Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Increase power supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

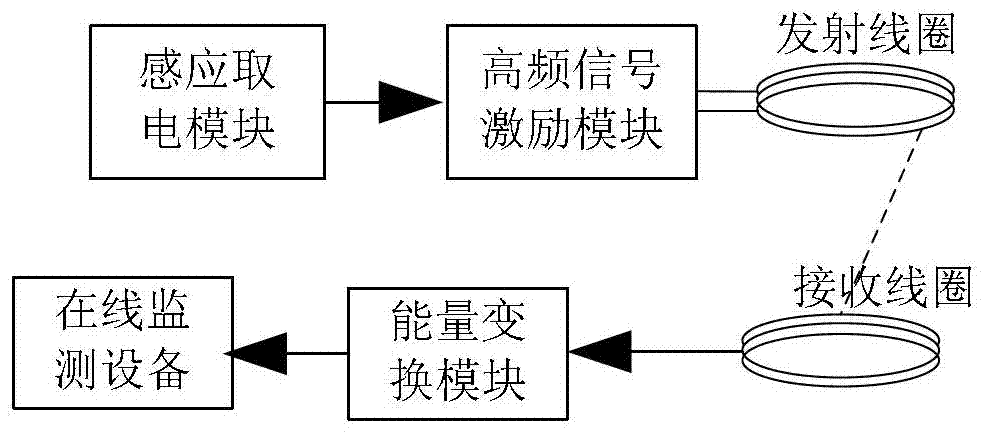

Online monitoring equipment power supply system based on wireless electric power transmission technology

InactiveCN102832720AIncrease power supplyGuaranteed uptimeElectromagnetic wave systemCircuit arrangementsElectric power transmissionWireless transmission

The invention discloses an online monitoring equipment power supply system based on wireless electric power transmission technology, comprising an induction power taking module, a high-frequency signal excitation module, a transmitting coil, a receiving coil and an energy conversion module; the induction power taking module, the high-frequency signal excitation module and the transmitting coil are mounted on a power transmission line in sequence; the induction power taking module is connected with the high-frequency signal excitation module; and the receiving coil and the energy conversion module connected sequentially are mounted on a pole tower. According to the online monitoring equipment power supply system, electric energy is supplied to online monitoring equipment on the pole tower in the manner of wireless transmission, so that the application range of the induction power taking technology is extended, a new power source is added, and the reliability and continuity of an online monitoring equipment power source for the power transmission line are improved.

Owner:SOUTH CHINA UNIV OF TECH

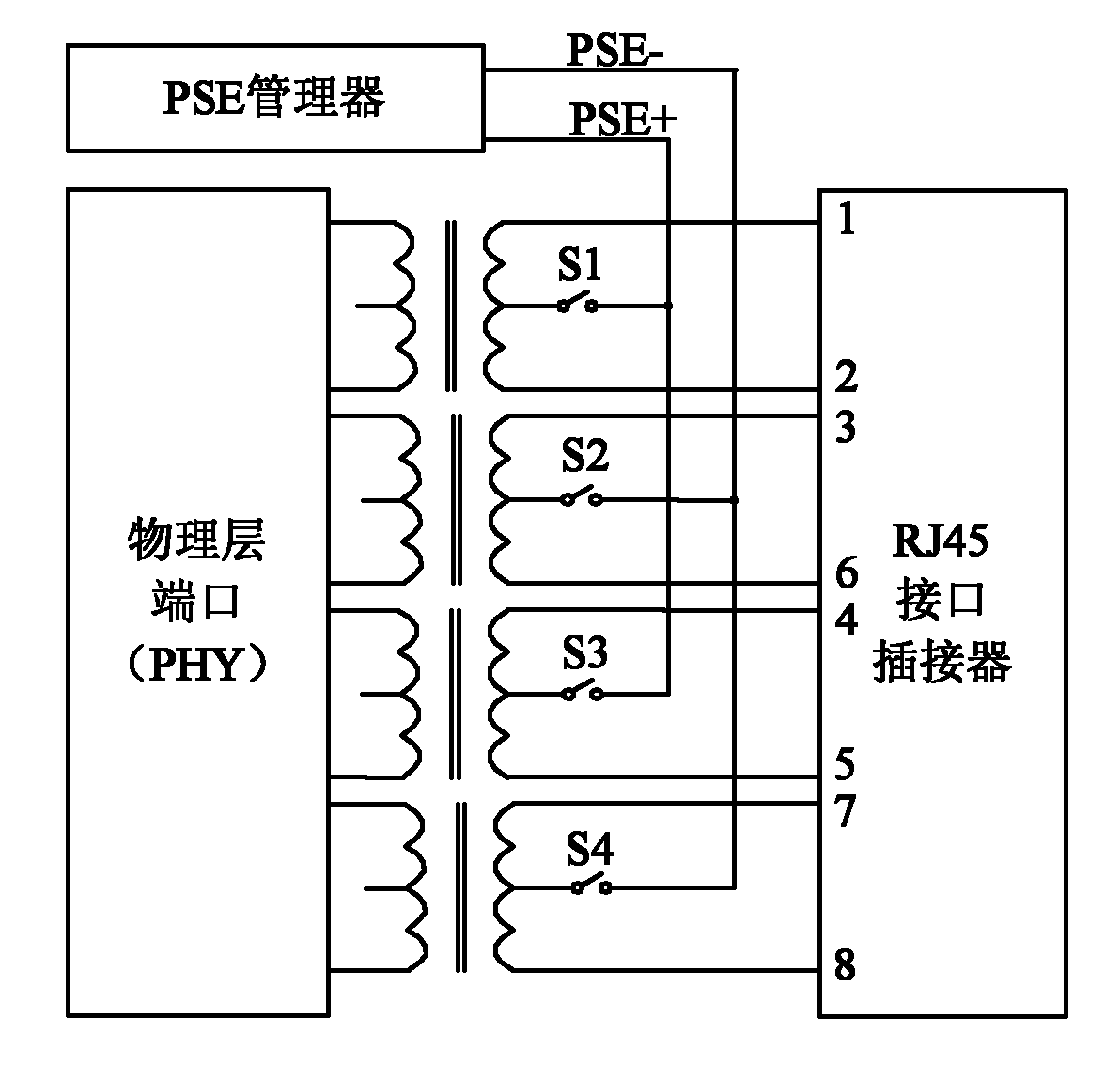

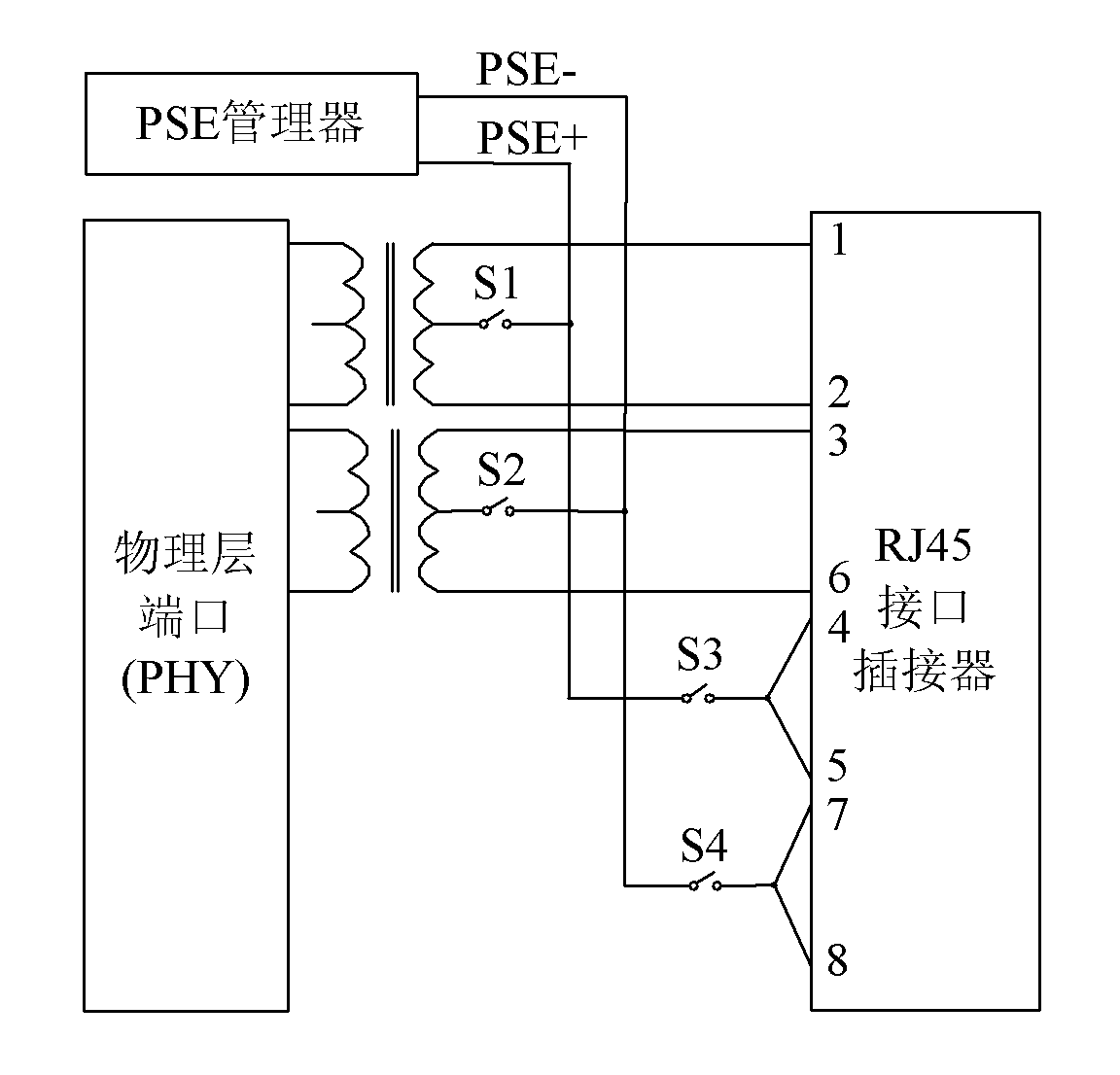

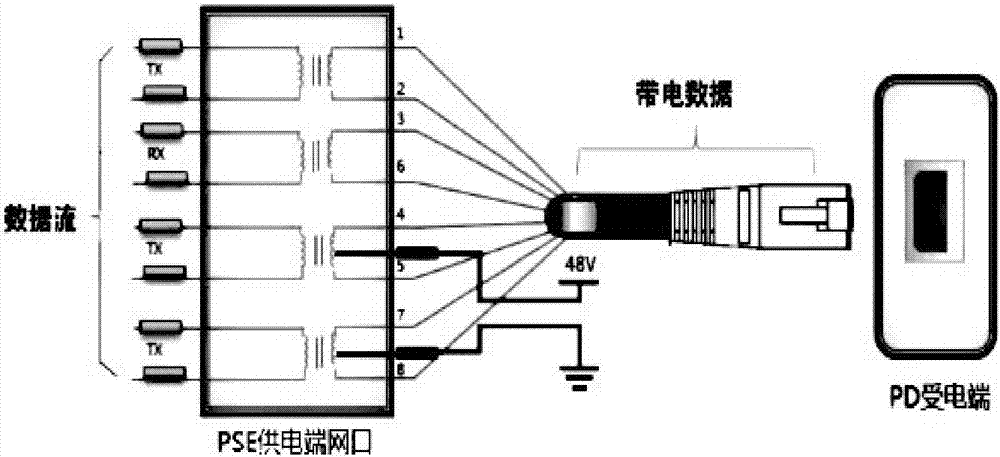

Ethernet power supply end equipment as well as system and method thereof for realizing power supply

InactiveCN102075331AIncrease power supplyIncrease flexibilityData switching current supplyPhysical layerCenter tap

The invention discloses Ethernet power supply end equipment as well as a system and method thereof for realizing power supply. The Ethernet power supply equipment comprises two pairs of transformers of a physical-layer port, and a power supply end equipment manager; in addition, a pair of switches is connected between each pair of transformers and the power supply end equipment manager respectively; wherein one switch of each pair of switches is connected between the positive end of the power supply end equipment manager and the central tap of one transformer of each pair of transformers, and the other switch in each pair of switched is connected between the negative end of the power supply end equipment manager and the central tap of the other transformer of each pair of transformers. By means of the invention, the compatibility and the flexibility of the entire POE (Power Over Ethernet) system are improved, power loss on lines is reduced, meanwhile, the operation management by a user is simplified.

Owner:WUHAN ZHONGXING SOFTWARE CO LTD

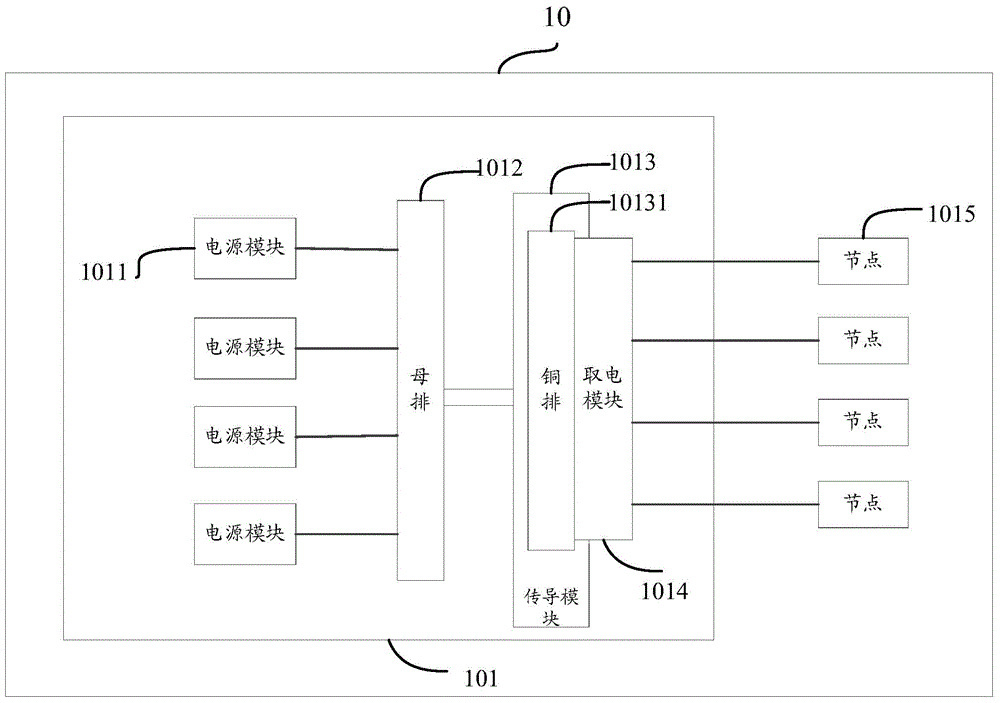

Power supply method and power supply device of cabinet server

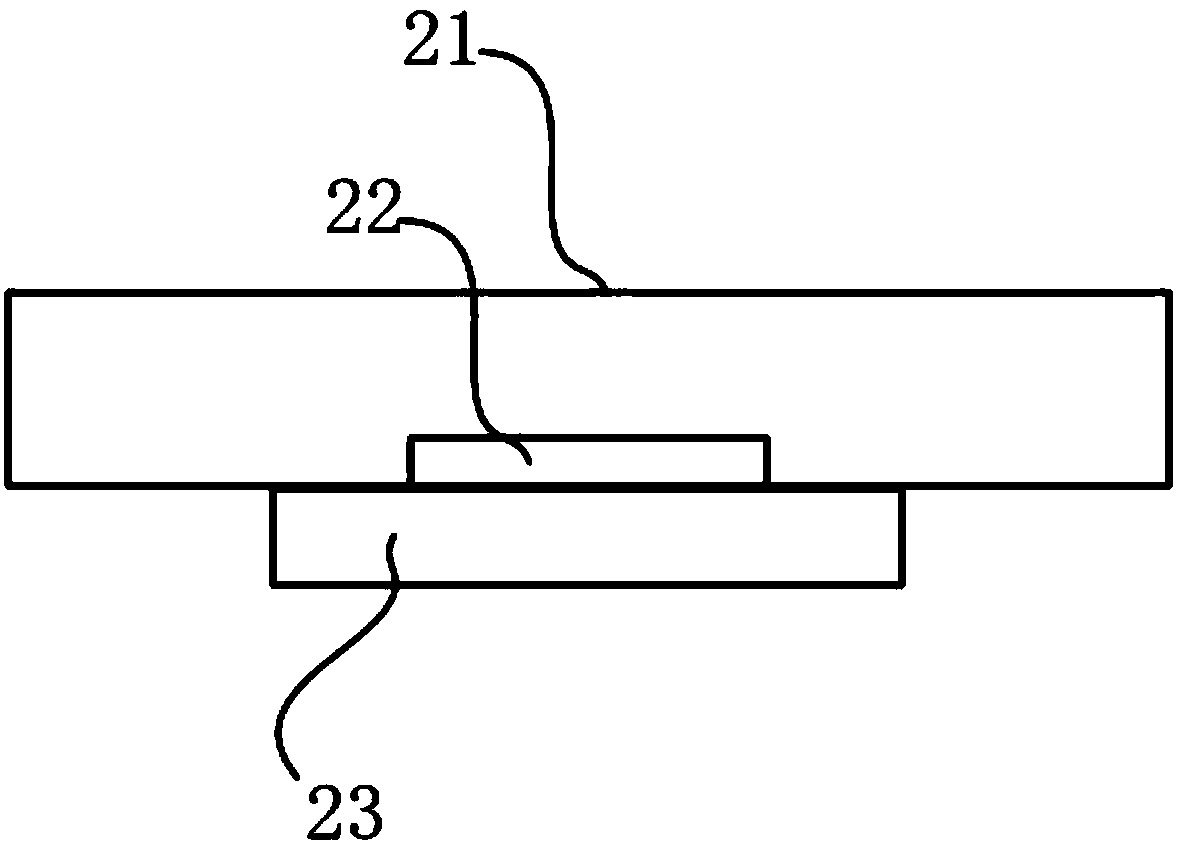

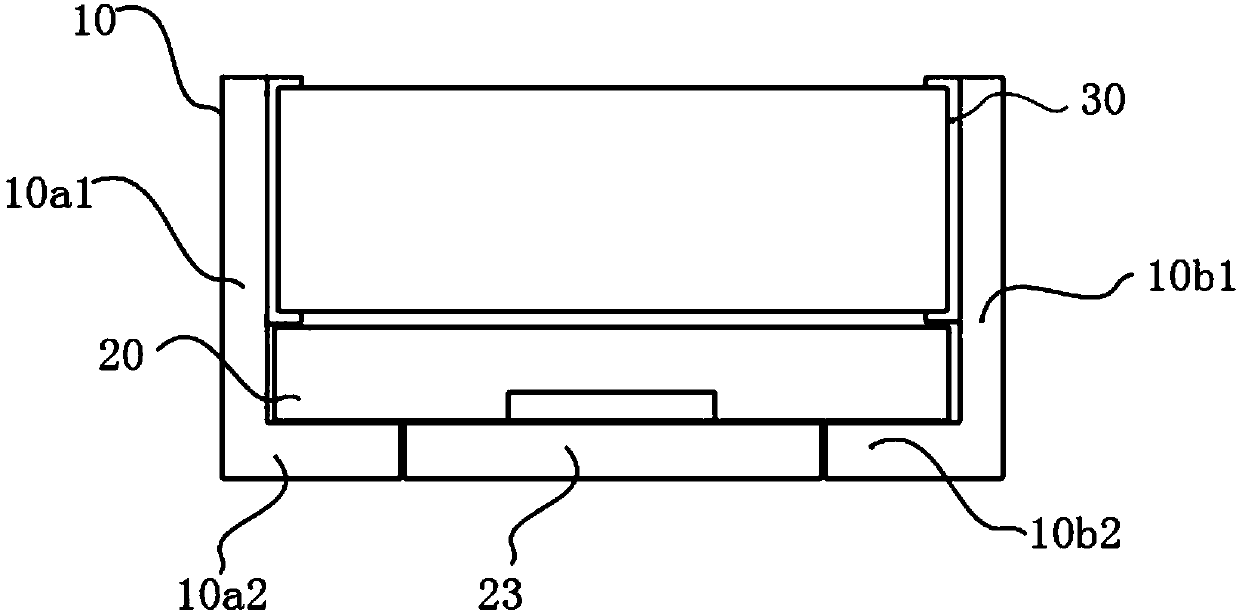

InactiveCN104866057AIncrease power supplyVolume/mass flow measurementPower supply for data processingElectricityPower flow

The invention provides a power supply method and a power supply device of a cabinet server. The device comprises: at least two power modules, wherein N+1 redundant power supply is performed by the power modules, that is, one of the power modules is in a standby state, the rest of the power modules are used for supplying power to the cabinet server, N 1 is a natural number greater than 1, and all of the power modules are connected to a bus bar; a conducting module, wherein the conducting module comprises a copper bar, the copper bar is used to connect the bus bar, and a current output by the power module is conducted to the copper bar via the bus bar; and a power taking module, used for conducting the current on the copper bar of the conducting module to more than one node of the cabinet server. The invention can increase power supplied to a cabinet server.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

