Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Improve the quality of environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermosetting plastic extruding and pelletizing process

InactiveCN1417015ASolve the dead angle problemGuaranteed continuityCyclonic separationExtrusion Granulation

The thermosetting plastic extruding and pelletizing process includes the steps of heating, feeding, extruding, pelletizing, negative pressure sucking, cyclonic separation of aggregate, wind cooling and sieving. The said process has optimized technological parameters and thus continuous production process.

Owner:上海欧亚合成材料股份有限公司

Coating wastewater treatment process

InactiveCN104876392AIncrease profitImprove the quality of environmental protectionMultistage water/sewage treatmentSludgeActivated carbon filtration

The invention discloses a coating wastewater treatment process which comprises the following steps: filtering through a crude fence and a fine fence, carrying out demulsification treatment on grease wastewater, dewatering sludge for recovery, carrying out surface phosphating on the workpiece, carrying out centralized treatment on electrophoresis wastewater, carrying out centralized treatment on the high-polymer resins, pigments, powder, surfactant and assistants in the coating wastewater, floating, carrying out aeration purification, mixing with low-concentration wastewater, carrying out batch treatment on the wastewater, inoculating into a biological oxidation pool, carrying out secondary treatment on the wastewater, trapping high-molecular organic substances by a membrane separation technique, adding sodium hypochlorite into ammonia nitrogen, recovering salts, filtering through drift sand, filtering the wastewater through activated carbon, and discharging the purified water. The coating wastewater treatment process is simple in technique and enhances the wastewater recovery and utilization ratio.

