Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Low monomer content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of instant ultra-high molecular weight polyacrylamide dry powder

InactiveCN103304714AIncrease the relative molecular massGood water solubilityWater/sewage treatment by flocculation/precipitationSolventAmmonia

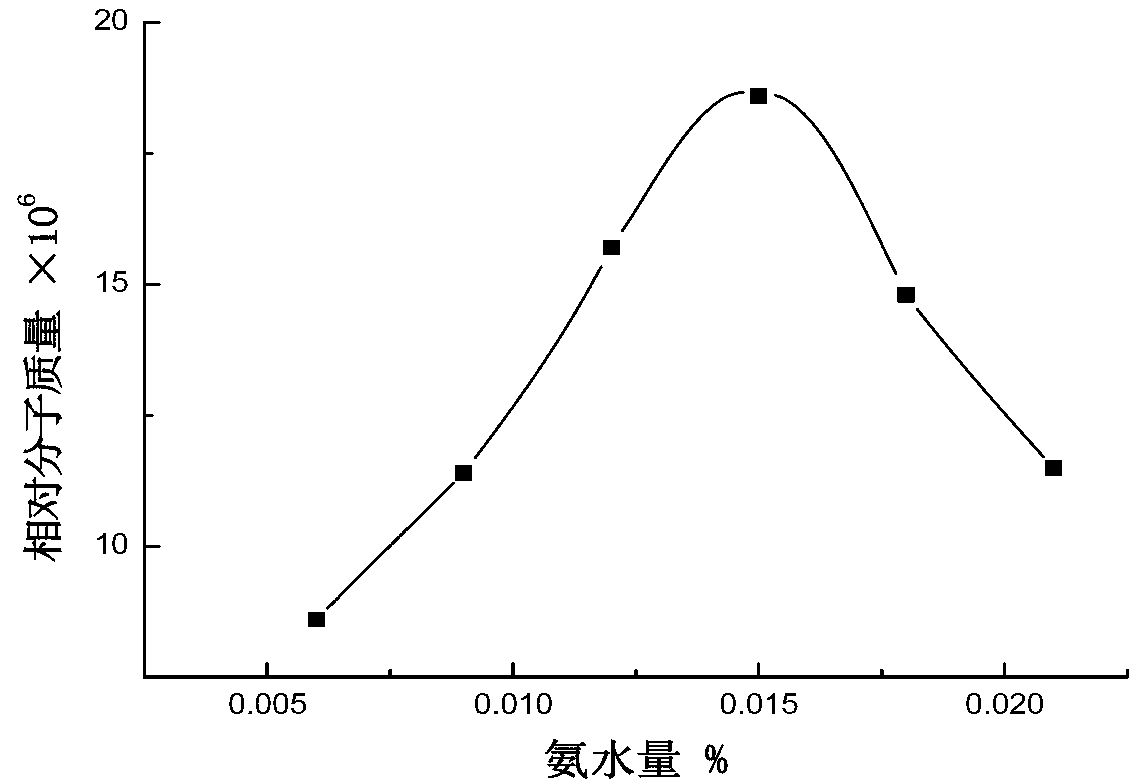

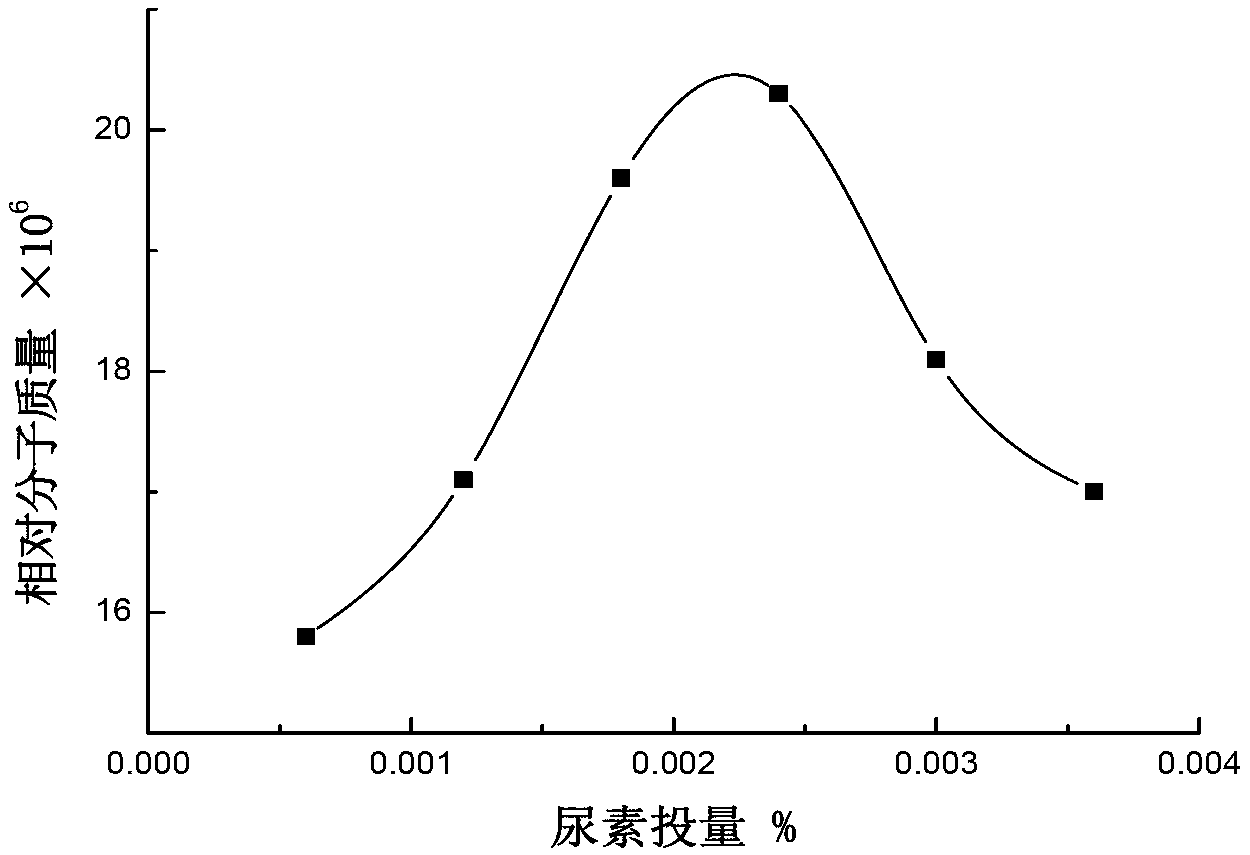

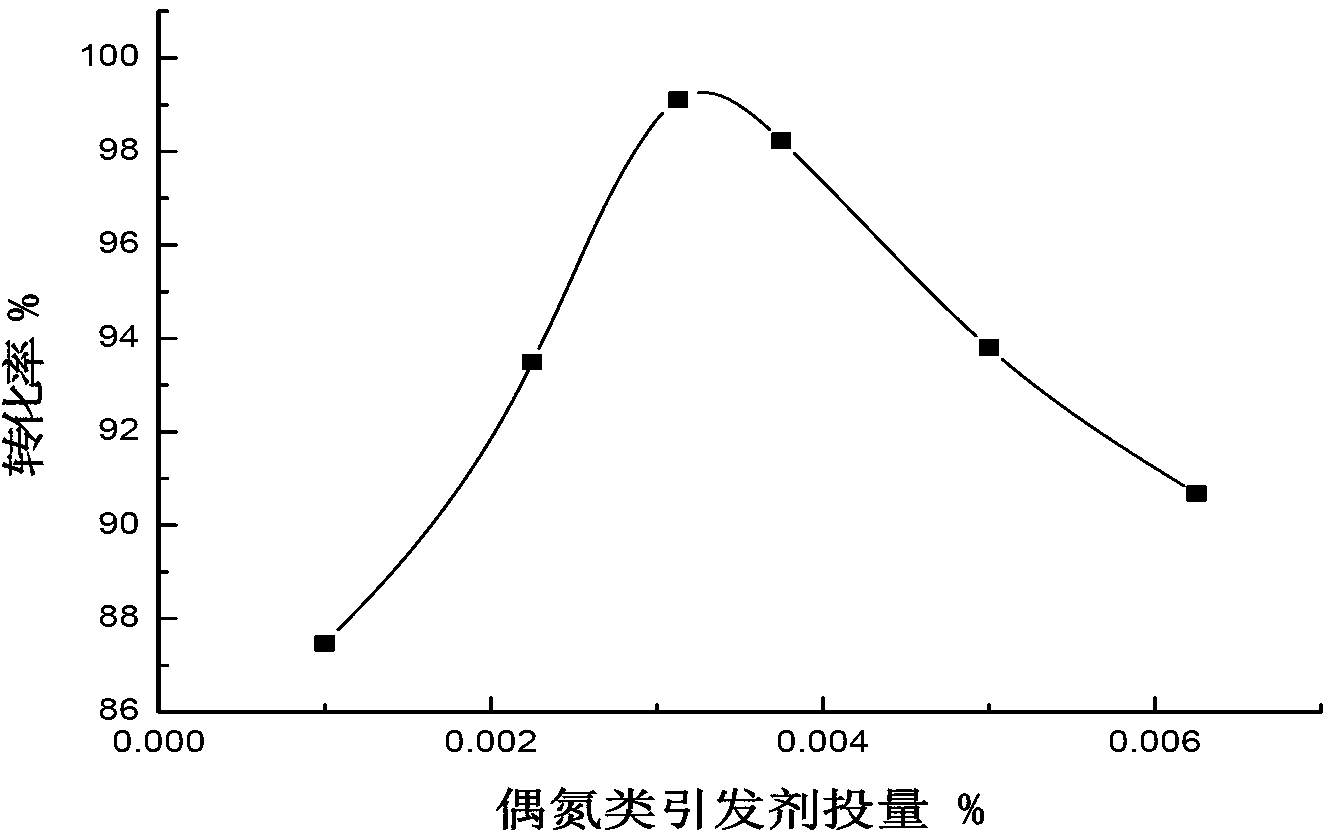

The invention relates to a preparation method of instant ultra-high molecular weight polyacrylamide dry powder. The method comprises the following steps of: taking acrylic amide AM as a monomer, adopting a low-temperature composite initiation system taking NTP and K2S2O8 as main initiators, and an azo compound as an auxiliary initiator; adopting ammonia water and urea as cosolvents; and adding the initiator in batches and controlling the concentration of the cosolvent and the pH value of the medium, so as to obtain the instant ultra-high molecular weight polyacrylamide dry powder. The relative molecular weight range of the ultra-high molecular weight polyacrylamide PAM is that Mw is smaller than or equal to 25000000 and greater than or equal to 5000000. The optimal production technology is determined by discussing the influence factors such as the initiation system, the cosolvent concentration, and the pH value of the medium; the obtained polyacrylamide is rapidly dissolved, and is high in relative molecular weight, high in percent conversion, low in monomer content, high in production efficiency, low in cost and suitable for industrial production.