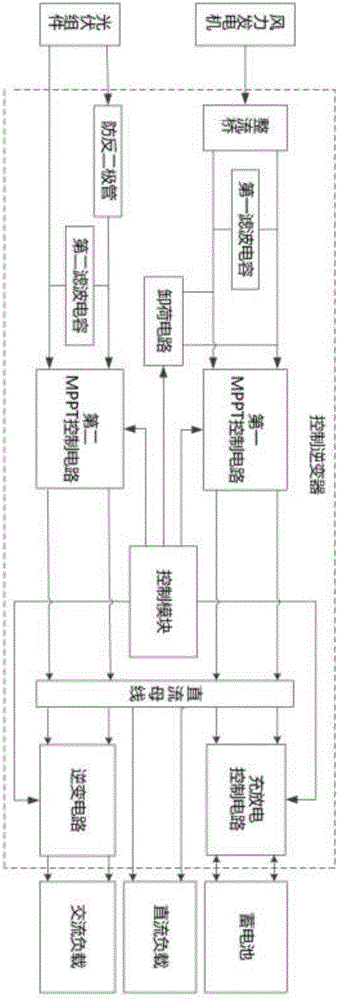

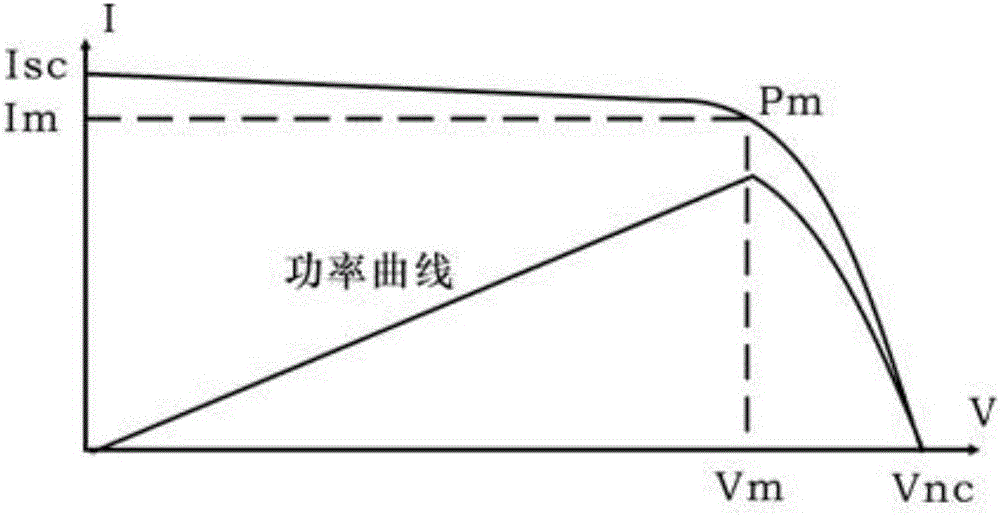

Portable wind-solar complementary power storage and supply system

InactiveCN105871303AIncrease in sizeReduce volumeBatteries circuit arrangementsPV power plantsElectrical batteryDynamo

The invention relates to a portable wind-solar complementary power storage and supply system. The system comprises a first power supply system and a second power supply system; the first power supply system comprises a wind driven generator, a photovoltaic module and a control inverter; the wind driven generator is used for conducting wind power generation so as to produce electric energy; the photovoltaic module is used for conducting photovoltaic power generation so as to produce the electric energy; the control inverter is connected with the wind driven generator and the photovoltaic module and used for tracking maximum power points of wind power generation and photovoltaic power generation respectively and outputting the electric energy produced by the wind driven generator and the photovoltaic module at the maximum power respectively, and the second power supply system is a solar rechargeable battery. According to the portable wind-solar complementary power storage and supply system, power generation can be conducted by means of wind energy and solar energy, regional power supply can be conducted on field operation, power supply can be conducted on equipment with certain power, and vehicle carrying, spreading and erecting are convenient to achieve.

Owner:ARMY ENG UNIV OF PLA

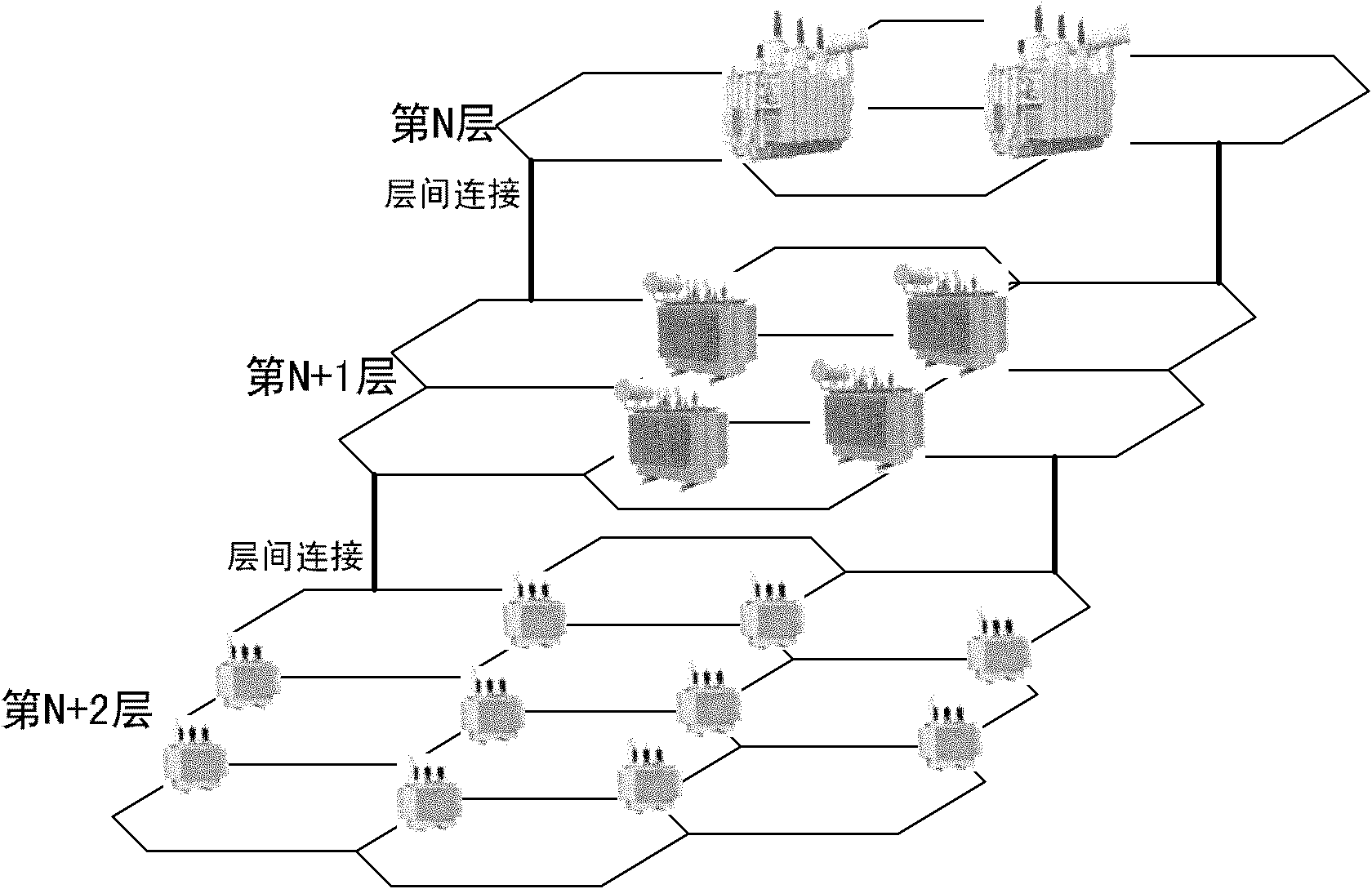

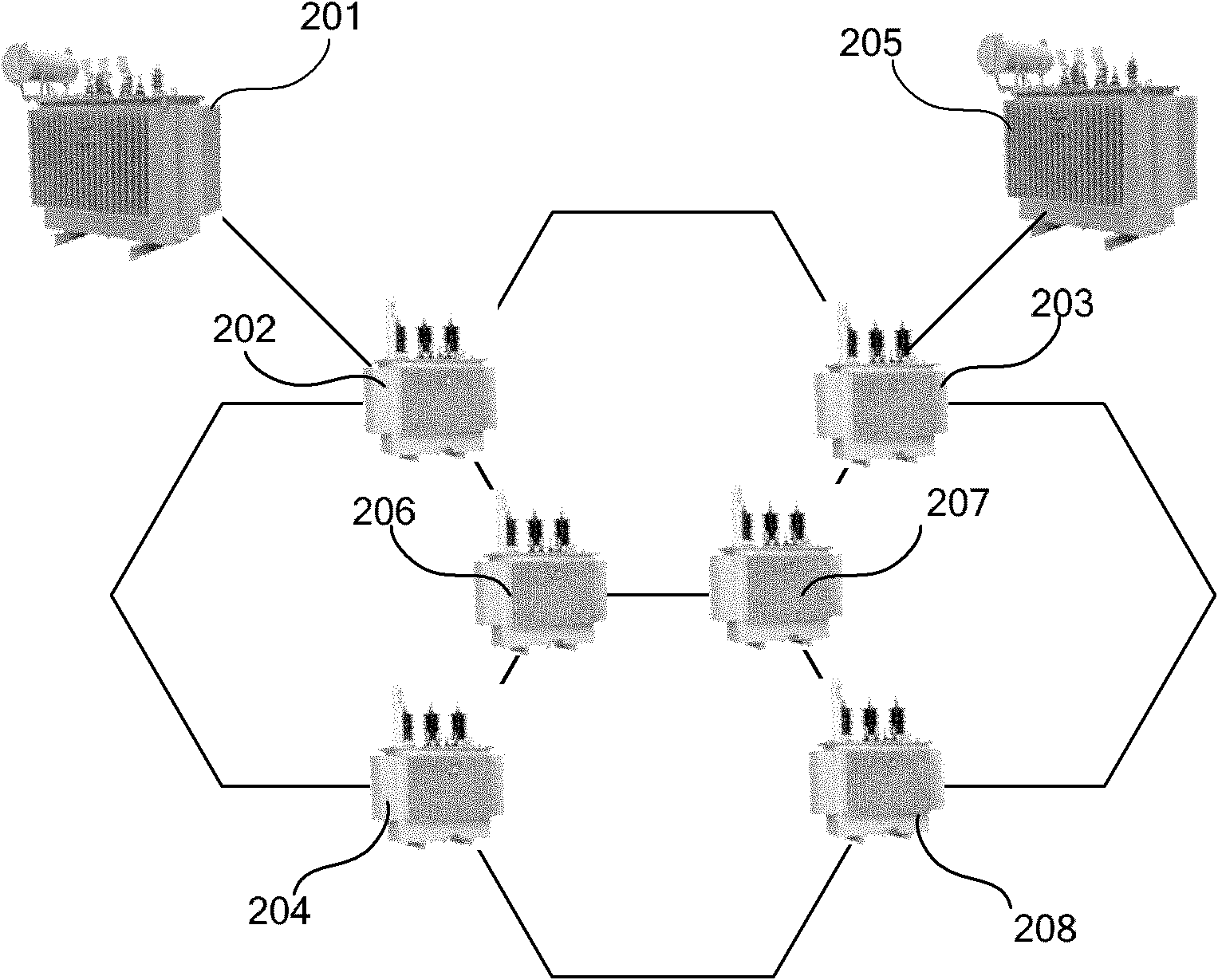

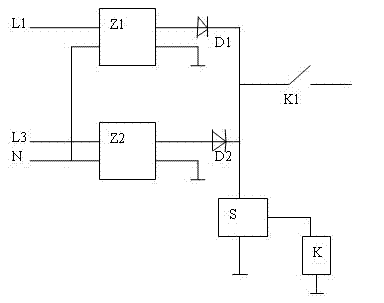

Cellular power supply network, intelligent gateway thereof and power supply control method

InactiveCN102122820AReasonable configurationIncrease profitEnergy efficient ICTEmergency protective circuit arrangementsElectricityTransformer

Owner:卢泳

Household magnesium air battery system

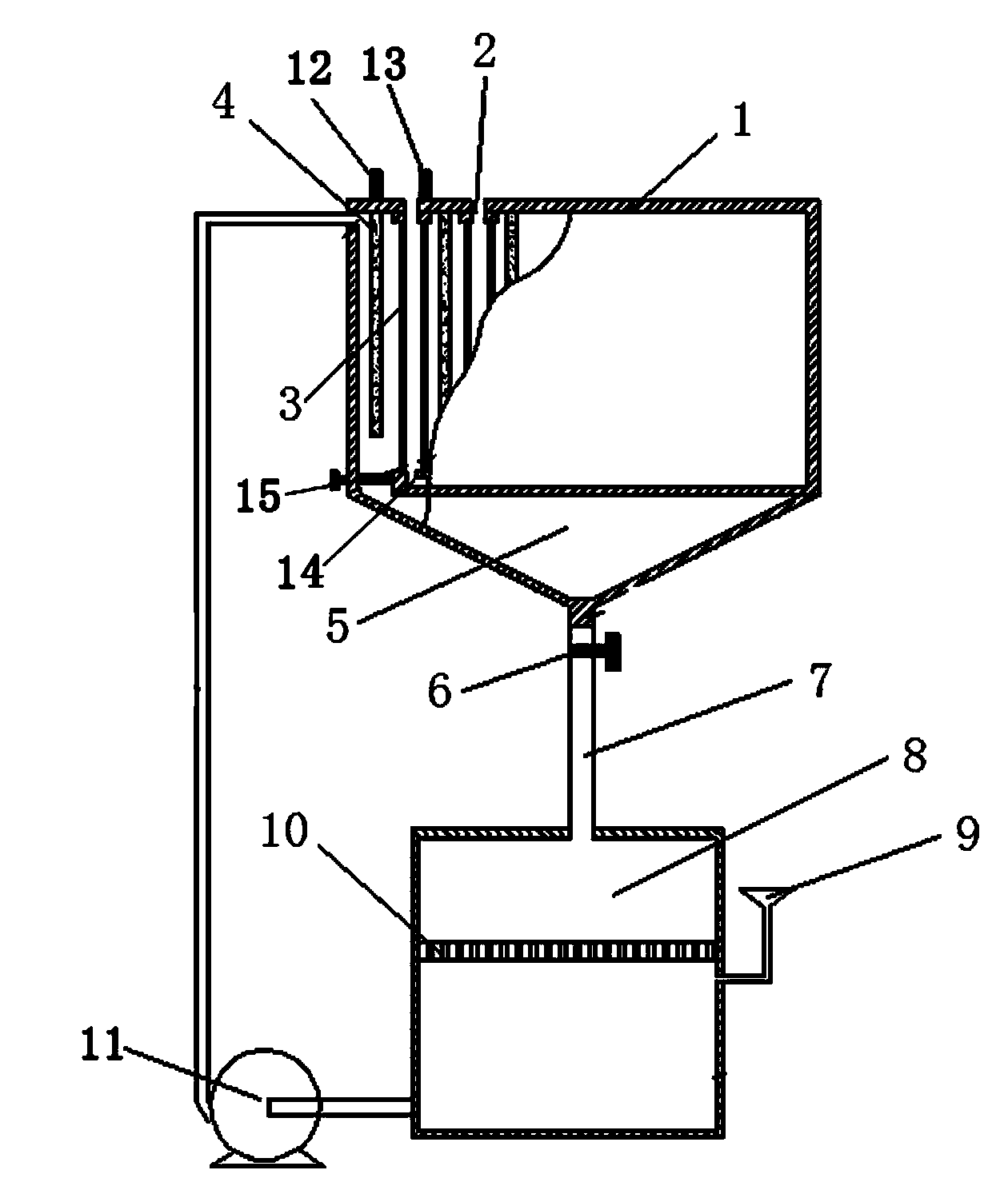

ActiveCN103531865AIncrease power supplyIncrease the supply voltageFuel and primary cellsFuel cellsEngineeringCirculating pump

The invention discloses a household magnesium air battery system including a magnesium air battery pack, an electrolyte regeneration tank and an electrolyte circulation pump. A conical funnel is arranged at the bottom of the magnesium air battery pack, and the bottom of each of anode plates of the magnesium air battery pack is provided with an opening communicated with the conical funnel; the conical funnel is communicated with the upper part of the electrolyte regeneration tank through a pipeline, the middle part of the electrolyte regeneration tank is provided with a filter plate, and the bottom of the electrolyte regeneration tank is communicated with the magnesium air battery pack through the electrolyte circulating pump. The household magnesium air battery system is provided with the electrolyte regeneration tank, so that an electrolyte can be regenerated for utilization, and simultaneously generated hydroxides can also be conveniently recycled, the waste discharge during a battery using process is reduced, and the battery using cost is reduced; and at the same time, electrolyte replacement adopts the pump to convey, and thus the battery maintenance is greatly facilitated.