Owner:SUZHOU RUIYUTE AUTOMATION TECH

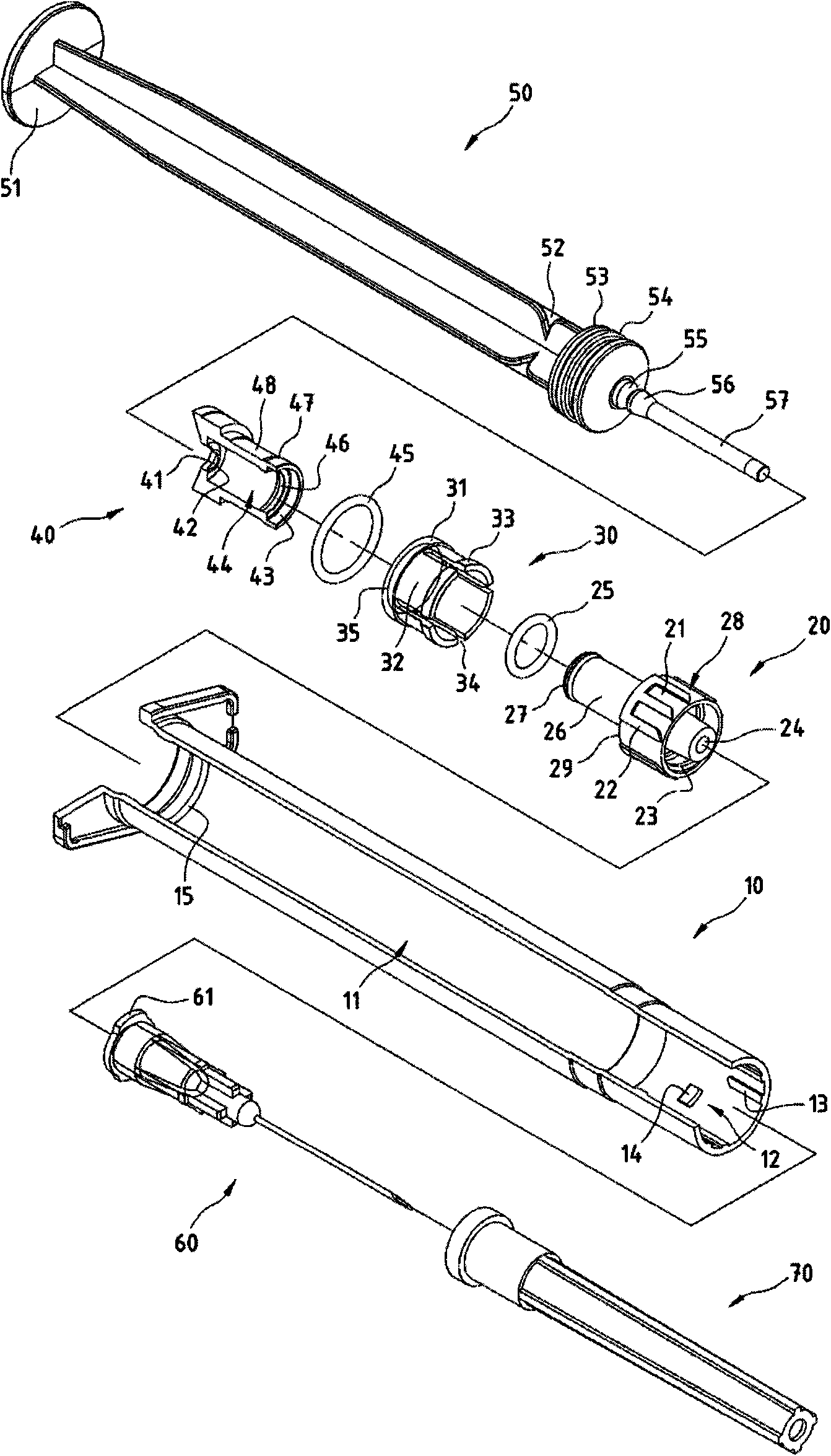

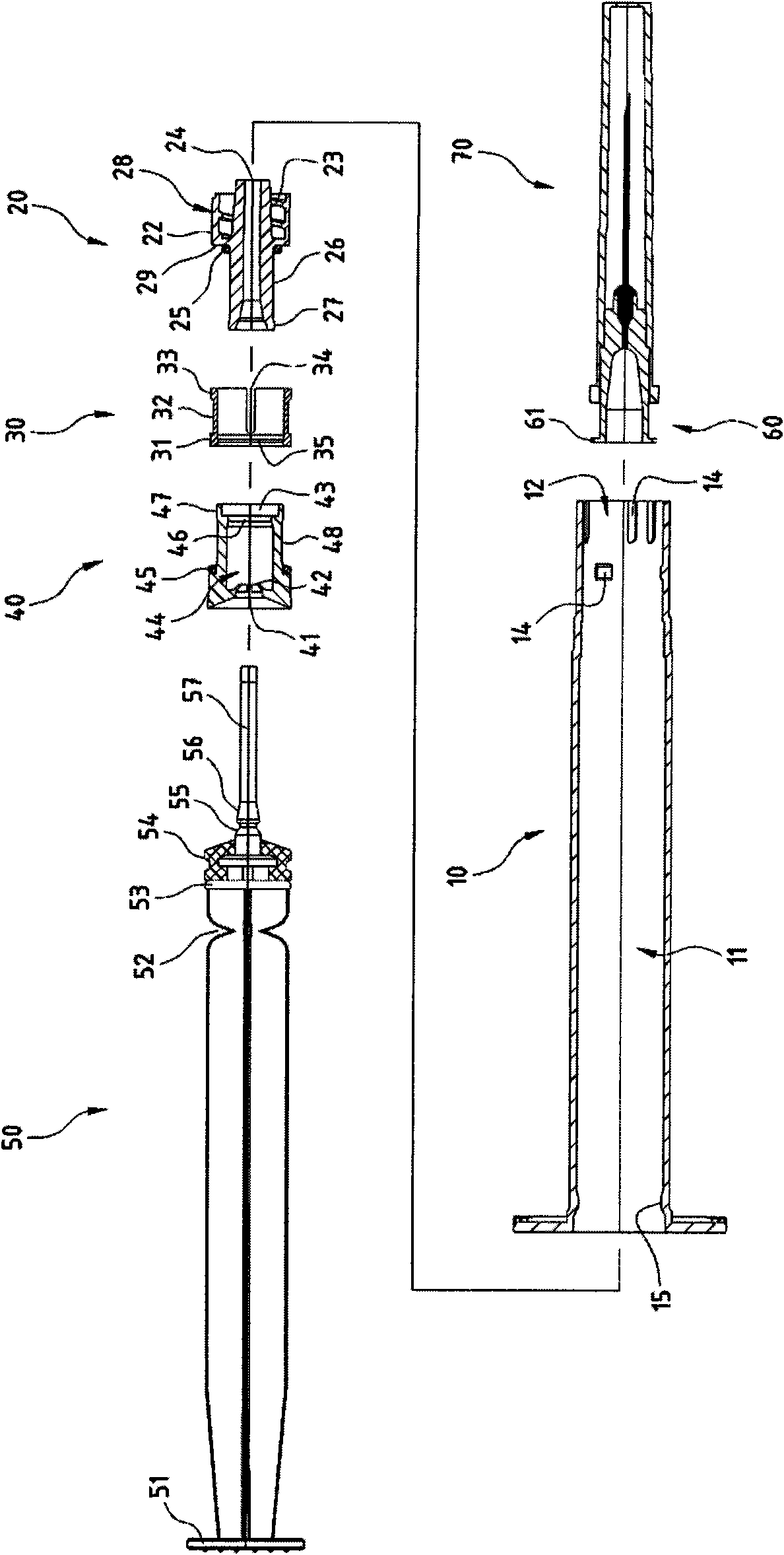

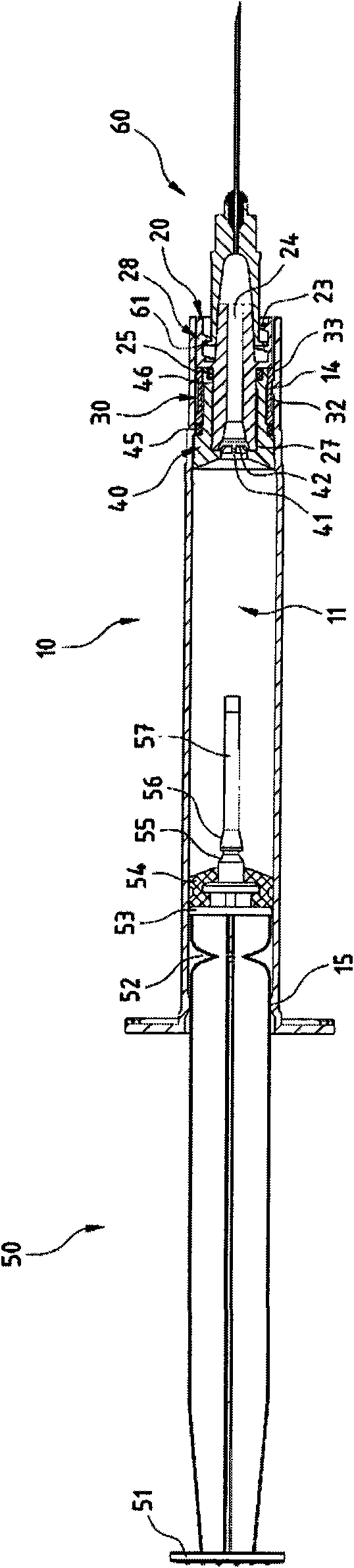

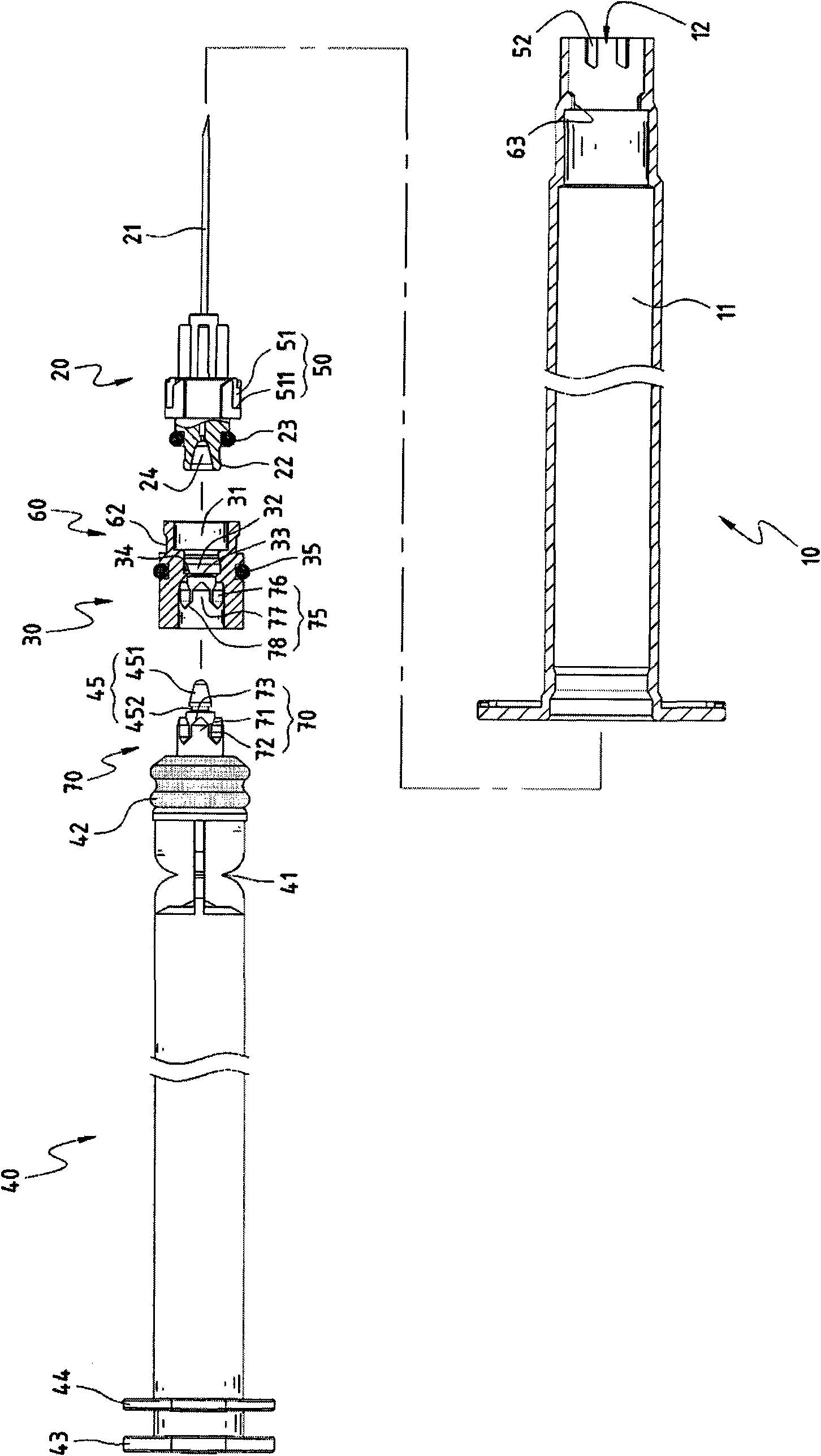

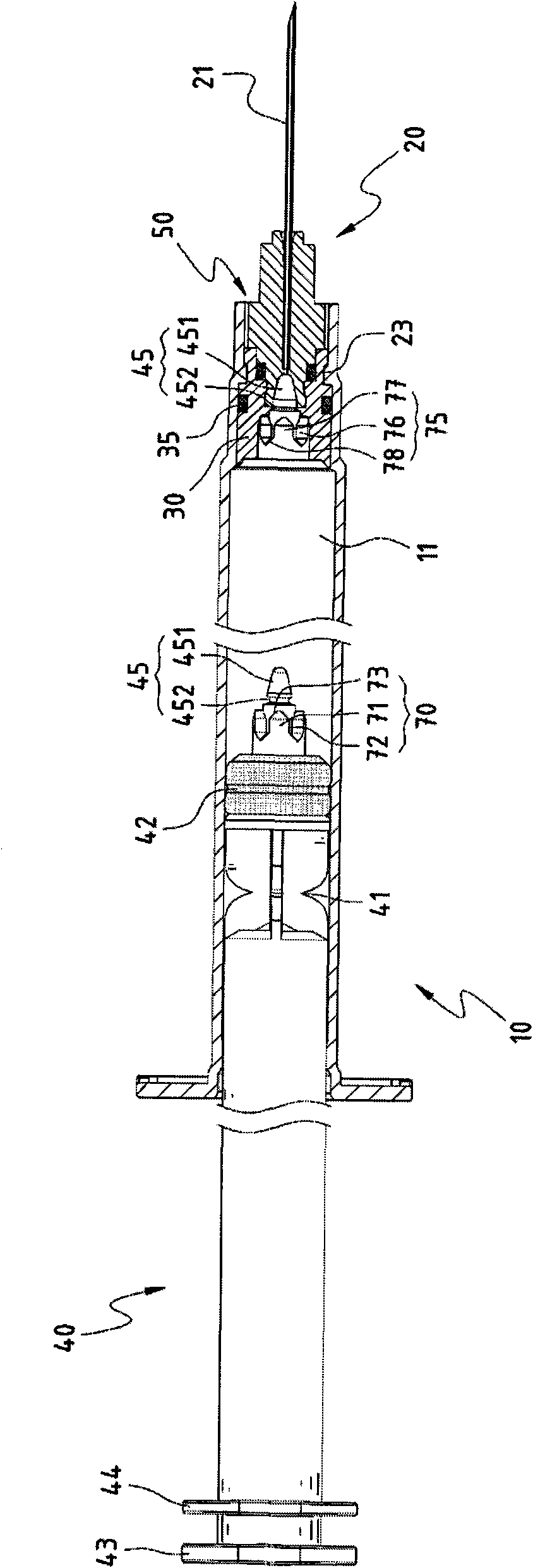

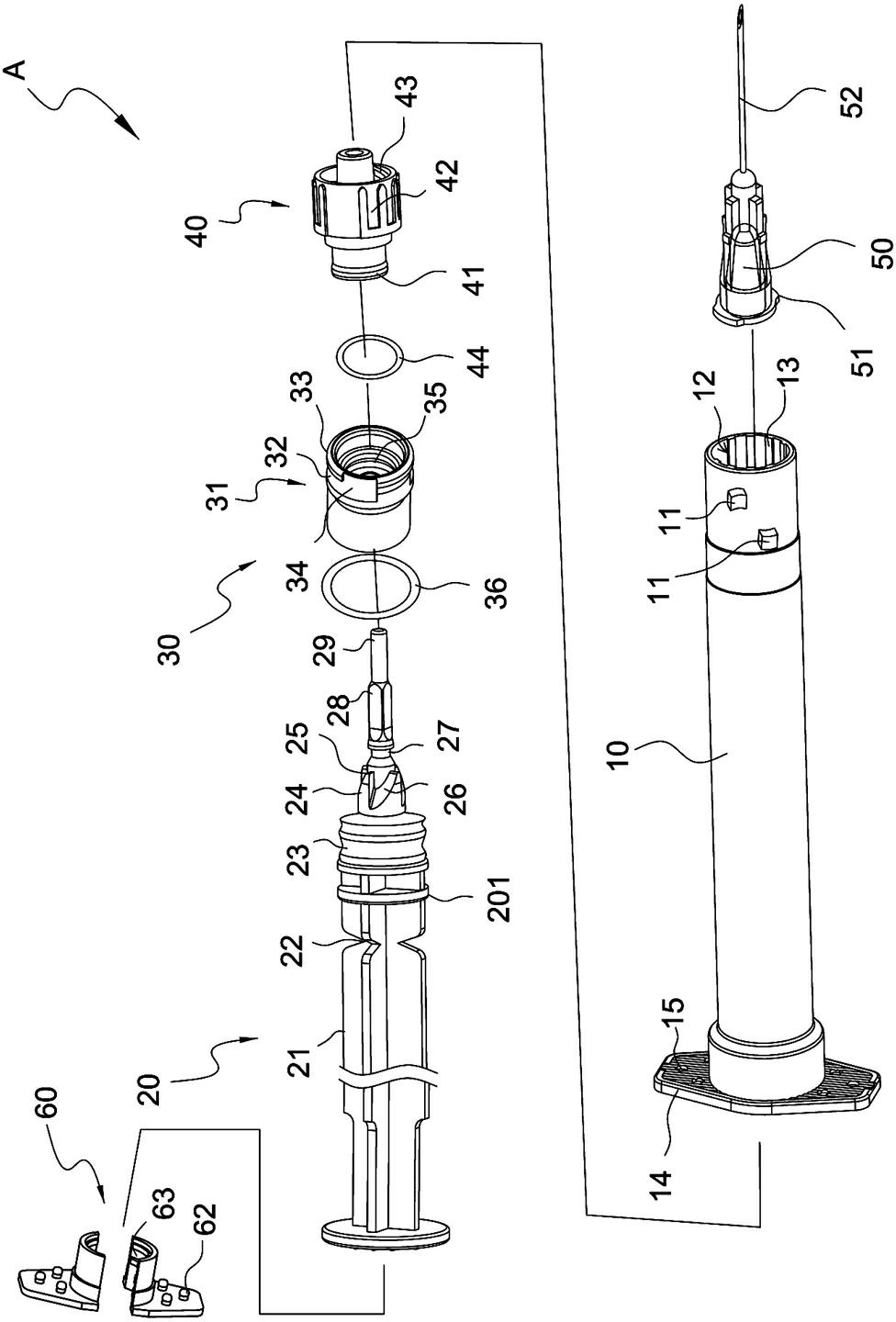

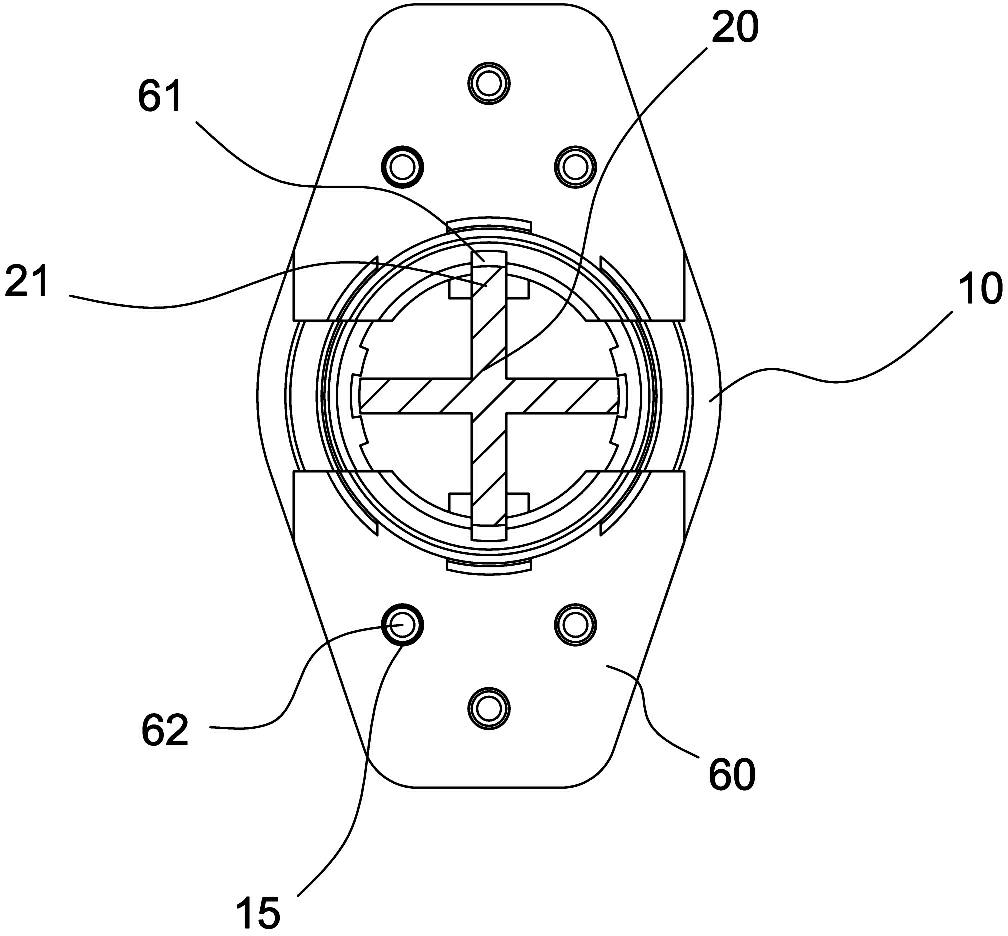

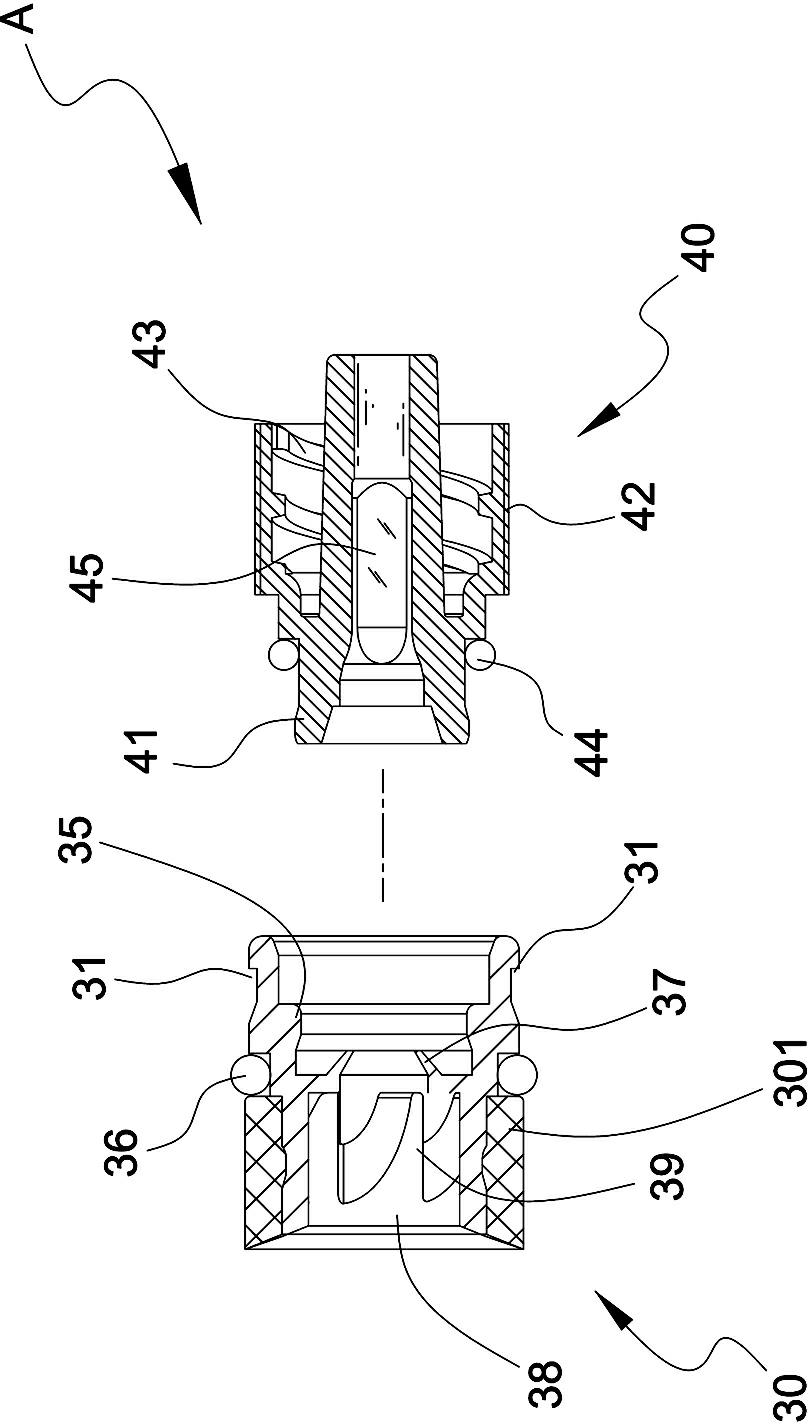

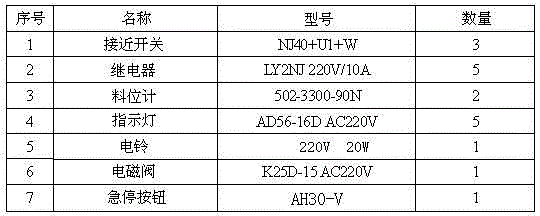

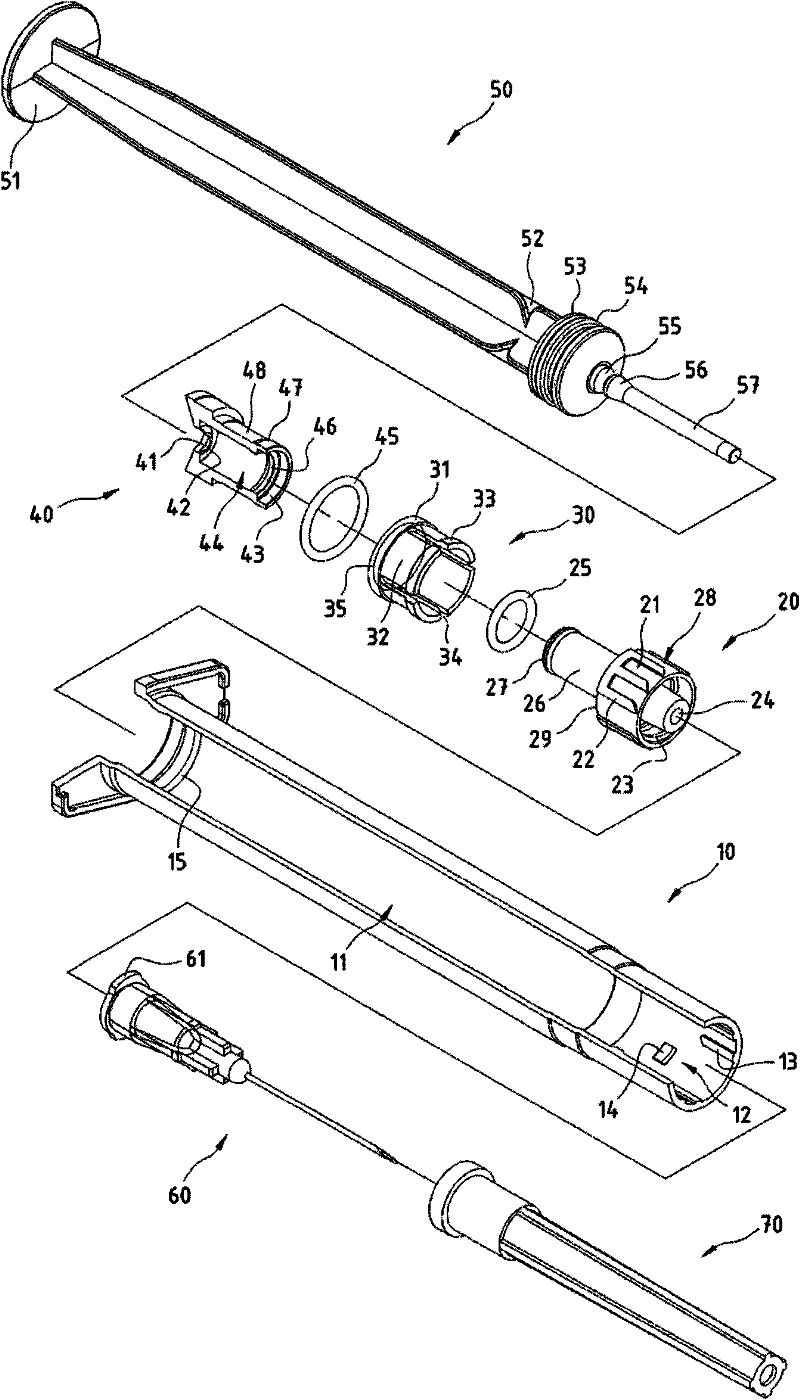

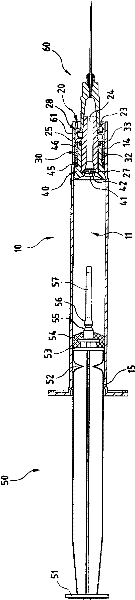

Retraction structure for safety syringe

InactiveCN101927048AImprove practical progressEasy retraction actionInfusion syringesInfusion needlesSyringe needleBiomedical engineering

The invention provides a retraction device for a safety syringe, in particular a creative design that a syringe needle bed is stably positioned at an opening end of a barrel. A borrow locking device and a retraction embedded linkage device are arranged between needle beds mutually. Due to the creative and unique design, a pull rod head of a pull rod can be rapidly clamped to be positioned on a needle bed group by means of the borrow locking device and the retraction embedded linkage device so as to provide convenience for a user to perform the next retraction action. Meanwhile, the needle bed group can be stably assembled and positioned at the opening end of the barrel and hardly makes clamping and sealing functionally damaged due to external temperature change. For example, the clamping degree between the needle bed and the barrel is reduced due to steep temperature rise so as to cause the inner retraction or leakage of the needle bed in the injection process, or the needle bed and the barrel are excessively clamped due to steep temperature reduction, and the injection needle cannot retract after injection and the needle bed enters the barrel, and the like. Therefore, the retraction device for the safety syringe can improve the safety and environmental protection quality.

Owner:张淑茗

Retraction structure of safety syringe

InactiveCN101898002AResidue reductionImprove the quality of environmental protectionInfusion syringesIntravenous devicesSyringe needleSafety syringe

The invention discloses a retraction structure of a safety syringe, in particular to an innovative design which is used for safely retracting a syringe needle into a cylinder body. The retraction structure mainly comprises the cylinder body, an upper needle seat, a lower needle seat, a push rod, a rotation limit unit, an L-shaped locking unit and a quick guide braking unit; therefore, the retraction structure leads a rotating seat of the push rod to be rapidly aligned and meshed with a rotating groove relatively to the needle seats by the L-shaped locking unit and the quick guide braking unit, so that the user can conveniently circularly rotate the push rod and lead the needle seat to be aligned in the next step, and open retraction mode of the syringe needle can be available; furthermore, as the quick guide braking unit is closely meshed and contacted, the residual liquid medicine is greatly reduced, the safety and environmental protection quality of the retraction structure of the safety syringe can be improved, and the syringe needle is convenient for retraction use and has progressive practicability.

Owner:张淑茗

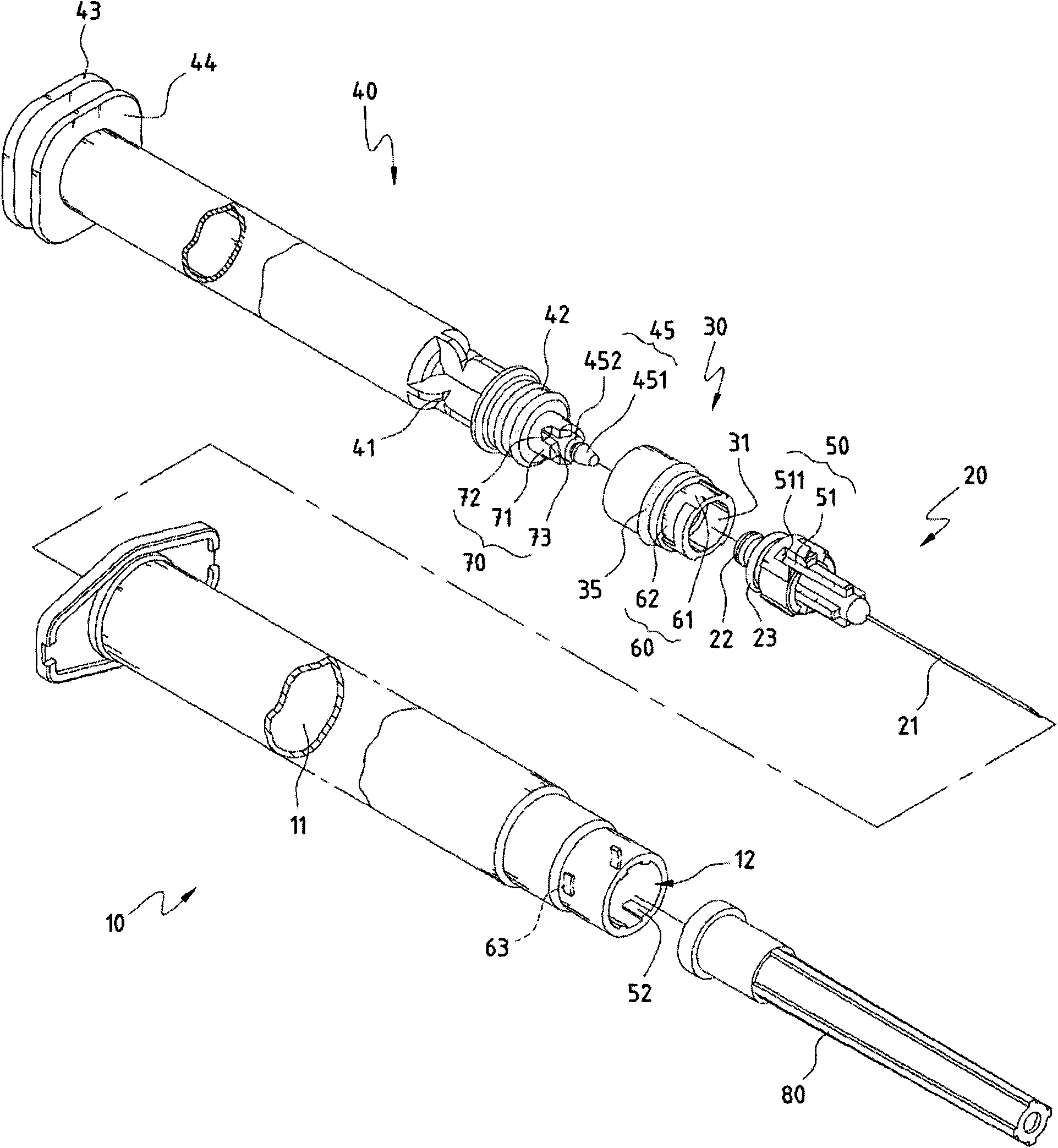

Needle base assembly rotating and retracting structure of safety injector

ActiveCN102652849AEasy to retractEasy retraction actionInfusion syringesInfusion needlesBiomedical engineeringSafety syringe

The invention provides a needle base assembly rotating and retracting structure of a safety injector. The structure has the following beneficial effects: fastening grooves of the needle base assembly and fastening stops corresponding to a drum body to rotate from the limit and lock state to the non-limit and open state by virtue of automatic deflectors of a needle base assembly, so that a push rod can be rapidly embedded in the needle base assembly and positioned and presents the mode of retracting an injection needle so that the user can carry out the next retraction action, and the needle base assembly can be stably assembled and positioned at the opening end of the drum body and hardly causes the following unexpected phenomena due to the external temperature: the fastening degree between a needle base and the drum body is reduced due to temperature surge, thus causing inward retraction or leakage of the needle base in the injection process, or the needle base and the drum body are excessively fastened due to sudden temperature drop and the injection needle and the needle base can not be retracted into the drum body after injection; therefore the structure can be safely operated by the operator with one hand, improves the environment quality and achieves convenience in retraction use of the injection needle.