Owner:SHANGHAI YUKING WATER SOLUBLE MATERIAL TECH

Preparation of biodegradable polyesters with low-burst properties by supercritical fluid extraction

ActiveUS20090305957A1Reduced initial burst effectNarrow molecular weight distributionBiocideOrganic active ingredientsLactideSolvent

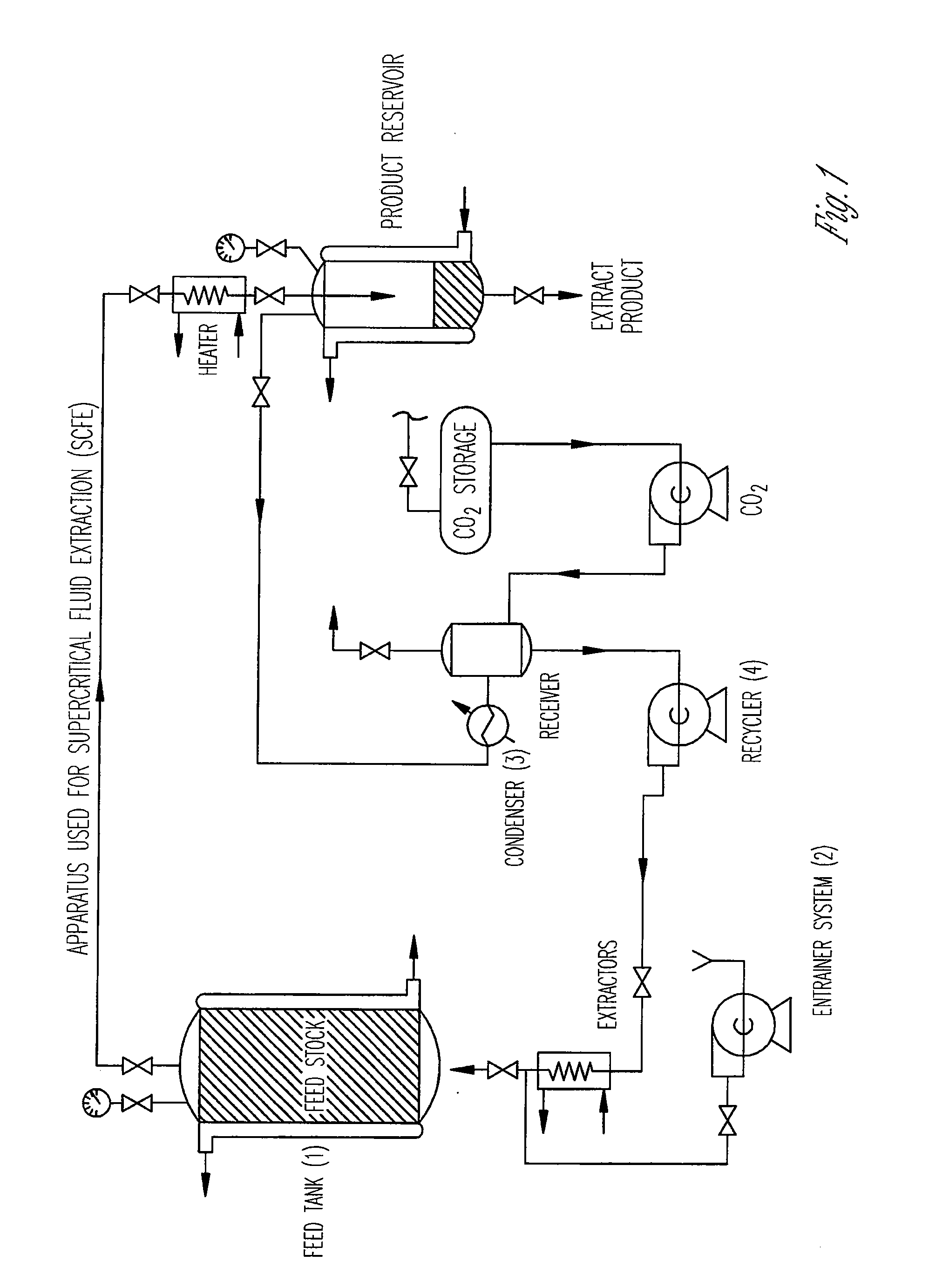

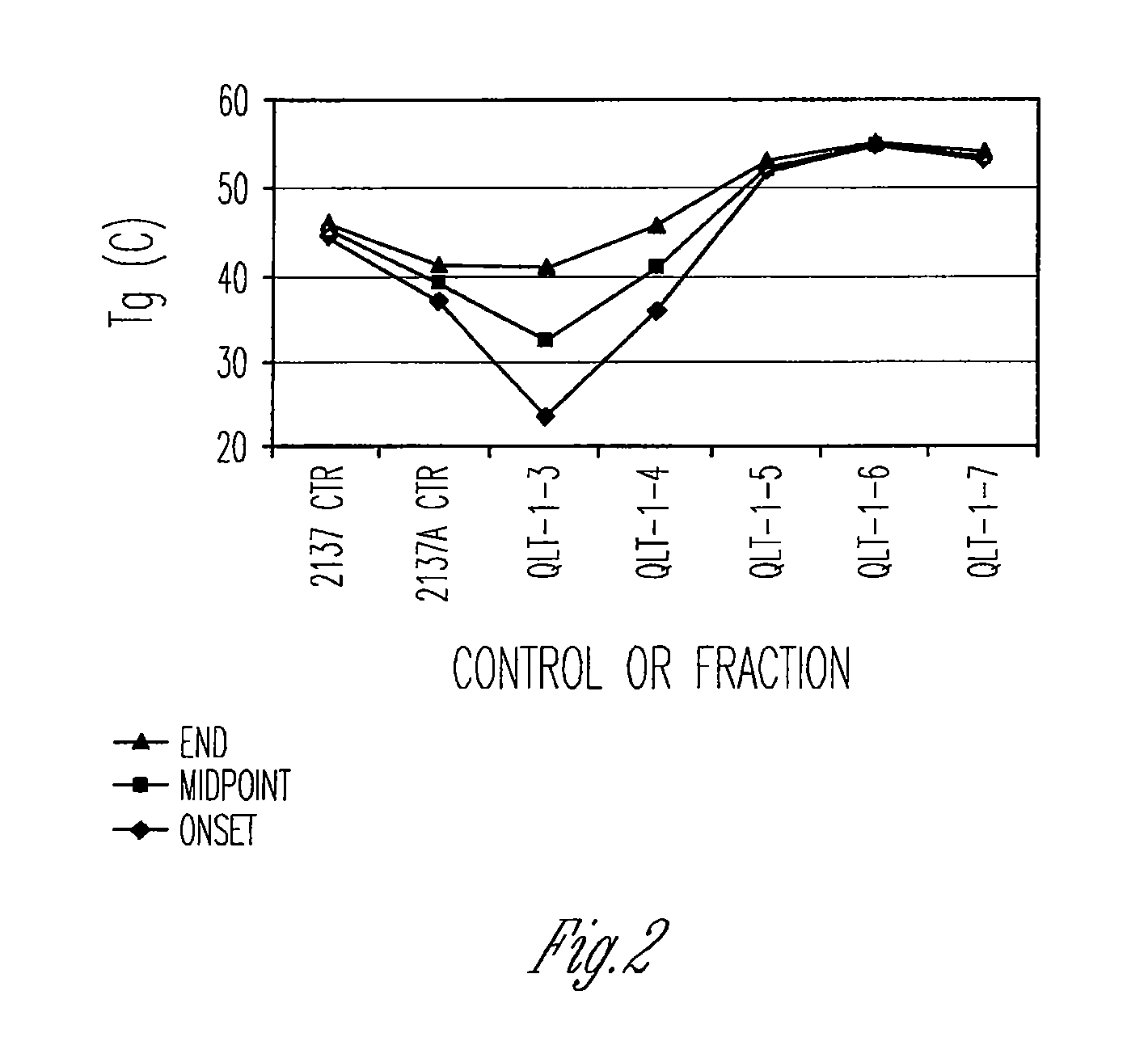

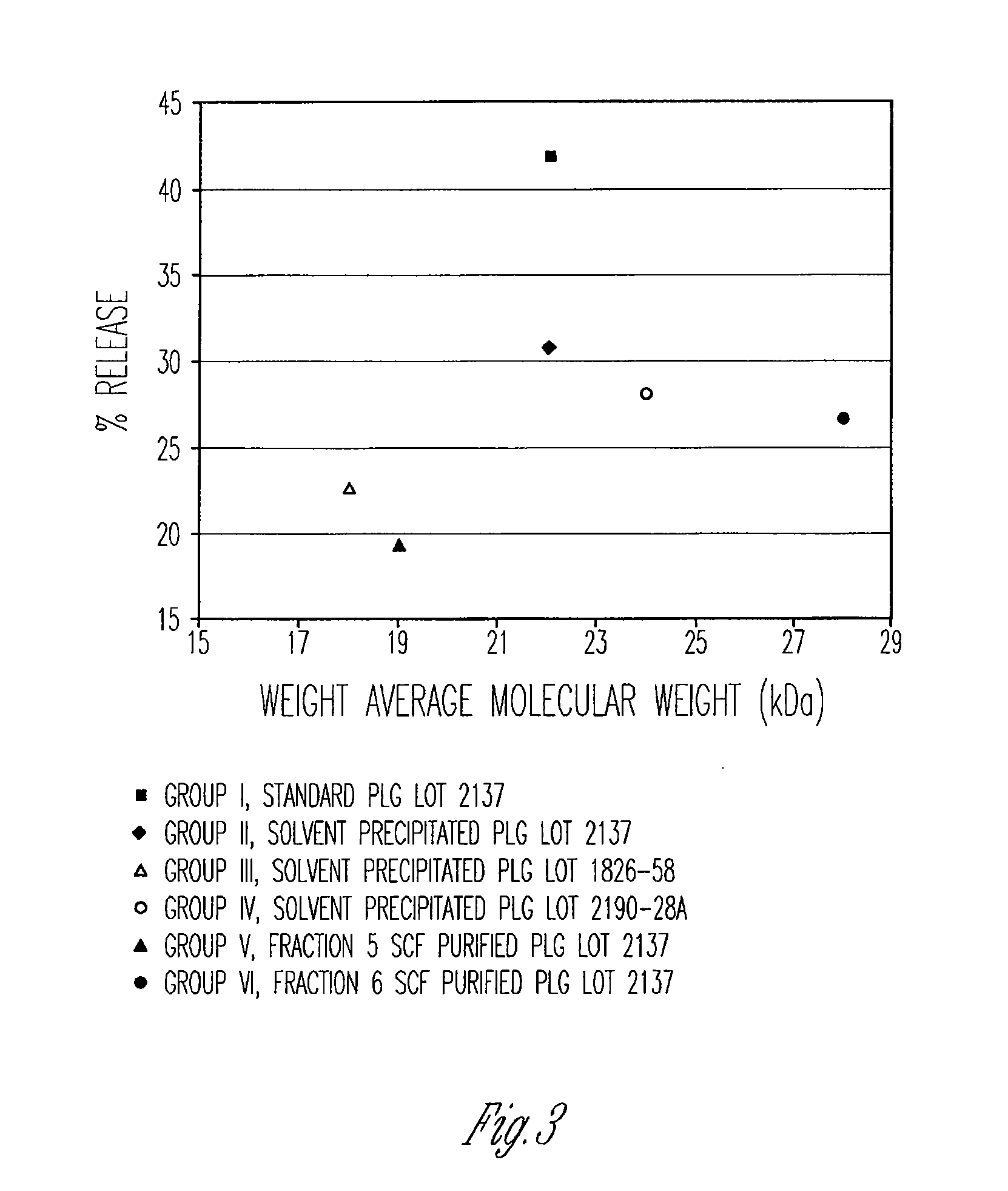

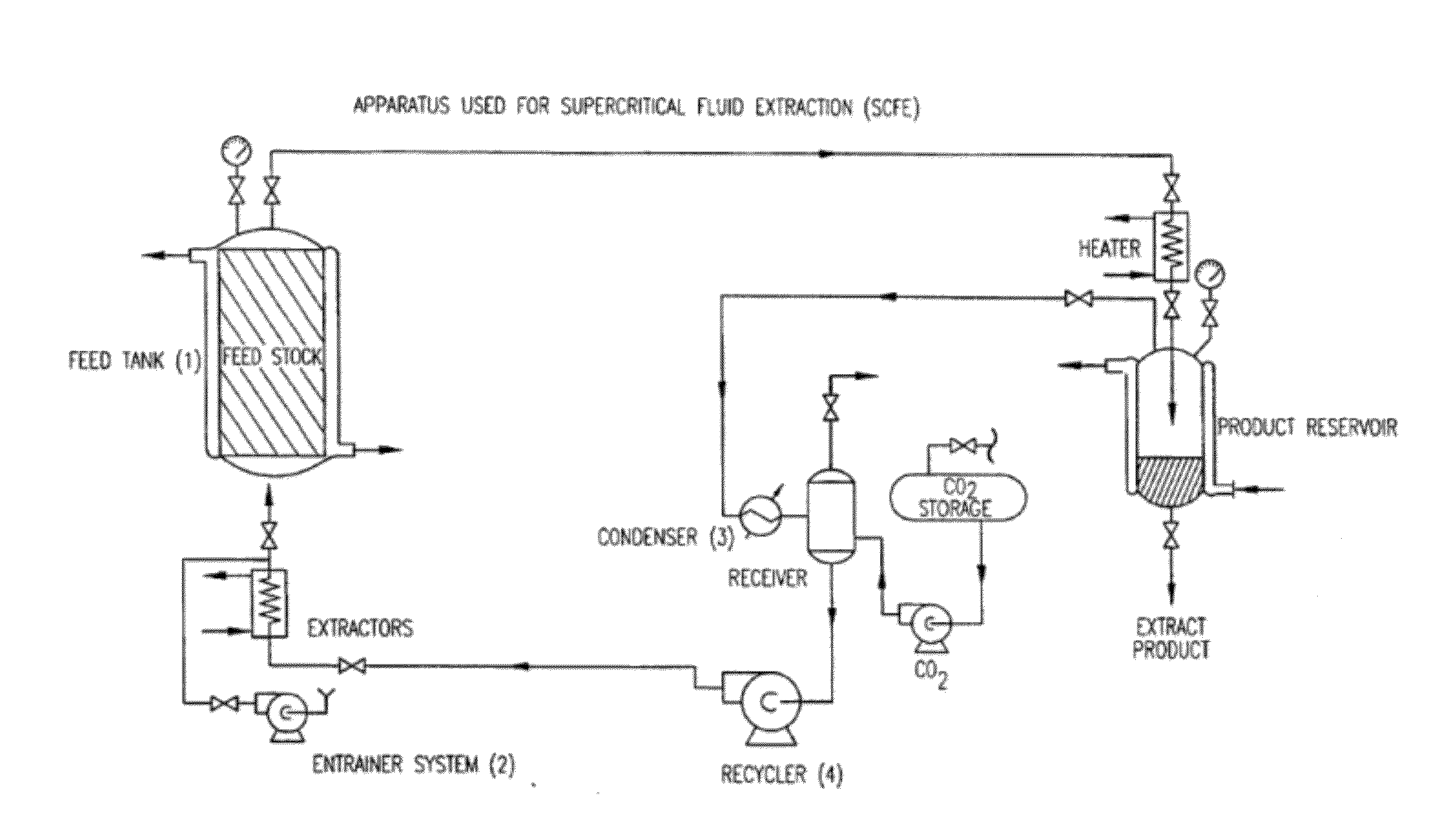

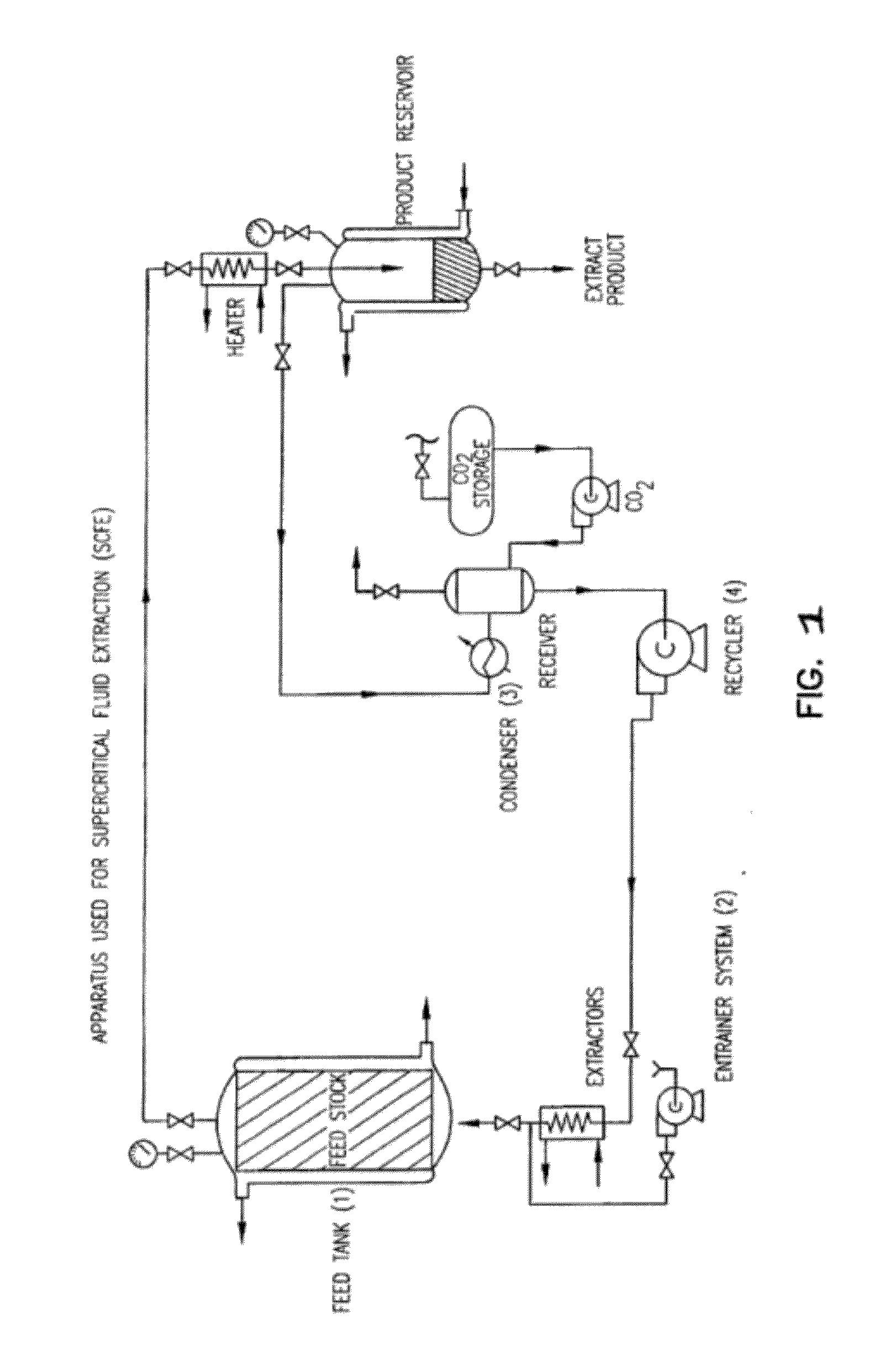

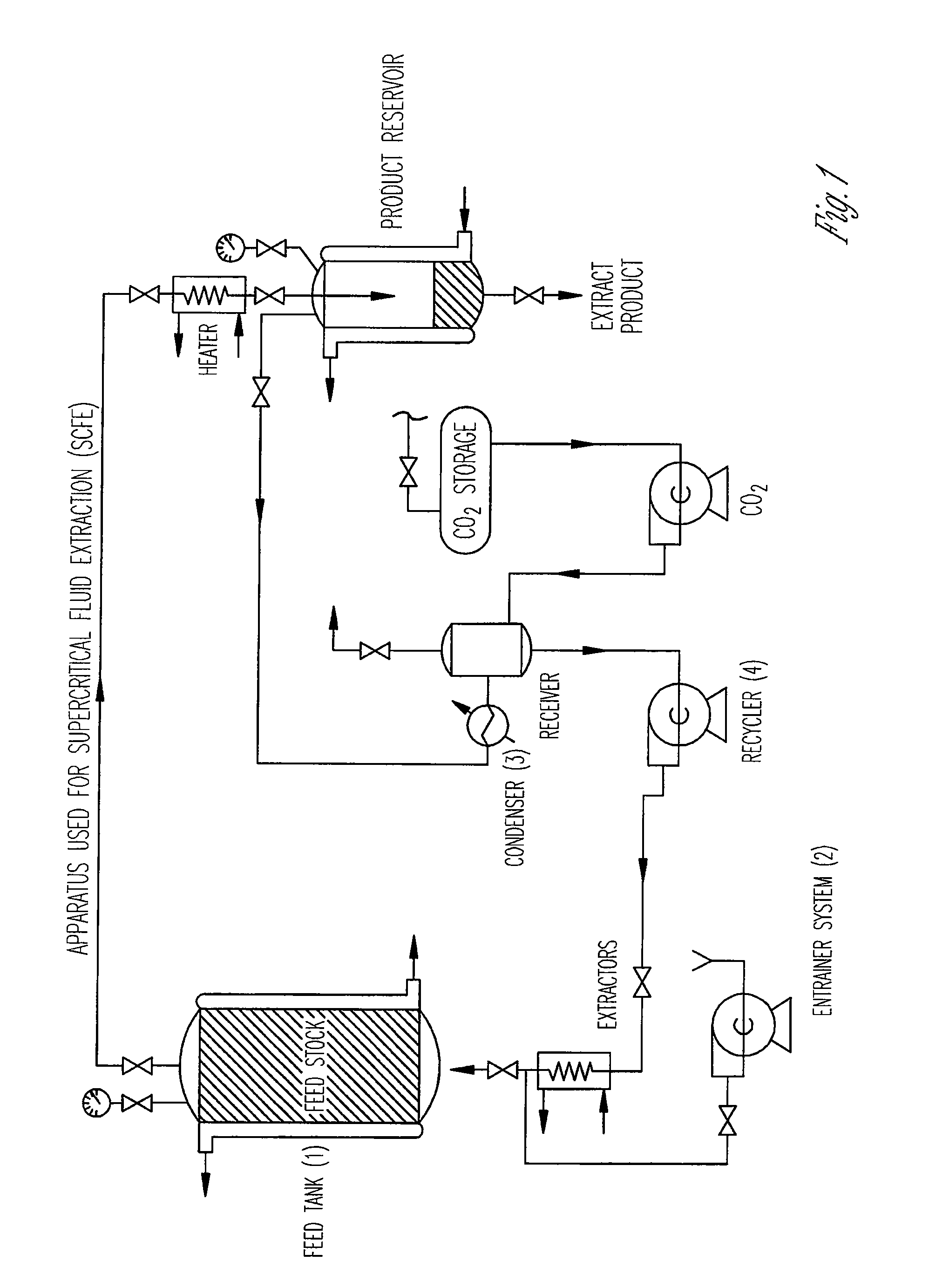

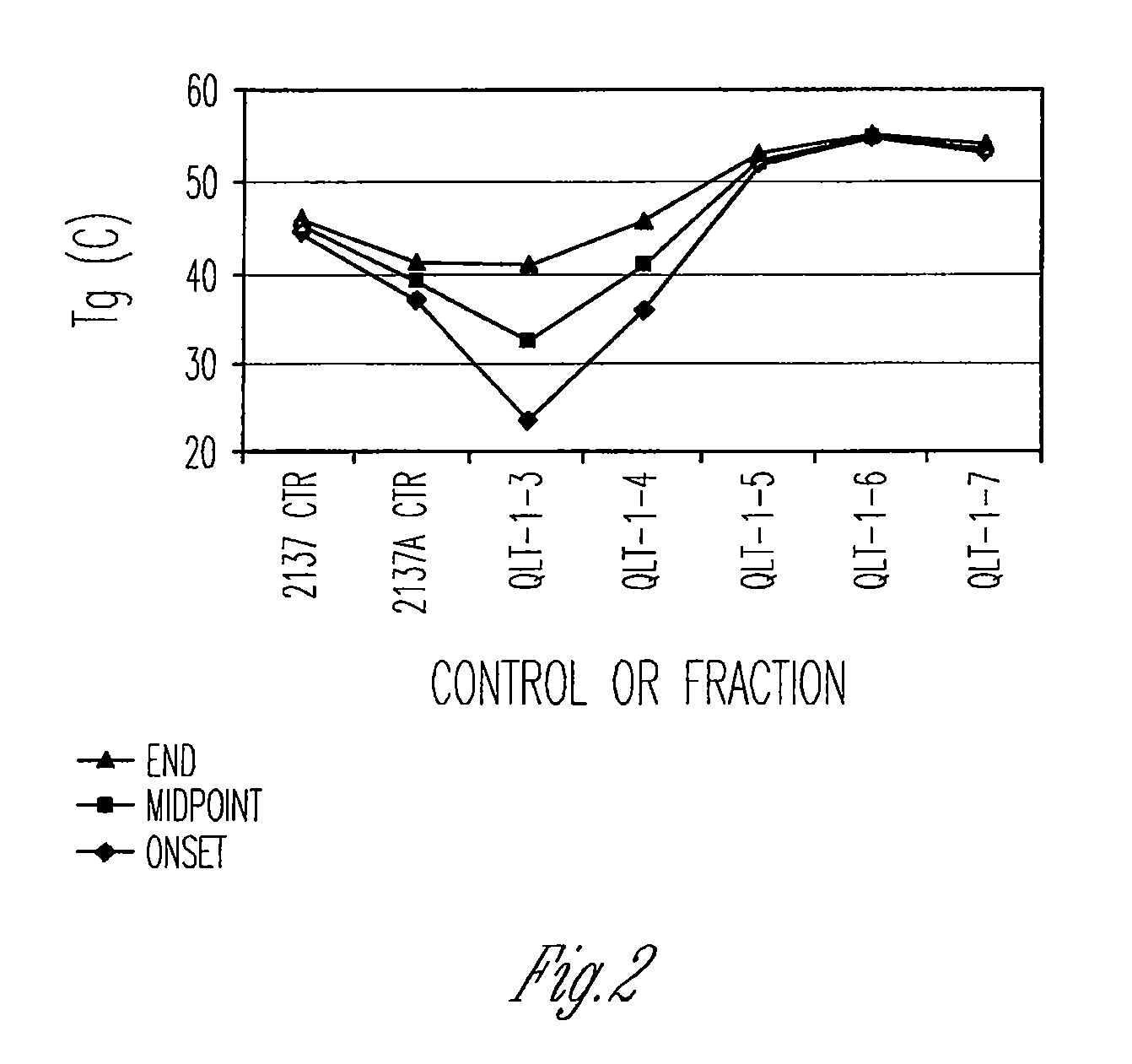

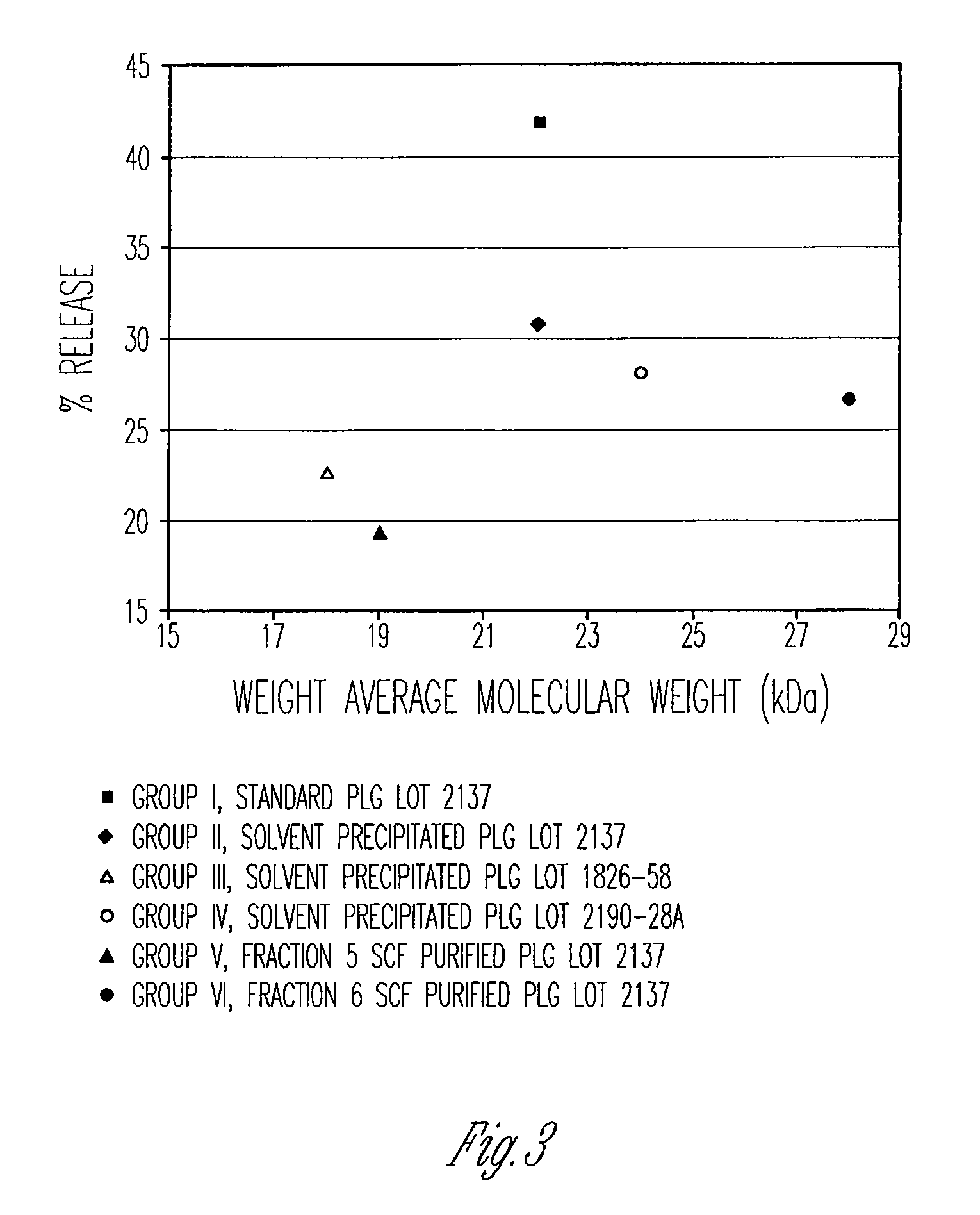

The invention provides methods of extracting a biodegradable polyester with a supercritical fluid effective to obtain a purified biodegradable polyester, such as a purified biodegradable poly(lactide-glycolide) (PLG). The supercritical fluid can be carbon dioxide at an elevated pressure, or can be carbon dioxide with one or more cosolvents. Methods for carrying out stepwise purification of the biodegradable polyester at multiple pressures or multiple temperatures, or both, are also provided. When the polyester is PLG, a purified PLG copolymer is obtained having a narrowed molecular weight distribution with respect to the unpurified polyester. The purified PLG copolymer can have a polydispersity index of less than about 1.7, less than about 2% monomers, and less than about 10% oligomers. The purified PLG copolymer can exhibit a reduced initial burst effect when incorporated into a controlled release formulation such as a flowable implant adapted to be injected into body tissues.

Owner:TOLMAR THERAPEUTICS

Preparation method for low-color number environment-friendly polyurethane curing agent

ActiveCN103848954ALow viscosityUniform molecular weight distributionChemical industryThermal energyAlcohol

