Fire protection system for belt conveyor

A belt conveyor and belt technology, which is applied to conveyor objects, conveyor control devices, applications, etc., can solve the problems of belt conveyors that do not have both cooling treatment methods, small collection surfaces, and local overheating, etc., to ensure comprehensive performance and effectiveness, avoiding the effects of small collection area and fast collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

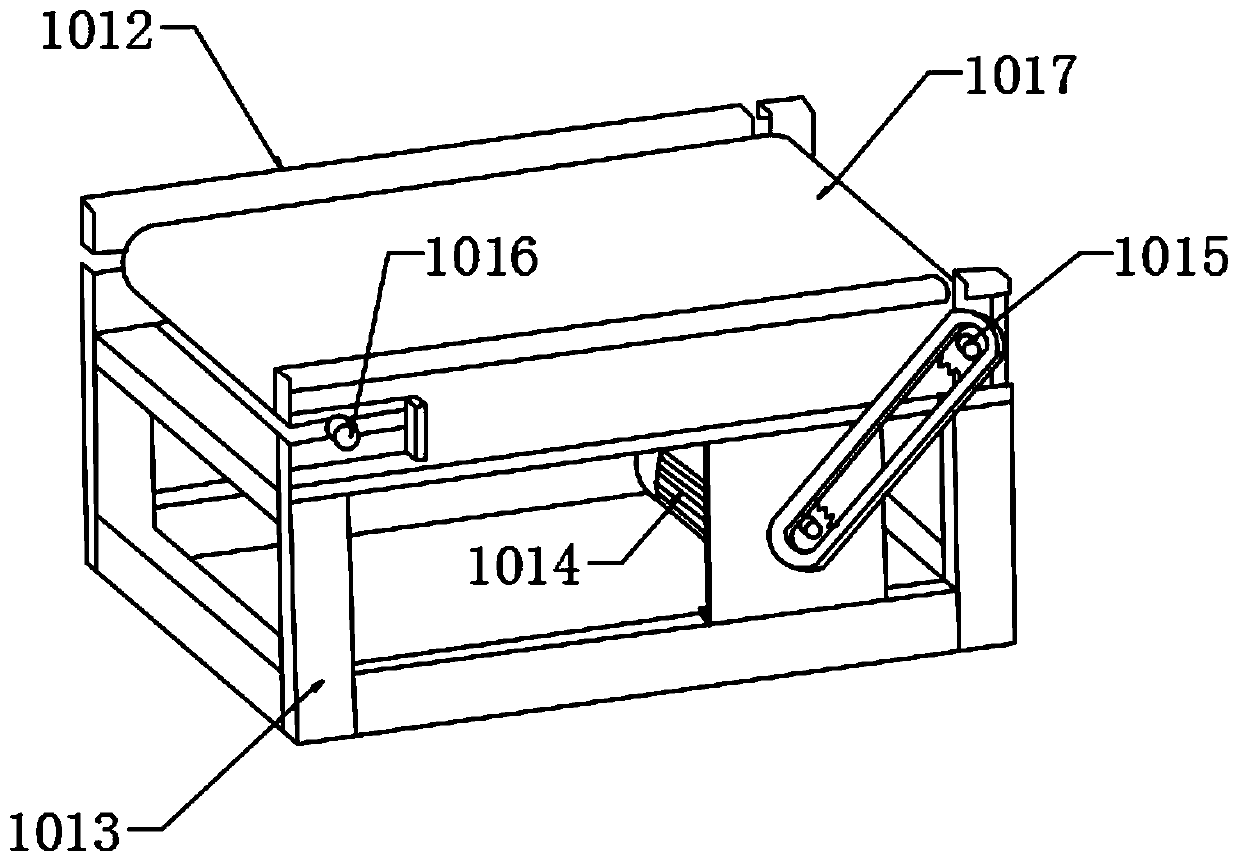

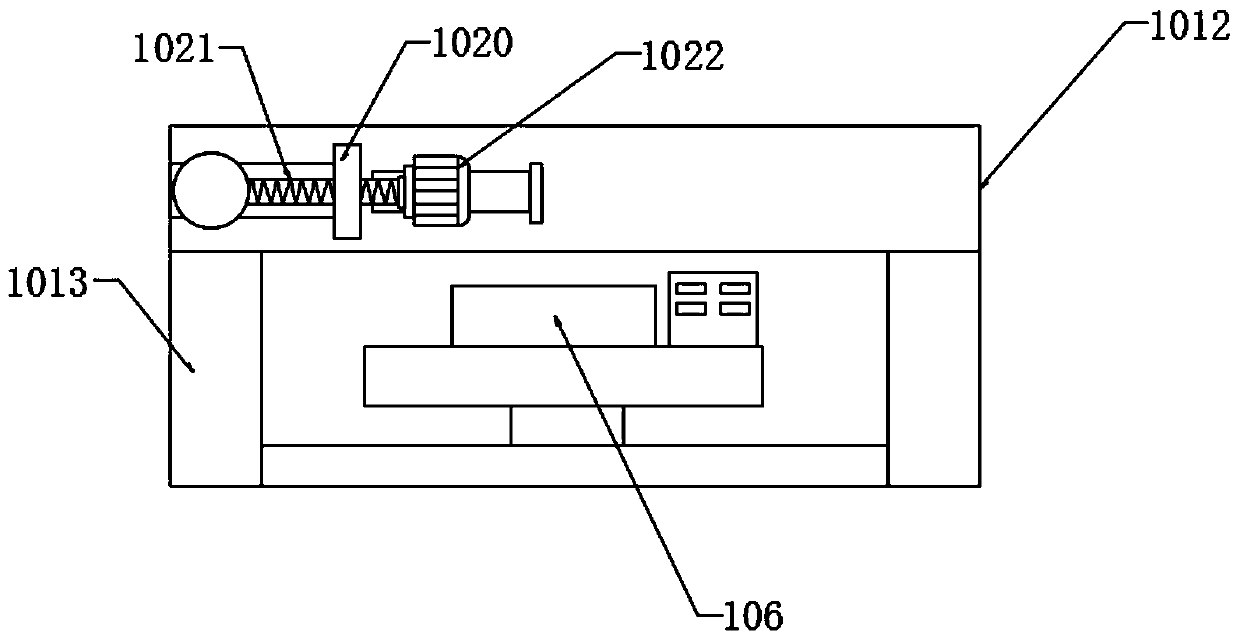

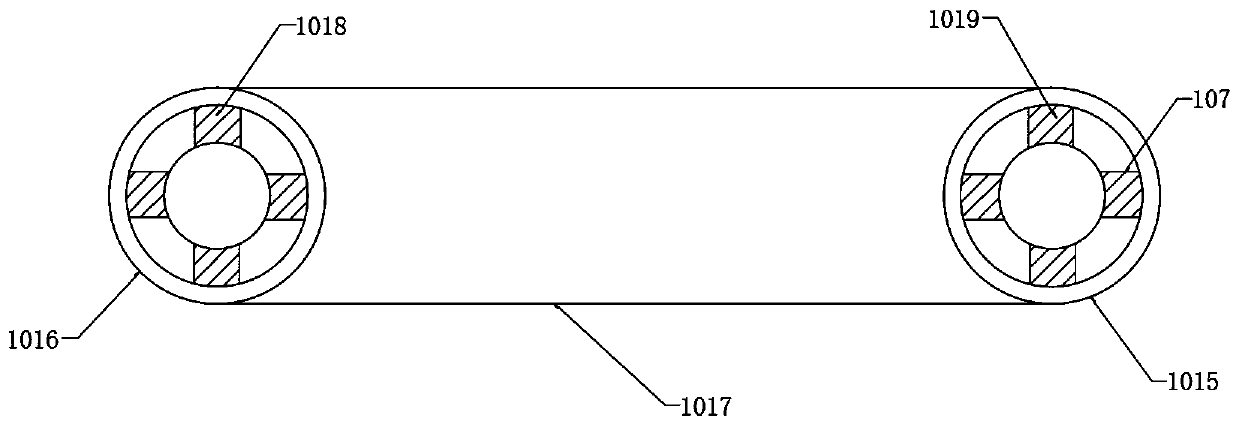

[0030] see Figure 1-6 , the present invention provides a technical solution: a fire protection system for belt conveyors, comprising:

[0031] Collection terminal 101, application platform 102, described collection terminal 101 and application platform 102 are connected through data transmission module 103;

[0032] A collection terminal 101, the collection terminal 101 is composed of a detector 104, a processing mechanism 105, and a detection unit 107, the detector 104 includes a temperature detection module and a data conversion module, and the detector 104 is electrically connected to the detection unit 107, The detector 104 adopts a thermal imager, a radiation thermometer or other bolometric temperature measuring instruments;

[0033] Application platform 102, described...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com