Air cooling-water cooling hybrid cooling permanent magnet roller

A hybrid cooling and permanent magnetic drum technology, applied in cooling/ventilation devices, magnetic circuit static parts, magnetic circuit shape/style/structure, etc., can solve problems such as limited heat dissipation area, high drum temperature rise, and single cooling method. To achieve the effect of improving the water cooling effect, increasing the cooling effect, and increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 This embodiment provides a permanent magnet drum cooled by air-water cooling

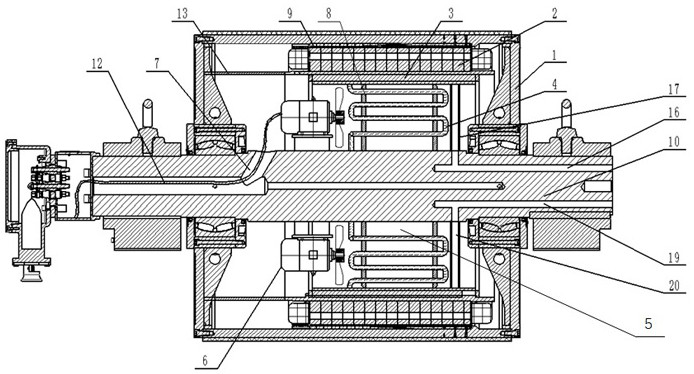

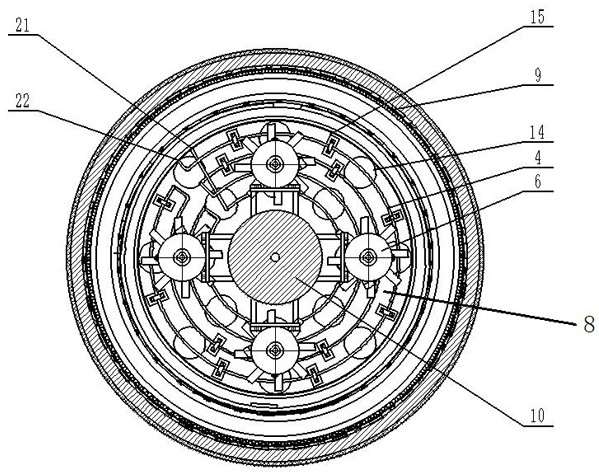

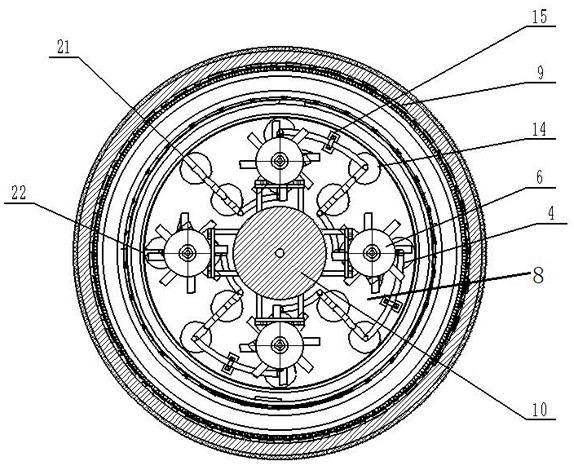

[0030] Such as figure 1 As shown, the permanent magnet drum includes: a main shaft 10, a reciprocating water pipe 4 and a fan 6 arranged in the cavity of the stator 5; the main shaft 10 is provided with radial plates 8 with holes uniformly distributed in the axial direction, and each spoke plate with holes 8 It is fixed on the main shaft 10 in the circumferential direction, the reciprocating water pipe 4 surrounds and is reciprocally fixed on a plurality of perforated webs 8, and the four fans 6 are evenly distributed in the circumferential direction on the main shaft 10 at the left end of the plurality of perforated webs 8, and the four fans 6 are directed toward The perforated spoke plate 8 at the left end is out of the air. The perforated web 8 is provided with a fixedly connected pipe clip 15 (such as figure 2 shown) to fix the reciprocating water pipe 4. Such as figure...

Embodiment 2

[0034] Embodiment 2 This embodiment provides a hydraulic motor-driven air-water-cooled hybrid cooling permanent magnet drum

[0035] The permanent magnet drum includes an end cover assembly 1, a stator coil assembly 2, a cooling water circuit 3 for the stator, a reciprocating water pipe 4, a fan 6 and a main shaft 10, a stator cavity 5 is formed inside the stator, and the reciprocating water pipe 4 and the fan 6 are located in the stator cavity 5 Inside, the water inlet 16 on the main shaft 10 is connected to the cooling water passage 3 of the stator through the water inlet pipe 17, the cooling water passage 3 of the stator is connected to the water inlet end of the reciprocating water pipe 4, and the water outlet end of the reciprocating water pipe 4 is connected to the outlet on the main shaft 10 through the water outlet pipe 20. Shuikou 19. The cooling waterway 3 and the reciprocating water pipe 4 each have a connection port, which are the water inlet connection port 21 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com