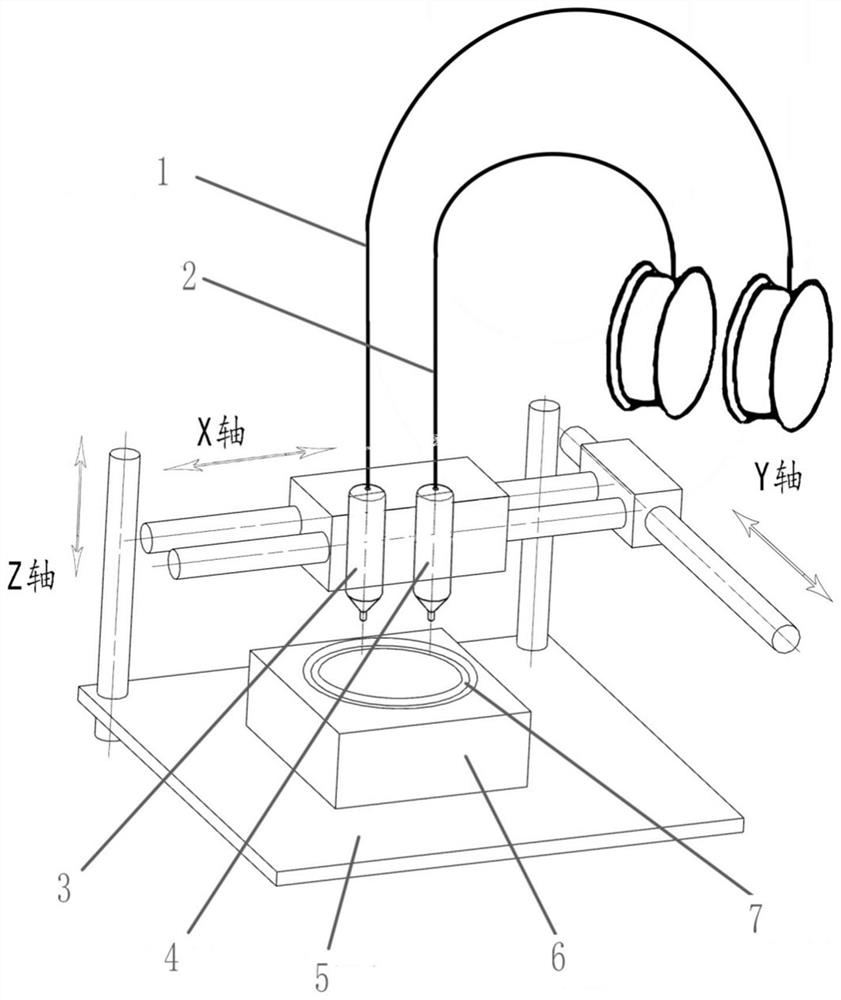

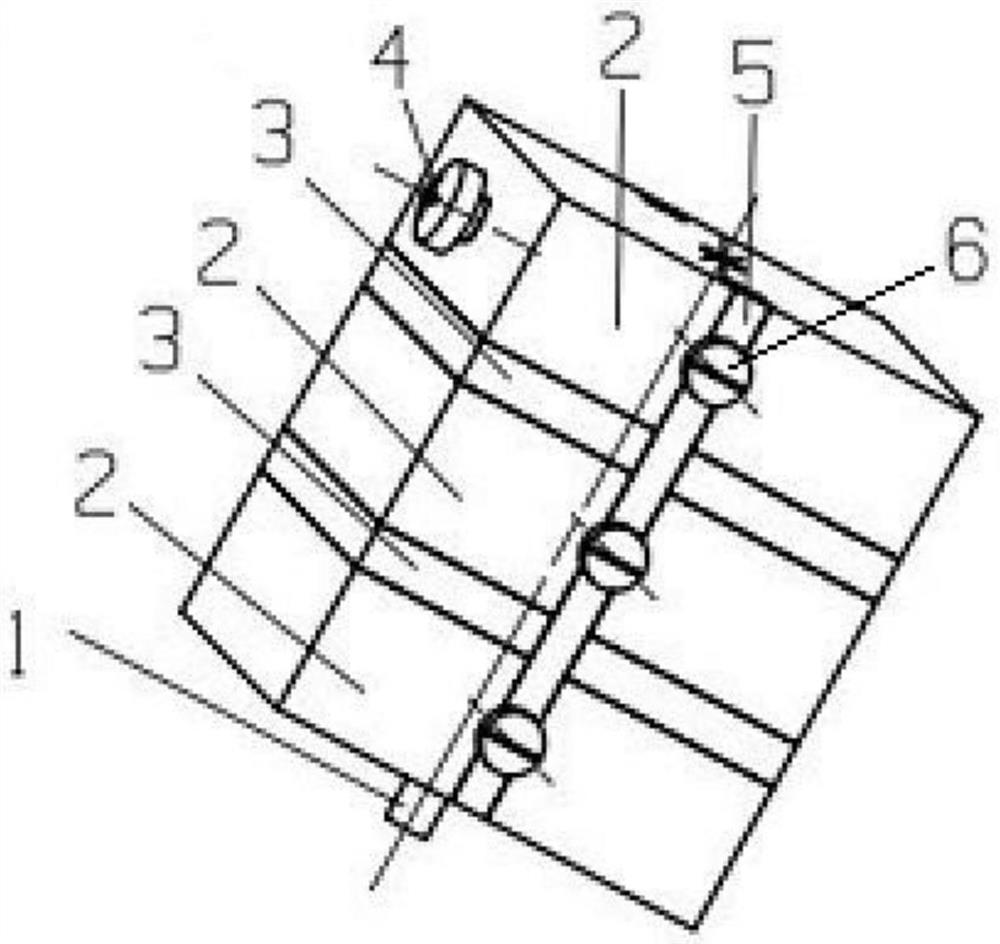

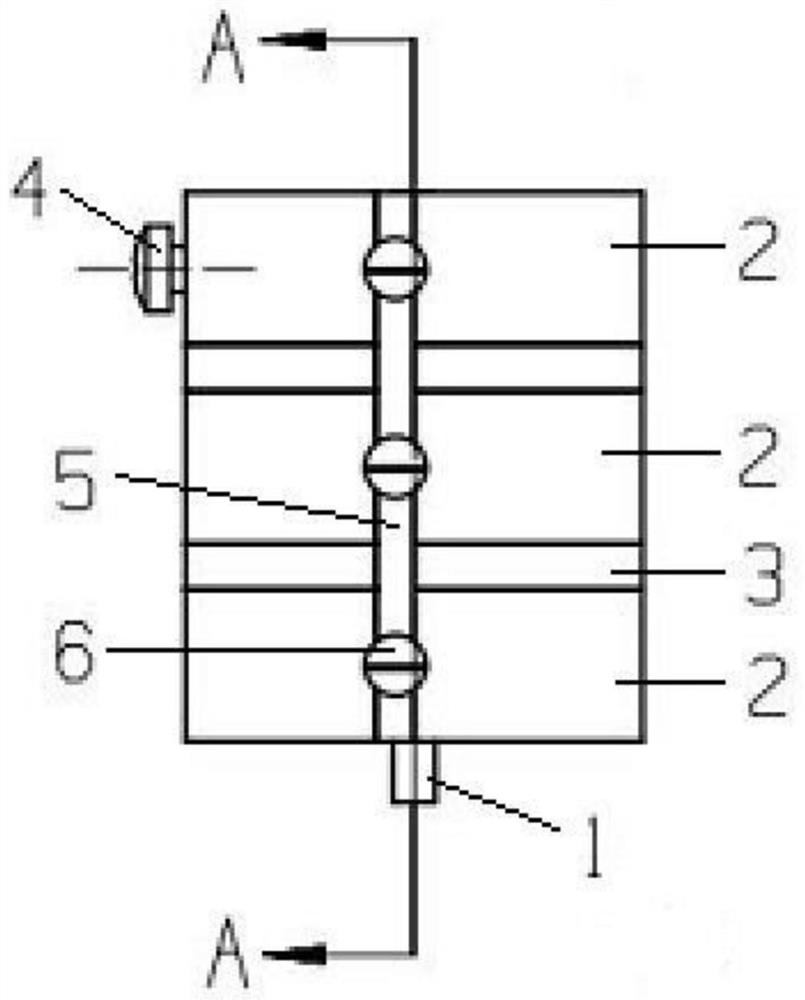

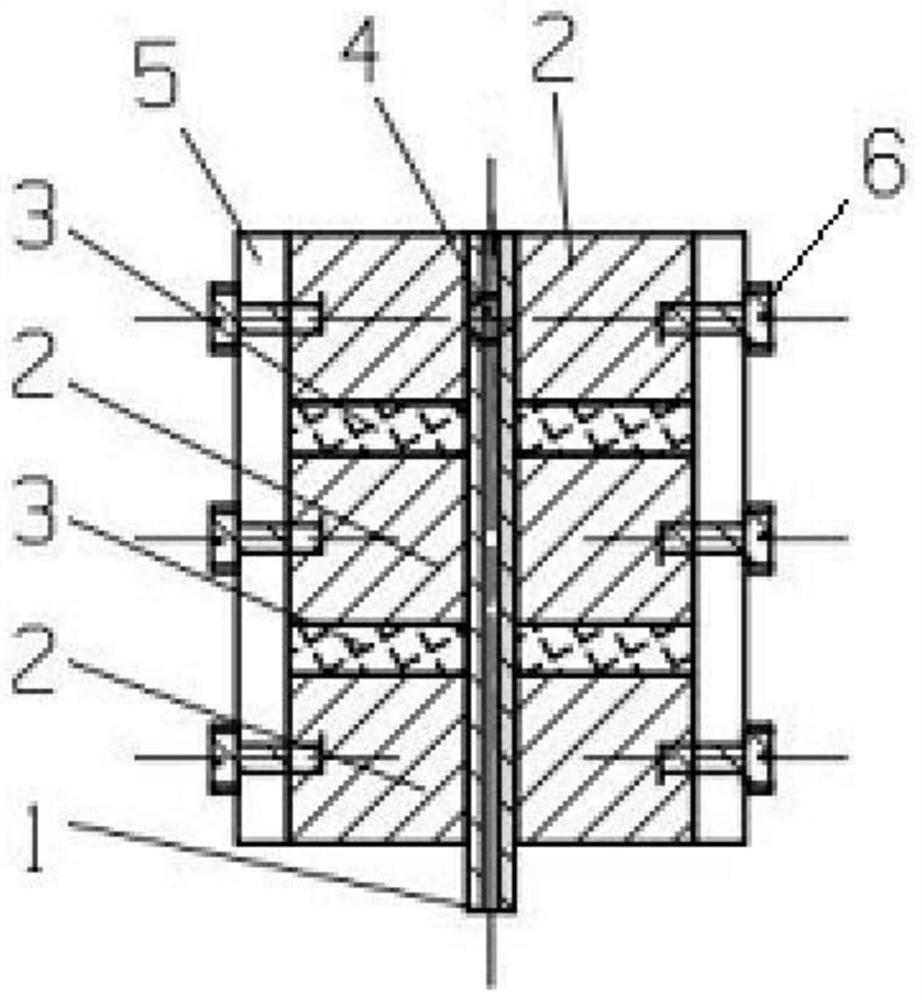

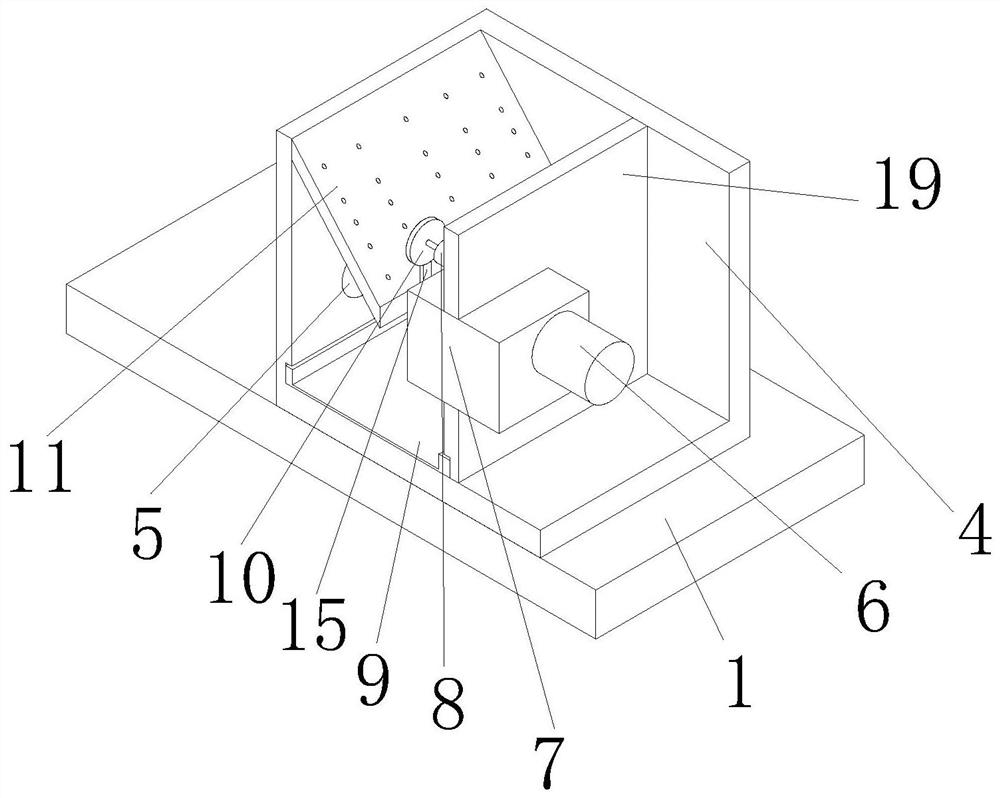

A self-cleaning continuous fiber-reinforced composite 3D printing head

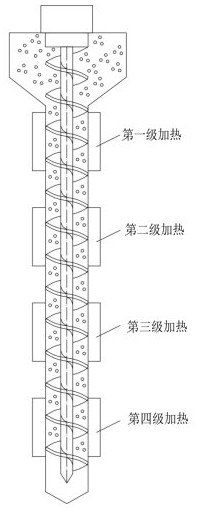

ActiveCN113119446BSolve technical problems that are prone to cloggingEliminate dynamic dead endsManufacturing heating elements3D object support structuresCapillary TubingFiber-reinforced composite

The invention discloses a continuous fiber-reinforced composite material 3D printing head with self-cleaning function, which relates to the technical field of 3D printing, and includes a