Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "Large cooling range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

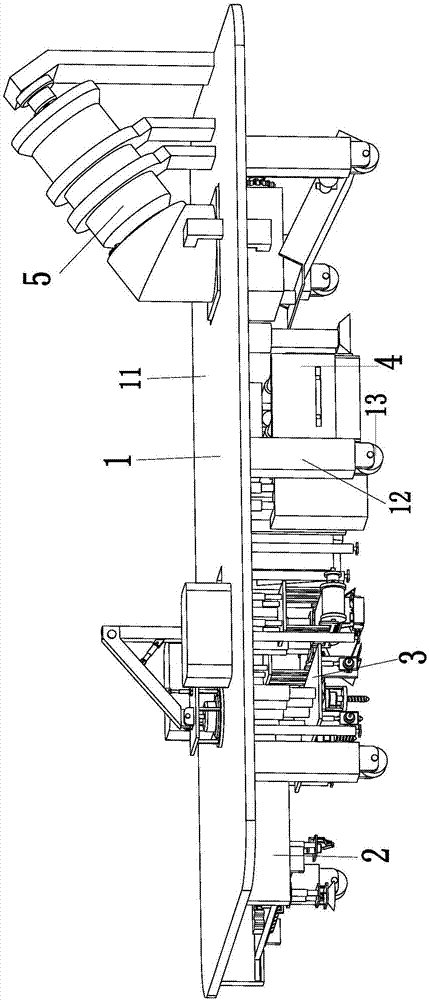

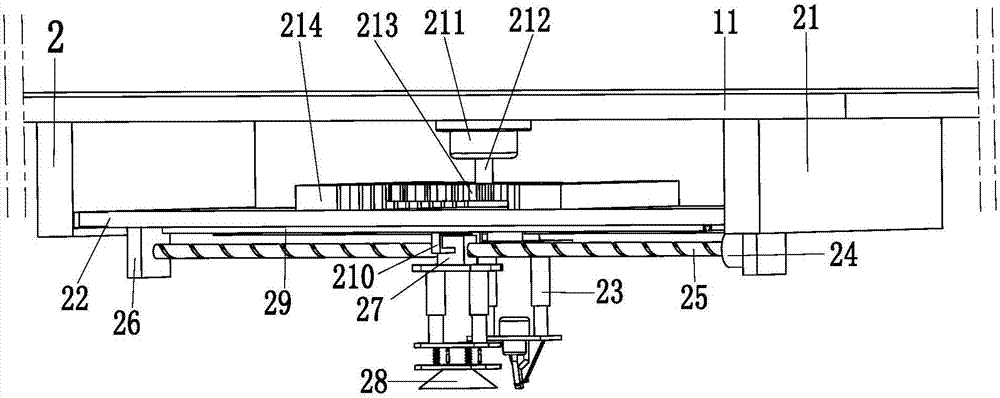

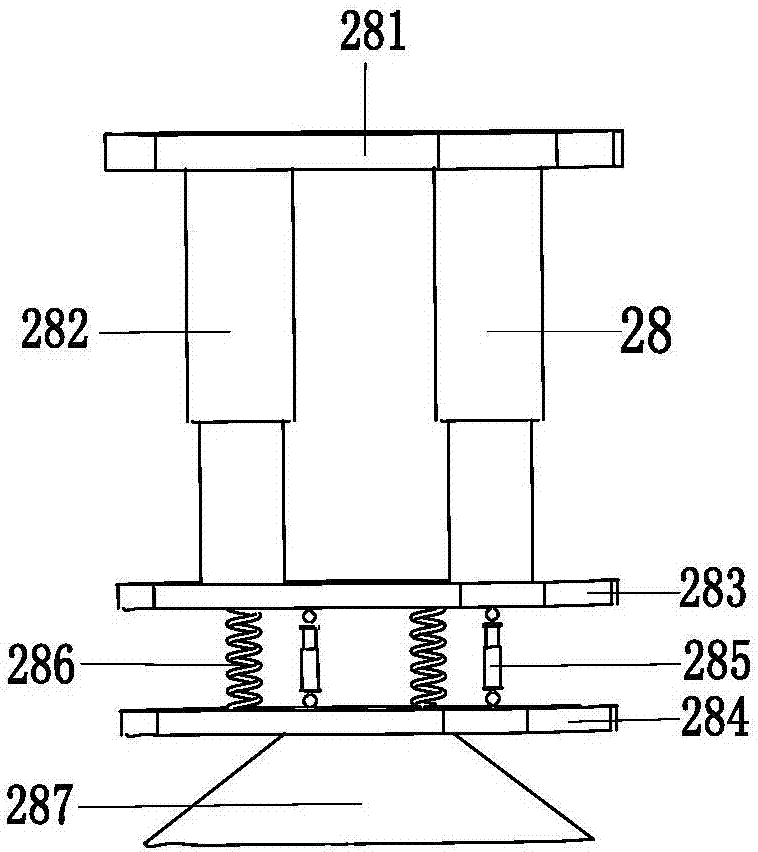

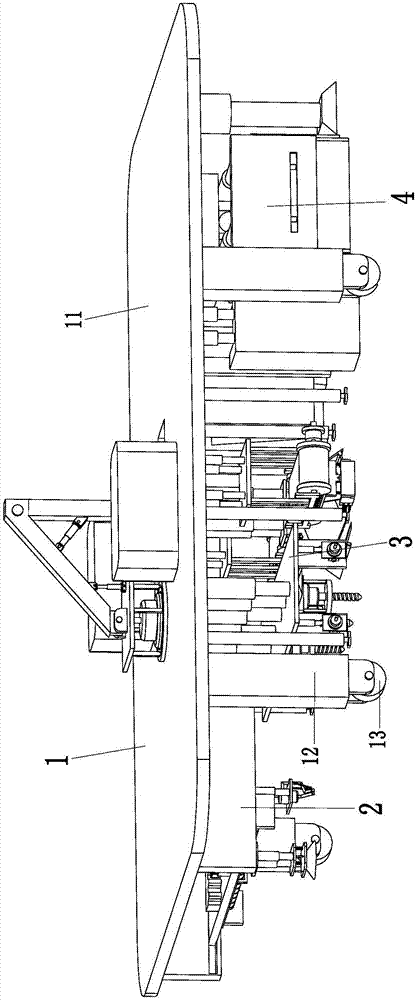

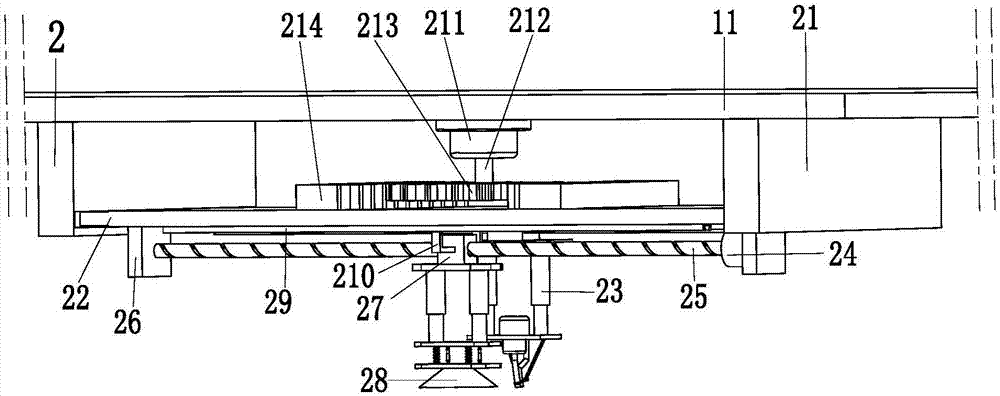

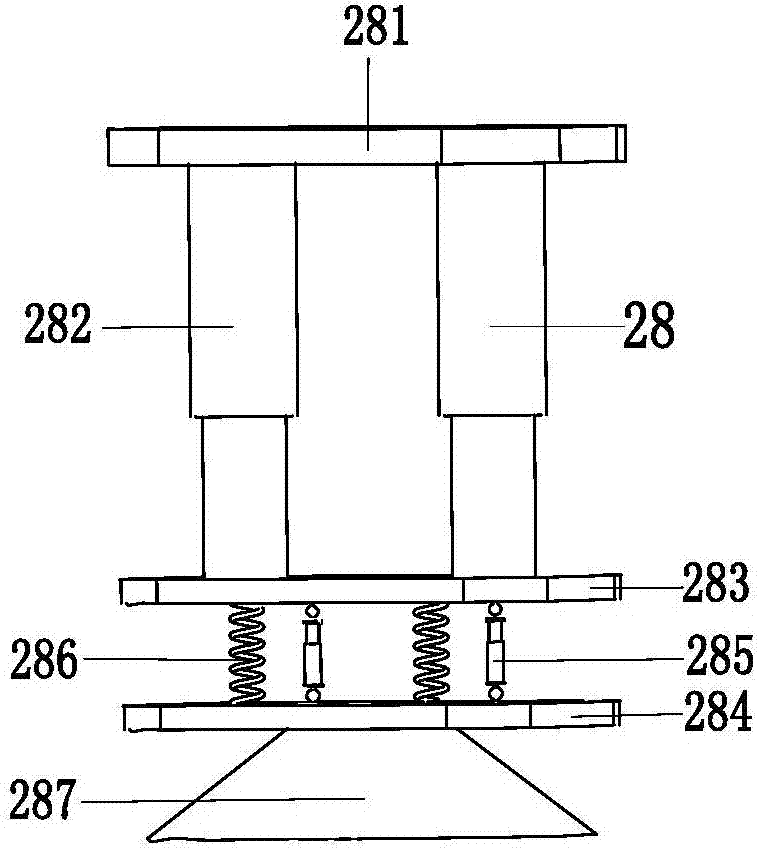

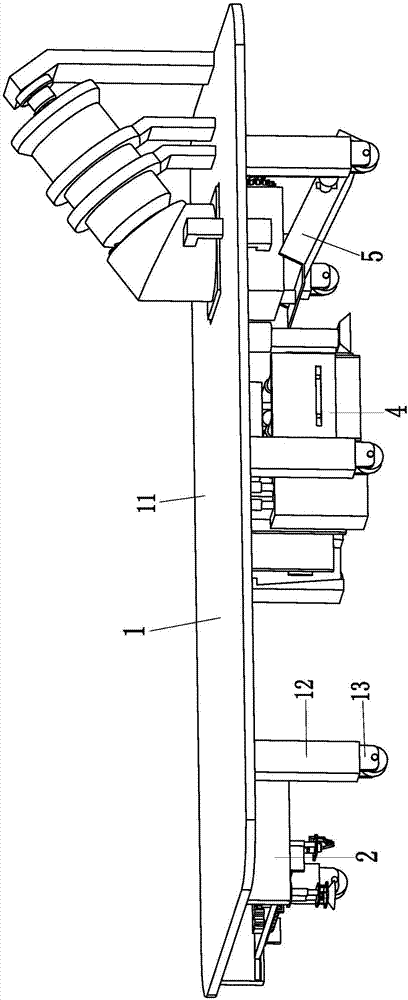

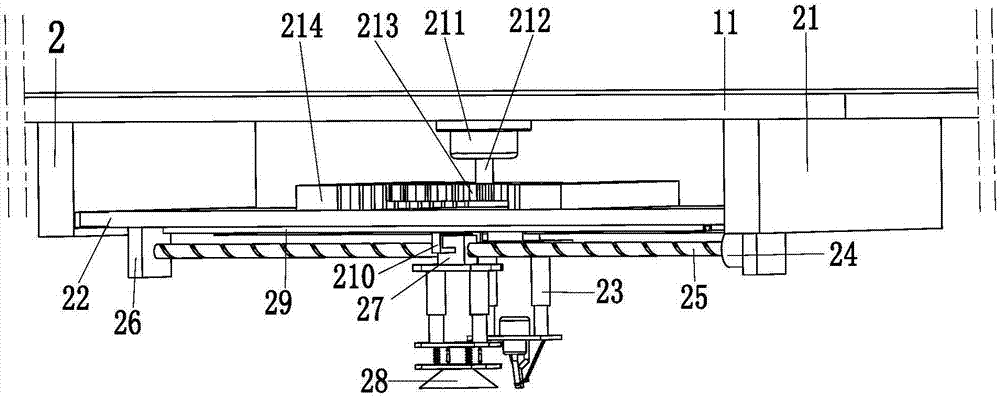

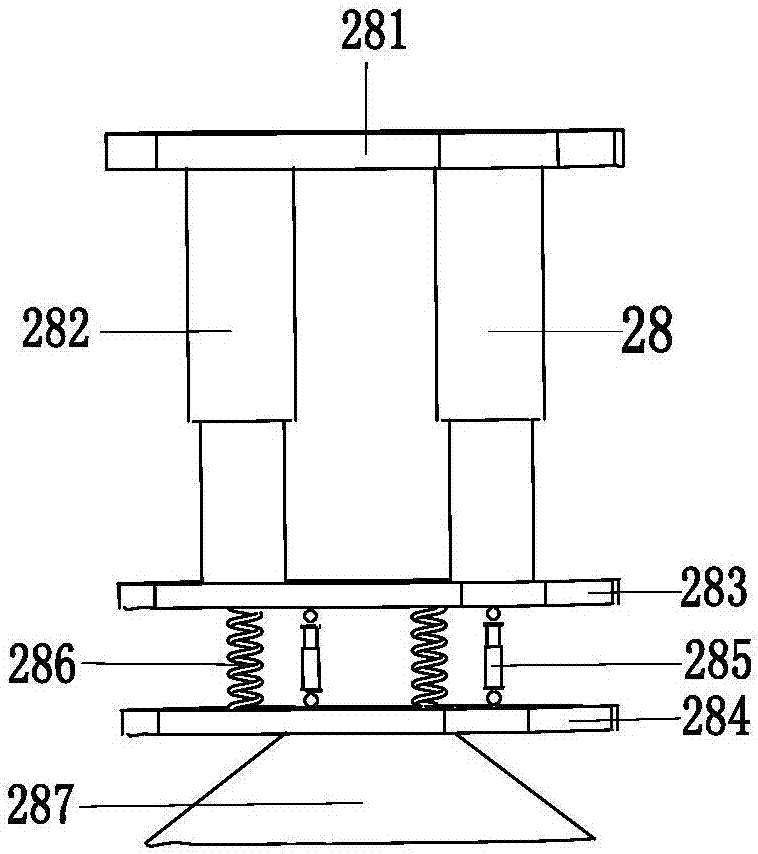

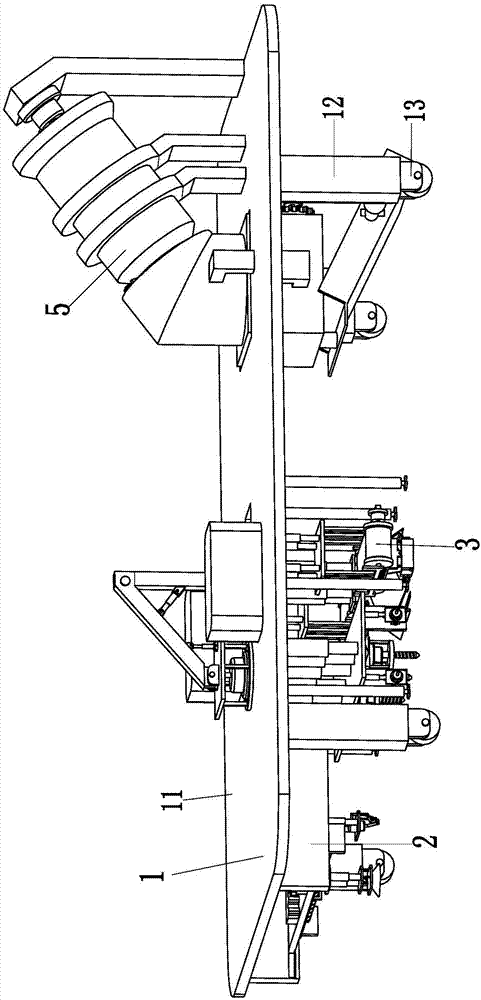

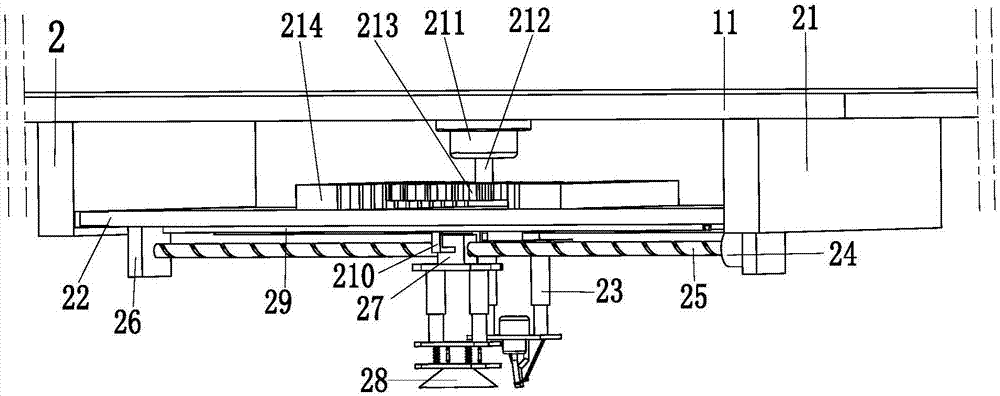

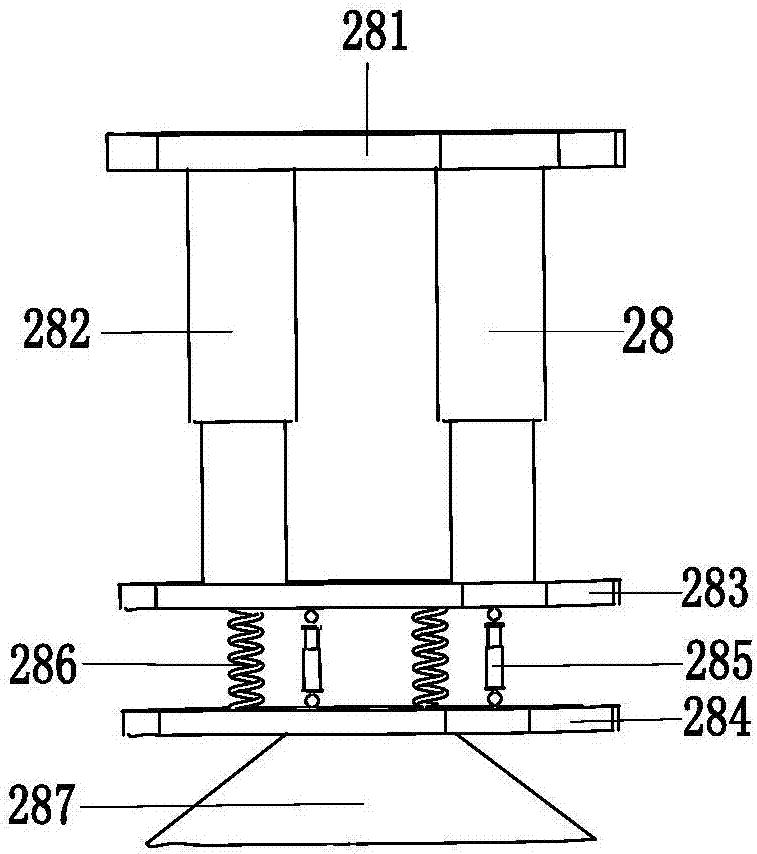

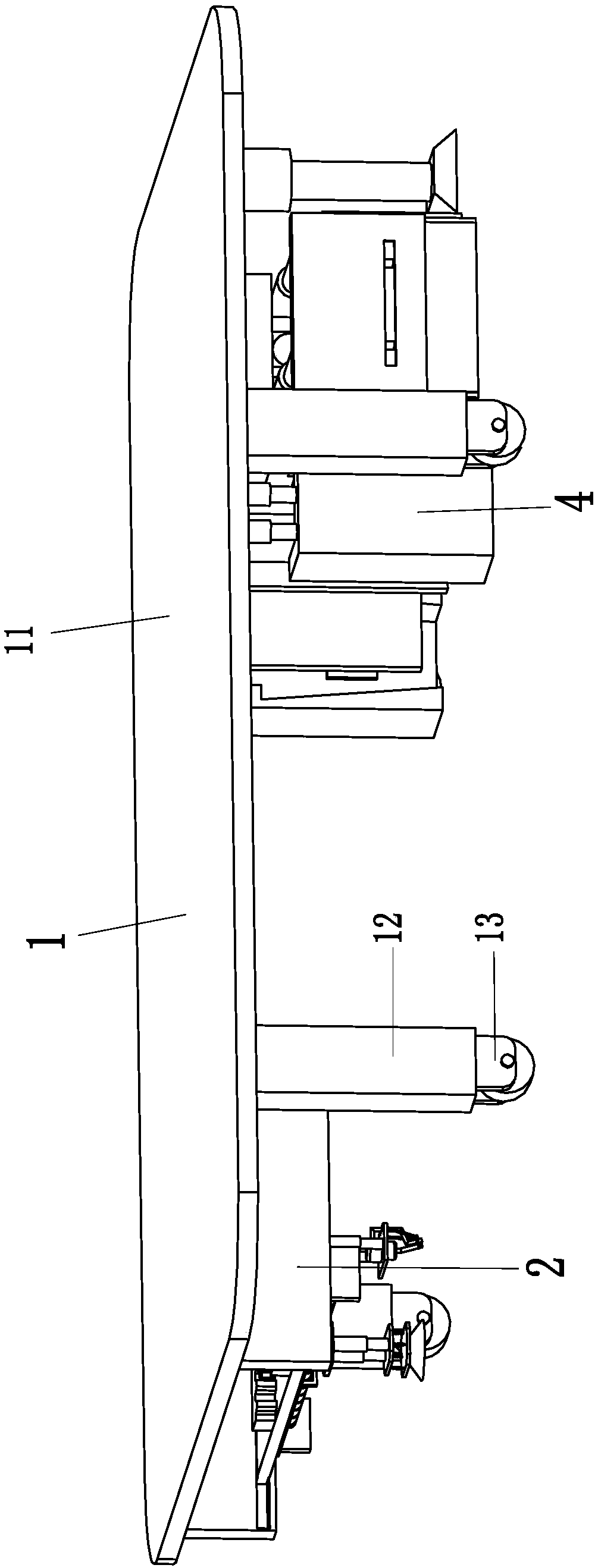

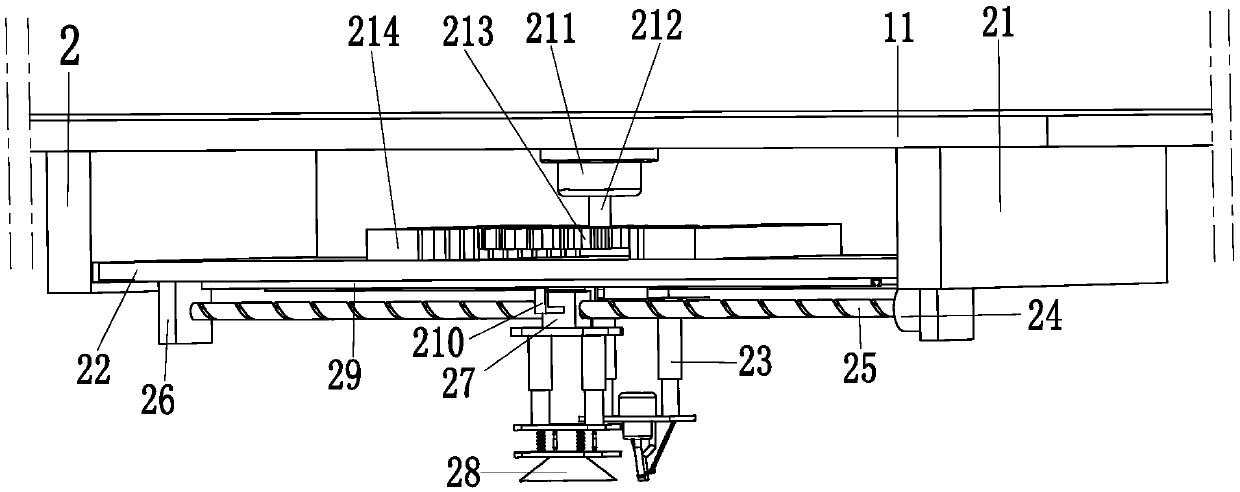

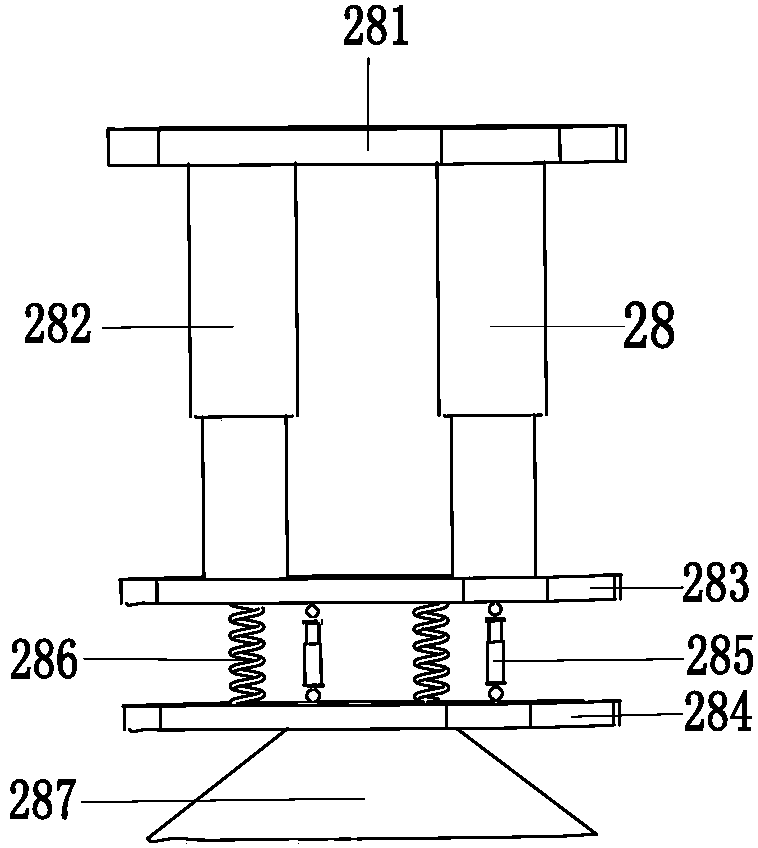

Bituminous concrete pavement renovation and construction all-in-one machine for road

