Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Low adhesiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Film for metal film transfer, method for transferring metal film and method for manufacturing circuit board

InactiveUS20100040874A1Good transferabilityUniform transferLamination ancillary operationsFilm/foil adhesivesCellulosePolymer science

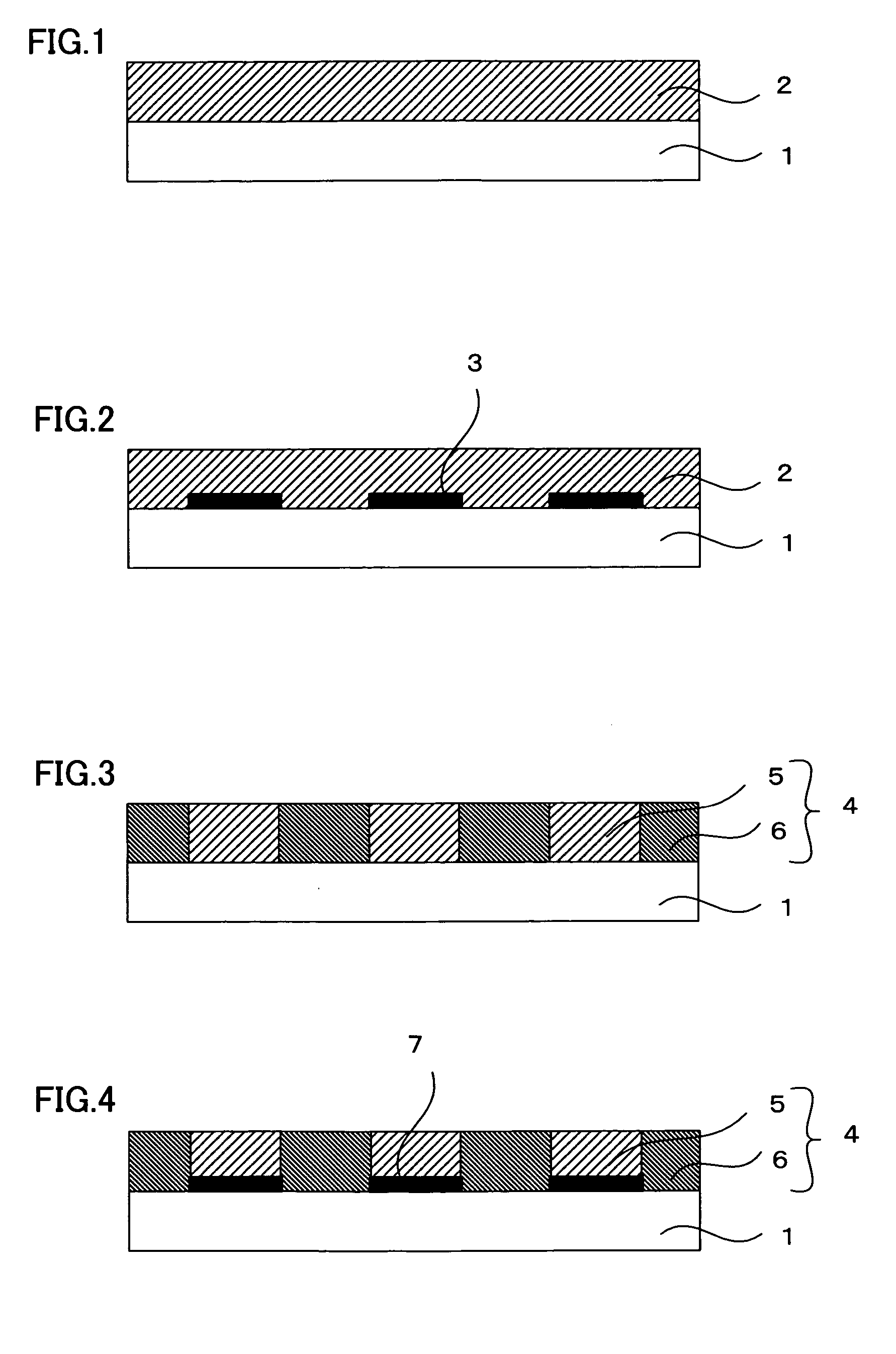

Films for metal film transfer, which contain (a) a support layer, (b) a release layer formed on the support layer, which is comprised of one or more kinds of water-soluble polymers selected from a water-soluble cellulose resin, a water-soluble polyester resin, and a water-soluble acrylic resin, and (c) a metal film layer formed on the release layer, show superior transferability of the metal film layer. Such films are useful for efficiently producing circuit boards by laminating the film for metal film transfer on a curable resin composition layer on a substrate such that the metal film layer is in contact with a surface of the curable resin composition layer, curing the curable resin composition layer, detaching the support layer, and removing the release layer on the metal film layer by dissolving the release layer in an aqueous solution.

Owner:AJINOMOTO CO INC

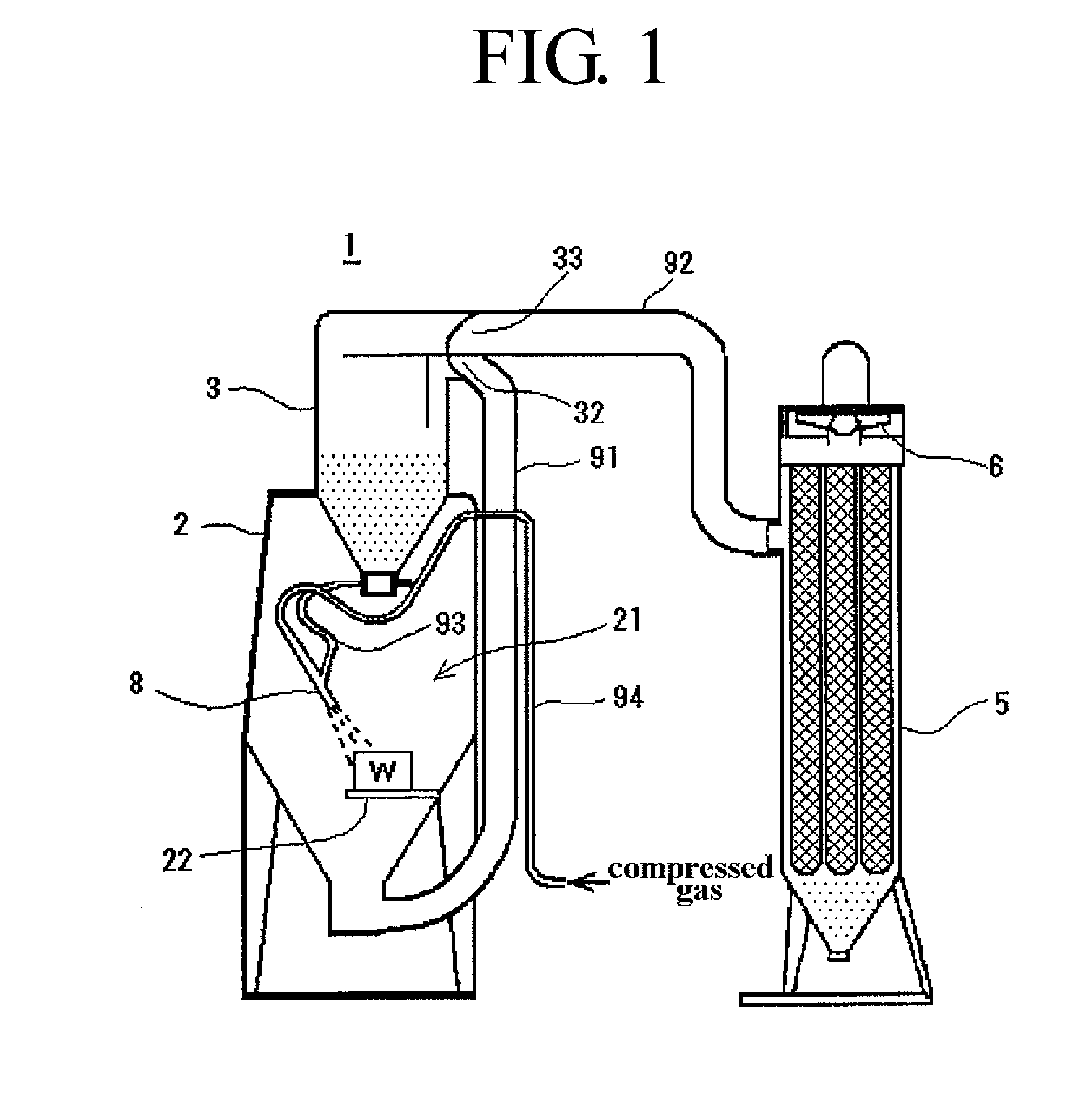

Blasting method and blasting machine

ActiveUS20090130959A1Maintaining cutting forceEasy to carryGrinding feed controlAbrasive feedersEngineeringAirflow