The invention discloses a preparation method for a low-color number environment-friendly polyurethane curing agent. The method comprises the following steps of 1, continuously reacting dihydric alcohol, trimethylolpropane and toluene diisocynate to generate prepolymer reaction liquid by using a continuous reaction device, wherein the trimethylolpropane is fed in a batch addition way; 2, separating the prepolymer reaction liquid by using two stages of film evaporators, pumping evaporation residues obtained by separation into a diluting tank by using a pump, and performing diluting to obtain low-free isocyanate monomer content polyurethane curing agent. The method has the advantages that the whole production process is continuous, the use of a solvent is avoided, reaction heat is maximally utilized, the method is energy-saving and environmentally friendly, the color of a product is improved, and the quality of the curing agent product is improved.

Owner:WANHUA CHEM GRP CO LTD +1

Preparation of biodegradable polyesters with low-burst properties by supercritical fluid extraction

InactiveUS20120108511A1Reduced initial burst effectNarrow molecular weight distributionBiocideOrganic active ingredientsLactideHigh pressure

The invention provides methods of extracting a biodegradable polyester with a supercritical fluid effective to obtain a purified biodegradable polyester, such as a purified biodegradable poly(lactide-glycolide) (PLG). The supercritical fluid can be carbon dioxide at an elevated pressure, or can be carbon dioxide with one or more cosolvents. Methods for carrying out stepwise purification of the biodegradable polyester at multiple pressures or multiple temperatures, or both, are also provided. When the polyester is PLG, a purified PLG copolymer is obtained having a