Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Low kappa" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bleaching stage using xylanase with hydrogen peroxide, peracids, or a combination thereof

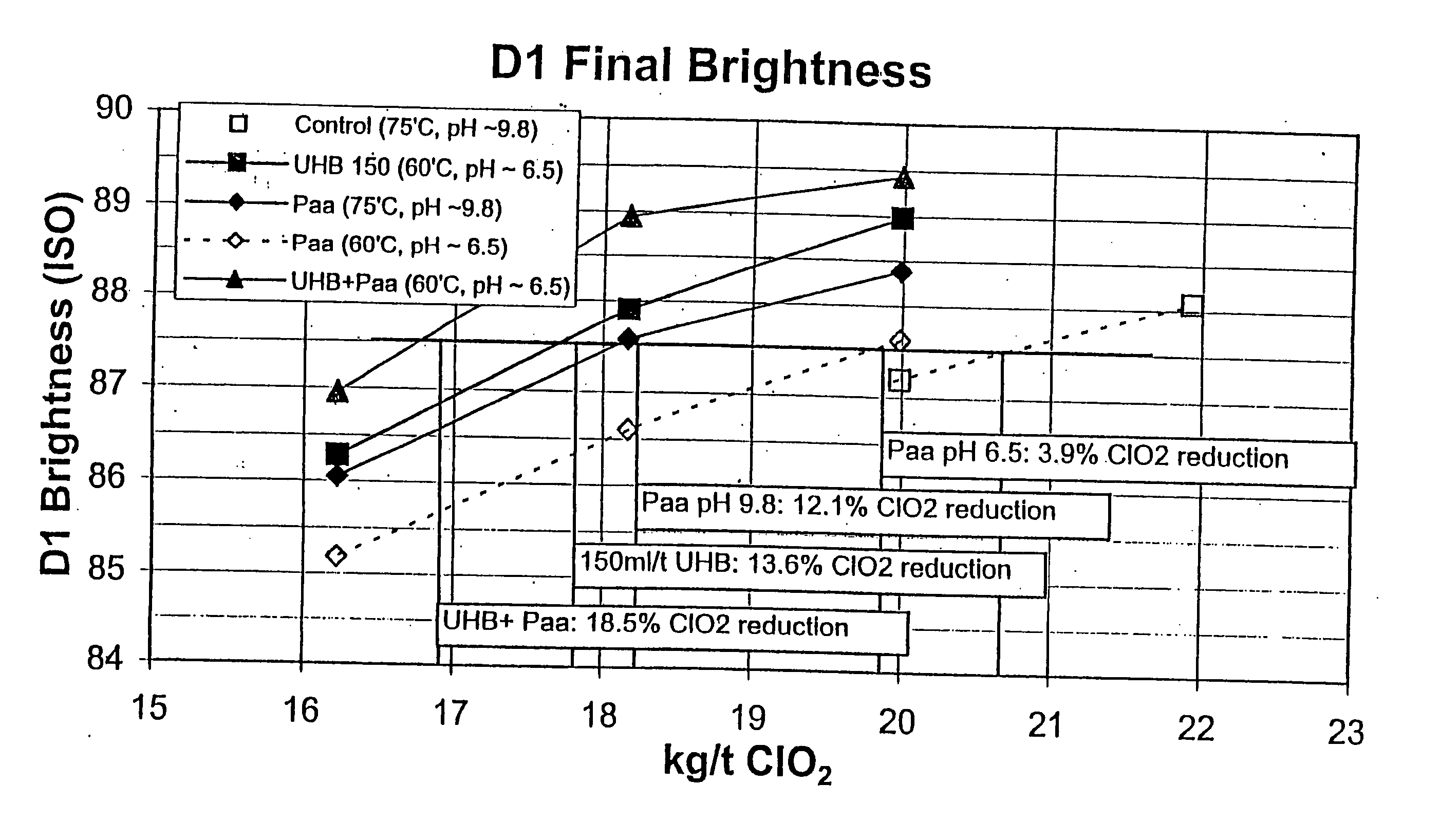

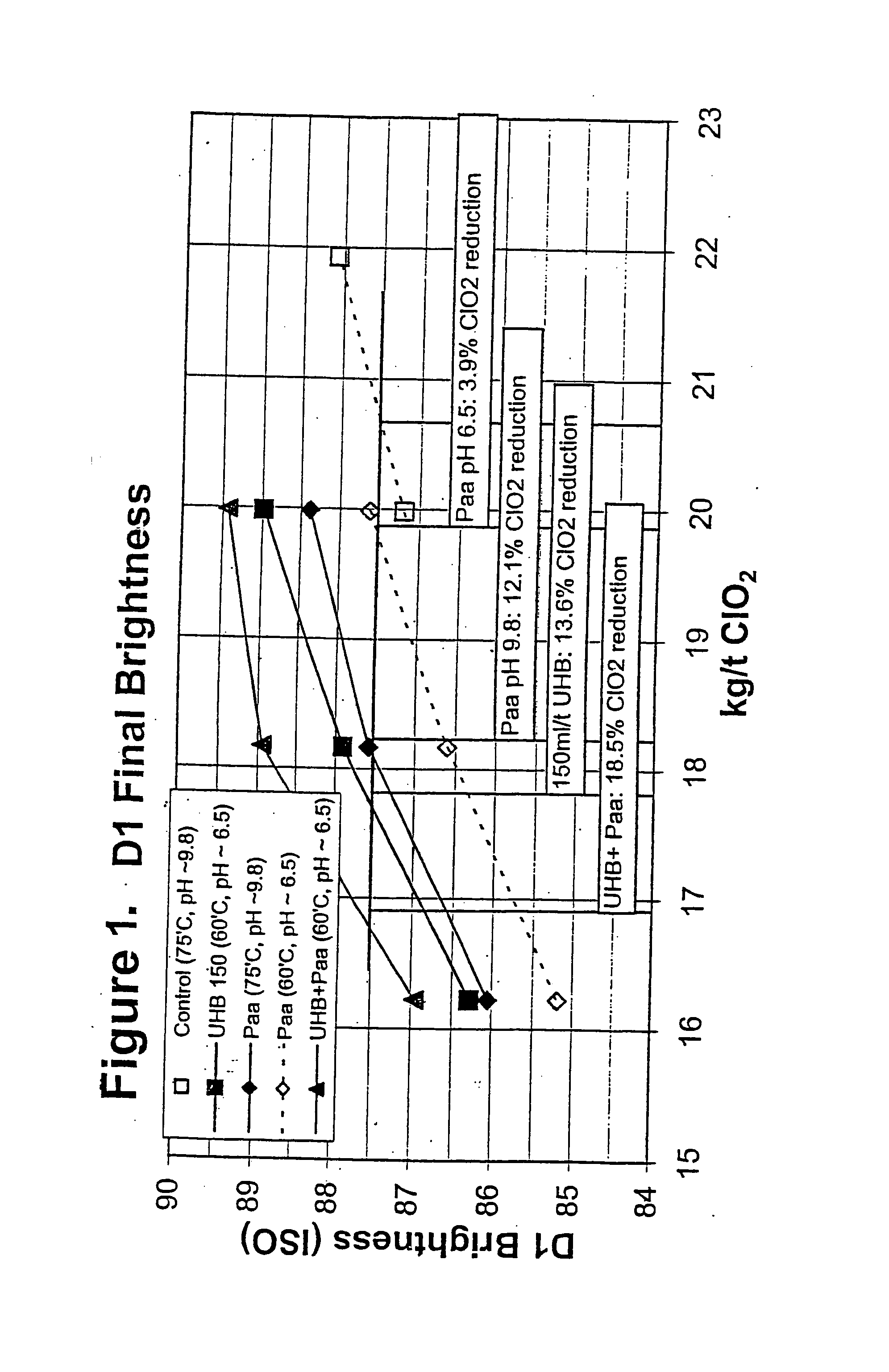

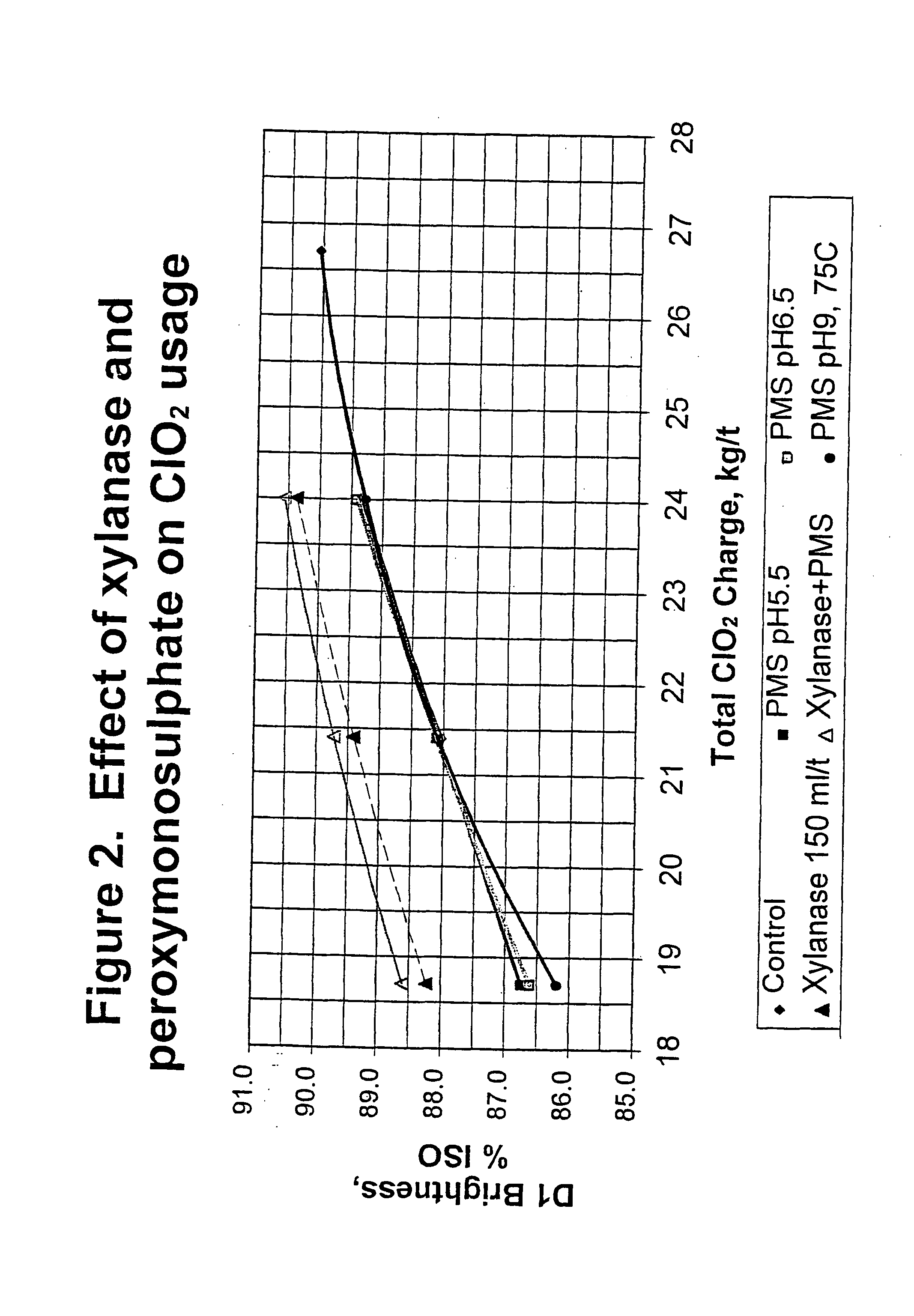

InactiveUS20040112555A1Less-costly bleaching operationReduce usagePulp bleachingPulping with inorganic basesChlorine dioxideXylanase Y

The present invention discloses methods of bleaching chemical pulp that combine xylanase enzymes with hydrogen peroxide, peracids, or a mixture. The method comprises the steps of carrying out a chemical pulping operation, optionally followed by delignifying the pulp with oxygen, then combining xylanase enzymes with hydrogen peroxide, peracids, or a mixture to bleach the pulp. The method allows the mill to use both xylanase and peracids in a single bleaching tower to decrease the usage of chlorine dioxide and other bleaching chemicals. The pulp bleaching method of the present invention may be performed in a pulp mill as part of a complex pulp bleaching process.

Owner:IOGEN BIO PRODUCKTS CORP

Stewing method for preparing bamboo wood dissolving pulp

InactiveCN102337689AIncrease productionQuality improvementPretreatment with water/steamPulping with inorganic basesLiquid wasteBlack liquor

The invention belongs to the technical field of dissolving pulp preparation and relates to a stewing method for preparing bamboo wood dissolving pulp, which comprises the following steps of: (a) introducing vapor to a boiler: preparing bamboo wood raw materials into slice materials, conveying the slice materials to a digester, and introducing low pressure vapor to the digester while conveying theslice materials; (b) vapor heating and pre-hydrolyzing: heating through the vapor after introducing the vapor to the boiler to pre-hydrolyze the slice materials; (c) neutralizing through white liquor: neutralizing the slice materials and vapor condensed water in the digester through the white liquor in a hot white liquor tank; (d) replacing through hot black liquor: replacing the neutralization liquid waste in the digester through the hot black liquor in a hot black liquor tank; (e) heating and stewing in a temperature control manner to prepare virgin pulp of the bamboo wood dissolving pulp; (f) replacing the washing black liquor, washing and cooling the virgin pulp; and (g) discharging at a low temperature. The invention has the advantages of reducing the production cost, increasing the production efficiency, effectively utilizing the stewing heat and improving the yield and the quality of the bamboo wood dissolving pulp.

