Preparation method of polyurethane prepolymer with low free isocyanate monomer

A polyurethane prepolymer and isocyanate technology, applied in the field of polyurethane prepolymer, can solve the problems of inability to prepare prepolymers with low free isocyanate monomers, inability to separate isocyanate monomers, and inability to obtain prepolymer products, and achieve NCO Adjustable and controllable content, high NCO content, adjustable and controllable NCO group content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

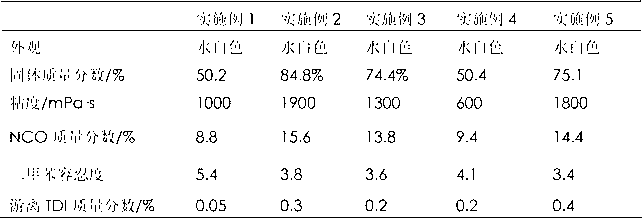

Examples

Embodiment 1

[0039] 10g of 1,3-propanediol and 65g of trimethylolpropane were used to form a mixed alcohol at 120°C for 2 hours in a vacuum to control its water content to be lower than 0.01%, and it was ready for use; under nitrogen protection, 482g of TDI 100 ( All are composed of 2,4-TDI) and 255g of ethylene glycol ether acetate into the reaction vessel and stirred evenly, maintaining the temperature at 60°C, and then adding the dehydrated mixed alcohol dropwise into the reaction vessel under stirring , adding time for 1 hour. After the dropwise addition, continue to react at 70°C under stirring for 6 hours, control the temperature to below 40°C, cool and discharge to obtain a polyurethane prepolymer;

[0040] The obtained polyurethane prepolymer enters the internally cooled molecular still through a distributor at a feed rate of 10 g / min, the primary separation temperature is controlled at 100°C, the primary cold trap temperature is controlled at 11°C, and the vacuum degree is control...

Embodiment 2

[0042] 31g of ethylene glycol and 32g of trimethylolethane form the mixed alcohol at 150°C, vacuum dehydrated for 4 hours, control its water content to be lower than 0.02%, and stand-by; under nitrogen protection, first 579g TDI80 (80% 2,4-TDI and 20% 2,6-TDI) and 148g of n-butyl acetate were put into the reaction vessel and stirred evenly, the temperature was maintained at 55°C, and then the dehydrated mixed alcohol was added dropwise to the In the above reaction vessel, the dropwise addition time was 1.5 hours. After the dropwise addition, continue to react at 65°C under stirring for 4 hours, control the temperature to below 40°C, cool and discharge to obtain a polyurethane prepolymer;

[0043] The obtained polyurethane prepolymer enters the internally cooled molecular still through the distributor at a feed rate of 7.5g / min, the primary separation temperature is controlled at 130°C, the primary cold trap temperature is controlled at 15°C, and the vacuum degree is controlled...

Embodiment 3

[0045] 49g of 1,4-butanediol and 11g of 1,2,6-hexanetriol to form a mixed alcohol were dehydrated under vacuum for 3 hours at 150°C, and the water content was controlled to be less than 0.01%, and it was ready for use; under the protection of nitrogen, First put 601g TDI80 (composed of 80% 2,4-TDI and 20% 2,6-TDI) and 139g propylene glycol methyl ether acetate into the reaction vessel and stir evenly, keeping the temperature at 40°C, then put the dehydrated mixed alcohol It was added dropwise into the reaction vessel under stirring condition, and the dropwise addition time was 1 hour. After the dropwise addition, continue to react at 45°C under stirring for 3 hours, control the temperature to below 40°C, cool and discharge to obtain a polyurethane prepolymer;

[0046] The obtained polyurethane prepolymer enters the externally cooled film still through a distributor at a feed rate of 6 g / min. The primary separation temperature is controlled at 160° C., the primary cold trap tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com