Embedding pin for injection mold

An injection mold and needle insert technology, which is applied in the field of insert needles of injection molds, can solve the problems that the cooling water channels of insert needles are not well combined and the cooling range is small, so as to shorten the product molding cycle, the cooling range is large, and the installation and disassembly are convenient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

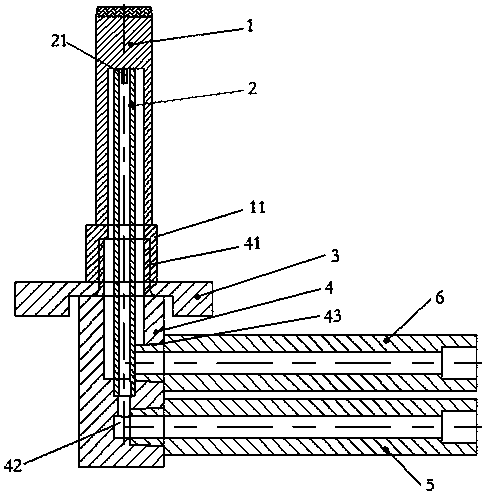

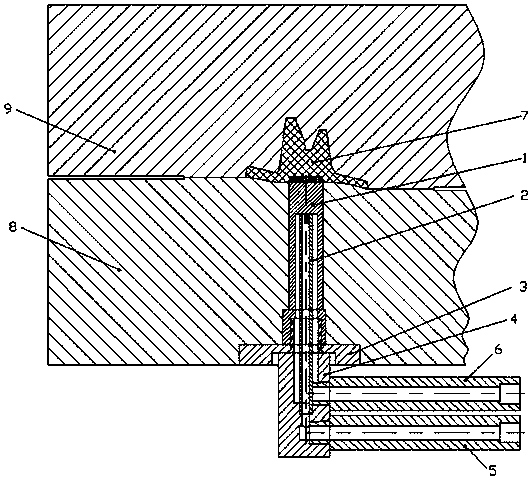

[0024] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] like Figure 1-2 As shown, this embodiment provides an insert for an injection mold, which includes an insert body 1 and a cooling pipe 2. A first cavity extending axially along the insert body 1 is provided inside the insert body 1 for cooling The top end of the tube 2 protrudes into the first cavity for cooling the insert body 1 and the injection molded product. There is a gap between the cooling pipe 2 and the first cavity, the top surface of the cooling pipe 2 is in contact with the inner top surface of the first cavity, and the top of the cooling pipe 2 is provided with a groove connecting the inside of the cooling pipe 2 and the first cavity 21. The cooling pipe 2 communicates with the water inlet pipe 5, and the first cavity communicates with the water outlet pipe 6.

[0026] The head of the insert body 1 participates in the injection mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com