InactiveCN107988884ADry thoroughlyProvides thorough drying in all directionsUsing liquid separation agentRoad cleaningRoad surfaceBituminous concrete

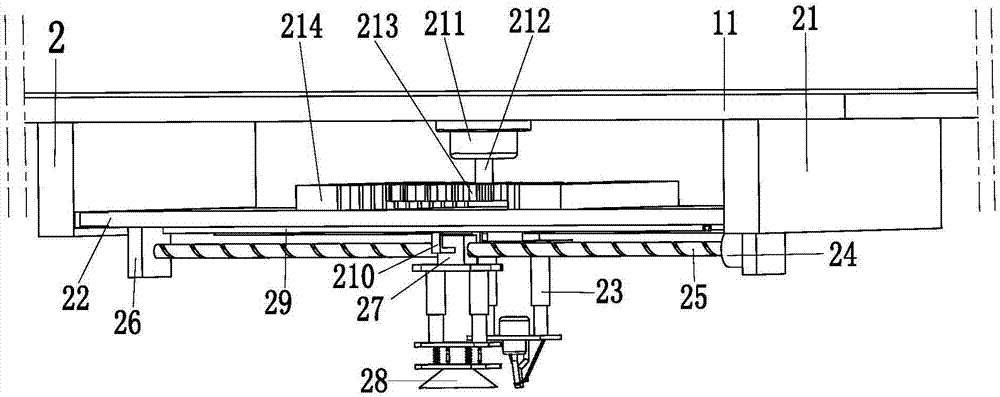

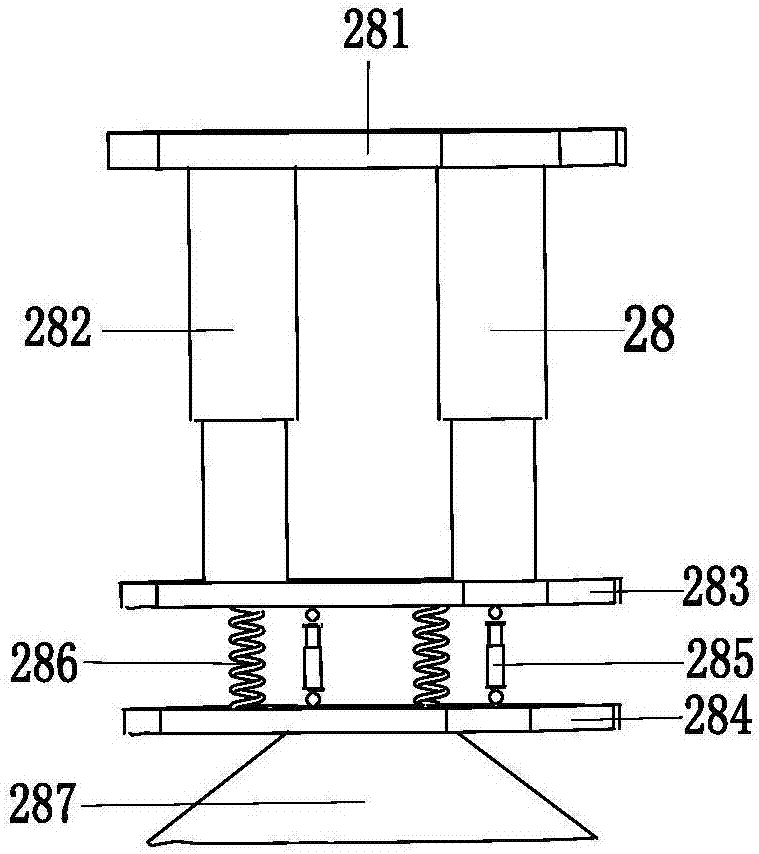

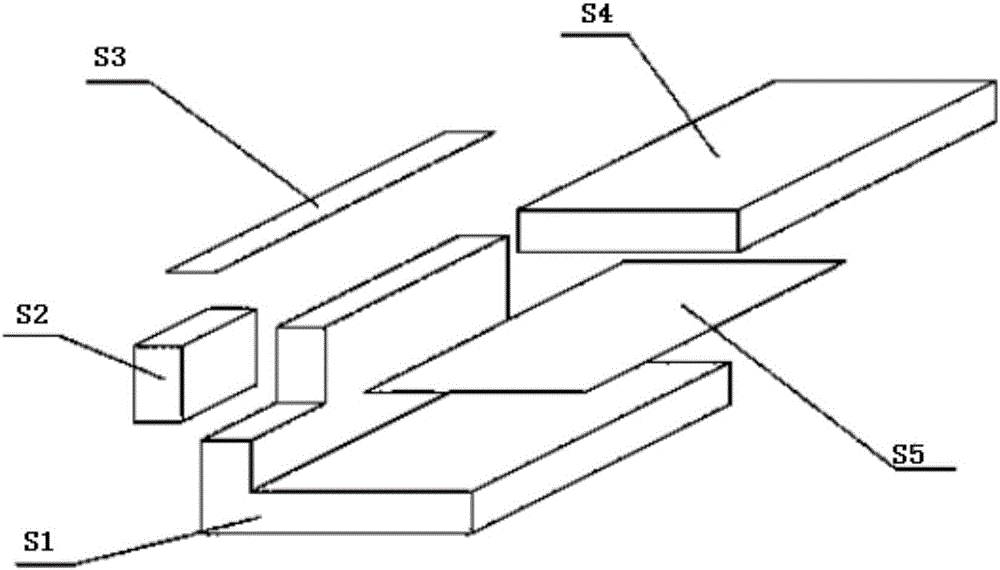

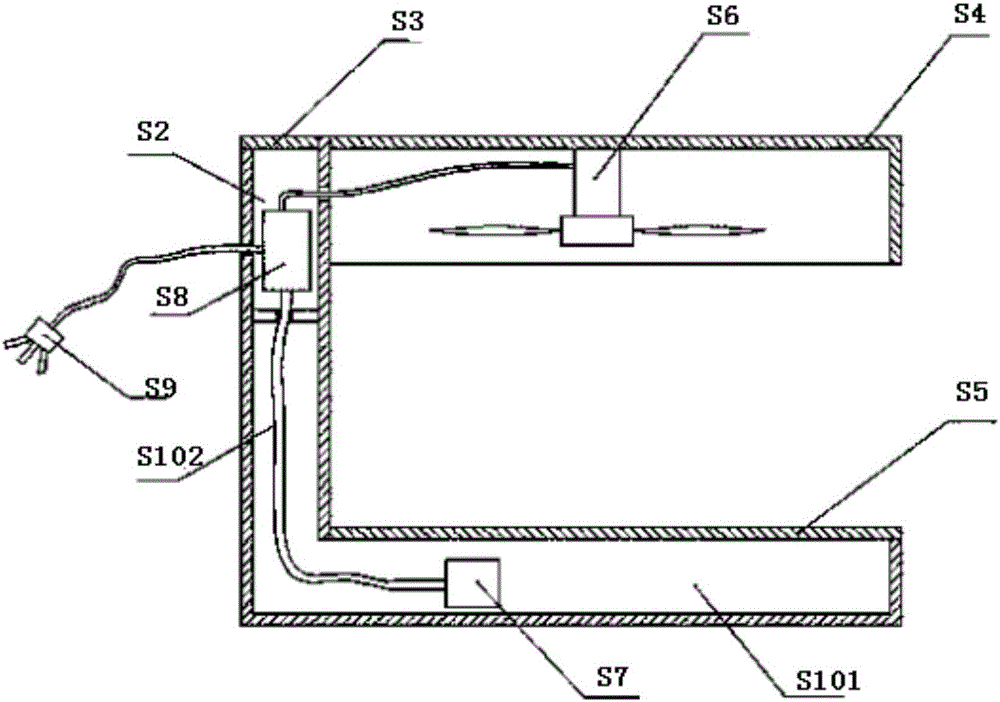

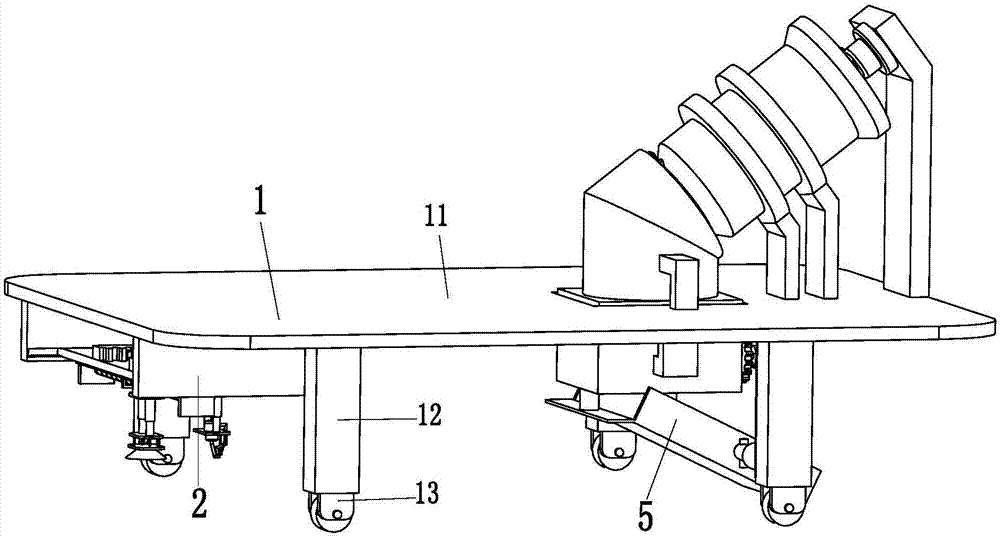

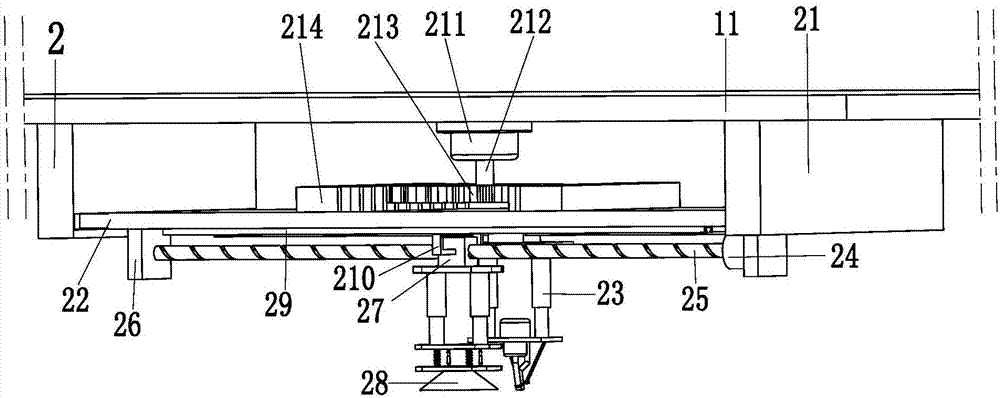

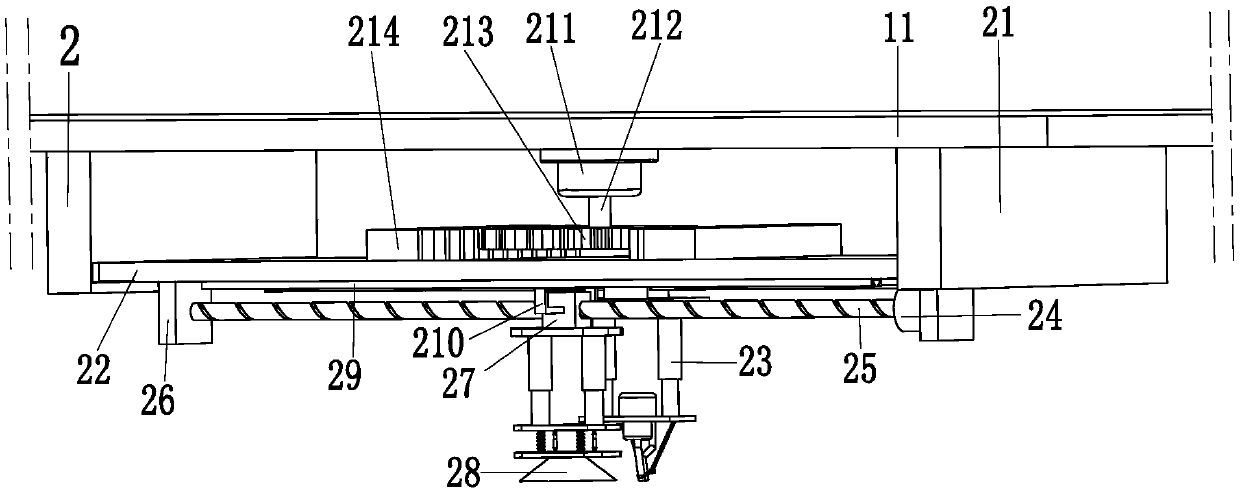

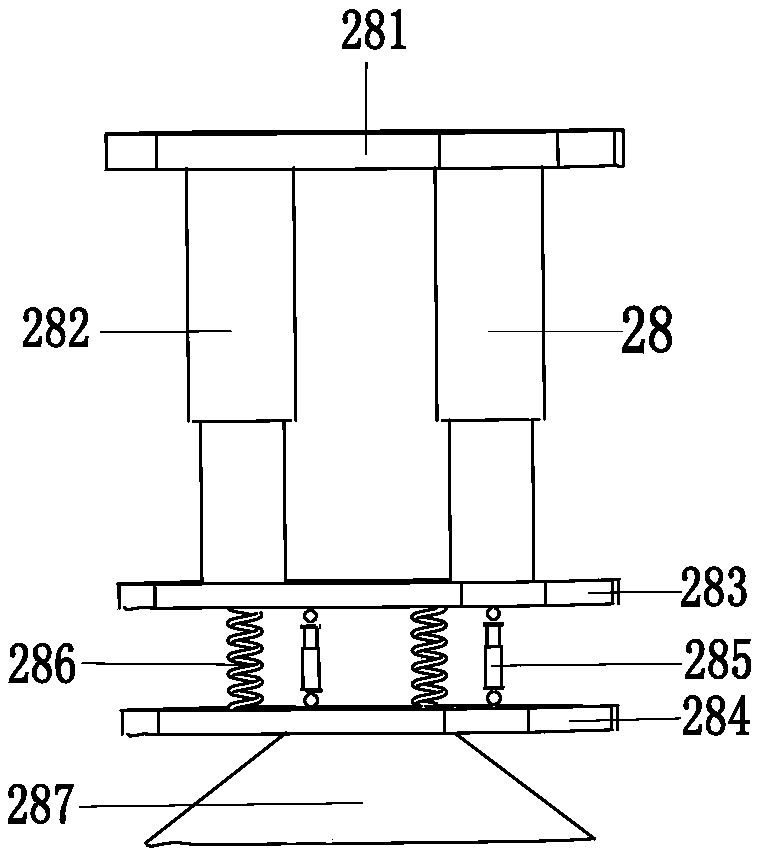

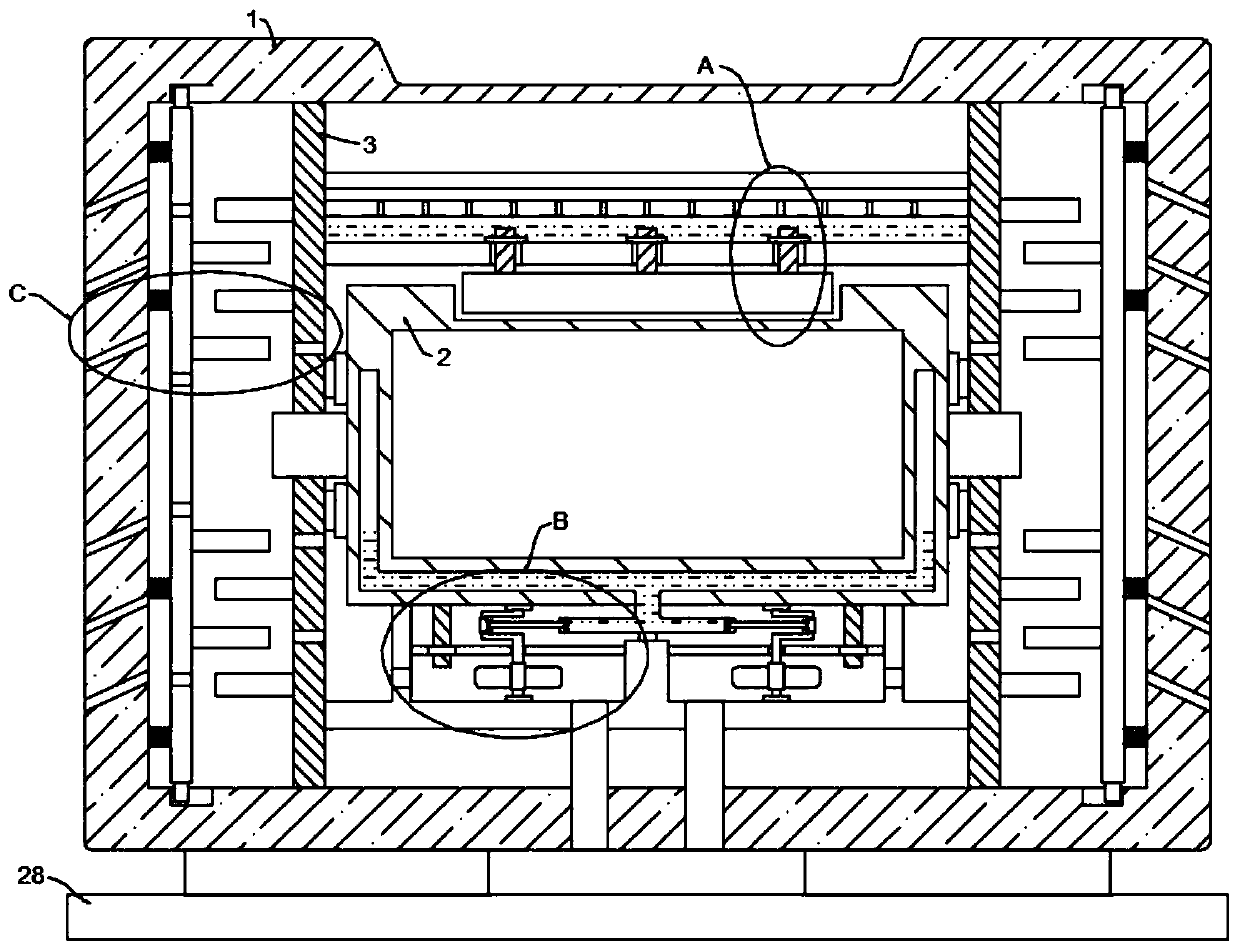

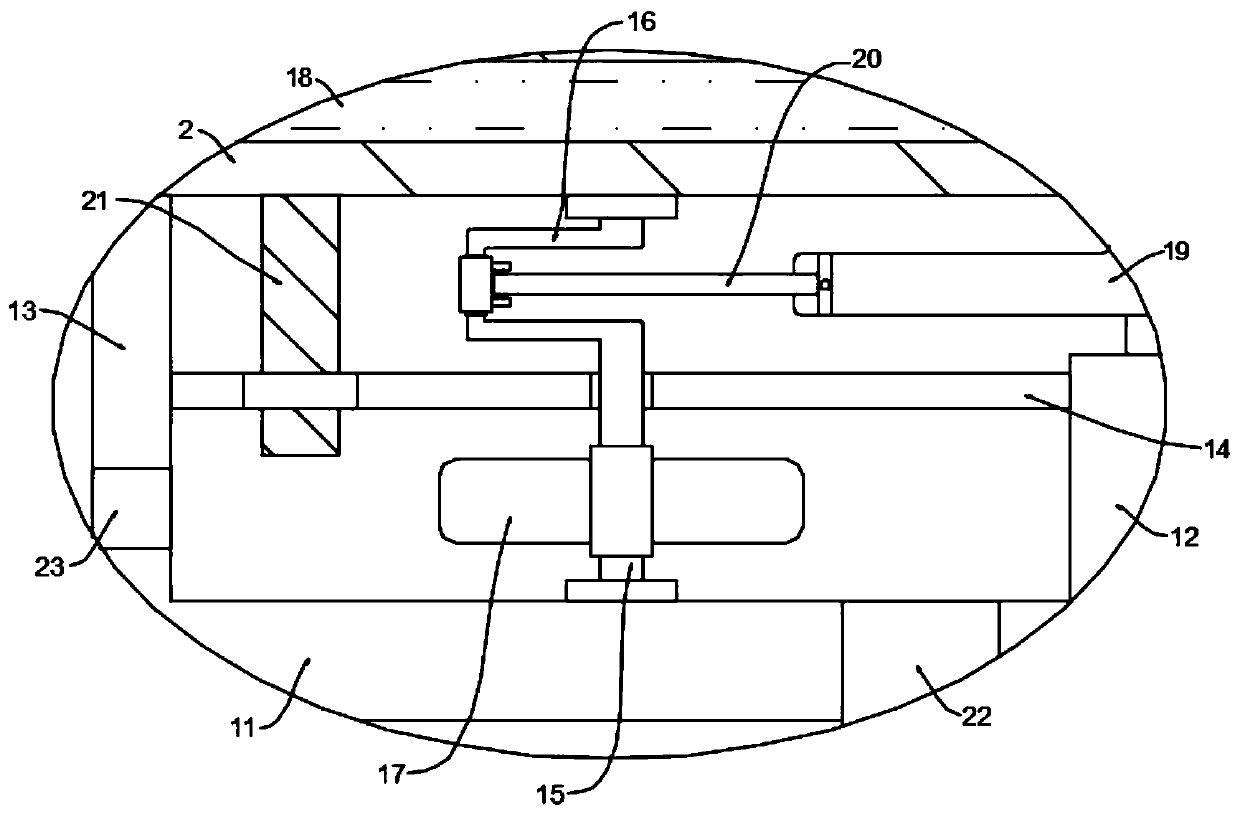

The invention relates to a bituminous concrete pavement renovation and construction all-in-one machine for a road. The bituminous concrete pavement renovation and construction all-in-one machine comprises a supporting device, a drying device, a shoveling device, a cleaning device and a paving device, wherein the drying device is mounted at the bottom of the left end of the supporting device; the shoveling device is mounted at the bottom of the supporting device; the shoveling device is located on the right side of the drying device; the cleaning device is mounted at the middle part of the supporting device; the paving device is mounted at the right end of the supporting device. The bituminous concrete pavement renovation and construction all-in-one machine for the road can solve the problems that a pavement cannot be dried completely, pavements with different slopes and gradients cannot be dried, pavements on two sides of the road cannot be dug, gravels on the road are difficult to grab, gravels on the side walls of a dug roadbed cannot be effectively cleared away, the dug roadbed is cleaned incompletely, bituminous concrete is stirred incompletely, and the bituminous concrete cannot be uniformly spread on the dug roadbed.

Owner:倪立秧

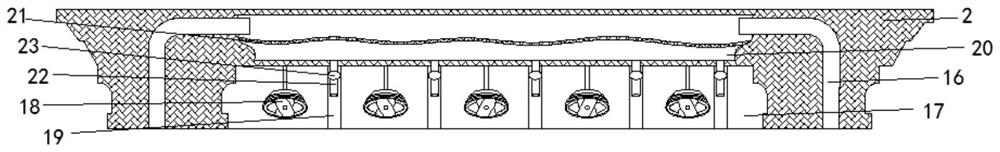

Expressway broken concrete pavement automatic cleaning device

The invention relates to an expressway broken concrete pavement automatic cleaning device. The expressway broken concrete pavement automatic cleaning device comprises a supporting device, a drying device, a shoveling device and a sweeping device. The drying device is installed at the bottom of the left end of the supporting device, the shoveling device is installed at the bottom of the supportingdevice and located on the right side of the drying device, and the sweeping device is installed at the right end of the supporting device. The expressway broken concrete pavement automatic cleaning device can solve the problems that in the existing pavement construction process, pavements are not completely dried, the pavements with different gradients and slopes cannot be dried, the pavements onthe two sides of a road cannot be excavated, road fragments are difficult to grab, fragments of the side walls of an excavated roadbed cannot be effectively cleaned away, and the excavated roadbed isnot completely swept; and the functions that in the pavement construction process, the pavements can be thoroughly dried in all directions and excavated, and the fragments generated after excavationcan be thoroughly cleaned away can be achieved.