Owner:北京恒泰岩磊科技有限公司

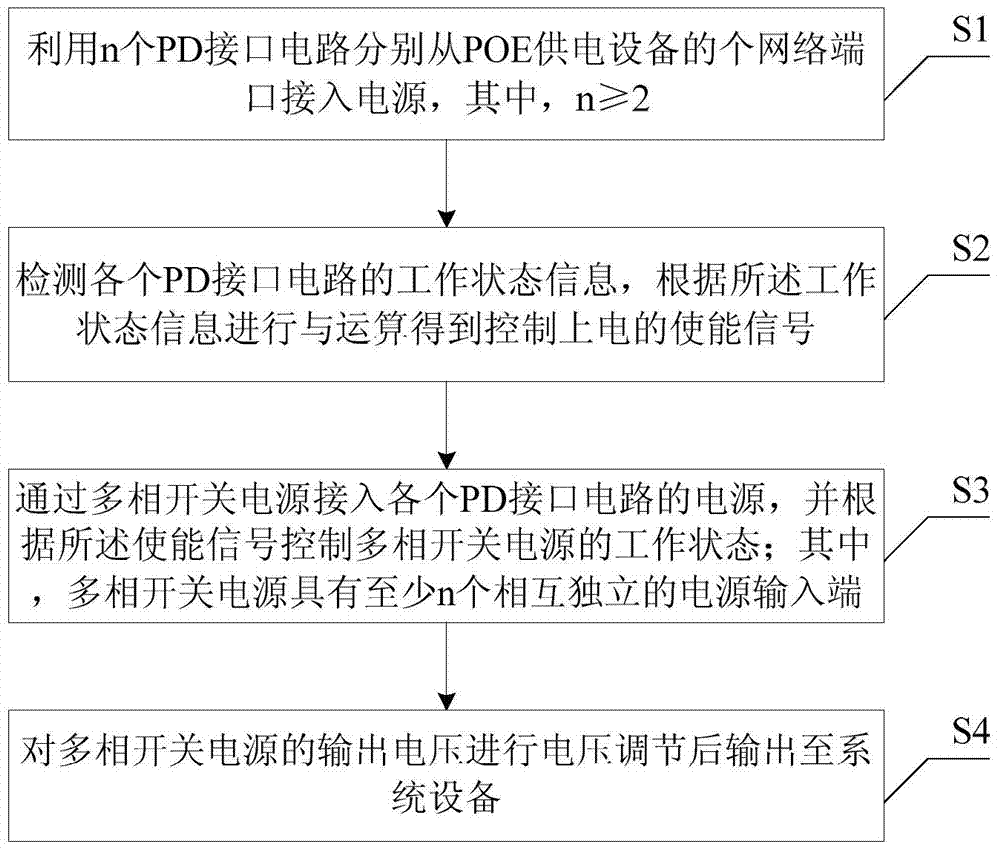

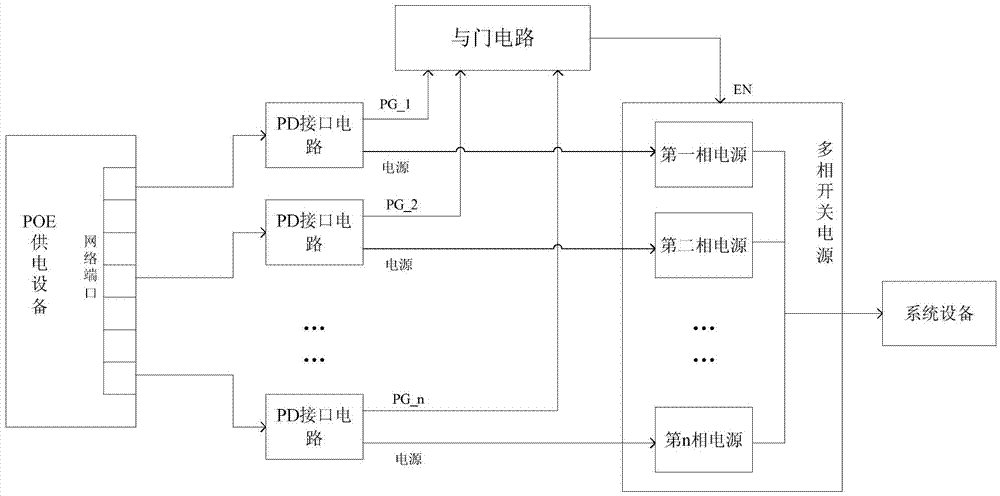

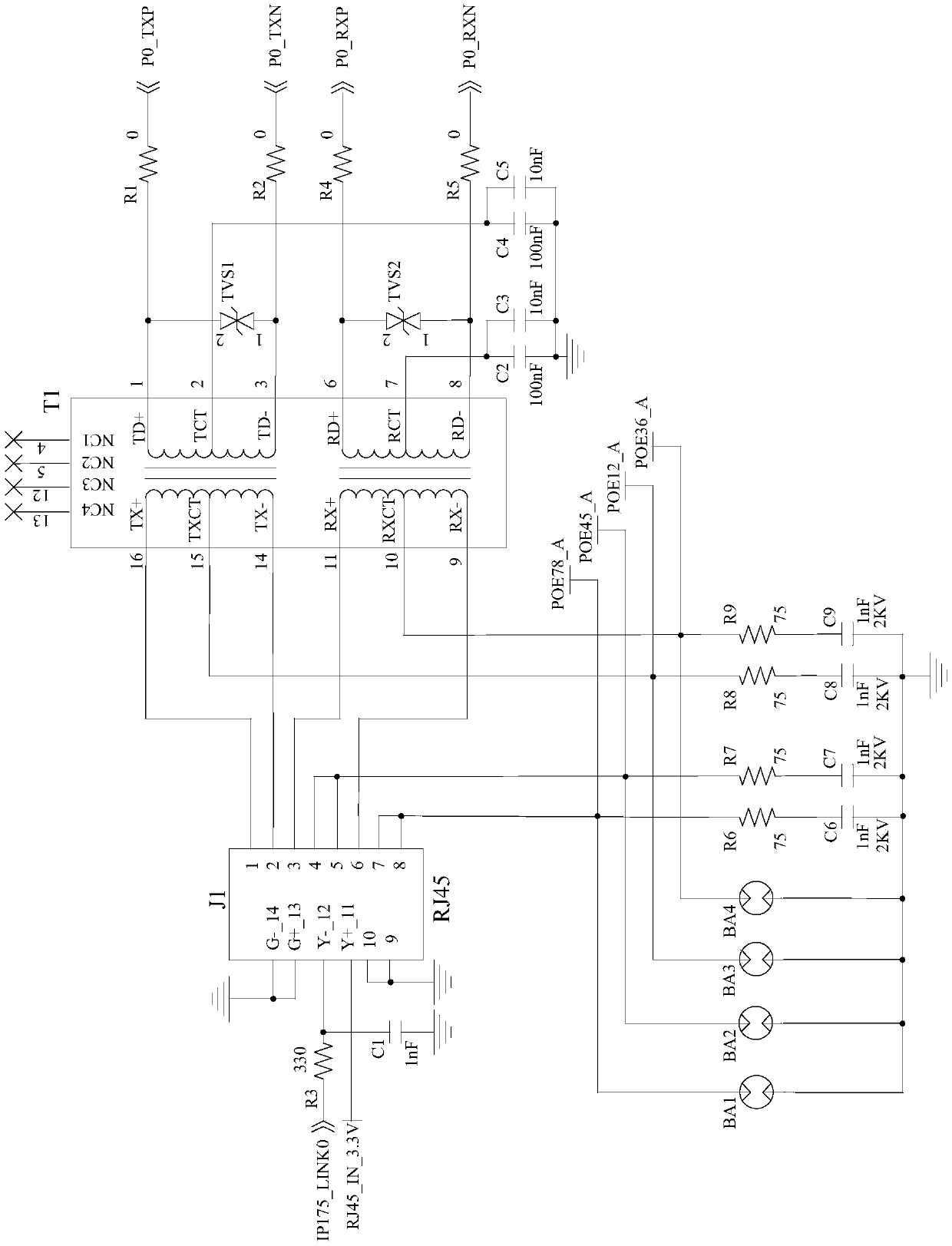

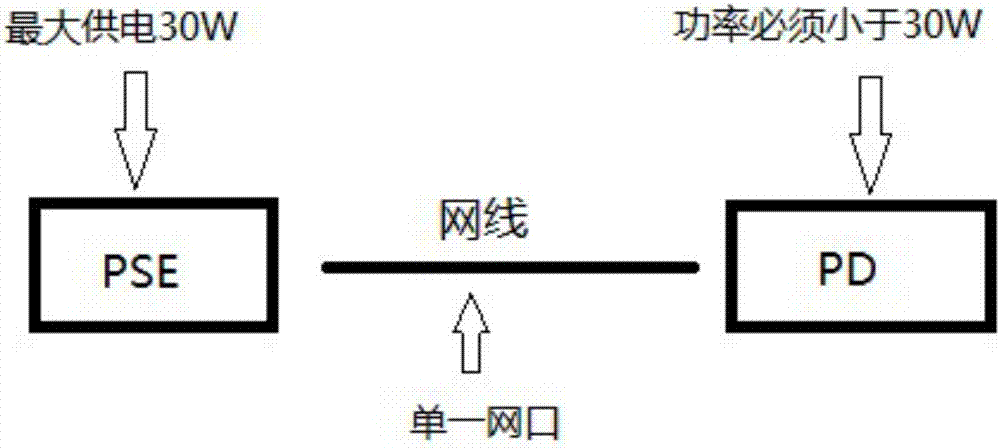

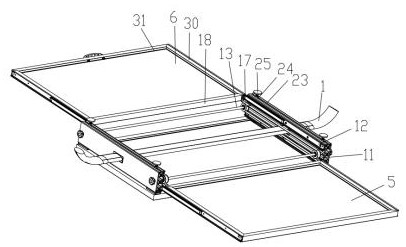

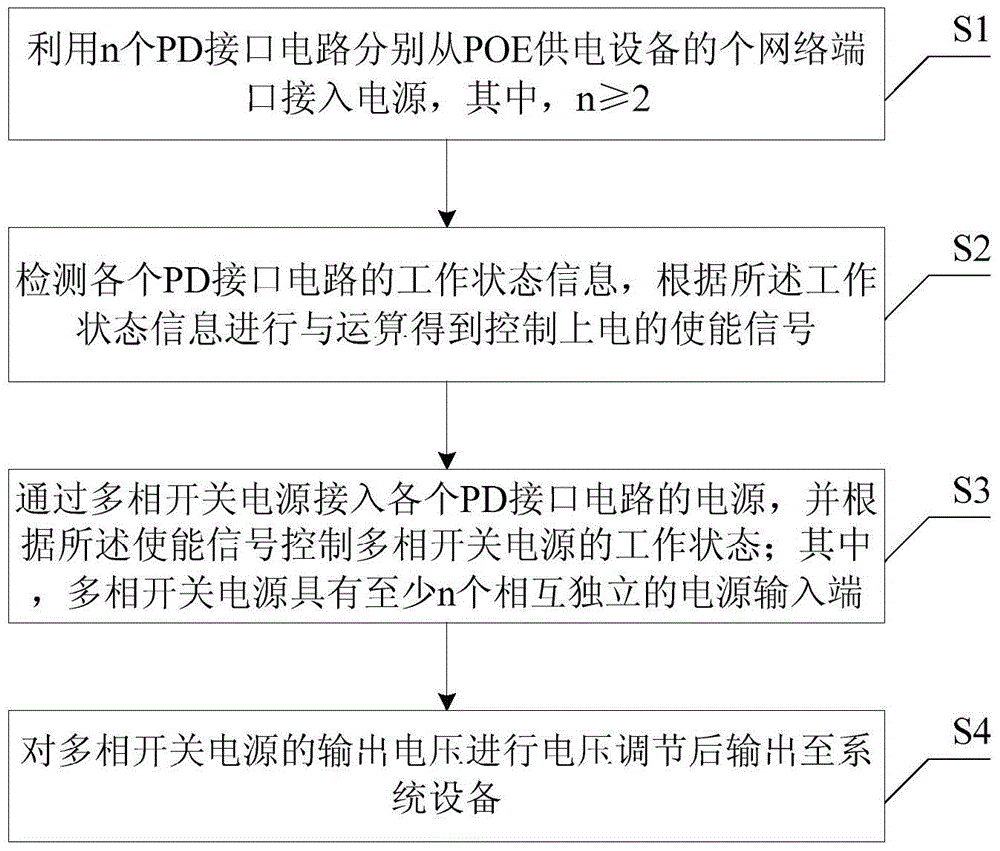

POE power source receiving method and POE power source receiving device

InactiveCN103490907AIncrease power supplyEnsure receiving securityEnergy efficient ICTData switching current supplyElectricityVoltage regulation

The invention provides a POE power source receiving method and a POE power source receiving device. The method comprises the steps that a power source is connected from n network ports of a POE power supply device respectively through n PD interface circuits, wherein n >=2; the working state information of the PD interface circuits is detected, and the AND operation is carried out according to the working state information to obtain an enable signal controlling electricity supplying; according to the enable signal, the working state of the multi-phase switch power source is controlled due to the fact that the multi-phase switch power source is connected with the output power sources of the PD interface circuits, wherein the multi-phase switch power source is provided with at least n power source input ends which are mutually independent, and the output voltage of the multi-phase switch power source is adjusted and output to a system device. According to the technical scheme, the power supply power of a POE device can be increased, data transmission cannot be affected, the safety of power source receiving can be effectively guaranteed, and the working stability of the system device is improved.

Owner:GUANGDONG VTRON TECH CO LTD

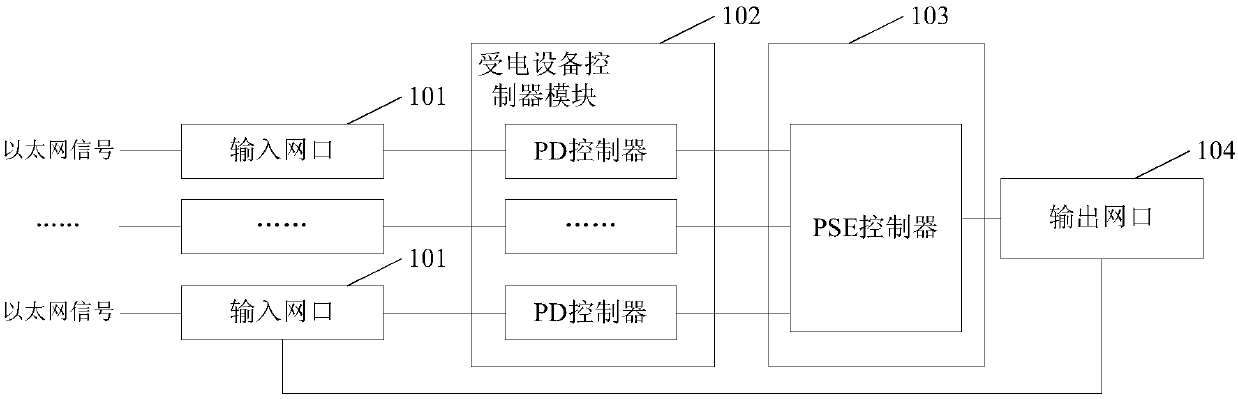

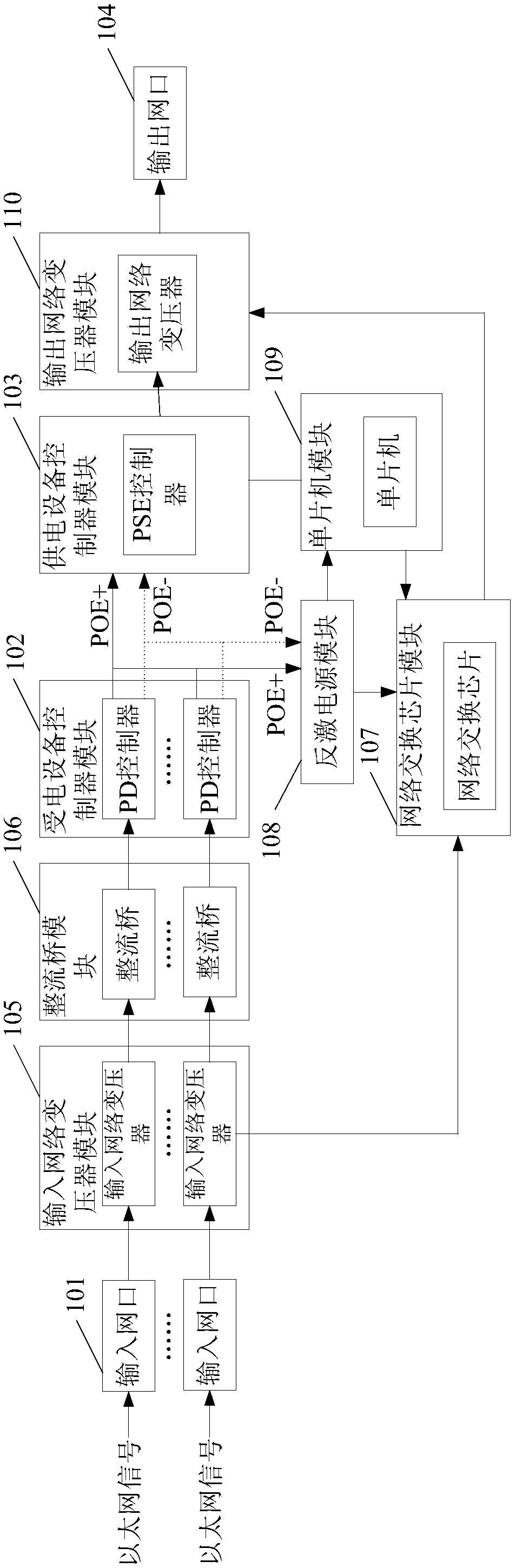

Repeater and power supply method

The embodiment of the invention provides a repeater and a power supply method, and relates to the technical field of POE power supply, and the power supply method comprises the steps: receiving a plurality of paths of input Ethernet signals; integrating a plurality of paths of input Ethernet signals to obtain Ethernet signals to be output, wherein the number of paths of the Ethernet signals to beoutput is smaller than the number of paths of the input Ethernet signals, and the power supply power of a single path of the Ethernet signals to be output is larger than that of a single path of the input Ethernet signals. According to the power supply method provided by the embodiment of the invention, the multiple paths of input Ethernet signals are integrated to obtain the to-be-output Ethernetsignal, and the power supply power of the single path of to-be-output Ethernet signal is greater than that of the single path of input Ethernet signal, so that the power supply power of the single path of output signal can be increased, and the application range of power supply equipment is enlarged.

Owner:HANGZHOU HIKVISION DIGITAL TECH

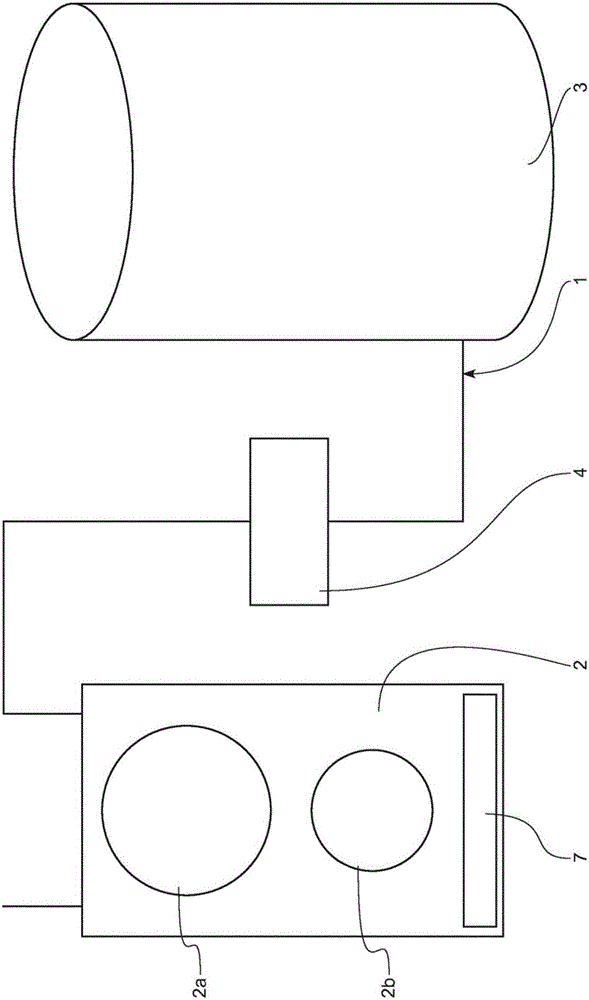

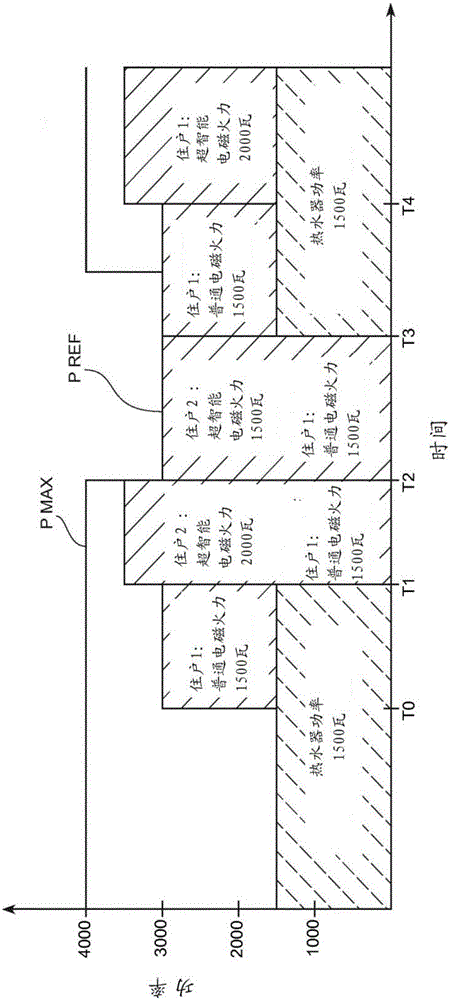

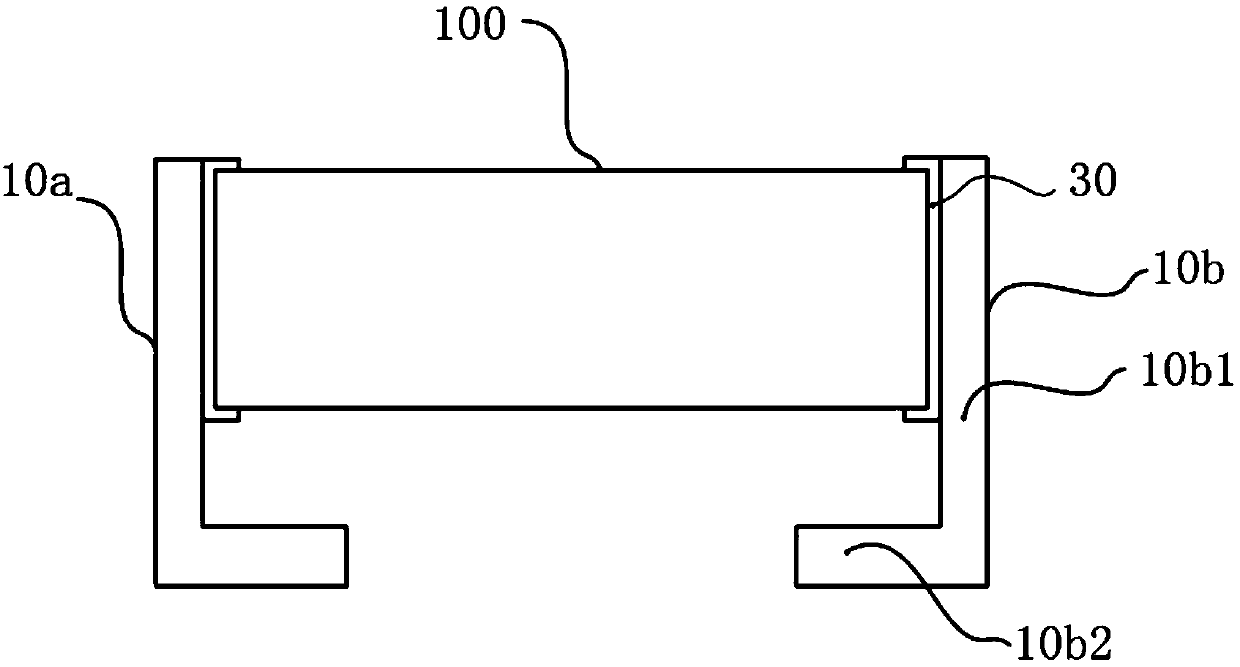

Power management method in an electrical installation and an electrical installation

InactiveCN106663290AReduce loadIncrease powerProgramme controlData processing applicationsElectrical devicesEngineering

The present invention relates to a power management method in an electrical installation (1) having electrical devices comprising at least one cooking appliance (2) provided with at least one induction heat source (2a, 2b) and a water heater (3), comprising determination of a maximum power value (Pmax) of the installation (1), determination of a rated power supply setpoint value of the water heater (3), measurement or estimation of the powers of each of the electrical devices in the installation(1), modification of the setpoint value of the water heater (3) between zero power and said rated power value when a control modification is made by a user to the heat source (2a, 2b) of the cooking appliance (2) in the direction of an increase in the power, such that the sum of the powers of the electrical devices of the installation (1) is kept less than or equal to the maximum value (Pmax) for the installation (1).