heating assembly, a fixing assembly and a metal capillary, and the heating assembly includes at least two stacked heating blocks , a heat insulation layer is set between adjacent heating blocks, and the heating assembly is fixed into a whole through a fixing assembly; the metal capillary runs through the heating assembly from top to bottom, and the two ends of the metal capillary are respectively the upper feeding end and the lower discharging end , the lower discharge end is used as a nozzle to extend out of the heating assembly. The invention integrates the feeding channel and the forming channel, and completely eliminates the dynamic dead angle in the printing head. At the same time, by designing the size of the feeding channel to match the diameter of the wire, the wire can peel off the resin that has stayed for a long time and bring out the residue that may be formed during the movement, realizing the self-cleaning function. Compared with the prior art, the invention effectively solves the technical problem that the existing nozzles are easily blocked.

Owner:SICHUAN UNIV

A kind of PBS/carbon material composite wire for 3D printing and preparation method thereof

The invention discloses a PBS / carbon material composite wire for 3D printing and a preparation method thereof. The technical scheme of the invention is as follows: 1. According to the weight percentage, the formula is PBS 70-80, carbon material 2-50, and chain extender 0.1 ‑0.5, crosslinking agent 0.1‑0.5, nucleating agent 0.1‑2, heat stabilizer 0.1‑0.5, antioxidant 0.2‑1, lubricant 0.2‑1. 2. The preparation method is: (1) drying; (2 ) weighing; (3) high-speed kneading; (4) melt extrusion; (5) cooling traction; (6) coil binding. The present invention uses fully degradable biomaterial polybutylene succinate (PBS) and carbon materials to prepare polymer materials suitable for 3D printing. Compared with traditional polylactic acid (PLA) wires, it has a lower printing temperature, Good tensile strength and flexibility, suitable for a variety of 3D molding technologies, and has broad application prospects in the field of 3D printing.