Owner:刘静

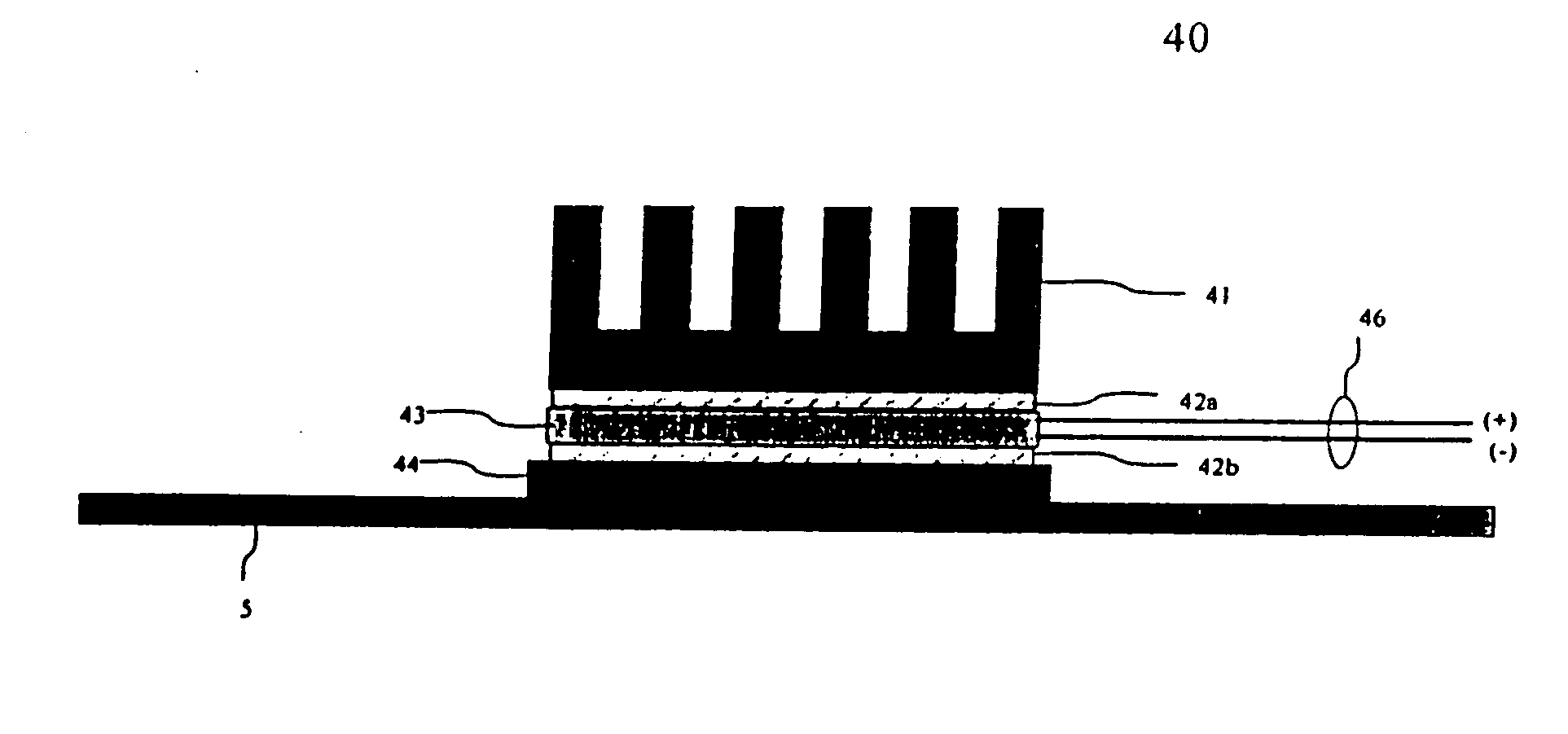

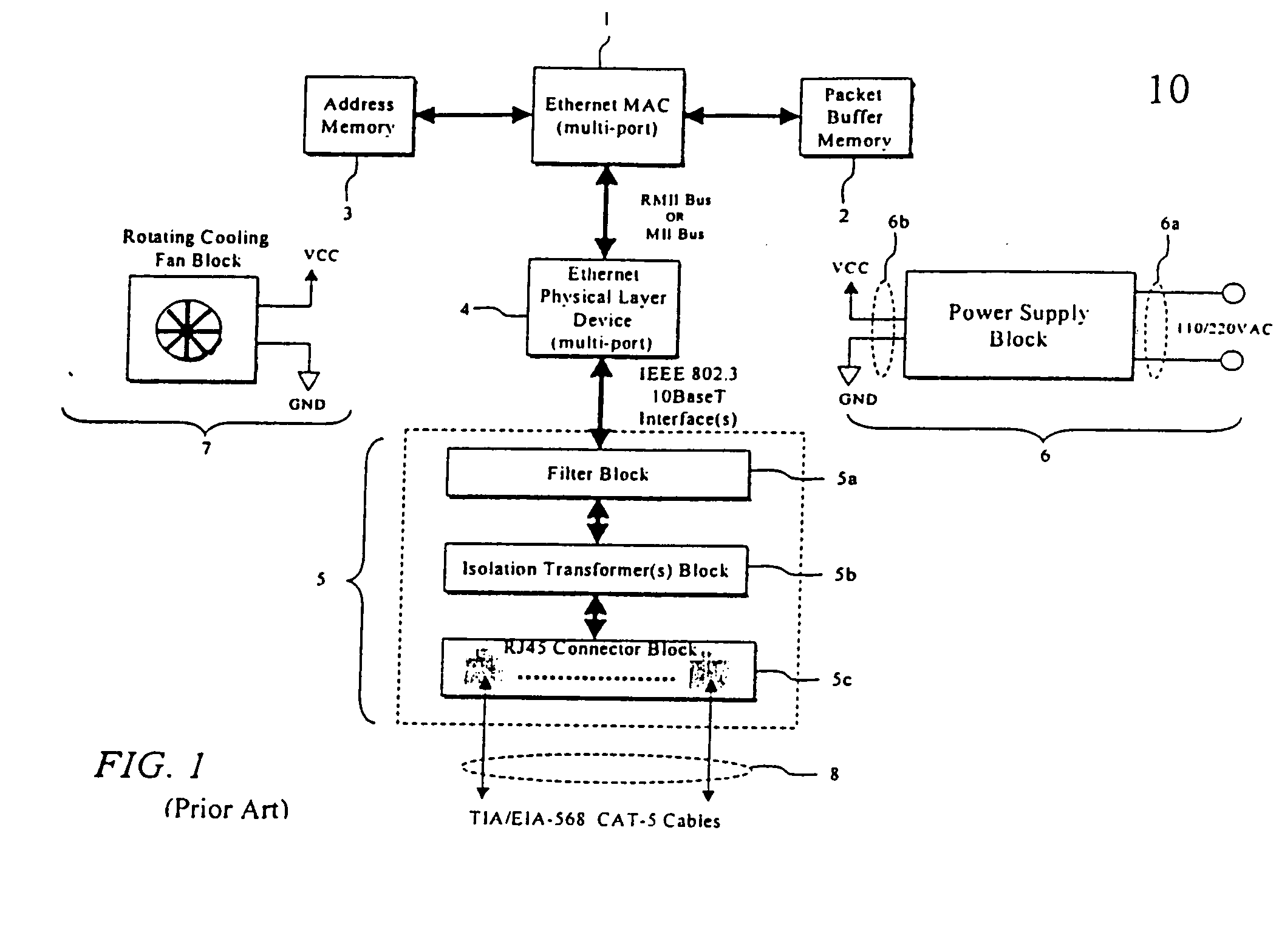

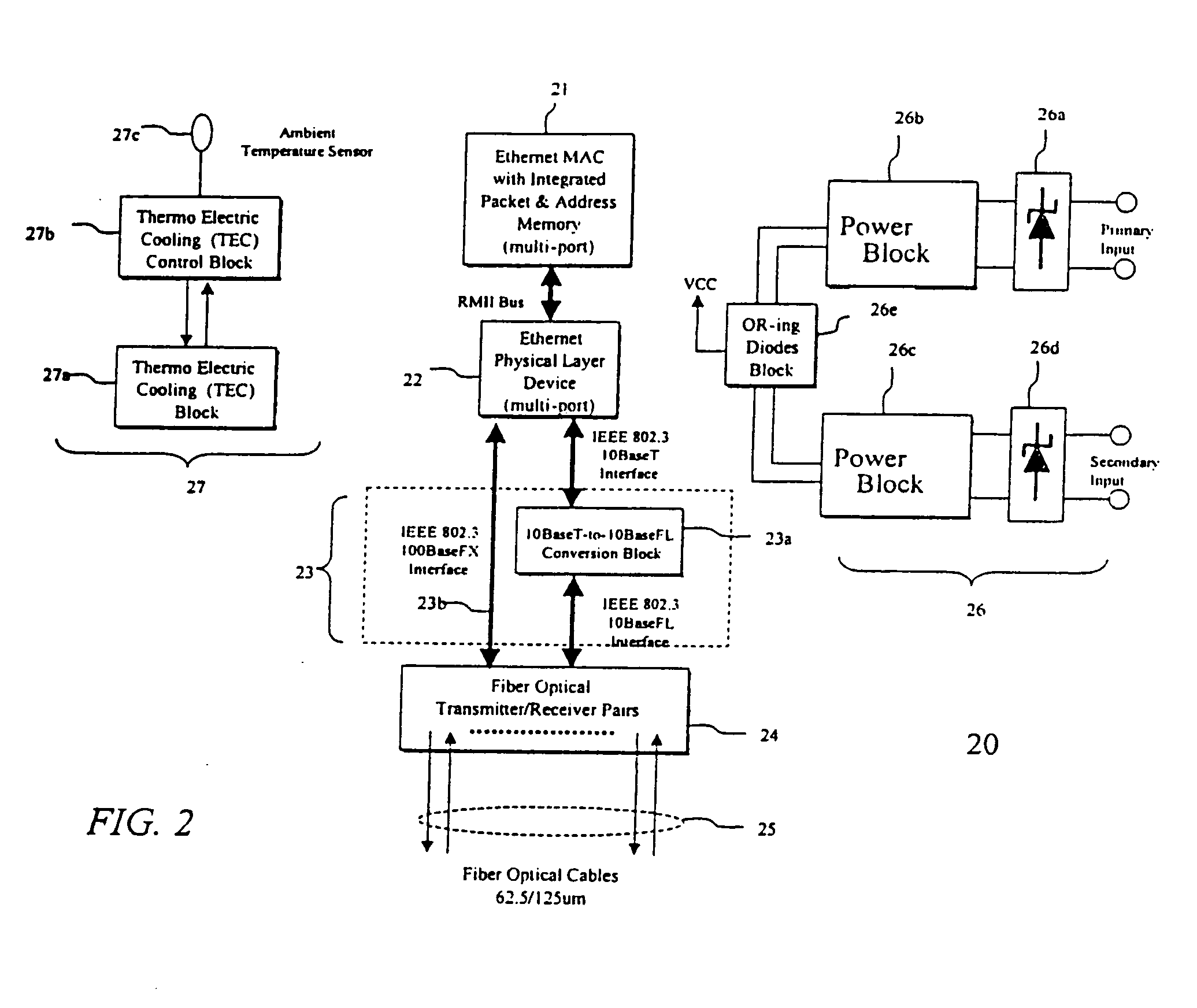

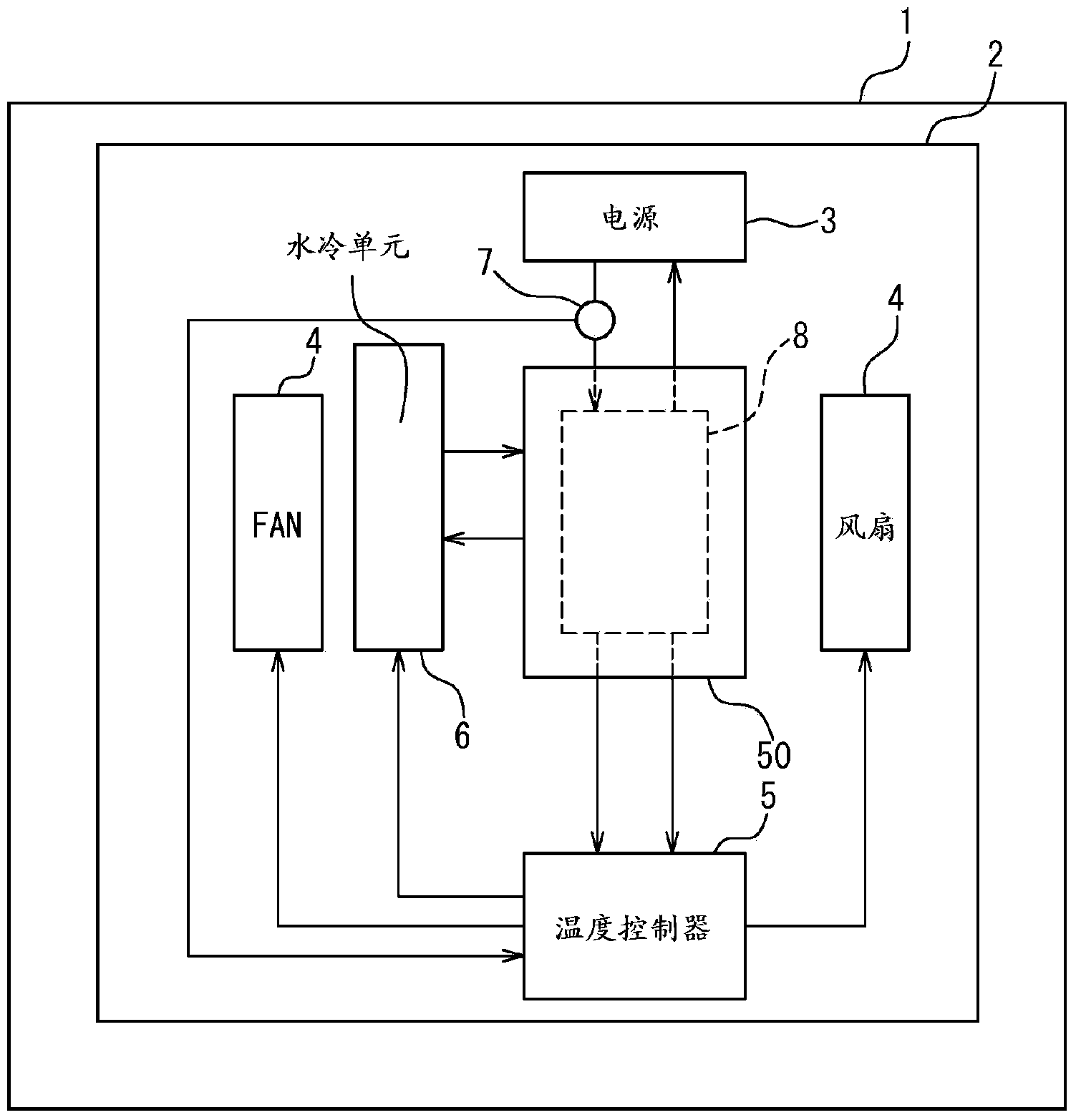

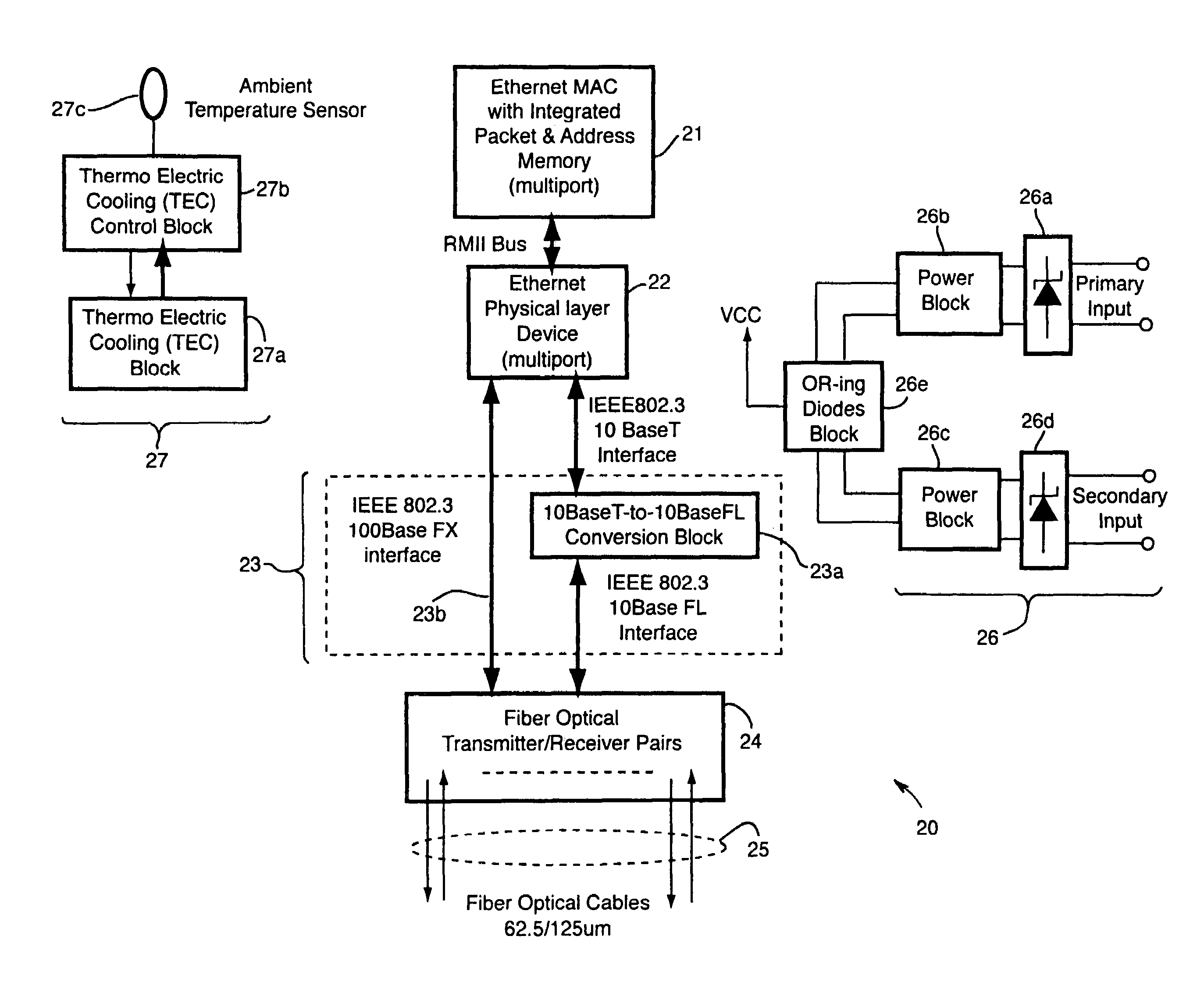

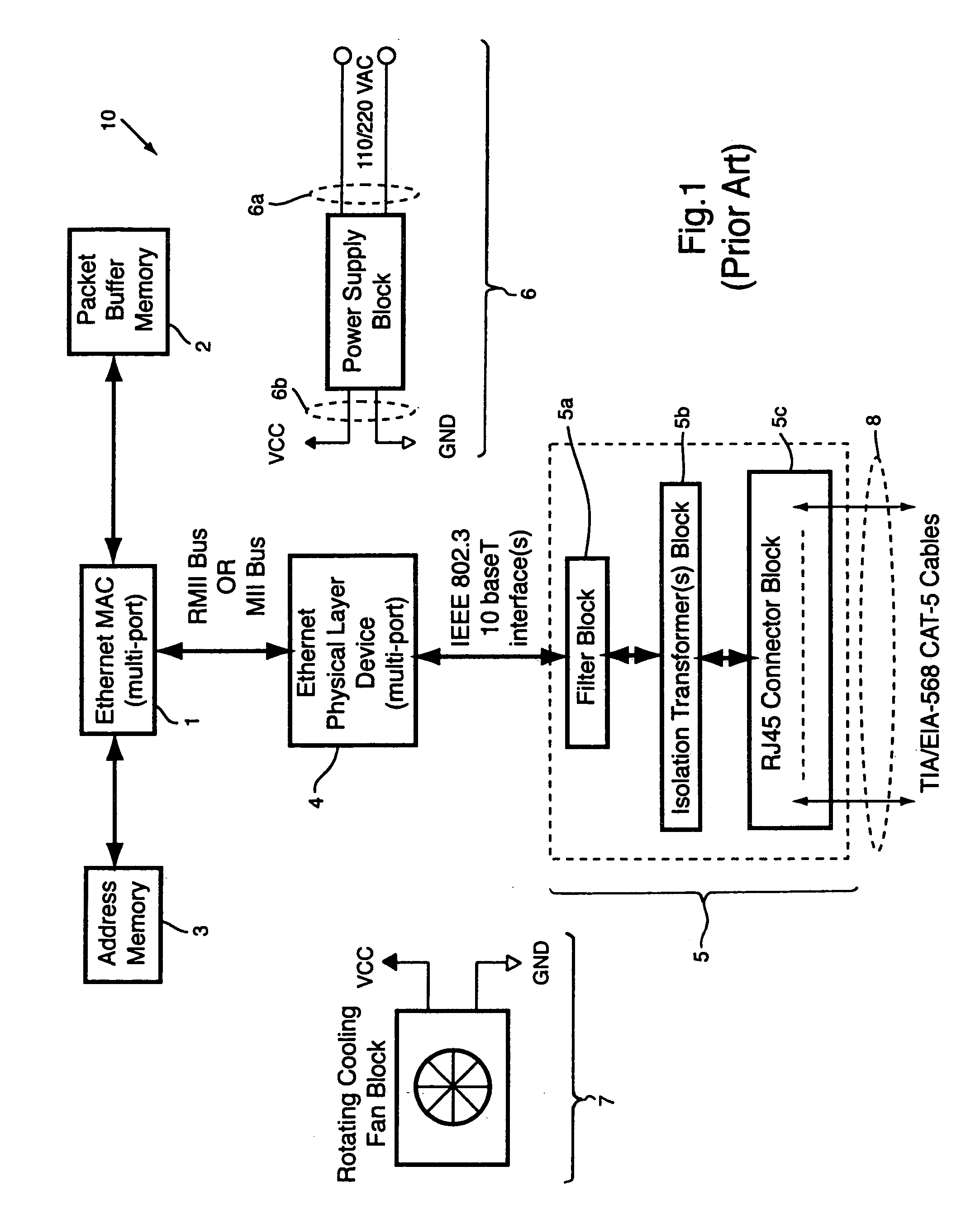

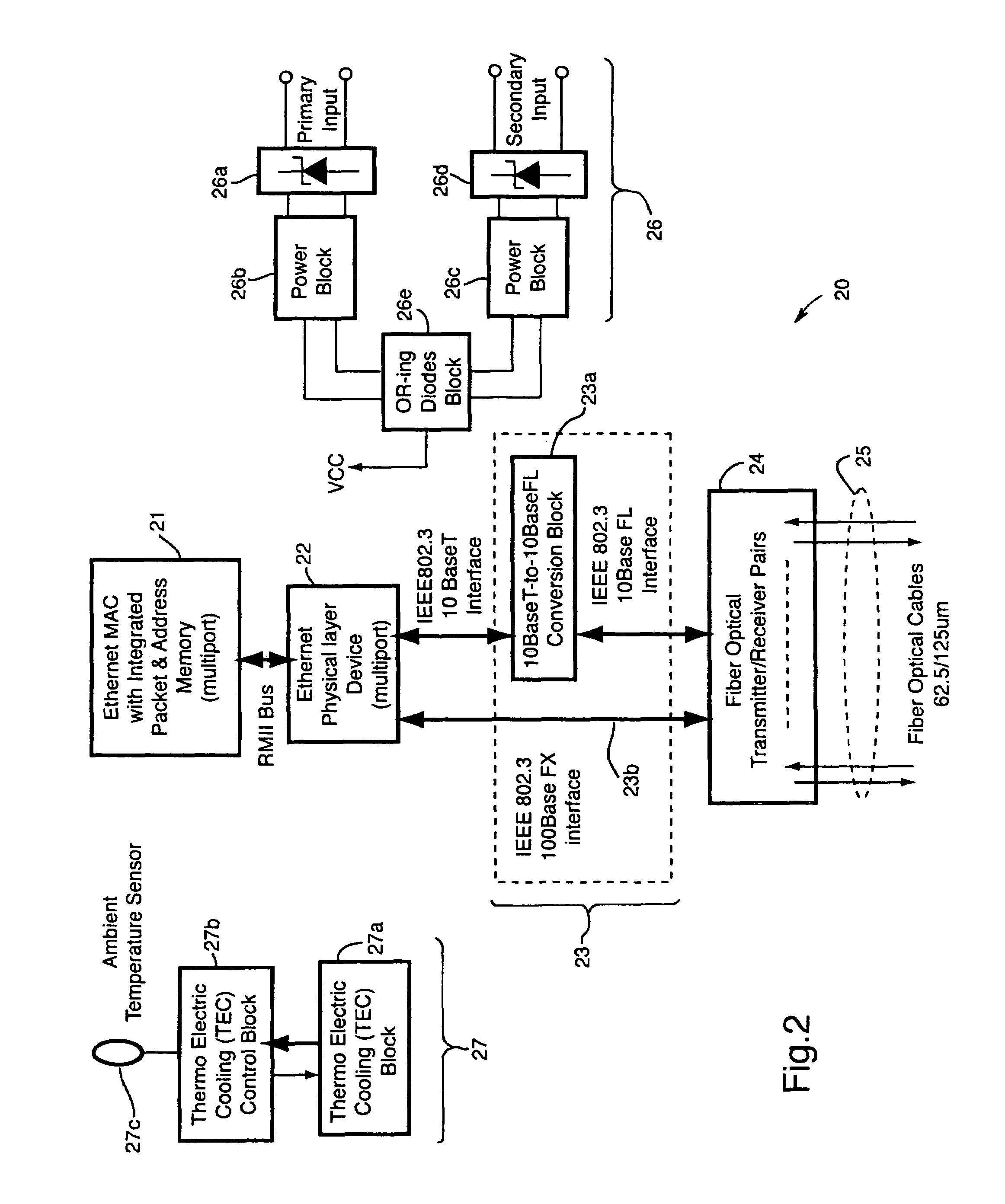

Environmentally hardened Ethernet switch

InactiveUS20050122689A1Improve the immunityImprove system reliabilityData switching current supplyComponent plug-in assemblagesPower utilityElectromagnetic interference

A device for hardening an Ethernet switch is disclosed. The device provides cooling for the switch, and, suppresses electrical transients and electromagnetic interference, which could affect the power supply, and data transmission of the Ethernet switch. Using this device, the Ethernet switch can be used in harsh industrial environments, such as those present in power utility substations.