In blasting with an abrasive containing liquid to confer elasticity, the abrasive from which liquid evaporates in the course of continuance use is uniformly supplied with liquid. Liquid for swelling an elastic abrasive is sprayed in an air flow for transporting the abrasive in a blasting machine 1 including an abrasive-recovery duct 91 communicating between a bottom of a cabinet 2 and an abrasive-recovery tank 3, the abrasive-recovery tank 3, a compressed gas before being introduced into a blasting gun 8, and so forth. Since the abrasive being transported in the air flow is separated into individual particles, each abrasive can be uniformly supplied with liquid.

Owner:FUJI MFG CO LTD

Patterning substrate and cell culture substrate

InactiveUS20050186674A1Improve adhesionWell formedImmobilised enzymesSemiconductor/solid-state device manufacturingAdhesion processCell adhesion

The present invention intends primarily to provide such as a cell culture patterning substrate that is used to adhere a cell in a highly precise pattern on a base material to culture and a cell culture substrate on which a cell is adhered in a high precision pattern. In order to achieve the above-mentioned object, the present invention provides a patterning substrate having a base material and a cell culture patterning layer that is formed on the base material and has at least a photocatalyst and a cell adhesive material that has the adhesiveness with the cell and is decomposed or modified owing to an action of the photocatalyst in combination with energy irradiation.

Owner:DAI NIPPON PRINTING CO LTD

Inorganic particles as a dental material and a method of producing the same

InactiveUS20030089276A1Reduced pore volumeReduce adhesionPigmenting treatmentImpression capsInorganic particleSilicic acid

The present invention provides amorphous inorganic particles as a dental material comprising silica and inorganic oxide(s) other than silica and having high x-ray impermeability. The inorganic particles as a dental material comprise silica with the content in the range from 70 to 98 weight % and oxide(s) of one or more elements selected from the group consisting of Zr, Ti, La, Ba, Sr, Hf, Y, Zn, AL, and B, wherein 5 to 70 weight % of the silica is originated from an acidic silicic acid solution and 30 to 95 weight % of the silica is originated from a sol of silica. This inorganic particles as a dental material have average particle diameter in the range from 1 to 10 mum, specific surface area in the range from 50 to 350 m2 / g, pore volume in the range from 0.05 to 0.5 ml / g, amorphous crystallinity as observed by x-ray diffraction, and the refractive index in the range from 1.47 to 1.60.

Owner:JGC CATALYSTS & CHEM LTD

Patch

ActiveUS20050175676A1Improve skinSkin permeabilityOrganic active ingredientsNervous disorderPolyesterSurface roughness

The present invention relates to a patch which is free from any migration of a drug into a substrate and has favorable anchoring properties between the substrate and a adhesive layer, in which the drug-containing adhesive layer firmly adheres onto the substrate and which gives no adhesive residue when applied to the skin and then peeled off. Namely, a patch comprising a substrate made of a polyester-based film and a drug-containing adhesive layer laminated thereon wherein the surface roughness of the polyester-based film surface in the side in contact with the adhesive layer is from 0.05 to 0.8 μmRa is provided.

Owner:HISAMITSU PHARM CO INC

Polymide film and process for producing polyimide film

InactiveUS20120156482A1Improve adhesionIncrease heatPrinted circuit aspectsPrinted circuit manufactureCarboxylic acidPolyimide membrane

A polyimide film, which is produced by the reaction of a tetracarboxylic acid component comprising 3,3′,4,4′-biphenyltetracarboxylic dianhydride as the main component and a diamine component comprising p-phenylenediamine as the main component, is heated at a temperature of from 460° C. to 550° C., and then water or an alkaline aqueous solution is sprayed on a surface of the polyimide film for surface treatment, thereby improving adhesiveness, while maintaining the excellent properties inherent in the polyimide film.

Owner:UBE IND LTD

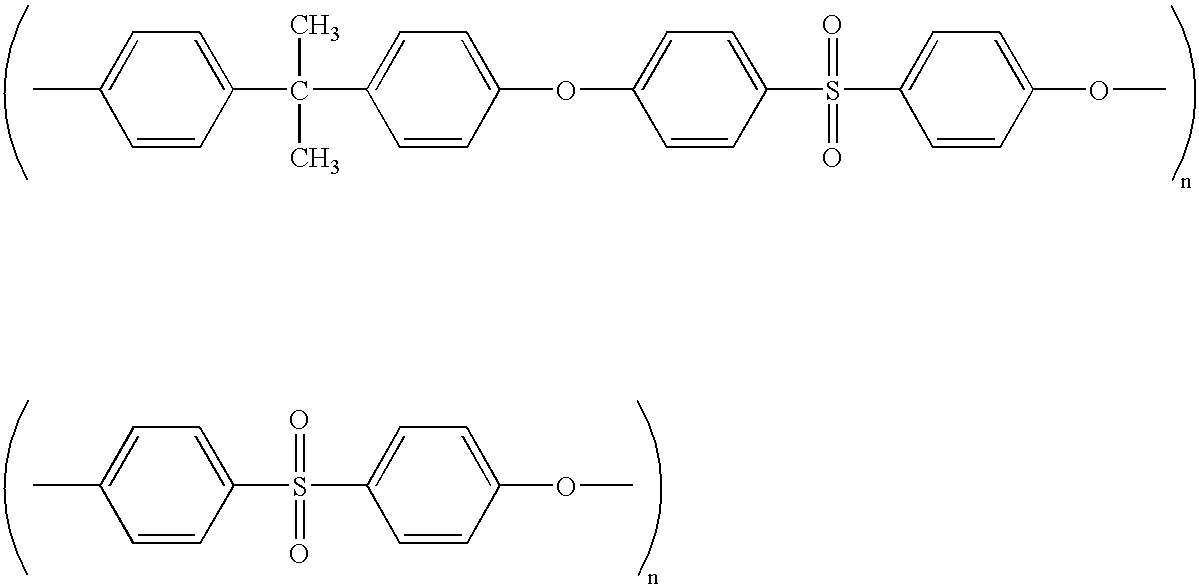

Adhesive composition, film-like adhesive, adhesive sheet, circuit connection structure, method for connecting circuit members, use of adhesive composition, use of film-like adhesive and use of adhesive sheet

InactiveUS20130140083A1Improve adhesion strengthLow heat resistanceConductive materialMacromolecular adhesive additivesSilicon particleEngineering

An adhesive composition for bonding a first circuit member including a first circuit electrode formed on a first circuit substrate and a second circuit member including a second circuit electrode formed on a second circuit substrate, the first circuit electrode and the second circuit electrode being electrically connected, wherein at least one substrate among the first circuit substrate and the second circuit substrate includes a thermoplastic resin having a glass transition temperature of not more than 200° C. The adhesive composition contains core-shell type silicon particles having a core layer and a shell layer provided for coating the core layer.