Owner:XIAMEN LUHAI ENVIRONMENT PROTECTION CO LTD

3D-printed heart stent

InactiveCN113058077AReduce rejectionEasy to makeAdditive manufacturing apparatusSurgeryEngineeringRat heart

The invention relates to the field of medical instruments, in particular to a 3D-printed heart stent. The 3D-printed heart stent comprises diphenylmethane diisocyanate, an auxiliary agent, a filling agent, a lubricating agent and a stabilizing agent. The 3D-printed heart stent for an cardiac interventional operation is prepared by blending and dissolving the diphenylmethane diisocyanate, the auxiliary agent, the filling agent, the lubricating agent and the stabilizing agent, then conducting filtering and concentrating to obtain printing slurry, and finally, performing 3D printing preparation. The printing slurry is prepared by conducting blending, dissolving, compressing and the like on different components including the diphenylmethane diisocyanate, a flexibilizer and the filler, preparation is simple, economic and environment-friendly, and a foundation is laid for further 3D printing of the heart stent. The heart stent is printed through a 3D printing method, a needed printing temperature is low, heat energy consumption is low, and mechanical properties meet 3D printing requirements.

Owner:郝治安

A low-melting-point metal wire for 3D printing

ActiveCN109047768BReduce the temperatureLow print temperatureAdditive manufacturing apparatus3D object support structuresLow melting point3D printing

The invention relates to a low-melting-point metal wire for 3D printing, which is prepared from raw materials with the following weight percentages: Bi 20-45%, Sn 25-40%, and In supplemented to 100%. The melting point of the metal wire described in the present invention is 75-100°C. By adjusting the relative content of Bi, Sn and In, the present invention can effectively improve the hardness and tensile strength of the metal wire, which can meet the needs of circuit printing, three-dimensional metal structural parts The demand for printing and printing of functional structural parts combined with plastics has broad application prospects and high commercial promotion value.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

Photochromic PBS composite wire rod for 3D printing

InactiveCN106243639ARound and full colorImprove uniformity of discolorationAdditive manufacturing apparatusWire rodMultiwalled carbon

The invention discloses a photochromic PBS composite wire rod for 3D printing. The photochromic PBS composite wire rod for 3D printing is composed of the following raw materials (by weight): 75-85 parts of PBS, 0-2 parts of PHA, 0-5 parts of a compatilizer, 0.1-0.5 part of a chain extender, 0.1-0.5 part of a cross-linking agent, 0.1-2 parts of a nucleating agent, 0.2-1 part of an antioxidant, 0.2-2 parts of a lubricant, 0.5-2 parts of multiwalled carbon nanotube / ZnO composite powder, and 0.5-1 part of multiwalled carbon nanotube / photochromic powder. According to the invention, multiwalled carbon nanotube is treated in advance, and photochromic powder is adsorbed on the multiwalled carbon nanotube to form composite powder; and then, a scientific ratio is obtained by multiple tests, and the composite powder is combined with PBS and PHA so as to prepare the composite wire rod for a 3D printer. In comparison with a traditional wire rod, the wire rod of the invention can show different colors under irradiation of different light intensities. In addition, the color is mellow and full, photochromic uniformity is good. The wire rod of the invention also has low printing temperature and good tensile strength and flexibility. Meanwhile, the wire rod has low shrinkage so as to prevent the problem of warping after printing. The wire rod of the invention is applicable to multiple 3D moulding technologies, and has a wide application prospect in the field of 3D printing.