narrowed molecular weight distribution with respect to the unpurified polyester. The purified PLG copolymer can have a polydispersity index of less than about 1.7, less than about 2% monomers, and less than about 10% oligomers. The purified PLG copolymer can exhibit a reduced initial burst effect when incorporated into a controlled release formulation such as a flowable implant adapted to be injected into body tissues.

Owner:QLT USA INC

Preparation of biodegradable polyesters with low-burst properties by supercritical fluid extraction

ActiveUS8076448B2Reduced initial burst effectNarrow molecular weight distributionBiocideOrganic active ingredientsOligomerLactide

Owner:TOLMAR THERAPEUTICS

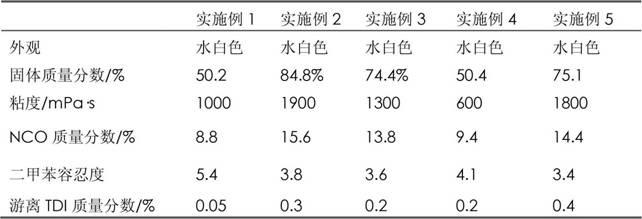

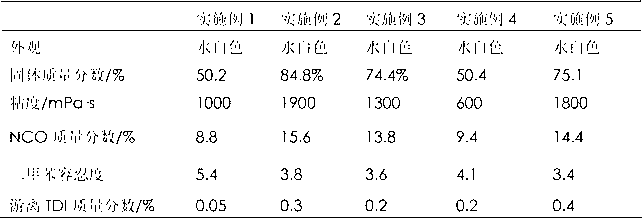

Preparation method of polyurethane prepolymer with low free isocyanate monomer

The invention discloses a preparation method of polyurethane prepolymer with low free isocyanate monomer. The preparation method comprises the following steps of: forming into mixed alcohol by trihydric alcohol and dihydric alcohol under the temperature of 120-150DEG C, and carrying out vacuum dehydration; putting isocyanate monomer and ester solvents into a reactor to keep the temperature at 30-70DEG C, and dropwise adding the mixed alcohol into the reactor; after dropwise adding, continuously reacting for 3-6h under the temperature of 40-70DEG C under stirring, and discharging in a cooling way to obtain polyurethane prepolymer; and separating the obtained polyurethane prepolymer, and adjusting the solid content of polyurethane prepolymer solid and the content of free isocyanate monomer in the separated heavy components by diluted solvent. According to the preparation method, the real continuous production can be realized, all the recovered