Owner:WINSLIM

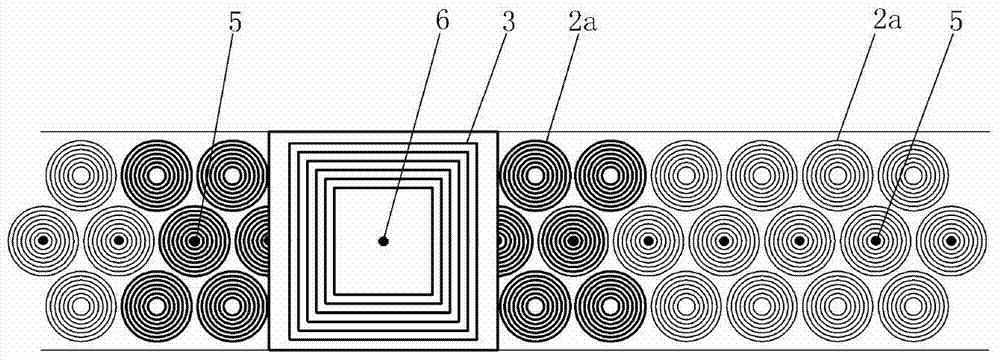

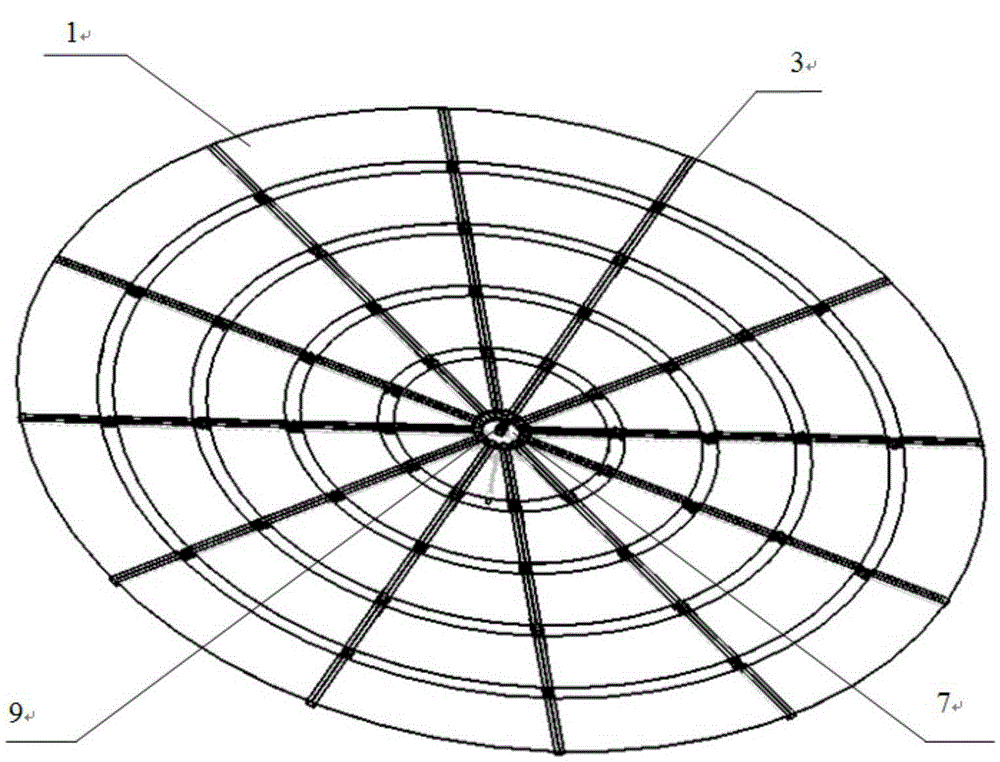

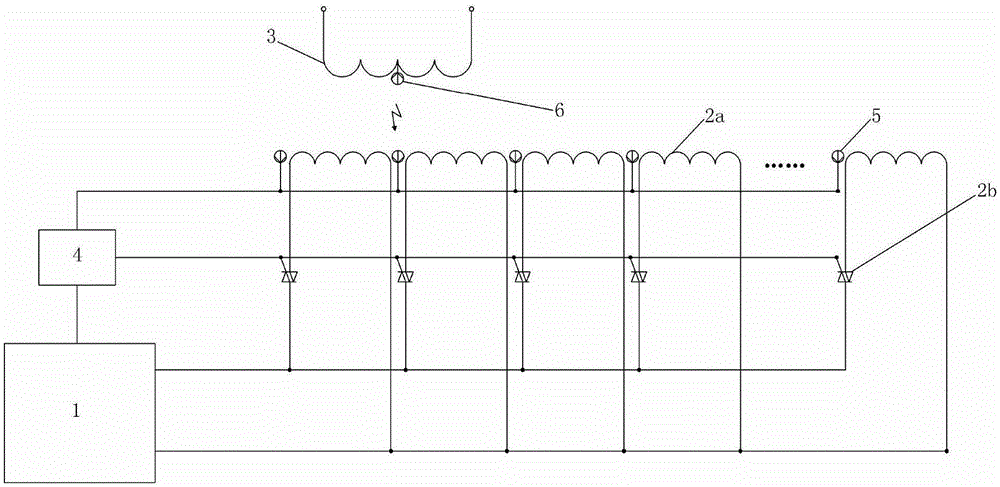

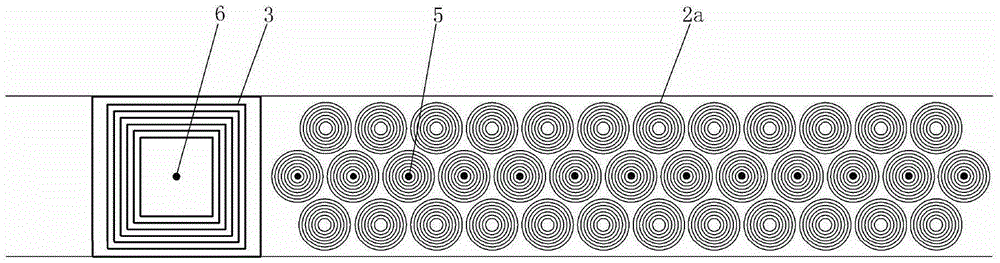

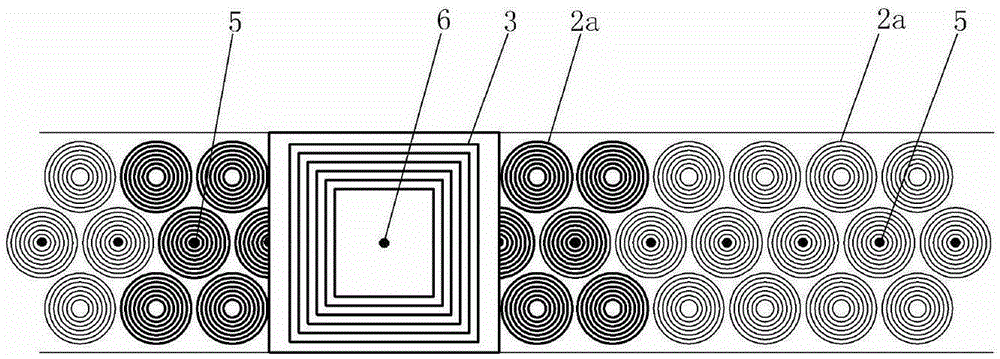

Rail transit non-contact power supply device with honeycomb-type coils and power supply method thereof

ActiveCN103795156AIncrease distribution densityIncrease the magnetic field strengthElectromagnetic wave systemCircuit arrangementsFrequency changerHoneycomb

Disclosed are a rail transit non-contact power supply device with honeycomb-type coils and a power supply method of the rail transit non-contact power supply device. The power supply device comprises a pickup coil and a controller of a power supply station, wherein the pickup coil is arranged at the bottom of a locomotive. The controller is connected with an ADA converter, and the ADA converter is connected with a power supply coil buried below the earth surface of a track power supply section, wherein the power supply coil is formed by connecting a plurality of small power supply coil bodies in parallel, and the small power supply coil bodies are equal in size, are distributed below the earth surface of the whole track power supply section in a honeycomb mode and are in series connection with switching tubes respectively. The control ends of the switching tubes are connected with the controller. Signal receivers for detecting the pickup coil are evenly arranged on the center line of the earth surface of the track power supply section at intervals of the distance of a small power supply coil body and are connected with the controller. A signal generator is arranged on the pickup coil. The non-contact power supply device is high in power supply power and magnetic field utilization ratio, saves energy resources and obviously reduces electromagnetic radiation.

Owner:SOUTHWEST JIAOTONG UNIV

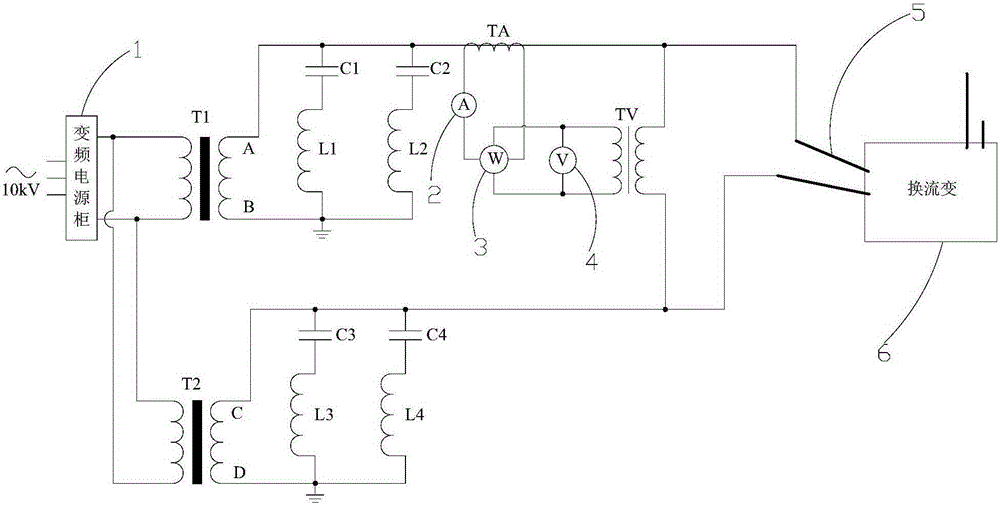

Converter transformer symmetrical voltage boosting no-load test circuit

InactiveCN105182103AReduce volumeReduce the overall heightElectrical testingThird harmonicEngineering

The invention discloses a converter transformer symmetrical voltage boosting no-load test circuit. The converter transformer symmetrical voltage boosting no-load test circuit comprises a variable-frequency power supply cabinet, an excitation transformer T1 and an excitation transformer T2 which are of the same structure, three-order harmonic filters, five-order harmonic filters, a converter transformer, a voltage transformer TV and a current transformer TA; one three-order harmonic filter and one five-order harmonic filter are connected in parallel between an A end and a B end as well as between a C end and a D end respectively; a grid-side bushing of the converter transformer is suspended; two ends of a valve-side bushing of the converter transformer are respectively connected with the A end and the C end; the primary winding of the current transformer TA is connected in series with the A end or on a connecting line between the C end and the valve-side bushing of the converter transformer; and two ends of the primary winding of the voltage transformer TV are respectively connected with the A end and the C end. According to the converter transformer symmetrical voltage boosting no-load test circuit of the invention, the three-order harmonic filters and the five-order harmonic filters are adopted to effectively filter out harmonic generated in the converter transformer in a no-load test, and the excitation transformers and the capacity of a variable-frequency power supply can be effectively used.