Owner:佛山市高明区诚睿基科技有限公司

A kind of polybutylene succinate 3D printing wire material and preparation method thereof

The invention discloses a polybutylene succinate 3D printing wire and a preparation method thereof, which relates to a printing material. The purpose of the present invention is to provide a 3D printing polymer material that can be printed at a lower temperature and has better toughness. The technical scheme of the present invention is as follows: 1. According to the mass part ratio, the formula is PBS100, nucleating agent 0.05-2, antioxidant 0.02-2, anti-ultraviolet agent 0.03-2, lubricant 1-2. 2. The preparation method is: (1) Drying; (2) Weighing; (3) High-speed kneading; (4) Melting extrusion; (5) Cooling traction; (6) Coiling. The present invention uses PBS, which is the same complete biodegradable resin as polylactic acid (PLA), as the wire material, which not only has good biodegradability and biocompatibility, but also can be printed at a lower temperature, and the product has good flexibility. sex.

Owner:FUJIAN NORMAL UNIV

A preparation method of 3D printing intelligent deformation material

ActiveCN109648817BChange crossing angleThe pre-deformation structure is complex and diverseAdditive manufacturing apparatus3D object support structures3d printFiber

The invention relates to a preparing method of a 3D printing intelligent deforming material. The method aims at printing complex irregular shapes such as a gradient structure, a biology structure, a spiral structure and a microstructure, the method is precise and efficient, simple and easy to implement, and the 3D printing intelligent deforming material of a complex structure and with large deforming is prepared, and the method comprises following steps of firstly, preparing of polymer wires, and secondly, 3D printing of the intelligent deforming material. On the basis of the 3D printing technology, polyether-ether-ketone powder and a carbon fiber serve as the main material, through control design of the printing shape in the 3D printing process, the path can be programmed, the crossed angle between layers can be changed, the pre-deformed structure is more complicated and diverse, deforming is benefited due to being parallel to the printing path, the larger deforming and the deformingrestore rate can be obtained, through the preparing method, the machining step is simplified, production cost is saved, and machining efficiency is improved.

Owner:JILIN UNIV

Continuous fiber reinforced composite 3D printing head with self-cleaning function

ActiveCN113119446ASolve technical problems that are prone to cloggingEliminate dynamic dead endsManufacturing heating elements3D object support structuresInsulation layerCapillary Tubing

The invention discloses a continuous fiber reinforced composite 3D printing head with a self-cleaning function, and relates to the technical field of 3D printing. The continuous fiber reinforced composite 3D printing head comprises a heating assembly, a fixing assembly and a metal capillary tube, the heating assembly comprises at least two stacked heating blocks, a heat insulation layer is arranged between the adjacent heating blocks, and the heating assembly is fixed into a whole through the fixing assembly; and the metal capillary tube penetrates through the heating assembly from top to bottom, the two ends of the metal capillary tube are an upper feeding end and a lower discharging end respectively, and the lower discharging end serves as a nozzle and extends out of the heating assembly. A feeding channel and a forming channel are integrated, and dynamic dead angles in the printing head are thoroughly eliminated. Meanwhile, the size of the feeding channel is designed to be matched with the diameter of a wire material, so that the wire material peels off resin staying for a longer time and carries out possibly formed residues in the moving process, and the self-cleaning function is achieved. Compared with the prior art, the technical problem that an existing nozzle is prone to being blocked is effectively solved.

Owner:SICHUAN UNIV

High-strength low-shrinkage PETG-G material for 3D printer consumables and preparation method thereof

PendingCN113773616AImprove performanceImprove printing accuracyAdditive manufacturing apparatusComputer printingAnoxomer

The invention discloses a high-strength low-shrinkage PETG-G material for 3D printer consumables and a preparation method thereof. The high-strength low-shrinkage PETG-G material for 3D printer consumables comprises the following components in parts by weight: 60-80 parts of a PETG resin, 20-40 parts of a PBAT resin, 5-15 parts of an ABS resin, 1-5 parts of a compatilizer, 0.1-0.5 part of a lubricant, 0.1-0.5 part of an antioxidant and 0.1-0.5 part of diffusion oil. The high-strength low-shrinkage PETG-G material for 3D printer consumables has the beneficial effects that the printing wire drawing performance is improved, the printing precision is improved, and the printing temperature is reduced.