solvent and isocyanate monomer can be recycled, the zero emission can be realized, and the real clean production can be realized; and the product has the characteristics of being low in viscosity, high and adjustable in NCO value content, low in the content of the free isocyanate monomer, high in solid content, good in compatibility, etc.

Owner:SOUTH CHINA UNIV OF TECH +1

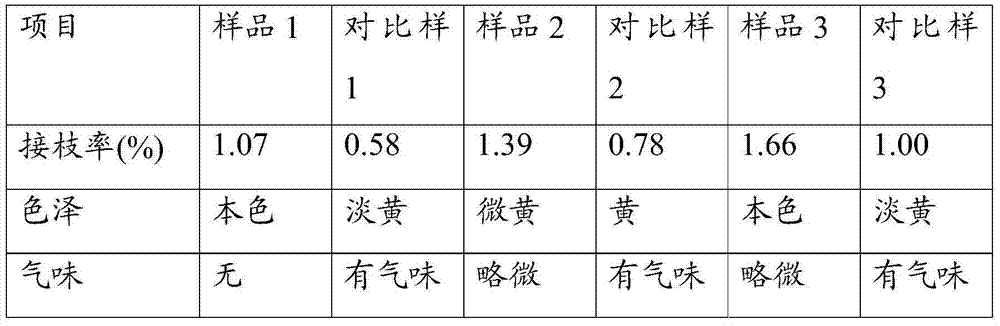

High-grating-rate and low-odor polypropylene resin composition and preparation method thereof

The invention provides a high-grating-rate and low-odor polypropylene resin composition and a preparation method thereof. The polypropylene resin composition consists of the following components in parts by weight: 100 parts of polypropylene resin, 1-3 parts of a polar monomer, 0.01-1 part of an initiator A, 0.01-1 part of an initiator B and 0.5-2 parts of a second monomer. The preparation method comprises the steps of weighing raw materials according to the weight part, mixing the raw materials in a high-speed mixer for 2-5min and discharging materials; and implementing reactive extrusion grafting on the mixed raw materials through a dual-screw extruder. The polypropylene resin composition disclosed by the invention, through selecting initiator and comonomer, reduces pungent odor of materials and improves grafting efficiency. The prepared polypropylene disclosed by the invention has the advantages of light product odor, high grating rate and low gel rate, and is applicable to a flexibilizer and a compatilizer of polar monomer and non-polar polymer alloy; the polypropylene resin composition is used for filling or strengthening polypropylene, and is capable of improving the mechanical performance and the heat resistance of the material.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