Owner:张淑茗

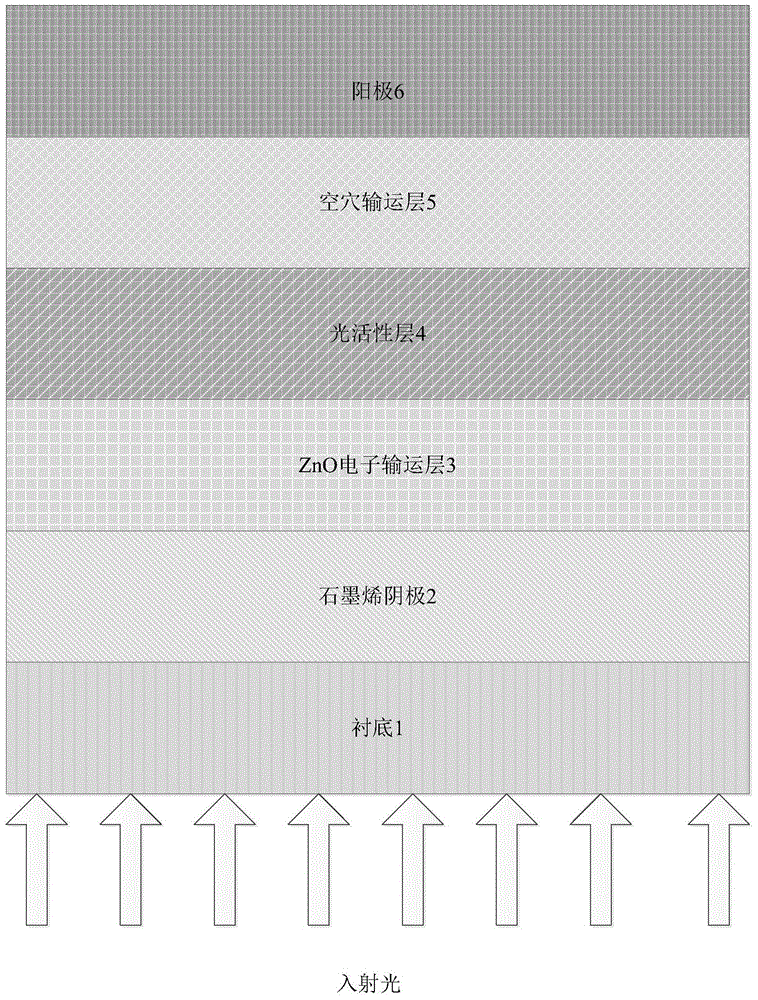

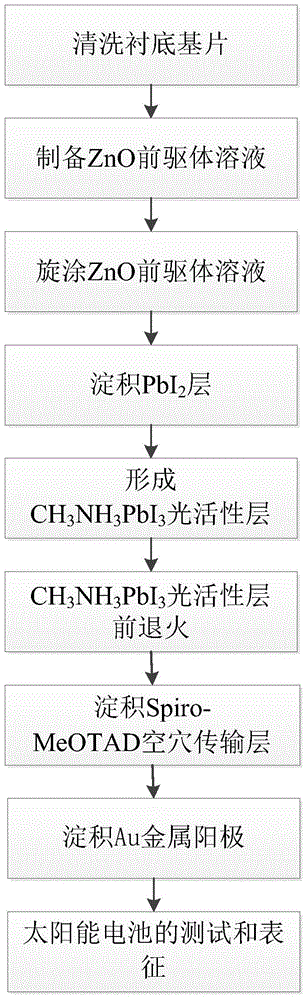

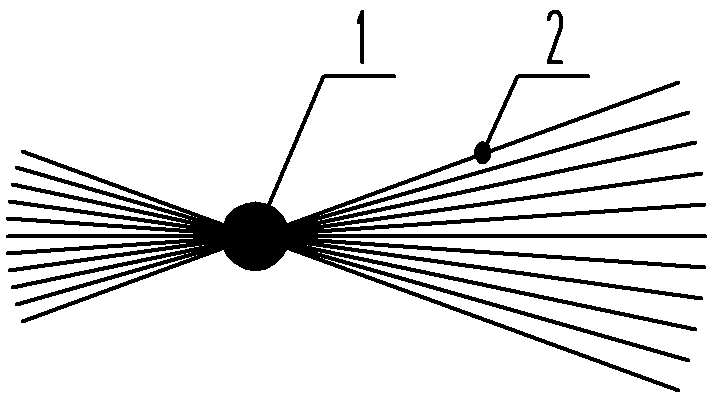

Planar perovskite solar cell based on graphene ZnO cathode and preparation method thereof

InactiveCN104617220AImprove energy conversion efficiencyHigh selectivitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellWork function

The invention discloses a planar perovskite solar cell based on graphene ZnO cathode and a preparation method thereof, which are used for solving the problems that an existing perovskite solar cell is high in transparent electrode cost, unmatched in energy level and poor in interface characteristic. The planar perovskite solar cell comprises a substrate (1), a cathode (2), an electron transfer layer (3), an optical active layer (4), a cavity transmission layer (5) and an anode (6) from bottom to top, wherein the cathode (2) is made of graphene and used for collecting electrons; the electron transfer layer is made of ZnO and used for modifying an interface, blocking a cavity and transferring electrons. The graphene is adopted as the cathode, the ZnO electron transfer layer is prepared by spinning a precursor solution, so that the work function of the graphene function is reduced, the energy level matching between the graphene and the CH3NH3PbI3 is realized, the interface characteristic is improved, and the performances of the planar perovskite solar cell are effectively improved.