Owner:EXAMING & EXPERIMENTAL CENT OF ULTRAHIGH VOLTAGE POWER TRANSMISSION COMPANY CHINA SOUTHEN POWER GRID

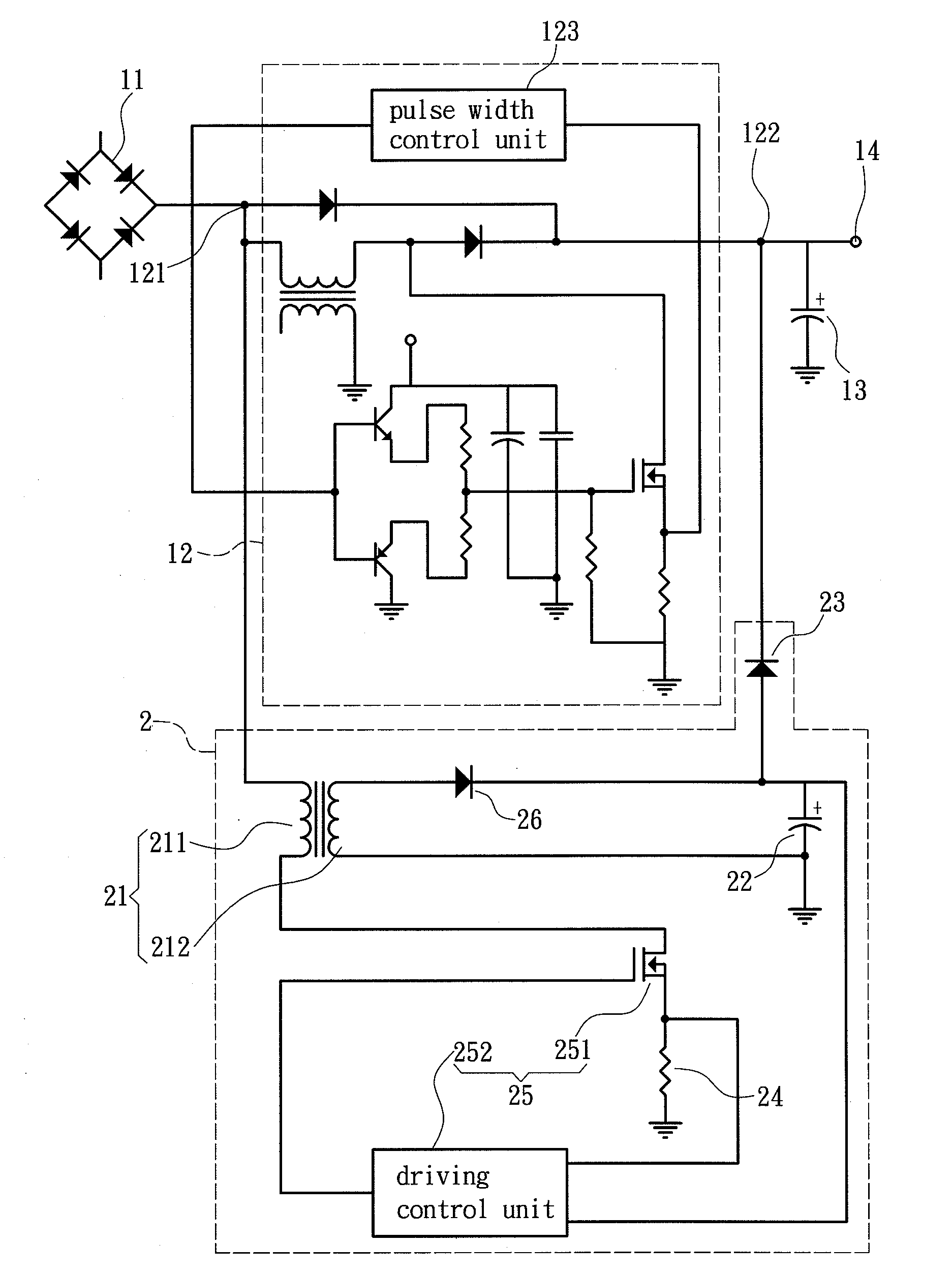

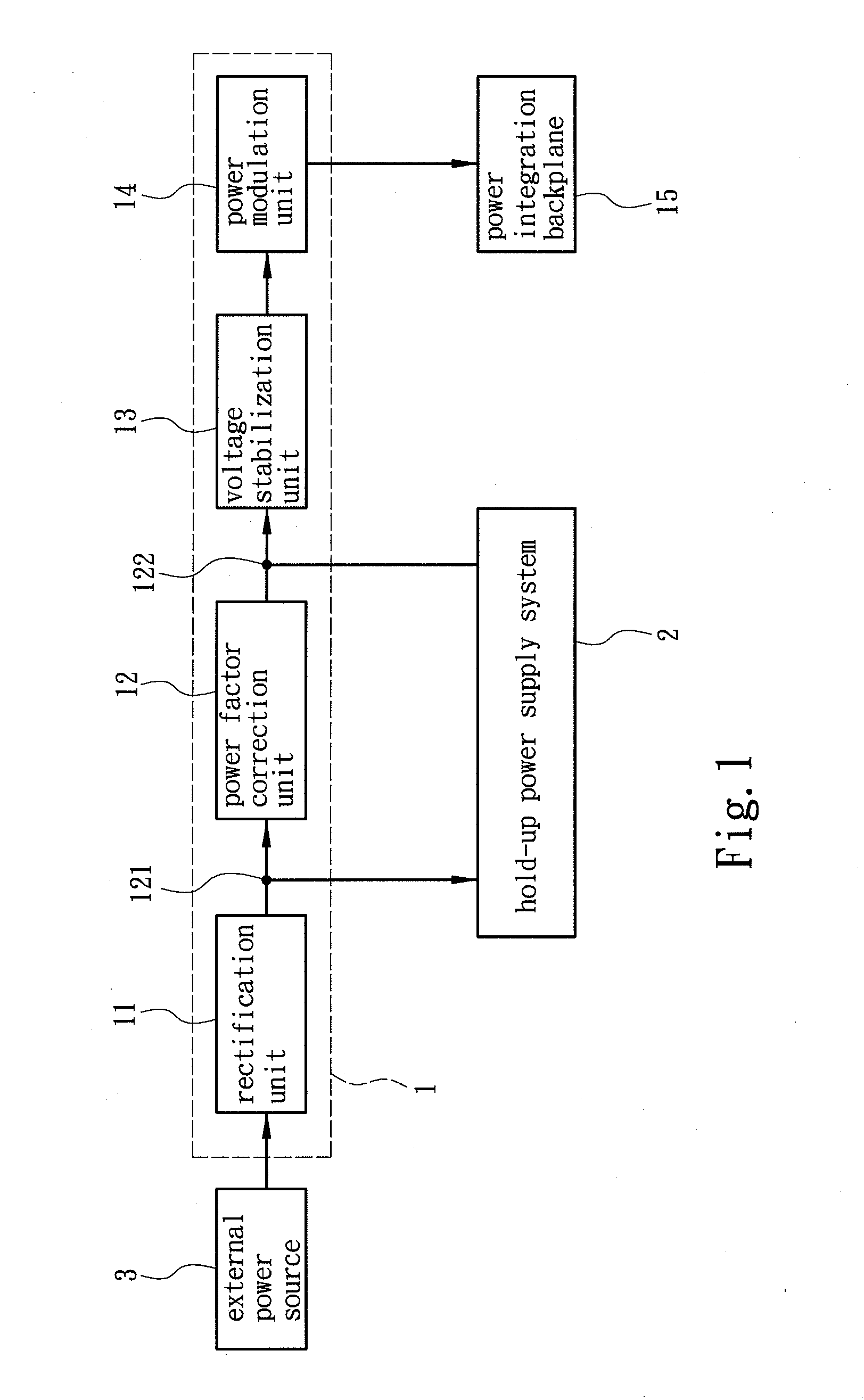

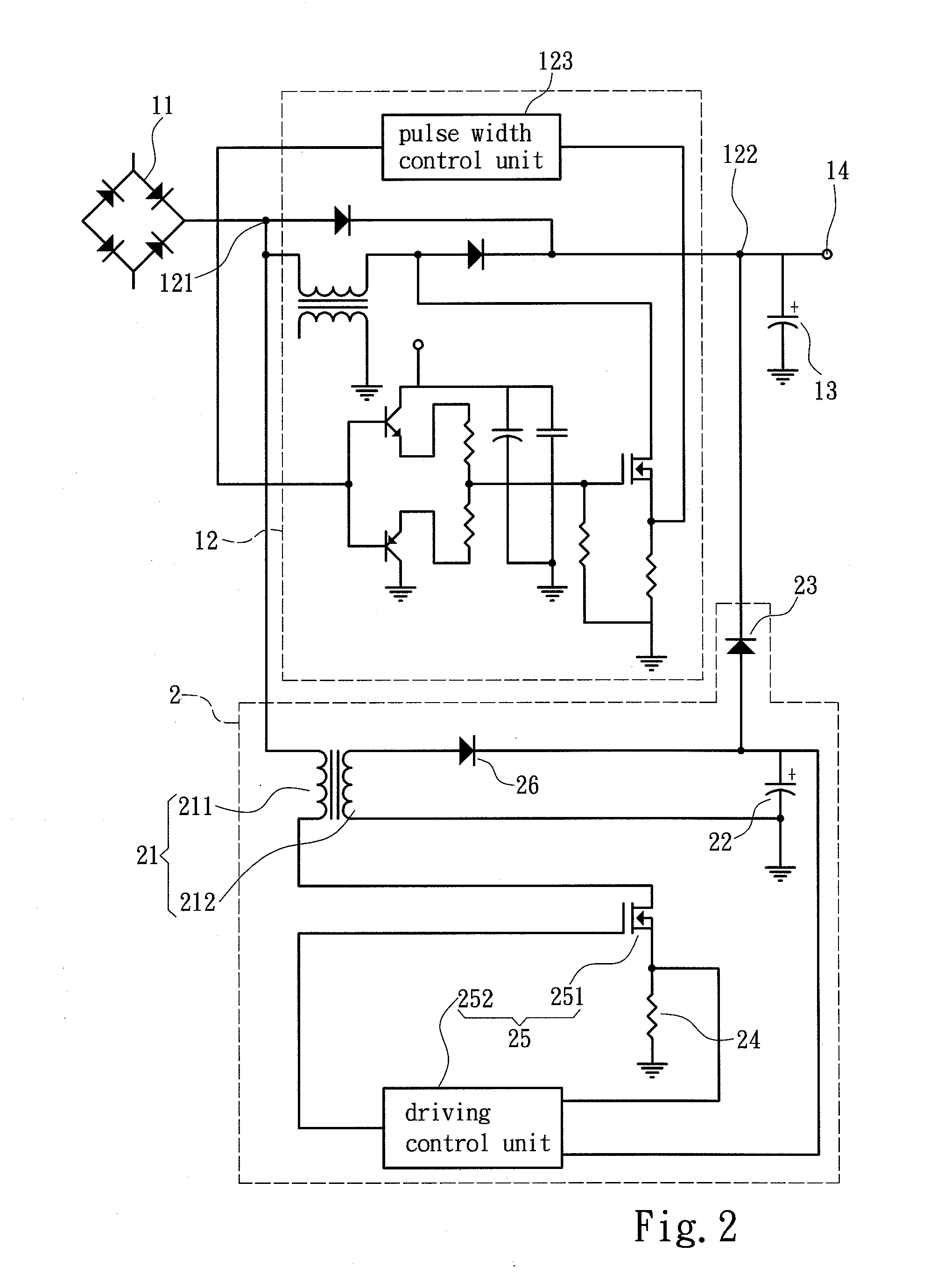

Power supply for prolonging hold-up time

InactiveUS20140254201A1Slow booting processIncrease power supplyDc network circuit arrangementsEfficient power electronics conversionPower factor correctorPower storage

A power supply for prolonging a hold-up time includes a main power supply system, and a hold-up power supply system connected in parallel to a power factor correction unit in the main power supply system. The hold-up power supply system includes an isolation transformer element connected to the power factor correction unit for receiving and transforming a first power to a third power, a power storage element for receiving the third power and storing as a hold-up power, and a power comparison unit connected between the power factor correction unit and the power storage element. The power comparison unit compares a second power generated from phase modulation performed by the power factor correction unit and the hold-up power, and outputs the hold-up power when the second power is smaller than the hold-up power, so as to sustain the power modulation unit to continue operating for a hold-up time.

Owner:ZIPPY TECH

Portable air conditioner

InactiveCN104764246ASolve charging problemsFix bugs that don't workMachines using electric/magnetic effectsMachines using solar energyElectricityRefrigeration

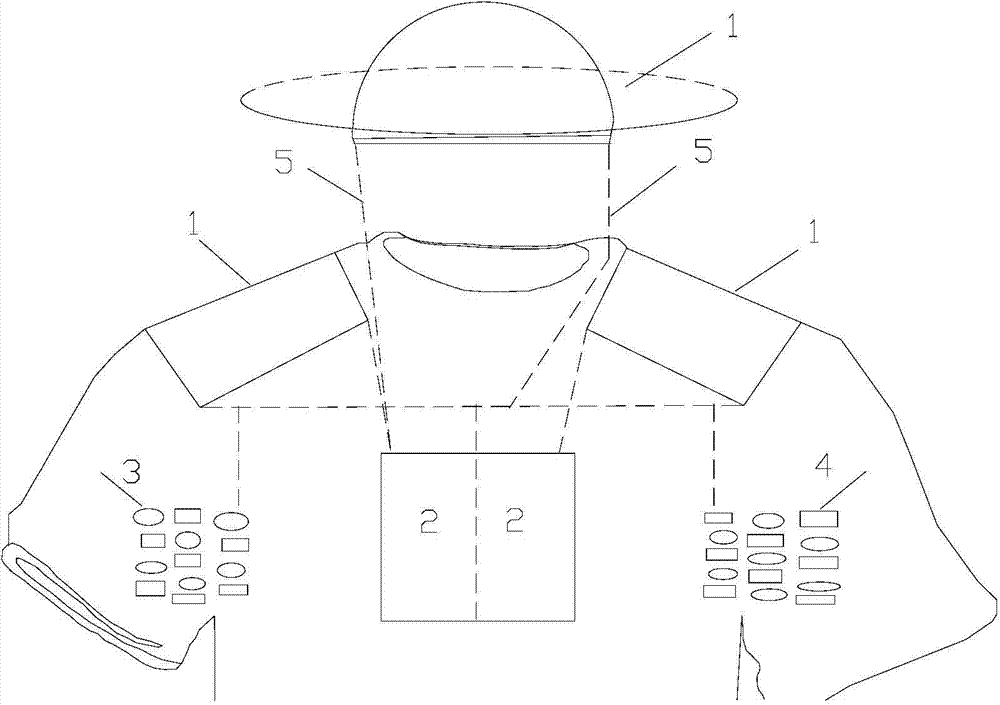

The invention relates to the technical field of air conditioners, and in particular relates to a portable air conditioner. The potable air conditioner comprises a temperature adjusting unit, a wearable device and a power supplying unit used for supplying rated current for the temperature adjusting unit, wherein the temperature adjusting unit is a semiconductor chilling plate, the semiconductor chilling plate comprises a refrigeration side and a heating side; the power supplying unit comprises a semiconductor thermoelectric power generation chip, and the semiconductor chilling plate and the semiconductor thermoelectric power generation chip are arranged on the wearable device. The power supplying unit further comprises a chargeable regulating type energy storage power supply; the regulating type energy storage power supply is respectively connected with the semiconductor thermoelectric power generation chip and the semiconductor chilling plate. The portable air conditioner can solve the defect that the work cannot be performed continuously in the muggy weather without sunlight or under this circumstance that the battery is out of power; the solar energy and the regulating energy storage power are used as the auxiliary power supply source for saving the energy, protecting the environment, ensuring the stability of power supply and starting the thermoelectric power generation chip.

Owner:GREE ELECTRIC APPLIANCES INC

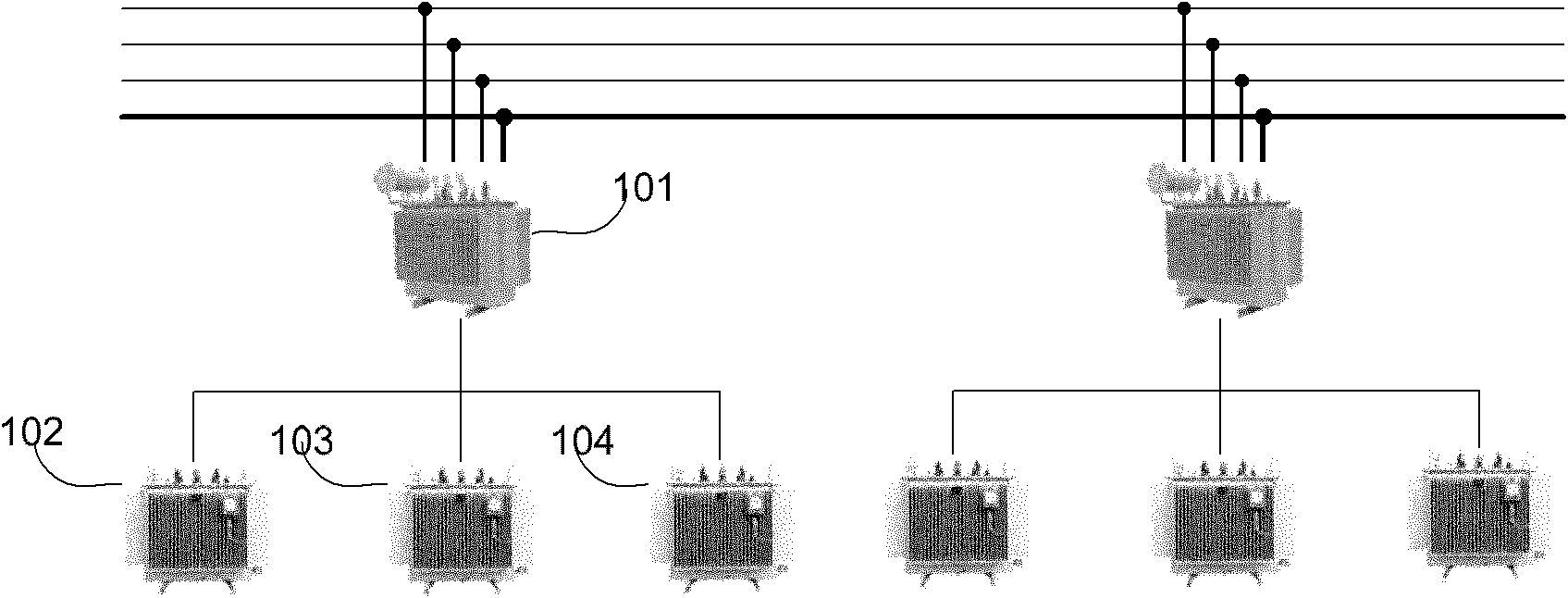

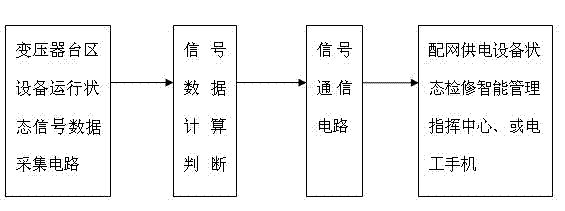

Intelligent managing device for condition based maintenance of 10-20kv transformer

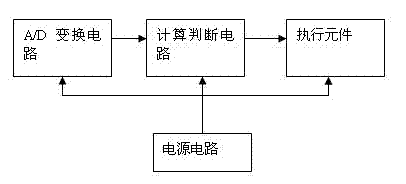

InactiveCN102868230AShorten incident handling timeIncrease power supplyCircuit arrangementsInformation technology support systemCondition-based maintenanceDistribution transformer

The invention discloses an intelligent managing device for condition based maintenance of a 10-20kv transformer. The intelligent managing device comprises a running state signal data collecting circuit of station area equipment of the transformer, a signal data calculation judging circuit and a signal communication circuit. The running state signals of various equipment of a station area equipment system of the transformer are collected by the running state signal data collecting circuit of the station area equipment of the transformer and are output to the signal data calculation judging circuit. The signal data calculation judging circuit is in output connection with the signal communication circuit. The signal communication circuit is connected with a state maintenance intelligent managing command center of network distribution power supply equipment or mobile phones of electricians. The abnormal circumstances of running data such as voltage, current, temperature and the like of a station area power distributing device of a distributing transformer can be known by the state maintenance intelligent managing device at any time by remote measuring and the remote signaling, the maintenance is planned in time according to the running state of the equipment on site, the processing time of accidents is shortened, the power supply volume is improved, and the creditworthiness of power supply enterprises is improved.

Owner:ZHUMADIAN POWER SUPPLY ELECTRIC POWER OFHENAN +5

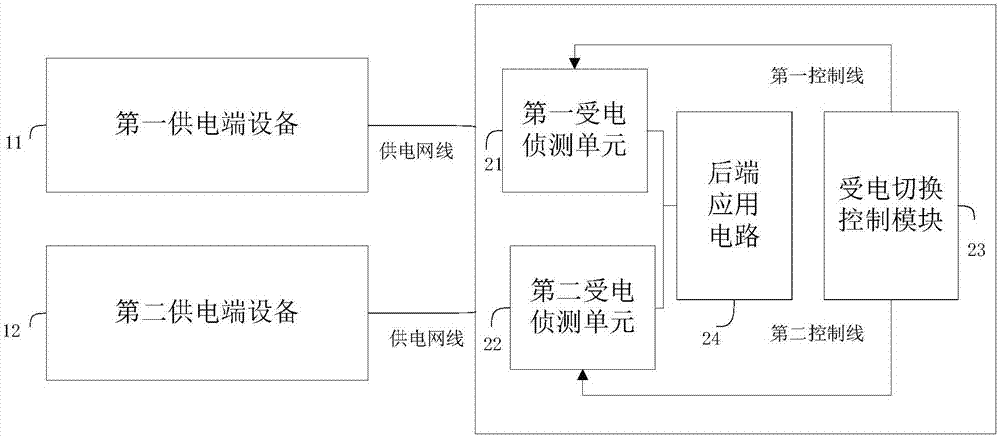

Common power supply system and method by using two power supply end devices

InactiveCN107135082AIncrease powerIncrease power supplyData switching current supplyInstabilityElectricity

The invention discloses a common power supply system and method by using two power supply end devices for solving the problem that power receiving end devices cannot work because of the instability of a single power supply end device in the traditional POE power supply. The system is composed of a first power supply end device, a second power supply end device and a power receiving end device; the first power supply end device and the second power supply end device are separately connected with a first power supply network port and a second power supply network port of the power receiving end device for providing another path of electric power; the power receiving end device comprises a first power receiving detection unit used for feeding back information to the power supply end devices; a second power receiving detection unit used for feeding back information to the power supply end devices; and a power receiving switch control module connected with the first power receiving detection unit and the second power receiving detection unit at the same time and used for controlling the on-off of the power supply of the first power receiving detection unit and the second power receiving detection unit to a back end application circuit. By adoption of the common power supply system and method disclosed by the invention, non interruption of the transmission backup is ensured.

Owner:PHICOMM (SHANGHAI) CO LTD

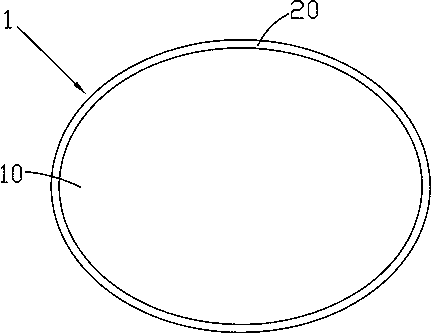

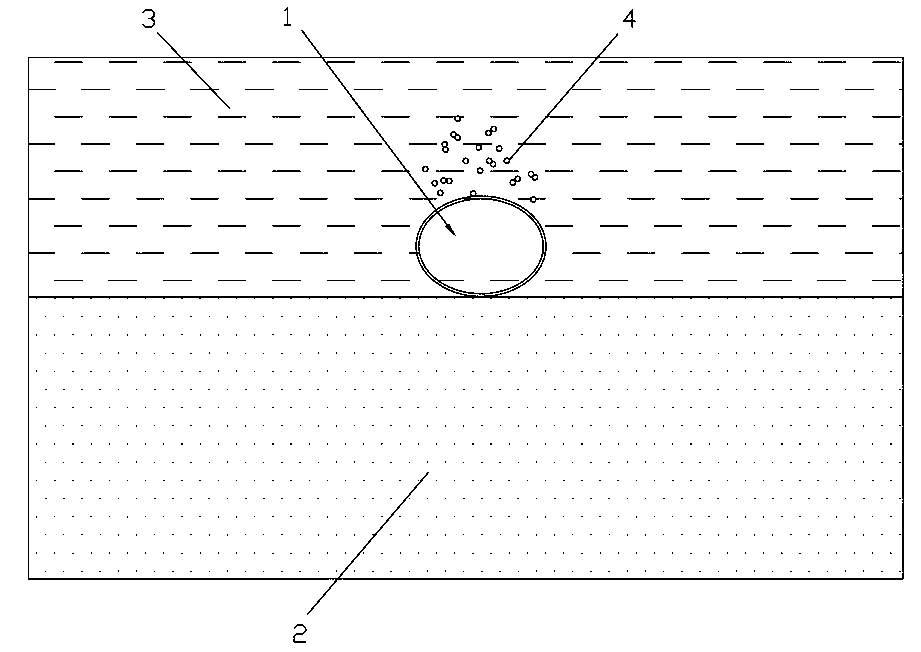

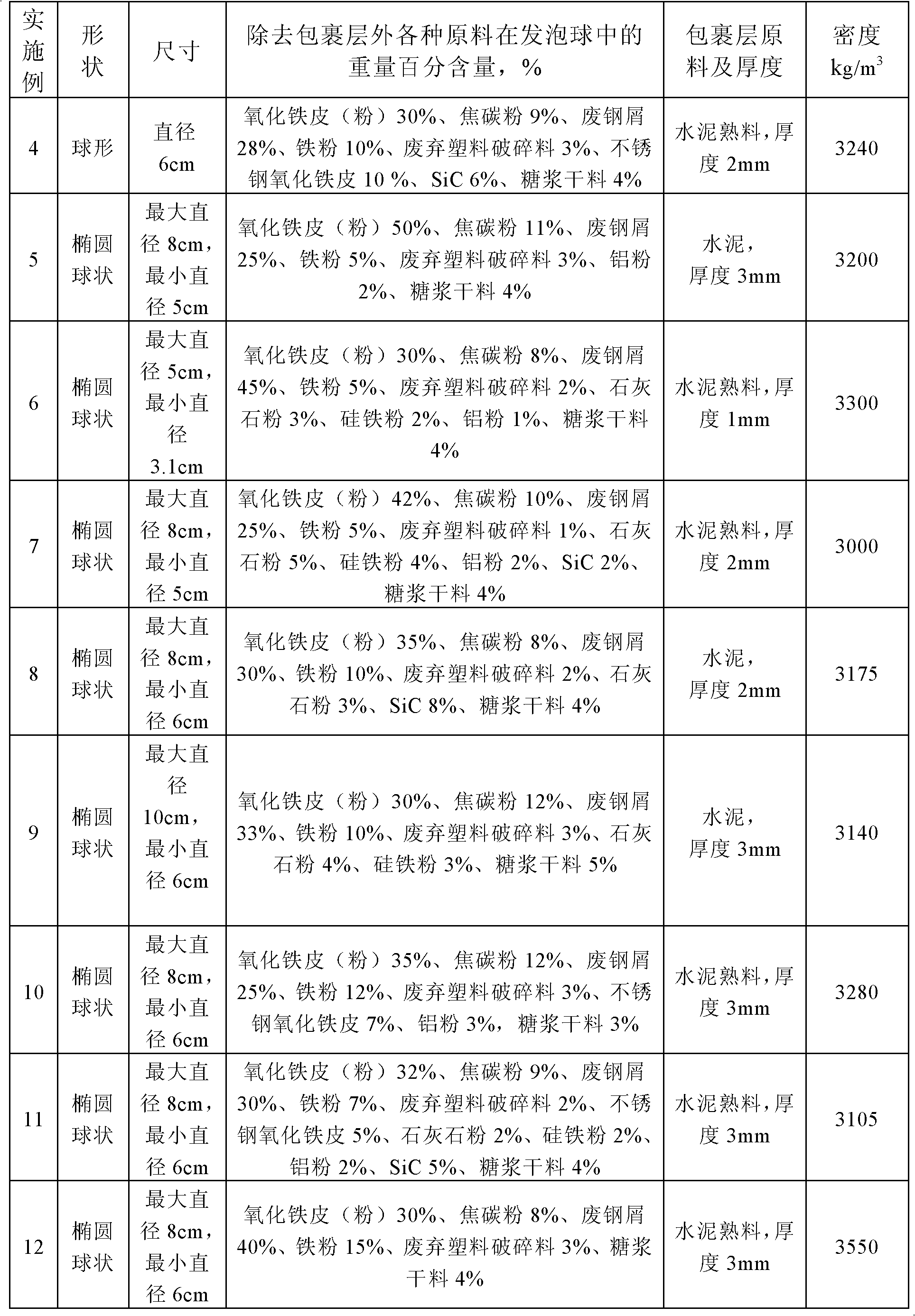

Foamed ball for producing foam slag in process of stainless steel smelting by an electric arc furnace and a manufacture method thereof

ActiveCN102719605AImprove protectionReduce consumptionProcess efficiency improvementElectric furnaceMelting tankElectric arc furnace

The invention provides a foaming ball for producing foam slag in the process of stainless steel smelting by an electric arc furnace and a manufacture method thereof. The foamed ball is a hot pressed pellet consisting of iron oxide pieces or powder, coke powder, wasted steel cuttings, iron powder, and wasted plastic crumbles as main materials; The exterior of the pellet is covered by a hard layer comprising a raw material of cement clinker or cement. The manufacture method includes the following steps of: well mixing main materials, and dry materials of the adhesive; adding water to bond the materials; performing hot pressing and pelletization for 0.5-1 hours and mixing the pellets with the cement clinker to enable the surface of the pellets to be covered by the cement clinker slurry; and performing secondary pelletization, airing and baking the pellets. The foaming ball produced by the invention has good strength, such that the foaming ball is not easily broken when falling off from an elevated bunker in the process of stainless steel smelting by an electric arc furnace. Furthermore, the pellet can also produce good foam slag which has a foaming height of over 10cm on average and a foaming time of over 8 min for one time material feeding.The foaming ball can protect electric arc, improve thermal efficiency of the electric arc, reduce power consumption, shorten smelting time and protect the furnace lining.