Owner:HITACHI CHEM CO LTD

Composite material and resin mold

InactiveUS20050154113A1Improve wear resistanceExcellent unwettability against the fluid resinCoatingsCeramic shaping liningsWear resistanceMaterials science

The present invention relates to a composite material used for a resin mold for forming hardened resin by hardening fluid resin. The composite material comprises a first material having excellent wear resistance against the fluid resin and a second material having excellent unwettability against the fluid resin. The resin mold comprises a substrate of the first material, a large number of pores each provided to form an opening on a surface of the substrate opposite to the fluid resin and a film of the second material formed along the inner wall surface of each pore at least around the opening. Each of the large number of pores is a communicating hole connecting the surface opposite to the fluid resin and the remaining surface with each other. Therefore, releasability between a mold surface and the hardened resin and wear resistance of the composite material against the fluid resin can be improved.

Owner:TOWA +1

Steel sheet for hot press-forming, method for manufacturing the same, and method for producing hot press-formed parts using the same

ActiveUS20150027596A1Improve reliabilityExcellent paint adhesivenessHot-dipping/immersion processesPretreated surfacesSheet steelMaterial Perforation

The invention provides a steel sheet for hot press-forming that can reliably give hot press-formed parts having excellent paint adhesiveness, perforation corrosion resistance and joint corrosion resistance, and also provides a method for manufacturing the steel sheet for hot press-forming, and a method for producing hot press-formed parts using the steel sheet for hot press-forming. The steel sheet for hot press-forming includes a base steel sheet and a Zn-based coating layer with a mass of coating of 10 to 90 g / m2 on the base steel sheet, wherein the average ferrite grain diameter in the surface microstructure of the base steel sheet is not more than 20 μm.

Owner:JFE STEEL CORP

Hydrophilic material and process for producing the same

InactiveUS20040247682A1Material removalIncrease surface areaPowder deliverySemi-permeable membranesHydrophilePlatelet

The present invention relates to a hydrophilic substance production method characterized in that polyvinylpyrrolidone-containing material wetted with an aqueous solution of a cationic polymer is treated with radiation. The invention makes it possible to produce material for blood treatment that prevents adsorption of blood platelets.

Owner:TORAY IND INC

Electric contact member

ActiveUS20110214900A1Low adhesivenessDifficult to obtainNon-insulated conductorsElectrical measurement instrument detailsCarbon filmElectricity

Provided is an electric contact member which reduces, to the utmost, peel-off of a carbon film that is caused at the time of use of the electric contact member having at least an edge to keep stable electric contact over a long period of time. Disclosed is an electric contact member which repeatedly contacts with a device under test at a tip part of the electric contact member in which the tip part has an edge, the electric contact member comprising: a base material; an underlying layer comprising Au, Au alloy, Pd or Pd alloy, which is formed on a surface of the base material of the tip part; an intermediate layer which is formed on a surface of the underlying layer; and a carbon film comprising at least one of a metal and a carbide thereof which is formed on a surface of the intermediate layer, wherein the intermediate layer has a lamination structure comprising: an inner layer comprising Ni or Ni alloy; and an outer layer comprising at least one of Cr, Cr alloy, W and W alloy.