Owner:XIDIAN UNIV

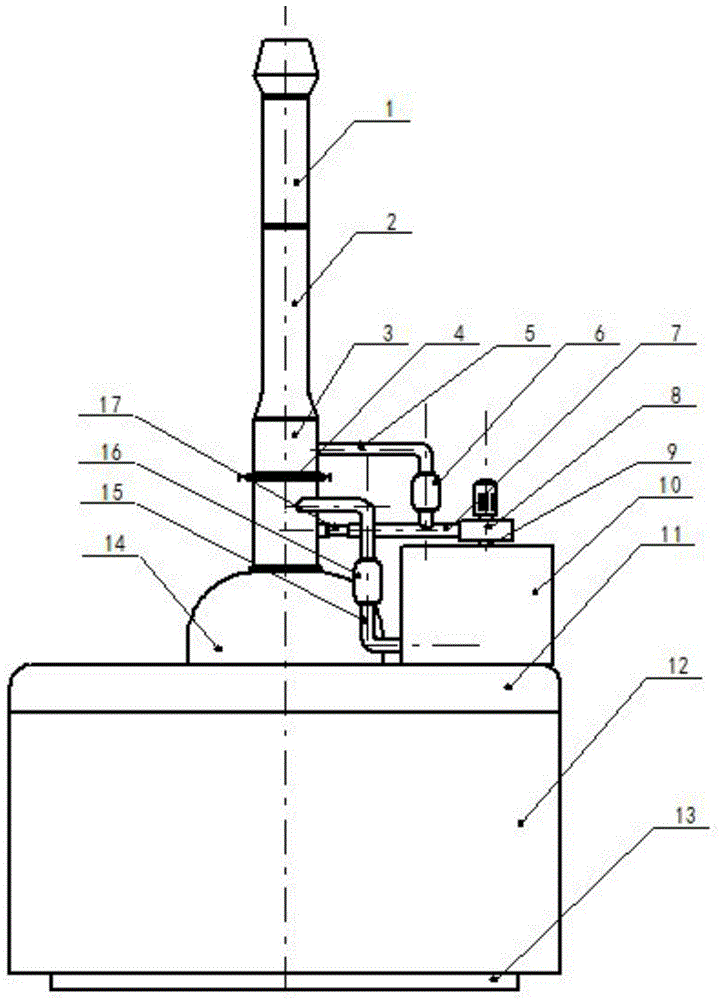

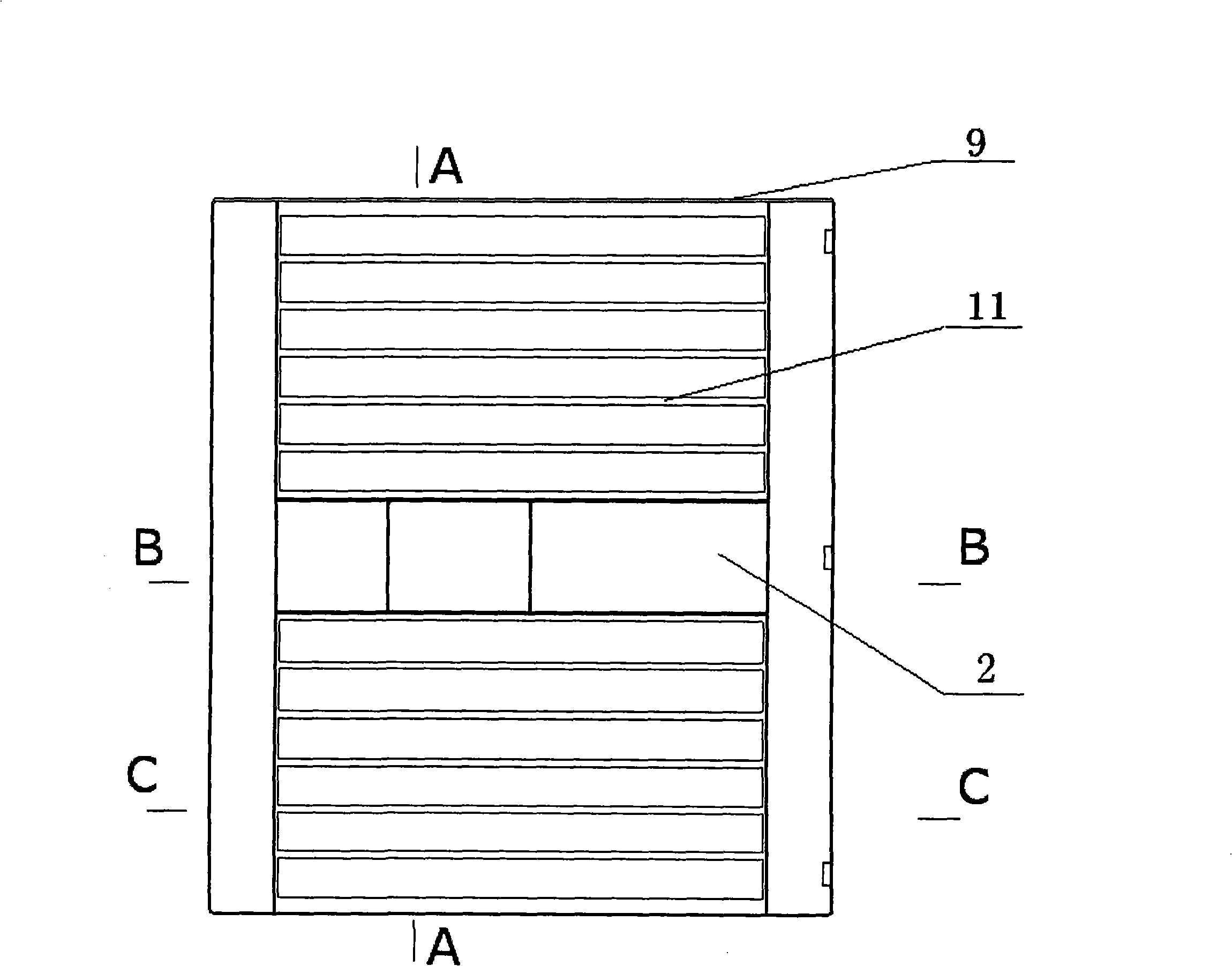

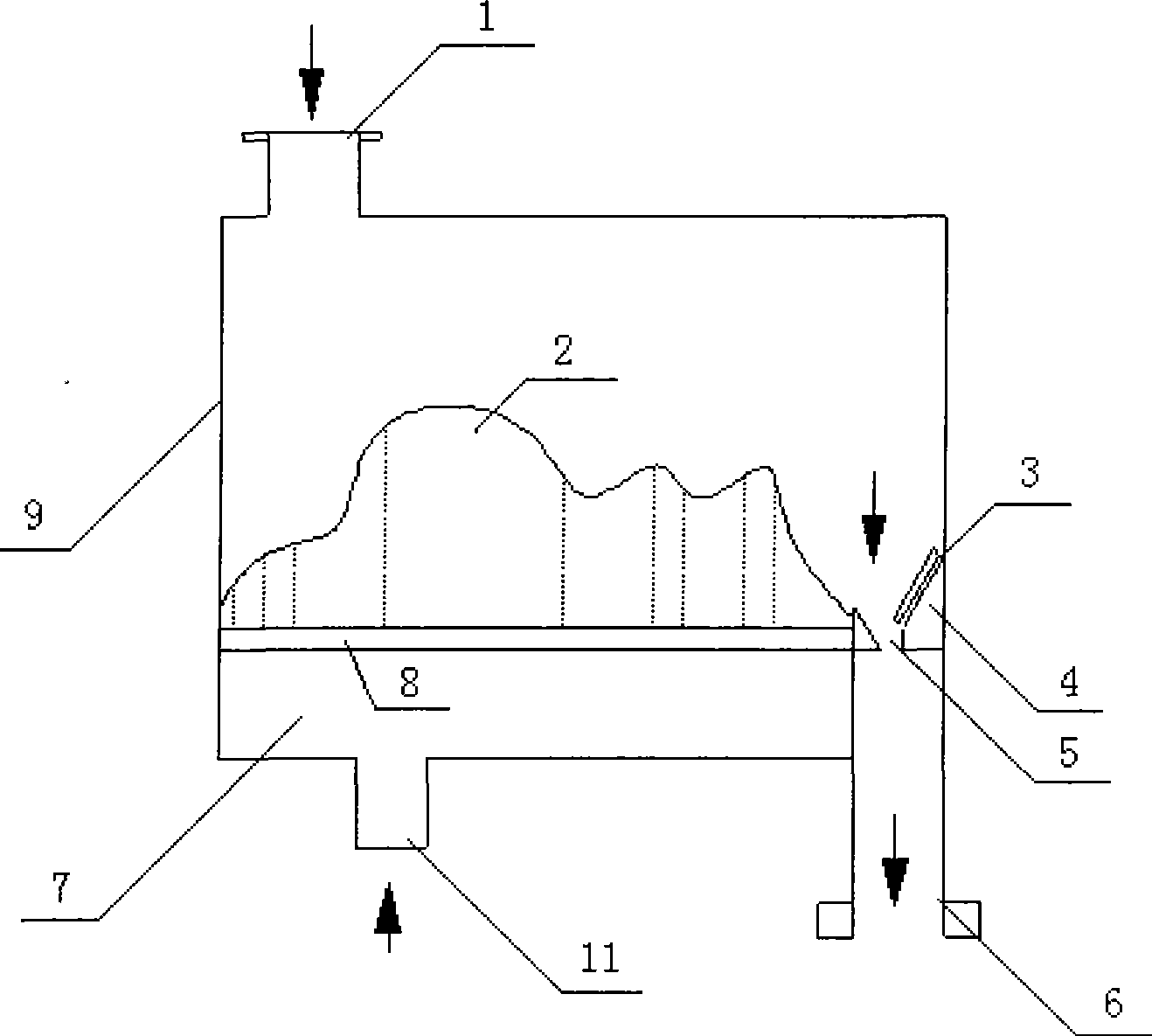

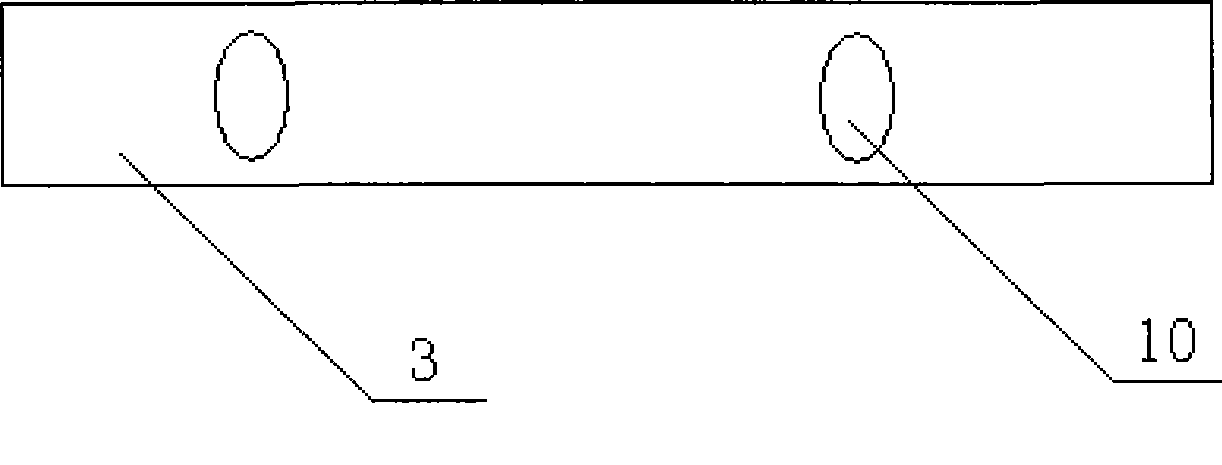

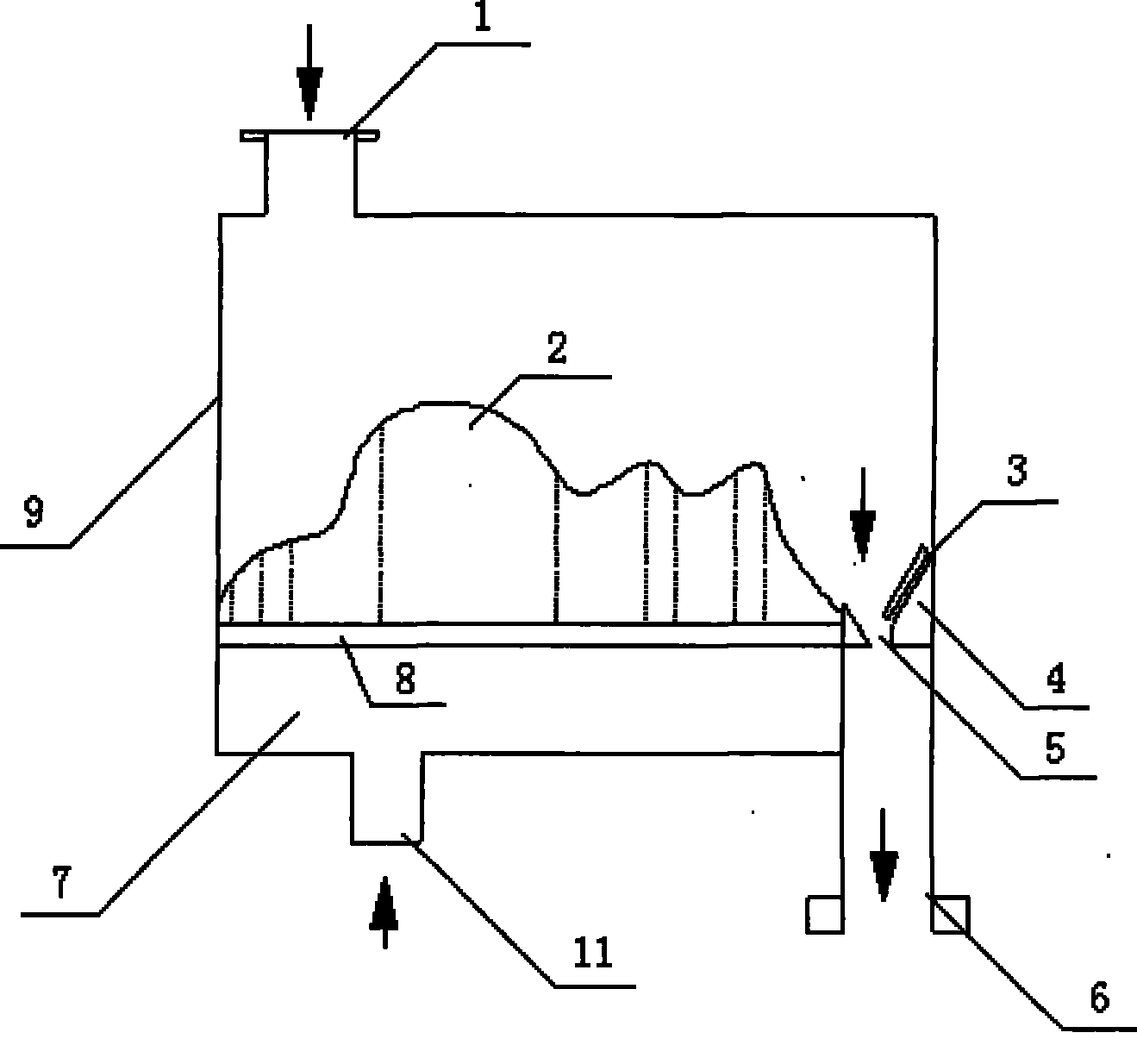

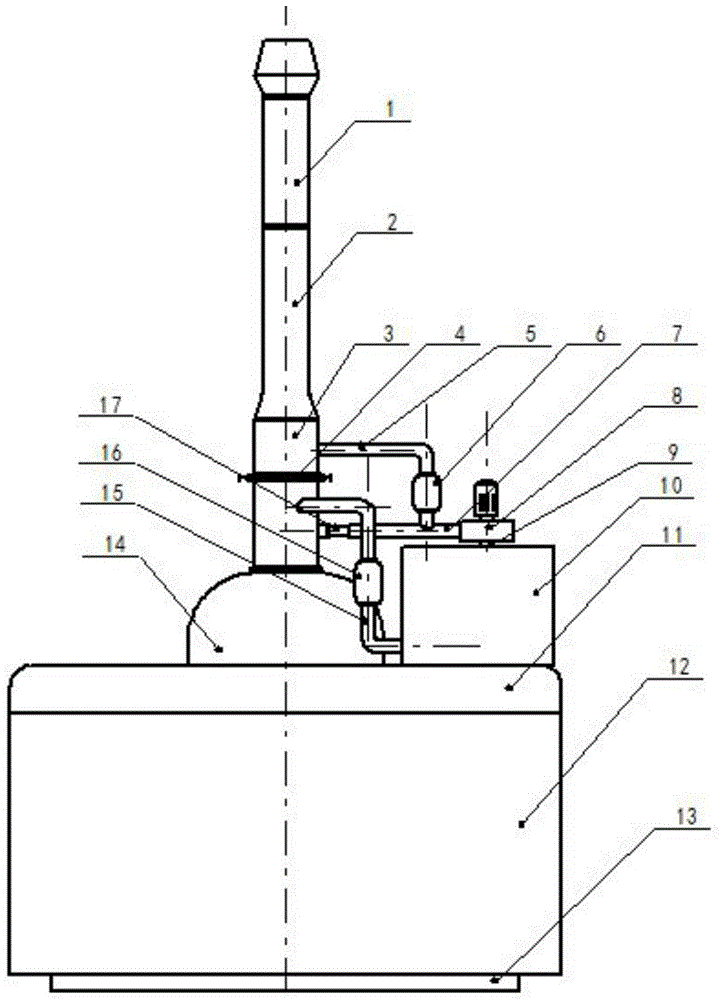

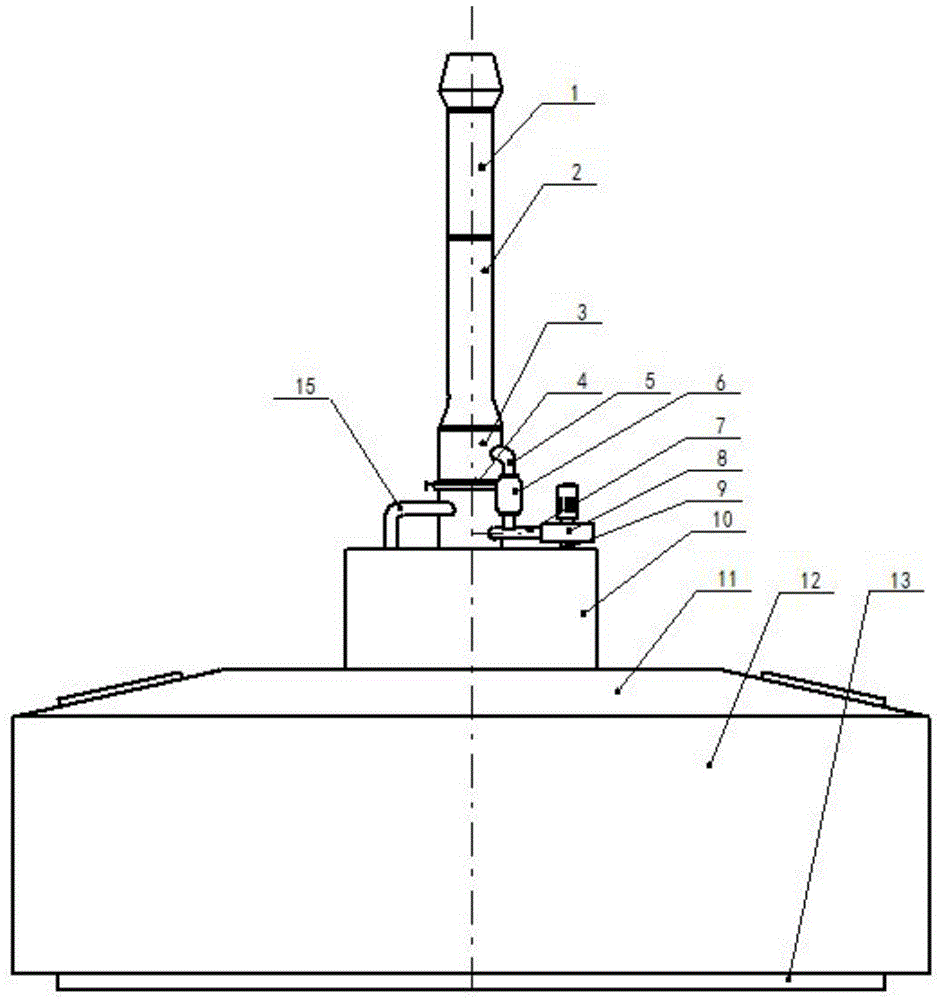

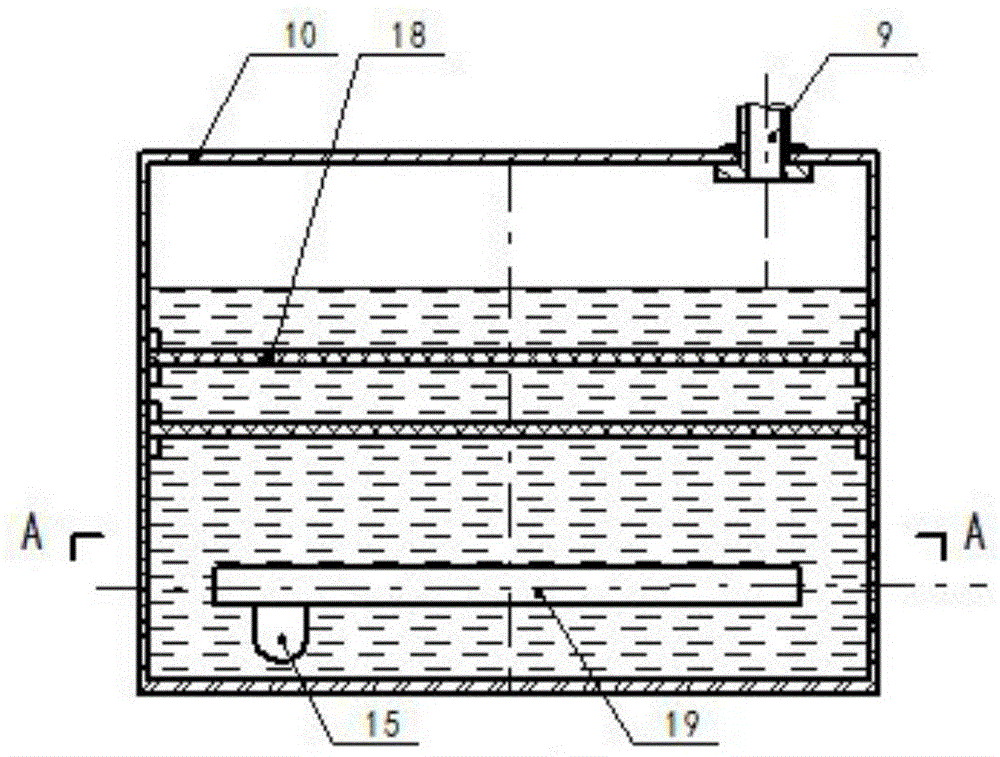

Gas purification device of household garbage flashing mineralization treatment device

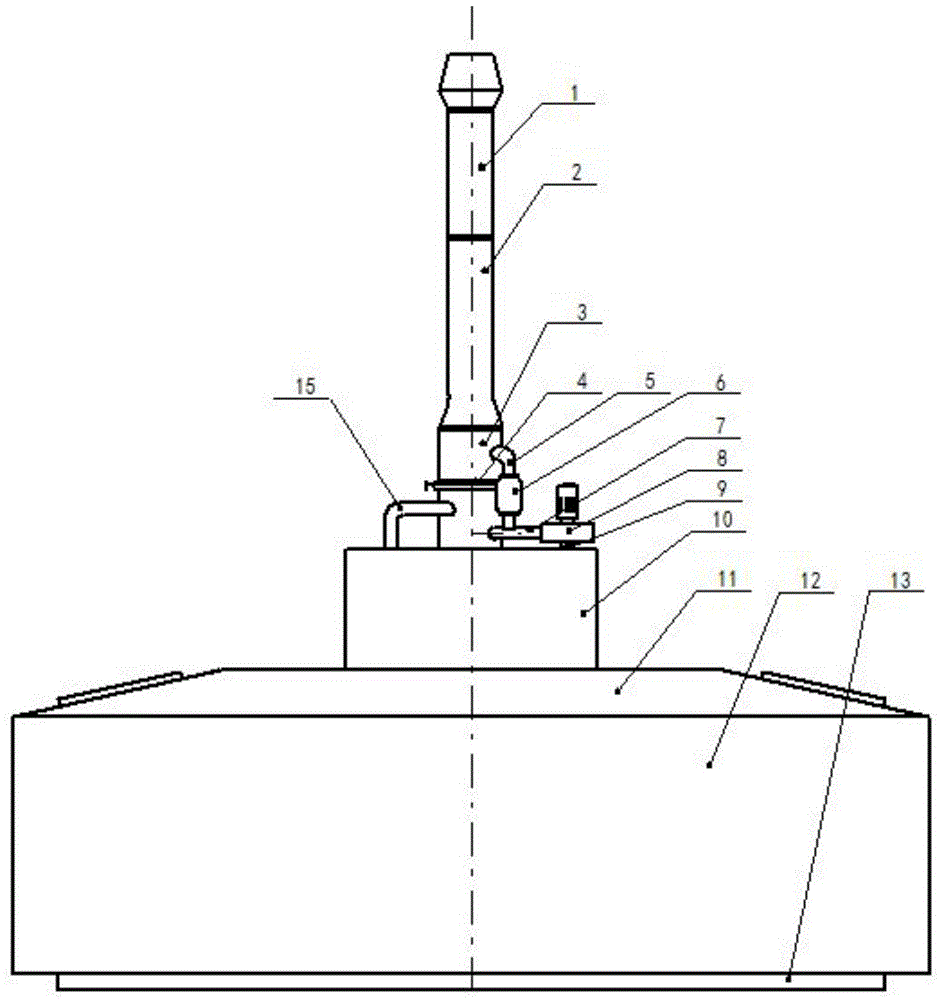

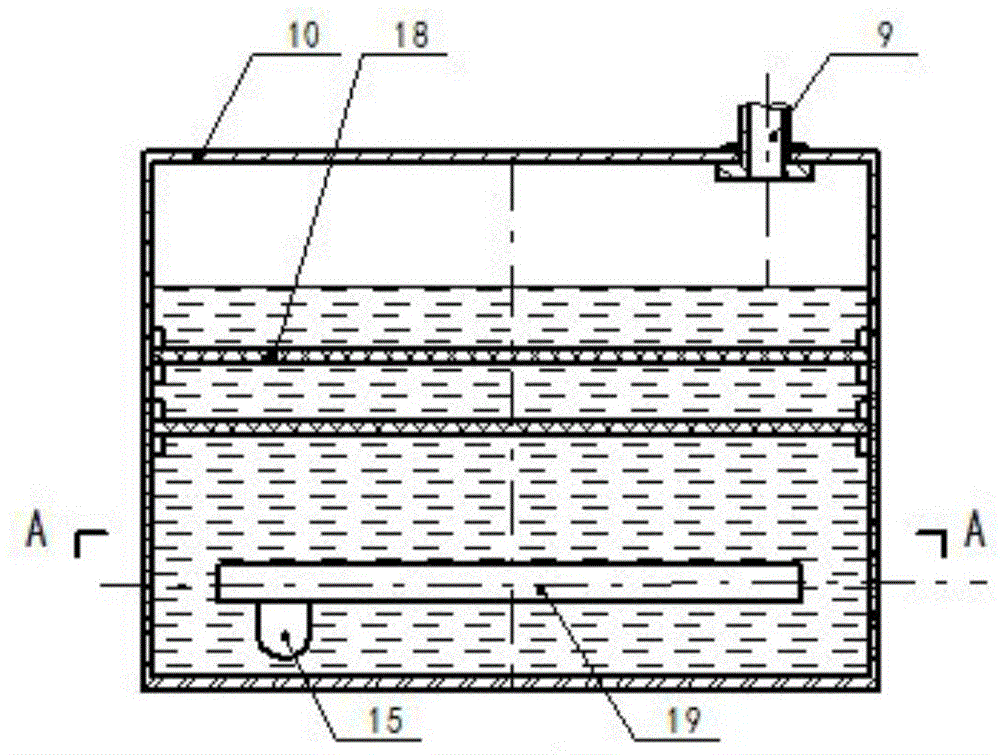

ActiveCN104815503AImprove processing efficiencyQuality improvementCombination devicesActivated carbonPtru catalyst

The invention relates to a gas purification device of a household garbage flashing mineralization treatment device. The treatment device comprises a box body and a chimney, the box body is in a sealed rectangular box body structure formed by a top plate, side stand plates and a bottom plate, the top plate is in an upward arch shape, a dome arch smoke seat is formed at the center of the top plate, and a gas mixing pipe of the chimney is fixedly arranged on the dome arch smoke seat. The treatment device is characterized in that a stop valve is installed on the gas mixing pipe, the gas purification device is fixedly mounted on the top plate of the side of the dome arch smoke seat, and a main gas inlet pipe and a main gas outlet pipe of the gas purification device are respectively communicated with the gas mixing pipe and fixedly mounted on gas mixing pipes above and below the stop valve of the gas mixing pipe. According to the gas purification device of the household garbage flashing mineralization treatment device, catalyst filtration, water filtration, cleaning agent filtration, active carbon filtration and automatic reminding of water replenishing and discharging can be performed while reinforced circulation can be performed on smoke dust by designed external power, gas purification level is extremely increased, and environmental protection qualities of discharged gas are guaranteed.

