Photovoltaic solar printer

A photovoltaic solar energy and printing machine technology, applied in printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of inaccurate positioning of silicon wafers, insufficient printing accuracy, and insufficient printing effect, and achieve good printing effect. , The effect of high production efficiency and high printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solution of the invention will be described below in conjunction with the accompanying drawings.

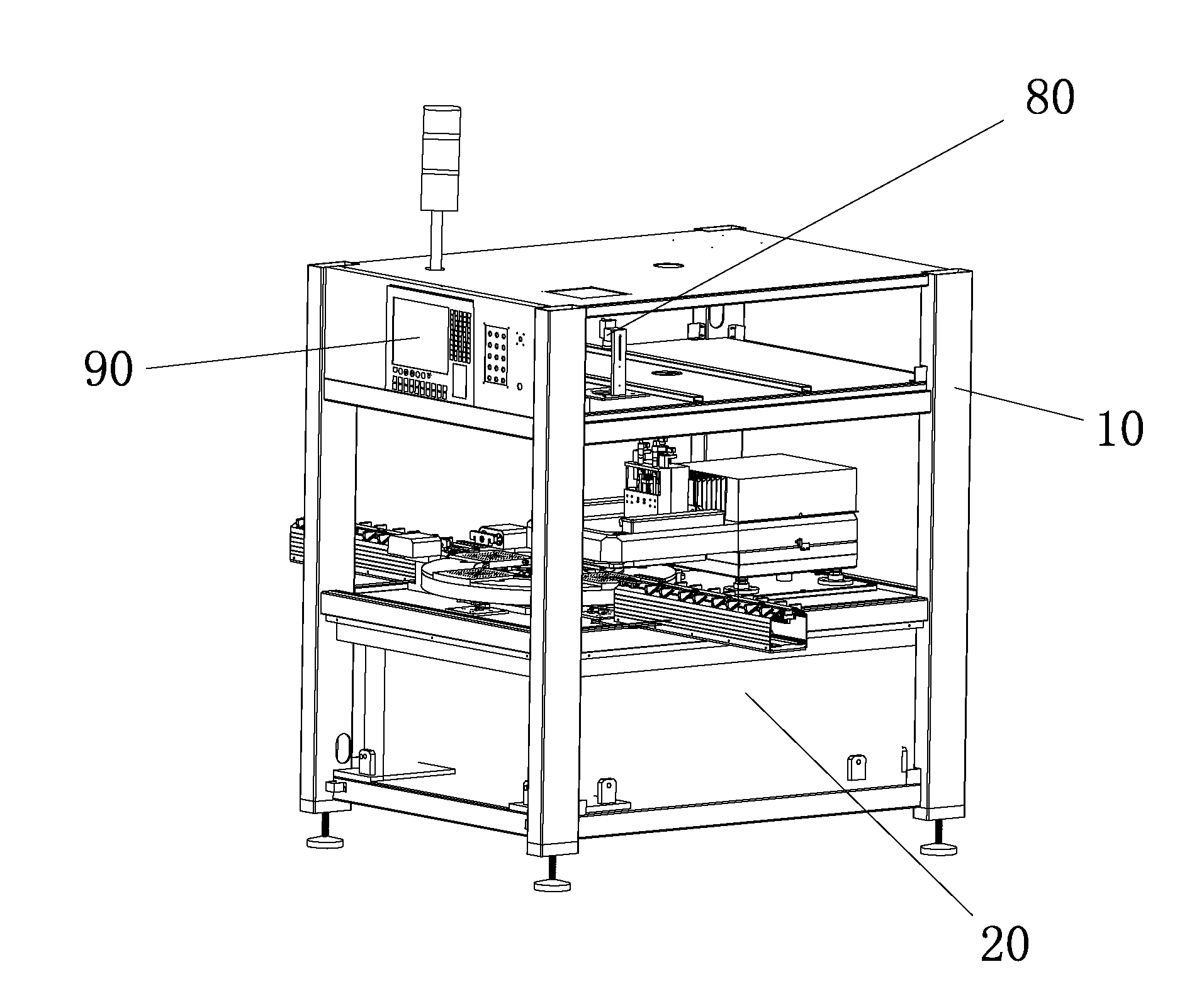

[0049] like figure 1 As shown, the photovoltaic solar printing machine includes a frame 10 and an industrial control device 90, and it also includes a working turntable mechanism connected to the industrial control device 90, a transmission mechanism, a top plate mechanism 260, a vacuum suction plate mechanism, a steel mesh seat mechanism, and a pressing mechanism. Net and net adjustment mechanism, scraper mechanism and vision system device 80.