Owner:SIEMENS CANADA LTD

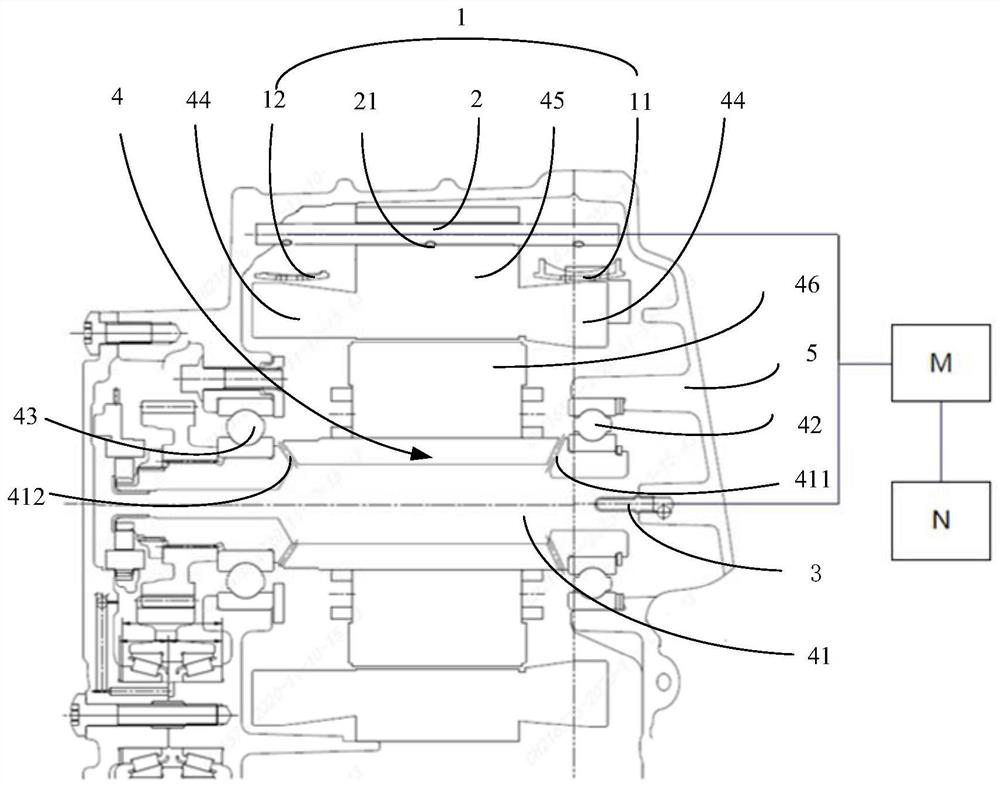

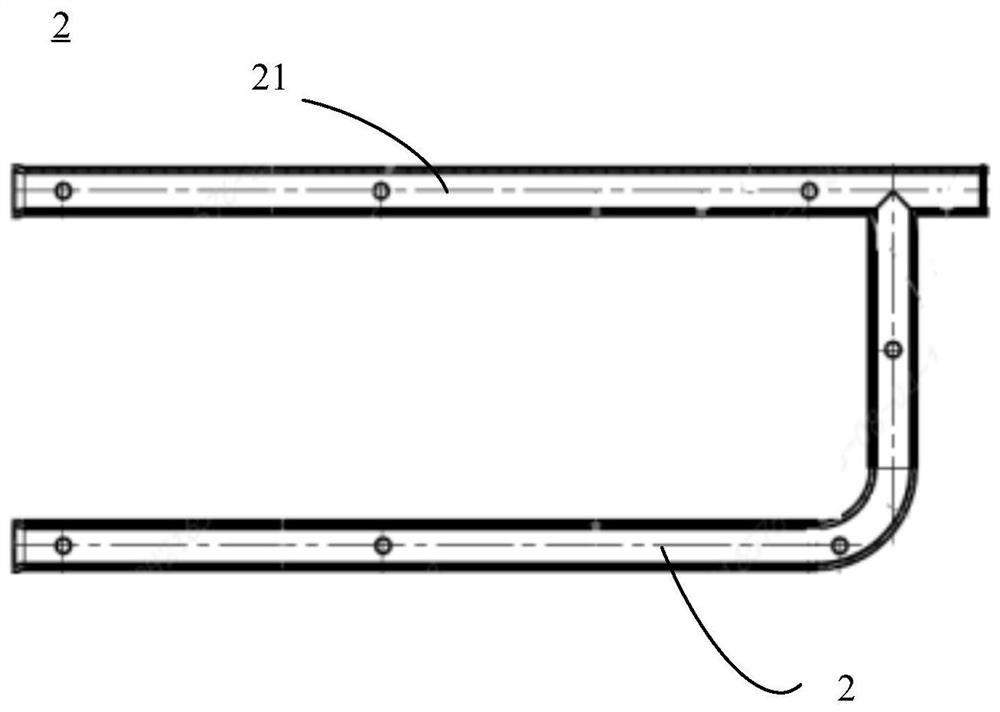

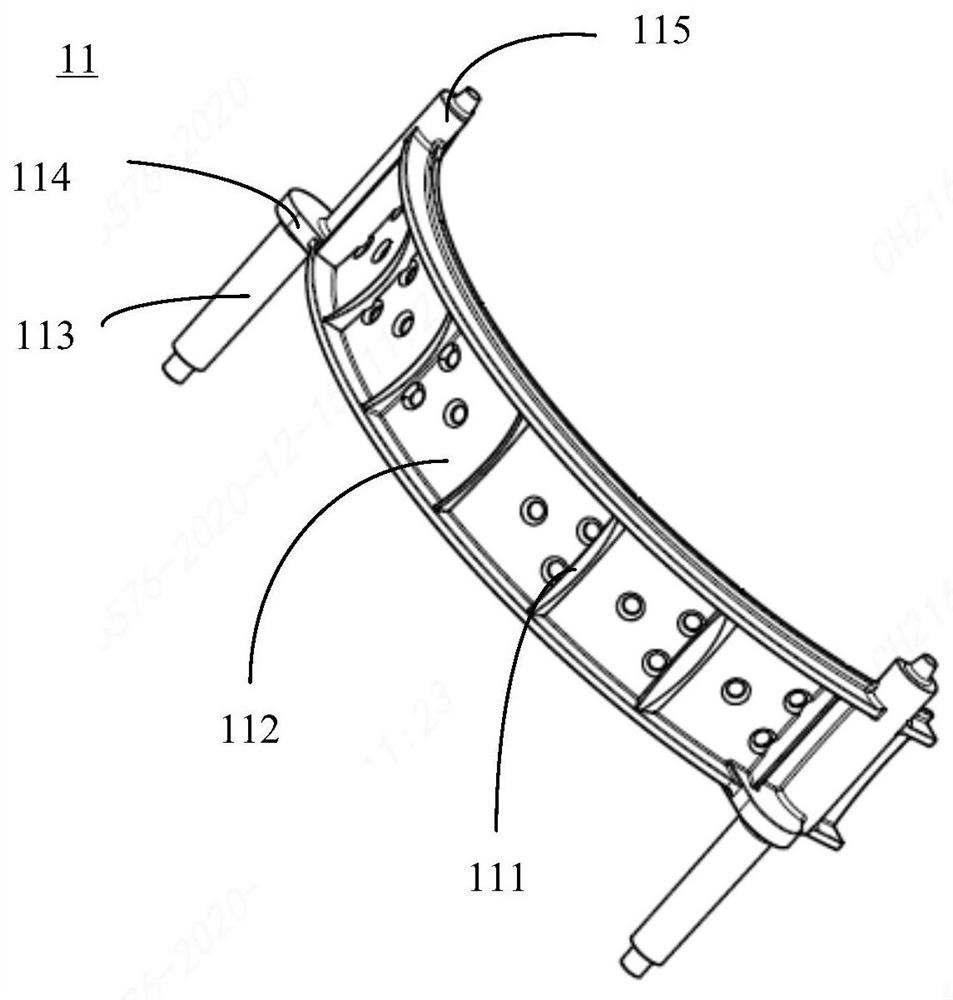

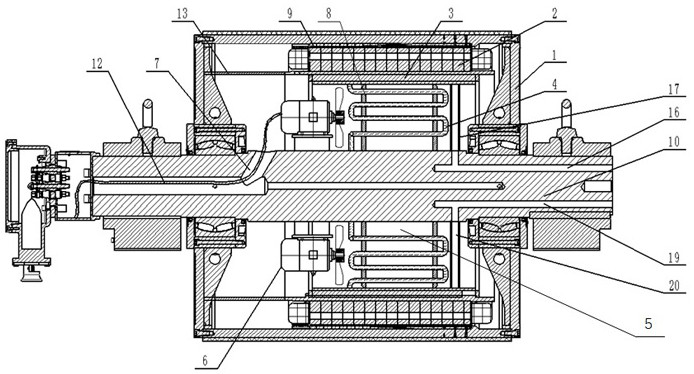

Oil-cooled motor cooling system

ActiveCN112701856AAchieve coolingAvoid accumulationMechanical energy handlingCooling/ventillation arrangementThermodynamicsElectric machine

The invention discloses an oil-cooled motor cooling system. The system comprises an oil collecting assembly, an oil spraying pipe, an oil guiding pipe and a motor. A plurality of oil throwing holes are formed in a rotor shaft of the motor, and when the rotor rotates, cooling oil injected through the oil guide pipe is thrown and splashed to the inner sides of bearings on the two sides of the rotor shaft through the oil throwing holes in the rotor shaft and then rebounded to the inner side of a stator winding and a rotor iron core. A plurality of oil spraying holes are formed in the oil spraying pipe, so that cooling oil in the oil spraying pipe can be sprayed to the oil collecting assembly. The oil collecting assembly comprises a first oil collecting disc and a second oil collecting disc which are arc-shaped and provided with a plurality of through holes, and cooling oil in the oil collecting discs is dripped on the stator winding and the stator iron core through oil holes. According to the system, the oil collecting assembly, the oil spraying pipe and the oil guiding pipe which are simple in structure are utilized, cooling of the inner side and the outer side of the stator winding, the stator iron core, the rotor and the inner sides of the bearings on the two sides of the rotor shaft is achieved through the two oil cooling paths, the cooling range is wide, and the cooling effect is good.

Owner:CHERY AUTOMOBILE CO LTD

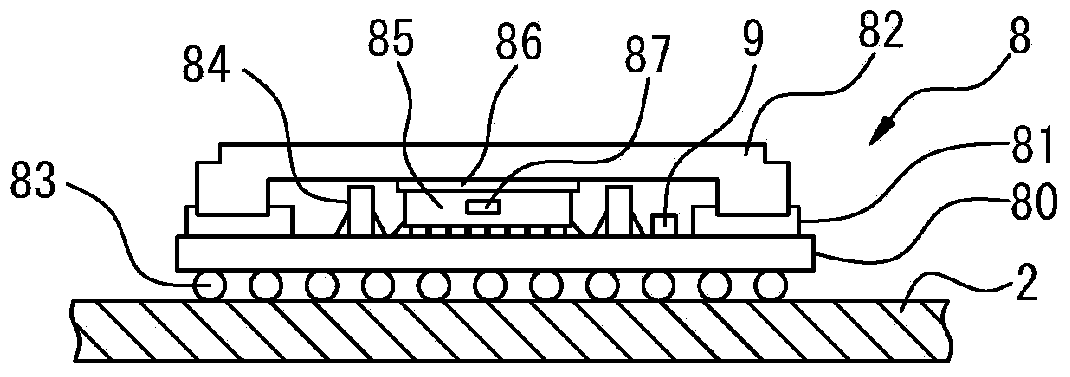

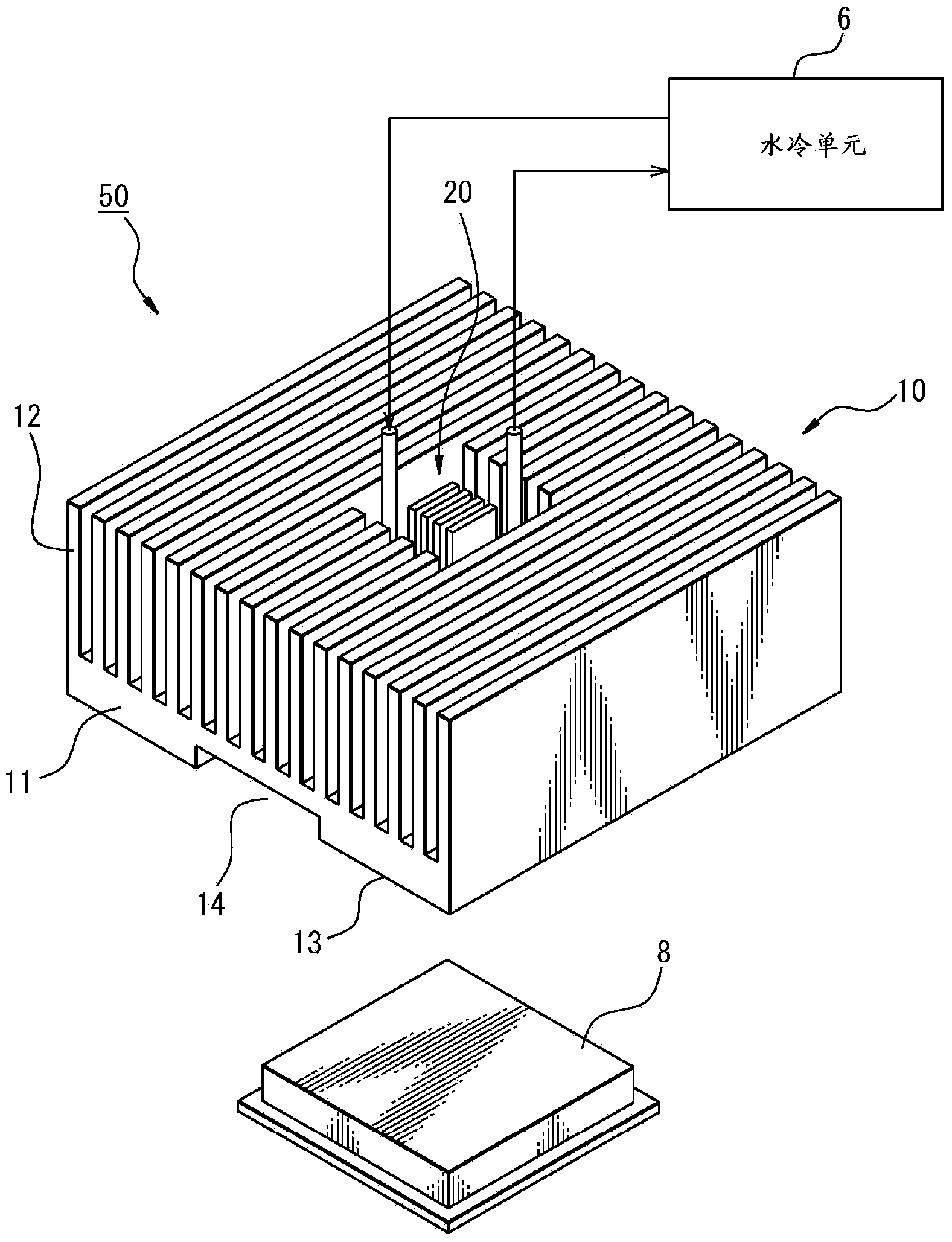

Heat sink and electronic apparatus provided with heat sink

InactiveCN103582393ALarge cooling rangeHigh-speed response to cooling needsDigital data processing detailsSemiconductor/solid-state device detailsEngineeringHeat spreader

A heat sink for cooling a heat generating member, provided with a first cooling part which cools the peripheral edge part of the heat generating member and a second cooling part which cools the center part of the neat generating member, the first cooling part is equipped with a first base member having first fins on the top surface thereof and a recess at the bottom surface thereof, the second cooling part is equipped with a second base member which can be accommodated in the recess, a slide member which is provided on the top surface of the second base member and which is inserted in a through hole which is provided in the recess, second fins which are provided on the free end of the slide member, and a cooling water passage which is provided inside of the second base member and which is supplied with cooling water.

Owner:FUJITSU LTD

Traffic road pavement renovation automatic bituminous concrete roadbed paving machine

The invention relates to a traffic road pavement renovation automatic bituminous concrete roadbed paving machine which comprise a supporting device, a drying device, a sweeping device and a paving device. The drying device is installed at the bottom of the left end of the supporting device, the sweeping device is installed on the middle portion of the supporting device, and the paving device is installed at the right end of the supporting device. The machine can solve the problems that in the existing pavement construction process, pavements are not completely dried, the pavements with different gradients and slopes cannot be dried, fragments of the side walls of an excavated roadbed cannot be effectively cleaned away, the excavated roadbed is not completely swept, bituminous concrete is not fully mixed, and the excavated roadbed cannot be evenly paved with the bituminous concrete; and the functions that in the pavement construction process, the pavements can be thoroughly dried in alldirections, the excavated roadbed with the fragments shoveled away is completely swept, and the roadbed is evenly paved with the bituminous concrete can be achieved.

Owner:段莉娟 +9

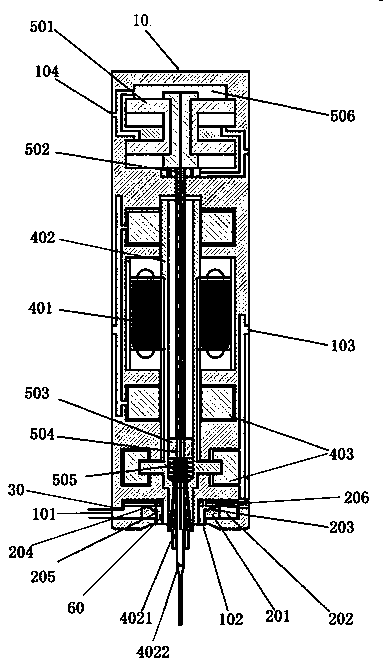

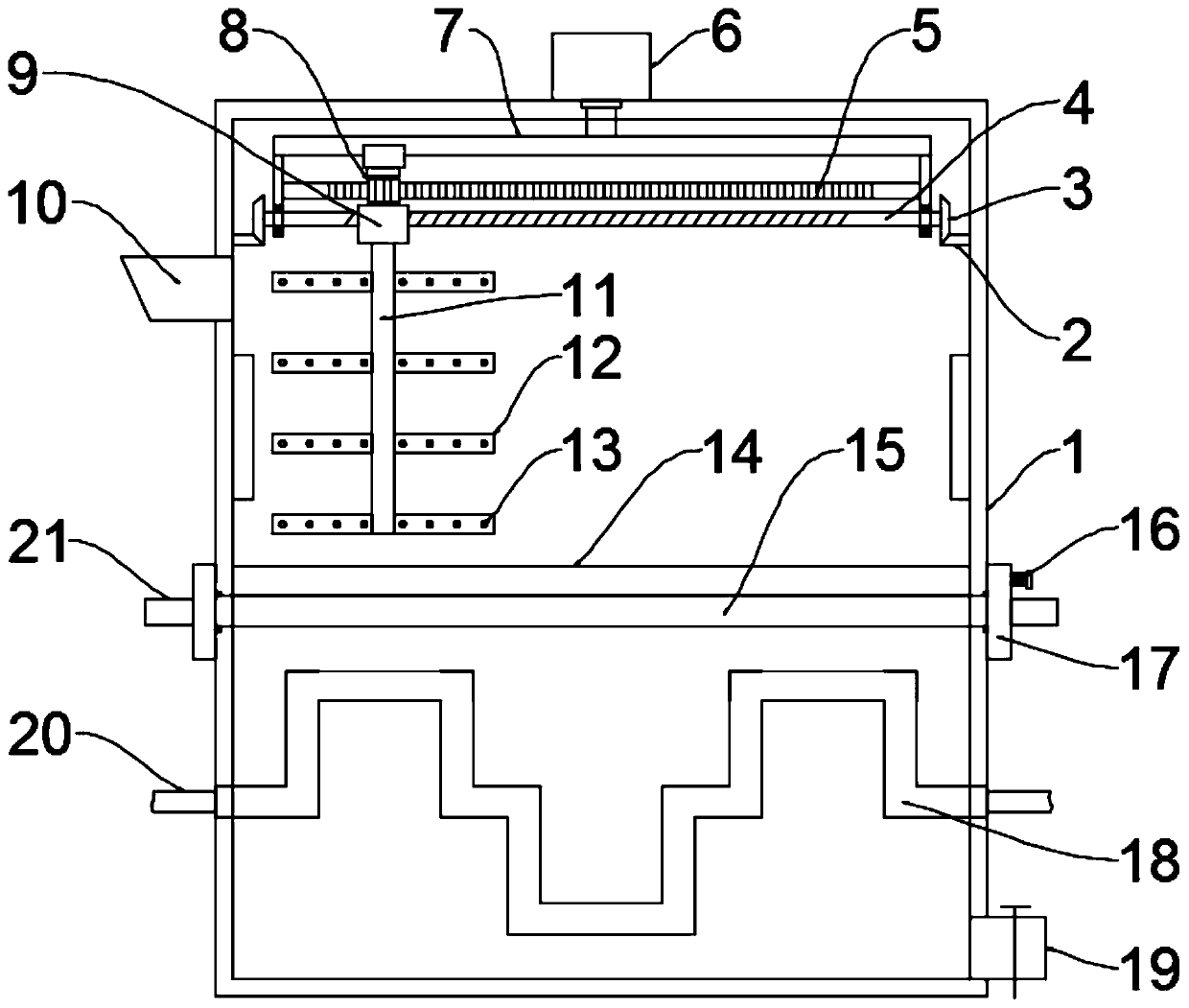

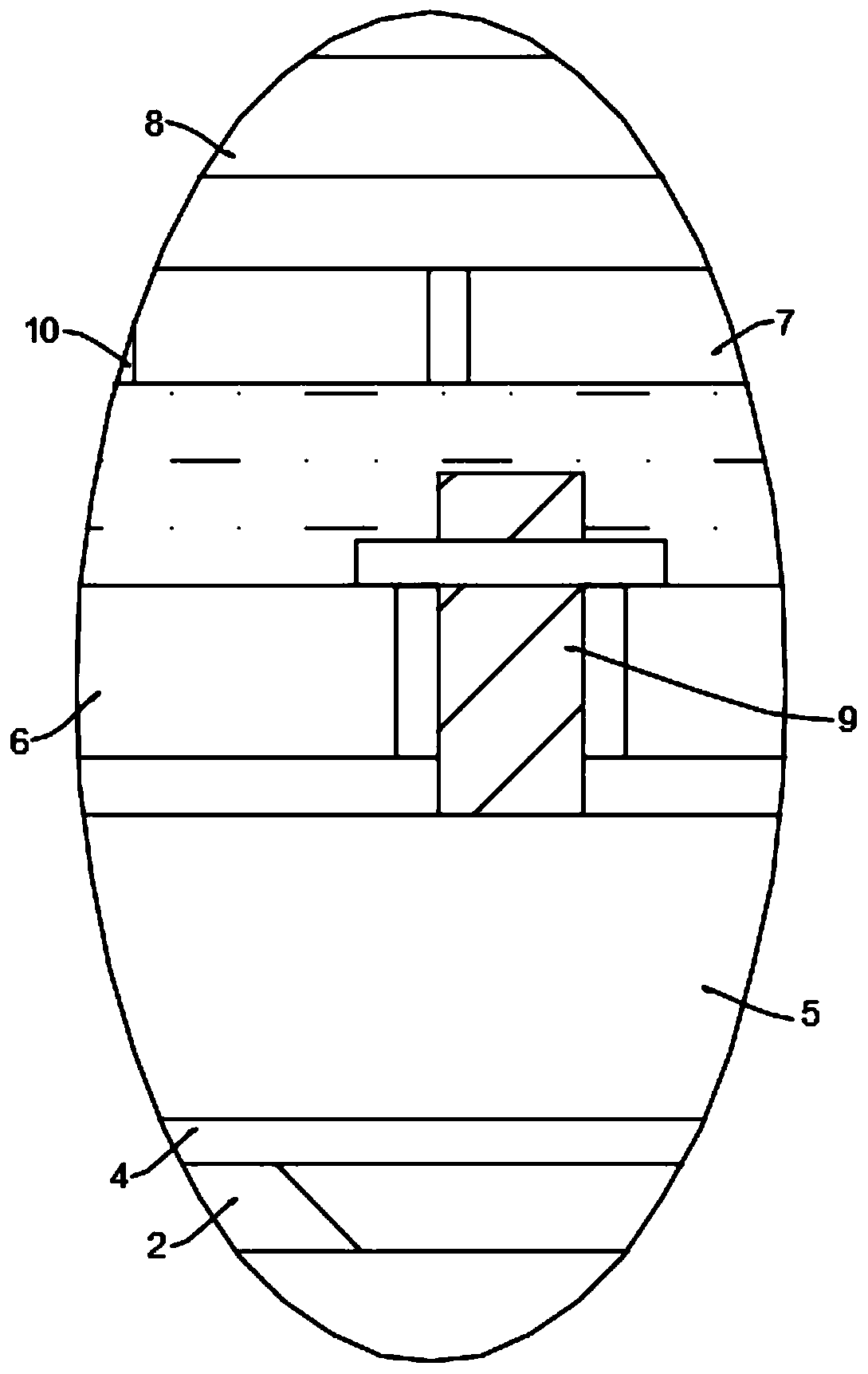

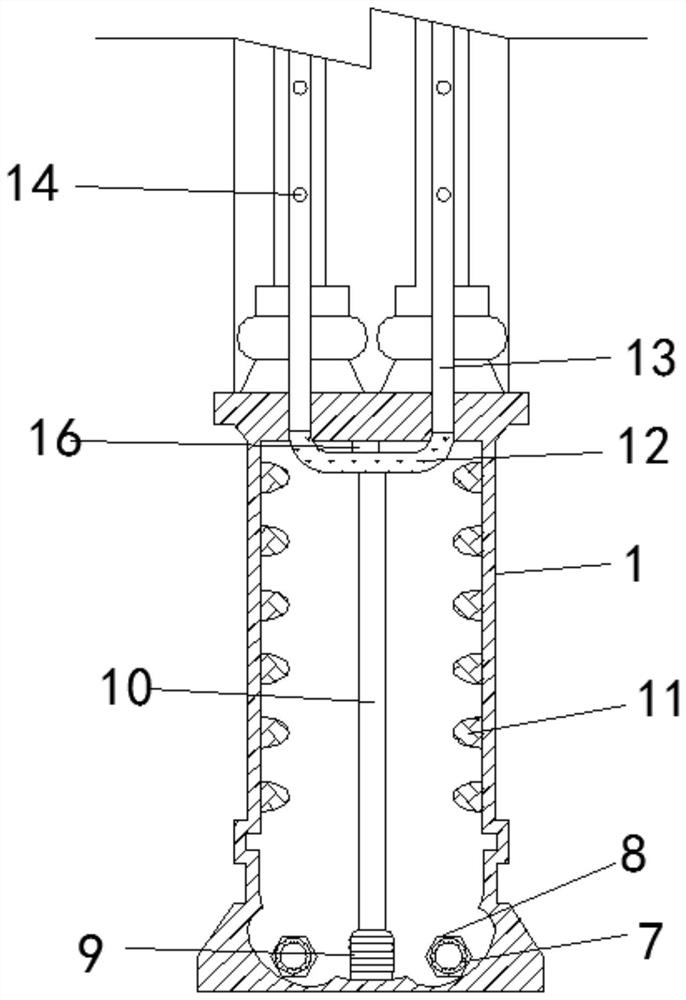

Ultra-high-speed electric spindle with embedded cold air device

PendingCN107716953AReduce radial vibrationImprove machining accuracyLarge fixed membersPositioning apparatusHeat sinkEngineering

The invention provides an ultra-high-speed electric spindle with an embedded cold air device. The ultra-high-speed electric spindle comprises a spindle main body, a spindle shell and the cold air device. The spindle main body and the cold air device are arranged inside the spindle shell. An air inlet is formed in the side face of the spindle shell, and an air outlet is perpendicularly formed in the lower end of the spindle shell. The cold air device is sleeved with the spindle main body and comprises a hollow chamber, and a cooling fin is arranged at the bottom of the hollow chamber. The upperend of the side, away from the air inlet, of the cooling fin is provided with a spherical groove, and the cooling fin divides the hollow chamber into a mixed gas chamber body and a swirl chamber body. The upper end of the cooling fin and the top of the hollow chamber form an air guide groove, and the mixed gas chamber body communicates with the air inlet. The air guide groove is in pipeline connection with the air outlet through a cold air pipe, a hot air port is formed in the hollow chamber, and the hot air port communicates with outside air. Cold air is low temperature compressed air, low temperature CO2, supercritical CO2 or low temperature nitrogen. The cooling effect of the electric spindle is good, chip removal is facilitated, and a needle is not prone to being broken.

