Starch-based composite seed coating agent and preparation method thereof

A starch-based and starch technology, applied in the agricultural field, can solve the problems of poor film-forming property, difficult to meet the requirements of film-forming property and cohesiveness at the same time, easy to dissolve and run off, etc. Good adhesion and film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

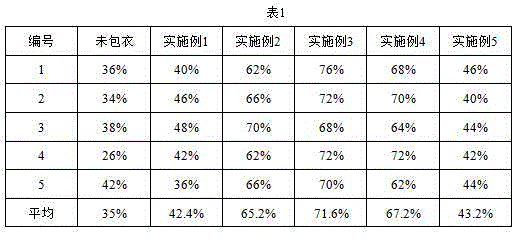

Examples

Embodiment 1

[0031] (1) The composition of the active ingredient layer (inner layer) is as follows: 40g of carboxymethyl starch with a degree of substitution of 0.6 is pregelatinized in a drum dryer, 1.1g of root powder and aspirin are mixed at a mass ratio of 5:6, Thiram 4g, Carbofuran 4g, KNO 3 : NH 4 NO 3 : KH 2 PO 4 :MgSO 4 Take 12g after mixing according to the mass ratio of 5:5:8:1, and mix the above ingredients evenly.

[0032] (2) Film-forming water-retaining layer (outer layer):

[0033] A. Preparation of grafted starch:

[0034] a) Under stirring, add starch to a certain amount of deionized water to form starch milk with a concentration of 25% by mass.

[0035] b) Raise the temperature to 85°C and fully gelatinize for 30 minutes.

[0036] c) Lower the temperature to 70°C, add acrylic acid and acrylamide-2-methylpropanesulfonic acid in a mass ratio of 1:0.8 as a comonomer, the mass ratio of the total amount of monomers to starch is 3:1, and the added mass is Cross-linkin...

Embodiment 2

[0041](1) The composition of the active ingredient layer (inner layer) is as follows: Carboxymethyl starch with a substitution degree of 1.0 is pregelatinized in a drum dryer, and then 20 g of hydroxypropyl starch with a substitution degree of 0.5 is pregelatinized in a drum dryer. After taking 10g, rooting powder and aspirin are mixed according to the mass ratio of 5:6 and then taking 1.5g, thiophanate-methyl 4.2g, butylthiocarbofuran 4.5g, KNO 3 : NH 4 NO 3 : KH 2 PO 4 :MgSO 4 Take 10g after mixing according to the mass ratio of 5:5:8:1, and mix the above ingredients evenly.

[0042] (2) Film-forming water-retaining layer (outer layer):

[0043] A. Preparation of grafted starch:

[0044] a) Under stirring, add starch to a certain amount of deionized water to form starch milk with a concentration of 25% by mass.

[0045] b) Raise the temperature to 80°C and fully gelatinize for 25 minutes.

[0046] c) Lower the temperature to 73°C, add a comonomer of acrylic acid and ...

Embodiment 3

[0051] (1) The composition of the active ingredient layer (inner layer) is as follows: take 15 g of carboxymethyl starch after pregelatinization in a drum dryer, 5 g of hydroxyethyl starch with a degree of substitution of 0.4 after pregelatinization in a drum dryer, and root powder Take 1.8g after mixing with aspirin at a mass ratio of 5:6, mix thiram and triadimefon at a mass ratio of 1:1 to take 4.5g, 5.0g of carbofuran, KNO 3 : NH 4 NO 3 : KH 2 PO 4 :MgSO 4 Take 5g after mixing according to the mass ratio of 5:5:8:1, and mix the above ingredients evenly.

[0052] (2) Film-forming water-retaining layer (outer layer):

[0053] A. Preparation of grafted starch:

[0054] a) Under stirring, add starch to a certain amount of deionized water to form starch milk with a concentration of 20% by mass.

[0055] b) Raise the temperature to 90°C and fully gelatinize for 35 minutes.

[0056] c) Lower the temperature to 71°C, add comonomers that are methacrylic acid and acrylamide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com