Owner:CHONGQING LEE & MAN PAPER MFG

Microwave-assisted preparation method of bagasse bleached pulp

InactiveCN104005247AObvious advantagesHigh whitenessCellulose material pulpingAnthraquinonesSodium hydroxide

The invention discloses a microwave-assisted preparation method of bagasse bleached pulp, which is a method for clean and high-efficient preparation of bagasse bleached pulp by microwave radiation technology. The method comprises: performing microwave heating and water extracting treatment of air-dried bagasse raw materials, repeatedly soaking and cleaning the treated materials with deionized water to be neutral, then performing dehydration and dispersion, rapidly determining the water content of the dispersed materials, then performing delignification treatment of the materials with a known water content by sodium hydroxide / hydrogen peroxide / anthraquinone, finally soaking, dispersing and washing the treated pulp to be neutral, removing excessive water, and sealing to obtain the bagasse bleached pulp. The bagasse bleached pulp prepared by the method is milk white or in a white fiber form, low in paper pulp kappa number, high in whiteness, and moderate in viscosity.

Owner:KUNMING UNIV OF SCI & TECH

ECF bleaching technology of fast growing poplar by NaOH-AQ pulp biochemical method

The invention discloses an ECF bleaching technology of fast growing poplar by a NaOH-AQ pulp biochemical method. The technology provided by the invention is characterized by comprising the following steps: (1) steaming: taking fast growing poplar chips, stewing the fast growing poplar chips in a digester to obtain virgin pulp, washing and screening to obtain paper pulp; (2) xylanase pretreatment; and (3) ECF bleaching: bleaching the above paper pulp which has undergone enzyme treatment, wherein the bleaching process is ODED and comprises steps of: oxygen delignification or reinforced oxygen delignification is firstly carried out on the paper pulp which has undergone enzyme treatment; after oxygen delignification, the paper pulp is washed and D-stage chlorine dioxide bleaching is then carried out; after D-stage chlorine dioxide bleaching, the paper pulp is washed and then E stage is performed; and after E stage, the paper pulp is washed and secondary D stage is carried out. According to the invention, xylanase is used to pretreat the paper pulp, and then bleaching is performed by the ODED bleaching process so as to obtain the paper pulp with higher whiteness and viscosity. Under the condition that the total dosage of ClO2 is 1%, the whiteness of bleached pulp reaches up to 88.6% ISO as the highest level and to 88.1% ISO as the lowest level.

