Coated matte PP synthetic paper for thermal transfer ribbon printing and preparation method thereof

A synthetic paper, matte technology, applied in the direction of copying/marking method, printing device, coating, etc., can solve the problems of low printing speed, reduce the service life of the printer, reduce the printing effect, etc., achieve the improvement of barcode scanning level and prevent heat The effect of passing too fast and reducing the amount of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

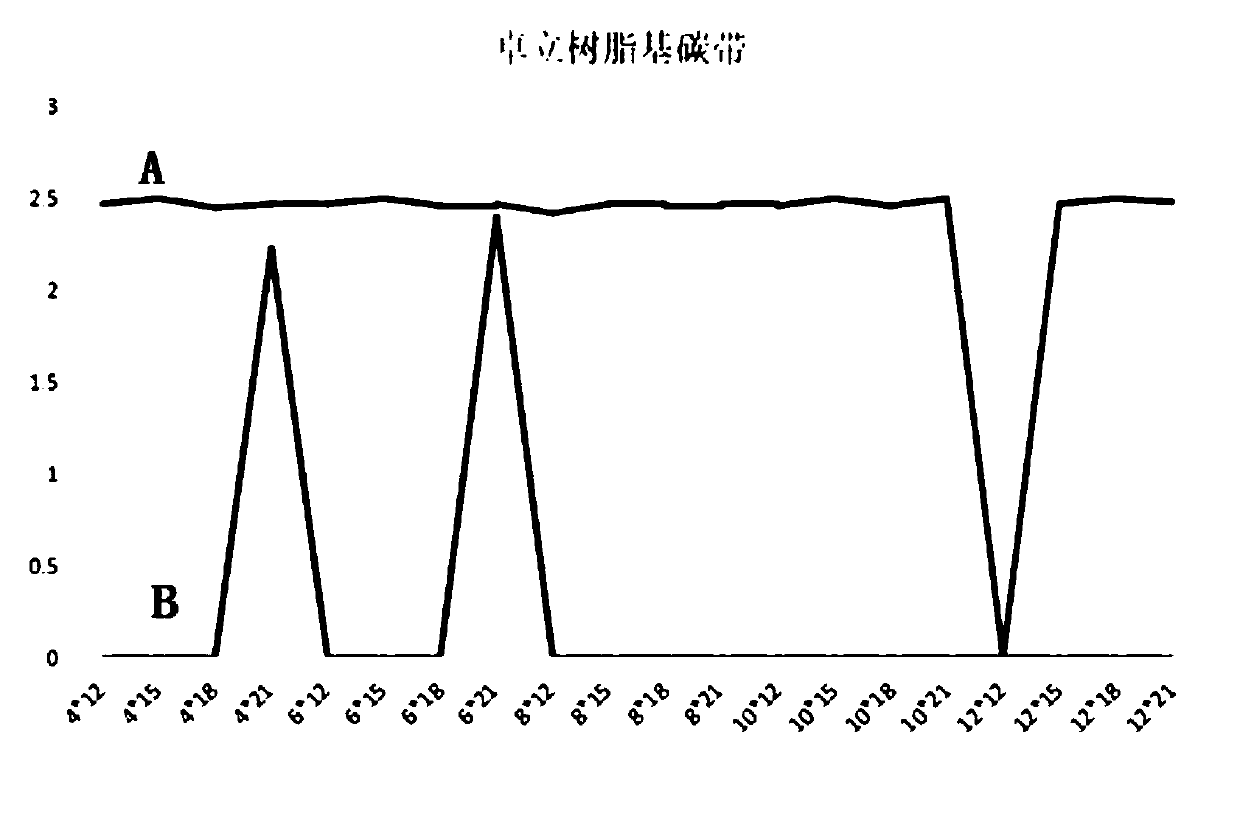

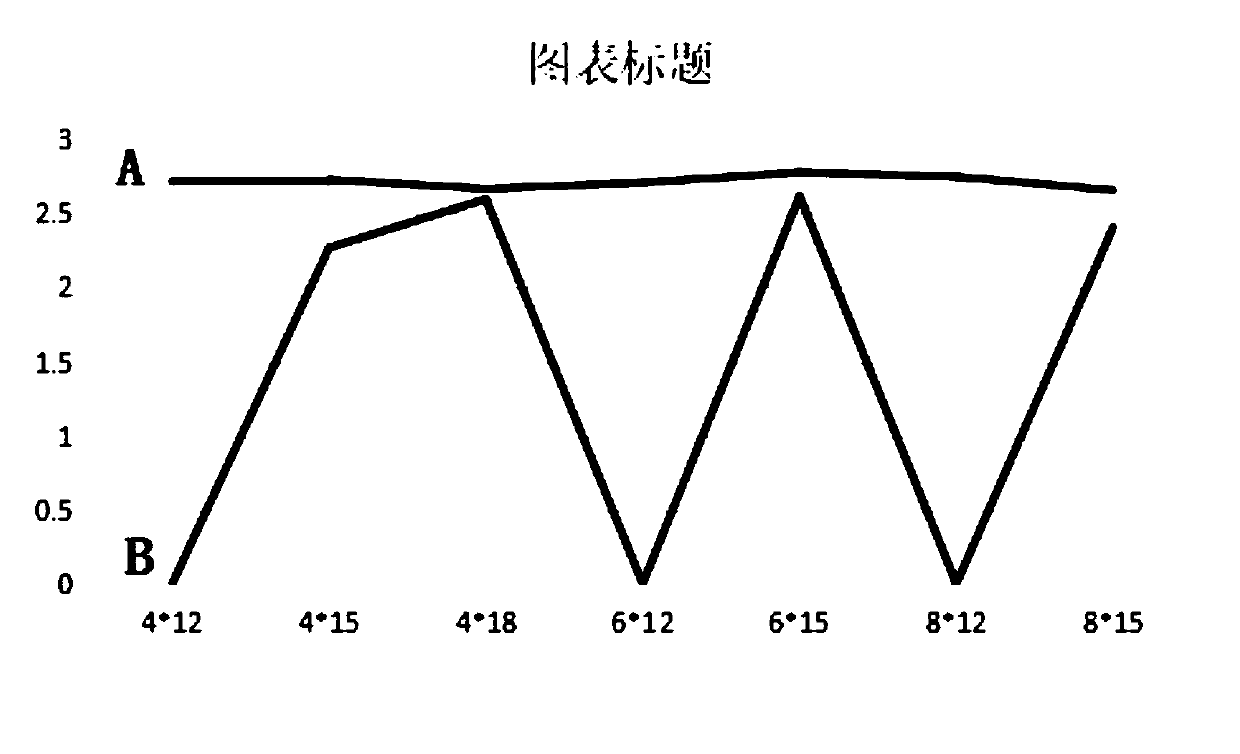

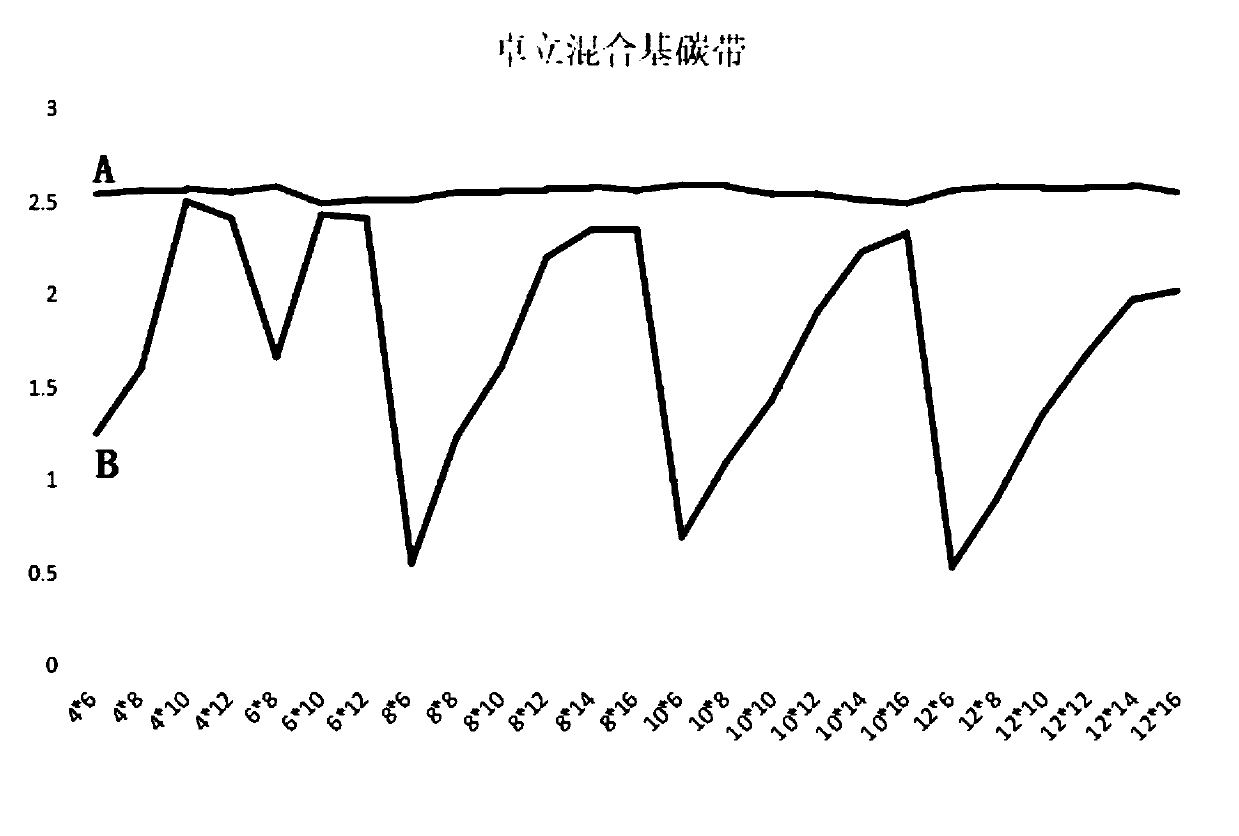

Image

Examples

Embodiment 1

[0033] Synthetic paper coating formula is selected: take the solid weight part of heat-insulating layer as benchmark part (others are all measured with solid content part, and the water part of solution nature is included in the part of water), PMMA microsphere 100 parts, pure 130 parts of acrylic emulsion adhesive, 0.12 parts of synthetic acrylic copolymer water retaining agent, 0.8 part of polyethylene wax lubricant, 0.5 part of defoamer and 800 parts of water.

[0034] The preparation process of above-mentioned coating comprises:

