Papermaking stewing accessory ingredient and preparation method thereof

A cooking aid and a technology for preparation steps, which are applied in the field of cooking aids for papermaking, can solve the problems of long lignin decomposition and dissolution time, influence on pulp quality and yield, poor solubility, etc., and achieve good ecological safety and compatibility. Solubility, good anti-scaling effect, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

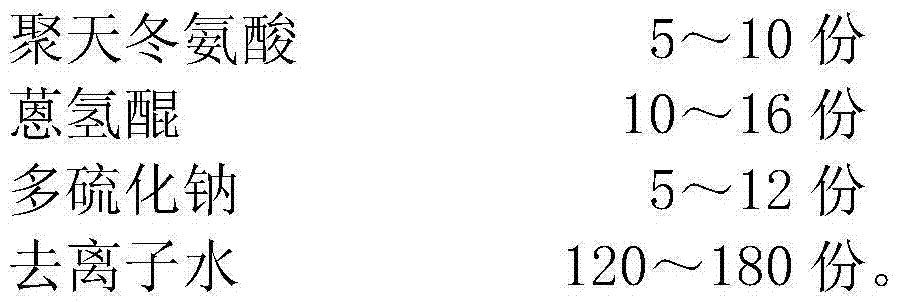

Image

Examples

Embodiment 1

[0028] (1) Take by weight 25 parts of sodium dodecyl benzene sulfonate, 30 parts of alkyl glycosides, 5 parts of polyaspartic acid, 10 parts of anthrahydroquinone, 5 parts of sodium polysulfide, deionized water 120 copies;

[0029] (2) get the deionized water of half of the proportion and add it into the reactor, raise the water temperature to 55 ℃, add polyaspartic acid while stirring, make it dissolve completely;

[0030] (3) add sodium dodecylbenzenesulfonate and alkyl glycosides again, stir and homogenize 30min;

[0031] (4) add sodium polysulfide, continue to stir and homogenize for 30min, then add the remaining amount of deionized water, and raise the temperature to 95°C;

[0032] (5) Finally, add anthrahydroquinone, keep the temperature for 20 minutes, stir and homogenize for 35 minutes, and cool to room temperature.

Embodiment 2

[0034] (1) take by weight 28 parts of sodium dodecyl benzene sulfonate, 25 parts of alkyl glycosides, 6 parts of polyaspartic acid, 12 parts of anthrahydroquinone, 7 parts of sodium polysulfide, deionized water 140 copies;

[0035] (2) get the deionized water of half of the proportion and add it to the reactor, raise the water temperature to 58 ℃, add polyaspartic acid while stirring, and make it dissolve completely;

[0036] (3) add sodium dodecyl benzene sulfonate and alkyl glycoside again, stir and homogenize 33min;

[0037] (4) add sodium polysulfide, continue to stir and homogenize for 28min, then add the remaining amount of deionized water, and raise the temperature to 98°C;

[0038] (5) Finally, add anthrahydroquinone, keep the temperature for 23 minutes, stir and homogenize for 33 minutes, and cool to room temperature.

Embodiment 3

[0040] (1) Take by weight 30 parts of sodium dodecylbenzene sulfonate, 23 parts of alkyl glycosides, 7 parts of polyaspartic acid, 13 parts of anthrahydroquinone, 8 parts of sodium polysulfide, deionized water 150 copies;

[0041] (2) get the deionized water of half of the proportion and add it into the reactor, raise the water temperature to 60 ℃, add polyaspartic acid while stirring, and make it dissolve completely;

[0042] (3) add sodium dodecylbenzenesulfonate and alkyl glycosides again, stir and homogenize 35min;

[0043] (4) add sodium polysulfide, continue to stir and homogenize for 25min, then add the remaining amount of deionized water, and raise the temperature to 100°C;

[0044] (5) Finally, add anthrahydroquinone, keep the temperature for 25 minutes, stir and homogenize for 30 minutes, and cool to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com