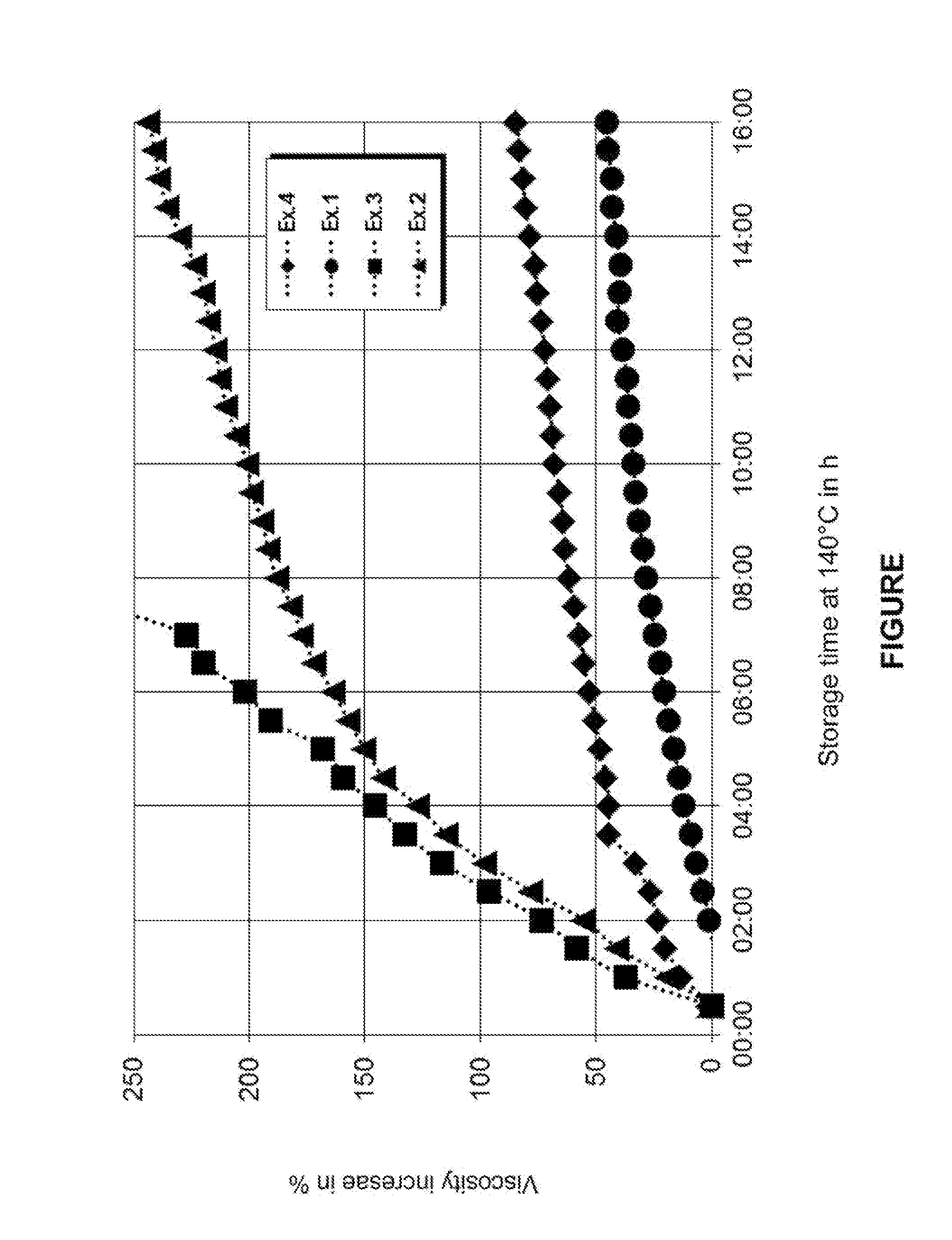

Polyurethane hot-melt adhesive having a low content of diisocyanate monomers and good cross-linking speed

ActiveUS20170002239A1Reduce contentStable storageAdhesive processesPolyureas/polyurethane adhesivesPolymer scienceHot melt

A moisture-cured hot-melt adhesive can be formulated as a PUR-HM that is R-40 classification-free and stable during storage and processing, having a residual monomer content of less than 1 wt. % and having good cross-linking density and full-curing speed. The hot-melt adhesive is particularly suitable for vehicle construction in industrial manufacture, in particular of automobiles, in the textile or furniture industry or in the packaging industry.

Owner:SIKA TECH AG

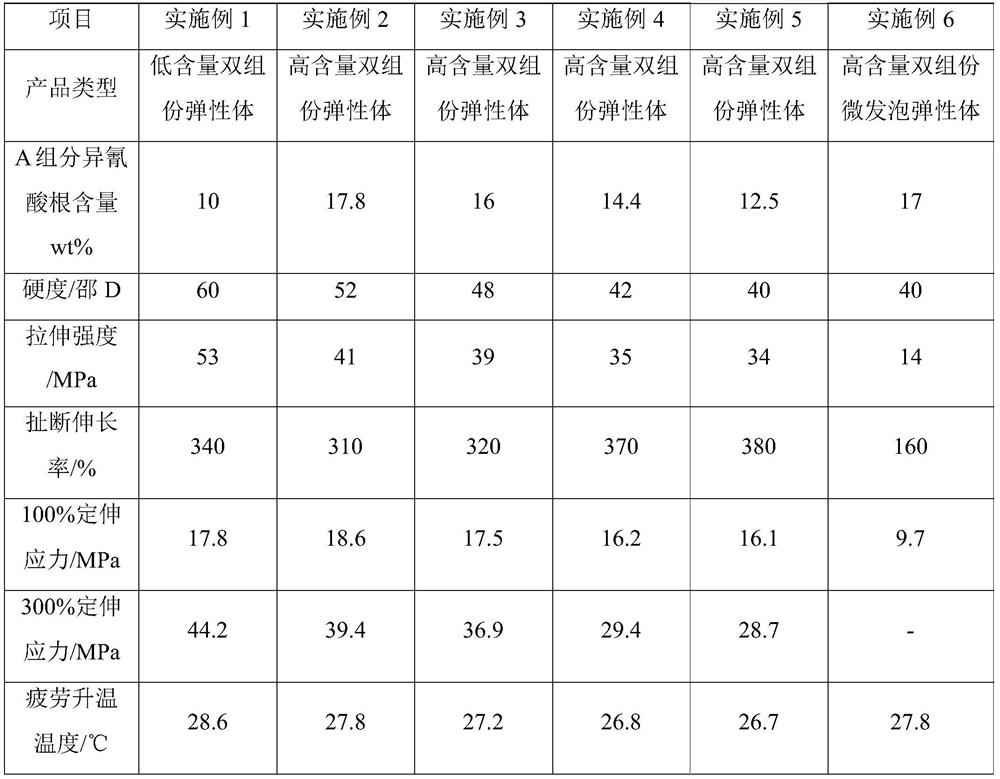

Polyurethane for CMP polishing pad and preparation method of polyurethane

The invention belongs to the technical field of polyurethane application, and particularly relates to polyurethane for a CMP polishing pad and a preparation method of the polyurethane. The polyurethane for the CMP polishing pad comprises a polyurethane prepolymer component A and a curing agent component B. The component A is composed of polymeric polyol A, diisocyanate and an anti-hydrolysis agent, and the component B is composed of an amine chain extender, polymeric polyol B, a hollow filler, a plasticizer and a catalyst. The structures of prepolymer molecules are arranged more regularly, andthe forming speed is high; the stability is good; the quality risk is reduced; the high-content prepolymer component does not crystallize at room temperature, has low initial viscosity, and has higher proportion when being mixed with the curing agent component, the uniform mixing is easier, consistency of hardness and uniformity after slicing of the prepared product is guaranteed, the breakage rate of electronic elements in the later polishing process is greatly reduced, and on the basis of micro-foaming, the hollow filler is added, so that the product has longer service life and storage lifeand good mechanical performance.

Owner:SHANDONG INOV POLYURETHANE

Method for preparing high-density polyethylene-maleic anhydride grafted copolymer by adopting suspension method

ActiveCN102060961AReduce dosageReduce manufacturing costGraft polymer adhesivesLow-density polyethyleneCross-link

The invention discloses a method for preparing a high-density polyethylene-maleic anhydride grafted copolymer adopting a suspension method. The polymer prepared by the method has high grafted rate, less solvent is used, the content of a cross-linking substance tends to zero, simple equipment and process are adopted, and the polymer is convenient to produce in a large scale. According to the grafting method for grafting maleic anhydride (MAH) to high-density polyethylene (HDPE), the grafting reaction is carried out in a high-pressure reactor by adopting a suspension polymerization method by adding the HDPE and swelling agent thereof, the MAH, an interface agent, a surfactant and water in the high-pressure reactor, stirring, increasing temperature to fuse the HDPE, and dropwise adding an initiating agent to carry out a suspension grafting reaction, wherein the initiating agent is dispersed in the swelling agent of the HDPE first.

Owner:NANJING UNIV OF TECH

Nonionic and anionic mixed waterborne polyurethane curing agent and preparation method thereof

The invention discloses a nonionic and anionic mixed waterborne polyurethane curing agent and a preparation method thereof. The method comprises the following steps of: adding oligomer polyols to an HDI monomer in the presence of nitrogen, stirring and heating the oligomer polyols and the HDI monomer to 60-80 DEG C, and carrying out heat preservation and reaction for 2-3 hours to obtain an additive product; adding a trimer catalyzer to the additive product, carrying out thermal reaction at 60-80 DEG C; when the NCO content reaches a target value, removing unreacted HDI monomer under the conditions of 150-180 DEG C and 0.01-0.05Torr to obtain an HDI prepolymer; cooling the obtained HDI prepolymer to 60-70 DEG C, adding an anion modifier and carrying out thermal reaction for 2-4 hours; and adding a neutralizer, reacting for 0.5-1 hour, cooling and discharging the product to obtain the waterborne polyurethane curing agent. The preparation method disclosed by the invention is simple; the obtained waterborne polyurethane curing agent is light in color, high in effective -NCO content, yellowing-resistant and good in storage stability.