[0035] Add the formulated amount of water into the preparation container, turn on the stirring and adjust it to 300r / min, add the formulated amount of heat insulating material PMMA microspheres and pure acrylic emulsion adhesive, stir for 5 minutes and then add lubricant, water retaining agent and defoamer , increase the speed to 500r / min, stir for 30min and set aside;

[0036] The paint in the storage tank is conveyed to the coating roller thro...

Embodiment 2

[0038] Synthetic paper coating formulation selection: take the solid parts by weight of the heat-insulating layer as the reference part (others are all measured by the solid content part, and the water part of the solution property is included in the part of water), styrene-acrylic copolymer microspheres 100 100 parts of epoxy resin, 33 parts of curing agent, 0.10 parts of synthetic acrylic copolymer water retaining agent, 0.6 parts of polyethylene wax lubricant, 0.5 parts of defoamer and 900 parts of water.

[0039] The preparation process of above-mentioned coating comprises:

[0040] Add the formula amount of water into the preparation container, turn on the stirring and adjust it to 300r / min, add the formula amount of heat insulation material styrene-acrylic copolymer microspheres, epoxy resin and curing agent, stir for 5 minutes, add lubricant, water retaining agent and For defoaming agent, increase the rotation speed to 500r / min, stir for 30 minutes and set aside; (Note:...

Embodiment 3

[0043]Synthetic paper coating formulation selection: take the solid parts by weight of the heat-insulating layer as the reference part (others are all measured by the solid content part, and the water part of the solution property is included in the part of water), styrene-acrylic copolymer microspheres 100 160 parts of polyurethane adhesive, 0.10 part of synthetic acrylic copolymer water retaining agent, 0.5 part of polyethylene wax lubricant, 0.5 part of defoamer and 700 parts of water.

[0044] The preparation process of above-mentioned coating comprises:

[0045] Add the prescribed amount of water into the preparation container, turn on the stirring and adjust it to 300r / min, add the prescribed amount of heat-insulating material styrene-acrylic copolymer microspheres and polyurethane adhesive, stir for 5 minutes and then add lubricant, water-retaining agent and defoaming agent agent, increase the speed to 500r / min, and stir for 30min for later use;

[0046] The paint in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com