Owner:GUANGDONG UNIV OF TECH

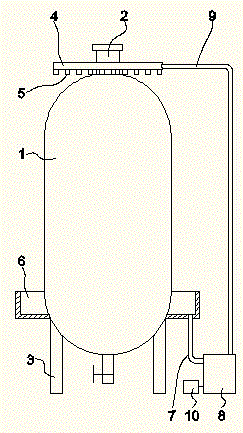

Chemical stock tank cooling system

InactiveCN105857975AReduce the possibility of explosionRelieve pressureLarge containersTank wagonsCompound (substance)Water collection

The invention discloses a chemical raw material tank cooling system, which comprises a tank body, the top of the tank body is provided with a feed port, the bottom of the tank body is provided with a bracket, and the top of the tank body is provided with an annular water pipe. The lower end of the annular water pipe is provided with a plurality of spray ports; the top of the support is provided with an annular sump close to the outer wall of the tank, and the bottom of the sump is provided with an outlet pipe, which is connected to the water pump. The water pump is connected to the annular water pipe through the water inlet pipe. The chemical raw material tank cooling system of the present invention has reasonable structural design, fast cooling speed, and high cooling efficiency. The present invention has the advantages of simple structure, convenient use and maintenance, low cost, and high work efficiency.

Owner:WUXI AOYUTE NEW TECH DEV

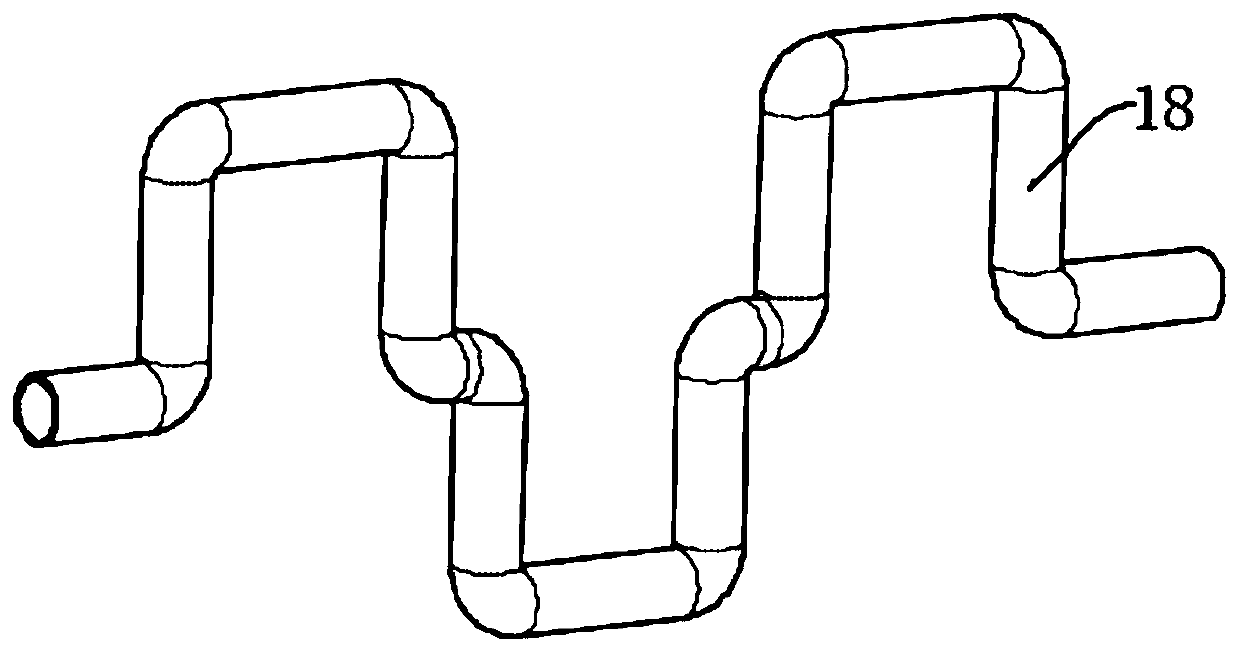

Stirring device for preparing phytosterol

InactiveCN110280198AExpand the mixing rangeImprove stirring efficiencyProductsReagentsEngineeringDrive motor

The invention discloses a stirring device for preparing phytosterol, and relates to the technical field of preparation of phytosterol. The stirring device mainly aims to solve the problems that an existing device has a stirring dead zone, and the stirring efficiency is reduced. The stirring device comprises a cylinder body and a stirring device body arranged in the cylinder body, and further comprises a mounting plate, a reciprocating lead screw, a movable block, bevel gears and annular inner bevel gear rings; the stirring device body comprises a stirring shaft, a driving motor and stirring rods, wherein the driving motor is used for driving the stirring shaft to rotate, and the stirring rods are arranged on the stirring shaft; a cooling pipe is arranged at the lower part of an inner cavity of the cylinder body and is connected to the side wall of the cylinder body in a rotating mode through a sealing bearing; and a driving mechanism used for driving the cooling pipe to rotate is arranged on the outer wall of the cylinder body and comprises a second motor, a driving gear and a driven gear. According to the stirring device, the stirring device body is arranged, so that the stirring range is widened, and therefore the stirring efficiency is improved; and the crankshaft-shaped cooling pipe and the driving mechanism for driving the cooling pipe to rotate are arranged, so that the cooling pipe can fully and uniformly make contact with liquid, and therefore the cooling range is widened, and the cooling efficiency is improved.

Owner:FUJIAN FUERJIN BIOTECHNOLOGY CO LTD

Road excavation and eradication equipment before bridge road renovation

The invention relates to road excavation and eradication equipment before bridge road renovation. The road excavation and eradication equipment before bridge road renovation comprises a supporting device, a drying device and an eradication device. The drying device is arranged on the bottom of the left end of the supporting device. The eradication device is installed on the bottom of the right endof the supporting device. By means of the road excavation and eradication equipment, the difficult problems that in construction of an existing road surface, the road surface is not dried thoroughly,the road surfaces with different slopes and grades cannot be dried, the road surface on the two sides of a road cannot be excavated, and road fragments are troublesome to grab can be solved; when road surface construction is conducted, the functions that omni-bearing thorough drying can be conducted on the road surface, and thorough excavation can be conducted on the road surface are achieved; and the road excavation and eradication equipment has the advantages of being capable of drying the road surface thoroughly, drying the road surface with the different slopes and grades, and excavatingthe road surfaces on the two sides of the road, grabbing the road fragments conveniently and fast and the like.

Owner:吴传江

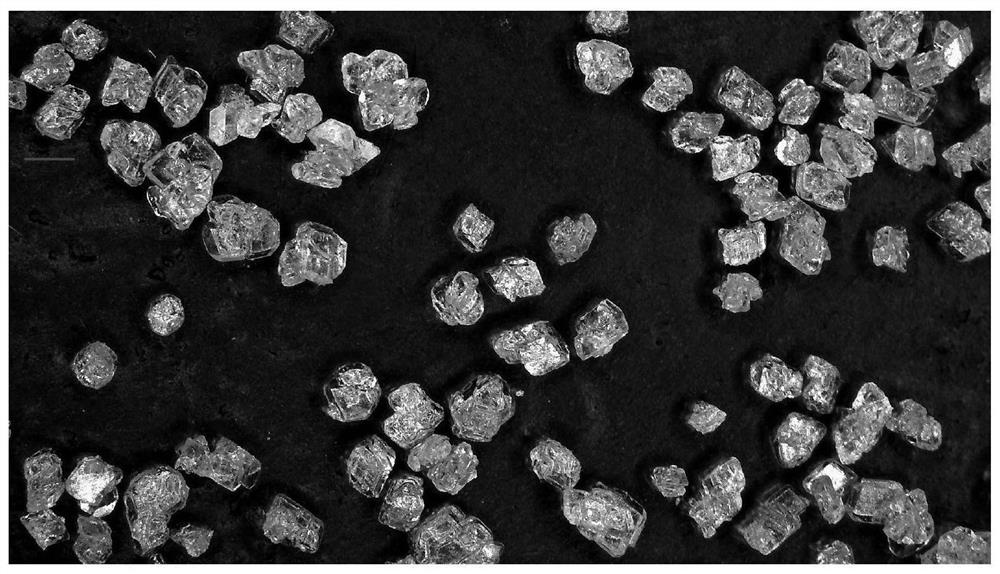

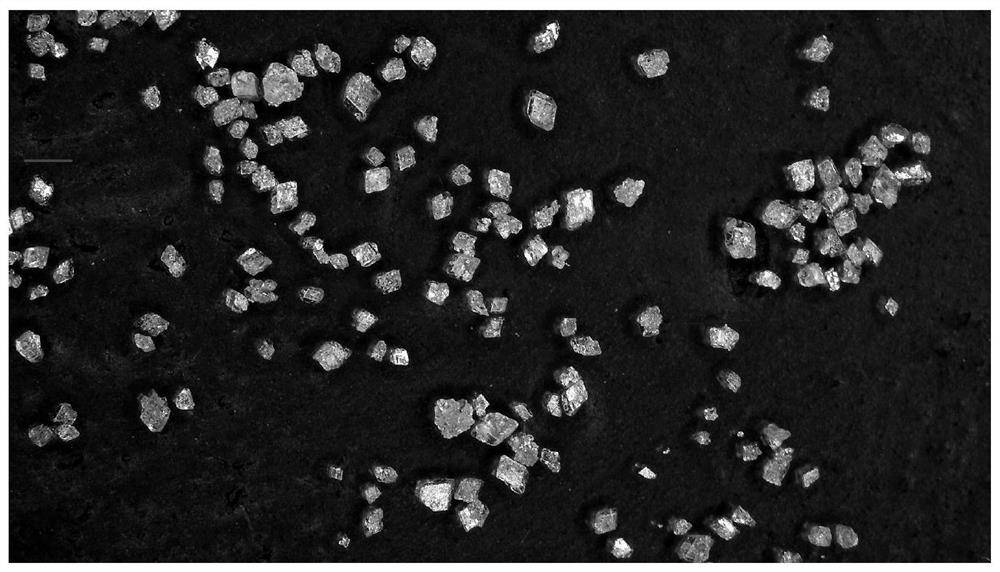

Preparation method of ammonium persulfate crystal

ActiveCN112678779AEasy to controlHigh purityPeroxyhydrates/peroxyacidsPhysical chemistrySeed crystal

The invention provides a preparation method of an ammonium persulfate crystal. The preparation method comprises the following steps of: adding an ammonium persulfate seed crystal into a mixed solution of ammonium persulfate and ammonium sulfate at 25-35 DEG C under the stirring action of a push-type stirrer with a guide cylinder to carrying out seeding; slowly heating to 0.5-1 DEG C; and cooling to -3 to -10 DEG C at a cooling rate of 3-18 DEG C / h, and carrying out cooling crystallization to obtain the ammonium persulfate crystal. The average particle size of the ammonium persulfate crystal is greater than 800 microns. According to the preparation method of the ammonium persulfate crystal of the present invention, the push-type stirrer with the guide cylinder is used, the micro-amplitude 0.5-1 DEG C heating process is performed, and a cooling range is extended; and the growth and crystallization process of the crystal can be well controlled through the synergistic effect of a plurality of factors, and therefore, the purity, the uniformity and the average particle size of the crystal can be increased, the anti-caking performance of the ammonium persulfate crystal can be improved, and the application range of the product is greatly extended.

Owner:TIANJIN UNIV

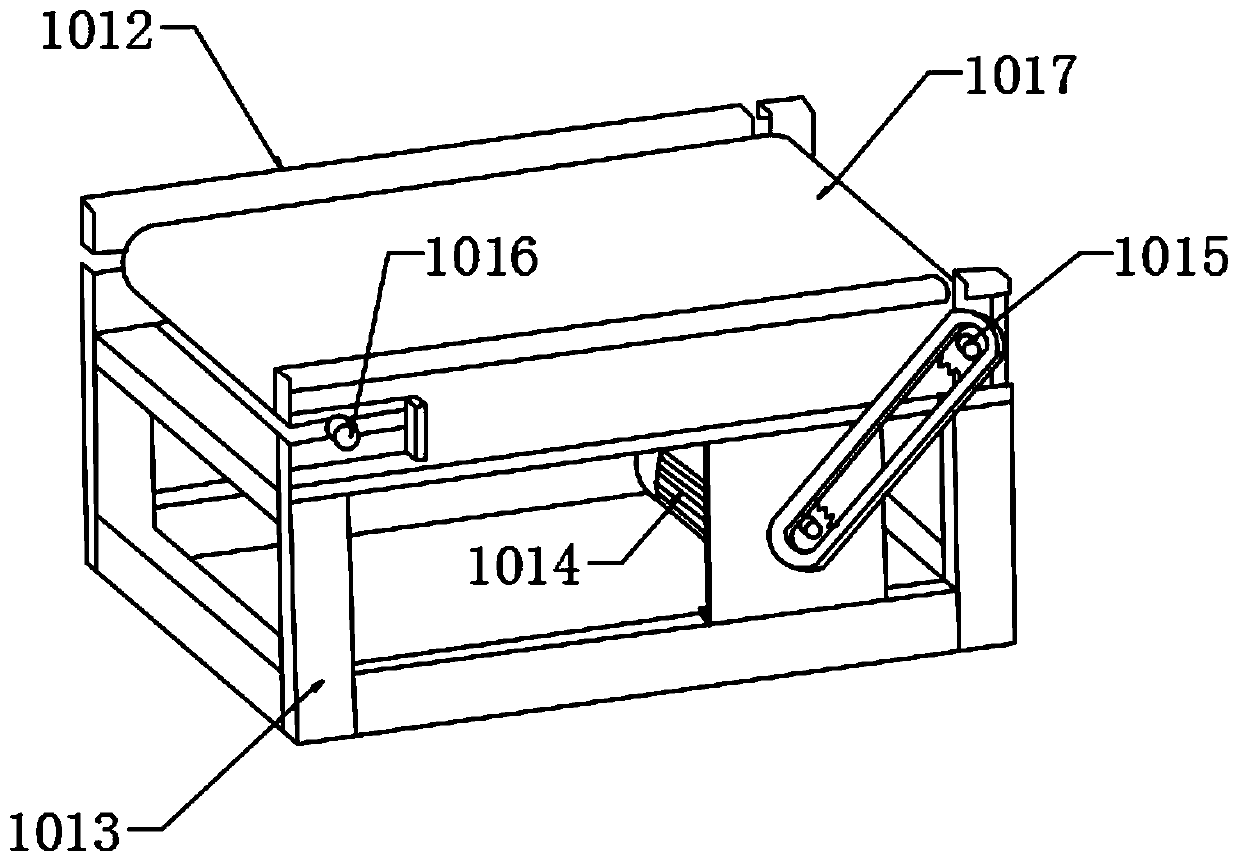

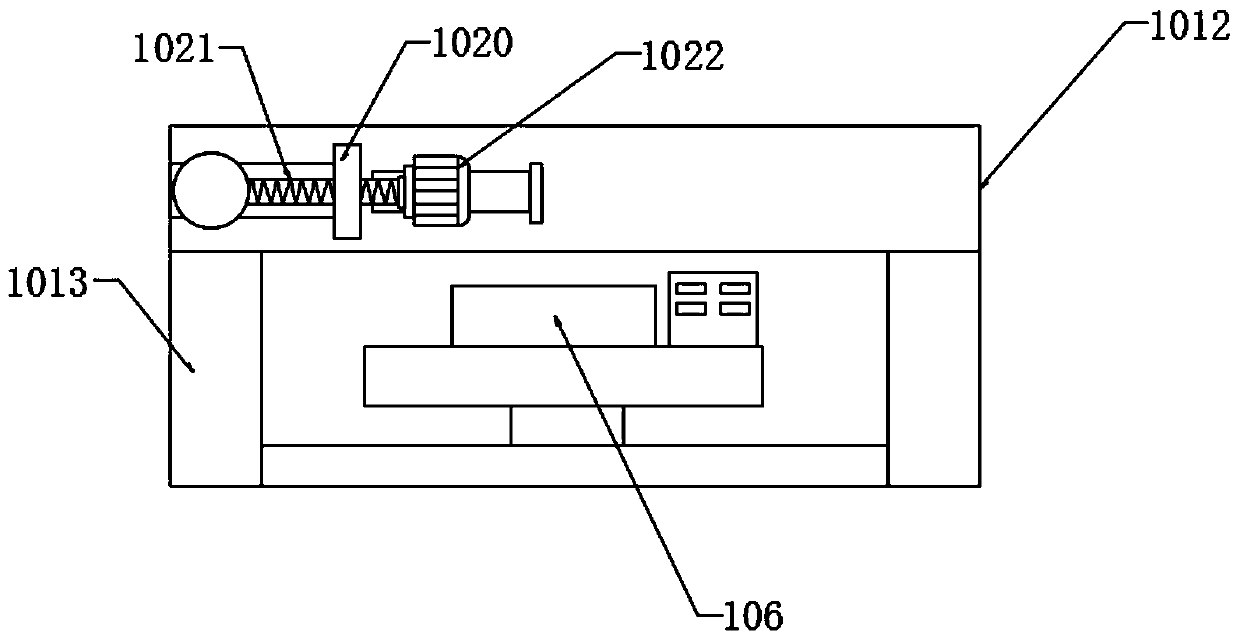

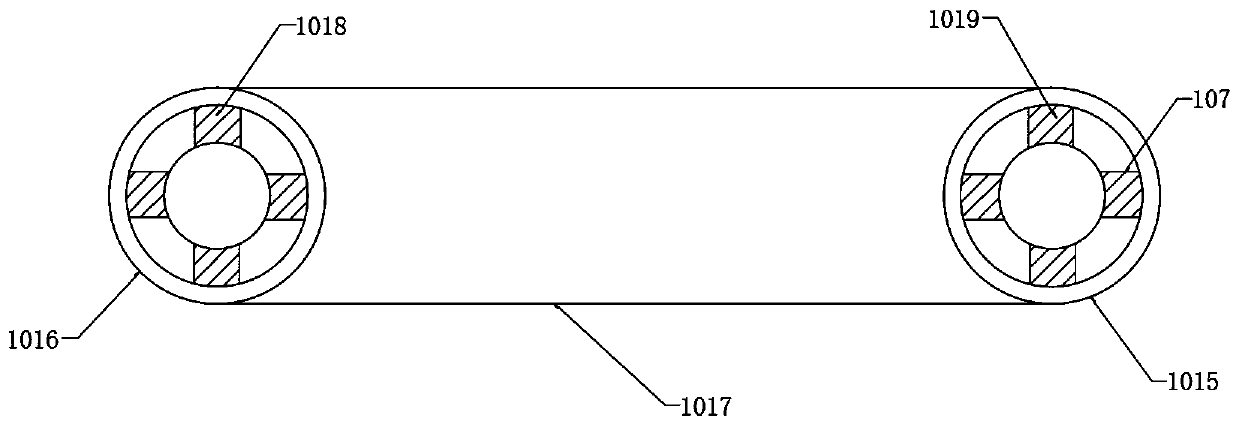

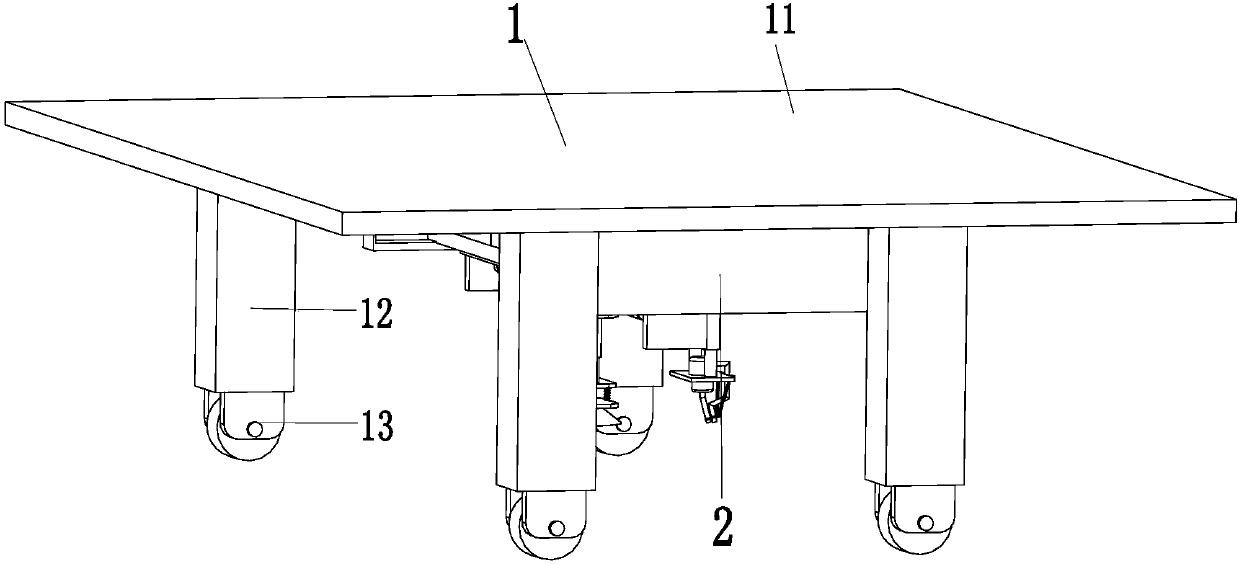

Urban municipal road transformation construction integrated equipment

InactiveCN107964861ADry thoroughlyEasy to grabRoad cleaningRoads maintainenceRoad surfaceAsphalt concrete

The invention relates to urban municipal road transformation construction integrated equipment. The urban municipal road transformation construction integrated equipment comprises a supporting device,a drying device, a shoveling device and a paving device; the drying device is mounted at the bottom of the left end of the supporting device; the shoveling device is mounted at the bottom of the supporting device and located on the right side of the drying device; and the paving device is mounted at the right end of the supporting device. According to the urban municipal road transformation construction integrated equipment, the problems that in existing road surface construction, drying of the road surface is not thorough, drying treatment of the road surfaces with the different inclinationsand gradients and excavating of the road surfaces on the two sides of a road cannot be achieved, grabbing of road fragments is troublesome, asphalt concrete is stirred insufficiently, and the situation that an excavated roadbed is paved with the asphalt concrete uniformly cannot be achieved can be solved; and the functions that in road surface construction, the road surface is dried comprehensively and thoroughly and is excavated and shoveled thoroughly, and the roadbed is paved with the asphalt concrete uniformly can be achieved.

Owner:储茂松

Environmentally hardened Ethernet switch

InactiveUS7239497B2Improve the immunityImprove system reliabilityData switching current supplyComponent plug-in assemblagesPower utilityElectromagnetic interference

A device for hardening an Ethernet switch is disclosed. The device provides cooling for the switch, and, suppresses electrical transients and electromagnetic interference, which could affect the power supply, and data transmission of the Ethernet switch. Using this device, the Ethernet switch can be used in harsh industrial environments, such as those present in power utility substations.

Owner:SIEMENS CANADA LTD

Rapid cooling device for joint of lining stainless steel pipe

InactiveCN111069806ALarge cooling rangeEasy to retractWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelElectric machine

The invention discloses a rapid cooling device for a joint of a lining stainless steel pipe. The rapid cooling device comprises a base, wherein the two ends of the upper parts of the surfaces, opposite to each other, of bottom vertical plates are symmetrically and fixedly connected with a transverse plate; a water outlet pipe communicates with the middle position of the bottom of a water tank; a sprayer is fixedly connected to the bottom of the water outlet pipe; a motor is fixedly arranged on the side wall of a support; an output shaft of the motor is fixedly connected with one short shaft, and the other end of the short shaft penetrates through the side wall of one vertical plate; a driving wheel fixedly sleeves the outer wall of the short shaft and is connected with a driven wheel through a belt; the inner ring of the driven wheel fixedly sleeves a rotating shaft, and the other end of the rotating shaft penetrates through another vertical plate to be fixedly sleeved with the inner ring of a driven wheel which is far away from the motor; the side wall of the other end of a cylinder and the side wall of a turntable on the left side are rotatably attached with a clamping column andfixedly connected with a clamping column respectively; fixing grooves are respectively formed in the surfaces, opposite to each other, of the clamping columns; and the steel pipe is movably clamped in the fixing grooves. According to the rapid cooling device, the rotating shafts are utilized to rotate, so that the turntables at the two ends of the device are further driven to simultaneously rotate, finally the steel pipe are made to rotate along with the turntables, and the cooling range is wider.