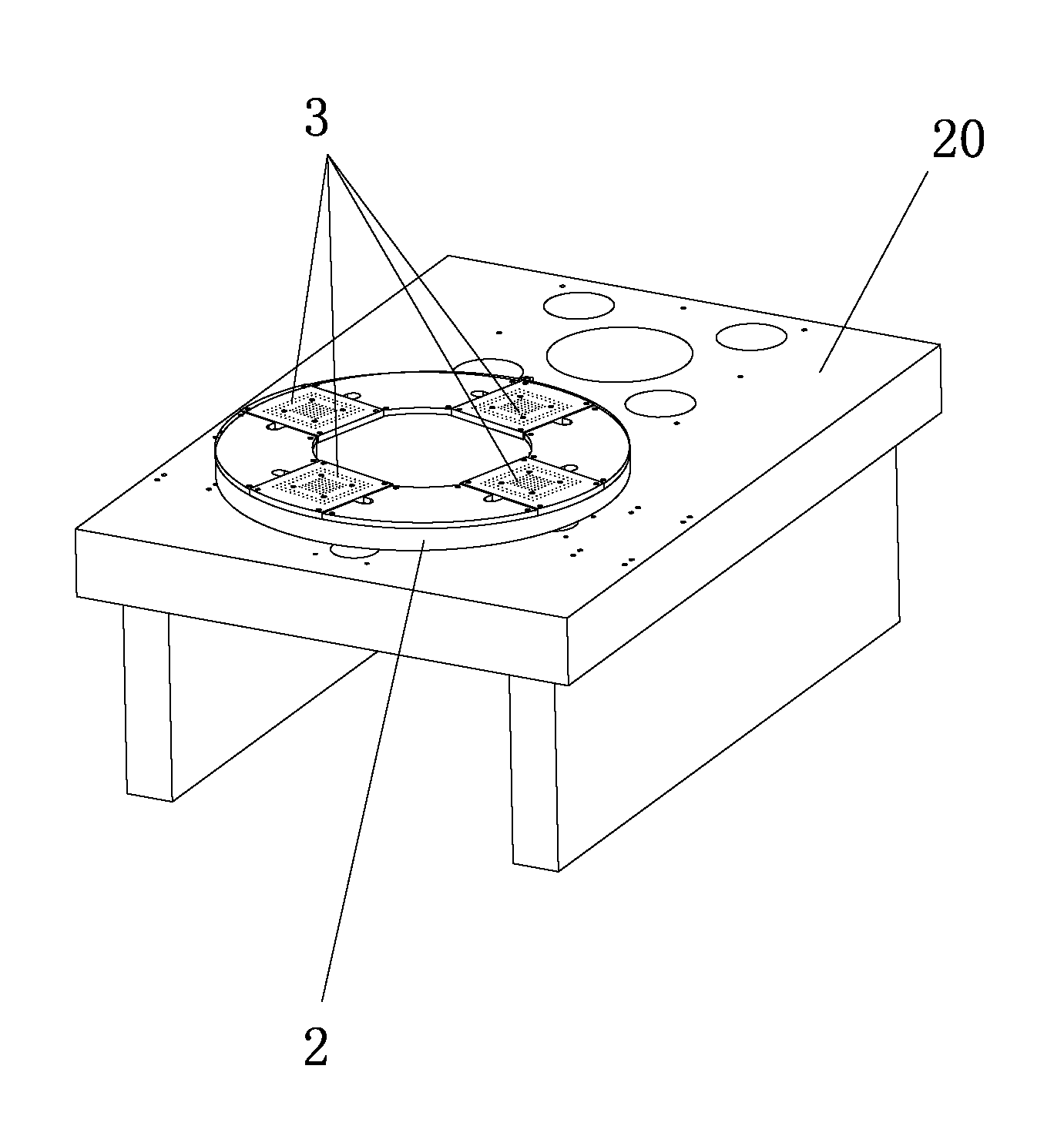

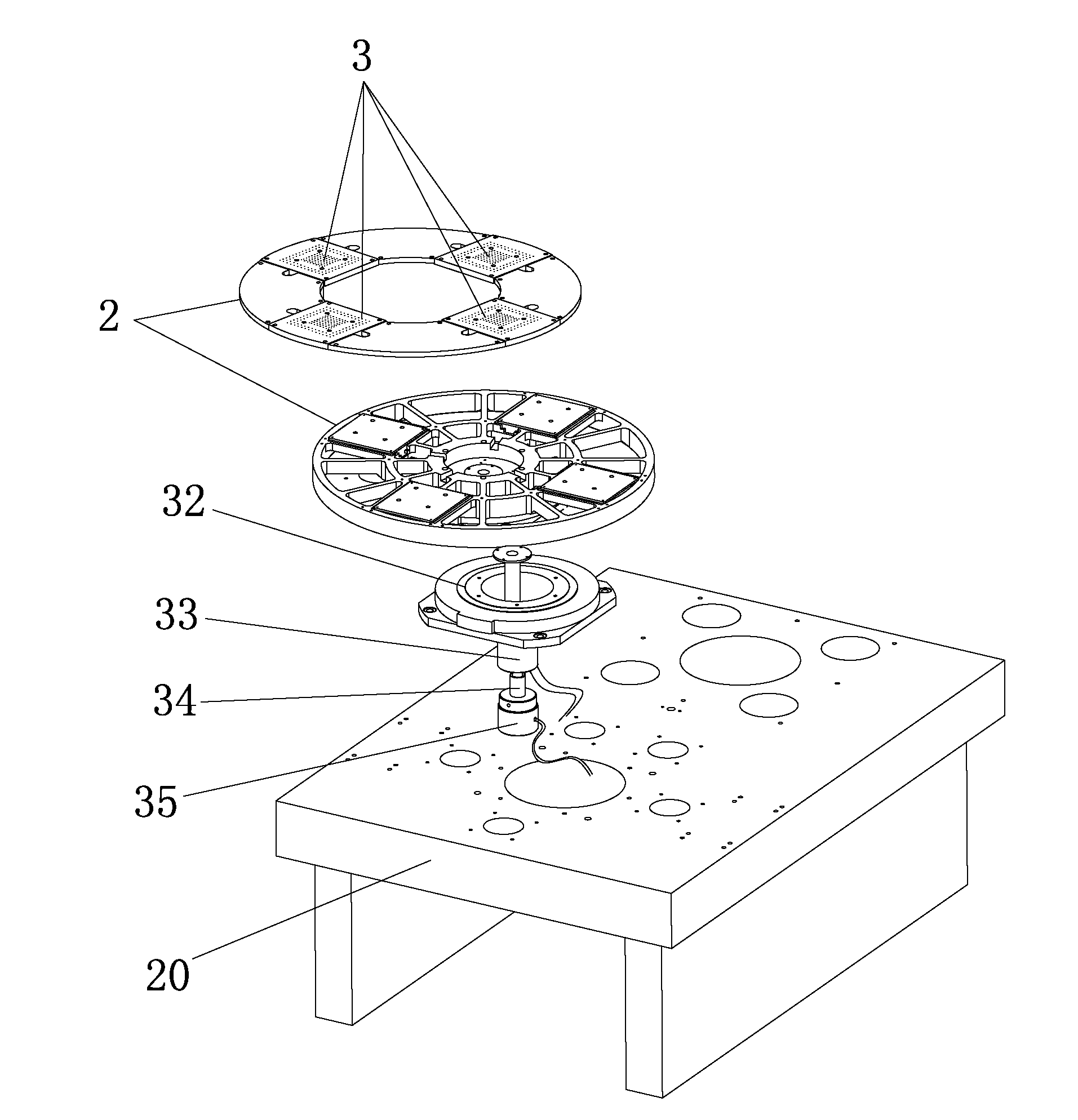

[0050] like figure 2 and image 3 As shown, the working turntable mechanism includes a turntable 2, a rotating motor 32, a platform 20, and a workbench 3 for placing and transporting silicon wafers. The number of the workbenches 3 is four, and the four workbenches 3 are sequentially formed The included angle of 90° is evenly distributed on the turntable 2 , the rotating motor 32 is driven and connected to the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com