Ultra-high-speed electric spindle with embedded cold air device

An ultra-high-speed, motorized spindle technology, applied in positioning devices, clamping, supporting and other directions, can solve problems such as high requirements for skilled workers, affecting drilling accuracy, affecting drilling results, etc., to achieve simple and convenient operation and ensure cooling effect. , The effect of high working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

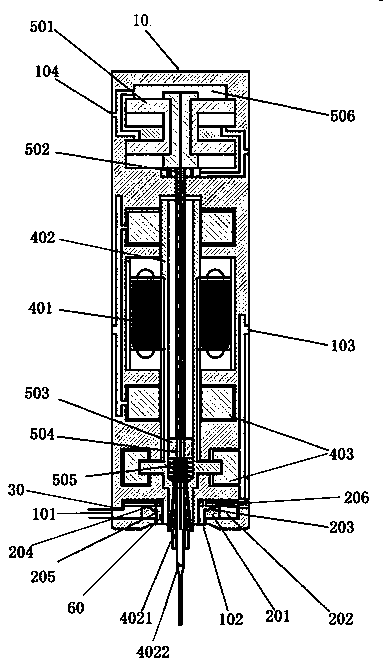

[0033] Such as figure 1 As shown, this embodiment provides an ultra-high-speed electric spindle with a built-in cold air device, which includes a spindle body, a spindle housing 10 and a cold air device. The spindle body and the cold air device are arranged inside the spindle housing 10; the side of the spindle housing 10 is provided with an inlet The air port 101, the lower end of the spindle housing 10 is vertically provided with an air outlet 102; the cold air device is sleeved on the main shaft body, the cold air device includes a hollow chamber, the bottom of the hollow chamber is provided with a heat sink 201, the upper end of the heat sink 201 on the side away from the air inlet 101 With spherical grooves, the radiating fin 201 divides the hollow chamber into a mixed gas chamber 202 and a vortex chamber 203, the upper end of the radiating fin 201 and the top of the hollow chamber form a gas guide groove 204, and the mixed gas chamber 202 communicates with the gas inlet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com