Owner:BAOSHAN IRON & STEEL CO LTD

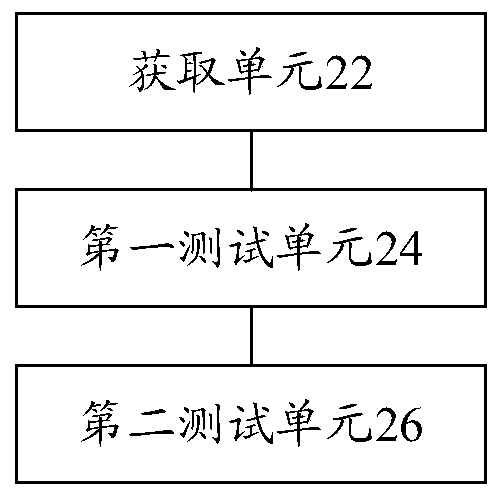

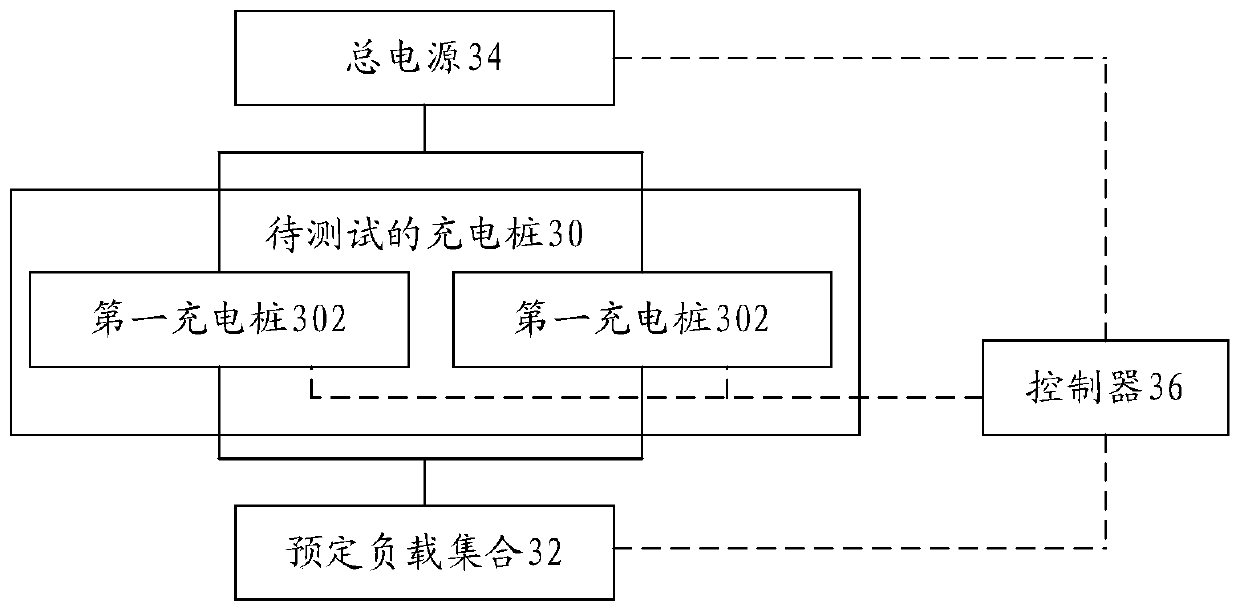

Charging pile test method, device and system, storage medium and processor

ActiveCN111157820AIncrease power supplyIncrease load powerComponent separationBase element modificationsSimulationReliability engineering

The invention discloses a charging pile test method, device and system, a storage medium and a processor. The method comprises the steps of obtaining a test task set of the charging pile, and the testtask set at least comprises a first test task and a second test task; configuring a first power supply and a first load for the first charging pile based on the first test task, controlling the firstcharging pile to execute the first test task, configuring a second power supply and a second load for the second charging pile based on the second test task, and controlling the second charging pileto execute the second test task; and under the condition that the first charging pile completes the first test task and the second charging pile completes the second test task, interchanging the firsttest task and the second test task. According to the invention, the technical problem of low efficiency of batch detection of the charging piles is solved.

Owner:STATE GRID BEIJING ELECTRIC POWER +1

Preparation process of carbon slide plate

InactiveCN111002835AWith airtight safety functionUniform structurePower current collectorsSlide platePipe

The invention relates to the technical field of carbon slide plate preparation. The invention relates to the technical field of pantograph carbon sliding plate manufacturing, in particular to a carbonsliding plate manufacturing process, a copper pipe groove is pre-embedded in one side of an inner arc of a carbon sliding strip of a pantograph carbon sliding plate, an intact copper pipe air channelis embedded during bonding and curing, and the two ends of a copper pipe are welded to air pipe connectors respectively to form the complete pantograph carbon sliding plate with the airtight safety function. By researching the raw material formula and the process method, the carbon slide strip capable of improving the process quality of a product forming process, a roasting process, an impregnation process and the like and key quality indexes of the product volume density, resistance, breaking strength, compressive strength, uniform structure, impact toughness and the like is prepared. Afterthe pantograph carbon slide plate without the copper pipe air passage is mounted on a pantograph device of an electric locomotive, the carbon slide plate is continuously abraded in continuous operation, the abrasion thickness of the carbon slide strip is continuously reduced, and crack air leakage of the carbon strip possibly occurs under the action of impact force.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

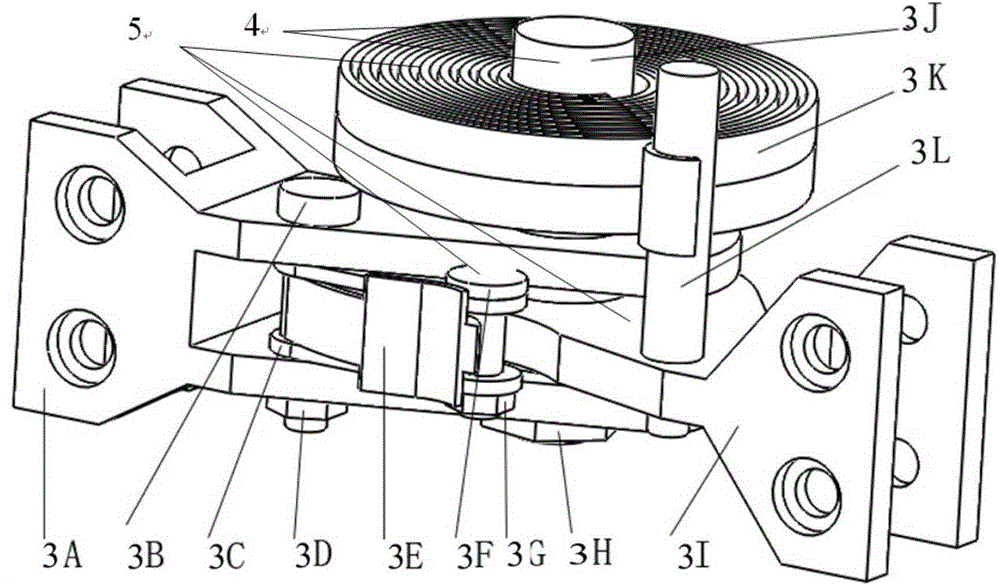

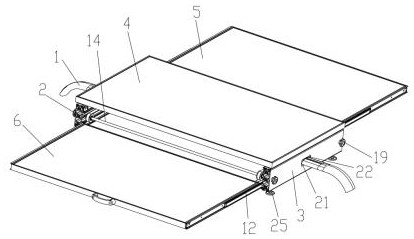

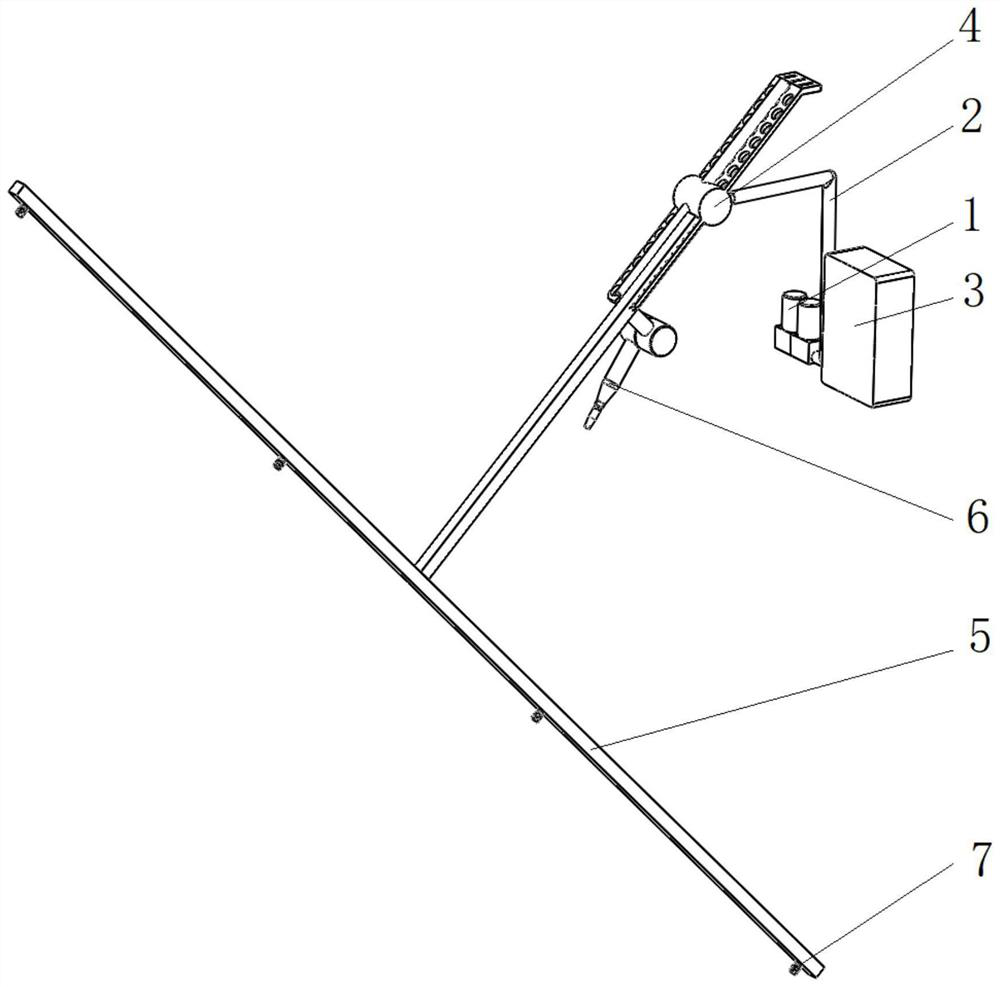

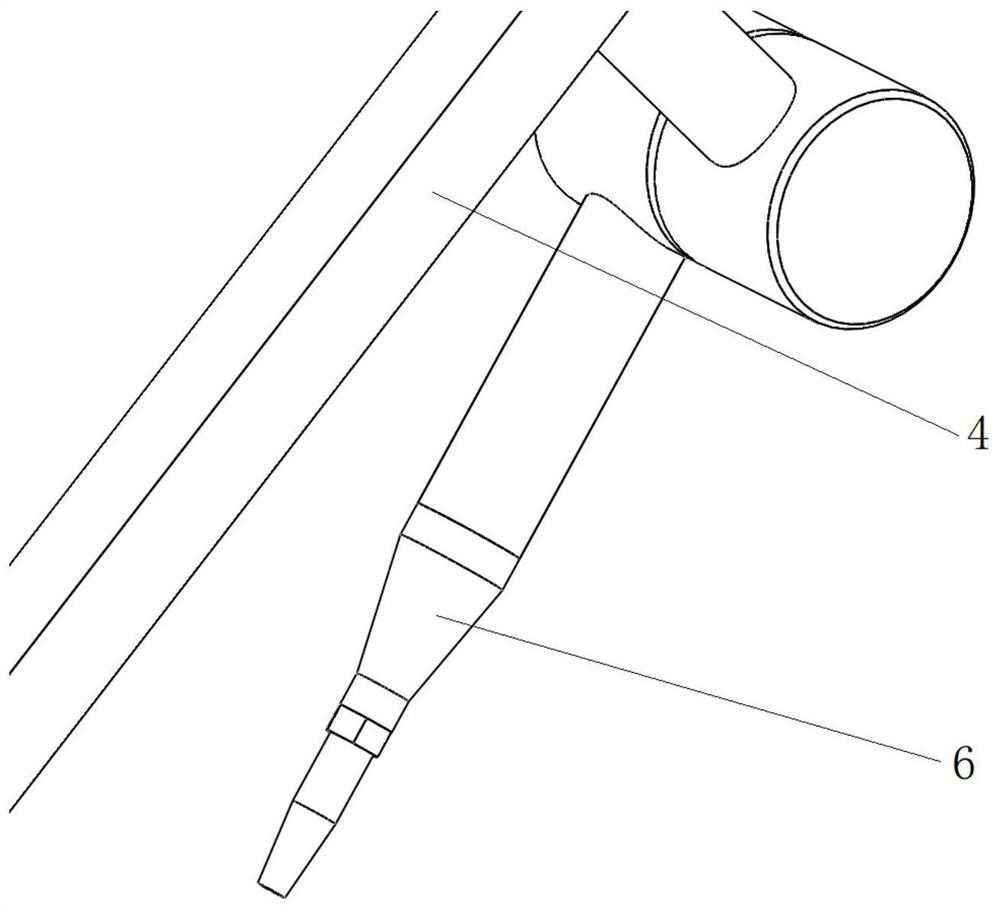

A new type of flexible solar cell array deployment device

ActiveCN103595339BEasy to adjust preloadIncrease power supplyPhotovoltaic supportsPhotovoltaic energy generationMotor driveLocking mechanism

The invention discloses a novel flexible solar cell array unfolding device and belongs to the technical field of civil aerospace engineering. The device is composed of a synchronous extending mechanism and a central driving mechanism. The synchronous extending mechanism is composed of a flexible solar cell array sailboard, a driving mechanism, an unfolding mechanism, a synchronizing mechanism and a locking mechanism, wherein the flexible solar cell array sailboard uses five annular amorphous silicon films, the driving mechanism uses a method that torsion spring driving and servo motor driving are combined, a torsion spring at the hinge position can complement driving torque required in an unfolding process, the unfolding mechanism uses a gap hinge, a driving pin shaft of the gap hinge is replaceable, the synchronizing mechanism uses a steel wire rope to drive a linkage mechanism, and the locking mechanism uses a cam pin type locking mechanism. The novel flexible solar cell array unfolding device provides a flexible solar cell array unfolding method, solves the problems that a traditional solar cell array is complex in structure, small in folding ratio and low in work reliability, fully utilizes the material characteristics of a flexible substrate and improves the power generation efficiency of a solar cell array and the use reliability of the solar cell array.

Owner:TSINGHUA UNIV

Vehicle photovoltaic unfolding device and working method

PendingCN112165150AIncrease power supplyPhotovoltaic supportsBatteries circuit arrangementsEngineeringStructural engineering

The invention relates to a vehicle photovoltaic unfolding device and a working method thereof. The vehicle photovoltaic unfolding device comprises an installation crossbeam arranged on a vehicle roof,and a left installation frame and a right installation frame which are oppositely arranged on the installation crossbeam, and a first photovoltaic panel, a second photovoltaic panel and a third photovoltaic panel are arranged between the left installation frame and the right installation frame from top to bottom. The first photovoltaic panel is fixed between the left installation frame and the right installation frame, the second photovoltaic panel and the third photovoltaic panel slide relative to the left installation frame and the right installation frame in the length direction of the vehicle body, and the second photovoltaic panel and the third photovoltaic panel achieve synchronous stretching and retracting through a belt wheel synchronizing mechanism arranged on the inner side of the left installation frame and the inner side of the right installation frame. The photovoltaic unfolding device for the vehicle can be used on the vehicle, large power supply power can be provided after the photovoltaic unfolding device is unfolded, and the photovoltaic unfolding device is stable and reliable in installation.

Owner:英利能源(江西)有限公司

Poe power receiving method and poe power receiving device

InactiveCN103490907BIncrease power supplyEnsure receiving securityData switching current supplyHigh level techniquesElectricityVoltage regulation

The present invention provides a PoE power supply receiving method and a PoE power supply receiving device, wherein the method includes the step of accessing a power source from the N network ports of the PoE power supply device using N PD interface circuitry, wherein N ≥ 2; detects each PD interface.The working status information of the circuit is performed according to the working state information to obtain an enable signal to control power-on, and the output power source of each PD interface circuit is accessed by the multi-phase switching power source, and the multi-phase switch is controlled according to the enable signal.The power supply status of the power supply; wherein the multi-phase switching power source has at least n mutually independent power input; outputting the output voltage of the multi-phase switching power supply to the system device.The technical solution of the present invention can increase the power supply power of the PoE device without affecting data transmission, and it is possible to effectively support the power supply reception security, and improve the operation stability of the system equipment.

Owner:GUANGDONG VTRON TECH CO LTD

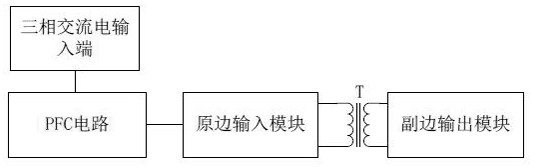

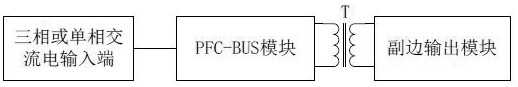

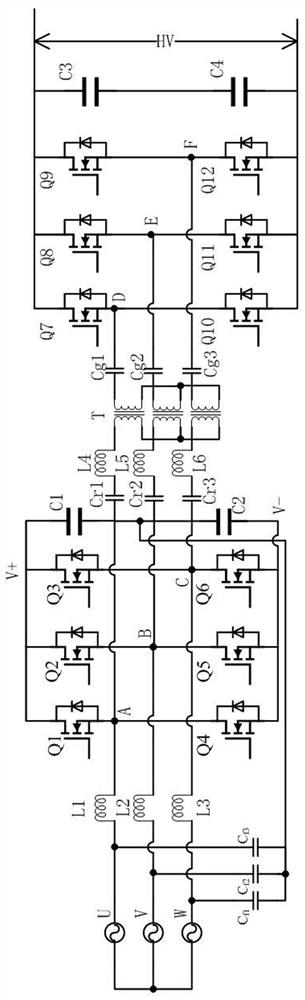

AC-DC resonant conversion circuit and control method thereof

PendingCN113394996AImprove work efficiencyCompact structureEfficient power electronics conversionAc-dc conversionHemt circuitsAlternating current

The invention discloses an AC-DC resonant conversion circuit and a control method thereof. The AC-DC resonant conversion circuit comprises an AC connecting end, a PFC-BUS conversion module, a transformer and a secondary side conversion module which are connected in sequence. The PFC-BUS conversion module adopts a control pulse signal generated by an SVPWM (Space Vector Pulse Width Modulation) algorithm to implement switch control, can perform power factor correction on input AC, converts the AC into DC transmits the DC to a primary side of the transformer; and a secondary side conversion module control pulse signal follows an PFC-BUS conversion module control pulse signal, and a phase shift control angle phi is arranged between the PFC-BUS conversion module control pulse signal and the secondary side conversion module control pulse signal. A switching tube is shared in the PFC-BUS conversion module, correction of a power factor and a current waveform can be completed, adjustment of output voltage can also be completed; and two-stage conversion of the whole circuit shares the same switching device, so that the whole circuit is simple and compact in structure, and control is simplified and convenient.