Owner:QILU UNIV OF TECH

Method for bleaching dendrocalamus giganteus chemical pulp

InactiveCN102587186AGood strength performanceStrong delignificationPulp bleachingWastewaterHigh intensity

The invention discloses a method for bleaching dendrocalamus giganteus chemical pulp. By the method, the dendrocalamus giganteus chemical pulp serving as special wood assortment in Yunnan is subjected to clean chlorine-free bleaching in four steps. The method comprises the following steps of: 1, performing acidification chelating treatment; 2, bleaching by using deoxidized lignin intensified by hydrogen peroxide; 3, bleaching by using peracetic acid; and 4, bleaching by using the hydrogen peroxide. Paper pulp prepared by the method has the characteristics of high whiteness and high intensity and is low in wastewater pollution.

Owner:KUNMING UNIV OF SCI & TECH

Dendrocalamus hamiltonii pre-impregnated diethanol amine-anthraquinone cooking and pulping method

InactiveCN103835173AHigh yieldLow kappaDigestersPaper material treatmentChemistryDendrocalamus hamiltonii

The invention discloses a dendrocalamus hamiltonii pre-impregnated diethanol amine-anthraquinone cooking and pulping method. According to the method, a special wood assortment dendrocalamus hamiltonii of Yunnan is adopted and is pre-impregnated; then the dendrocalamus hamiltonii is cooked and pulped by a diethanol amine solvent and an anthraquinone auxiliary agent. Paper pulp prepared by the method disclosed by the invention has the characteristics of high yield, high viscosity and good strength; separated waste liquid can be directly used as a pre-impregnating solution and a cooking solvent to be circularly utilized.

Owner:KUNMING UNIV OF SCI & TECH

ECF bleaching technology of fast growing poplar by sodium hydroxide anthraquinone pulp bio-chemical method

The invention discloses an ECF bleaching technology of fast growing poplar by a sodium hydroxide anthraquinone pulp bio-chemical method. The ECF bleaching technology is characterized by comprising the following steps: (1) boiling: taking fast growing poplar chips, stewing the fast growing poplar chips in a digester to obtain virgin pulp, washing, and screening to obtain paper pulp; (2) xylanase pretreatment; and (3) ECF bleaching: bleaching the above paper pulp which has undergone enzyme treatment, wherein the bleaching process is one of three bleaching processes, namely ODQP, OPDQP or O1O2PDQP. According to the invention, xylanase is used to pretreat the paper pulp, and one of the three bleaching processes, namely ODQP, OPDQP or O1O2PDQP, is carried out for bleaching so as to obtain the paper pulp with higher whiteness and viscosity. In comparison with paper pulp which is directed bleached without xylanase pretreatment, the paper pulp produced by the ECF bleaching technology has the following advantages: beating whiteness loss is less, folding strength is averagely higher by 30 times, burst index is averagely higher by 0.35N.m.g<-1>, breaking length is averagely higher by 0.25KM, and tear index difference is basically unchanged or slightly reduced by a very small magnitude.

Owner:QILU UNIV OF TECH

Rapid-growth poplar sodium hydroxide anthraquinone pulp biochemical method TCF bleaching process

ActiveCN103362009AHigh viscosityHigh folding resistancePulp bleachingCellulose material pulpingXylanasePre treatment

The invention discloses a rapid-growth poplar sodium hydroxide anthraquinone pulp biochemical method TCF bleaching process. The process is characterized in that the process comprises the steps that: (1) steaming is carried out, wherein rapid-growth poplar wood sheets are steamed in a steaming pot, such that an original pulp is obtained; washing and screening are carried out, such that paper pulp is obtained; (2) xylanase pretreatment is carried out; (3) TCF bleaching is carried out, wherein the treated paper pulp is bleached with one of the bleaching sequence selected from OP-Q-P, O1-O2P-Q-P and O1P-O2P-Q-P. According to the invention, paper pulp is pretreated by using xylanase, and bleaching is carried out with one of the three bleaching sequences of XOPQP, XO1O2PQP and XO1PO2PQP, such that paper pulp with higher whiteness and viscosity are obtained. Compared with paper pulp obtained by direct bleaching without xylanase pretreatment, the paper pulp provided by the invention has lower beating whiteness loss. A folding resistance is higher by 30-49 times, a burst index is higher by 0.3-0.6N.m.g<-1>, a breaking length is higher by 0.15-0.36KM, and a tearing index is not significantly changed. When a same or similar beating degree is reached, needed beating revolutions are less, and beating energy consumption can be saved by approximately 17.8%.

Owner:QILU UNIV OF TECH

Preparation method of straw pulp

InactiveCN103255661AImproved lignin removal efficiencyEasy accessPulping with inorganic basesNon-woody plant/crop pulpPulp and paper industryHardness

The invention discloses a preparation method of straw pulp. The preparation method comprises the steps of: (1) adding straw raw materials and cooking liquor into cooking equipment according to the weight ratio being (1:3)-(1:6) and evenly mixing, and then sealing then cooking equipment, wherein the cooking liquor contains alkali; (2) introducing oxygen into the sealed cooking equipment to keep the oxygen pressure in the cooking equipment be 0.3-1.0MPa, and cooking the straw raw materials at 90-130 DEG C for 30-240 minutes by using the cooking liquor; and (3) washing and screening pulp obtained after the cooking process is completed. By adopting the preparation method of the straw pulp, provided by the invention, the advantages of the straw raw materials can be fully achieved, and the straw pulp with low hardness, high yield and good quality can be obtained.

Owner:KUNMING UNIV OF SCI & TECH +1

Combined process using grasses as raw materials

The invention discloses a combined process using grasses as raw materials. The combined process is a whole-process reaction process comprising a preparation process of a high-grade paper slurry, a preparation process of a pulp for packaging paper, and a preparation process of a foliar fertilizer. The preparation process of the high-grade paper slurry mainly includes the process steps of: three reactions in three reaction tanks, four times of extrusion and pulping by a high concentration pulping machine; and the slurry with high yield is prepared. Pulp squeezing water obtained by first alkali addition softening, first pulp squeezing and / or first two times of pulp squeezing in the preparation process of the high-grade paper slurry is used as a raw material for the preparation process of thepulp for packaging paper; the pulp squeezing water containing a part of cellulose and unreacted agents is subjected to softening and grinding treatment to obtain the slurry for packaging paper. Squeezing water produced in the preparation process of the pulp for packaging paper is recovered and treated as a raw material for preparation of the foliar fertilizer. The combined process has the advantages of no black liquor discharge, water recycling, and energy conservation; therefore, the combined process is a green pulping process.