Owner:JIANGSU SHUNLONG PIPE TECH CO LTD

Energy-saving chicken house

PendingCN107517880AAchieve cleanupImprove cleaning efficiencyBird housingsEngineeringMechanical engineering

Owner:贵州松羽禽业有限公司

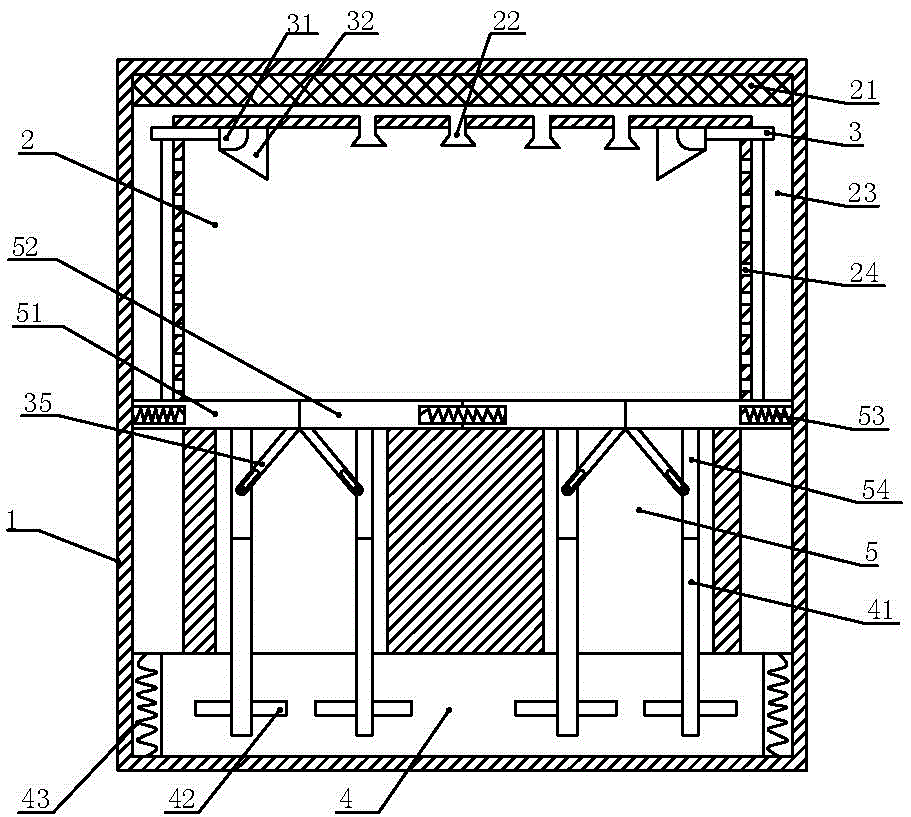

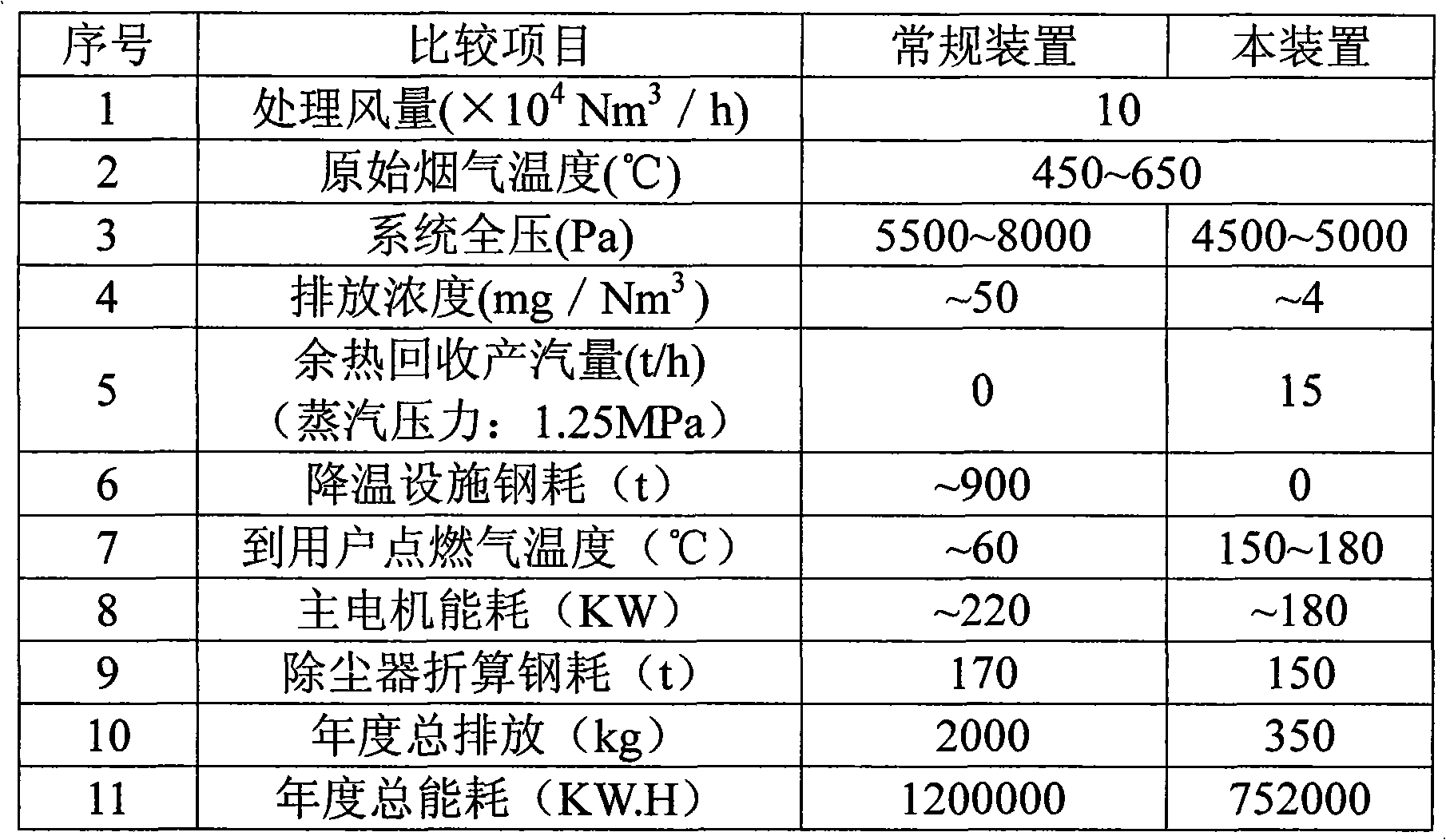

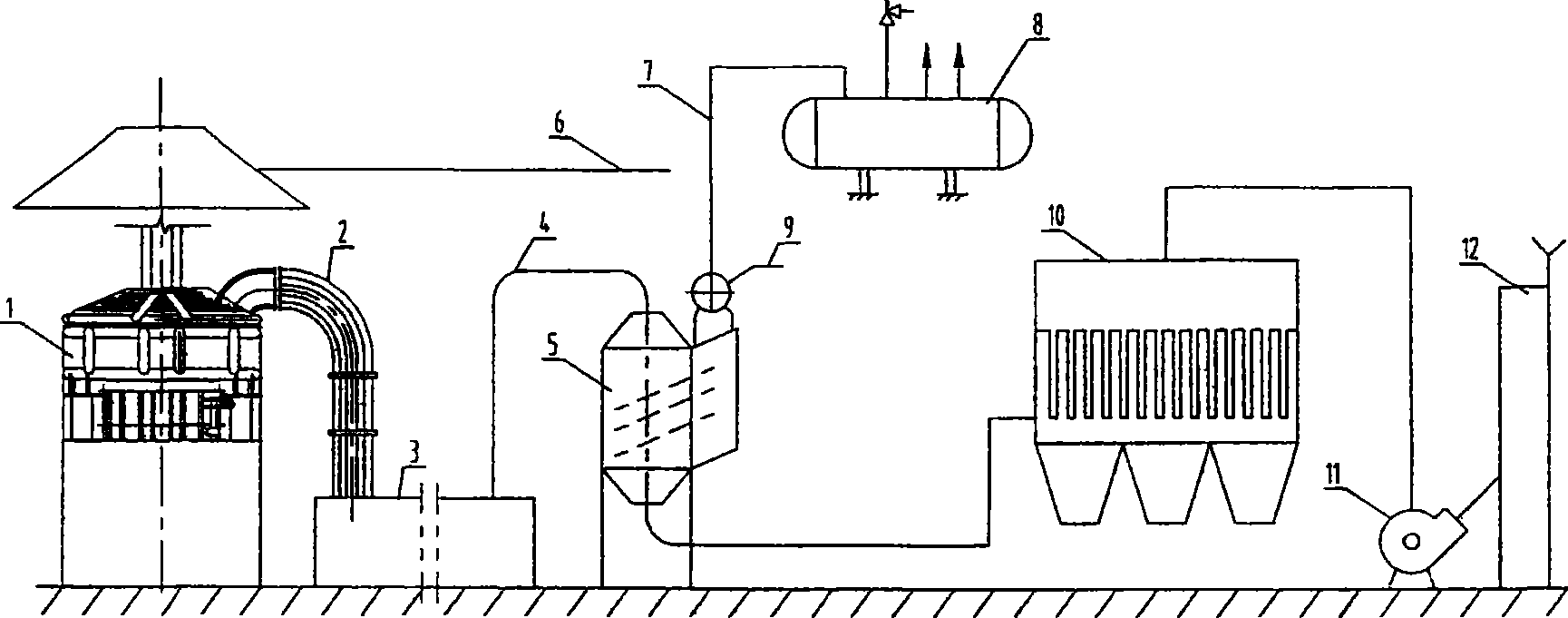

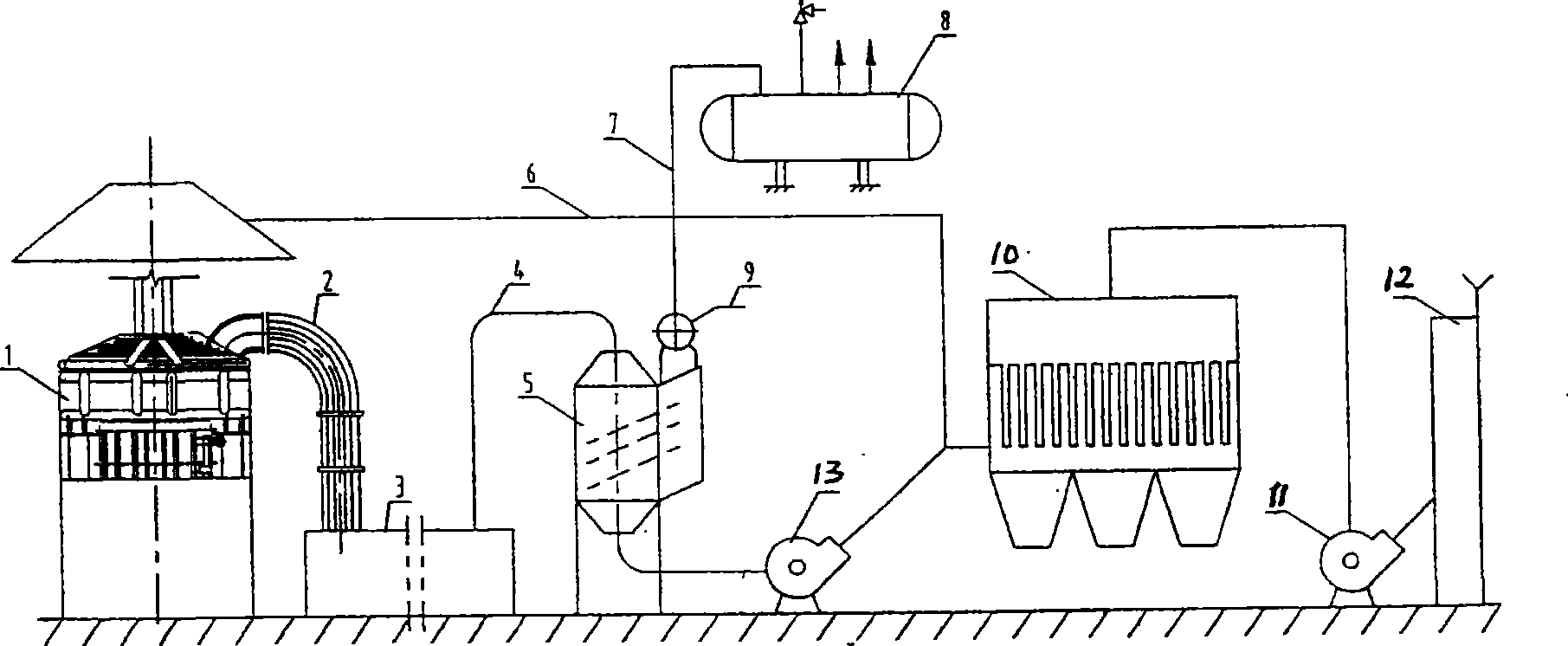

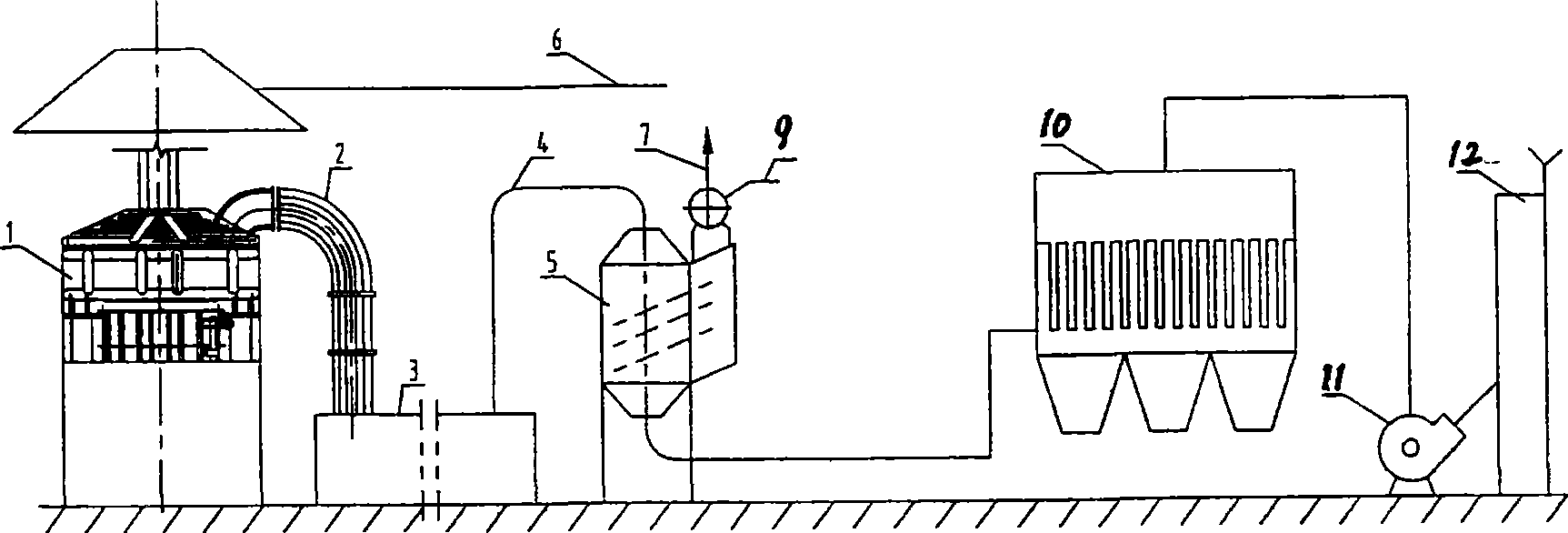

Electric furnace waste heat recycling and dedusting device

InactiveCN101995165ANo grayWork noDispersed particle filtrationIncreasing energy efficiencyElectric arc furnaceEngineering

The invention relates to an electric furnace waste heat recycling and dedusting device which comprises a deduster, a main fan, an exhaust cylinder and a heat pipe steam generator that are sequentially connected. The electric furnace waste heat recycling and dedusting device is characterized in that the heat pipe steam generator is connected with a fully-closed electric furnace through an insulation flue, and the output end of the heat pipe steam generator is connected with the deduster. The electric furnace waste heat recycling and dedusting device is further characterized in that the heat pipe steam generator is formed by combining a heat exchange pipe bundle, the heated section of the heat exchange pipe bundle is arranged in a high-temperature flue, the smoke transversely passes through the heat pipe heated section, and the heating section of a heat pipe element is inserted into a water-steam system. In the structure, the heat pipe steam generator is replaced with an equipment combination of a power cooler, a spraying cooler and the like, thus the system configuration is simplified, the smoke waste heat is recycled furthest, the cooling range is large and the operation cost is lowered.

Owner:无锡市曜通环保机械有限公司

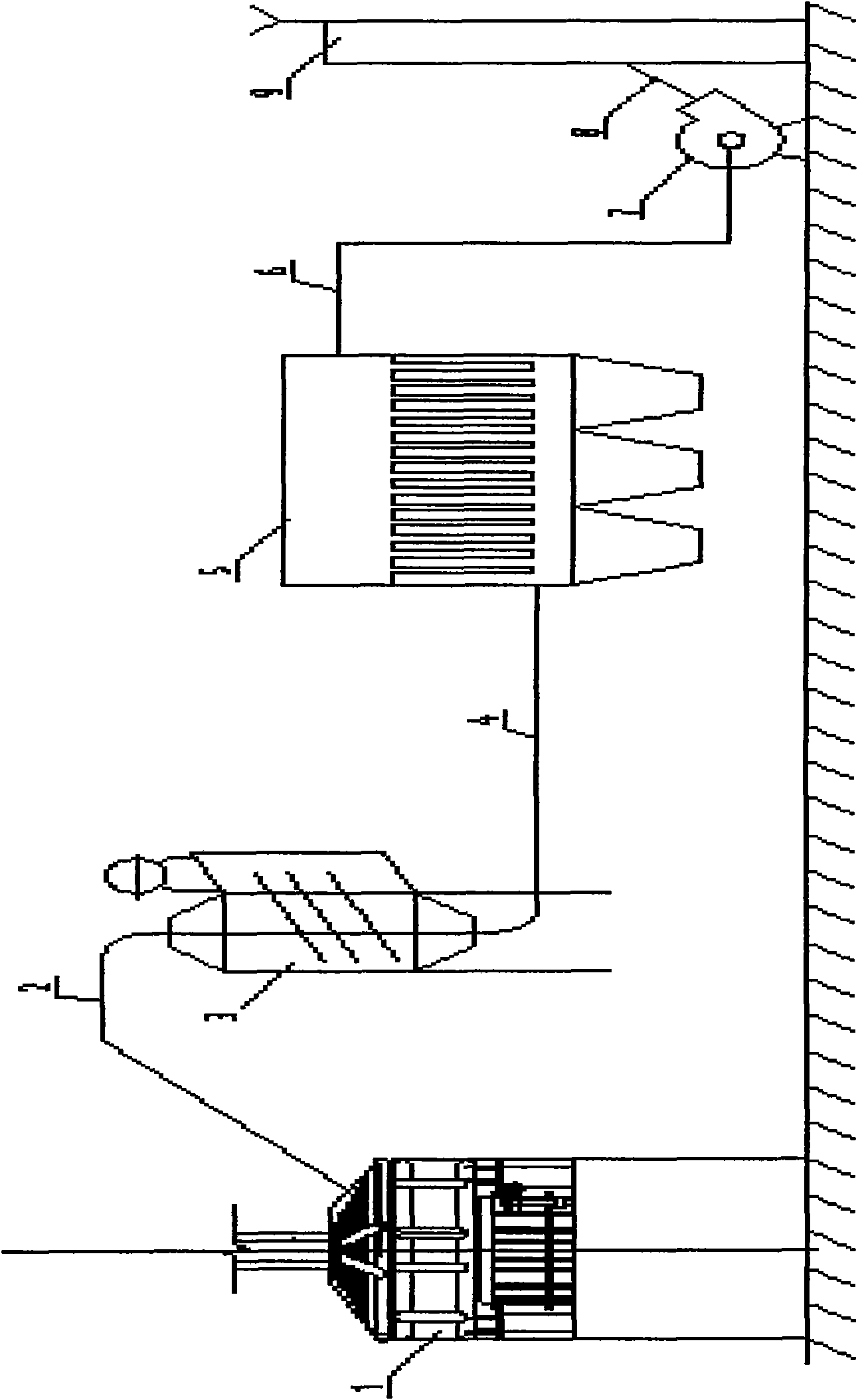

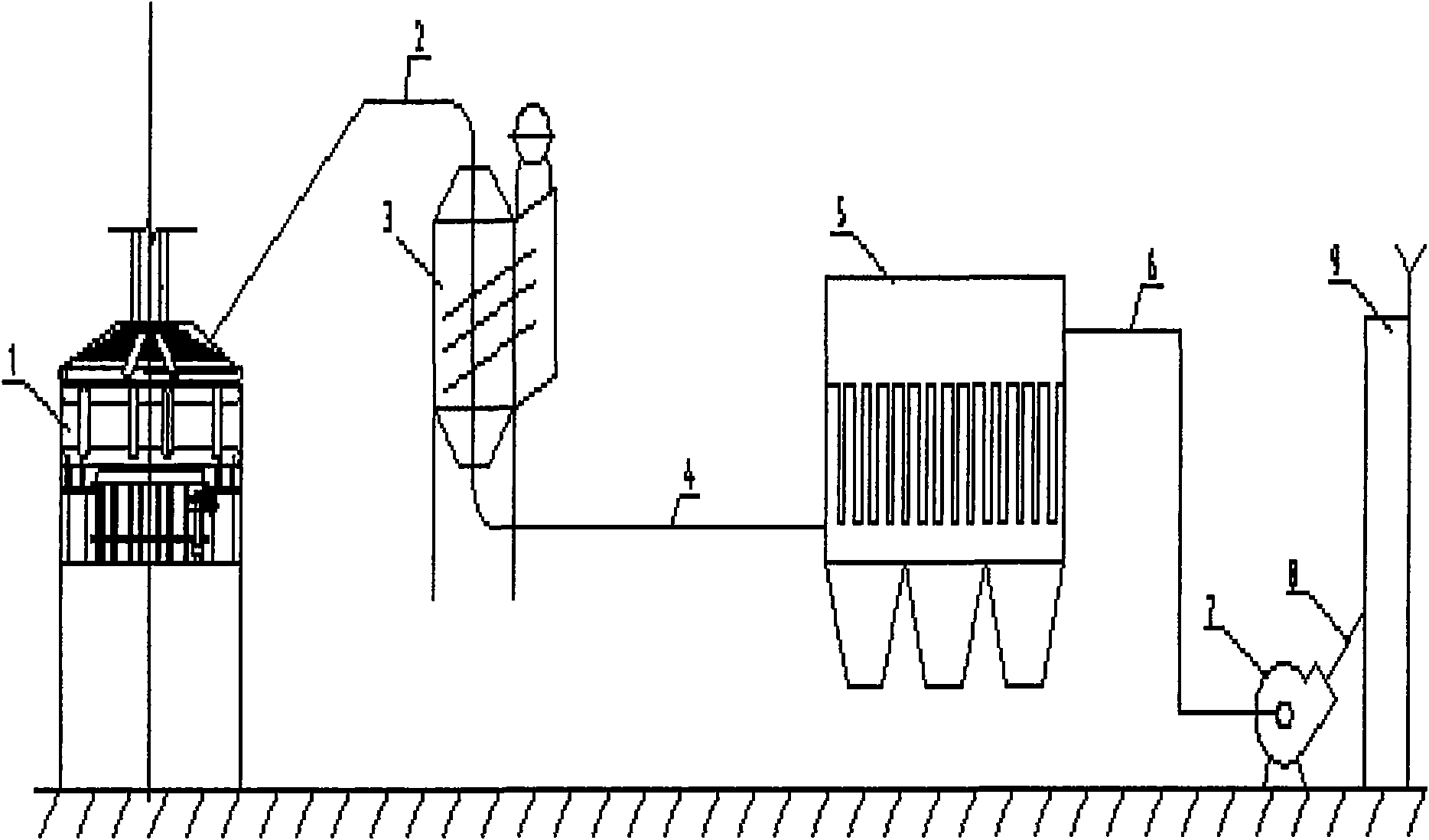

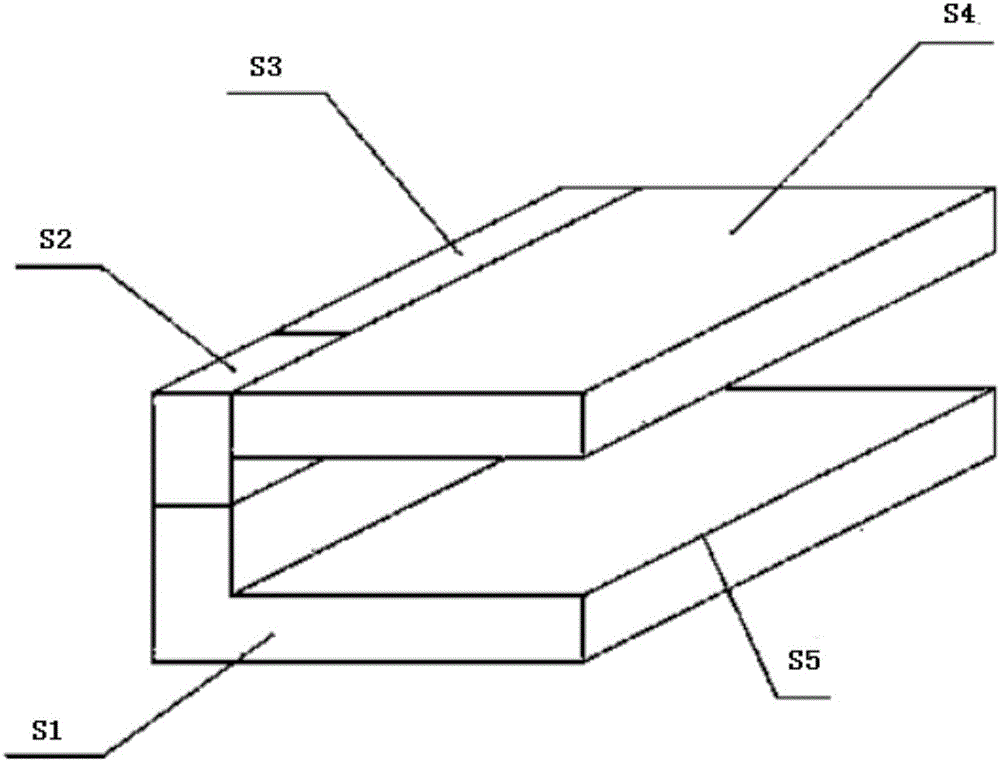

Smoke removing, temp lowering, afterheat using and recovering system in arc furnace and its dust removing technology