Owner:广州嘉宝莉地坪材料有限公司

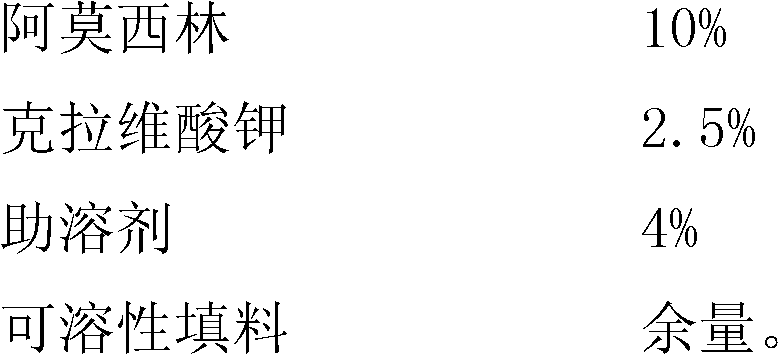

Amoxicillin potassium clavulanate powder injection and preparation method thereof

InactiveCN102406614AAvoid the hidden danger of excessive moistureGood curative effectAntibacterial agentsPowder deliverySolubilityCurative effect

The invention discloses an amoxicillin potassium clavulanate powder injection which is prepared from the following raw materials in percentage by weight: 10% of amoxicillin, 2.5% of potassium clavulanate, 4% of cosolvent and the balance of soluble filler. The invention also discloses a preparation method of the amoxicillin potassium clavulanate powder injection. The test proves that the amoxicillin potassium clavulanate powder injection disclosed by the invention has the characteristics of stability in storage, convenience in transportation, good water solubility and the like and greatly improves the curative effect of the amoxicillin and potassium clavulanate, thereby being a novel broad-spectrum and efficient special powder injection for animals.

Owner:上海恒丰强生物技术有限公司

Preparation method for hexamethylene diisocyanate biruet

ActiveCN102702476AHigh yieldReaction is easy to controlUrea derivatives preparationOrganic compound preparationDiluentSolvent

The invention discloses a preparation method for hexamethylene diisocyanate biruet, according to the method, azeotrope formed by a mixture of deionized water and a polar aprotic solvent is heated into a temperature of 30-100 DEG C; hexamethylene diisocyanate monomer is put into a reactor, and the temperature is maintained at 90-140 DEG C; the azeotrope is dropped into the reactor at a dropping speed of 0.05-0.20g / min; the temperature is increased into 110-150 DEG C in a mixing state, and the azeotrope is reacted for 1-4h; the temperature is reduced below 40 DEG C for cooling and discharging; and the discharging material enters into a separation device for separating a solvent and hexamethylene diisocyanate biruet ingredient, and a solid content of hexamethylene diisocyanate biruet ingredient is adjusted between 50 percent and 90 percent by a diluent. According to the preparation method, new solvent is not needed for addition, production formula and operation process are not required to be changed, only the monomer of isocyanate and water are added to realize continuous production, and the real clean production is realized via zero-release.

Owner:SOUTH CHINA UNIV OF TECH +1

Oxide-reduction method for prepn. of emulsion polymer with low monomer content

A process for preparing an aqueous emulsion polymer including providing at least one ethylenically unsaturated monomer and a free radical redox initiator system under emulsion polymerization conditions, the redox initiator system including a water-soluble oxidizing agent, a water-insoluble oxidizing agent, and a sulfinic acid, or salts thereof, reducing agent; and effecting the polymerization of at least some of the ethylenically unsaturated monomer is provided. Also provided is a process for reducing the residual ethylenically unsaturated monomer content of an aqueous emulsion polymer.

Owner:ROHM & HAAS CO

Functionalized polymer

InactiveUS20060058472A1Elimination and least reduction in amountAffect of quality of boardPhotosensitive materialsPhotomechanical apparatusPolymer scienceBackbone chain

A functionalized copolymer containing a main chain derived from polymerizable monomers and pendent functional groups terminated with one or more α or β ethylenically or acetylenically unsaturated groups. The functionalized copolymers are self cross-linking and are suitable for use as binders.

Owner:SHIPLEY CO LLC

Waterborne hybrid polymer dispersion

The process for the manufacture of an auto-oxidatively cross-linking hybrid polymer, in particular an aqueous hybrid polymer dispersion, comprises the step of reacting in a mini-emulsion process one or more ethylenically unsaturated monomers to form an addition polymer in the presence of a modified auto-oxidatively crosslinkable (AOC) polymer which has been modified with terminal unsaturated groups of the formula —C(R1)═CH2 wherein R1 is hydrogen, alkyl or aryl and wherein the AOC polymer is a hydrophobic polymer having an acid number between 5 to 30. The resulting aqueous hybrid polymer dispersion can be used for the manufacture of coating compositions, ink compositions or adhesives and coating compositions comprising the hybrid polymer dispersion as a binder.

Owner:ALLNEX NETHERLANDS BV

Waterborne hybrid polymer dispersion

ActiveUS20130018127A1Improve coating compositionLow residual ethylenically unsaturated monomer contentInksEmulsion paintsEmulsionPolymer chemistry

The invention relates to a process for the manufacture of an auto-oxidatively cross-linking hybrid polymer, in particular an aqueous hybrid polymer dispersion, comprising the step of reacting in a mini-emulsion process one or more ethylenically unsaturated monomers to form an addition polymer (also referred to as a vinyl polymer) in the presence of a modified auto-oxidatively crosslinkable (AOC) polymer which has been modified with terminal unsaturated groups of the formula C(R1)═CH2 wherein R1 can be hydrogen, alkyl or aryl and wherein the modified AOC polymer is a hydrophobic polymer having an acid number between 5 to 30. In particular, the invention relates to a process comprising mixing one or more modified AOC polymers, one or more ethylenically unsaturated monomers and one or more surfactants and forming a mini-emulsion in water and addition polymerizing the unsaturated monomers in the mini-emulsion to form a dispersion of hybrid particles of the modified auto-oxidatively crosslinkable polymer and the addition polymer. The invention further relates to the aqueous hybrid polymer dispersion obtainable by the process according to the invention, the use thereof for the manufacture of coating compositions, ink compositions or adhesives and to coating compositions comprising the hybrid polymer dispersion as a binder.

Owner:ALLNEX NETHERLANDS BV

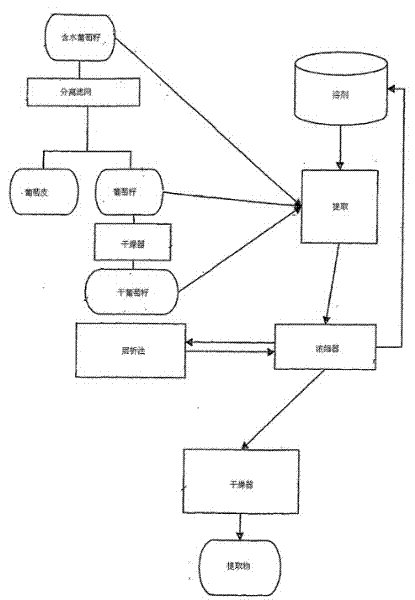

Method for producing grape seed extract

InactiveCN102228256AHigh in polyphenolsLow monomer contentFood preparationBiotechnologyVitis vinifera

The invention provides a method for producing a grape seed extract, which comprises the following steps: (1) separation: immediately separating grape dregs, which are produced in a wine preparation process, grape juice production process or any other grape working process without fermentation, into grape skin, grape seed and scrap; and (2) extraction: A. extraction: extracting by using alcohol and water as an extraction solvent under the conditions of low oxygen content, low humidity and high pressure, wherein the ratio of water to alcohol is 30:70, and the ratio of grape seed to solvent is 1:10; B. concentration: concentrating the liquid part in a concentrator to eliminate the water phase; and C. drying: drying the concentrated eluate or any product from the concentrator. The invention has the following advantages: before any fermentation situation occurs, the seed and skin in the grapes can be directly separated; in the obtained extract, the content of polyphenols is high, and the content of monomeric substances is low; and by referring to the scrap extraction process, the grape seed can also be used for producing grape seed oil.

Owner:JIANGSU GUOYIN INVESTMENT

Novel color base and vulcanization process thereof

The invention discloses a novel color base and a vulcanization process thereof. Adhesive materials in different colors are independently prepared and are prepared from coloring agents, natural rubber, styrene-butadiene rubber, high styrene, zinc oxide, octadecanoic acid, magnesium oxide, anti-ageing agents, reinforcing agents, white smoke, coumarone resin, rubber oil, vulcanization agents and promoting agents. The novel color base and the vulcanization process of the novel color base start in the aspects that the hardness and the vulcanization speed of the colored adhesive materials are controlled, the low-content vulcanization agents and the high-content promoting agents are adopted, it is guaranteed that after one time of vulcanization press fit, colored adhesives are basically sized and not totally vulcanized, the colored adhesives can be well combined with basic color adhesive materials in the secondary vulcanization process, and the problem that colors of colored adhesives are mixed when the colored adhesives flow is solved.

