Heat sink and electronic apparatus provided with heat sink

A technology for radiators and controllers, which is applied in the construction of electrical equipment components, instruments, circuits, etc. It can solve the problems of impossible elimination of failure rate, narrow cooling control range, difficulty in suppressing heat generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present application will be explained based on specific examples using the drawings.

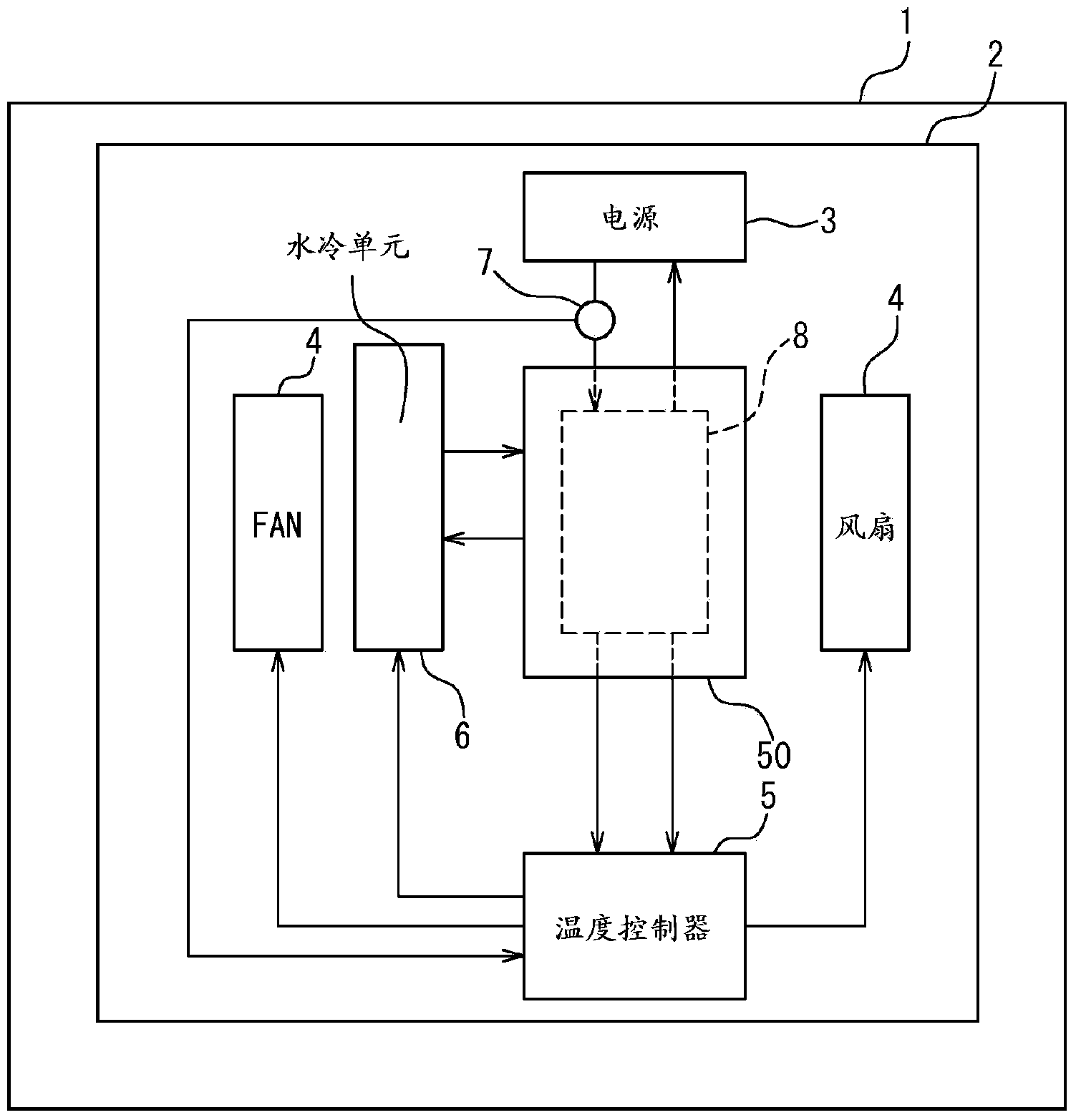

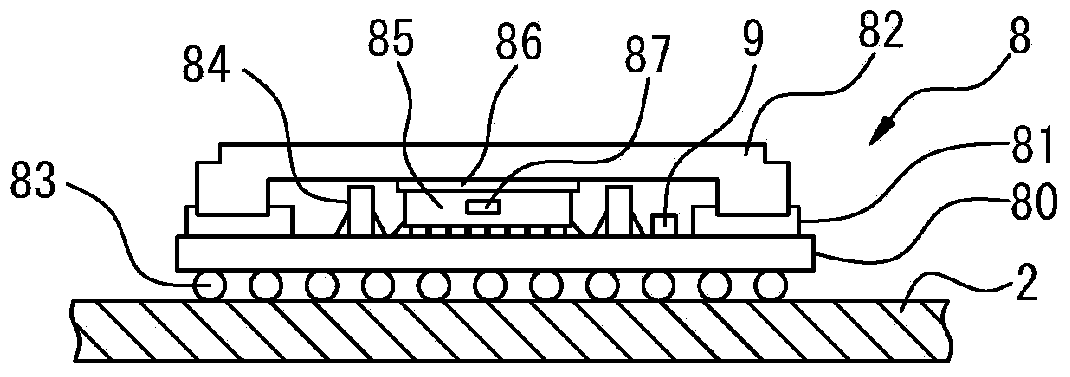

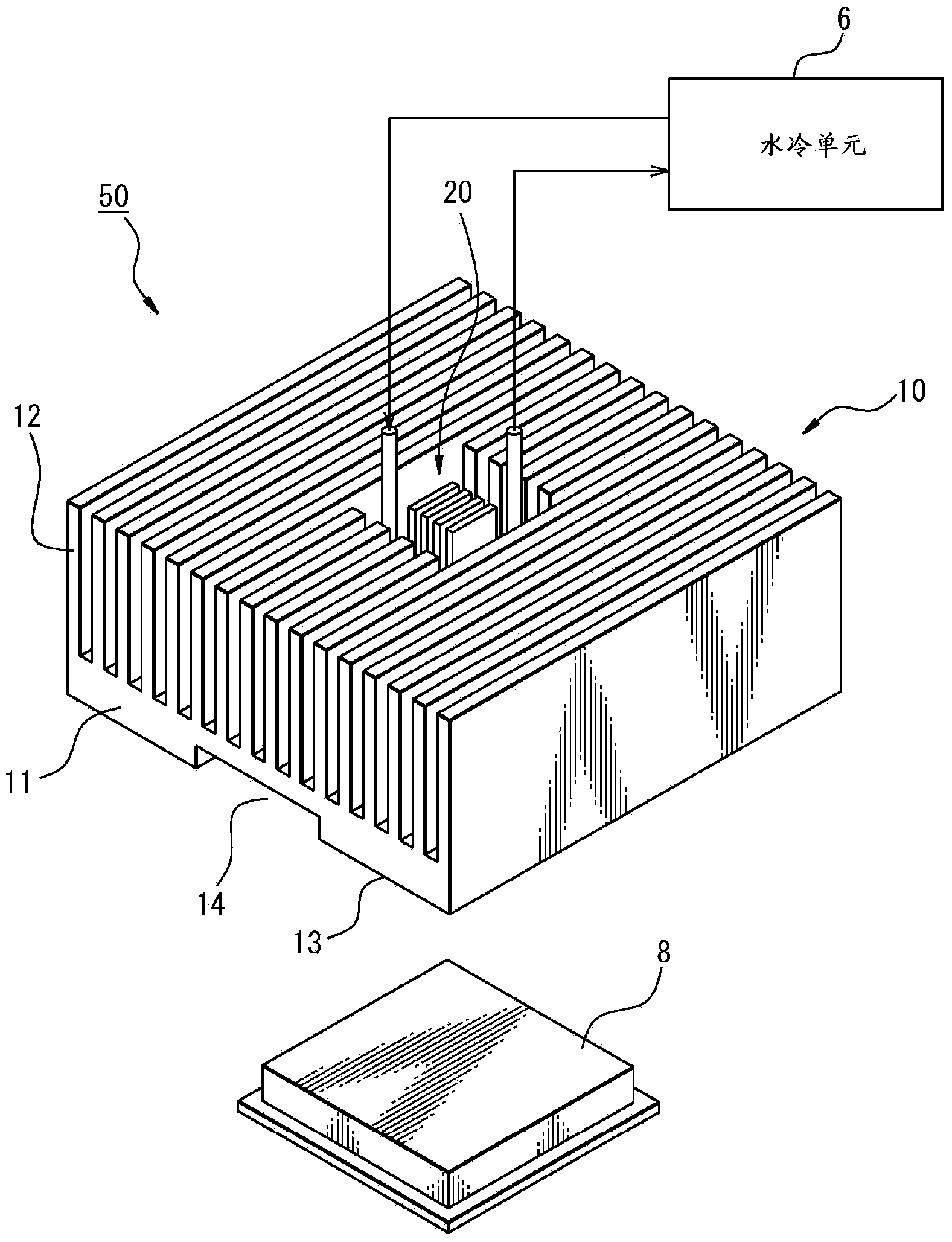

[0025] FIG. 1 is a layout diagram showing the layout of circuit elements mounted on a unit 2 mounted on an electronic device 1 and a heat sink 50 pair forming one of the circuit elements of a heat generating member 8. Allow to cool. The heat generating member 8 is, for example, a semiconductor package 8 . On the unit 2 , a power supply 3 for supplying electric power to the semiconductor package 8 and a fan 4 for cooling the semiconductor package 8 are provided. The radiator 50 of the present application comprises a fluid path through which the cooling water circulates, so that the unit 2 is provided with a water cooling unit 6 .

[0026] The water cooling unit 6 , the power supply 3 and the temperature controller 5 can also be arranged outside the unit 2 . In addition, the unit 2 may be provided with a temperature controller 5 controlling the fan 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com