ActiveCN100513962CLow running costGuaranteed uptimeIncreasing energy efficiencyWaste heat treatmentAir volumeElectric arc furnace

Owner:无锡市东方环境工程设计研究所有限公司

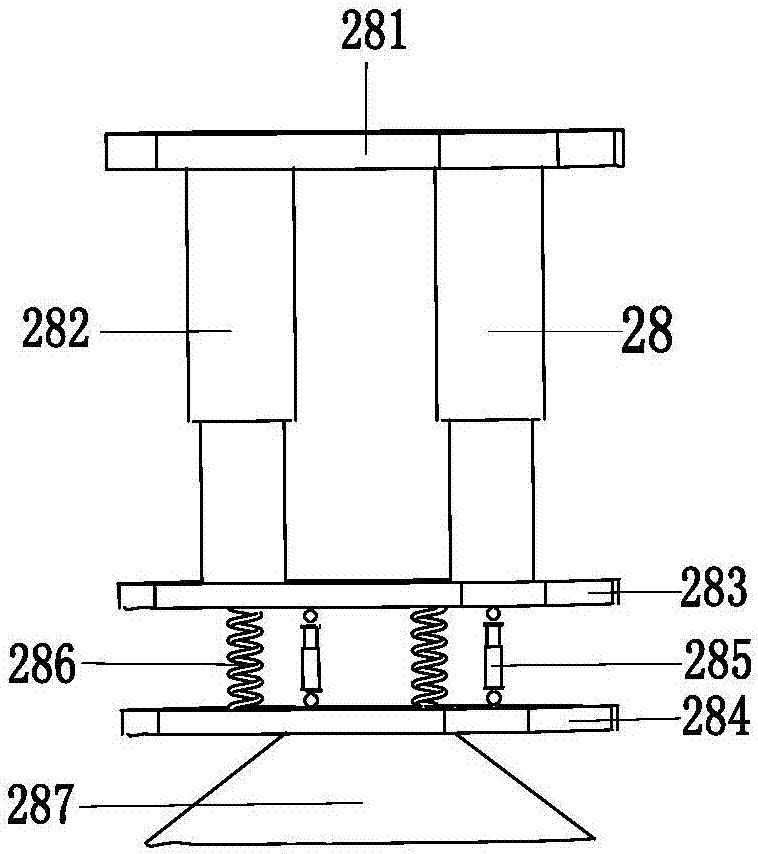

Full function testing device for AC charging pile

ActiveCN105978062ASuspension stabilityIncrease the application cycleBatteries circuit arrangementsCharging stationsPrimary stationComputer module

The invention discloses a full function testing device for an AC charging pile. A terminal main control CPU controls other modules through communication ports. A wireless communication module connects the terminal CPU module of the charging pile for an electric automobile with an upper computer system of a dispatching main station, so as to realize wireless communication. Besides, the upper computer system of the dispatching main station is also provided with a cooling device. The cooling device contains an L-shaped cabinet containing refrigerating fluid. The refrigerating fluid is used for assisting cooling for the upper computer of the dispatching main station. A snap fastener includes a slave buckle and a master buckle embedded with each other. The slave buckle includes a pedestal and an embedding head. The pedestal is connected with the bottom wall of the outer side of a cuboid or cylindrical box. By adopting the device provided by the invention, shortcomings of insufficient cooling range, low efficiency, incapability of ensuring the correctness of upper computer operation of the dispatching main station and untight combination of the slave buckle and the master buckle are avoided.

Owner:ZHEJIANG WELLSUN INTELLIGENT TECH CO LTD

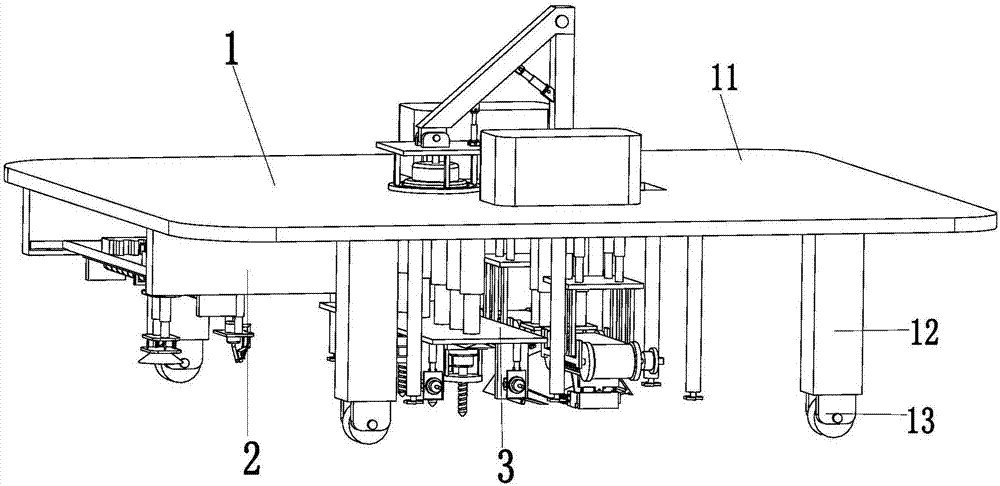

Concrete road renovation engineering pavement construction operation intelligent robot

The invention relates to a concrete road renovation engineering pavement construction operation intelligent robot which comprises a supporting device, a drying device and a paving device. The drying device is installed at the bottom of the left end of the supporting device, and the paving device is installed at the right end of the supporting device. The robot can solve the problems that in the existing pavement construction process, pavements are not completely dried, the pavements with different gradients and slopes cannot be dried, bituminous concrete is not fully mixed, and an excavated roadbed cannot be evenly paved with the bituminous concrete; and the functions that in the pavement construction process, the pavements can be thoroughly dried in all directions, and the roadbed can beevenly paved with the bituminous concrete can be achieved, and the robot has the beneficial effects that the pavements are completely dried, the pavements with different gradients and slopes can be dried, the bituminous concrete is fully mixed, and the excavated roadbed can be evenly paved with the bituminous concrete.

Owner:刘静

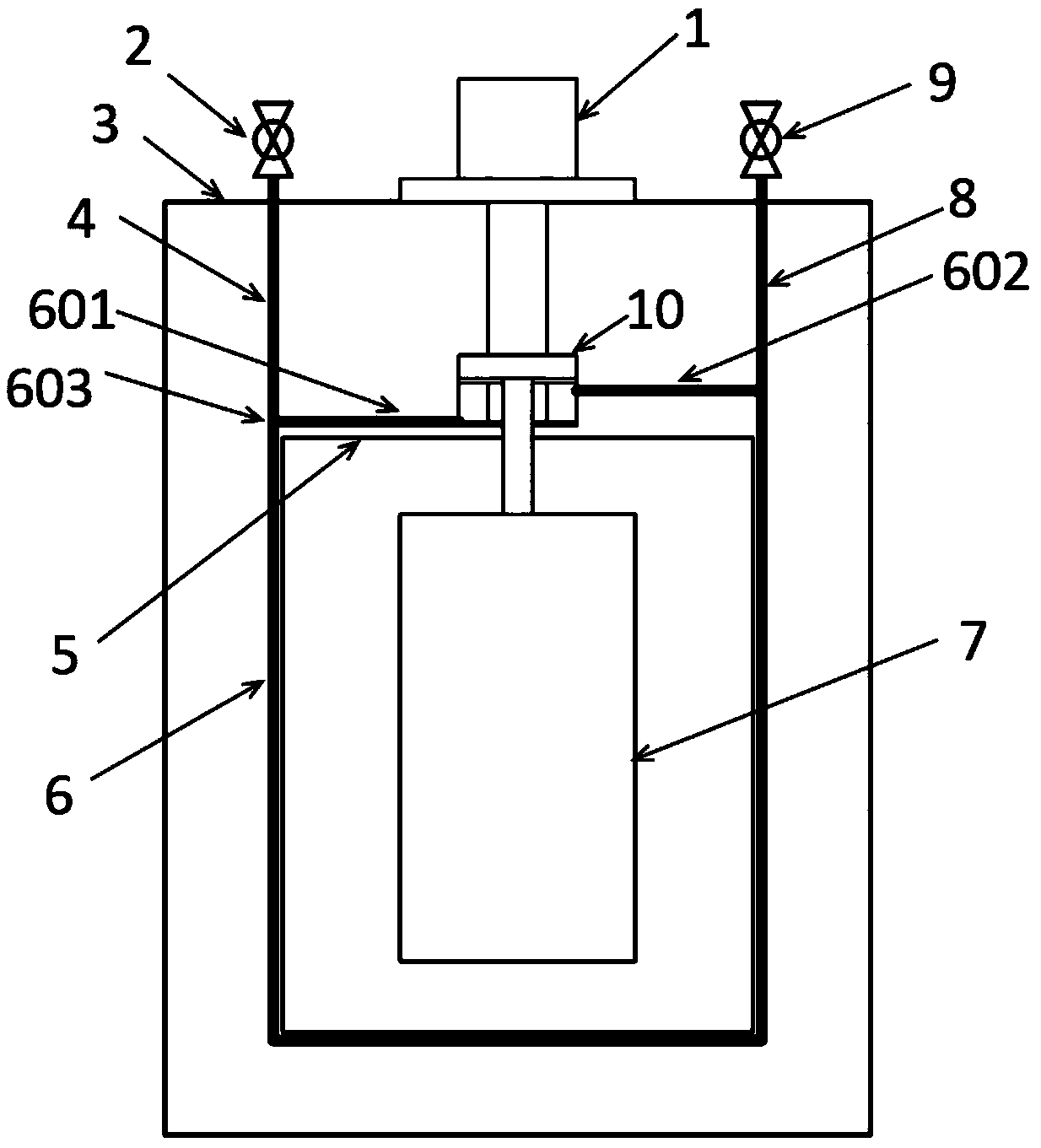

Structure and method for cold shied rapid temperature reduction

ActiveCN109285646ARapid coolingSmall temperature differenceSuperconducting magnets/coilsCold shieldInlet valve

The invention discloses a structure for cold shied rapid temperature reduction. The structure comprises a refrigerating machine, an inlet valve, a room temperature dewar, a liquid injection passage, acold shied, a heat pipe, a liquid helium container, an air outlet passage, an outlet valve, a condensed heat exchanger, an external liquid injection pipe, and the refrigerating mechanism longitudinally penetrates through the dewar and arranged above the middle of the room temperature dewar. According to the structure, low-temperature liquid is introduced to the heat pipe from the exterior, heat coupled with a cold shied outer tube and a cold shield end plate can be rapidly absorbed, and the rapid temperature reduction of the cold shield can be achieved. A manner of 'gas-liquid circulation' formed by using low-temperature liquid can effectively maintain the low temperature of the cold shield, and additional low-temperature liquid replenishment is not needed. Compared with a current technology in which the cold shield is cooled down by using the conduction of a copper weaving belt, the structure and a method have the advantages of compact structure and low temperature difference of a cooling object, and the structure is firm and durable, has good social benefits and is suitable for popularization and use.

Owner:HEFEI CAS ION MEDICAL & TECHNICAL DEVICES CO LTD

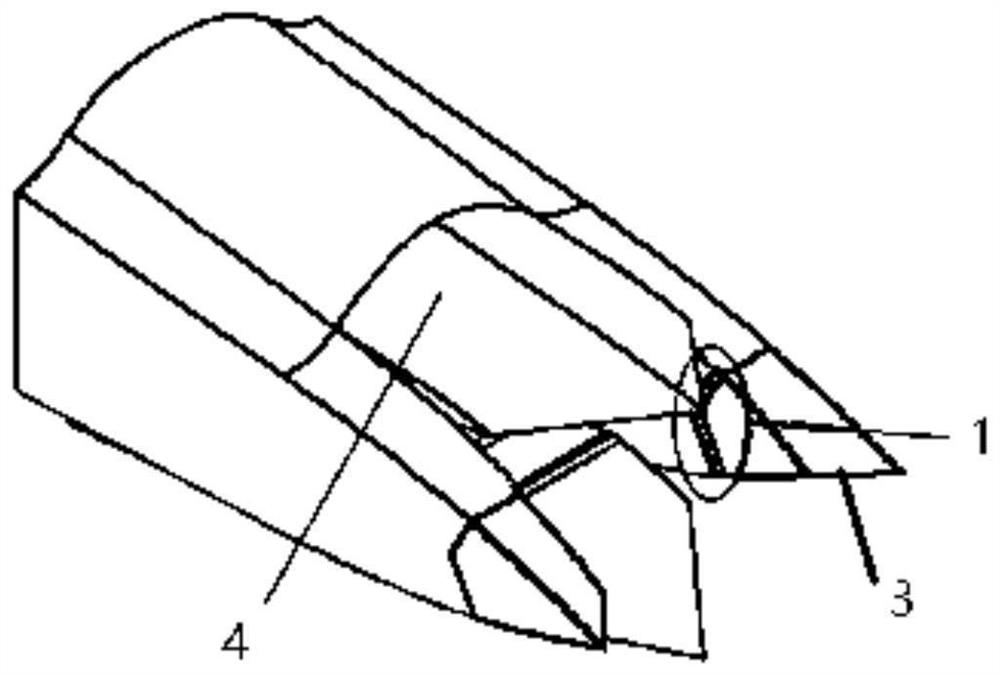

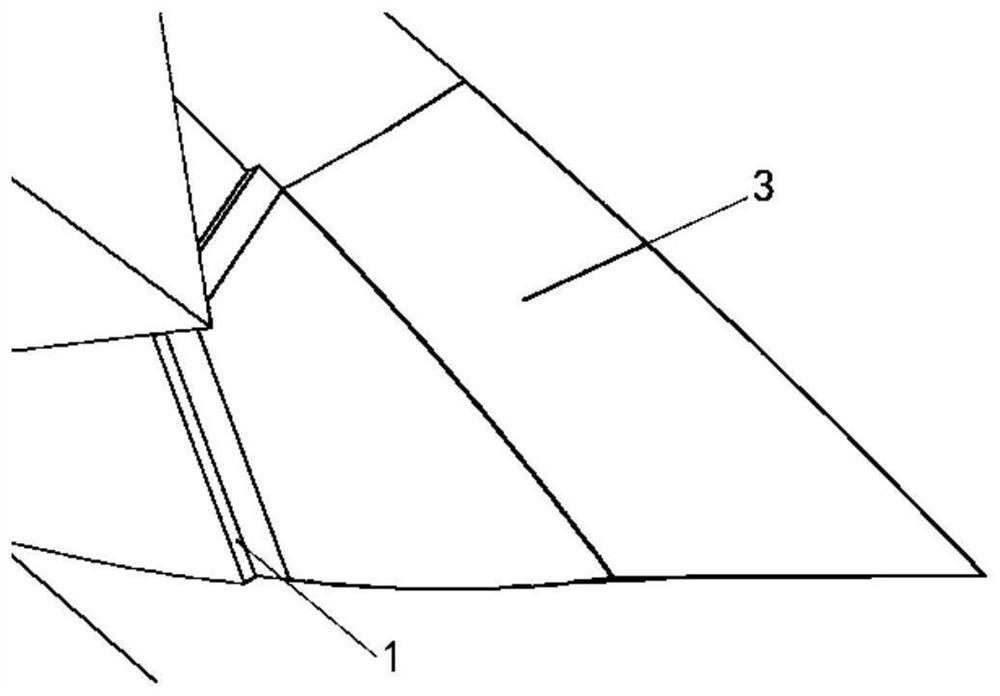

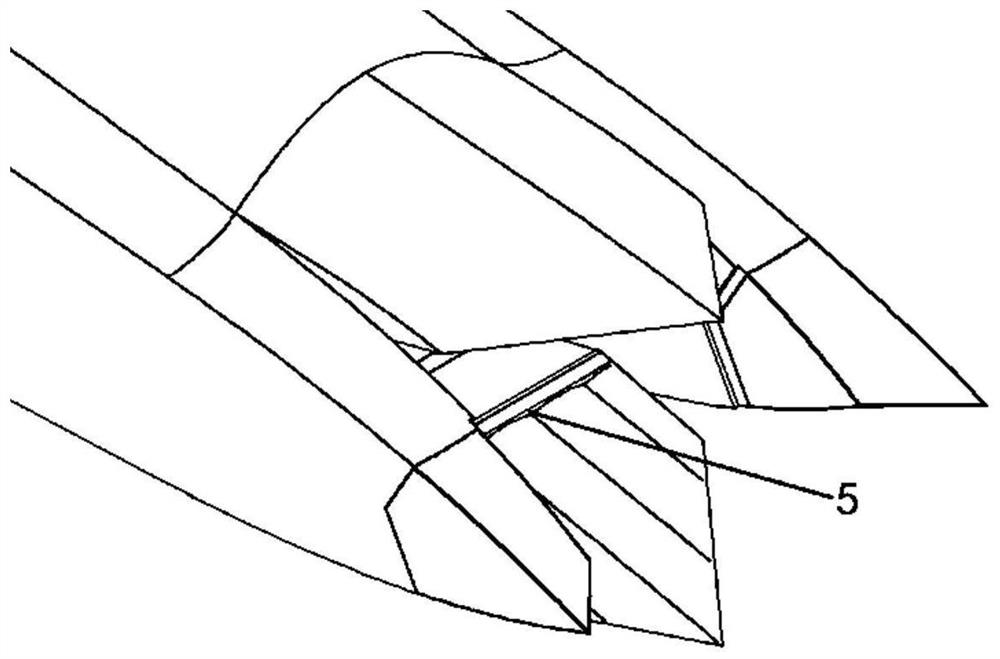

Spray pipe and aircraft afterbody slit exhaust cooling device

PendingCN114017203AHigh strengthLarge cooling rangePower plant exhaust arrangementsJet propulsion plantsJet flowCooling effect

The invention belongs to the technical field of engine design, and particularly relates to a spray pipe and an aircraft afterbody slit exhaust cooling device. The device comprises a gas collecting cavity communicated with an engine outer culvert, the gas collecting cavity is located between the side wall of a spray pipe and the inner wall face and the outer wall face of a throat adjusting piece, the gas collecting cavity is provided with a side wall exhaust slit (1) at the rear end of the side wall of the spray pipe, the side wall exhaust slit (1) is formed in the front side of an aircraft afterbody or a tail cone (3), and exhaust of the side wall exhaust slit (1) is roughly parallel to the jet flow direction of the spray pipe; the air collecting cavity is provided with an expansion section exhaust slit (5) on the inner wall surface of the expansion section of the throat adjusting sheet of the spray pipe, and the exhaust direction of the expansion section exhaust slit (5) is approximately parallel to the airflow flowing direction of the near wall surface of the expansion section adjusting sheet of the spray pipe. The overall strength of the cooling mechanism is improved, the machining difficulty and the machining cost are reduced, the cooling range of the spray pipe and the aircraft afterbody is larger, the cooling effect is better, and meanwhile the backward radar stealth and infrared stealth effects of an aircraft can be better improved.

Owner:AECC SHENYANG ENGINE RES INST

First-class highway pavement cleaning device with pavement drying function

The invention relates to a first-class highway pavement cleaning device with a pavement drying function. The first-class highway pavement cleaning device comprises a supporting device, a drying deviceand a sweeping device. The drying device is installed on the bottom of the left end of the supporting device. The sweeping device is installed on the right end of the supporting device. The first-class highway pavement cleaning device can solve the problems that, in the existing pavement construction, the pavement is not thoroughly dried, pavements with different slopes and gradients cannot be dried, debris of the side wall of a subgrade after excavation cannot be effectively cleaned, and the subgrade sweeping after excavation is not thorough; and the first-class highway pavement cleaning device can fulfill the functions of comprehensively thoroughly cleaning the pavement and thoroughly cleaning the excavated debris in pavement construction, and has the advantages of thoroughly drying thepavement, capability of drying the pavements with different slopes and gradients, capability of effectively cleaning the debris of the side wall of the subgrade after excavation, thoroughly sweepingthe subgrade after excavation and the like.