Owner:KOBE STEEL LTD +1

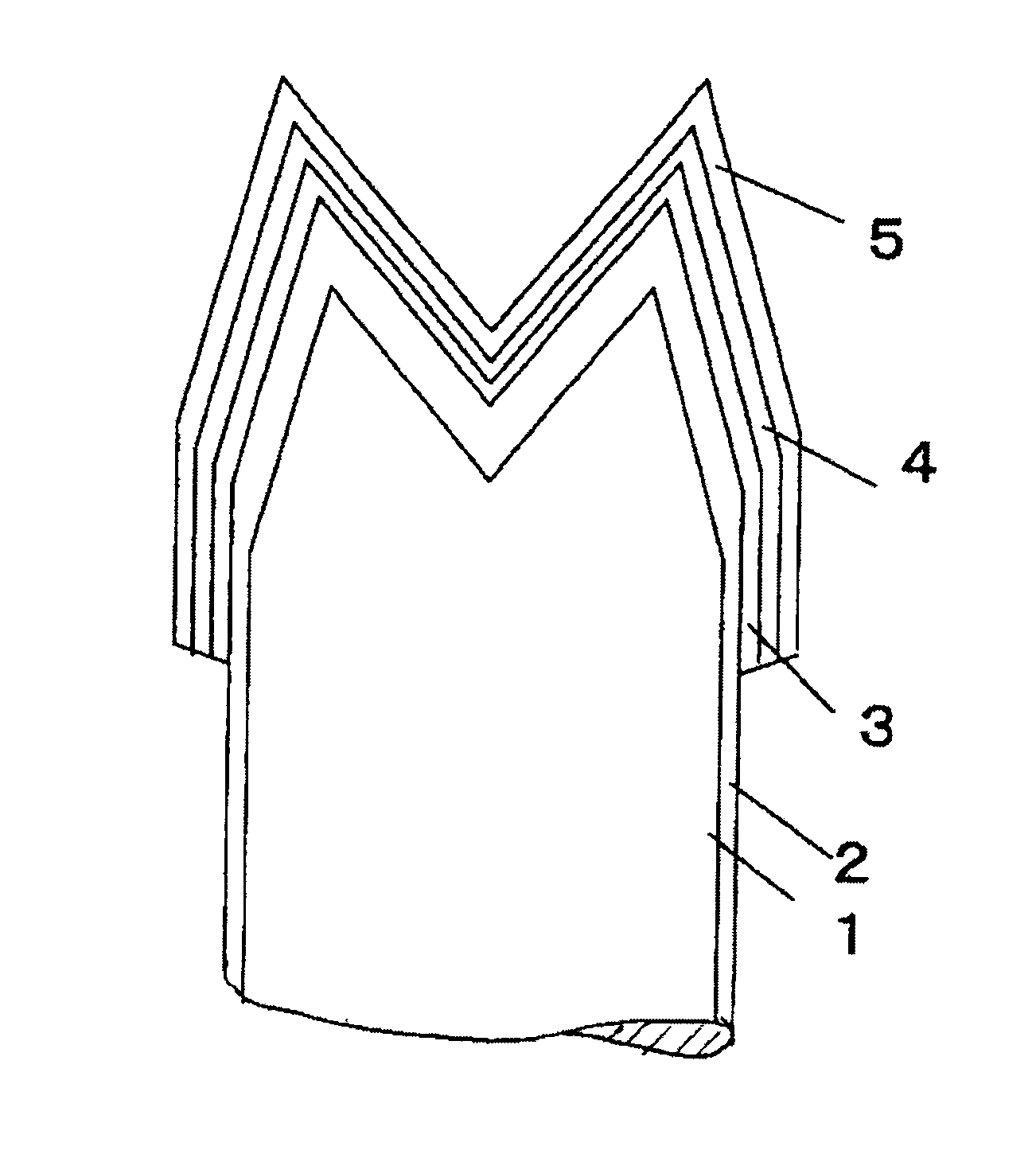

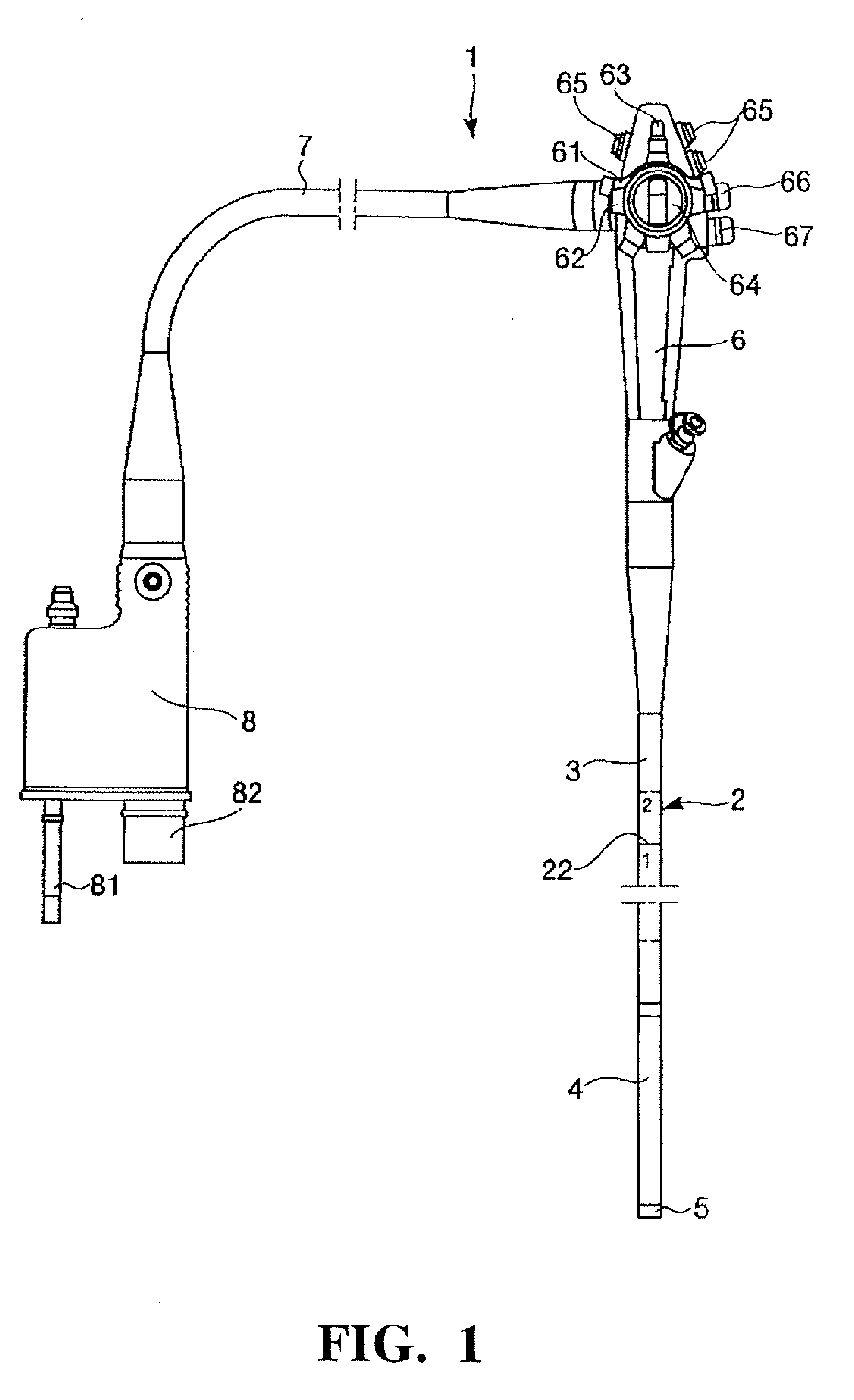

Insertion section flexible tube and an endoscope equipped with the flexible tube

InactiveUS20070156115A1Improve reliabilityIncrease stickinessEndoscopesCatheterEndoscopeBiomedical engineering

A insertion section flexible tube for use in an insertion section of an endoscope includes a flexible tube portion which includes a first core member and a first outer cover which covers the first core member, a bendable portion which includes a second core member and a second outer cover which covers the second core member, the bendable portion having a base end coupled to a tip end of the flexible tube portion; a tightening string for tightening a tip end part of the first outer cover and a base end part of the second outer cover from the outer surfaces thereof; and an adhesive agent for covering and securing the tightening string, wherein at least an outer surface and its vicinity of the first outer cover is formed of a constituent material having low adhesiveness with the adhesive agent, and a region of the outer cover which is covered by the adhesive agent has been subjected to a primary treatment with a primary treatment agent for enhancing the adhesiveness of the outer cover with respect to the adhesive agent.

Owner:ASAHI KOGAKU KOGYO KK

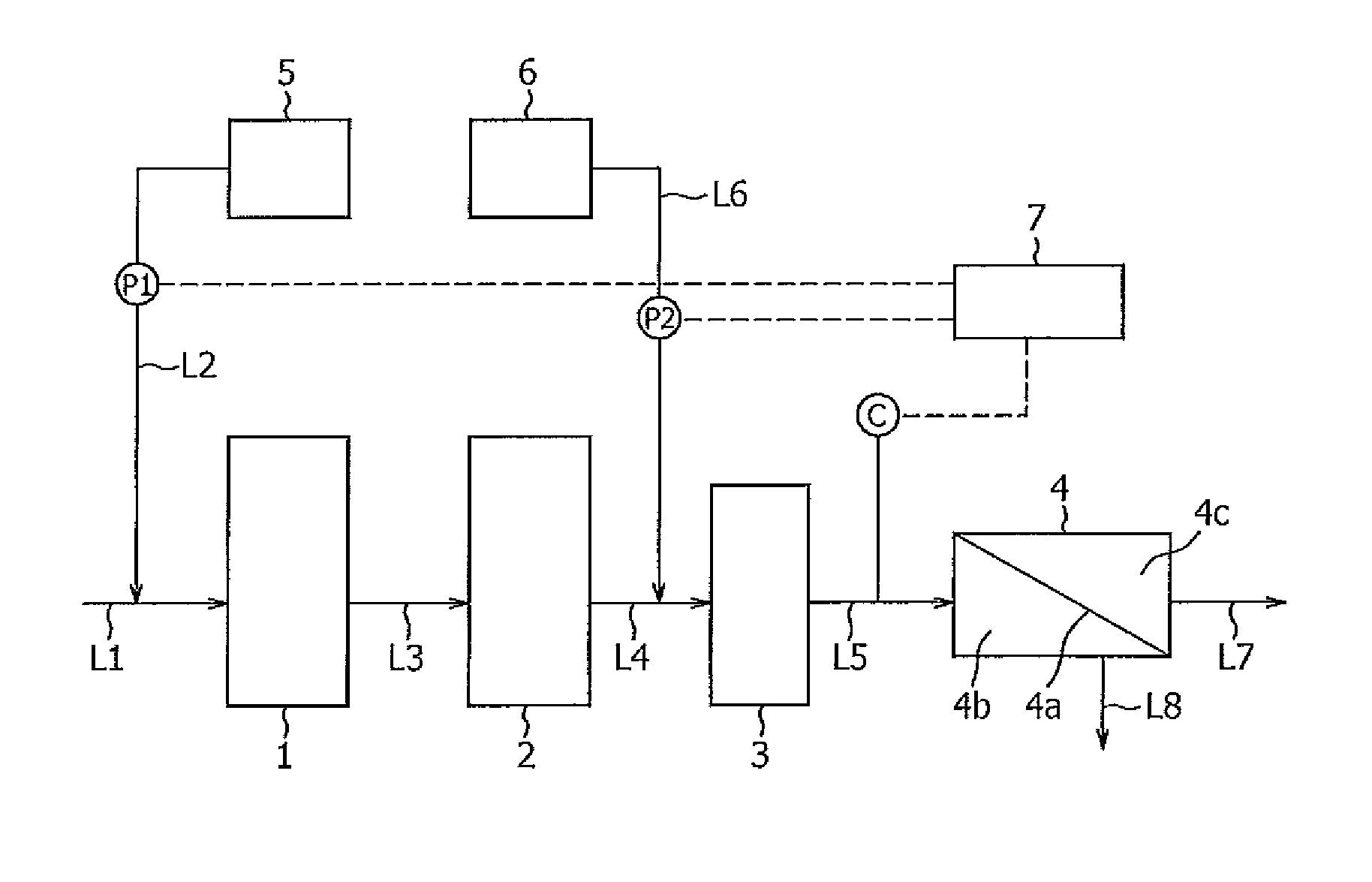

Method of membrane separation

ActiveUS20140124442A1Avoid cloggingLow adhesivenessWater treatment parameter controlMembranesWater qualityBiological membrane