Owner:苑忠宝

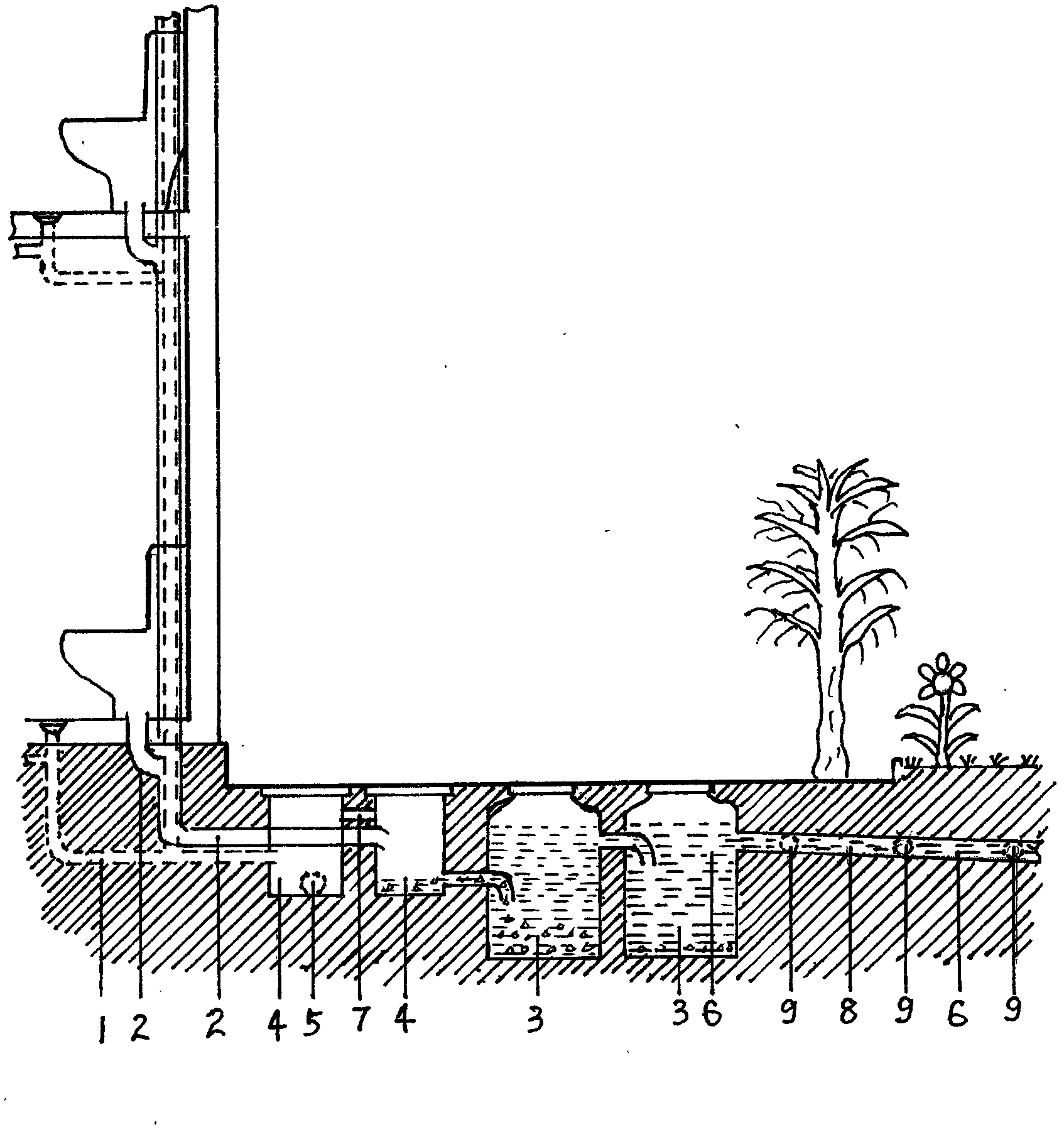

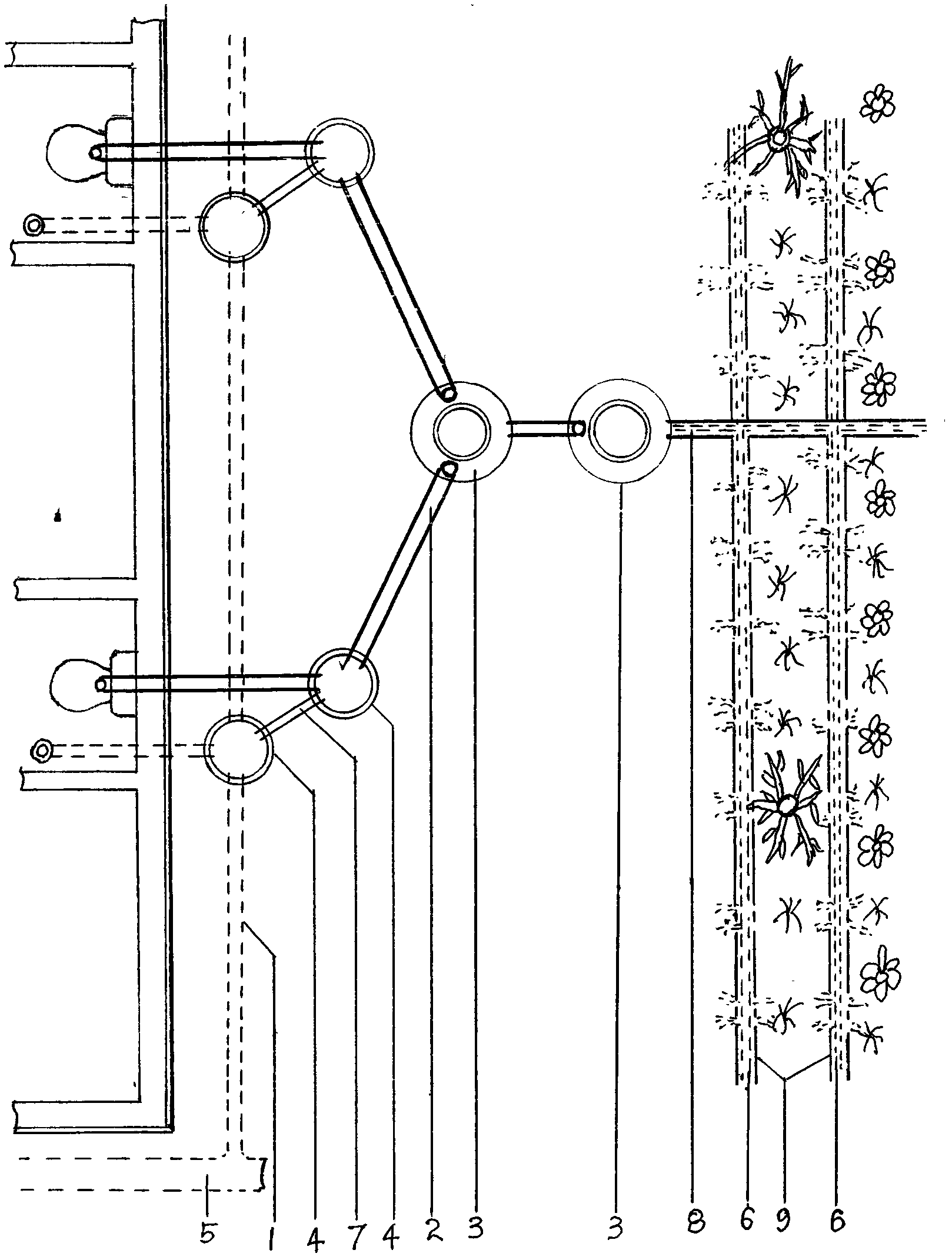

Automatic water and manure supply technology for greenbelt duplex septic tanks

InactiveCN103250496APromote growthLow maintenancePressurised distribution of liquid fertiliserSewer pipelinesAlkali freeSalt free

The invention provides an automatic water and manure supply technology for greenbelt duplex septic tanks, and the technology is characterized in that: each unit of a building is additionally provided with a special pipeline system for salt-free and alkali-free organics and sewage discharged from the toilet; each building is provided with duplex tandem septic tanks; and a drip irrigation type pipe network is arranged under the surface of the greenbelt to realize continuous automatic drip irrigation and topdressing on flowers and trees. The technical scheme effectively solves long-term water and manure maintenance work for watering and fertilization of a residential area greenbelt and even surrounding roadside greenbelts once for all, and there can be no excrement or other domestic organic matters difficult to treat, the environmental quality can be improved, and investment of supporting infrastructure construction is reduced. Therefore, the technology provided in the invention has remarkable social and economic benefits.

Owner:TIANJIN SANCHUN TECH

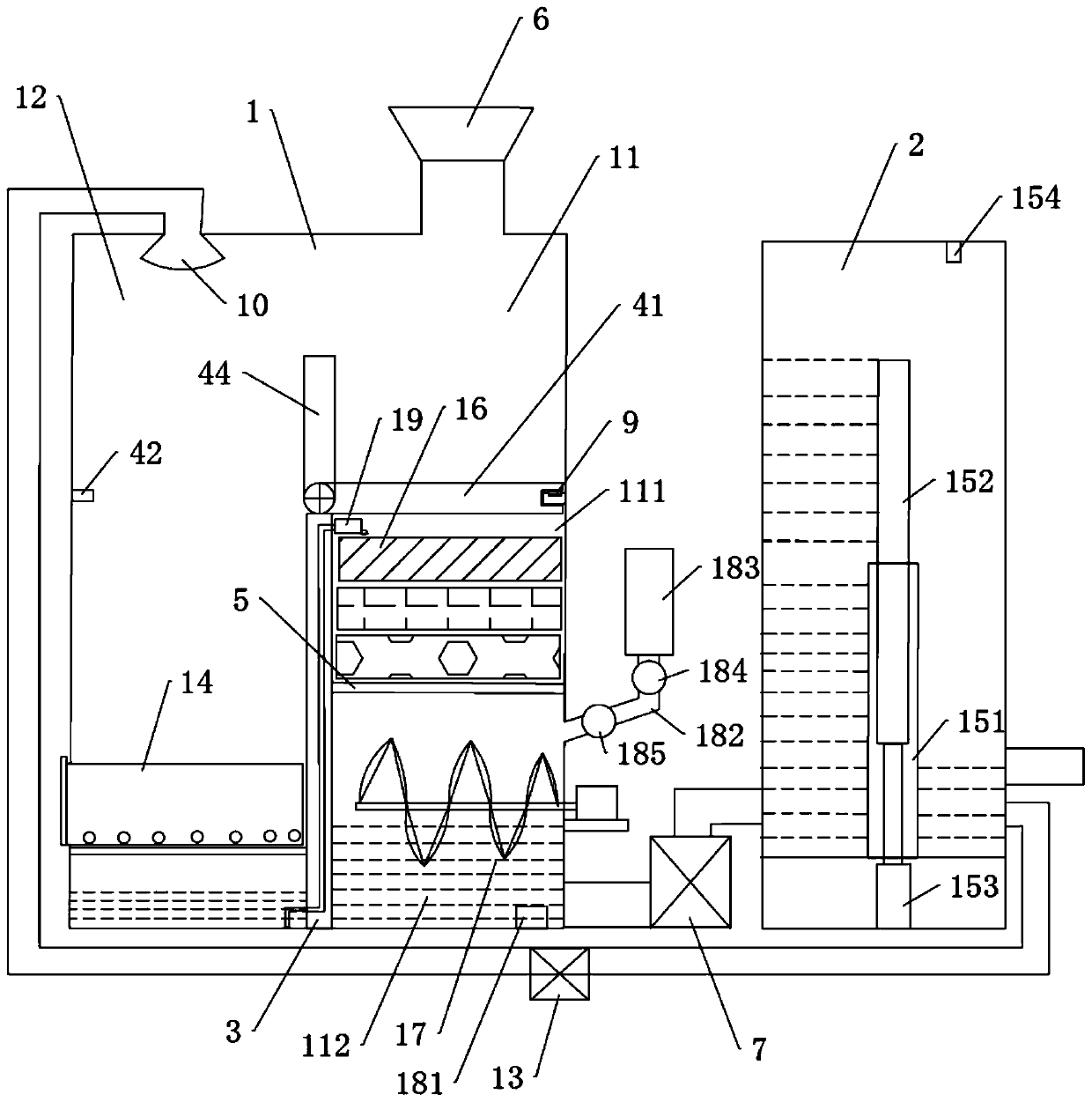

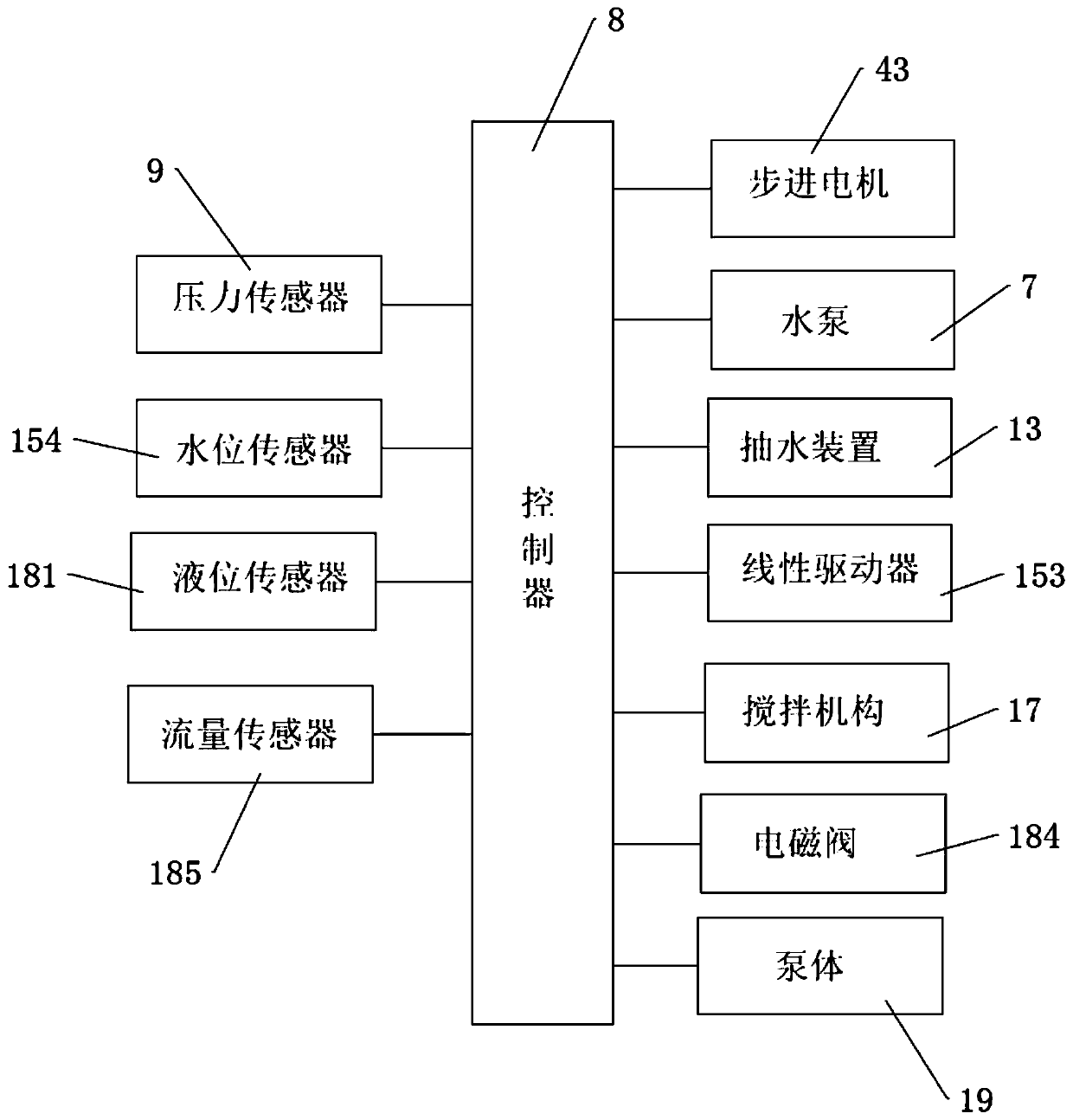

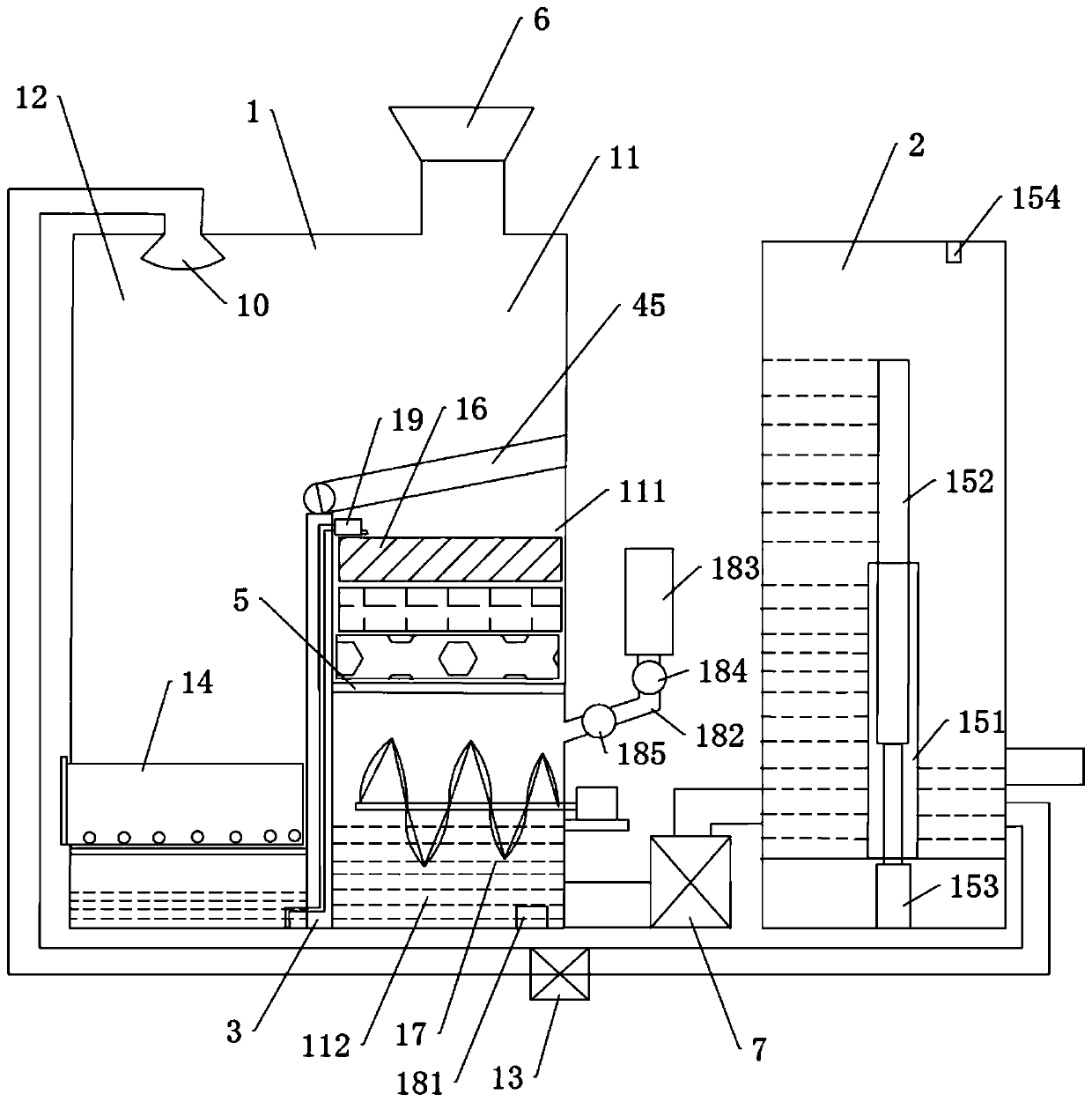

Domestic sewage treatment device

InactiveCN111592132AEfficient use ofImprove the quality of environmental protectionSpecific water treatment objectivesTreatment involving filtrationWater storage tankSewage

The invention discloses a domestic sewage treatment device which comprises a sewage treatment tank and a water storage tank communicated with the sewage treatment tank, wherein a sewage receiving pipeis arranged at the top of the sewage treatment tank; a partition plate is fixed at the bottom of the sewage treatment tank so as to divide the interior of the sewage treatment tank into a sewage treatment chamber and a sundry separation chamber; a filtering separation mechanism for filtering and separating sundries is arranged at the top end of the partition plate, and the filtering separation mechanism is used for filtering large-particle sundries in sewage and separating the large-particle sundries into a sundry separation chamber; a screen is horizontally fixed to the sewage treatment chamber and divides the sewage treatment chamber below the filtering and separating mechanism into a filtering cavity and a disinfecting cavity; the water storage tank is communicated with a disinfectingcavity through a water pump, and the water storage tank is connected with a water discharge system. According to the treatment device for the domestic sewage, the domestic sewage is effectively treated and utilized, and pollution to the living environment is avoided.