Owner:ZHUHAI SUNLU IND

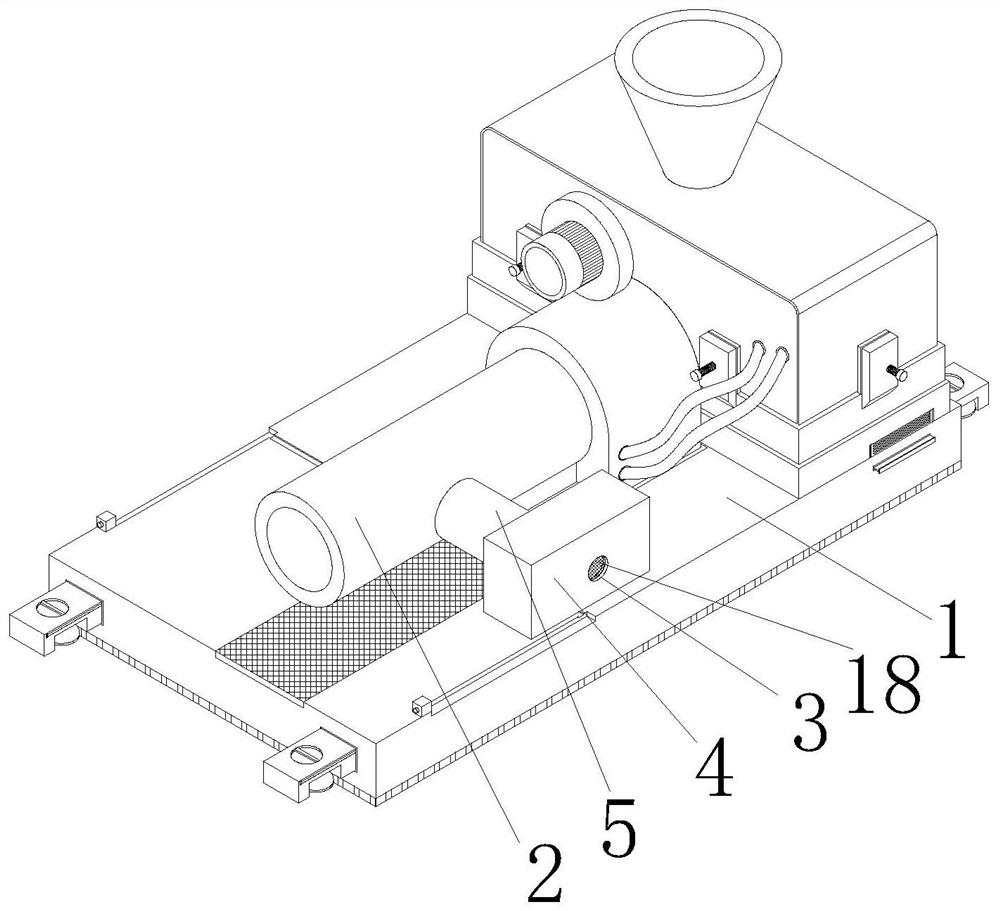

Preparation device and method of PCL material for 3D printing

InactiveCN112721164AMeet cutting requirementsLow print temperatureGas treatmentAdditive manufacturing apparatus3d printComputer printing

The present invention relates to the technical field of preparation of high polymer materials, and discloses a preparation device and method of a PCL material for 3D printing. The preparation method includes the steps: firstly, adding 80-95 g of polycaprolactone, 5-20 g of starch, 1 g of chain extender 4468, 5 g of calcium stearate serving as a lubricant, 0.5 g of antibacterial agent, 3-5 g of silicon dioxide and 5-15 g of polyethylene glycol into a sealed bag; manually shaking up the materials; and weighing the materials according to a formula ratio. According to the preparation device and method for the PCL material for 3D printing, the material is low in printing temperature, high in precision and good in printing performance. Meanwhile, the preparation method disclosed by the present invention is simple and easy to implement, conditions are controllable, and the preparation cost is low; and the prepared low-temperature 3D printing consumable is low in 3D printing equipment requirements and wide in selectivity and can be used by common household 3D printers, so that the application range of the materials is wider, more people can perform 3D printing on the material, and the printing cost is reduced.