Clogging of membrane by slime adhesion is efficiently prevented and stable treatment can be carried out for a long period of time at a low cost by a small amount of chemicals without the membrane deterioration and trihalomethane formation even if applied to the water having a large number of viable cell counts and having water quality of harsh. The method comprises supplying water to be treated to a membrane separation apparatus 4, adding intermittently to the water to be treated a combined chlorine agent comprising sulfamic compound, and repeating a non-addition feeding period in which water to be treated is supplied for 6-120 hours without addition of combined chlorine agent, and an intermittent addition feeding period in which water to be treated is supplied for 0.5-40 hours under addition of a combined chlorine agent at biofilm exfoliating concentration in an early stage of biofilm formation during the non-addition feeding period, wherein viable cell count (log CFU / mL) of water to be treated is 3 or more, and the concentration of the combined chlorine agent in the water in the intermittent addition feeding period is 0.5-20 mg / L as total chlorine, and additive amount of the combined chlorine agent added in the intermittent addition feeding period is the amount in which R represented by the following Formula [4] is 3 or more.R=(Intermittent addition feeding period (h)×[1000×Intermittent addition concentration (mg-Cl / L)]2.5 / (Non-addition feeding period (h)3.0×10log CFU / mL) [4]

Owner:KURITA WATER INDUSTRIES LTD

Acrylic pressure-sensitive adhesive composition and acrylic pressure-sensitive adhesive tape

InactiveUS8299182B2Reduce polarityReduce temperature riseFilm/foil adhesivesMacromolecular adhesive additivesGlass transitionAcrylic polymer

A single-layered acrylic pressure-sensitive adhesive tape having a pressure-sensitive adhesive layer formed of an acrylic pressure-sensitive composition. The acrylic pressure-sensitive adhesive composition contains an acrylic polymer (A) and a (meth)acrylic polymer (B) having glass transition temperature (Tg) such that Tg≦45° C. and a mass average molecular weight (Mw) is such that 1500≦Mw≦4000.

Owner:NITTO DENKO CORP

Ink jet recording head unit and production process thereof

InactiveUS20090066771A1Improve hydrophobicityReduce hydrophobicityPrintingEngineeringElectrical and Electronics engineering

In an ink jet recording head unit, on a surface of an ejection outlet surface of an ink jet recording head, a tape is applied so that a portion at the tape with a relatively high adhesiveness corresponds to an area of the ejection outlet surface with a relatively high hydrophobicity and a portion of the tape with a relatively low adhesiveness corresponds to an area of the ejection outlet surface with a relatively low hydrophobicity.