Owner:陈玉凤

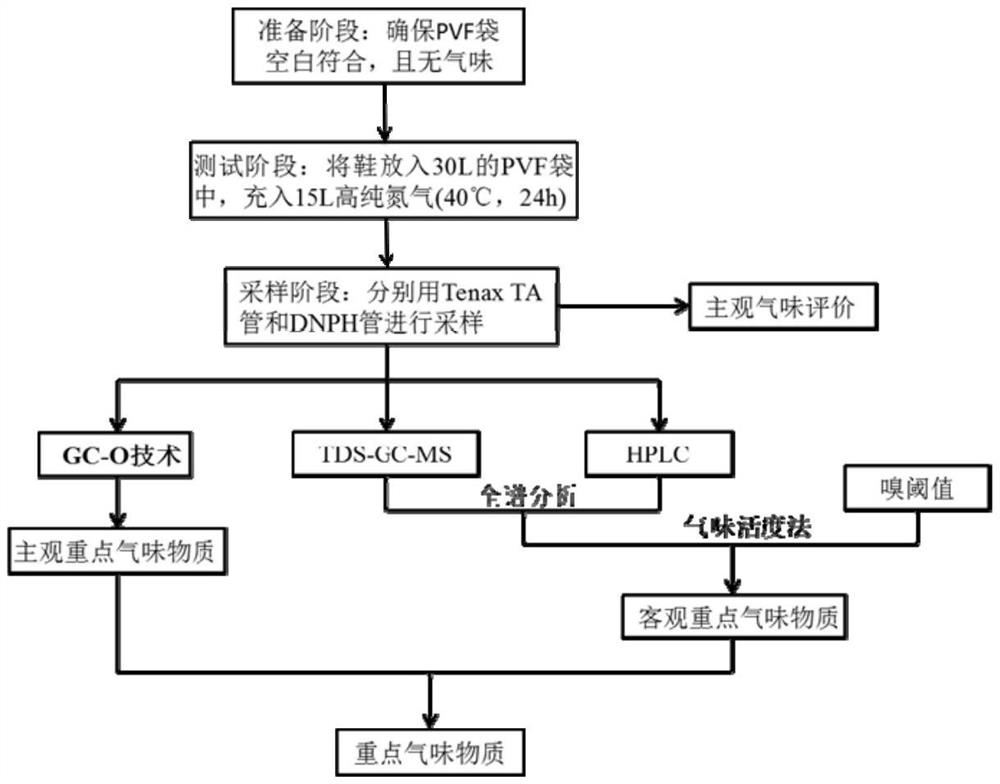

Method for determining key odor substances in shoes

PendingCN111812239AEnsure consistencyImprove the quality of environmental protectionComponent separationBiochemical engineeringProcess engineering

The invention discloses a method for determining key odor substances in shoes. The method comprises the following steps of S1, collecting odor substances of the whole shoe by adopting a bag method; S2, performing subjective smell evaluation on the gas collected in the step S1, and giving a subjective evaluation result about the smell grade and type of the whole shoe; S3, respectively carrying outqualitative and quantitative detection on the gas collected in the step S1 by using HPLC and TDS / GC-MS, and determining to obtain objective key odor substances according to an odor activity method; S4, simultaneously carrying out GC-O olfactory discrimination analysis in the TDS / GC-MS detection process, and determining to obtain subjective key odor substances; and S5, determining the key odor substances of the whole shoe according to the results obtained in the steps S3 to S4. The method is advantaged in that a GC-O technology is combined with an odor activity method, the detection process issimple, cost is saved, subjective and objective evaluation results are adopted at the same time, sample consistency of finished shoe smell evaluation and sampling analysis results is ensured, the detection results are more comprehensive and important, and improvement of the environmental protection quality of shoe products can be protected.

Owner:广电计量检测(天津)有限公司

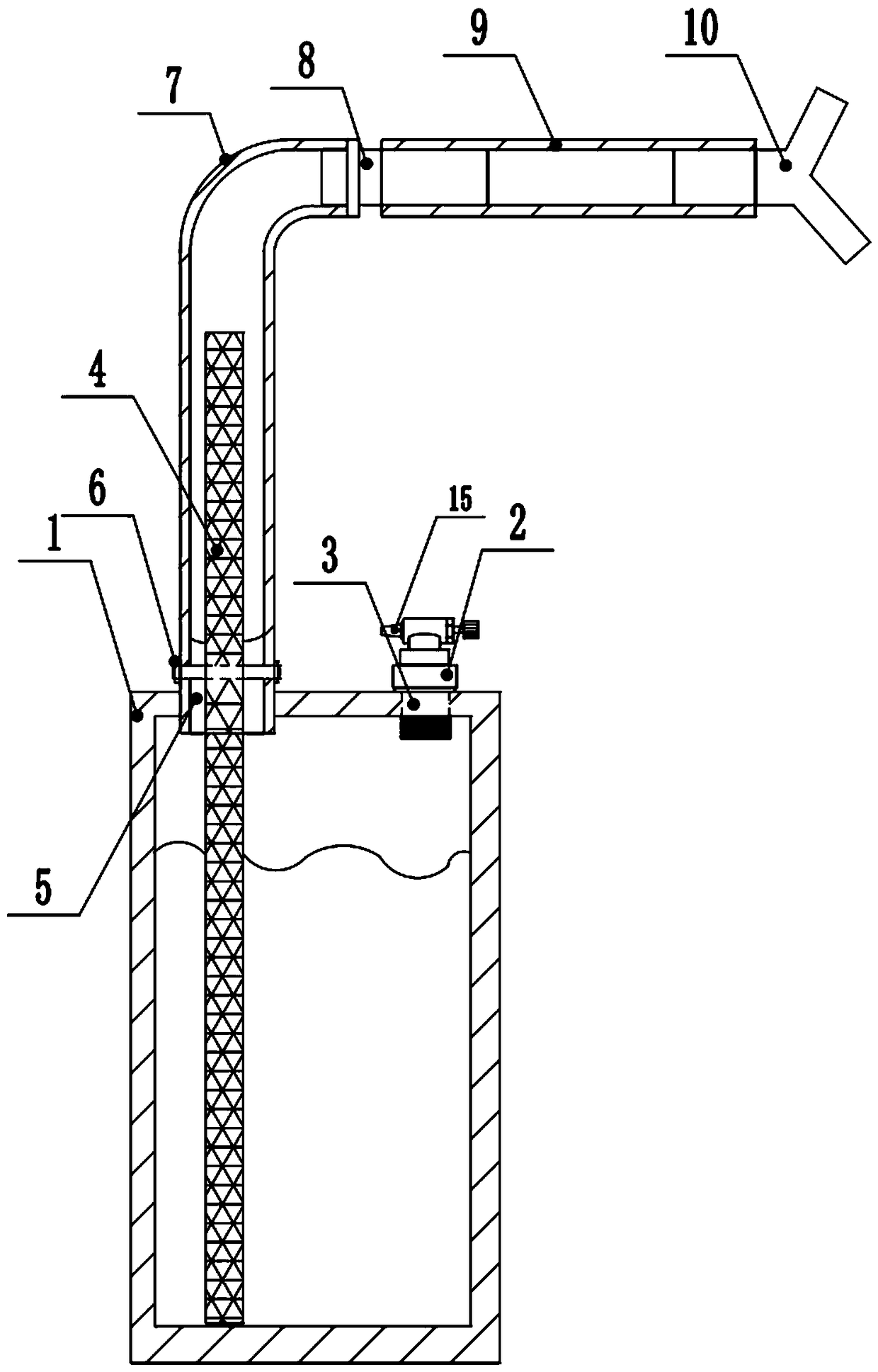

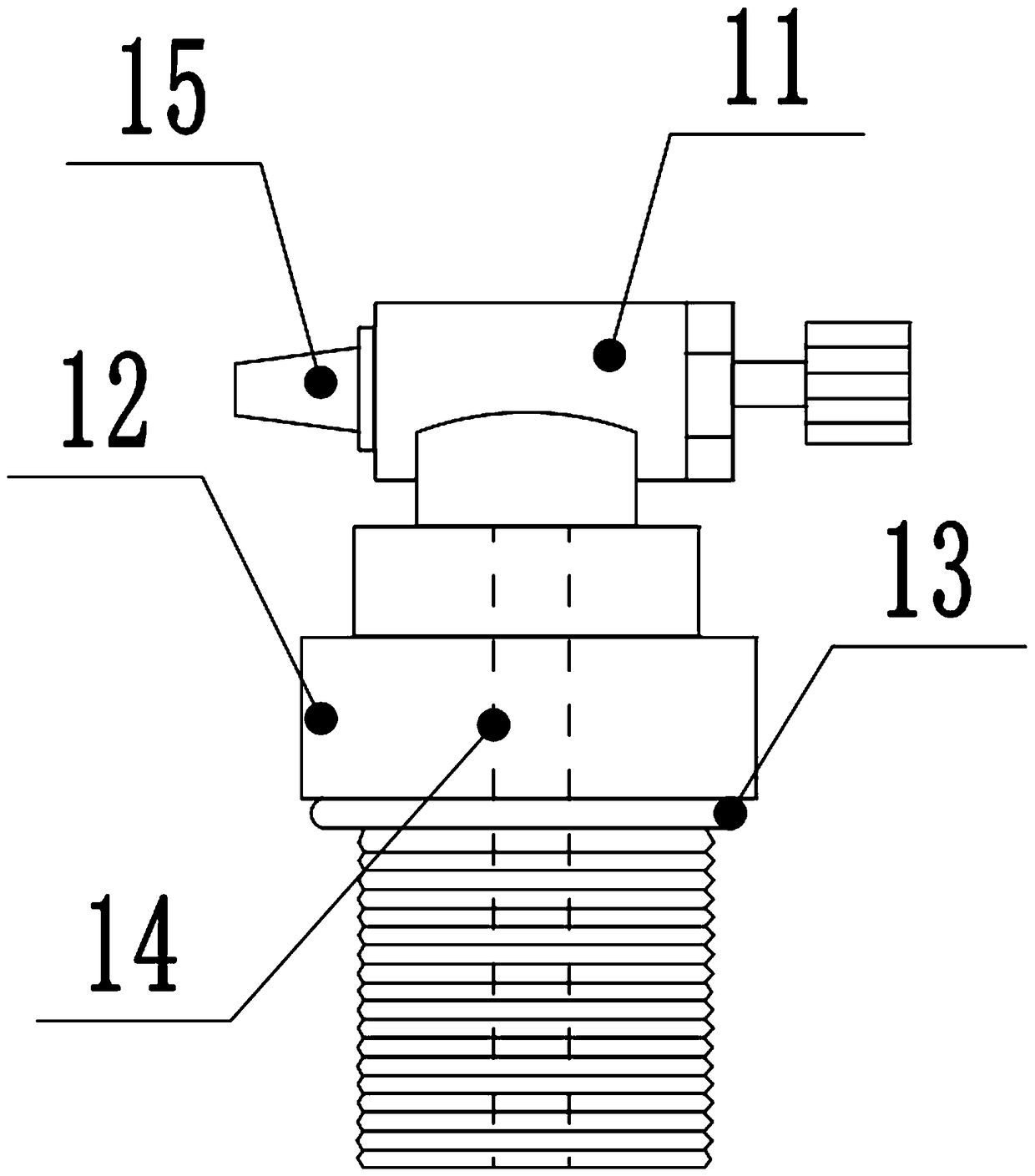

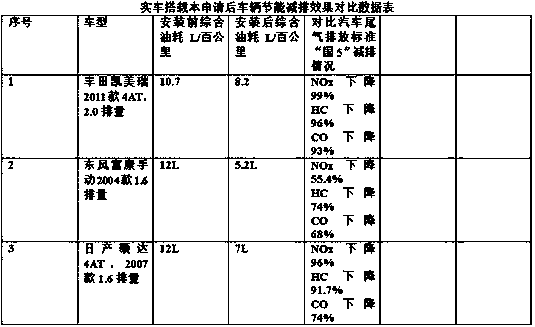

Suction type emission reduction carrying device for gasoline engine

PendingCN109404184ASimple structureReduce volumeMachines/enginesLiquid fuel feedersSiphonInjection port

Provided is a suction type emission reduction carrying device for a gasoline engine. The suction type emission reduction carrying device for the gasoline engine comprises an oil storage tank, an oil injecting bolt, an oil injection port, a wick rope, an oil outlet, a fixing bolt, an observing tube, a converting joint, an oil outlet pipe, and a three-way valve. The emission reduction carrying device is arranged in an automobile engine chamber, and connects an electromagnetic valve outlet end of a carbon tank and an inlet manifold through the three-way valve. The siphon effect of the wick rope in the observing tube is utilized to fit with an inlet regulating valve on the oil injecting bolt to stably and effectively suck combustion improvers stored in the oil storage tank into the inlet manifold of the engine to mix with air, thereby improving the combustion efficiency of the engine fuel.