Owner:SHENZHEN VMAX NEW ENERGY CO LTD

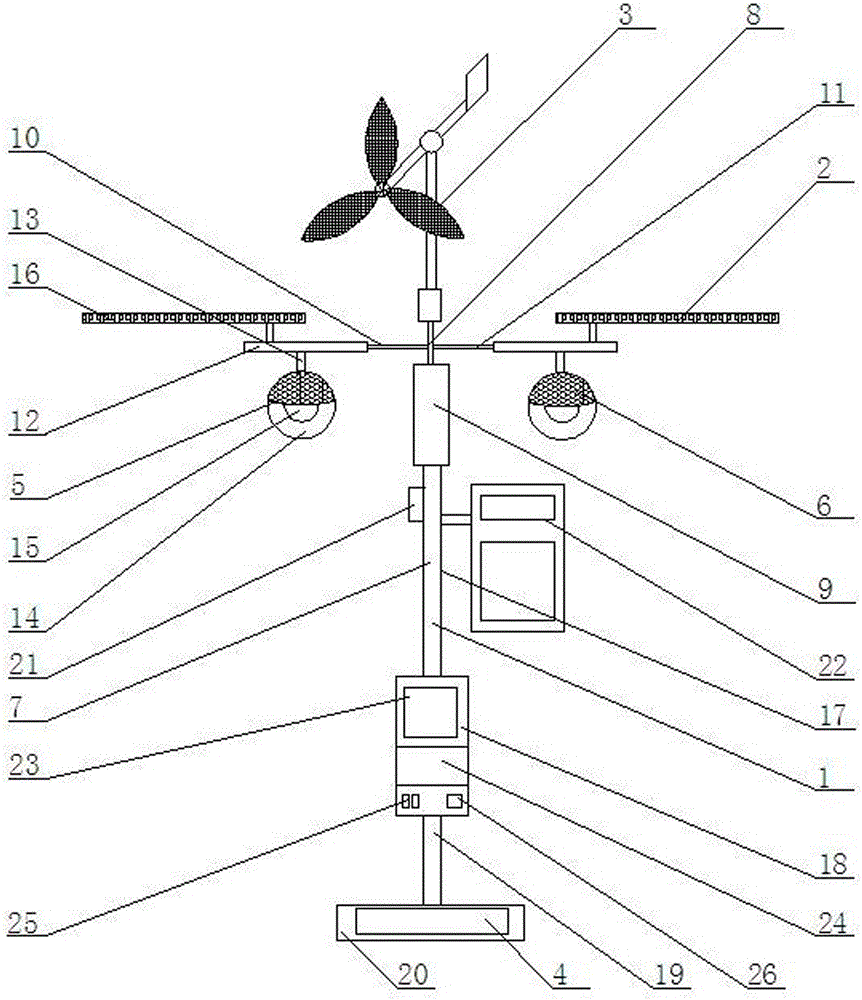

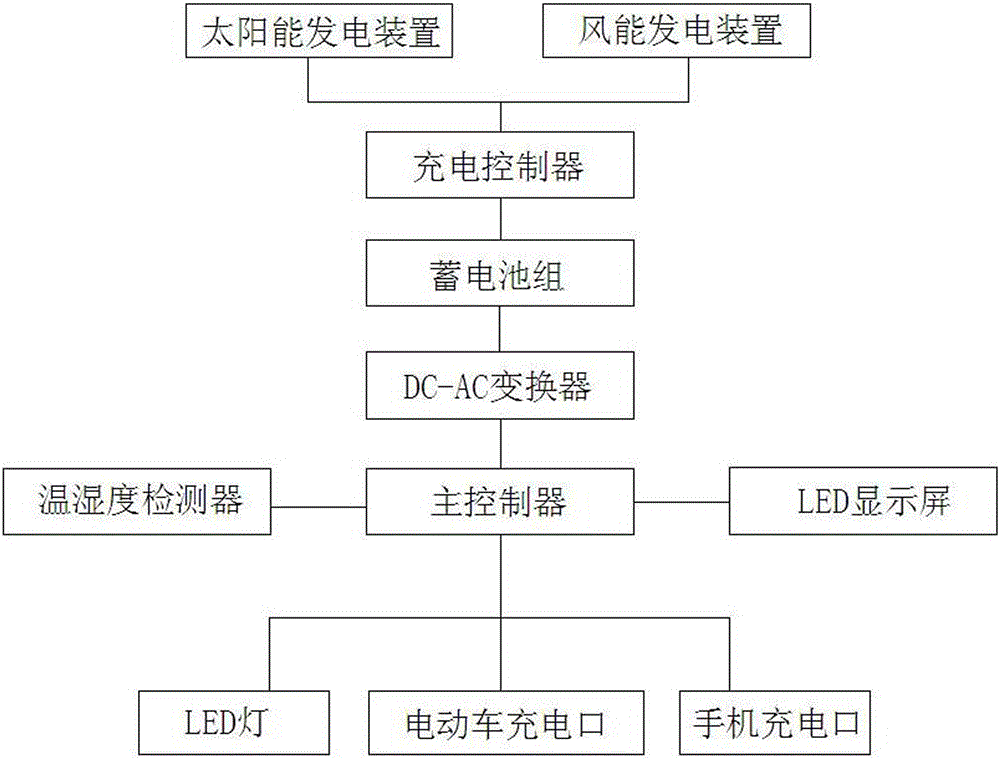

Wind and solar complementation street lamp

InactiveCN106382597AOvercoming power shortagesIncrease power supplyMechanical apparatusPoint-like light sourceAutomotive engineeringCharge controller

A wind and solar complementation street lamp comprises a lamp body, a solar energy generation device and a wind power generation device, wherein the wind power generation device is mounted on the top end of the lamp body; the lower end of the wind power generation device is connected with a charging controller via a first vertical supporting rod; the left end of the first vertical supporting rod is connected with a left street lamp device via a left connection rod; the right end of the first vertical supporting rod is connected with a right street lamp device via a right connection rod; the upper end of the left street lamp device and the upper end of the right street lamp device are respectively provided with a solar energy heat collection plate; the lower end of the charging controller is in a connection with a main control case via a second vertical supporting rod; the main control case is connected to a pedestal via a third vertical supporting rod; the left upper end of the second vertical supporting rod is provided with a temperature-humidity detector; and the right upper end of the second vertical supporting rod is provided with an LED display screen. Solar energy is taken as the principal and wind power as secondary energy for generation of the power supply system, so the wind and solar complementation street lamp is advantaged by high generation efficiency, great stability and energy conservation and environment protection.

Owner:HARBIN JINDU SOLAR ENERGY TECH

A rail transit non-contact power supply device with honeycomb coil and power supply method thereof

ActiveCN103795156BIncrease distribution densityIncrease the magnetic field strengthCircuit arrangementsFrequency changerHoneycomb

Disclosed are a rail transit non-contact power supply device with honeycomb-type coils and a power supply method of the rail transit non-contact power supply device. The power supply device comprises a pickup coil and a controller of a power supply station, wherein the pickup coil is arranged at the bottom of a locomotive. The controller is connected with an ADA converter, and the ADA converter is connected with a power supply coil buried below the earth surface of a track power supply section, wherein the power supply coil is formed by connecting a plurality of small power supply coil bodies in parallel, and the small power supply coil bodies are equal in size, are distributed below the earth surface of the whole track power supply section in a honeycomb mode and are in series connection with switching tubes respectively. The control ends of the switching tubes are connected with the controller. Signal receivers for detecting the pickup coil are evenly arranged on the center line of the earth surface of the track power supply section at intervals of the distance of a small power supply coil body and are connected with the controller. A signal generator is arranged on the pickup coil. The non-contact power supply device is high in power supply power and magnetic field utilization ratio, saves energy resources and obviously reduces electromagnetic radiation.

Owner:SOUTHWEST JIAOTONG UNIV

Switching power supply module and packaging method thereof

PendingCN107808879AReduce volumeImprove power densitySemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsInductorInductance

The invention discloses a switching power supply module and a packaging method thereof. The switching power supply module includes a power inductor and a switching power supply chip. The power inductor includes a magnetic core and L-type metal end electrodes welded to the two ends of the magnetic core. The switching power supply chip includes a packaging body, a bare chip inside the packaging body, and a bottom pad of the bare chip. Each L-type metal end electrode is composed of a first electrode part and a second electrode part perpendicular to each other, wherein the first electrode part iswelded to the magnetic core and forms a right angle with the magnetic core, and the second electrode part extends in parallel from the first electrode part to the middle of the magnetic core. The barechip and the packaging body are embedded between the first and second electrode parts and the magnetic core. The bottom pad is abutted between the two second electrode parts and is insulated from thesecond electrode parts, and the welding surface of the bottom pad is flush with the welding surfaces of the second electrode parts. The packaging method is to package the power inductor with the L-type metal end electrodes and the switching power supply chip in a nesting manner.

Owner:SHENZHEN SUNLORD ELECTRONICS

Efficient water spraying cleaning system for photovoltaic module

PendingCN112436800AReduce usageEasy to cleanPhotovoltaicsCleaning using liquidsWater useWater source

The invention discloses an efficient water spraying cleaning system for a photovoltaic module and a working method of the efficient water spraying cleaning system, and belongs to the technical field of photovoltaic power generation. The device comprises a high-pressure water pump, a high-pressure water conveying pipe, a power supply system, a support assembly, a spraying pipe, directional long-shot nozzles and a plurality of fan-shaped nozzles. The high-pressure water pump is connected with a water source and a power supply system, one end of the high-pressure water conveying pipe is connectedwith the high-pressure water pump, the other end of the high-pressure water conveying pipe is connected with the spraying pipe and the directional long-shot nozzles, the spraying pipe is horizontallyarranged on the support assembly, and the fan-shaped nozzles are evenly distributed on the spraying pipe and communicated with the spraying pipe. The directional long-shot nozzles are movably connected to the support assembly. A working mode of small flow and high water pressure of the spray head and the high-pressure water pump is adopted, and the cleaning water is utilized to the maximum extentin a mode of greatly improving the spray pressure; and meanwhile, by adopting a mode of combining the directional long-shot spray head and the plurality of fan-shaped nozzles, the optimal cleaning effect is achieved, and the application prospect is good.

Owner:华能宁夏能源有限公司 +1

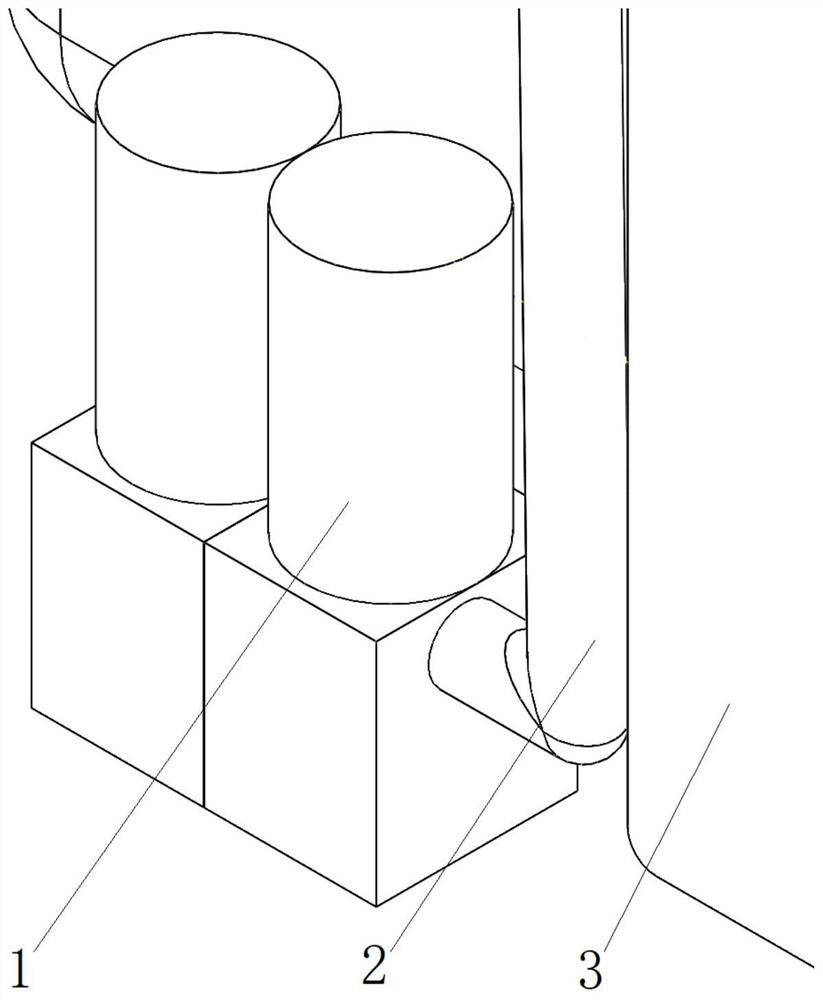

Method for power generation of manpower-driven gravity electric generator

InactiveCN103670965AIncrease power supplyExtend power supply timeFrom muscle energyMachines/enginesPower gridSprocket

The invention relates to a method for power generation of a manpower-driven gravity electric generator. The method for power generation of the manpower-driven gravity electric generator can be used by any person with normal movement ability in various environments. The electric generator, a transmission chain wheel connected with the electric generator, a chain, a container A, a container B, a guide pipe connected between the container A and the container B, a guide pipe valve and the like are adopted in the method, wherein the container A and the container B are fixed to the two ends of the chain. Work is done through movement of the human body, so that liquid in the container at the lower end is pressed to the container at the higher end and power is generated. Compared with other manpower power generating modes, the method for power generation of the manpower-driven gravity electric generator has the advantages that the traditional power generating mode that work needs to be done by manpower for a long time is changed to the mode that work is done for a short time and power is generated stably for a long time, the method is simple, reliable, low in price and capable of being used by any person with normal movement ability, a device can be large or small, and the lowest requirement for a power source in a region without a fixed power grid can be well met.

Owner:王仲明

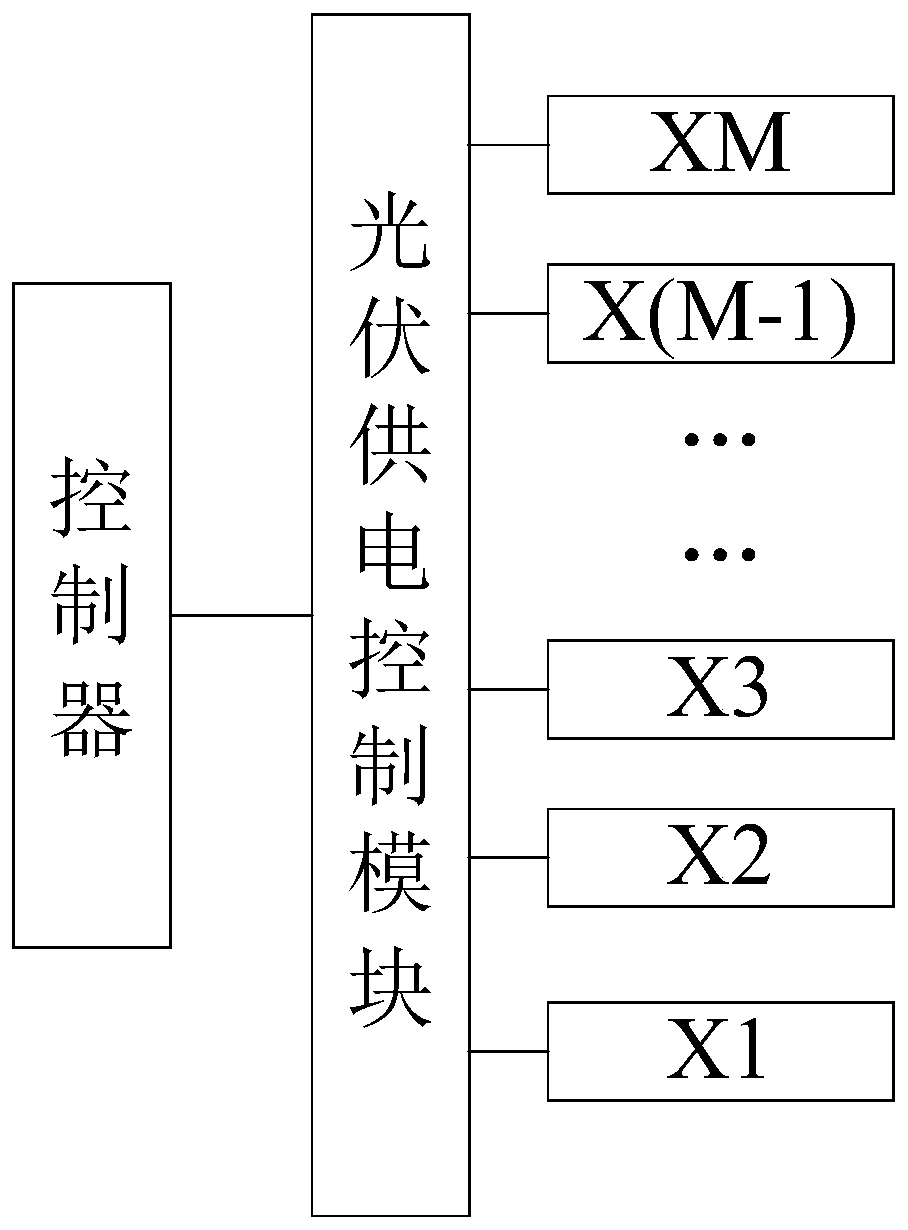

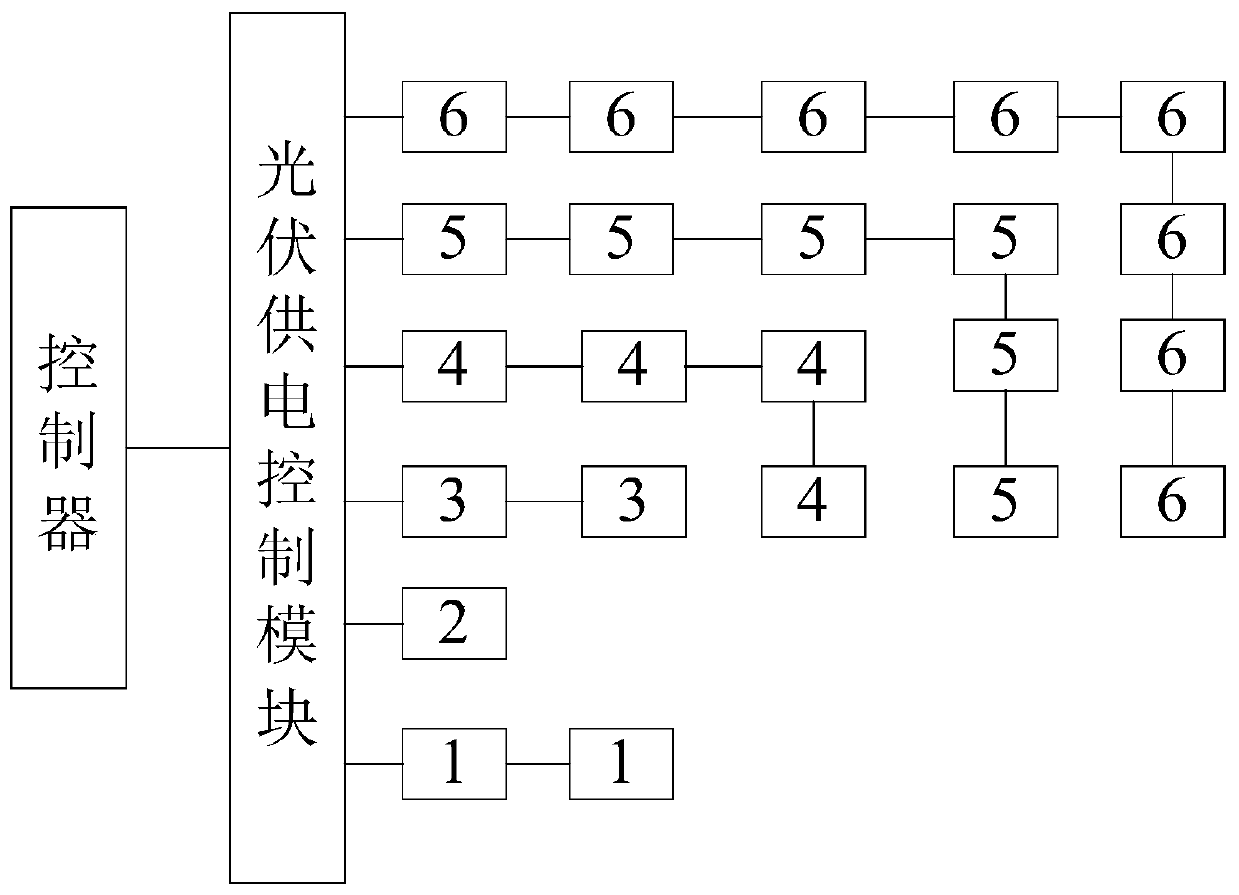

Control module and system capable of realizing Domino type automatic snow melting of photovoltaic modules