Owner:CANON KK

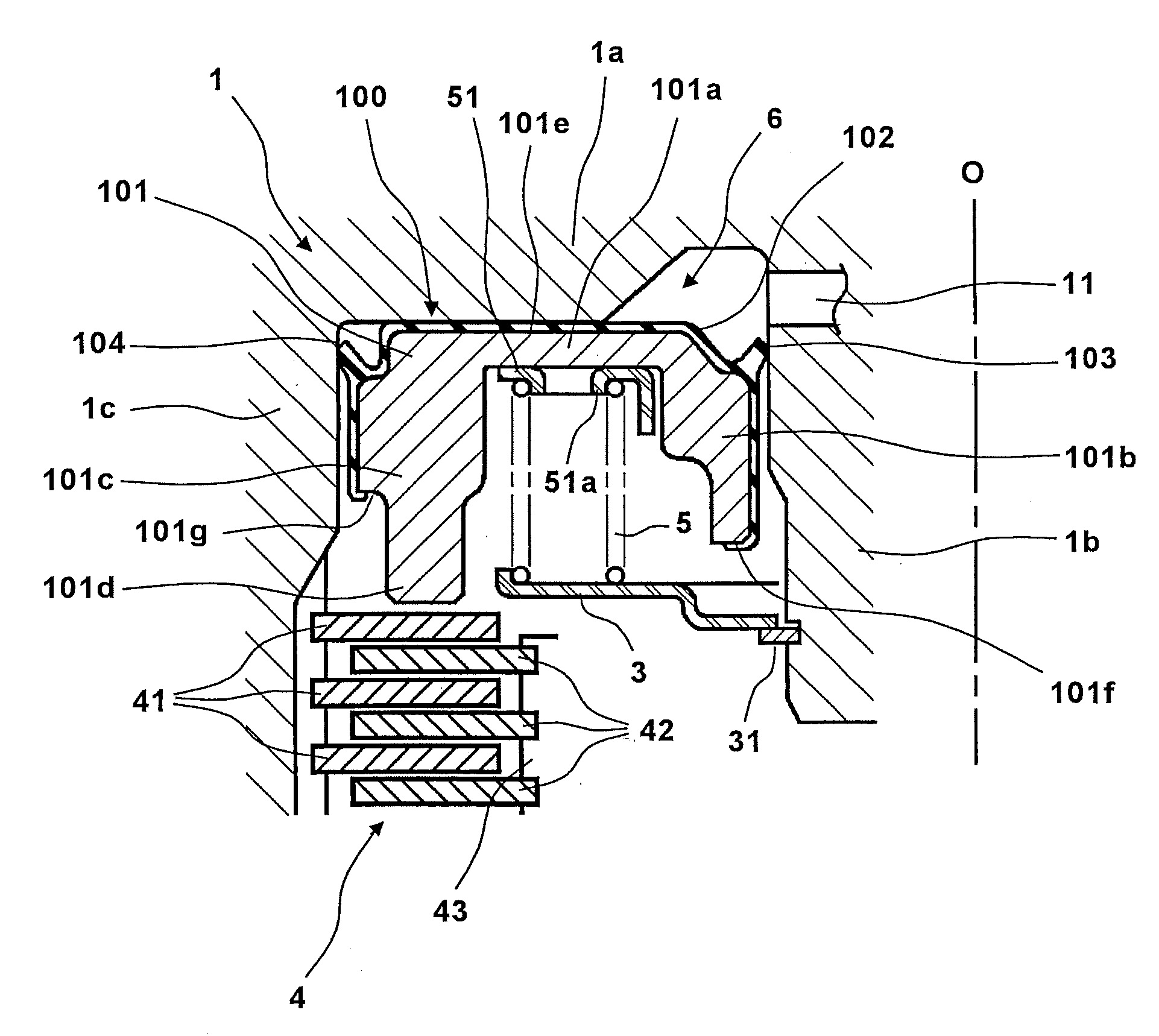

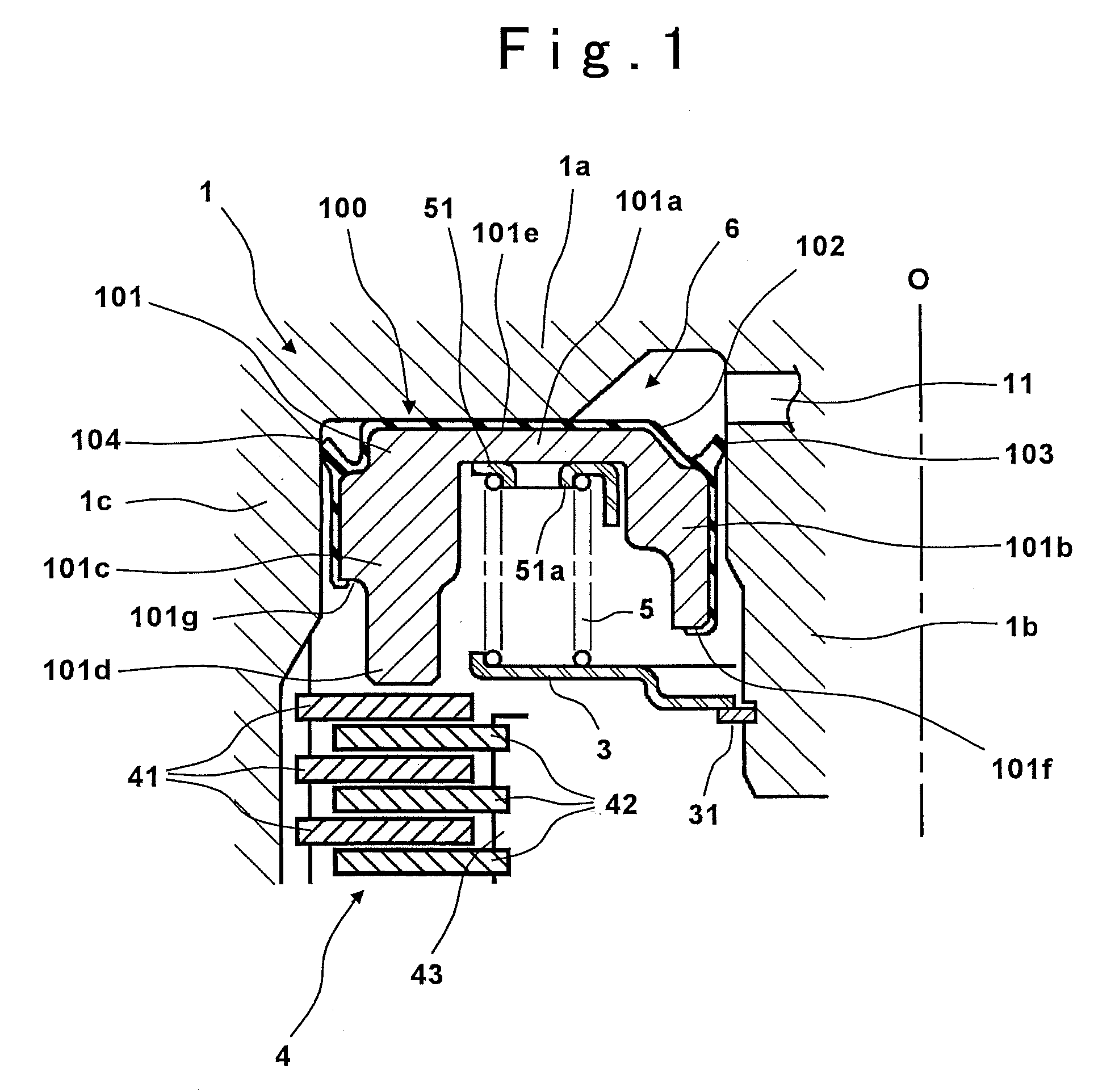

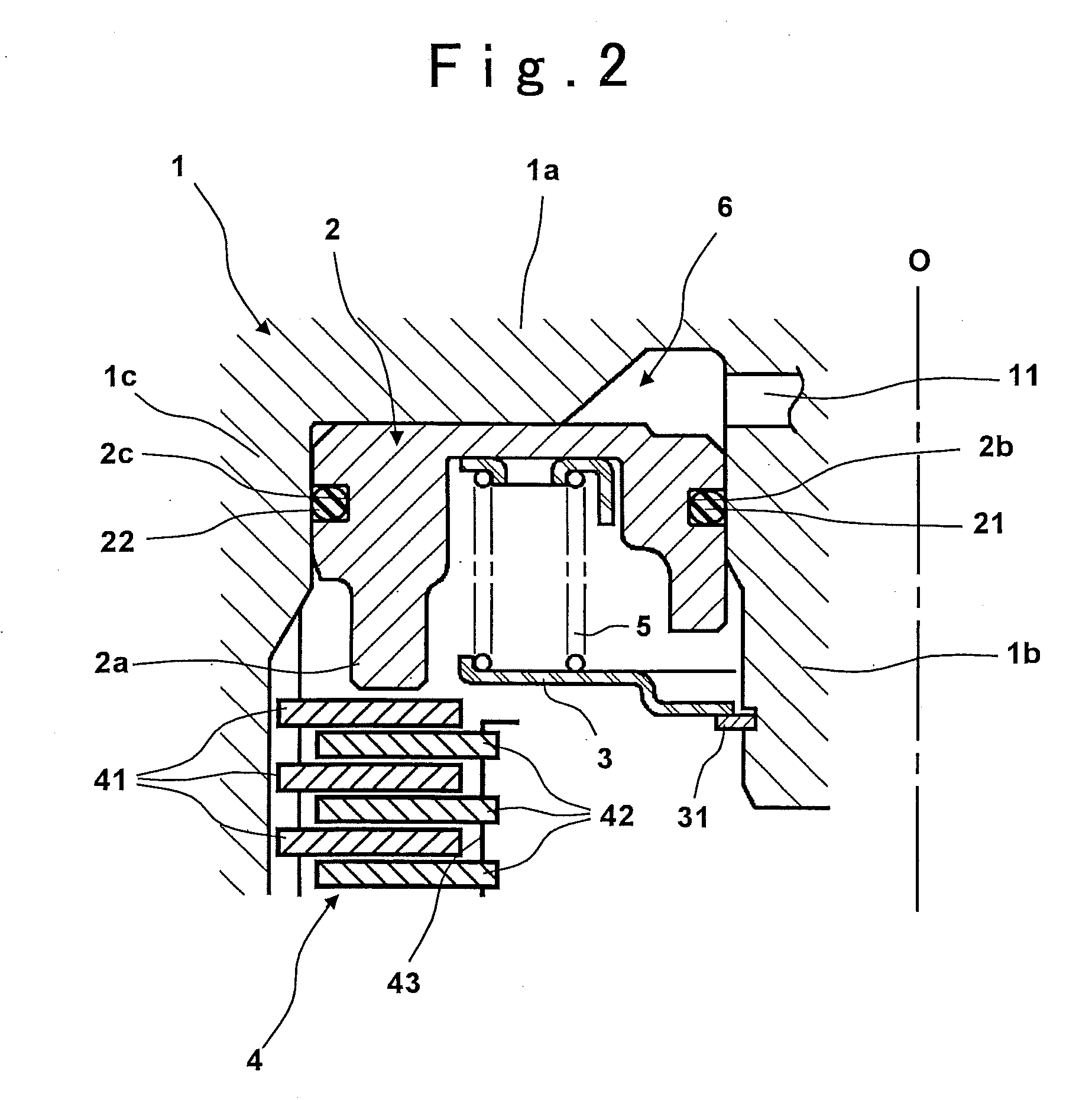

Aluminum piston with an incorporated seal

InactiveUS20080276799A1Reduce weightWide design flexibilityEngine sealsPlungersProduction rateDie casting

In order to reduce product weight, enhance design freedom, reduce production cost and improve productivity, an aluminum piston with an incorporated seal is provided, the piston comprising an aluminum die-cast piston main body (101) arranged to be axially movable in a clutch cylinder (1), a film (102) which is made of a rubber-like elastic material and covers a region from a pressure-receiving end surface (101e) of the piston main body (101) to surfaces (101f, 101g) facing toward the opposite side to said pressure-receiving end surface (101e) through inner and outer peripheral surfaces thereof, and seal lips (103, 104) formed on the film (102) at inner and outer peripheral portions of the piston main body (101) so as to be slidably in close contact with the clutch cylinder (1).

Owner:NOK CORP

Method for vulcanization-adhering rubber composition to adherent of brass or plated with brass, reinforcing member for rubber article, rubber-reinforcing member composite and pneumatic tire

InactiveUS20090277559A1Improve heat resistanceImprove adhesionAdhesive processes with surface pretreatmentSpecial tyresVulcanizationPolymer science

This invention relates to a method for vulcanization-adhering a rubber composition to an adherent made from a brass or plated with a brass in the vulcanization adhesion between the rubber composition and the adherent made from the brass or plated with the brass by stably adhering a metal having a catalytic action to vulcanization adhesion reaction to the surface of the brass through a silane coupling agent as well as a reinforcing member for rubber article having an adhesion property to a coating rubber by subjecting a steel filament plated with a brass or a steel cord formed by twisting a plurality of such steel filaments to a surface treatment with a metal-containing silane coupling agent solution, and a rubber-reinforcing member composite and a pneumatic tire using such a reinforcing member for rubber article.

