Preparation method of instant ultra-high molecular weight polyacrylamide dry powder

An ultra-high molecular weight, polyacrylamide technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of decreased polymerization degree, difficult to initiate polymerization, and decreased initial polymerization temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Synthesize polyacrylamide with the method of the present invention in the laboratory, synthetic scale carries out step by step according to 1200g / still, 10Kg / still, 20Kg / still, 50Kg / still, each raw material specification and source are as shown in table 4.

[0071] 1. Instrument

[0072] Polymerization kettle, stirrer, high-pressure nitrogen cylinder, porous ceramics, analytical balance, constant temperature water bath, temperature recorder, oven, colloid mill, etc.

[0073] Table 4

[0074]

[0075] 2. Chemical reagents

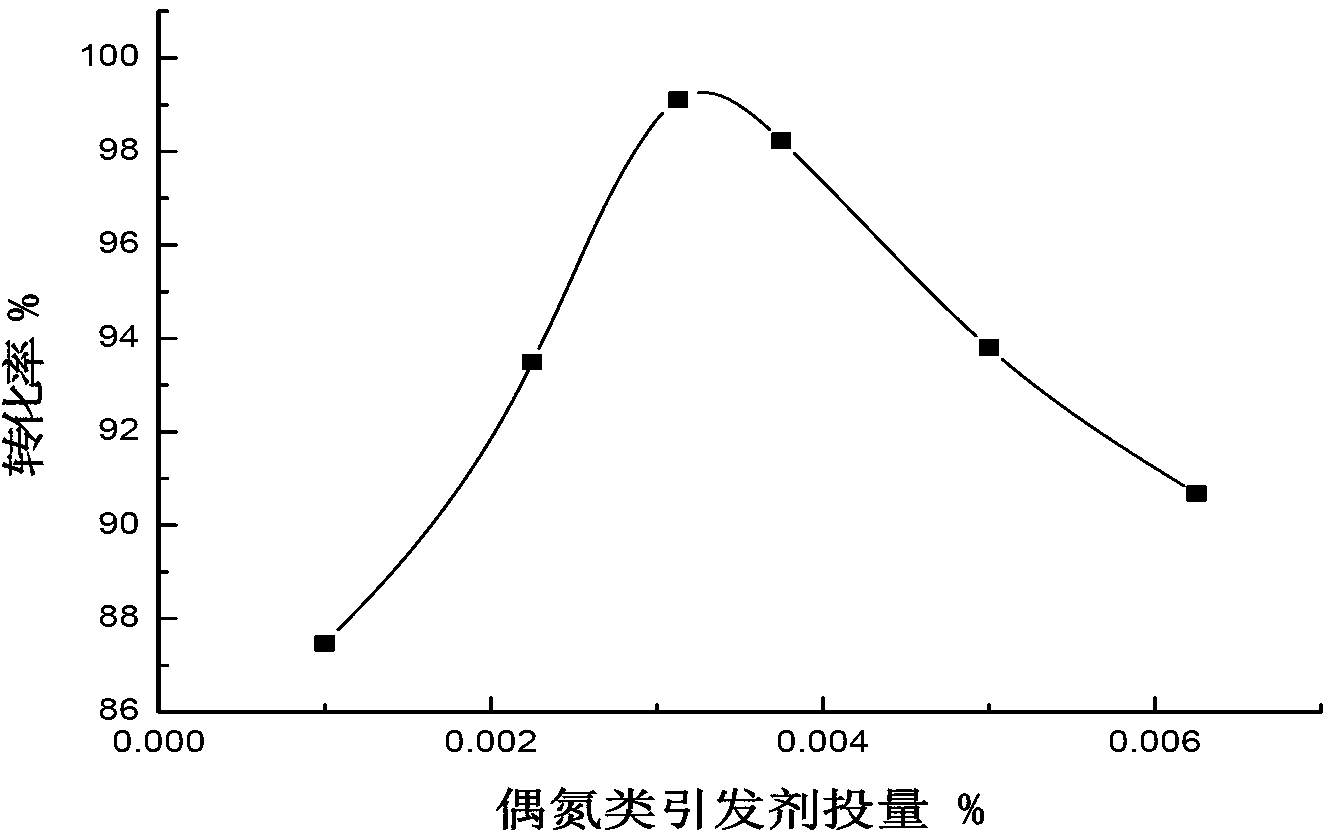

[0076] Acrylamide AM (technical grade); Azotripropionamide, analytically pure; Potassium persulfate, analytically pure; Ammonia, chemically pure; Urea, chemically pure; Azobisisobutylamidine hydrochloride, analytically pure; Sulfuric acid, chemically pure ; Sodium hydroxide, chemically pure