ActiveCN110212633AGuaranteed continuityGuaranteed reliabilityBatteries circuit arrangementsPhotovoltaicsSnow meltingEngineering

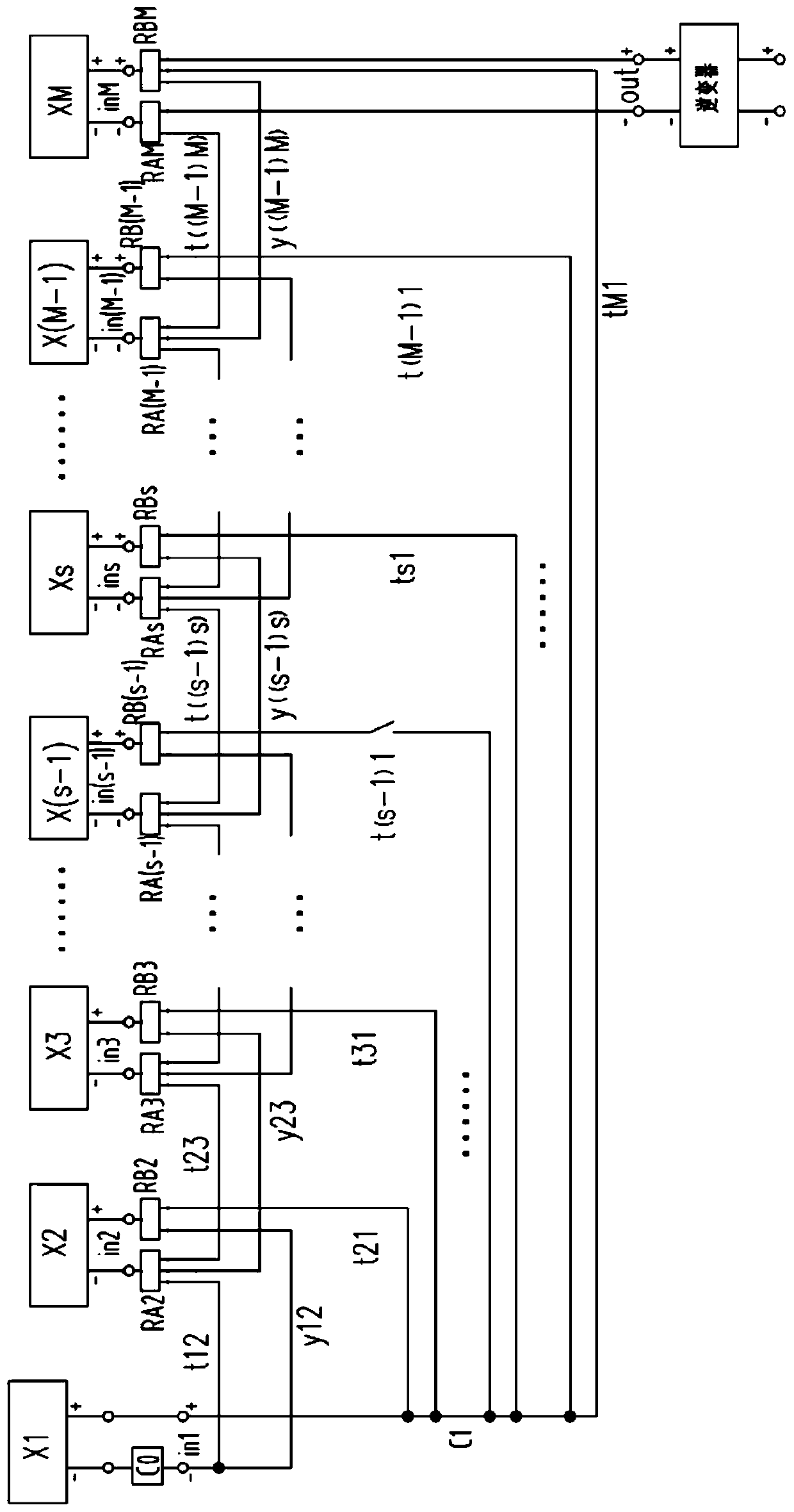

The invention provides a system capable of realizing Domino type automatic snow melting of photovoltaic modules. The system comprises a controller, the M photovoltaic modules and a photovoltaic powersupply control module; the photovoltaic power supply control module at least has a first working state and a second working state; and in the second working state, when the photovoltaic module connected with a kth photovoltaic interface is in a load mode and the photovoltaic modules connected with first to (k-1)th photovoltaic interfaces supply power to the photovoltaic module connected with the kth photovoltaic interface, k is greater than or equal to 2 and less than or equal to M. The M photovoltaic modules are correspondingly connected with the M photovoltaic interfaces of the photovoltaicpower supply control module; and the controller is connected with the photovoltaic power supply control module and is used for controlling a working state of the photovoltaic power supply control module. The power supply amount is gradually increased, so that the Domino effect is realized, the snow melting efficiency is improved, and the snow melting time is shortened. The system is especially beneficial to the improvement of working time and power generation benefit of photovoltaic power generation of a roof photovoltaic power generation system in a freezing season.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

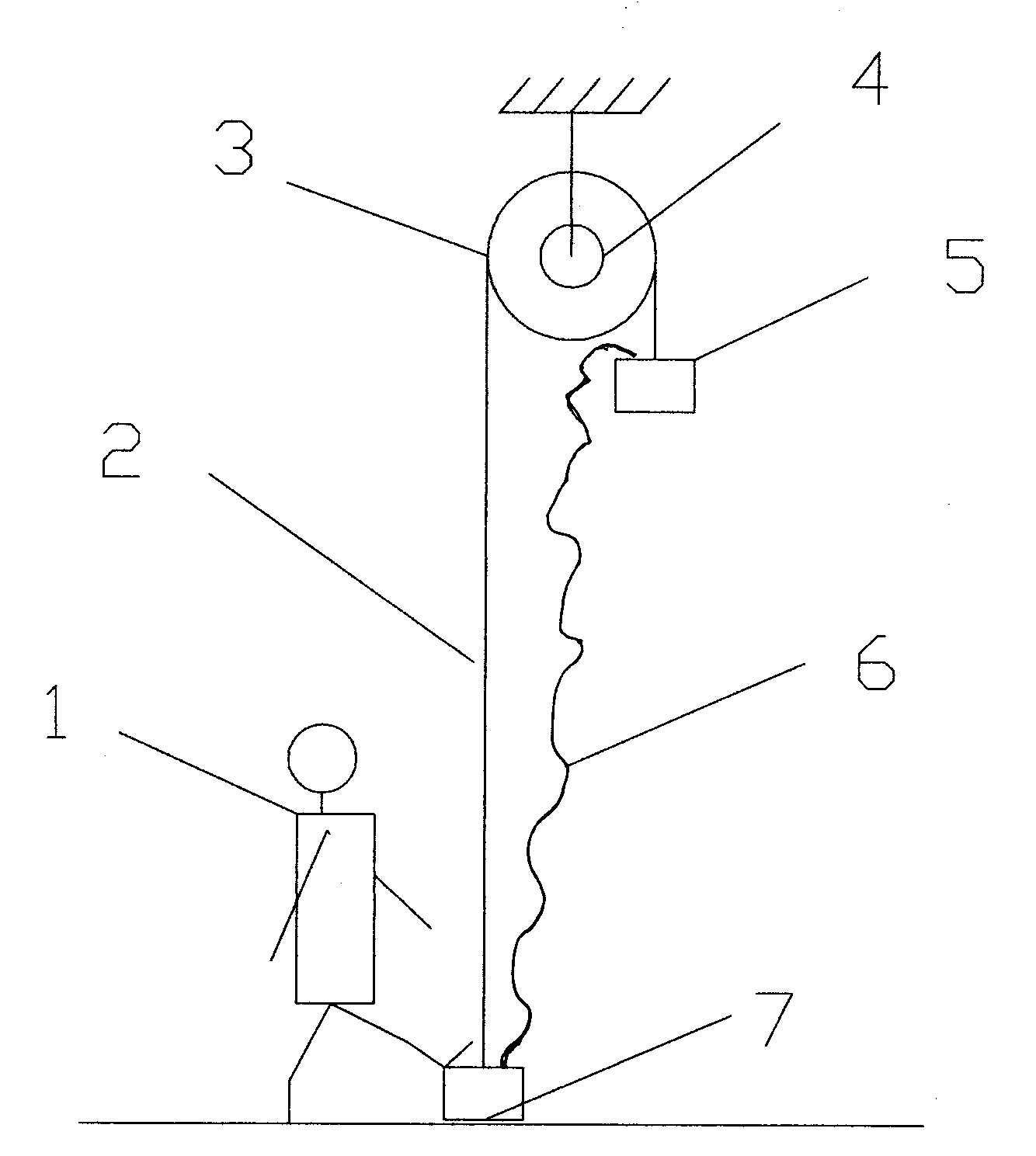

Portable apparatus for generating electricity

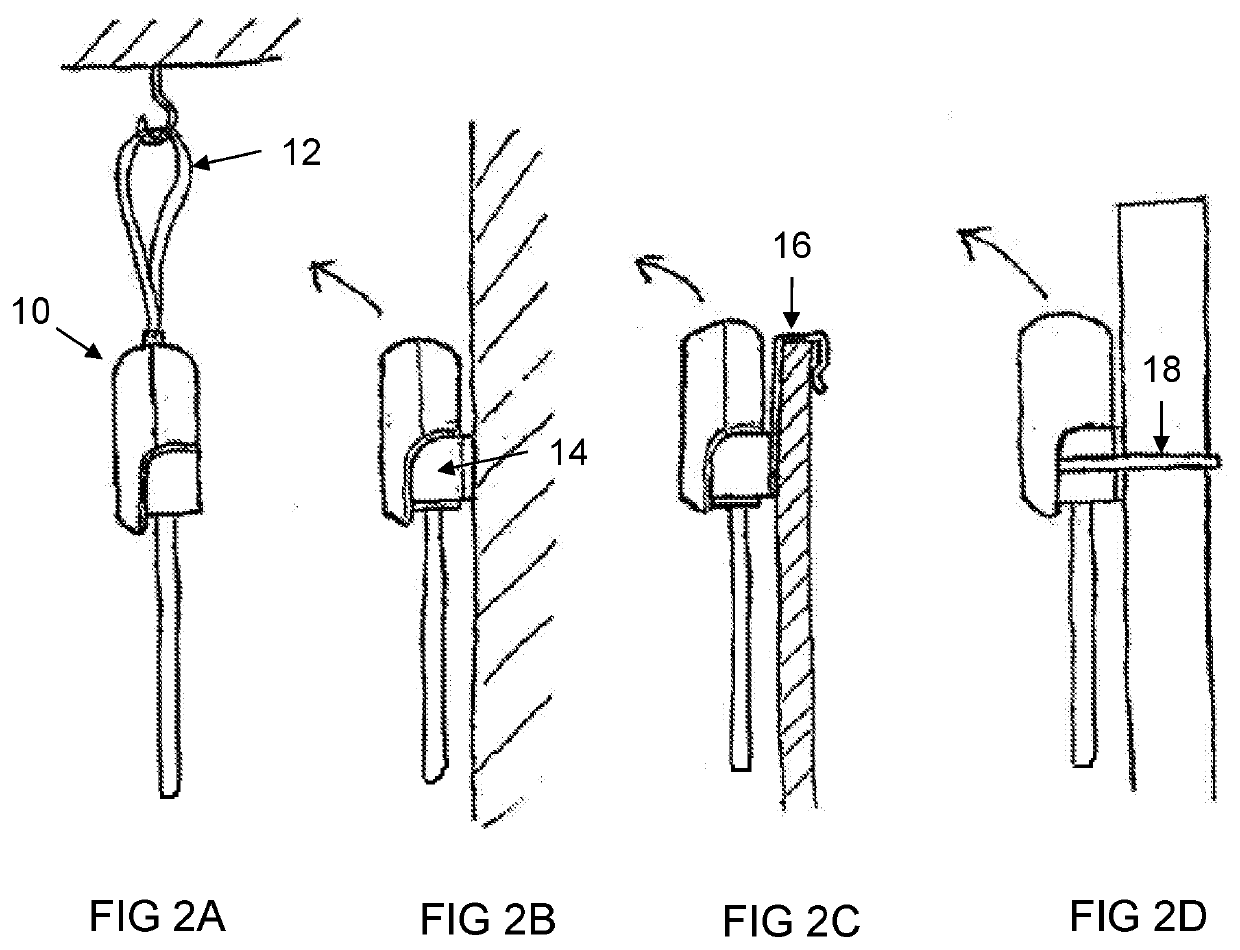

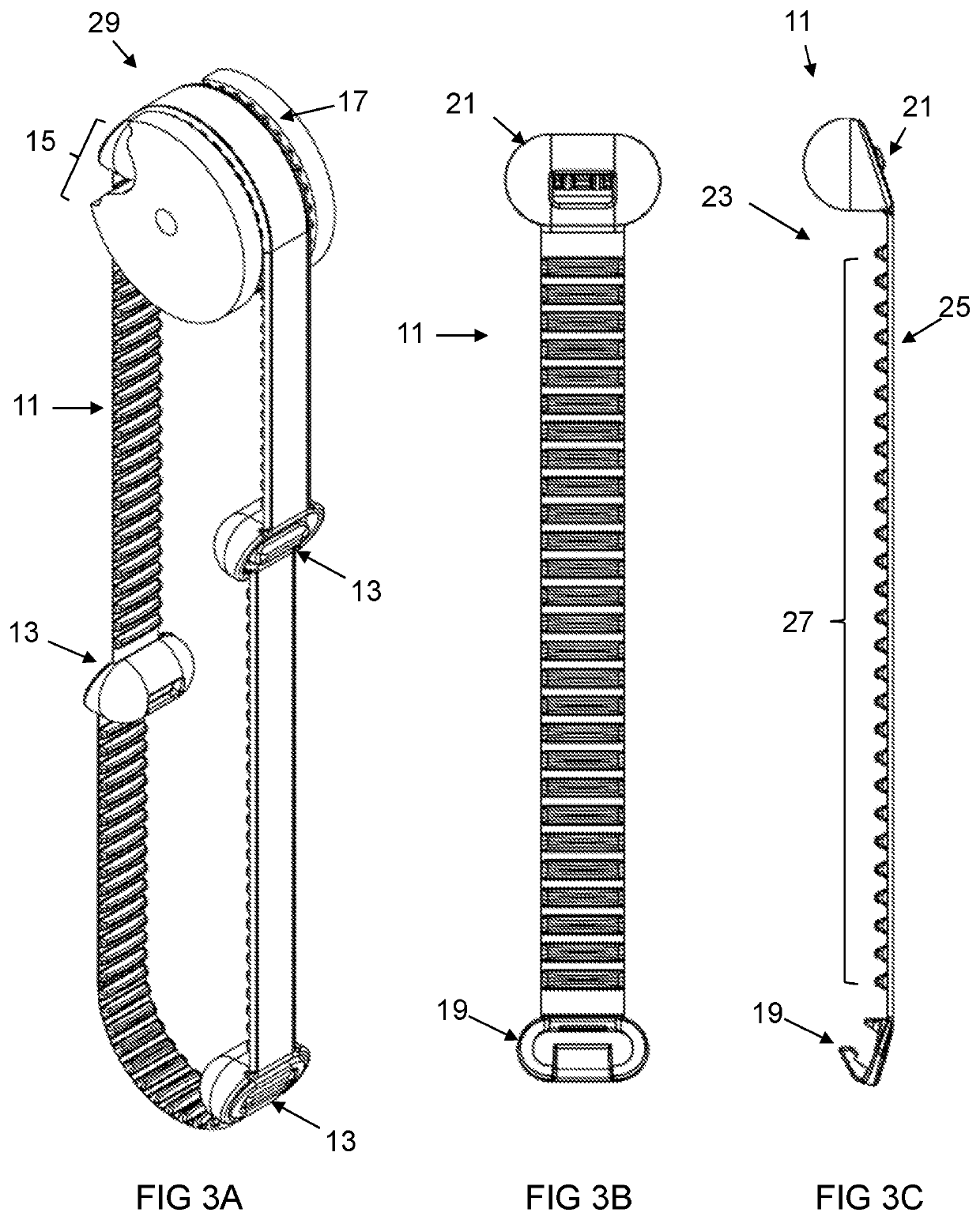

ActiveUS20200395819A1Increase power supplyHigh electric powerCircuit monitoring/indicationDifferent batteries chargingElectric energyMechanical engineering

A portable apparatus for generating electricity is provided comprising an electrical energy-generating device for generating electrical energy in response to input mechanical action. The apparatus comprises a drive mechanism having an elongate flexible member provided as a closed endless loop. A portion of the elongate flexible member is exposed so as to enable a user to grasp and pull said portion downward by a distance of at least 30 cm. The drive mechanism supplies the said mechanical action to the electricity-generating device, wherein said mechanical action is provided by user applying a downward force to the elongate flexible member so as to cause the elongate flexible member to move with respect to the mounting element. A re-chargeable battery is further provided for storing the electrical energy generated by the electrical energy-generating device. A mounting element enables the apparatus to be supported at a suspended position relative to the ground during use.

Owner:DECIWATT

Silicon carbide smelting process

ActiveCN108658078AGuaranteed feasibilityEvenly distributedSilicon carbideElectric power transmissionMaterials science

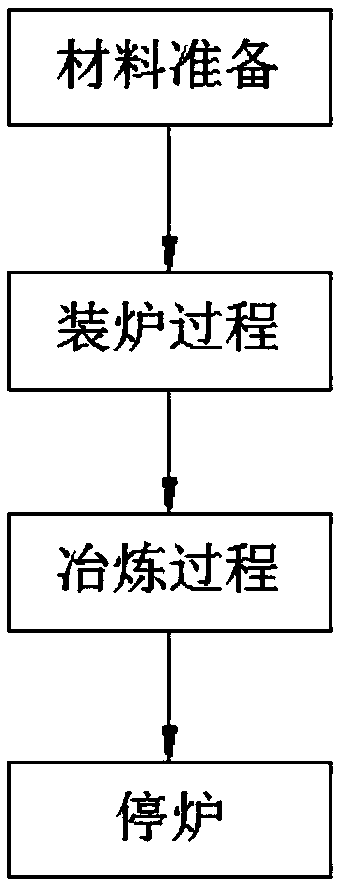

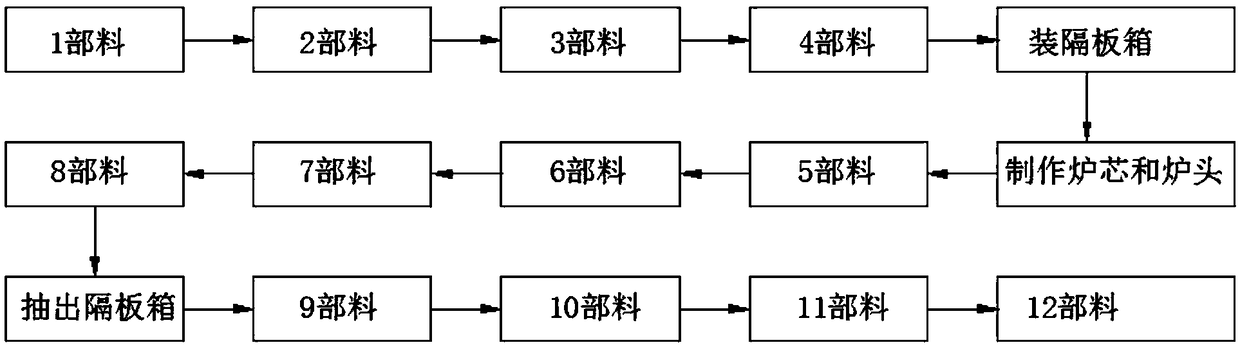

The invention provides a silicon carbide smelting process and relates to the technical field of silicon carbide smelting. The process comprises steps of material preparation, charging process and smelting process, wherein for material preparation, sectional-material raw materials in various ratios constitute smelting raw materials; the charging process comprises sequential implantation of first-twelfth sections of materials, and steps of placing and drawing a partition box, making a furnace core and making burners are included in the charging process; in the smelting process, power transmission is performed in three stages, power transmission is performed under power of 20,000-25,000 kW in a first stage, and operation continues for 48 h; in a second stage, power transmission power is gradually and stably increased to 32,000-36,000 kW within 12 h; in a third stage, 32,000-36,000 kW is kept unchanged, and operation continues for 7-9 d. Power supply is stopped after the designed total power transmission power, and natural cooling is performed. According to the silicon carbide smelting process, by controlling the ratios of the sectional-material raw materials, the charging process andthe smelting process, power consumption of each ton of products is low, production cost is low, bumps of a crystallization cylinder after smelting are avoided, the silicon carbide products are high indensity and quality, and output of first-grade products is high.

Owner:宁夏和兴碳基材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com