Owner:BRIDGESTONE CORP +1

Blasting method and blasting machine

ActiveUS8277277B2Eliminate variationUniform supplyGrinding feed controlAbrasive feedersEngineeringMechanical engineering

In blasting with an abrasive containing liquid to confer elasticity, the abrasive from which liquid evaporates in the course of continuance use is uniformly supplied with liquid. Liquid for swelling an elastic abrasive is sprayed in an air flow for transporting the abrasive in a blasting machine 1 including an abrasive-recovery duct 91 communicating between a bottom of a cabinet 2 and an abrasive-recovery tank 3, the abrasive-recovery tank 3, a compressed gas before being introduced into a blasting gun 8, and so forth. Since the abrasive being transported in the air flow is separated into individual particles, each abrasive can be uniformly supplied with liquid.

Owner:FUJI MFG CO LTD

Adhesive agent composition, adhesive sheet, and method for manufacturing semiconductor device

InactiveUS20160086908A1Reduce thicknessLow adhesivenessFilm/foil adhesivesSemiconductor/solid-state device detailsEpoxyDouble bond

An adhesive composition includes an acrylic polymer (A), a heat curable resin (B) having a reactive double bond group, and a filler (C) having a reactive double bond group on a surface thereof. The acrylic polymer (A) has a weight average molecular weight of 500,000 or more, and the heat curable resin (B) comprises an epoxy resin and a heat curing agent, in which at least one of the epoxy resin and the heat curing agent has the reactive double bond group.

Owner:LINTEC CORP

Polyester resin, hot melt adhesive, and hot melt adhesive solution

The polyester resin for a hot melt adhesive includes polycarboxylic acid residues and polyhydric alcohol residues. The polycarboxylic acid resides contain aliphatic polycarboxylic acid residues in a proportion within the range of 50 to 80 mol %. The polyhydric alcohol residues contain propylene glycol residues in a proportion within the range 5 to 60 mol %.

Owner:GOO CHEM IND

Cleaning method for coating systems

ActiveUS20110281026A1Low adhesivenessInhibition is effectiveVacuum evaporation coatingSputtering coatingPretreatment methodCoating system

The present invention relates to a pretreatment method to be applied to secondary surfaces in coating systems prior to coating. To this end, a non-stick coating is applied to the secondary surfaces, which can be easily detached from the secondary surfaces, even after coating material has been deposited thereon. In this way, the cleaning process of the coating system after the coating process is considerably simplified.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

Electrical contact member

ActiveUS20140091823A1Low adhesivenessReduce contact resistanceElectrical measurement instrument detailsVacuum evaporation coatingElectrical resistance and conductanceCarbon coating

Provided is an electrical contact member which is capable of maintaining stable conductivity over a long period of time, while achieving low adhesion to a test subject, in particular, an electrical contact member which is capable of maintaining stable electrical contact over a long period of time by suppressing increase in the contact resistance, while achieving low adhesion to a test subject even after repeated contact at high temperatures around 85° C. or after being left in the atmosphere for a long period of time. The present invention relates to an electrical contact member, which repeatedly comes into contact with a test subject, and wherein the surface of the electrical contact member, said surface coming into contact with the test subject, is configured of a carbon coating film that contains Pd.

Owner:KOBE STEEL LTD

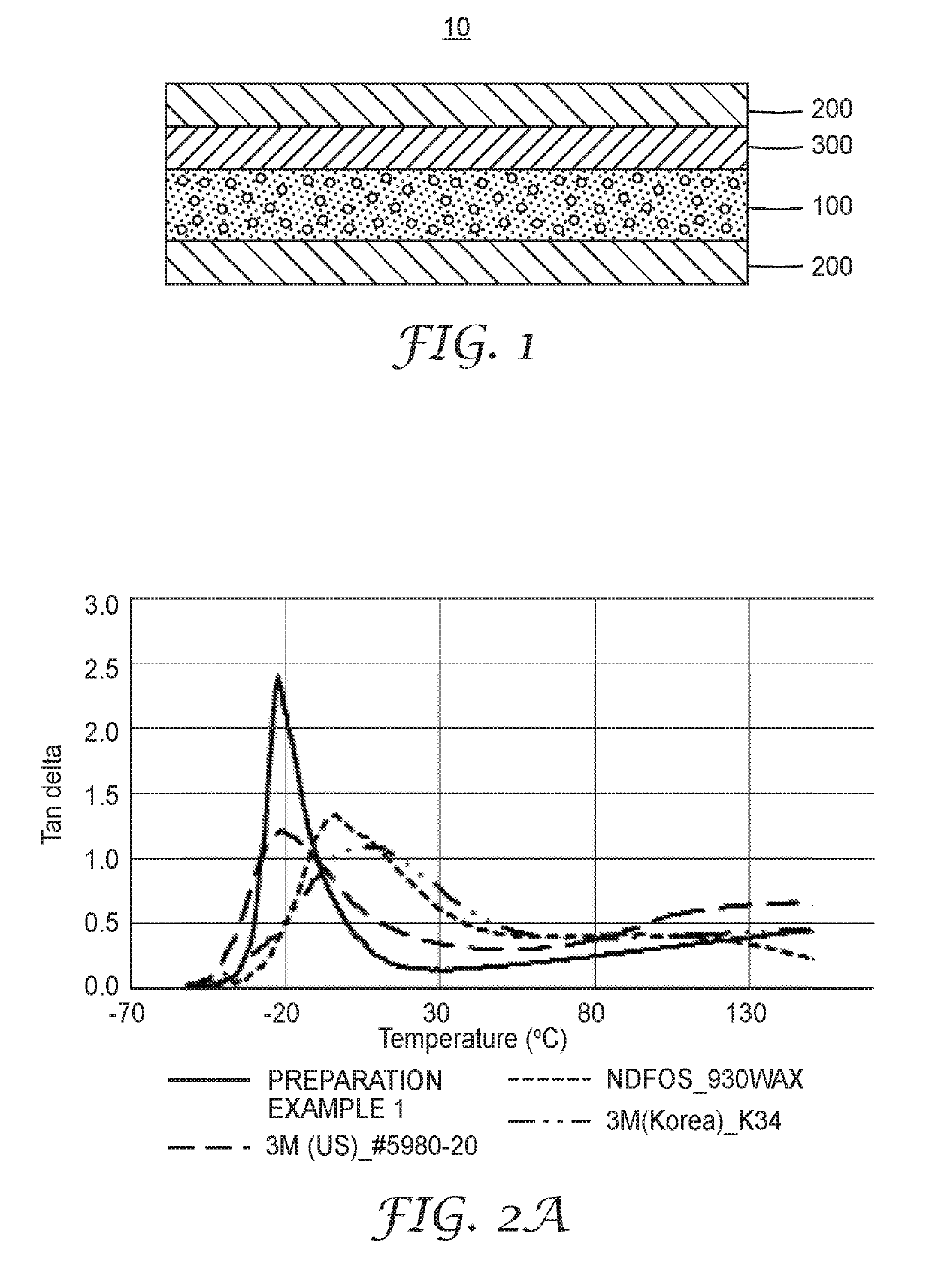

Acrylic rubber foam and double-sided adhesive tape comprising same

ActiveUS20190292411A1Improve adhesion strengthEasily applicable to processesFilm/foil adhesivesAdhesive articlesElastomerMicrosphere

The present invention relates to a double-sided adhesive tape used for applications including the attachment of front glass for mobile devices. A core layer of the double-sided adhesive tape is prepared by adding an acrylic elastomer free of carbon-carbon double bonds while being highly miscible with an acrylic resin to an acrylic monomer(s) and performing curing, and thus can improve the impact resistance of the final double-sided adhesive tape. Also, the core layer may take a form of foam due to the introduced filler such as glass bubbles or organic microspheres, and thus can further contribute to improving the impact resistance of the final double-sided adhesive tape.