Owner:黑龙江如柏科技有限公司

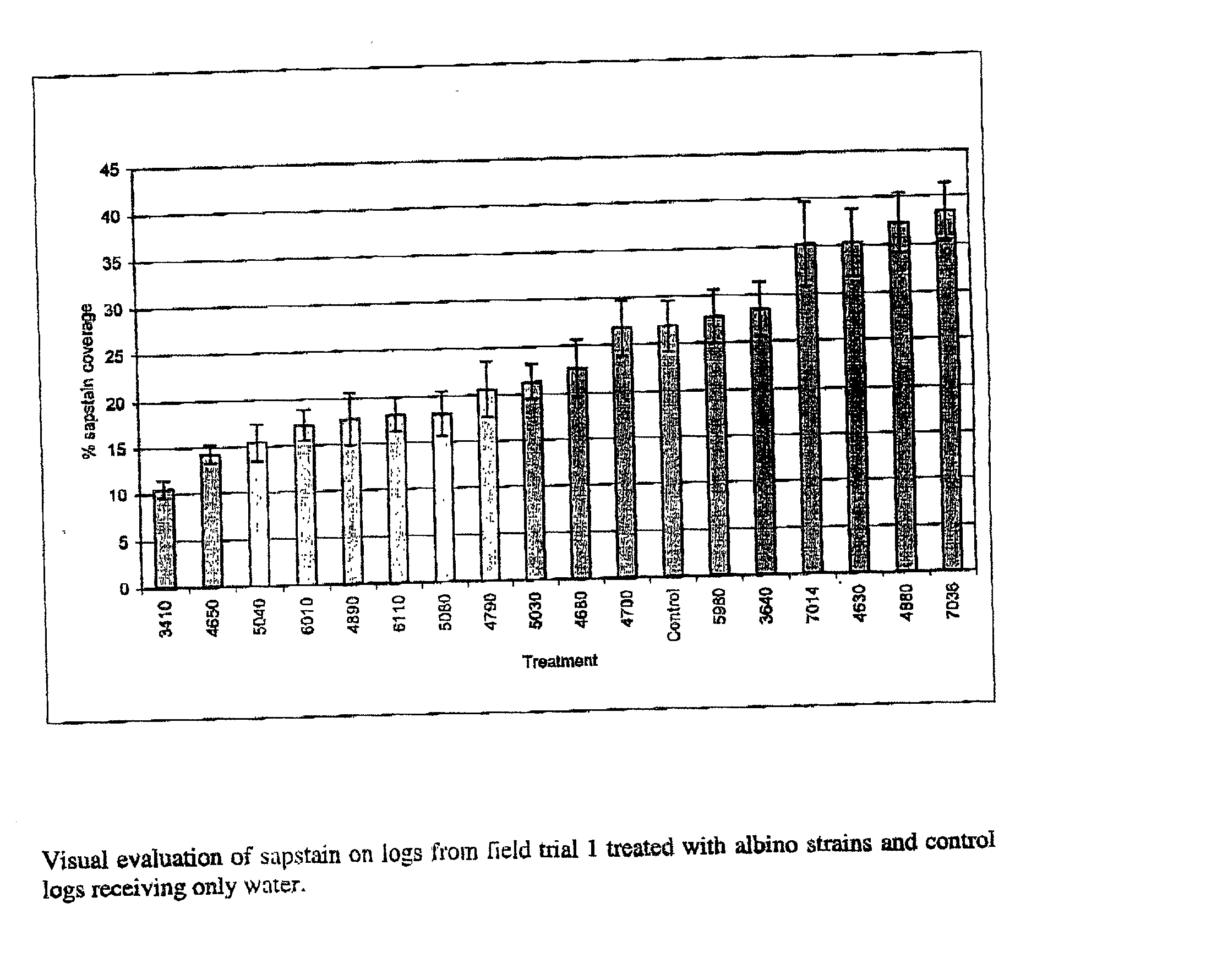

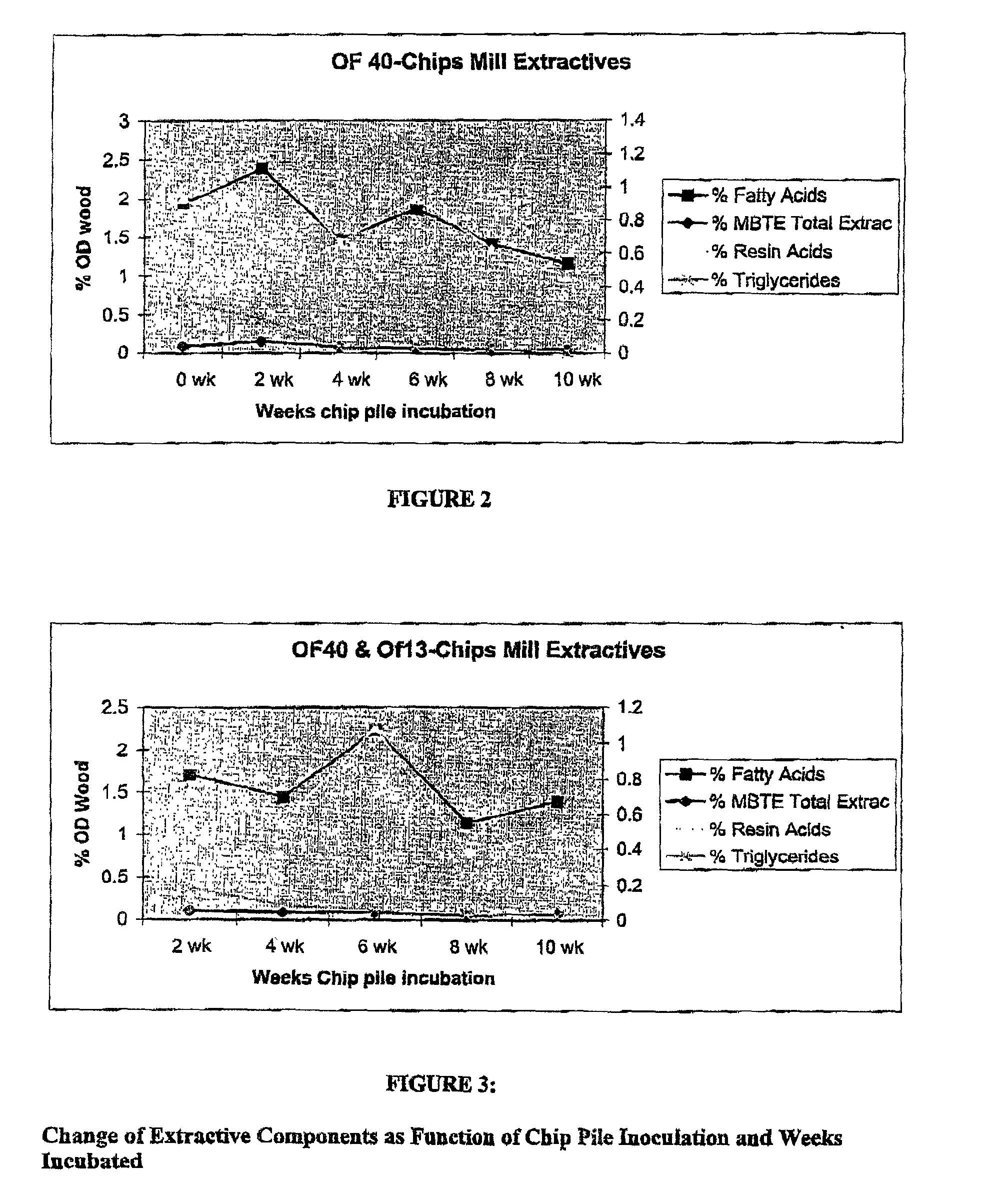

Fungi for improvements of wood and pulp appearance and qualities

InactiveUS20020096273A1Promote resultsIncrease brightnessFungi productsMicroorganismsOphiostoma floccosumBiology

The invention relates to the use of fungi stains of Ophiostoma floccosum, Ophiostoma piceae or Ophiostoma pluruanulatum, or mixtures on wood and pulp to improve chemical pulping processes and / or reduce cooking tie and / or improve brightness and / or decrease extractives.

Owner:UNIVERSITY OF WAIKATO

Pretreatment liquid of cotton rod boiling

InactiveCN1769584AIncreased yield of fine pulpHigh whitenessPretreatment with alkaline reacting compoundsChemistryPre treatment

This invention relates to a cotton pole paper making boiling preprocessing liquid. The character of this invention is that the liquid contains 1-5úÑ sodium hydroxide by weight , 0.01-0.5úÑ natrium borohydride by weight. After the cotton pole boiling preprocessing liquid of this invention does pretreatment on the cotton pole, compraring to the regular paper pulp, the minute pulping rate is improved by 1-6úÑú¼the white rate can be improved by 8-15úÑISOú¼and the kappa number drops to 6-10.

Owner:QILU UNIV OF TECH

Paper pulp continuous-replacement boiling process

InactiveCN102251425AReduce dosageImprove efficiencyDigestersPaper material treatmentBoiling processBoiling point

The invention relates to a paper pulp continuous-replacement boiling process. The purpose of the invention is to save energy and to eliminate the environmental pollution of exhaust gas during pot discharging. The scheme of the invention is that: a plurality of boiling pots forms a temperature gradient and is in procedures with different boiling periods; when one of the boiling pot reaches a boiling end point and needs pot discharging treatment, high-temperature boiling liquid in the pot is discharged into a next pot; boiling liquid in the next pot is discharged into a further next pot, that is, boiling liquid in each pot is replaced circularly; after the replacement, each on-off device is closed simultaneously; a subsequent procedure is continued, waiting for the next replacement time. The process of the invention effectively uses the boiling heat energy, has the characteristics of both intermittent and continuous boiling, simplifies the process flow of continuous replacement boiling, and simplifies the operation steps.