[0077] 3. Experimental steps

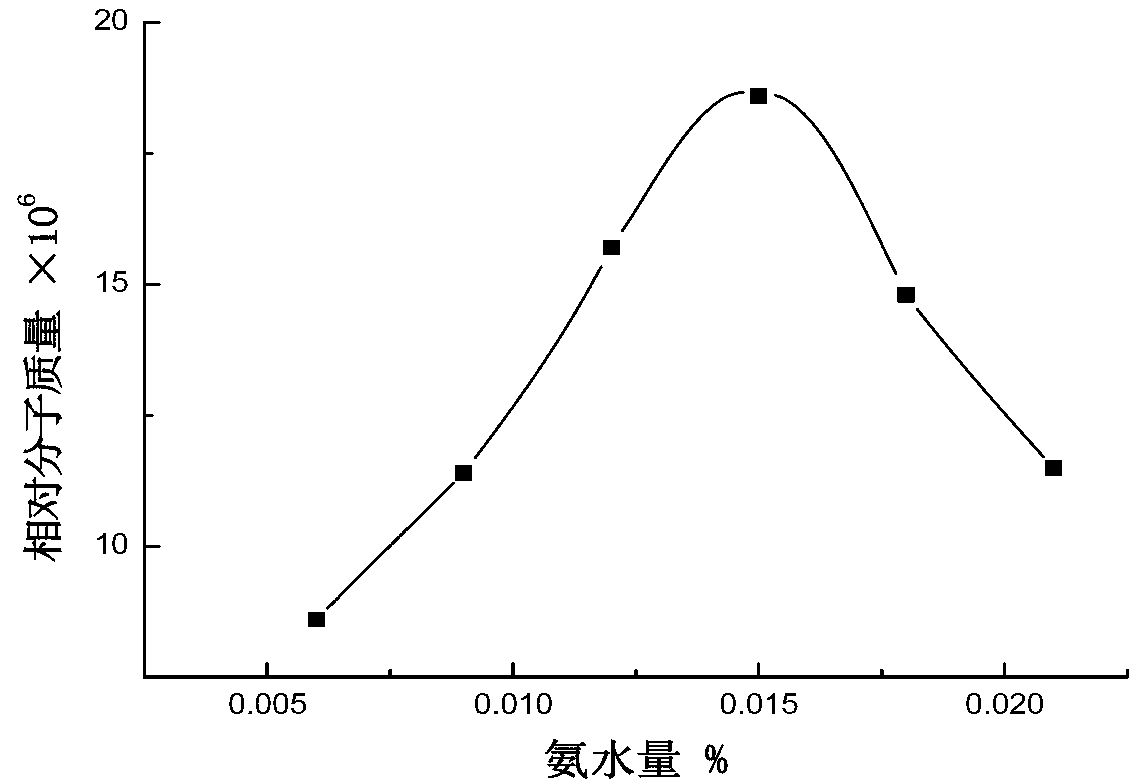

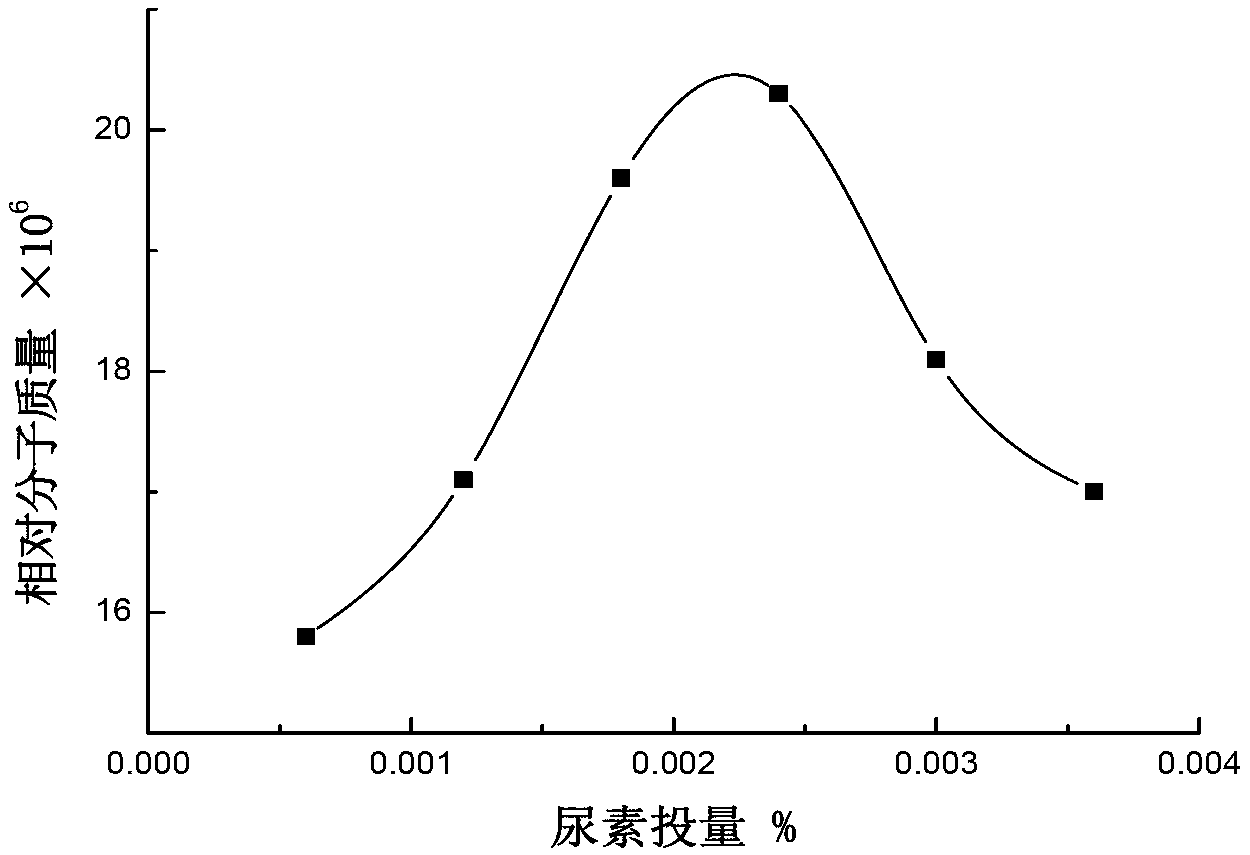

[0078] (5) Preparation of mother liquor: Mix acrylamide and water into a 15% reaction mother liquor according to a cert...

Embodiment 2

[0087] Industrialized production, using adiabatic tank reactor polymerization, the synthesis scale is 8 tons / kettle

[0088] 1. Equipment

[0089] Dissolving tank (10 tons), polymerization kettle (10 tons), pre-grinding machine, temperature recorder, granulator, high-pressure nitrogen bottle, etc.

[0090] 2. Chemical reagents

[0091] Acrylamide AM (technical grade); Azotripropionamide, analytically pure; Potassium persulfate, analytically pure; Ammonia, chemically pure; Urea, chemically pure; Azobisisobutylamidine hydrochloride, analytically pure; Sulfuric acid, chemically pure ; Sodium hydroxide, chemically pure

[0092] 3. Experimental steps

[0093] (1) Prepare 20% acrylamide in a dissolving tank, add 0.15% ammonia water, stir evenly, and transfer to a reaction kettle after completion.

[0094](2) Blow nitrogen into the reactor for 1 hour, add 0.2% NTP after deoxygenation, K 2 S 2 o 8 0.35%, stop blowing nitrogen. The reaction was continued for 1 hour.

[0095] (...

Embodiment 3

[0100] Equipment, reaction reagents, and reaction steps are the same as in Example 2, and the weight proportions of monomers, initiators and auxiliary agents are shown in Table 7 below:

[0101] Table 7

[0102]

[0103] Note: The data of each substance in Table 7 is the percentage of the weight of each substance to the weight of the reaction monomer solution.

[0104] Obtain the final product instant ultra-high molecular weight PAM, and each index is shown in the following table 8:

[0105] Table 8

[0106]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com