Owner:周伟传

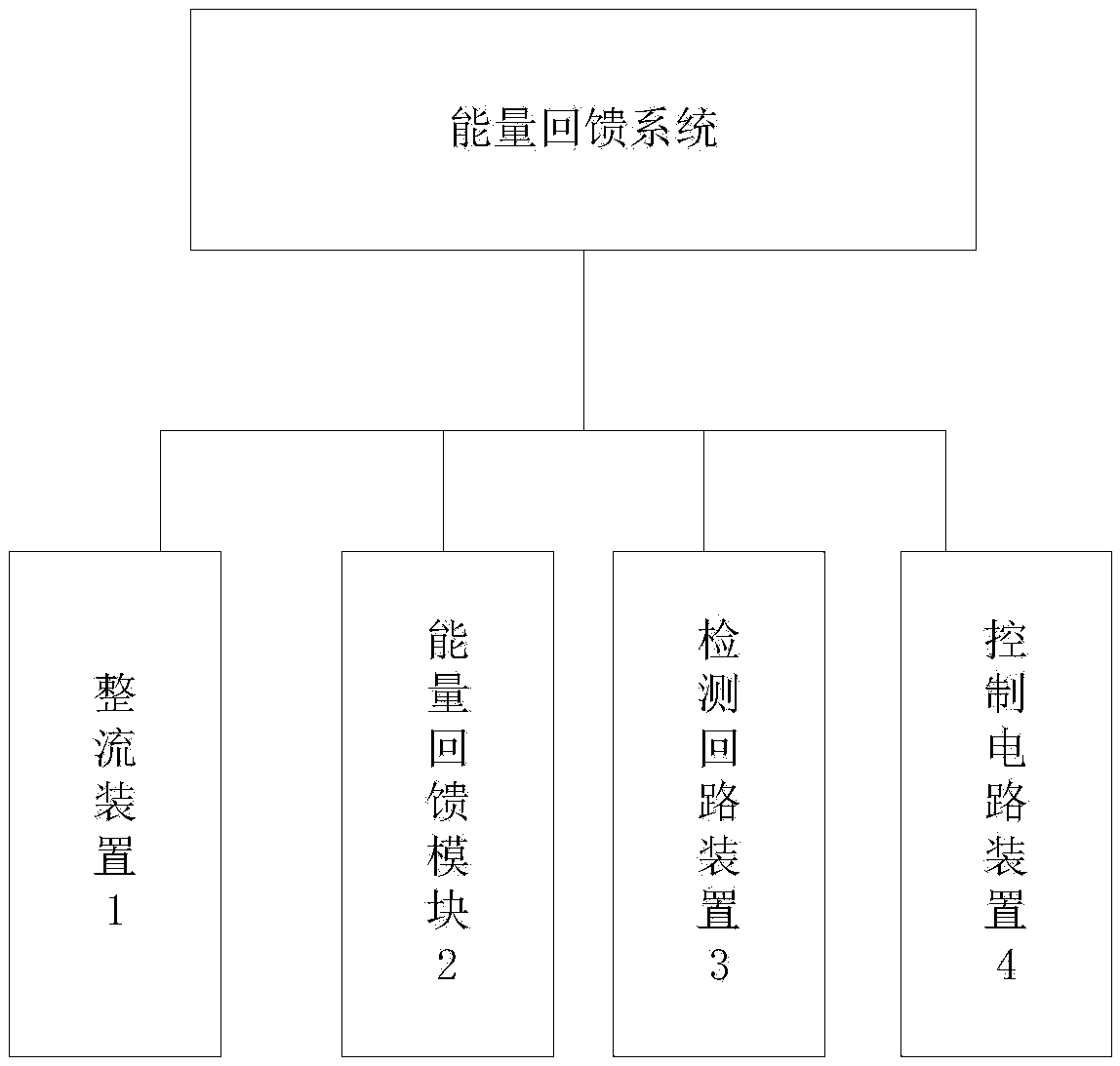

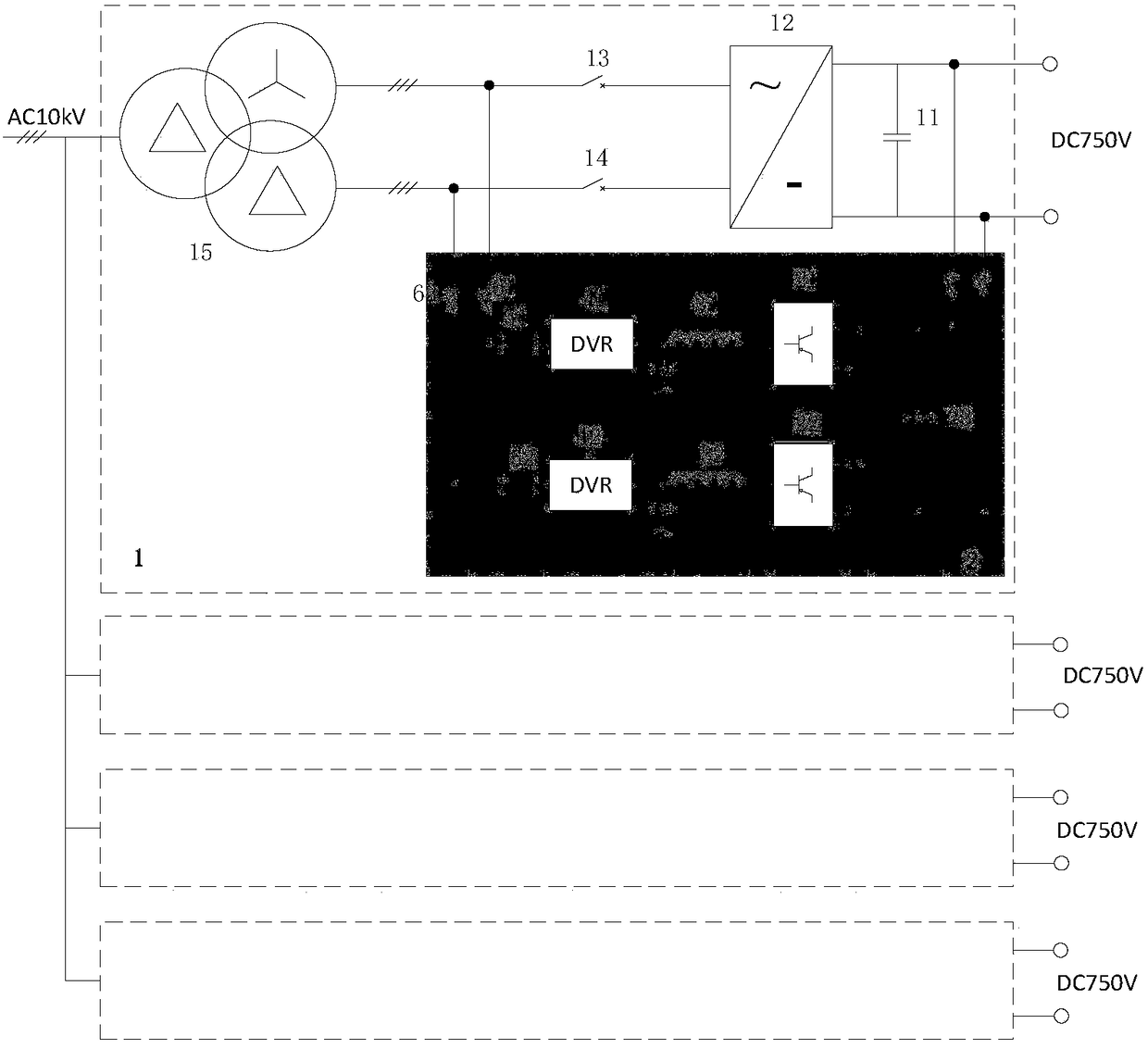

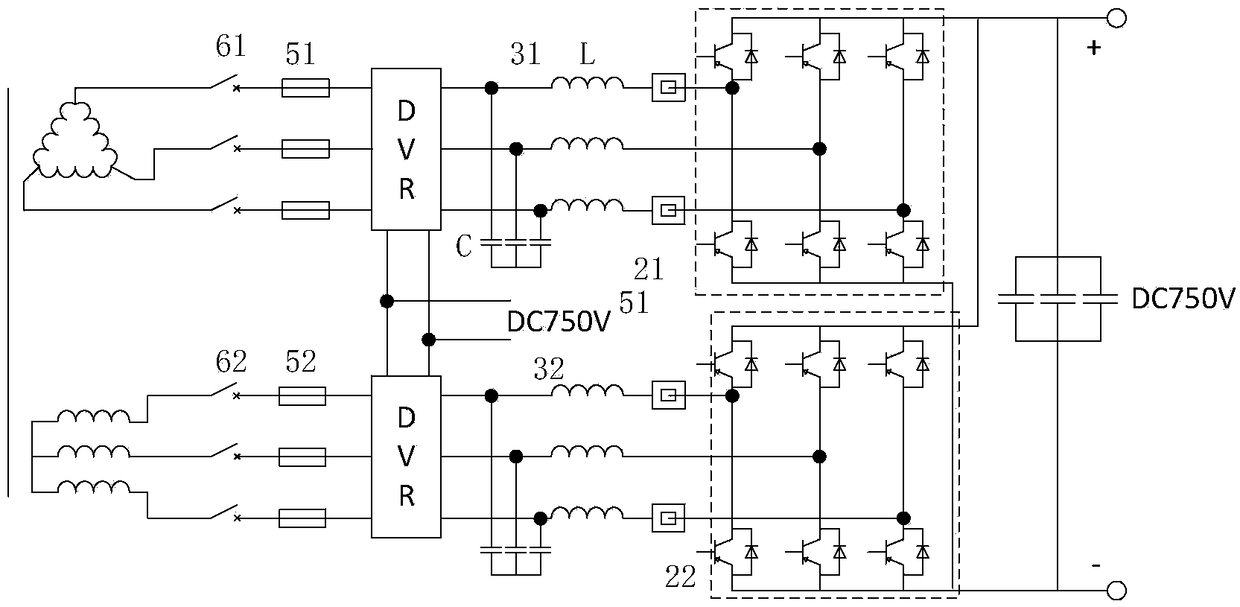

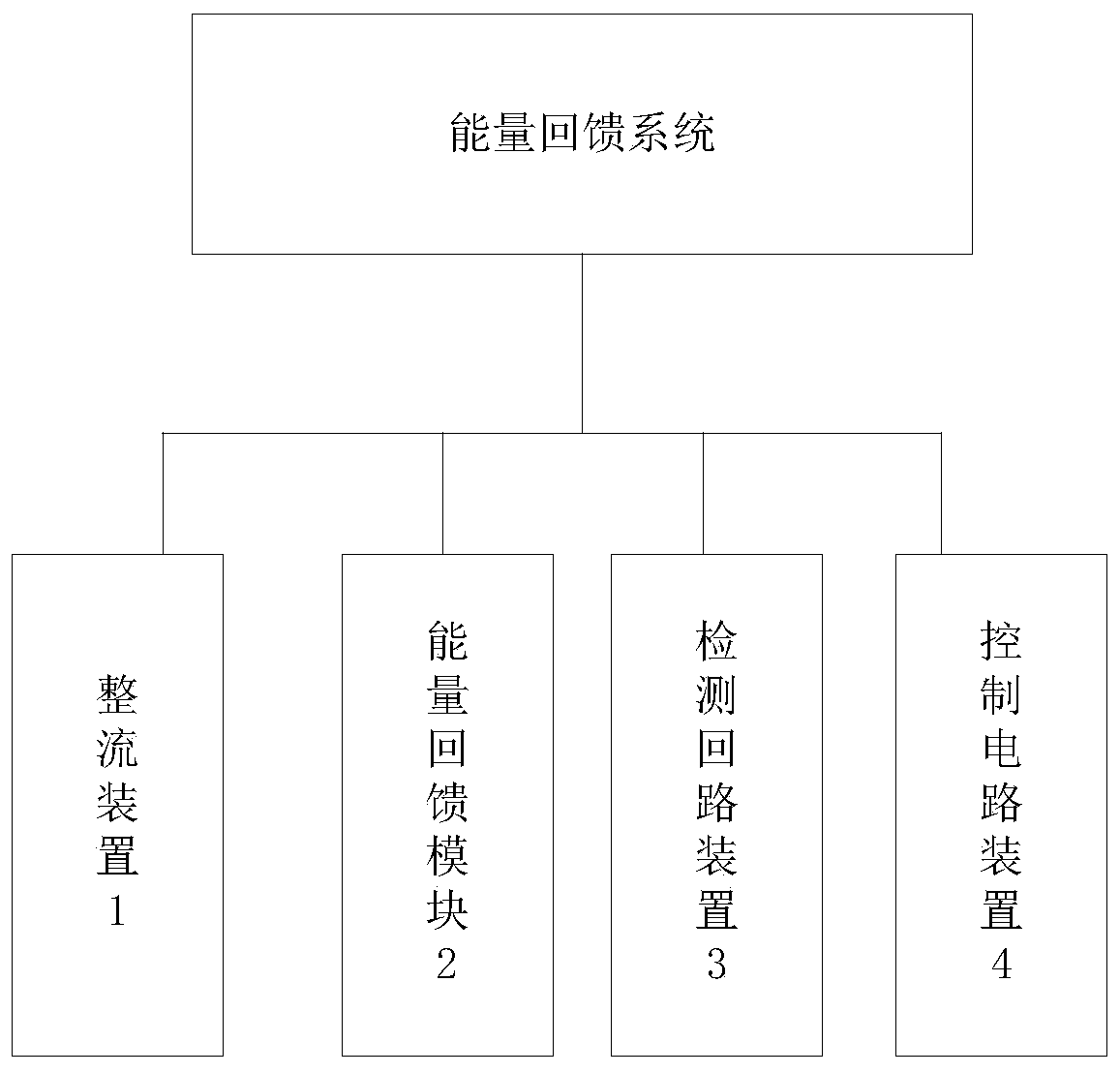

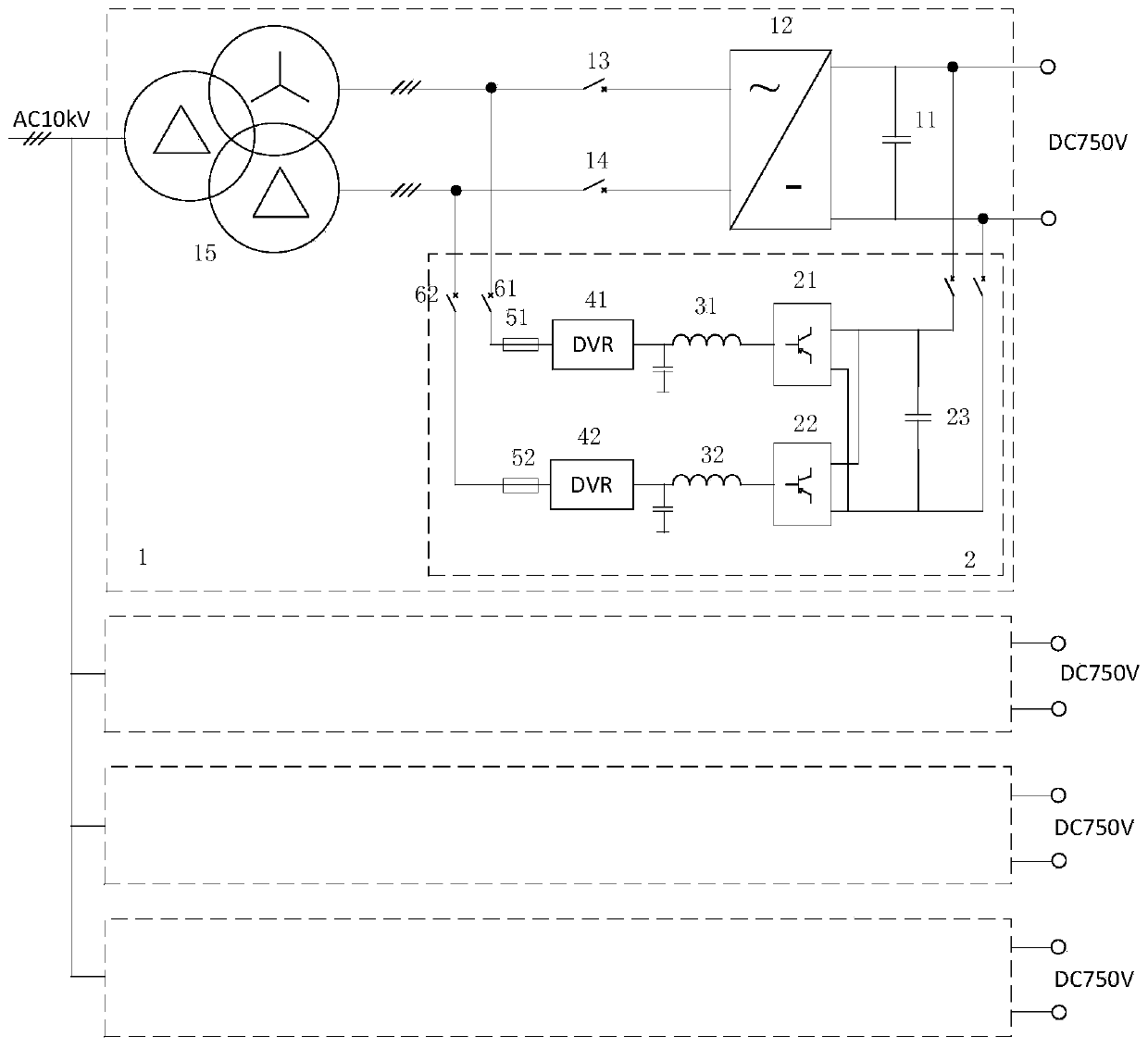

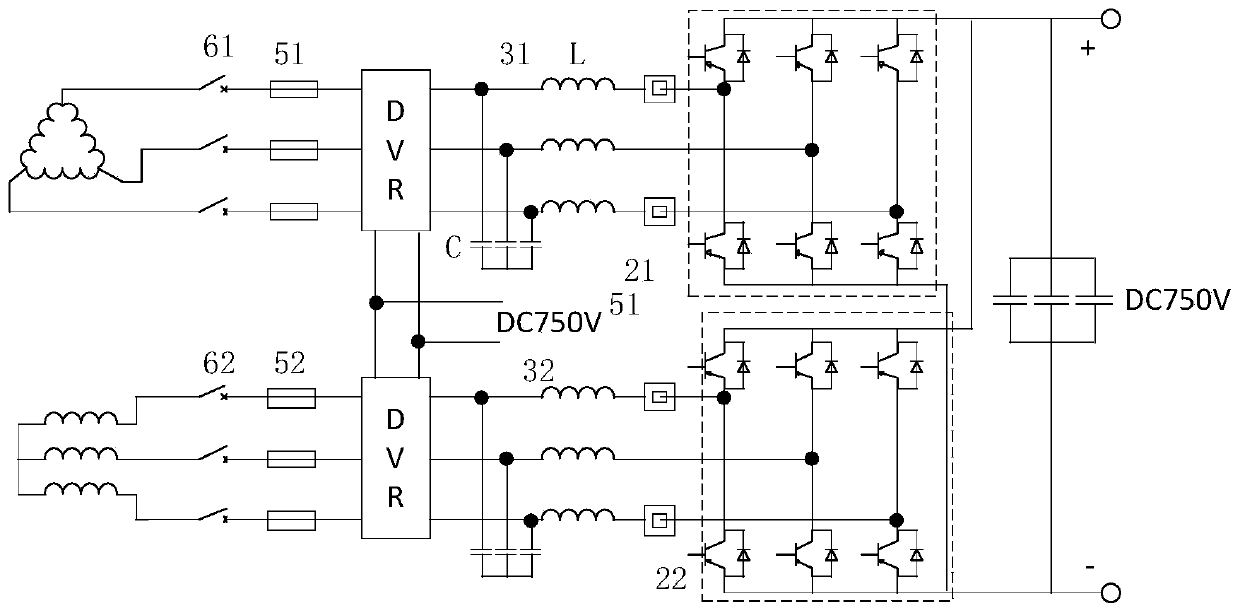

Regenerative braking energy feedback system

ActiveCN108215806AReduce wasteQuality improvementElectrodynamic brake systemsAc-dc conversionRegenerative brakeComputer module

The invention discloses a regenerative braking energy feedback system. The system comprises diode rectifiers, energy feedback modules, detection loop devices and control circuit devices, a group of energy feedback modules are connected with a group of diode rectifiers in anti-parallel, the energy feedback modules are connected with the detection loop devices, and the detection loop devices are also connected with the control circuit devices. The system can leave out an additional boost transformer for controlling braking energy, effectively reduce cost, reduce energy waste, and improve environmental protection quality.

Owner:NINGBO JIANGBEI GOFRONT HERONG ELECTRIC

Method for fabrication food wrap paper and cultural paper by using corn stalk to make no chlorin bleached pulp

A process for preparing food packing paper and cultural paper with chlorine free bleached paper pulp includes using corn straw or its pitch free ones as raw material, then cutting, dust removing, presoaking, cooking and bleaching. The cooking reagent uses ammonium sulfite and potassium sulfite or sodium sulfite as main, sulfur or sulfourea as assistant and urea as well as sodium hydroxide as buffer. The bleaching is two sections or multisection bleaching by using urea or sulfourea to protect fibre and activate hydrogen peroxide.

Owner:田新 +1

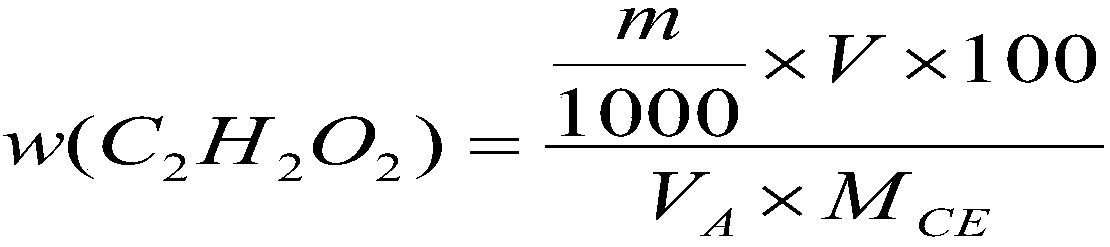

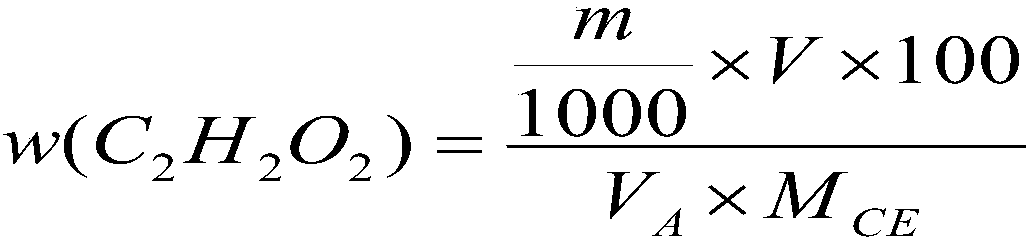

Detecting method for residual glyoxal content in ethoxyl/hydroxypropyl methyl cellulose

InactiveCN108982391AEfficient detectionAccurately calculate the amount addedPreparing sample for investigationColor/spectral properties measurementsAbsorbancePhenol

The invention discloses a detecting method for residual glyoxal content in ethoxyl / hydroxypropyl methyl cellulose. The method comprises the following steps: a, preparing phenol reagent solution; b, preparing glyoxal standard solution for future use; c, weighing a sample, adding tetrahydrofuran, and stirring in a low speed; d, filtering through a filter membrane, for future use; e, taking and transferring filtrate in the step d to a reaction flask, adding deionized water and phenol reagent solution, uniformly mixing, and testing absorbancy of the above testing solution through a spectrophotometer, wherein a wave length is 405 nm; f, drawing a standard curve; and g, calculating the residual glyoxal content in the ethoxyl / hydroxypropyl methyl cellulose through a classical formula. The methodcan be used for effectively and rapidly detecting the residual glyoxal content in the ethoxyl / hydroxypropyl methyl cellulose, effectively detecting aldehydes materials in a product harmful to a humanbody, and improving environmental production quality of the product.