Owner:曲传武 +1

Antibacterial paper towel and preparation method thereof

InactiveCN109914138AHigh whitenessEfficient degradationAntibacterial agentsCosmetic preparationsFiberMicrowave radiometry

The invention relates to an antibacterial paper towel and a preparation method thereof, and discloses a process for papermaking by using Qianjinfang medicine residue, wherein the process comprises: microwave pretreatment, fermentation, washing, paper making, extracting of medicinal ingredients from waste liquid, paper modification and the like. According to the present invention, the short fiber is prepared by using the Qianjinfang medicine residue, and the long fiber property of the cotton fiber is combined, such that the prepared antibacterial paper towel has good tensile property; the prepared antibacterial paper towel has remarkable wet strength through internal sizing and surface application; by using the microwave radiation method and the biological method, harmful chemicals are notintroduced during the whole process, such that the hygienic characteristics of the paper are ensured; and the medicinal ingredients are extracted from the pulping waste liquid, and are mixed with thebase medicine liquid component comprising Cortex Ailanthi, Sophora flavescens Ait, Cortex Moutan, frankincense and borneol, and the obtained mixture is applied on the paper, such that the obtained antibacterial paper towel has good anti-inflammatory and antibacterial effects, can prevent microbial infection, does not have irritation and side effects on the skin and vaginal mucosa, and is suitablefor women.

Owner:ZHUZHOU QIANJIN PHARMA

Pulping method of reed organic solvent slurry by pre-extracting hemicellulose and product thereof

InactiveCN104988783ALow kappaImprove pulping efficiencyPretreatment with water/steamWashing/displacing pulp-treating liquorsAlcoholOrganosolv

The invention relates to a pulping method of a reed organic solvent slurry by pre-extracting hemicellulose and a product thereof. The method includes: reed preparation, prehydrolysis, solid-liquid separation and washing, and pulp preparation by a high boiling alcohol solvent method from residues. The method can obtain a reed pulp and a reed extracting liquid which can be used for preparation of saccharide compounds or ethanol. Compared with the reed raw material which is not subjected to hemicellulose extraction by hydrolysis, the Kappa number of the slurry obtained under the same pulping conditions is reduced by 5-8 units after the reed is subjected to prehydrolysis. By prehydrolysis to extract hemicellulose before pulping, the problem of high sugar content in a high boiling alcohol solvent recovery system can be solved, and effective utilization of all components of wood biomass raw materials also can be realizes, so that the added value of a byproduct is improved, and the economic costs of high boiling solvent alcohol pulping are balanced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for cooking and pulping pinus khasys propylene glycol

InactiveCN103835172AReduce the maximum holding temperatureEasy to removePulping with organic solventsFiberOrganic solvent

The invention discloses a method for cooking and pulping pinus khasys by using a propylene glycol organic solvent. According to the method, a special wood fiber raw material pinus khasys of Yunnan is adopted and is cooked and pulped by using a propylene glycol solvent, citric acid and sulfuric acid. Paper pulp prepared by the method disclosed by the invention has the characteristics of high yield, high viscosity, good strength and good paper pulp whiteness.

Owner:KUNMING UNIV OF SCI & TECH

TCE bleaching technology for sulfate pulp of growing poplar by biological chemical method

The invention discloses a TCE (Total Chlorine-Free) bleaching technology for sulfate pulp of growing poplar by biological chemical method. The technology comprises the following steps: (1), cooking: getting fast-growing polar pieces; putting the fast-growing polar pieces into a distilling pan for cooking, so as to obtain primary pulp, and then washing and screening the primary pulp to obtain paper pulp; (2), pre-treating the paper pulp with xylanase; (3), TCE bleaching: bleaching the paper pulp pre-treated with the xylanase, wherein the bleaching process is one of OP-Q-P, O1-O2P-Q-P or O1P-O2P-Q-P. According to the TCE (Total Chlorine-Free) bleaching technology for sulfate pulp of growing poplar by biological chemical method, the xylanase is adopted to pre-treat the paper pulp, then one of the bleaching processes OP-Q-P, O1-O2P-Q-P or O1P-O2P-Q-P is adopted for bleaching, so that the paper pulp with higher whiteness and viscosity is obtained; compared with the paper pulp obtained through directly bleaching without xylanase pre-treatment, the paper pulp provided by the invention has the advantages that the loss value of whiteness is lesser, the folding strength is higher 45 times averagely, the bursting index is higher 0.45 N*m*g <-1> averagely, the breaking length is higher 0.35 KM, and the tearing index is quite. The beating revolution number is lesser when the paper pulp reaches the same or similar beating degree, and the 20% of beating energy consumption can be saved approximately.

Owner:QILU UNIV OF TECH

Continuous displacement and digestion process for dissolving pulp

The invention relates to a continuous displacement and digestion process for dissolving pulp. By adopting the traditional vertical pot digestion equipment and combining a continuous digestion technology, a fiber raw material is prepared into the dissolving pulp (chemical fiber pulp), and the purposes of saving energy, protecting the environment, improving the yield and the quality and reducing the consumption are fulfilled. A plurality of digestion pots are adopted in the digestion process for the dissolving pulp, the digestion solution outlet of each digestion pot is directly communicated with the digestion solution displacement outlet of other each digestion pot through a pipeline, and random two or more digestion pots form closed circular connection; during working, the same process conditions are set in the digestion process of each digestion pot from filling completion to pot feeding, and three periods of displacement time of all the digestion pots are set to be the same; and by adjusting the time interval between the digestion pots, the displacement time is superposed, namely at least two pots are in the process of acid displacement, neutralization displacement or alkali reclamation displacement in the displacement time, the displacement time is superposed and continuous displacement is performed at the time superposition point.

Owner:曲传武 +1

Pinus khasys diethanol amine stewing pulping method

ActiveCN106400565AStickyImprove securityPulp liquor regenerationWashing/displacing pulp-treating liquorsFiberViscosity

The invention discloses a pinus khasys diethanol amine stewing pulping method. Pinus khasys which is a Yunnan special wood fiber raw material is used, and after microwave cooperative pretreatment, stewing pulping is carried by using a diethanol amine solvent. Pulp prepared by the method is has the characteristics of high yield, high viscosity and high strength. Separated waste liquid can be directly reused as a pretreatment solution and a stewing solvent.