Owner:JIHUA 3515 LEATHER & SHOES

Multi-segment polymerization method and device for propylene

PendingCN108586644AControl the content of volatile organic compoundsLow monomer contentPolymer scienceGas phase

The invention relates to a multi-segment polymerization method and device for propylene. The method comprises the steps that firstly, a pre-polymerization reaction is conducted, then a liquid-phase polymerization reaction and a gas-phase polymerization reaction are conducted, a two-step reaction is set at the liquid-phase polymerization reaction, the reaction time is prolonged, a polymer can havewider molecular weight distribution, and the processing performance and mechanical performance of the polymer are improved; in the gas-phase polymerization reaction, a horizontal reactor and a vertical reactor are used for conducting the two-step reaction, and the molecular weight distribution is further widened. By means of the multi-segment polymerization method and device for propylene, homo-polypropylene, binary polypropylene random copolymer, ternary polypropylene random copolymer or impact copolymer polypropylene with high flow and high rubber content can be produced, and the prepared polymer is even in particle diameter distribution, low in volatile matter and organic content, wide in molecular weight distribution and excellent in processing performance and mechanical performance.

Owner:ZHEJIANG SATELLITE ENERGY CO LTD

Method for removing and recovering reaction monomer

This method for removing the unreacted monomers from the vinylidene chloride resin slurry comprises keeping an aqueous medium in the vinylidene chloride resin slurry containing the unreacted monomers and obtained by polymerization in the aqueous medium in a boiling state at <=80 deg.C temperature under a reduced pressure and vaporizing the unreacted monomers. The method for recovering the unreacted monomers from the vinylidene chloride resin slurry comprises cooling the removed unreacted monomer component, separating water, then further cooling the unreacted monomer component, liquefying the gaseous unreacted monomers and recovering the unreacted monomers.

Owner:KUREHA KAGAKU KOGYO KK

Multistage polymerization method and device of propylene

PendingCN108794669AControl the content of volatile organic compoundsImprove liquidityProcess control/regulationSequential/parallel process reactionsPolymer scienceGas phase

The invention relates to a multistage polymerization method and device of propylene. After prepolymerization reaction, liquid phase polymerization reaction is conducted and then gas phase polymerization reaction is conducted; and two-step reaction is adopted in the gas phase polymerization reaction, and material composition and reaction systems in two reaction regions are the same or different, sothat molecular weight distribution can be widened. By the method and the device, homo-polypropylene, binary random co-polypropylene, ternary co-polypropylene or impact-resistant co-polypropylene withhigh rubber content can be produced; and the prepared polymer is uniform in particle size distribution, has low volatile organic matter content, wide molecular weight distribution and excellent mechanical property and processing property.

Owner:ZHEJIANG SATELLITE ENERGY CO LTD

Pharmaceutical composition for treating hepatitis, pharmaceutical preparation as well as application and preparation method thereof

ActiveCN107569528AGood curative effectGood effectOrganic active ingredientsDigestive systemSalvia miltiorrhizaPatrinia

The invention relates to a pharmaceutical composition for treating hepatitis, a pharmaceutical preparation as well as an application and a preparation method thereof and belongs to the technical fieldof pharmaceutical preparations for treating hepatitis. The pharmaceutical composition preparation comprises the following components in parts by weight: 7.82-9.00 parts of creeping dichondra monomer,2.37-2.71 parts of berchemia lineata monomer, 1.66-2.15 parts of verbena monomer, 12.57-20.36 parts of radix stephaniae tetrandrae monomer, 1.20-1.74 parts of patrinia monomer, 2.56-3.17 parts of herba epimedii monomer, 0.62-0.77 part of astragalus monomer, 14.30-17.88 parts of red paeony root and 8.25-11.02 parts of salvia miltiorrhiza monomer. The previous medicinal monomers are selected, the auxiliary materials are added, and the pharmaceutical preparation prepared according to the conventional preparation process is applied to treating acute and chronic hepatitis caused by liver-gallbladder dampness-heat and qi-stagnation and blood stasis, achieves unexpected treatment effects, has low toxicity while treating hepatitis and is an ideal medicine.

Owner:GUIZHOU RUIHE PHARMA CO LTD LONGLI PHARMA FACTORY

Resource utilization method by using biological power plant waste

InactiveCN110615712AImprove physical propertiesImprove stress resistanceAgriculture tools and machinesOther chemical processesRoot systemScrap

The invention discloses a resource utilization method by using biological power plant waste, and relates to the technical field of biological power plant waste utilization. The biological power plantwaste is processed into a soil improvement agent, wherein the soil improvement agent comprises the following components in parts by weight: 15-25 parts of animal manure, 10-15 parts of straw, 3-4 parts of zeolite, 5-6 parts of bentonite, and 2-3 parts of vermiculite, the pH value being adjusted to 6.0-6.5. The method has the following advantages: through mutual cooperation of the animal waste, theplant straw, the bentonite, the zeolite and the vermiculite system, the toxic action of heavy metals can be effectively inhibited, the effectiveness of trace elements in soil is improved, the nutritional environment of crop roots is improved, the soil structure and the water retention property are effectively improved, and the continuity of the soil improvement effect of the soil conditioner is guaranteed.

Owner:正大农业科技(浙江)有限公司

Method for cleaning nylon 6 polymerization and recovery system filler tower

The invention discloses a method for cleaning a nylon 6 polymerization and recovery system filler tower. The method comprises the steps as follows: 1) superheated steam is fed into the lower part of the filler tower; 2) pure water is fed into the upper part of the filler tower; 3) the superheated steam rises into filler and is contacted with residues adhered to the filler, and the residues are heated and fall to the bottom of the filler tower under the elution effect of the pure water, so that the residues can be removed; and 4) an NaOH dilute solution is fed into the bottom of the filler tower, and a cleaning process of the filler is accelerated under the effect of the superheated steam. The method is simple in technology, small in equipment corrosion, capable of remarkably reducing the content of monomers in waste water produced during recovery of caprolactam and reducing the loss of the monomers and beneficial to environmental protection; in addition, the filler inside the filler tower is not required to be cleaned after disassembly, so that daily maintenance is greatly facilitated.

Owner:FUJIAN JINJIANG TECH

PA6 resin continuous polymerization process

PendingCN113861410AIncrease productionRelatively high intrinsic viscosityPolymer sciencePtru catalyst

The invention relates to a PA6 resin continuous polymerization process, which comprises: (1) heating, stirring and mixing caprolactam, water, a catalyst and a molecular weight regulator to obtain an auxiliary agent solution, feeding a formed mixture into a storage tank, conducting heating, and carrying out thermal insulation; (2) mixing and preheating caprolactam and an auxiliary agent solution, pumping a heated mixture into the top of a polymerization tube, and carrying out catalytic ring-opening polymerization reaction; (3) pumping the reaction system into a vertical film devolatilization device, and carrying out high-vacuum devolatilization; (4) feeding the system into a single-screw or helical ribbon extruder, and carrying out high-vacuum devolatilization; and (5) feeding the material into a multi-screw extruder for screw extrusion devolatilization, and conducting cooling, pelletizing and drying to obtain PA6 resin pellets. The process provided by the invention can replace and reduce four working procedures of recovering caprolactam through water extraction, preparing deionized water, refining recovered monomers and post-polymerizing, the relative intrinsic viscosity of the product is high, the content of monomers and low-molecular substances is low, the process is close to the level of the existing hydrolytic polymerization process, the process is simple, the production period is short, the energy consumption is low, the investment is small, and the process is suitable for industrial production.

Owner:湖南世博瑞高分子新材料有限公司

Oxide-reduction method for preparation of emulsion polymer with low monomer content

A process for preparing an aqueous emulsion polymer including providing at least one ethylenically unsaturated monomer and a free radical redox initiator system under emulsion polymerization conditions, the redox initiator system including a water-soluble oxidizing agent, a water-insoluble oxidizing agent, and a sulfinic acid, or salts thereof, reducing agent; and effecting the polymerization of at least some of the ethylenically unsaturated monomer is provided. Also provided is a process for reducing the residual ethylenically unsaturated monomer content of an aqueous emulsion polymer.

Owner:ROHM & HAAS CO

Preparation method of polyurethane prepolymer with low free isocyanate monomer

The invention discloses a preparation method of polyurethane prepolymer with low free isocyanate monomer. The preparation method comprises the following steps of: forming into mixed alcohol by trihydric alcohol and dihydric alcohol under the temperature of 120-150DEG C, and carrying out vacuum dehydration; putting isocyanate monomer and ester solvents into a reactor to keep the temperature at 30-70DEG C, and dropwise adding the mixed alcohol into the reactor; after dropwise adding, continuously reacting for 3-6h under the temperature of 40-70DEG C under stirring, and discharging in a cooling way to obtain polyurethane prepolymer; and separating the obtained polyurethane prepolymer, and adjusting the solid content of polyurethane prepolymer solid and the content of free isocyanate monomer in the separated heavy components by diluted solvent. According to the preparation method, the real continuous production can be realized, all the recovered solvent and isocyanate monomer can be recycled, the zero emission can be realized, and the real clean production can be realized; and the product has the characteristics of being low in viscosity, high and adjustable in NCO value content, low in the content of the free isocyanate monomer, high in solid content, good in compatibility, etc.

Owner:SOUTH CHINA UNIV OF TECH +1

Composition for oil and gas recovery

ActiveUS11155749B1Good suspensionEasy to hangFluid removalDrilling compositionFracturing fluidPolymer chemistry

A composition for preparing an injection fluid in oil and gas recovery comprising an inverse emulsion of a water-soluble polymer A comprising cationic monomer units, and solid particles of a water-soluble polymer B comprising cationic monomer units, and wherein water-soluble polymer A comprises between 10 and 40 mol % of a cationic monomer units based on the total amount of monomer units; and wherein the cationicity in mol % of polymer A is superior or equal to the cationicity in mol % of polymer B. Method of treating a portion of subterranean formation comprising providing said composition, preparing an injection fluid with at least said composition, introducing the injection fluid into portion of the subterranean formation. The composition is particularly useful to prepare fracturing fluid in fracturing operations.

Owner:S P C M SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com