Method for promoting removal rate, whiteness and viscosity of oxygen delignification by STPP

A technology of sodium tripolyphosphate and oxygen delignification, applied in the direction of adding inorganic compounds, etc., to reduce environmental pollution, improve lignin removal rate, and reduce dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

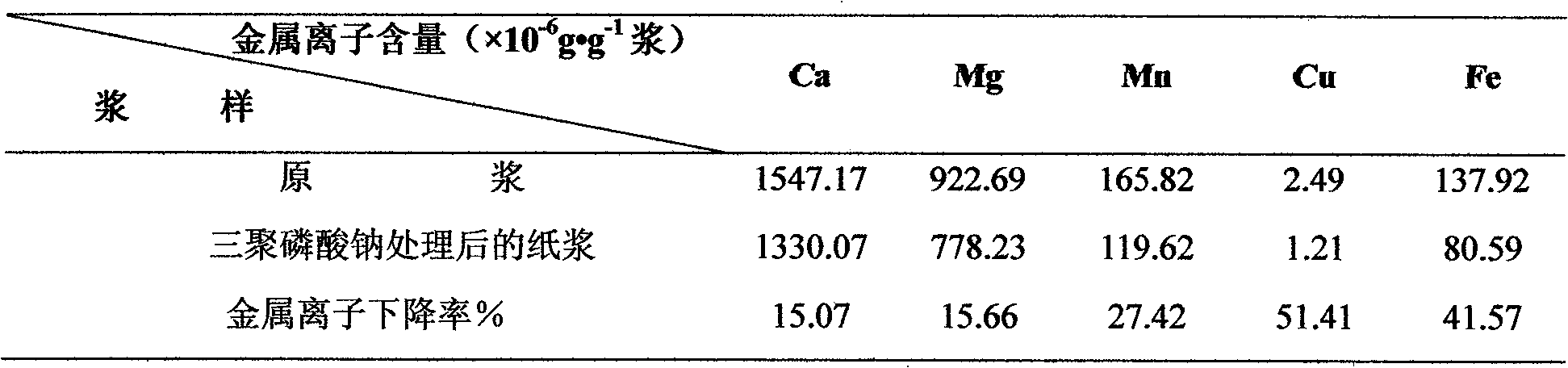

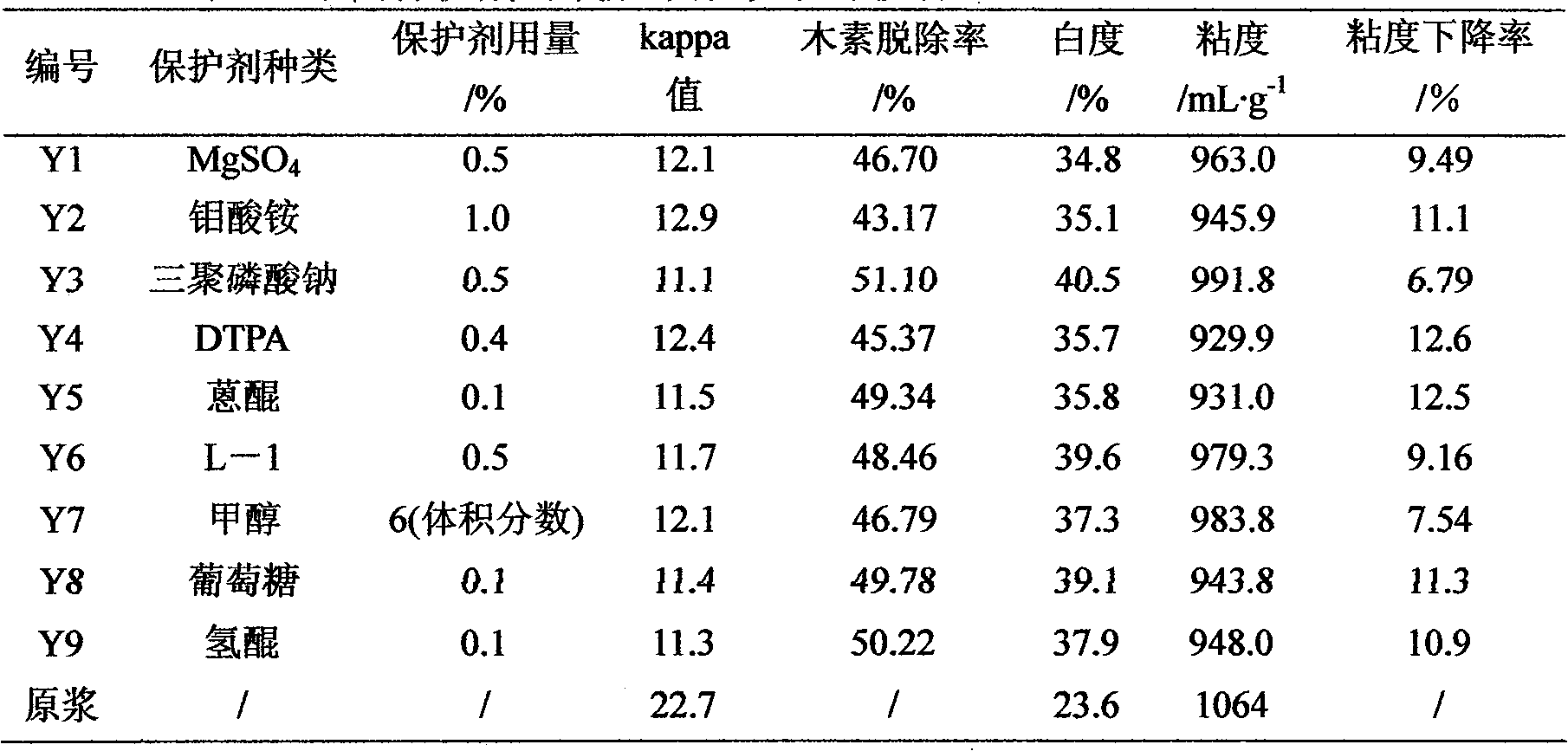

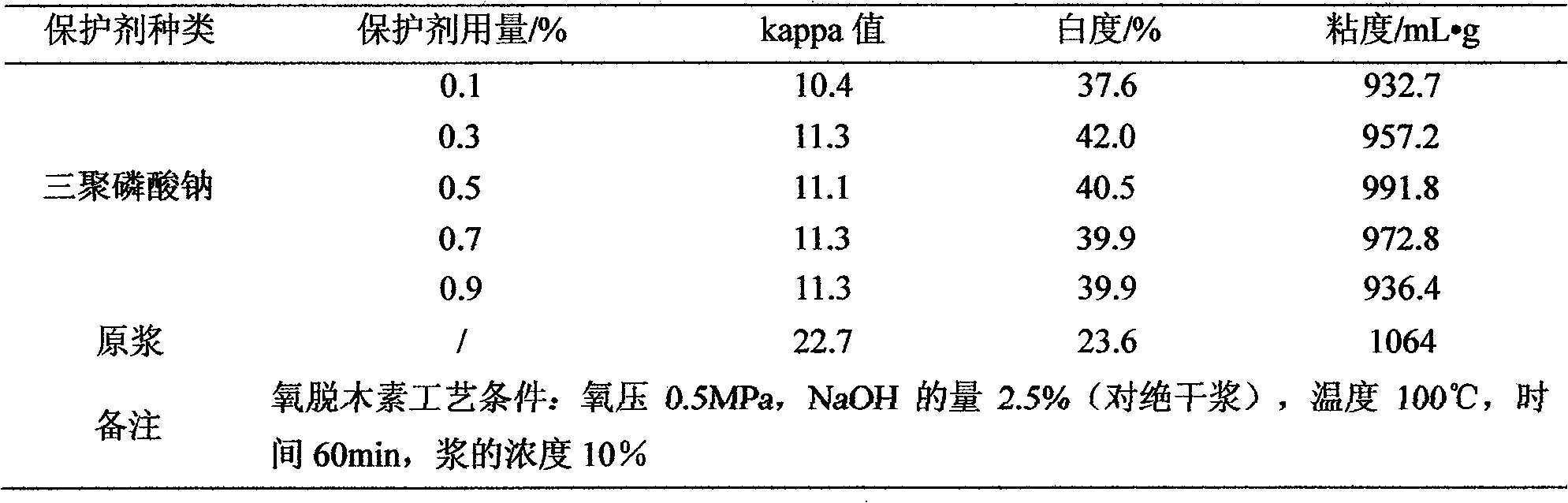

[0037] Effects of different protective agents on the effect of oxygen delignification

[0038] In order to find a suitable protective agent to replace MgSO4, 8 different protective agents were selected for research. The oxygen delignification process steps and process conditions are as follows: Unbleached sulfate bamboo pulp with a pulp concentration of 10% is fed with oxygen pressure Oxygen at 0.5 MPa, add NaOH so that the amount of NaOH accounts for 2.5% (for absolute dry pulp), add a protective agent, the type and amount of the added protective agent are shown in Table 2 below, at a temperature of 100 ° C, the reaction time is 60 minutes, wash with water Remove the residue, and the measured results are shown in Table 2. The pulp of this example selects unbleached sulfate bamboo pulp for use, is taken from the product produced by Shaowu Zhongzhu Paper Industry.

[0039] Table 2 Effects of different protective agents on the effect of oxygen delignification

[0040]

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com