Owner:KUNMING UNIV OF SCI & TECH

Papermaking stewing accessory ingredient and preparation method thereof

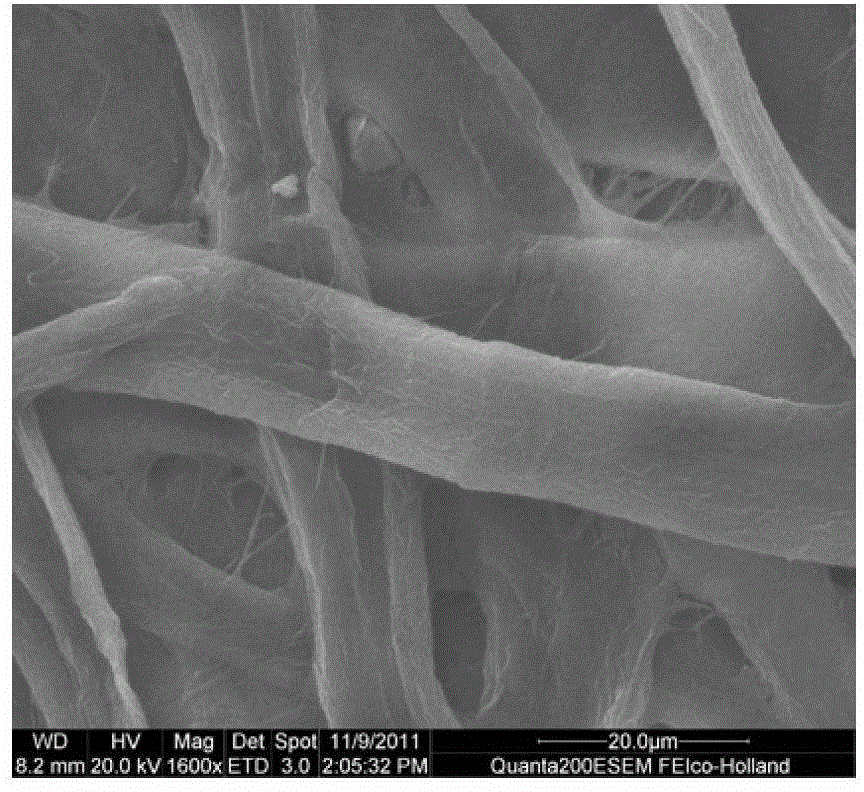

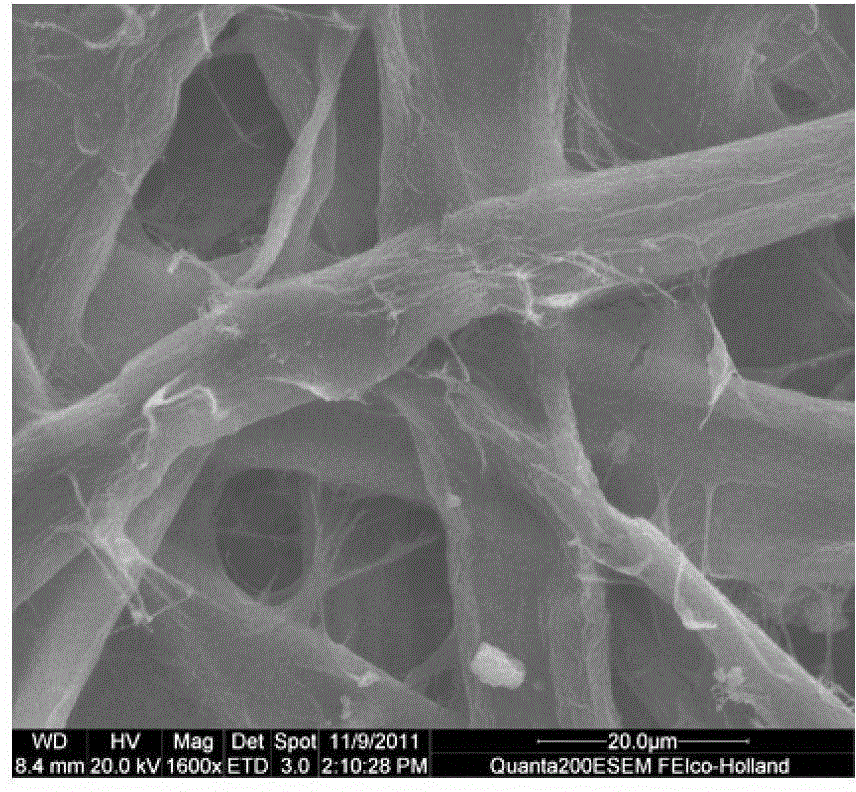

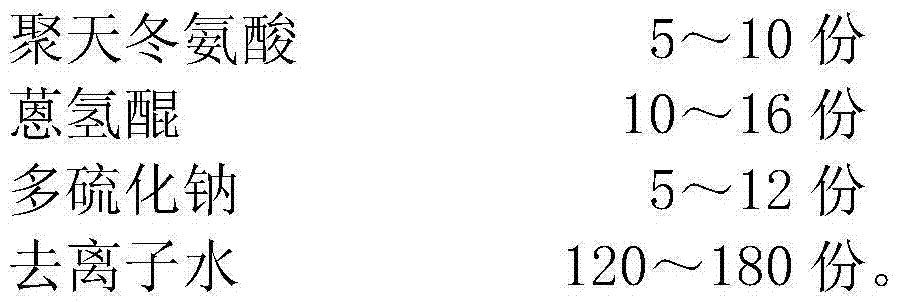

InactiveCN104762844AImprove permeabilityHigh yieldPulping with inorganic basesAdditive ingredientHardness

The invention belongs to the field of a papermaking technology, and in particular relates to a papermaking stewing accessory ingredient. The papermaking stewing accessory ingredient is prepared by the raw materials which comprise, by weight, 25-35 parts of sodium dodecyl benzene sulfonate, 15-30 parts of alkyl glucosides, 5-10 parts of poly aspartic acid, 10-16 parts of anthrahydroquinone, 5-12 parts of sodium polysulfide and 120-180 parts of deionized water. The invention further provides a preparation method of the papermaking stewing accessory ingredient. By means of the papermaking stewing accessory ingredient, the amount of alkali used for stewing is greatly reduced, the stewing time is shortened, the stewing temperature and the hardness of paper pulp can be lowered, the quality of the pulp is improved in all aspects, the yield of the pulp is improved, a pipeline is effectively prevented from forming scales, and continuous production is guaranteed.

Owner:陈朝民

Method of cooking pulping by preimpregnation of dendrocalamus giganteus in propylene glycol organic solvent

ActiveCN105155323AReduce the maximum holding temperatureEasy to removePulping with organic solventsNon-woody plant/crop pulpDistillationSlurry

Belonging to the technical field of pulping, the invention relates to a method of cooking pulping by preimpregnation of dendrocalamus giganteus in a propylene glycol organic solvent. The method includes: firstly splitting dendrocalamus giganteus into bamboo segments that are 2cm-3cm long and have a width of less than 3cm to serve as the pulping raw materials; adding the pulping raw materials into a propylene glycol analytically pure reagent to conduct preimpregnation, and then performing separation to obtain an impregnated material; adding a pulping agent into the impregnated material, then putting the mixture into a chain oil bath cooking pan, and separating the slurry and the waste liquid at the end of cooking; washing the separated slurry and then subjecting the slurry to screening in a pulp screener to obtain clean dendrocalamus giganteus paper pulp; adding cold water into the waste liquid to carry out dilution standing and centrifugal separation, performing microfiltration with a microfiltration membrane, conducting ultrafiltration with an ultrafiltration membrane, implementing reduced pressure distillation to remove water, and then using the obtained solution to replace the propylene glycol analytically pure reagent to serve as the preimpregnation reagent. The paper pulp prepared by the method has the advantages of high yield, high viscosity, high whiteness and good strength.

Owner:KUNMING UNIV OF SCI & TECH

A method of cooking and pulping Dalong bamboo pre-impregnated with propylene glycol organic solvent

ActiveCN105155323BReduce the maximum holding temperatureEasy to removePulping with organic solventsNon-woody plant/crop pulpLiquid wasteDistillation

Belonging to the technical field of pulping, the invention relates to a method of cooking pulping by preimpregnation of dendrocalamus giganteus in a propylene glycol organic solvent. The method includes: firstly splitting dendrocalamus giganteus into bamboo segments that are 2cm-3cm long and have a width of less than 3cm to serve as the pulping raw materials; adding the pulping raw materials into a propylene glycol analytically pure reagent to conduct preimpregnation, and then performing separation to obtain an impregnated material; adding a pulping agent into the impregnated material, then putting the mixture into a chain oil bath cooking pan, and separating the slurry and the waste liquid at the end of cooking; washing the separated slurry and then subjecting the slurry to screening in a pulp screener to obtain clean dendrocalamus giganteus paper pulp; adding cold water into the waste liquid to carry out dilution standing and centrifugal separation, performing microfiltration with a microfiltration membrane, conducting ultrafiltration with an ultrafiltration membrane, implementing reduced pressure distillation to remove water, and then using the obtained solution to replace the propylene glycol analytically pure reagent to serve as the preimpregnation reagent. The paper pulp prepared by the method has the advantages of high yield, high viscosity, high whiteness and good strength.

