Printing device for three-dimensional biological structure and printing method

A technology of three-dimensional biological and printing devices, which is applied in the fields of biomedical engineering and tissue engineering, and can solve problems such as failure to achieve expected results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

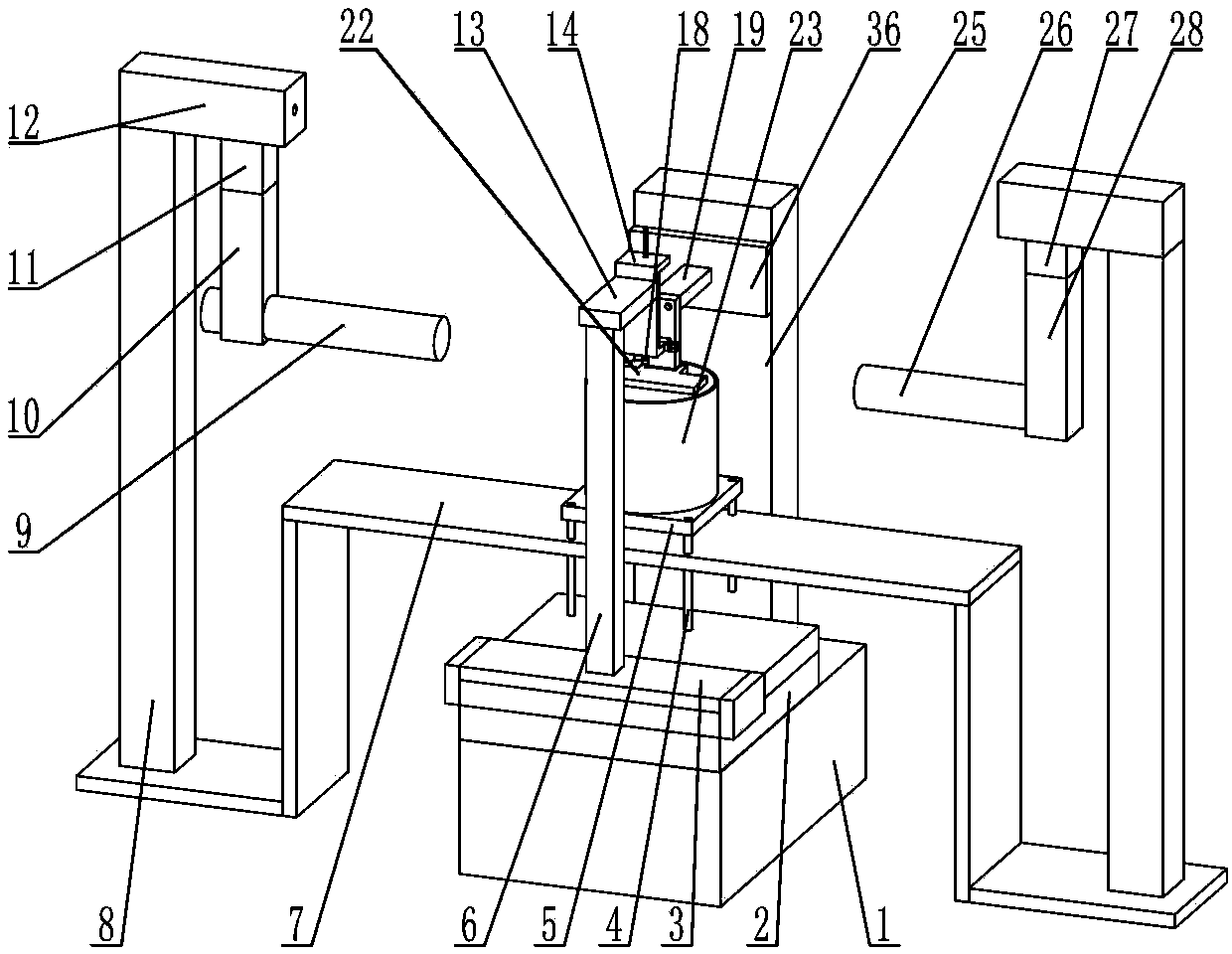

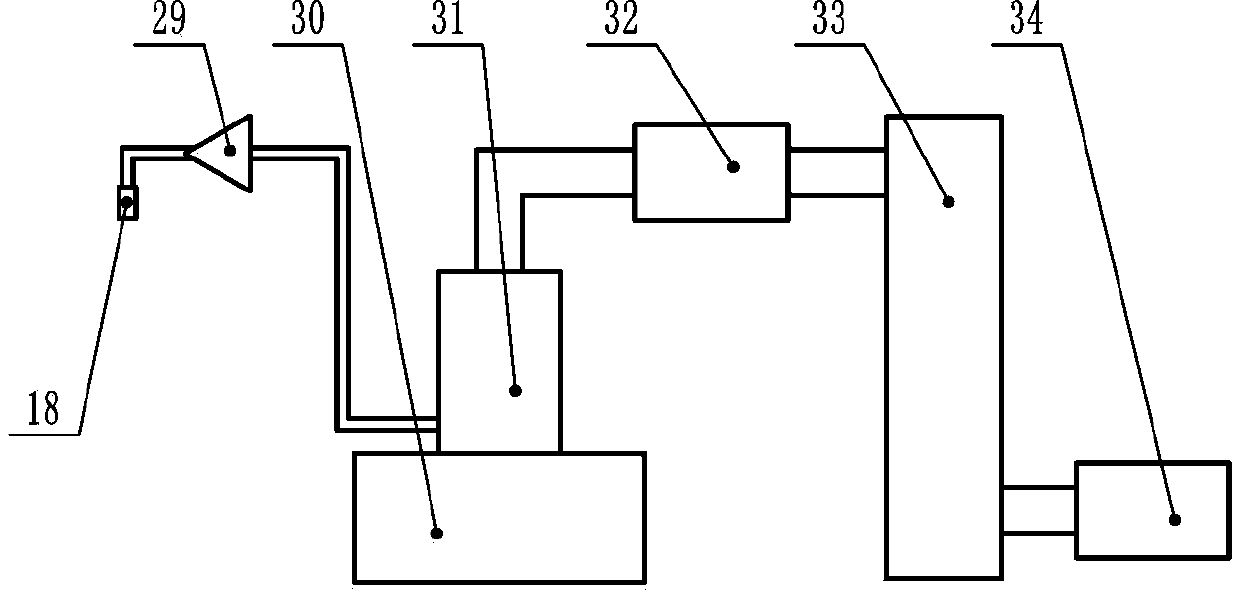

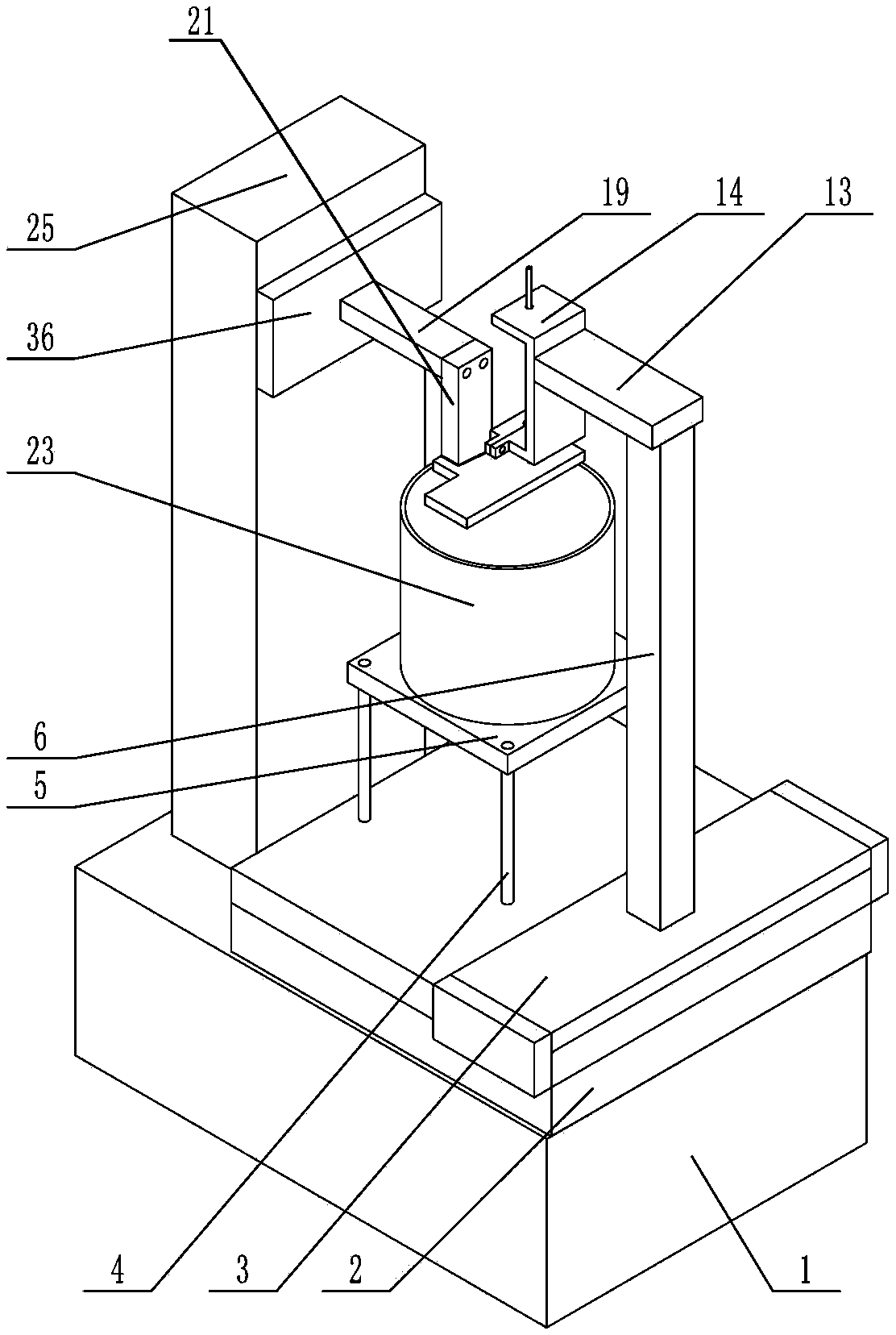

[0046] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a three-dimensional biological structure printing device includes: an execution unit for printing and generating a three-dimensional biological structure, a control unit for controlling the printing operation of the execution unit, and a detection unit.

[0047] Among them, the execution unit includes a nozzle 18 that ejects biological ink, a working panel 22 that supports a three-dimensional biological structure, a liquid supply system connected to the nozzle 18, and three-dimensional adjustment of the position of the nozzle or work panel to meet the requirements of printing the three-dimensional biological structure. mechanism.

[0048] The nozzle 18 can choose a piezoelectric nozzle, and the nozzle is squeezed by the driver to realize the ejection of biological ink. The drive generally can use the existing structure, which will not be described in detail here. The nozzle 18 is fixed on the nozzle holder 14. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com