Artificial bone material and preparation method thereof

A technology of artificial bone and raw materials, applied in the field of materials, can solve problems such as low porosity, poor pore traffic performance, and insufficient mechanical strength, and achieve the effects of low printing temperature, good formability, and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

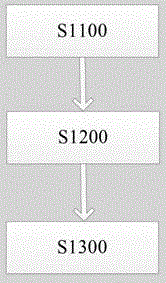

[0031] figure 1 Show the preparation method of artificial bone material according to one embodiment of the present invention, as shown in the figure:

[0032] First enter step S1100 to prepare collagen PO 4 3- Solution: Prepare 450ml of collagen aqueous solution with a concentration of 0.1%, add 0.1mol / l H 3 PO 4 30ml of the solution was dropped into the aqueous collagen solution and stirred for 20 minutes. Then enter step S1200 to prepare collagen / nanocellulose composite solution: the preparation concentration is 1ml of nanocellulose aqueous solution of 5%, and the collagen PO prepared in step S1100 4 3- The solution is blended and stirred, and then homogenized by a high-pressure homogenizer. Finally enter step S1300 to prepare collagen / hydroxyapatite / nanocellulose composite material: prepare CaCl with a concentration of 0.2mol / l 2 Solution 25ml, drop into the collagen / nanocellulose homogeneous solution, set the Ca / P molar ratio to 1.67, and stir for 1.5h to ensure tha...

Embodiment 2

[0034] figure 1 Show the preparation method of artificial bone material according to one embodiment of the present invention, as shown in the figure:

[0035] First enter step S1100 to prepare collagen PO 4 3- Solution: prepare 1ml of 10% collagen aqueous solution, mix 0.5mol / l (NH 4 ) 2 HPO 4 7ml of the solution was dropped into the aqueous collagen solution and stirred for 30 minutes. Then enter step S1200 to prepare collagen / nanocellulose composite solution: preparation concentration is 20ml of nanocellulose aqueous solution of 0.5%, mix it with the collagen PO prepared in step S1100 4 3- The solution is blended and stirred, and then homogenized by a high-pressure homogenizer. Finally enter step S1300 to prepare collagen / hydroxyapatite / nanocellulose composite material: prepare Ca(OH) with a concentration of 0.6mol / l 2 10ml of the solution was dropped into the collagen / nanocellulose homogeneous solution, neutralized with sodium hydroxide to pH 8, the Ca / P molar ratio...

Embodiment 3

[0037] figure 1 Show the preparation method of artificial bone material according to one embodiment of the present invention, as shown in the figure:

[0038] First enter step S1100 to prepare collagen PO 4 3- Solution: prepare 41ml of 1% collagen aqueous solution, add 0.3mol / l Na 2 HPO 4 14ml of the solution was dropped into the aqueous collagen solution and stirred for 30 minutes. Then enter step S1200 to prepare collagen / nanocellulose composite solution: prepare 2ml of nanocellulose aqueous solution with a concentration of 0.5%, and mix it with the collagen PO prepared in step S1100 4 3- The solution is blended and stirred, and then homogenized by a high-pressure homogenizer. Finally enter step S1300 to prepare collagen / hydroxyapatite / nanocellulose composite material: the preparation concentration is 0.8mol / l Ca(NO 3 ) 2 7ml of the solution was dropped into the collagen / nanocellulose homogeneous solution, the Ca / P molar ratio was set to 1.67, and stirred for 2h to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com