Owner:KUNMING UNIV OF SCI & TECH

Papermaking stewing accessory ingredient and preparing method thereof

InactiveCN103132355AGood effectImprove permeabilityCellulose material pulpingAnthraquinonesMethyl benzene

The invention discloses a papermaking stewing accessory ingredient and a preparing method thereof. The papermaking stewing accessory ingredient comprises, by weight, 2-20 parts of dimethyl benzenesulfonic acid, 10-35 parts of nonyl phenol polyoxyethylene ether, 1-15 parts of urea, 1-10 parts of anthraquinone, 1-10 parts of sodium sulphide and 40-100 parts of deionized water. The papermaking stewing accessory ingredient is good in alkali solubility, and capable of speeding delignification, reducing degradation of cellulose and hemicellulose, and improving performance of full stuff.

Owner:SHAANXI UNIV OF SCI & TECH

Method for synergistic treatment to improve effect of oxygen-alkali pulping

The invention discloses a method for synergistic treatment to improve the effect of oxygen-alkali pulping and belongs to the technical field of pulping and papermaking. The method comprises: pretreating raw materials through hot water at 30-60 DEG C, carrying out screw extrusion according to a compression ratio of 1: 1.5 to 1: 4, feeding the extruded materials into a digester, and adding a free radical controlling agent into the digester in digestion so that the oxygen-alkali pulping effect is improved. Compared with the conventional oxygen-alkali pulping method, the method utilizes combination of hot water pretreatment, spiral extrusion conveying and a free radical control agent to improve a fine pulp yield of oxygen-alkali pulping by 4-7%, reduce a Kappa number by 2.1 to 3.4 and improvewhiteness by 4% ISO to 6% ISO.

Owner:KUNMING UNIV OF SCI & TECH

Mask paper suitable for sensitive skin, and preparation method thereof

InactiveCN109914147AEfficient degradationFacilitate cross-linkingNon-fibrous pulp additionWashing/displacing pulp-treating liquorsMicrowave radiometryFiber

The invention relates to mask paper suitable for sensitive skin, and a preparation method thereof, and discloses a process for papermaking by using Qianjinfang medicine residue, wherein the process comprises: microwave pretreatment, fermentation, washing, paper making, medicinal ingredient extracting, paper modification, and the like. According to the present invention, the Qianjinfang medicine residue is used as the raw material for preparing fibers, the Qianjinfang medicine residue simultaneously has the characteristics of herbaceous plants and shrub raw materials, the microwave radiation method and the biological method are combined, the microwave radiation process, the temperature and the time in the pulping process, the papermaking process and the like are scientifically controlled, the performance of the paper prepared by using the method is good, harmful chemicals are not introduced during the whole process so as to ensure the hygienic properties of the paper, and the medicinalingredients are extracted from the pulping filtrate and are applied on the paper, such that the finally obtained product is not irritating to people with sensitive skin.

Owner:ZHUZHOU QIANJIN PHARMA

Paper prepared from forestry and agricultural waste and method thereof

InactiveCN108130773AObvious advantage in delignification reactionObvious advantagesPulp properties modificationWater-repelling agents additionFiberAgricultural engineering

The invention relates to paper prepared from forestry and agricultural waste and a method thereof, and discloses a technology for preparing fiber through the forestry and agricultural waste. The technology comprises the steps of spiral squeezing processing, biological enzyme fermenting, papermaking, paper modifying and the like. The forestry and agricultural waste serves as raw materials for preparing fiber, then through the cooperation of ultrasonic waves and biological enzymes, the prepared fiber has high yield, high whiteness and a low kappa number, in the whole process, no harmful chemicalproducts are introduced, and the hygiene of the fiber is ensured. Since graphene dispersion liquid is added in the pulping process, the obtained product has high electric conduction and antibacterialperformance, and particularly has an effect of effectively inhibiting and killing staphylococcus aureus, escherichia coli and hemolytic streptococcus.