Owner:3M INNOVATIVE PROPERTIES CO

Tile carpet

InactiveUS20150159324A1Raise the gradeLow adhesivenessLayered productsWoven fabricsAdhesiveEngineering

A carpet of a type to be used in such manner that square plate-like members having a predetermined size are laid over the floor, and more particularly, a tile carpet comprising a carpet body, a carpet base to which the carpet body is fixed, and a layer of non-hardening type adhesive arranged on the rear surface of the carpet base, characterized in that the non-hardening type adhesive layer of the tile carpet consists of a mixture of acrylic foaming resin and urethane resin hardening type adhesive and a ratio of mixing of urethane resin hardening type adhesive in the mixture is 10 to 30 weight %.

Owner:NIPPON JIYUUTAN

Composite material and resin mold

InactiveUS7407146B2Improve wear resistanceExcellent unwettability against the fluid resinCoatingsCeramic shaping liningsWear resistance

A composite material used for a resin mold for forming hardened resin by hardening fluid resin is provided. The composite material comprises a first material having excellent wear resistance against the fluid resin and a second material having excellent unwettability against the fluid resin. The resin mold comprises a substrate of the first material, a large number of pores each provided to form an opening on a surface of the substrate opposite to the fluid resin and a film of the second material formed along the inner wall surface of each pore at least around the opening. Each of the large number of pores is a communicating hole connecting the surface opposite to the fluid resin and the remaining surface with each other. Therefore, releasability between a mold surface and the hardened resin and wear resistance of the composite material against the fluid resin can be improved.

Owner:TOWA +1

Electric contact member

ActiveUS8410367B2Low adhesivenessReduced responseNon-insulated conductorsElectrical measurement instrument detailsCarbon filmInter layer

Owner:KOBE STEEL LTD +1

Patch with improved anchoring properties between a substrate and an adhesive

ActiveUS7754236B2Skin permeabilitySkin irritations tend to become largeOrganic active ingredientsNervous disorderPolyesterAdhesive

Owner:HISAMITSU PHARM CO INC

Steel sheet for hot press-forming, method for manufacturing the same, and method for producing hot press-formed parts using the same

ActiveUS10253386B2Low adhesivenessLow resistance to perforation corrosionHot-dipping/immersion processesFurnace typesMaterial PerforationCorrosion

The invention provides a steel sheet for hot press-forming that can reliably give hot press-formed parts having excellent paint adhesiveness, perforation corrosion resistance and joint corrosion resistance, and also provides a method for manufacturing the steel sheet for hot press-forming, and a method for producing hot press-formed parts using the steel sheet for hot press-forming. The steel sheet for hot press-forming includes a base steel sheet and a Zn-based coating layer with a mass of coating of 10 to 90 g / m2 on the base steel sheet, wherein the average ferrite grain diameter in the surface microstructure of the base steel sheet is not more than 20 μm.

Owner:JFE STEEL CORP

Polyimide film and process for producing polyimide film

InactiveUS9393720B2Improve adhesionIncrease heatInsulating substrate metal adhesion improvementPrinted circuit aspectsCarboxylic acidPolyimide membrane

A polyimide film, which is produced by the reaction of a tetracarboxylic acid component comprising 3,3′,4,4′-biphenyltetracarboxylic dianhydride as the main component and a diamine component comprising p-phenylenediamine as the main component, is heated at a temperature of from 460° C. to 550° C., and then water or an alkaline aqueous solution is sprayed on a surface of the polyimide film for surface treatment, thereby improving adhesiveness, while maintaining the excellent properties inherent in the polyimide film.

Owner:UBE IND LTD

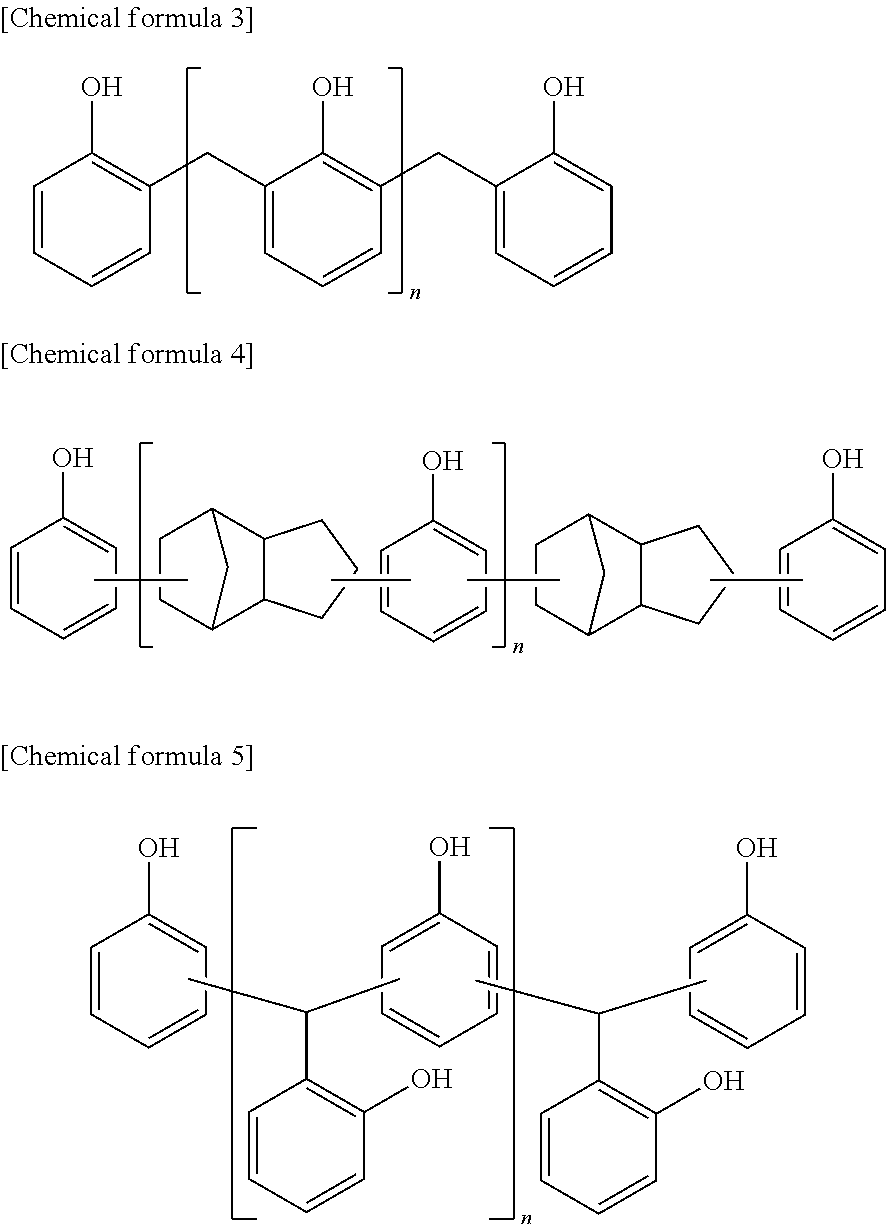

Adhesive aid composition

InactiveUS20070026227A1Improve adhesionImprove machinabilityInsulating substrate metal adhesion improvementSynthetic resin layered productsPolymer sciencePolyamide

The present invention provides an adhesive aid composition having excellent adhesive strength to polyimide films without decreasing mechanical properties and being useful in the field of electric materials. An adhesive aid composition of the present invention contains a phenolic hydroxyl group-containing polyamide and a solvent as essential components. The phenolic hydroxyl group-containing polyamide preferably has a segment represented by formula (1): (wherein R1 represents a divalent aromatic group, and n represents an average number of substituents and is a positive number of 1 to 4). The adhesive aid composition of the present invention is suitably used for bonding polyimide films.

Owner:NIPPON KAYAKU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com