Owner:王炯炜

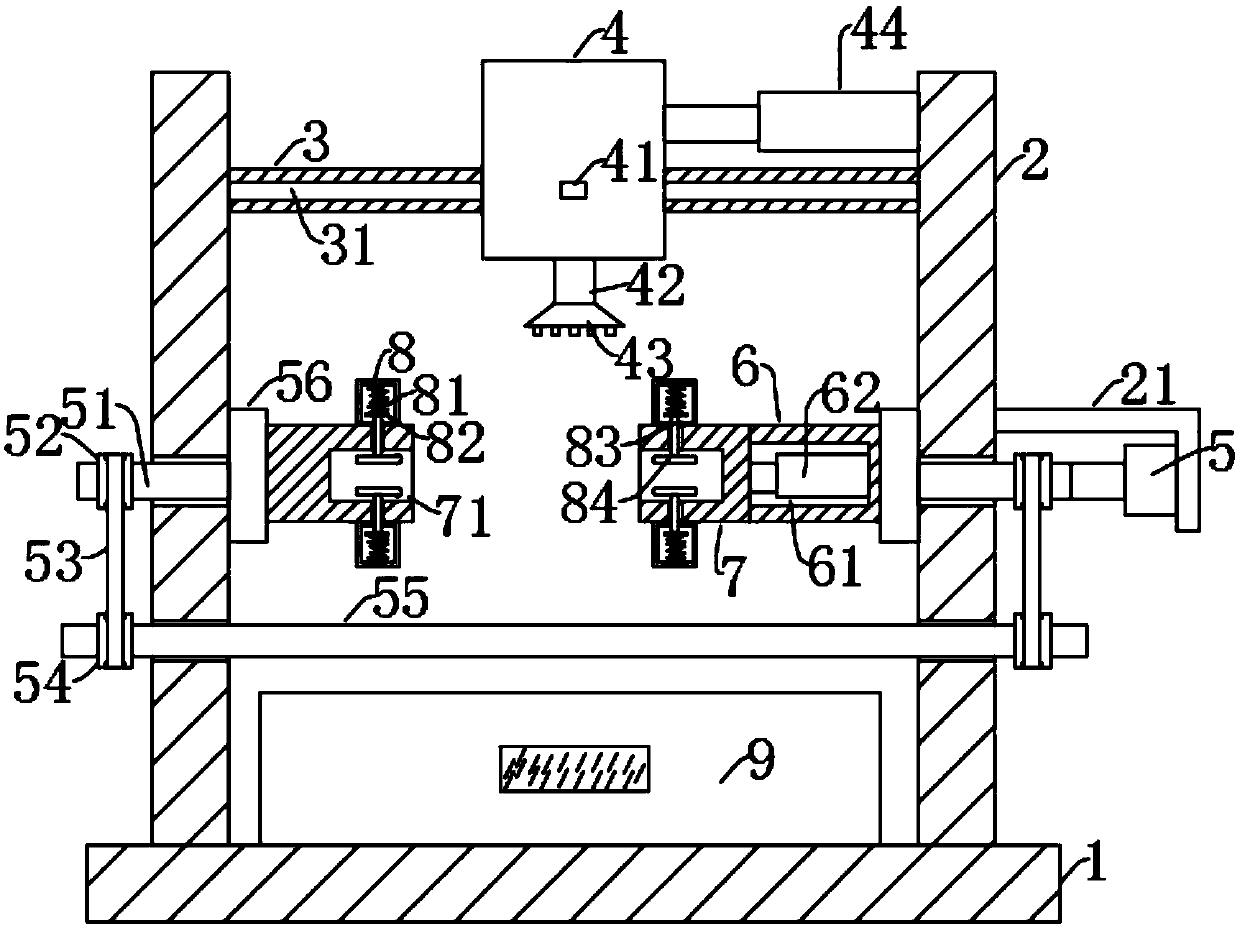

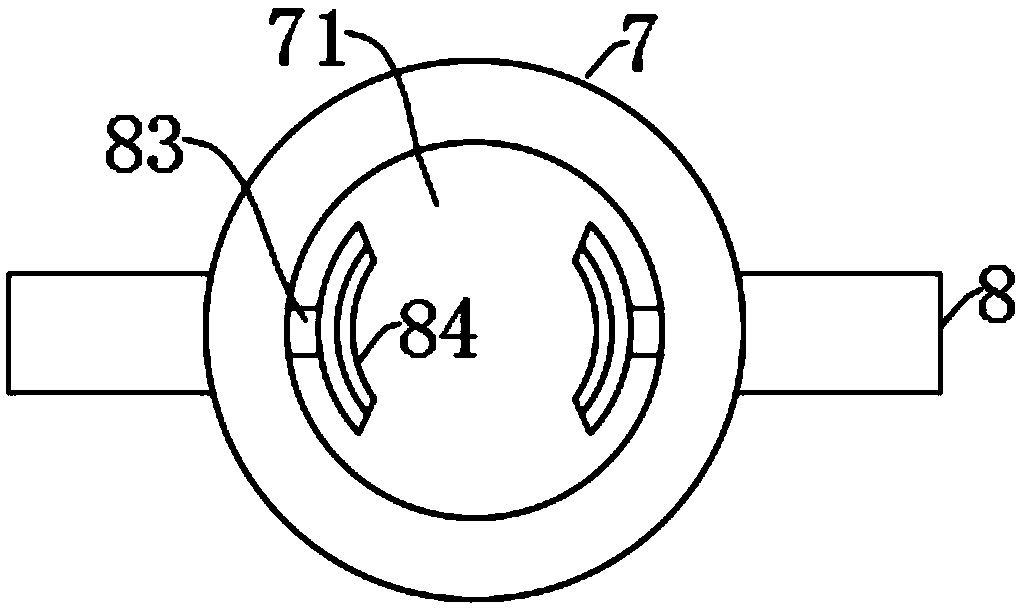

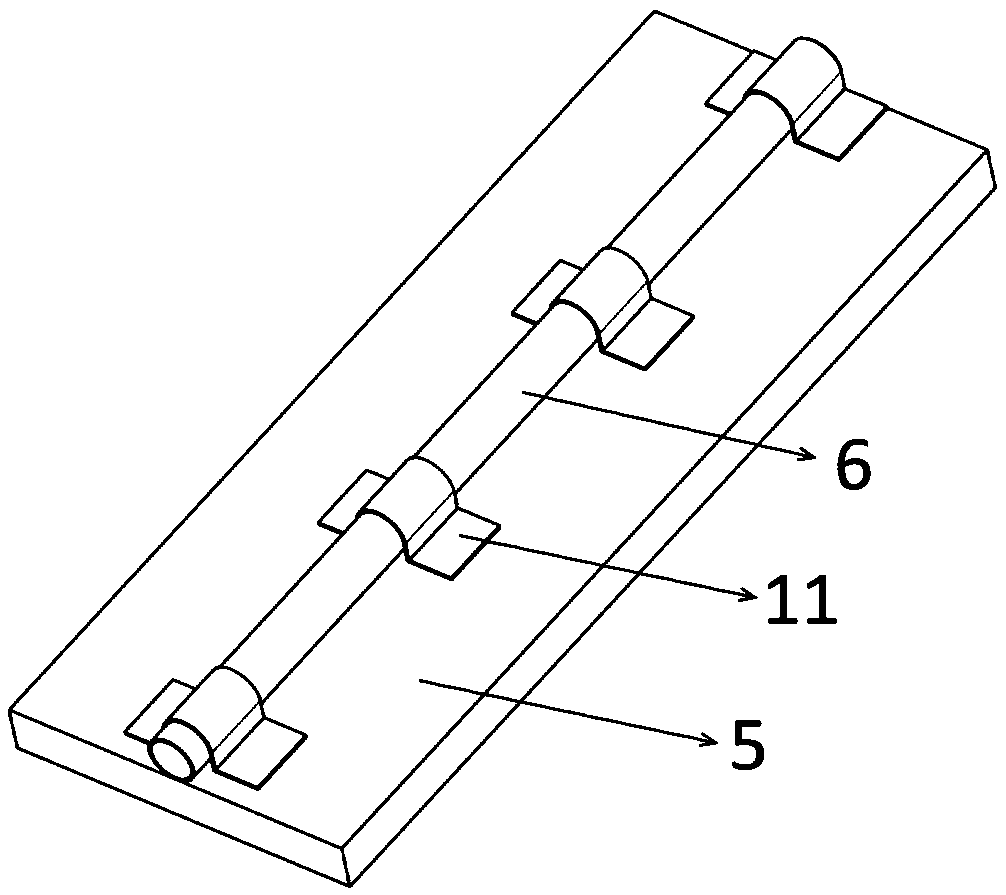

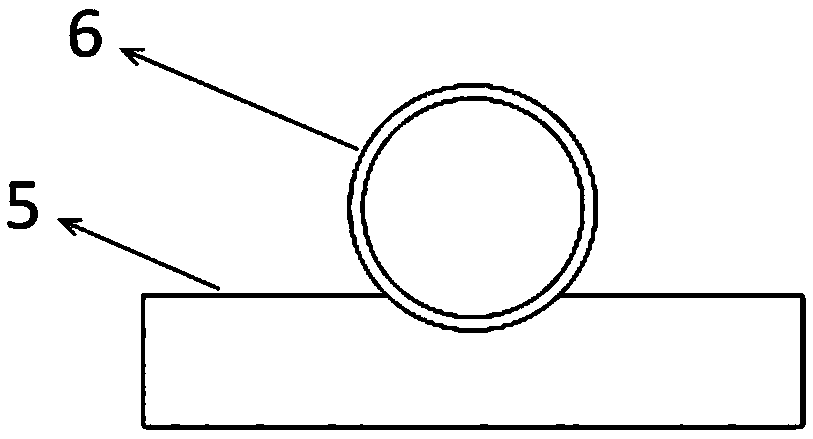

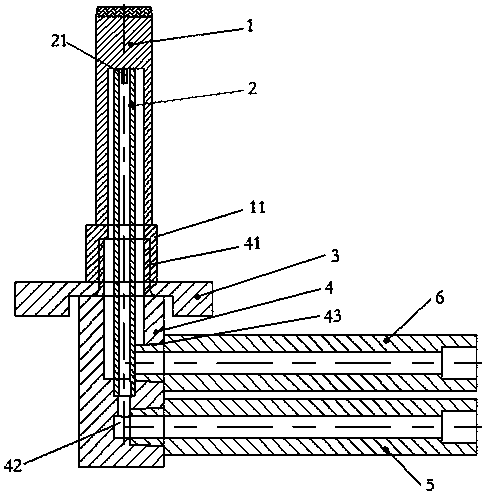

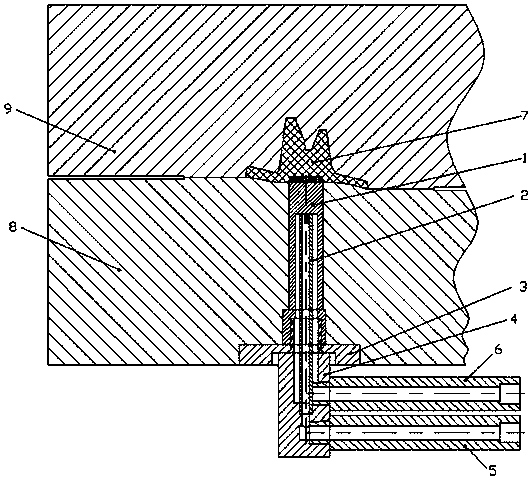

Embedding pin for injection mold

The invention relates to the field of injection molds, in particular to an embedding pin for an injection mold. The embedding pin for the injection mold comprises an embedding pin body and a cooling pipe, wherein a first cavity extending in the axial direction of the embedding pin body is arranged inside the embedding pin body; the top end of the cooling pipe extends into the first cavity; a gap is formed between the cooling pipe and the first cavity; the top end surface of the cooling pipe is in contact with the inner top surface of the first cavity; a groove body communicated with the insideof the cooling pipe and the first cavity is arranged on the top end of the cooling pipe; the cooling pipe is communicated with a water inlet pipe; the first cavity is communicated with a water outletpipeline. The problems that the structure of the embedding pin cannot be well combined with the cooling water path, and the cooling range is small in the prior art can be solved.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

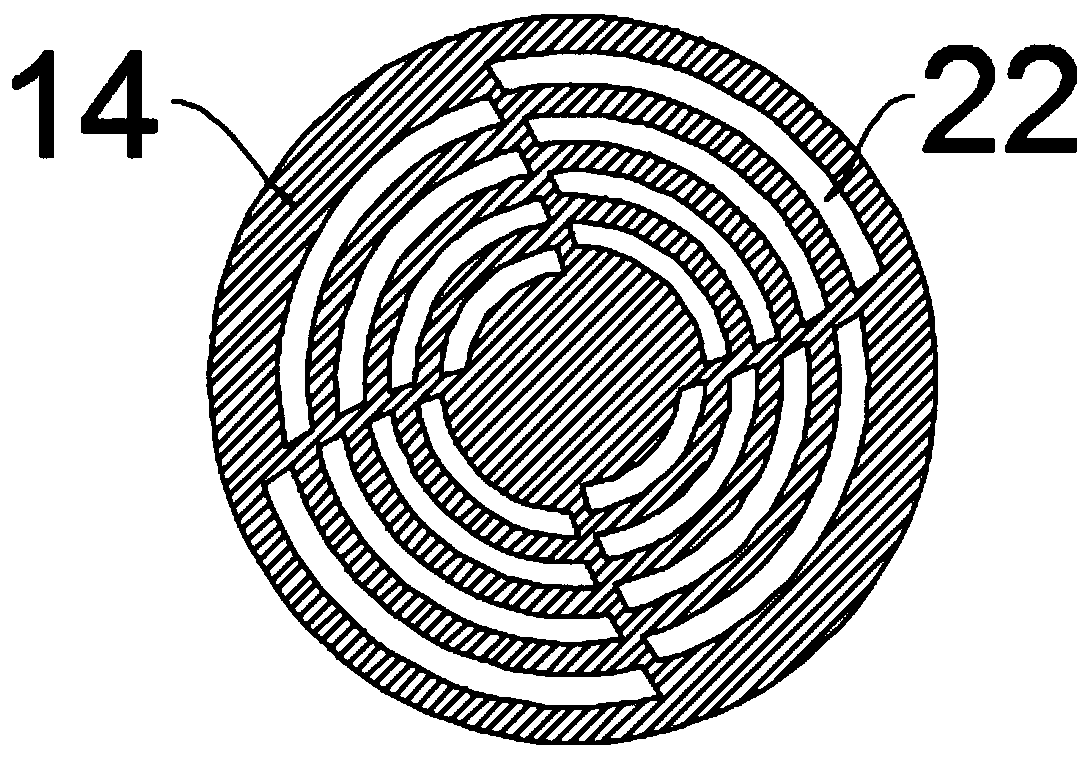

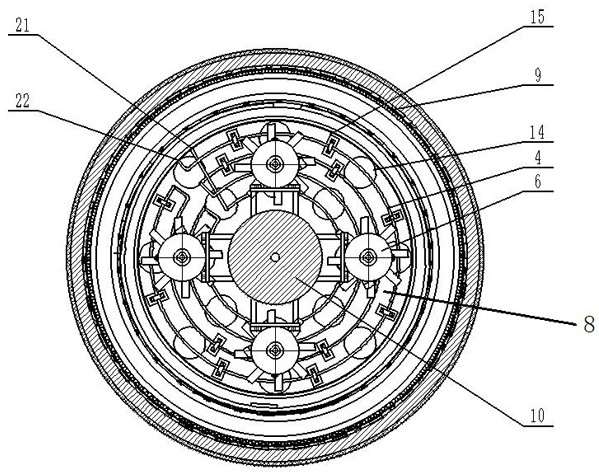

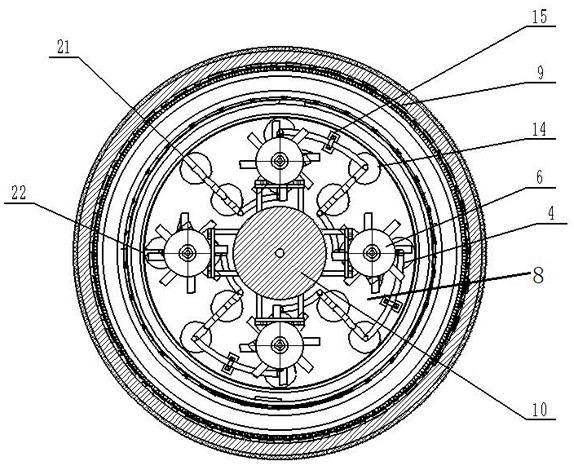

Air cooling-water cooling hybrid cooling permanent magnet roller

ActiveCN111740545AIncrease cooling areaLarge cooling rangeMagnetic circuit stationary partsCooling/ventillation arrangementStator coilCooling effect

The invention relates to the technical field of motor transmission, and discloses an air cooling-water cooling hybrid cooling permanent magnet roller, which comprises a main shaft (10), and a reciprocating water pipe (4) and fans (6) which are arranged in a stator cavity (5), wherein the main shaft (10) is provided with perforated radial plates (8) which are evenly distributed in the axial direction or rib plates (18) which are evenly distributed in the radial direction, the reciprocating water pipe (4) is fixed to the perforated radial plates (8) or the rib plates (18), and the fans (6) are evenly distributed on the main shaft (10) at the ends of the perforated radial plates (8) or the rib plates (18) in the circumferential direction. According to the permanent magnet roller provided by the invention, a stator coil assembly is cooled by a conventional cooling water path, and cooling water flows through a water pipe through a reciprocating water pipe, so that the heat dissipation areaof the cooling water in the stator cavity of the permanent magnet roller is increased; and hot air in the stator cavity is blown to the surface of the water pipe by a fan to exchange heat with the cooling water in the water pipe, so that the water-cooling heat dissipation area is increased, and the water-cooling effect is improved.

Owner:JIANGSU JIAXUAN INTELLIGENT IND TECH CO LTD

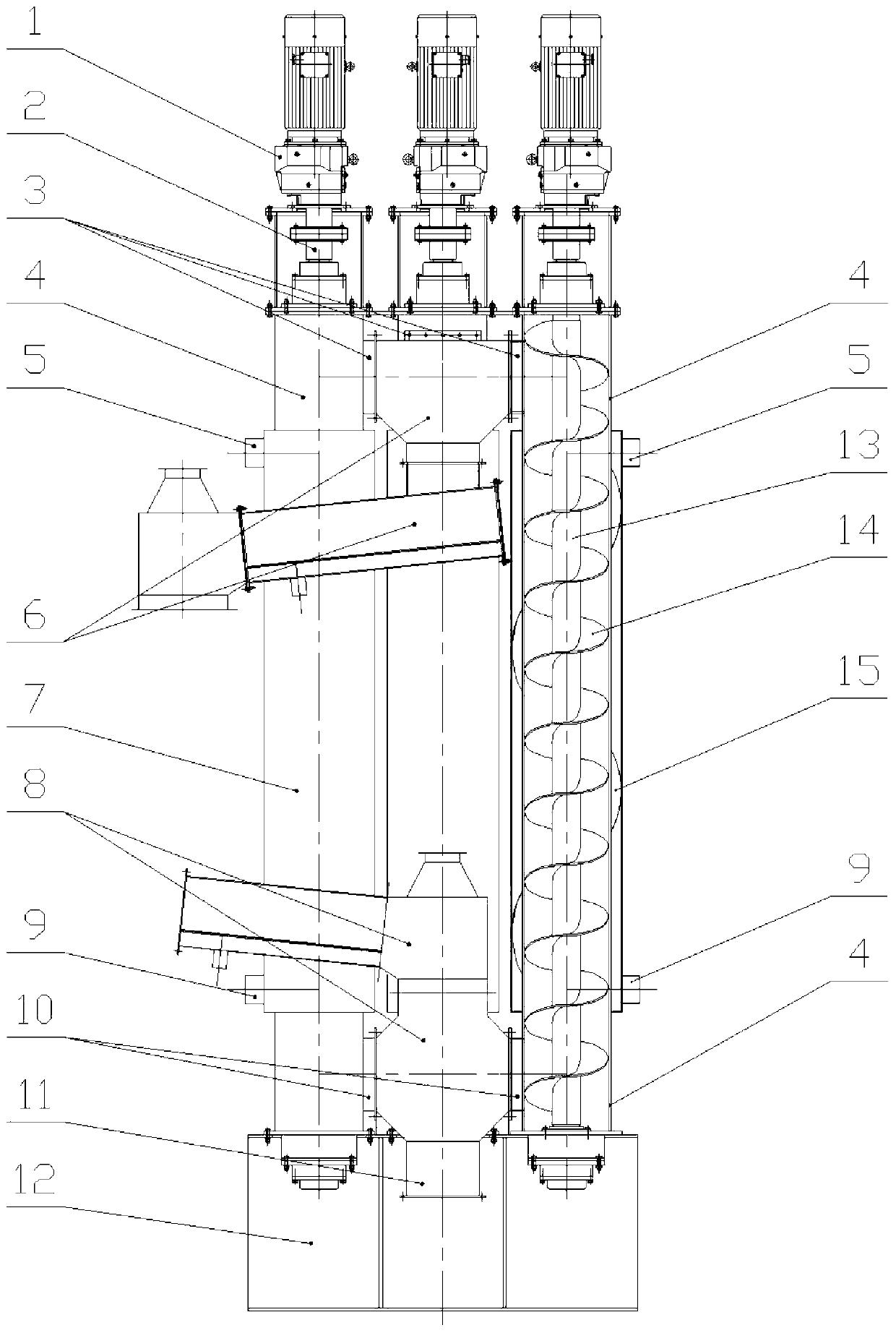

Multi-tube combined type spiral cooler

InactiveCN104197757AFull exchangeReduce consumptionMoving conduit heat exchangersSpiral bladeWater jacket

The invention discloses a multi-tube combined type spiral cooler. Vertical type tubular spiral cooling units of a plurality of independent units are combined together to form a combined part. Each independent unit comprises a tubular outer shell. One end of each outer shell is provided with a feed port used for feeding high-temperature powdery materials, and the other end of each outer shell is provided with a discharge port used for discharging the materials. The peripheral side of the portion, between the feed port and the corresponding discharge port, of each outer shell is provided with a cooling water jacket. One end of each cooling water jacket is provided with a water inlet used for injecting cooling water into the corresponding cooling water jacket, and the other end of each cooling water jacket is provided with a water outlet used for draining the cooling water. A main shaft is arranged in each outer shell and fixed to the corresponding outer shell through bearings of the two ends of the main shaft and accessories of the bearings to form a shafting part which can rotate, and each shafting part is provided with spiral blades. The end of each outer shell is provided with a power device. The combined part is provided with a feed hopper which is connected with the feed ports of all the independent units and used for distributing the high-temperature powdery materials. The combined part is provided with a discharge hopper which is connected with the discharge ports of all the independent units and used for collecting and discharging the materials.

Owner:CNBM HEFEI POWDER TECH EQUIP CO LTD

Fire protection system for belt conveyor

PendingCN110422587AFast collection efficiencyEnsure comprehensiveness and effectivenessDomestic cooling apparatusLighting and heating apparatusData conversionData transmission

The invention discloses a fire protection system for a belt conveyor. The fire protection system comprises a collection terminal and an application platform, wherein the collection terminal and the application platform are connected through a data transmission module; the collection terminal is composed of a detector, a processing mechanism and a detection unit; the detector comprises a temperature detecting module and a data conversion module; the detector is electrically connected with the detection unit; and the application platform comprises a processing module, an image display module andan alarm module. By arranging the detecting unit, omnidirectional detection operation on the temperature of a belt conveyor belt main body can be conducted rapidly, the normal use state of the belt conveyor belt main body is ensured, by arranging the processing mechanism, the belt conveyor belt main body can be effectively cooled in an assisted mode, then the belt conveyor belt main body is protected thoroughly, when the temperature of the belt conveyor belt reaches a limit value, the belt conveyor belt can be driven to stop in time, and thus the overall application safety is improved.

Owner:山东英发信息科技有限公司

Processing method of aluminum profile for passenger vehicle

The invention provides a processing method of an aluminum profile for a passenger vehicle. The processing method comprises the following steps: selecting an Al-Mg-Si series aluminum alloy ingot with the weight percentage of Mg being 0.5-1.1%, the weight percentage of Si being 0.4-0.8% and the weight percentage of Fe being less than 0.6% as an extrusion raw material of the aluminum profile; raw material selection and provided extrusion parameters are reasonable, during extrusion, metal flow is uniform, efficient and rapid, the machining range is wide, the aluminum profile extrusion device can be suitable for machining aluminum profiles of passenger vehicles with various sections and sizes, and the extruded aluminum profiles are fine in crystal grain, high in straightness, good in strength, stable in performance and high in rate of finished products. According to the provided combined online quenching method, accurate cooling control can be carried out according to the temperature and the structure state of the profile, quenching cooling is uniform, the quenching requirements of aluminum profiles with different thicknesses and complex section structures can be met, the cooling range is wide, the application range is wide, the cooling efficiency of some aluminum profiles not suitable for online quenching can also meet the online quenching requirement, and the service life of the aluminum profiles is prolonged. And the process of independent quenching can be omitted, so that the equipment investment is reduced, and the production cost is reduced.

Owner:江阴协宏金属制品有限公司

Multi-angle adjustable full-automatic pavement drying equipment for urban and rural arterial roads

InactiveCN107916614ALarge cooling rangeImprove the heating effectRoads maintainenceAir compressionEngineering

The invention relates to multi-angle adjustable full-automatic pavement drying equipment for urban and rural arterial roads. The multi-angle adjustable full-automatic pavement drying equipment comprises a support device and a drying device. The drying device is mounted at the bottom of the support device; the drying device comprises two support slide plates, a drying slide plate, an air compression mechanism, a lead screw motor, a lead screw, a lead screw connecting plate, a movable nut, a heating mechanism, lead screw slide grooves, two lead screw connecting rods, a drying motor, a drying rotary shaft, an intermittent gear and two racks. The multi-angle adjustable full-automatic pavement drying equipment has the advantages that the difficult problems of low work efficiency, incomplete pavement drying, incapability of carrying out drying treatment on pavements with different degrees of inclination and slope and the like during pavement construction at present can be solved by the aid of the multi-angle adjustable full-automatic pavement drying equipment; the multi-angle adjustable full-automatic pavement drying equipment can have a function of pertinently comprehensively thoroughlydrying pavements with different degrees of slope and inclination, and is high in work efficiency, the pavements can be thoroughly dried by the multi-angle adjustable full-automatic pavement drying equipment, drying treatment can be carried out on the pavements with the different degrees of inclination and slope by the multi-angle adjustable full-automatic pavement drying equipment, and the like.

Owner:黄正秀

LED driving power supply with high heat dissipation performance

ActiveCN111107694AIncrease contact areaRapid endothermic evaporationCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsWater pipeEngineering

The invention discloses an LED driving power supply with high heat dissipation performance. The LED driving power supply comprises a shell and a battery pack, and the battery pack is fixedly sleeved in the shell with a hollow structure. A heat collecting plate for absorbing heat and conducting heat and a heat conducting rod are arranged at the upper end of the battery pack, and a first-stage partition plate, a second-stage partition plate and a third-stage partition plate form a sealed cavity filled with an alcohol solution, so that the alcohol solution absorbs heat quickly through the heat conducting rod to be evaporated, and the cooling effect is achieved. The lower end of the battery pack is connected with a heat conducting plate to accelerate the flowing of cold and hot airflow in theshell. A cooling water tank and a water pipe are arranged in the lower end of the battery pack, and a piston pulled by a U-shaped shaft is arranged in the water pipe, so that a low-temperature water source can comprehensively flow in the cooling water tank. The contact area with the battery pack is increased, and the cooling range is enlarged. By arranging aluminum foil plates corresponding to each other in a crossed mode on a limiting plate and a buffer plate, flowing gas is cooled by means of the low-temperature characteristic of the aluminum foil plates, and therefore the purpose of lowering the environment temperature of the driving power supply is achieved.

Owner:台州市黄岩隆昕电子科技有限公司

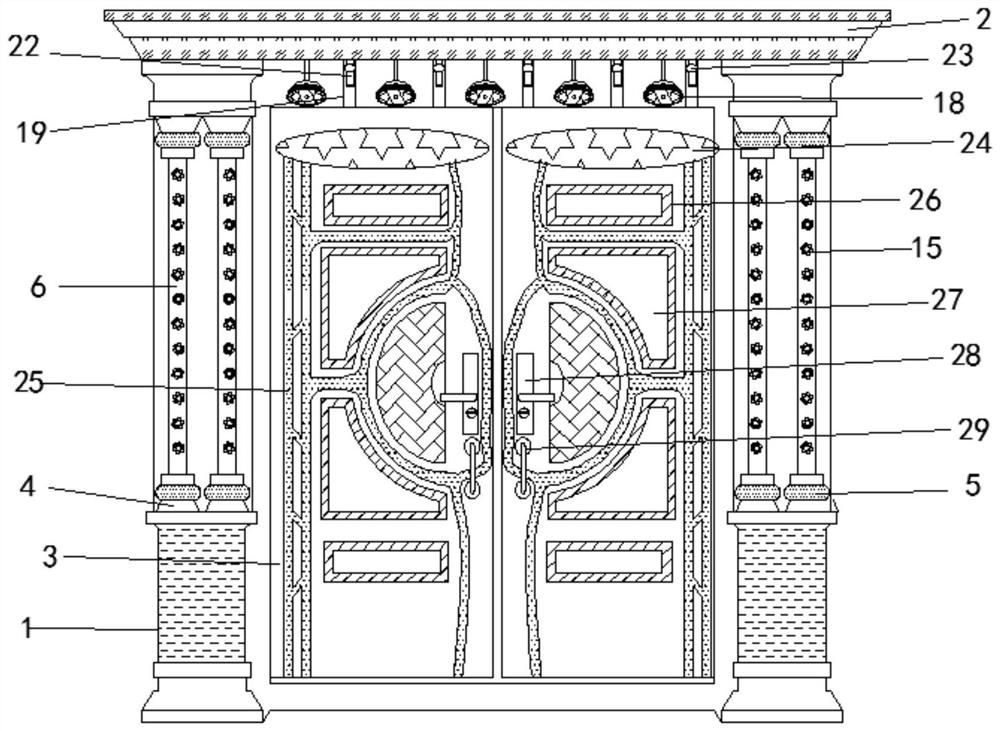

High-strength double-door type metal art villa door

InactiveCN113503123ALarge cooling rangeEvenly distributedLighting and heating apparatusNoise insulation doors/windowsAtomizer nozzleEngineering

The invention discloses a high-strength double-door type metal art villa door. The door comprises a door frame, a door beam and a door body, wherein the door beam is arranged at the top of the door frame, the door body is movably connected in the door frame through hinges, two decorative columns are arranged in the middle of the outer surface of the door frame, the two ends of each decorative column are fixedly connected with the door frame through mounting seats, and a temperature sensor is arranged on each mounting seat. The door has the beneficial effects that when the temperature sensors detect that the outside temperature is high, a controller starts a water pump, refrigerators and a cooling fan through a storage battery, a plurality of refrigerators conduct low-temperature treatment on water in a refrigeration cavity, and then a water pump conveys the low-temperature water into a water conveying sub-pipe and a communicating sub-pipe through a water conveying main pipe and a communicating main pipe, the low-temperature water in the water conveying sub-pipe can form water mist through a plurality of water conveying branch pipes and atomizing nozzles to be sprayed out, meanwhile, the cooling fan outputs air flow, the air flow drives the water mist to flow, and therefore the cooling range of the water mist is enlarged, and meanwhile the water mist is distributed more evenly.

Owner:浙江嘉宝工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com