Owner:山东创瑞增材制造产业技术研究院有限公司

Coated matte PP synthetic paper for thermal transfer ribbon printing and preparation method thereof

ActiveCN111087639AImprove printing effectHigh print densityPolyurea/polyurethane coatingsThermographyPolymer scienceInsulation layer

The invention relates to coated matte PP synthetic paper for thermal transfer ribbon printing. The synthetic paper comprises a PP synthetic paper base material and a coating layer coating the surfaceof the base material, wherein the coating layer comprises the following raw materials in parts by weight: on the basis of the solid weight part of a heat insulation layer and in terms of solid content, 100 parts of the heat insulation layer, 80-180 parts of an adhesive, 0.08-0.15 part of a water-retaining agent, 0.5-1.0 part of a lubricant, 0.2-0.8 part of a defoaming agent and 500-1300 parts of water (wherein the parts of moisture functioning as a solution are included in the parts of the water). The heat insulation layer is used in the coating layer, so the energy transfer loss of a printinghead is effectively reduced, poor transfer caused by temperature reduction of a printed thermal transfer ribbon is prevented, and the energy level of the printing head is reduced.

Owner:河北方大新材料股份有限公司

Preparation method of nanotube composite wire containing polyolefin ionomer

The invention discloses a preparation method of a nanotube composite wire containing a polyolefin ionomer. The technical scheme of the invention is as follows: 1, a formula is prepared from the ingredients in percentage by weight: PBS (Poly Butylene Succinate), the polyolefin ionomer, halloysite nanotubes, a coupling agent, a nucleating agent, a chain extension agent and the like; 2, the preparation method comprises the steps of (1) drying; (2) material weighting; (3) kneading at a high speed; (4) melting and extruding; (5) cooling and tracking; (6) rolling and bundling. According to the preparation method of the nanotube composite wire containing the polyolefin ionomer, disclosed by the invention, a high polymer material which is suitable for 3D (Three-dimensional) printing is prepared by adopting completely degraded biological materials of the PBS and the halloysite nanotubes, and better tensile strength and better flexibility are obtained while lower printing temperature is obtained.

Owner:叶晓青

3D printed heart stent for cardiac interventional surgery

InactiveCN108607120AEasy to makeDoes not affect inspectionAdditive manufacturing apparatusSurgeryThrombusPercent Diameter Stenosis

The invention provides a 3D printed heart stent for a cardiac interventional surgery. The 3D printed heart stent for the cardiac interventional surgery comprises poly-L-lactic acid as a matrix polymerizer, and a toughening agent, starch, a filler, a lubricant and a stabilizer as auxiliary agents. The 3D printed heart stent for the cardiac interventional surgery is prepared by blending, dissolving,filtering and concentrating the poly-L-lactic acid as the matrix polymerizer, and the toughening agent, the starch, the filler, the lubricant and the stabilizer as the auxiliary agents to obtain a printing paste, and finally performing 3D printing. The 3D printed heart stent for the cardiac interventional surgery comprises the poly-L-lactic acid, is a biodegradable material, does not contain anymetal component and is not affected by a magnetic field, so that examination of nuclear magnetic resonance is not affected; meanwhile, formation of a thrombus is unlikely, long-time use of an anticoagulant medicine for preventing thrombosis is not required, and after vascular functions are restored in a body, the 3D printed heart stent can be completely dissolved by itself and the rate of restenosis is extremely low.

Owner:代清燕

A kind of pbs wood-plastic composite wire for 3d printer

Owner:金晖兆隆高新科技股份有限公司

Polycarbonate composition for 3D printing as well as preparation method and application thereof

PendingCN114479402AImprove dispersionReduce thermal stressAdditive manufacturing apparatusPolymer scienceCopolyester

The invention provides a polycarbonate composition for 3D printing as well as a preparation method and application thereof. The polycarbonate composition for 3D printing provided by the invention is prepared from polycarbonate, aliphatic aromatic copolyester, graphene dispersion liquid and an optional functional additive. According to the polycarbonate composition for 3D printing provided by the invention, the temperatures of a printing nozzle and a bottom plate can be reduced, and meanwhile, the polycarbonate composition has relatively high printing size precision.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com