Owner:HUNAN UNIV OF TECH

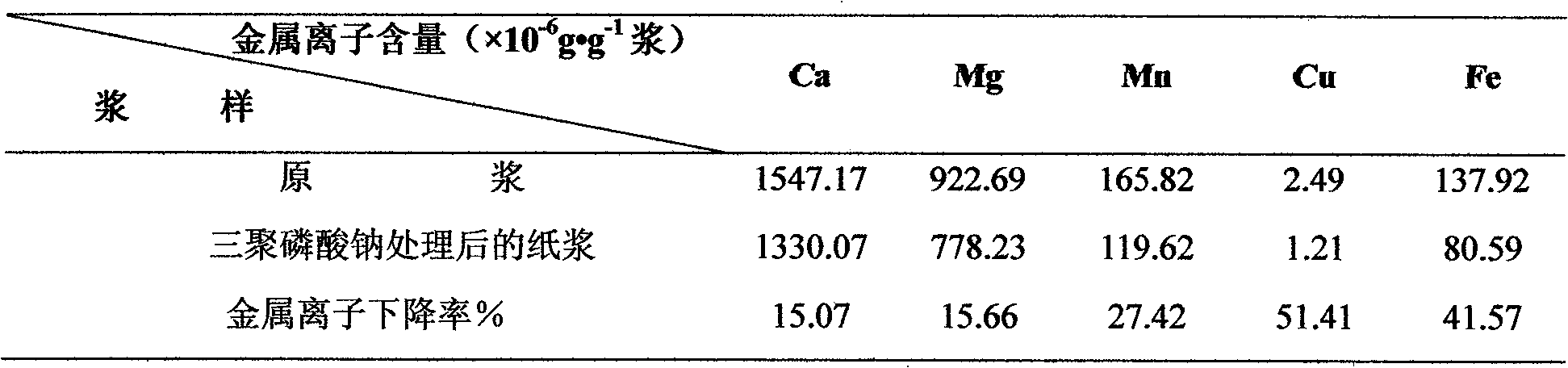

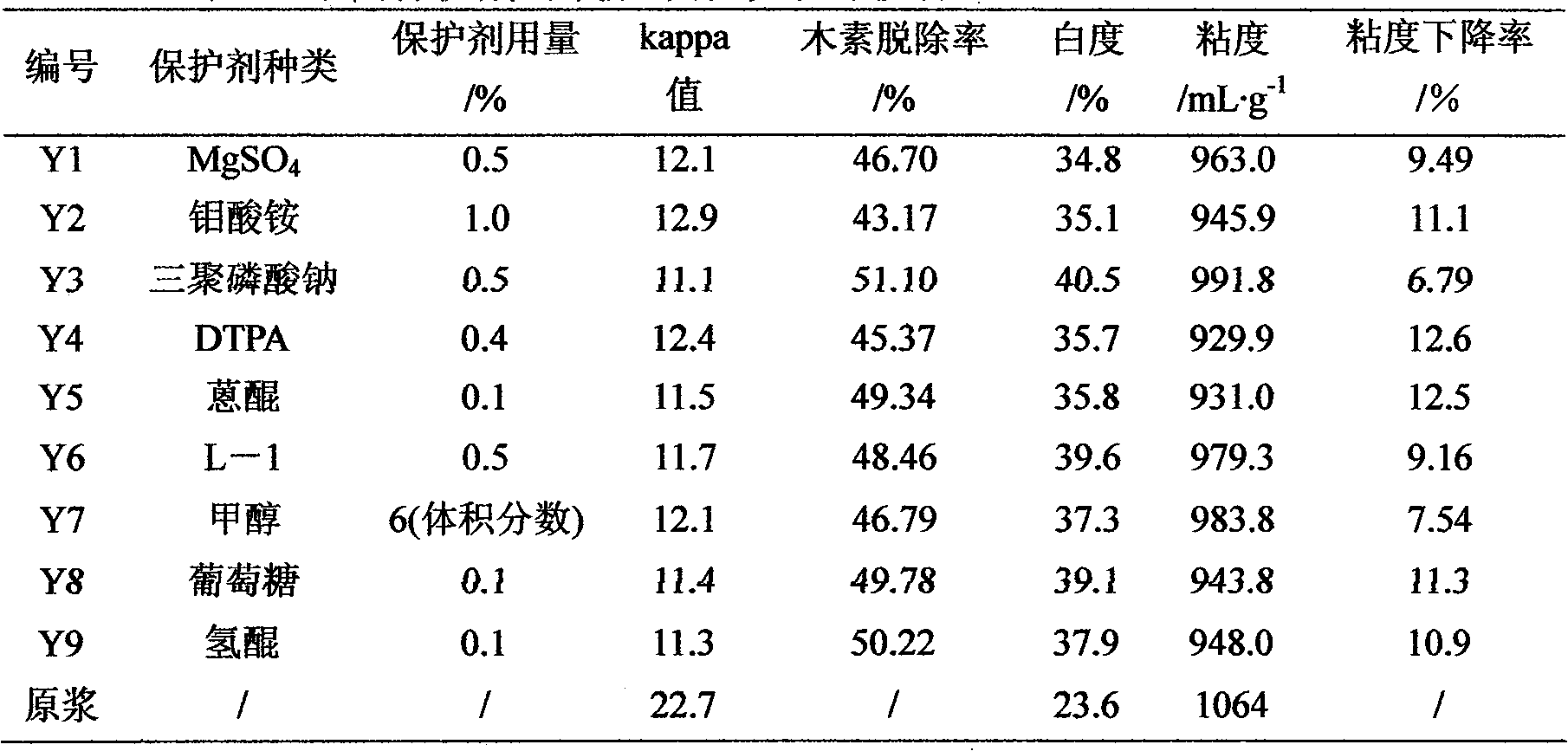

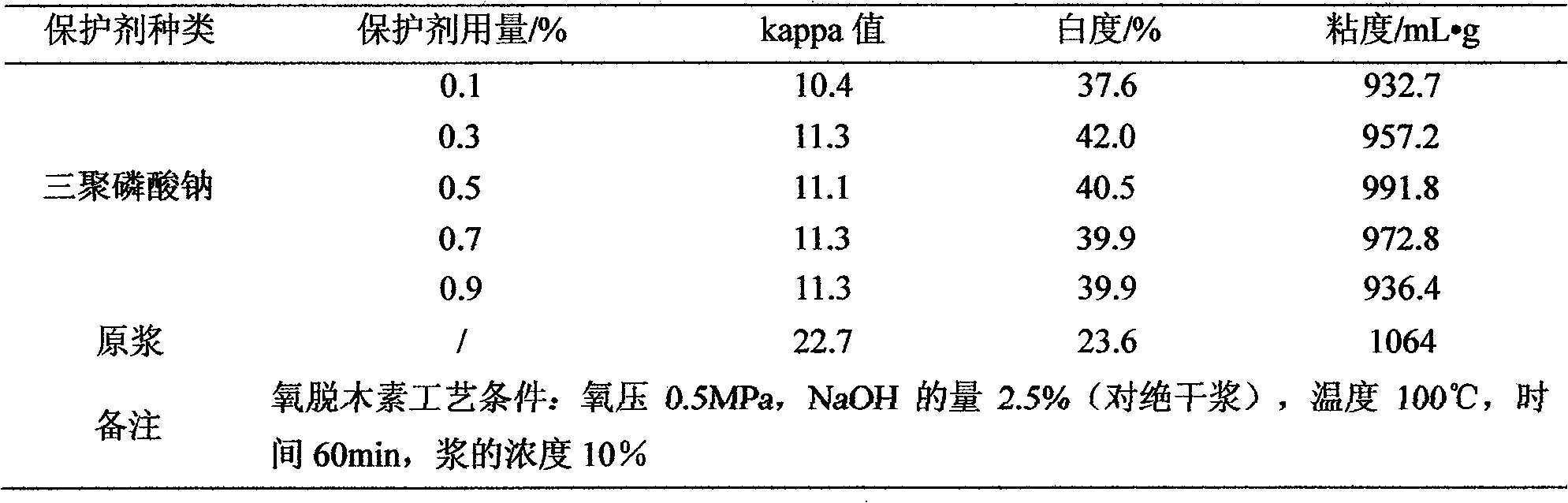

Method for promoting removal rate, whiteness and viscosity of oxygen delignification by STPP

InactiveCN101200863BHigh removal rateReduce pollutionCellulosic pulp after-treatmentInorganic compound additionSodium phosphatesToxicology

The present invention discloses an application of sodium tripolyph-osphate as protecting auxiliary in the oxygen delignification bleaching, and by weight percentage, the dosage of the sodium tripolyph-osphate of the protecting auxiliary is 0.1 percent to 0.5 percent. Compared with the prior universal protecting auxiliaries, such as bitter salt, the kappa value of the sodium tripolyph-osphate applied as the protecting auxiliary of oxygen delignification is low, that is, the delignification rate is high, exceeding 50 percent, while whiteness and viscosity are the highest, so the sodium tripolyph-osphate applied by the present invention, the protecting auxiliary of oxygen delignification, has the better effect than the bitter salt used as the protecting auxiliary of oxygen delignification, and while the sodium tripolyph-osphate protects carbohydrate, lignin is removed as much as possible. The environmental pollution is reduced. Using sodium tripolyph-osphate as the protecting auxiliary of oxygen delignification can increase the delignification rate, thus reducing the subsequent dosage of bleaching chemicals and therefore also reducing the pollution load of bleaching wastewater.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for preparing oxygen alkali pulping effect through cellulase pretreatment

ActiveCN107419578AReduce oxidative degradationHigh yieldPulping with inorganic basesCellulose treatment using microorganisms/enzymesKappa numberCellulase

The invention discloses a method for preparing an oxygen alkali pulping effect through cellulase pretreatment, and belongs to the technical field of pulping and paper making. The method comprises the following steps: pretreating raw materials with cellulase; and dehydrating the pretreated raw materials, and preparing paper pulp in a boiler by using an oxygen alkali boiling method. Under same oxygen alkali pulping conditions, compared with those of a control sample without enzyme treatment, the actual pulping yield of the method is increased by 1-5.5%, the kappa number of the paper pulp is reduced by 1-8 units, and the whiteness and the viscosity of the paper pulp are slightly increased; and under the condition of a similar pulping kappa number, the yield, the whiteness and the viscosity of oxygen alkali pulp treated with the cellulase are increased to certain extents.

Owner:KUNMING UNIV OF SCI & TECH

Papermaking cooking assistant

InactiveCN104790243AImprove solubilityEnhanced complexationCellulose material pulpingPhosphatePapermaking

The invention relates to the technical field of papermaking, and particularly relates to a papermaking cooking assistant which is prepared from the following raw materials in parts by weight: 10-20 parts of green oxygen, 12-24 parts of sulfated castor oil, 20-30 parts of surfactant, 5-10 parts of phosphate, 5-10 parts of water retention agent and 60-90 parts of deionized water. The papermaking cooking assistant greatly enhances the cooking effect, enhances the raw material permeability, improves the cooking uniformity, quickly adsorbs alkali liquor, increases the transmission speed of the reaction product in the raw materials, accelerates cooking, obviously shortens the cooking time, and greatly improves the pulp quality and paper strength.

Owner:陈朝民

Anti-inflammatory paper and preparation method thereof

InactiveCN109914157AEfficient degradationObvious advantagesSpecial paperPaper coatingFiberMicrowave radiometry

The invention relates to anti-inflammatory paper and a preparation method thereof, and discloses a process for papermaking by using Qianjinfang medicine residue, wherein the process comprises: microwave pretreatment, fermentation, washing, paper making, extraction of medicinal ingredients from filtrate, paper modification, and the like. According to the present invention, the Qianjinfang medicineresidue is used as the raw material for preparing fibers, the Qianjinfang medicine residue simultaneously has the characteristics of herbaceous plants and shrub raw materials, the microwave radiationmethod and the biological method are combined, the microwave radiation process, the temperature and the time in the pulping process, the papermaking process and the like are scientifically controlled,the paper prepared by using the method has good performance, harmful chemicals are not introduced during the whole process so as to ensure the hygienic properties of the paper, and the medicinal ingredients are extracted from the pulping filtrate and are applied on the paper, such that the finally obtained product has good anti-inflammatory effect.

Owner:ZHUZHOU QIANJIN PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com