Owner:CHONGQING PENGKAI FINE CHEM CO LTD

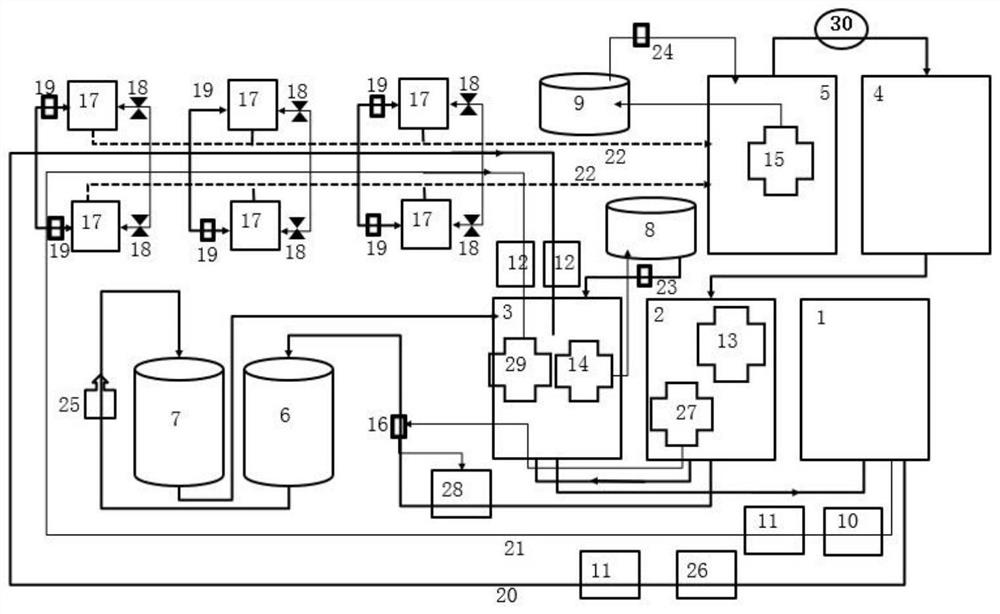

Regeneration and utilization system of diamond wire cooling liquid

InactiveCN112624404AAchieving processing powerAchieve recyclingWater treatment parameter controlWater/sewage treatment by irradiationLiquid storage tankProcess engineering

The invention discloses a regeneration and utilization system for diamond wire cooling liquid. The regeneration and utilization system comprises a first liquid storage tank used for storing blended cooling liquid and a slicing machine slurry cylinder communicating with the first liquid storage tank; a waste liquid tank connected with a slicer slurry cylinder and used for storing cut waste liquid, a first ion detector arranged in the waste liquid tank and used for detecting the content of metal ions, and a first liquid supplementing tank electrically connected with the first ion detector and connected with the waste liquid tank and used for conveying an ion scavenger to the waste liquid tank. The waste liquid tank is connected with a third liquid storage tank, the third liquid storage tank is connected with a second liquid supplementing tank for storing cooling liquid and used for regenerating the cooling liquid, and the third liquid storage tank is connected with the first liquid storage tank and used for conveying the regenerated cooling liquid to the first liquid storage tank. According to the invention, the treatment and cyclic utilization of the cooling liquid are realized, and the discharge amount of waste liquid is low; water resources are saved in the whole process, the environmental protection quality is improved, and a full-automatic regeneration system is achieved.

Owner:句容协鑫光伏科技有限公司

Production technology of environment-friendly anti-counterfeiting scintillating blue pearlescent ink

PendingCN110452582AImprove bindingImprove the quality of environmental protectionInksMass ratioEngineering

The invention provides a production technology of an environment-friendly anti-counterfeiting scintillating blue pearlescent ink. The technology includes the steps of: 1) stirring a scintillating bluepearlescent pigment with ink 30min before printing; 2) adding an environment-friendly mixed solvent, performing stirring for 15min, then detecting the ink viscosity and controlling the viscosity range at 28-32s of No.4 cup, at the same time adding an anti-settling agent with a mass ratio of no more than 3%, and performing stirring; 3) in the production process, detecting the ink viscosity every other 15-20min, and controlling the viscosity in the range of 28-32s of No.4 cup; 4) during printing preparation, using 80-line anilox roller and installing a new scraper; 5) before formal printing andeach halt printing, cleaning a rubber blanket with the environment-friendly mixed solvent; and 6) during production, detecting the ink viscosity every other 15-20min, and controlling the viscosity inthe range of 30-32s of No.4 cup. After printing by the technology, a packaging product has significant scintillating blue pearlescent effect, the ink has good stability on machine, the technology canadapt high speed machine stable production, also can combine with commonly used solvent medium easily, is convenient to operate, and does not bring pollution.

Owner:ZHUHAI S E Z CHENGCHENG PRINTING

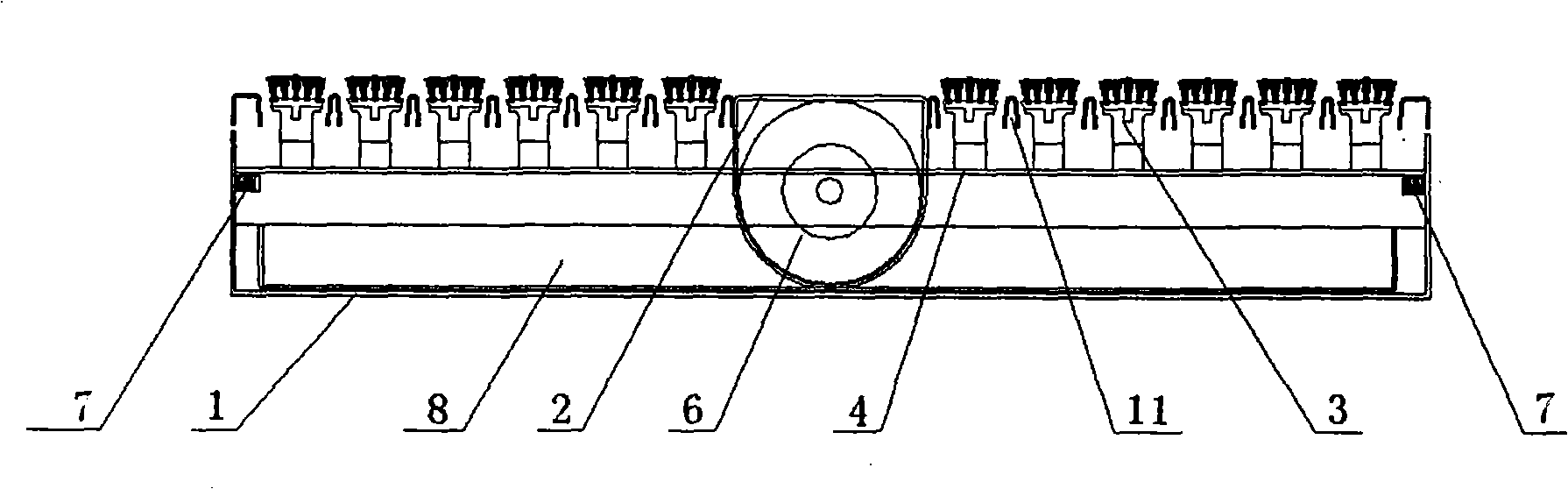

Automatic shoe sole dust collector

The invention relates to an automatic sole cleaner, belonging to the field of household appliances. Brush supports (4) are fixed below a brush board (3), all the brush supports (4) are arranged at intervals and are fixed on brackets (5) at the two ends of the brush supports (4), the interior of a base (1) is provided with an electromagnet (6), a telescopic shaft of the electromagnet (6) is connected with the bracket (5), the parts on the inner wall of the base (1) corresponding to the brush supports (4) are respectively provided with a slide supporting mechanism (7), a panel (2) is arranged above the base (1), a touch switch (12) is arranged below the panel (2), the other end of the touch switch (12) is connected with the base (1), and the touch switch (12) is provided with leads connected with the electromagnet (6) by a power supply (13). The automatic sole cleaner has rapid cleaning speed, stable action, less noise, reliable use, long service life, low manufacturing cost, small volume, convenient usage, fine cleaning effect of soles and is suitable for households as well as public places like restaurants.

Owner:武汉图奇科技有限公司

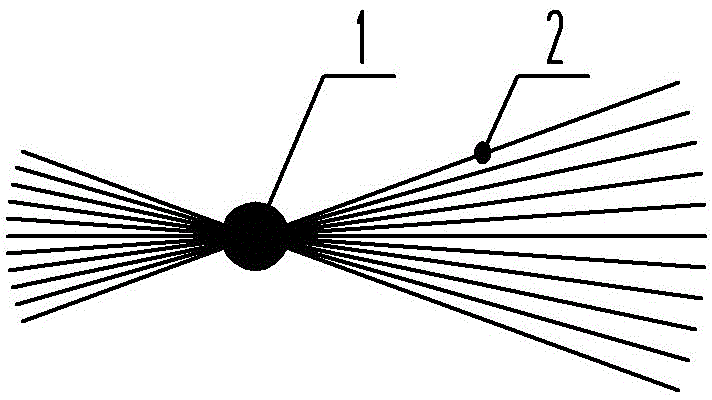

Preparation method of modified comet fiber filtering material

InactiveCN103394239ALarge specific surface areaIncrease elasticityFiltration separationPolyesterYarn

The invention relates to a preparation method of a modified comet fiber filtering material. According to the preparation method, polyester fiber raw material is spun into yarns, the polyester fiber yarns are bundled, the polyester fiber yarn bundles are subjected to injection molding and ball pressing and then cut off to obtain the modified comet fiber filtering material. The preparation method further comprises the following steps of: 1, stirring the mechanically processed modified comet fiber filtering material in a rinsing tank, then fishing out and draining water for later use; 2, uniformly stirring a chemical solution in a container and then conveying the prepared chemical solution into an autoclave, wherein the chemical solution comprises the following components in percentage by volume: 2vol% of viscose oil, 1.5vol% of silica gel oil and the balance of water; 3, putting the modified comet fiber filtering material in the autoclave, turning on a heating power supply for increasing temperature, cutting off the power supply when the temperature rises to 110 DEG C, keeping the pressure of 0.11-0.15MPa for 2-3 minutes, then adding cooling water to the autoclave to reduce the temperature to 50 DEG C, turning on an outlet valve so that the fiber filtering material subjected to modification chemical treatment and the chemical solution flow into another container at the same time; 4, fishing out the fiber filtering material subjected to modification chemical treatment, drying in a spin dryer, taking out of the spin dryer and air-drying to obtain the finished product.

Owner:HENAN LVYUAN WATER TREATMENT TECH

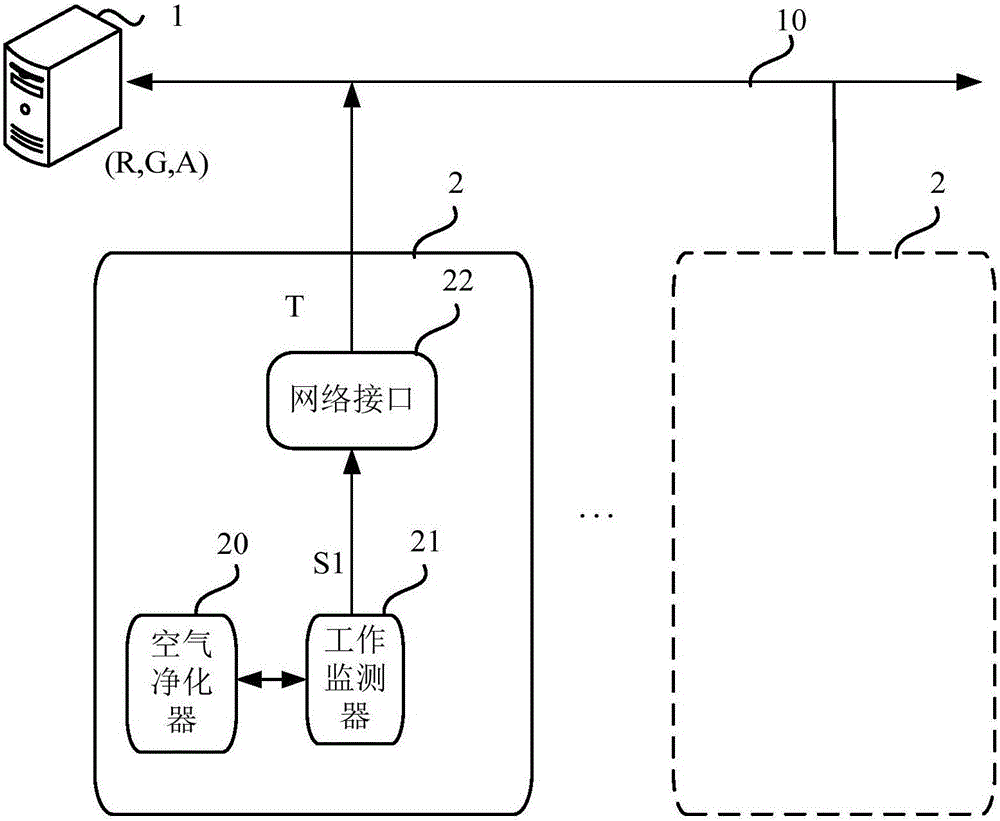

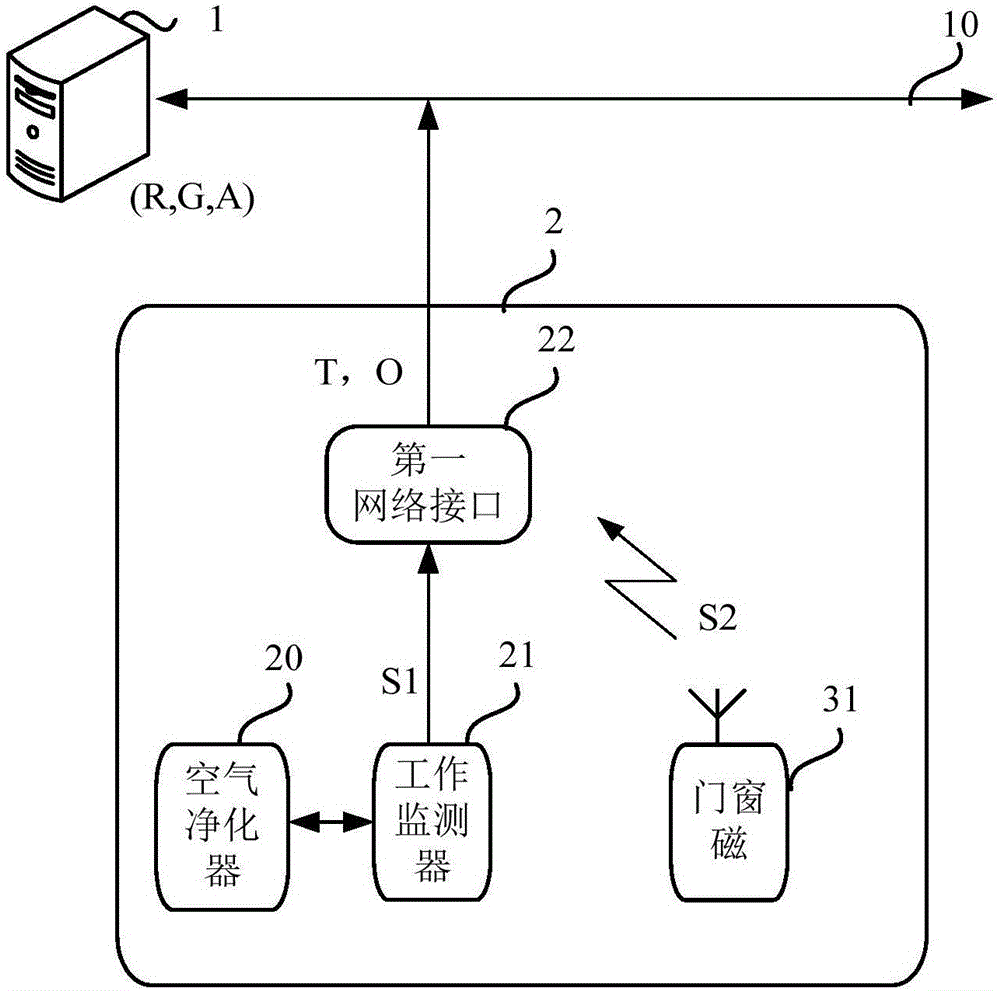

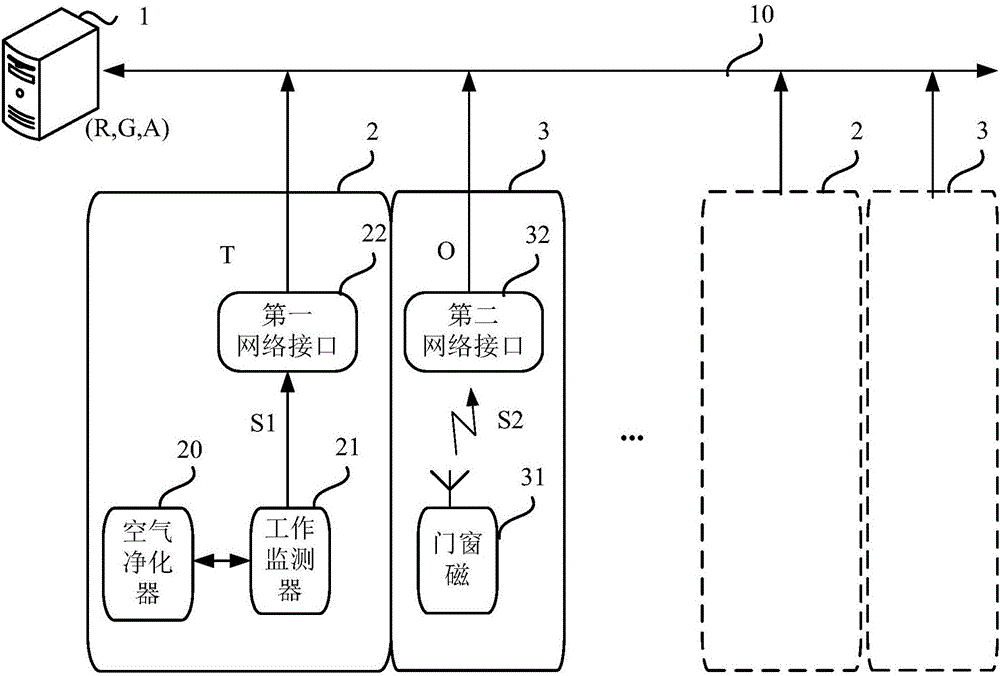

Internet purifier based guest room environment protection monitoring network and environment protection integration method

ActiveCN106444414AUse wellImprove the quality of environmental protectionComputer controlTransmissionWork statusSystem monitor

The invention provides an internet purifier based guest room environment protection monitoring network and an environment protection integration method, and solves the problem about acquisition of environment protection attributes of guest behavior habits as well as evaluation. The system comprises a server and at least one guest room air purification system. Each guest room air purification system comprises a guest room controller, an air purifier and a work monitor; the air purification system monitors working time of the air purifier, generates environment protection data and sends the same to the server; the server receives the environment protection data and makes statistics on the environment protection data to generate evaluation data. The environment protection integration method includes the following steps: recording identification information and check-in person identity information of the guest room air purification systems; monitoring the working status of the air purifiers, and recording working time of the air purifiers; making statistics on the working time of the air purifiers and generating evaluation data; subjecting the evaluation data and person identity information to associative storage.

Owner:中关村科技租赁股份有限公司

Preparation method of modified comet fiber filtering material

The invention relates to a preparation method of a modified comet fiber filtering material. According to the preparation method, polyester fiber raw material is spun into yarns, the polyester fiber yarns are bundled, the polyester fiber yarn bundles are subjected to injection molding and ball pressing and then cut off to obtain the modified comet fiber filtering material. The preparation method further comprises the following steps of: 1, stirring the mechanically processed modified comet fiber filtering material in a rinsing tank, then fishing out and draining water for later use; 2, uniformly stirring a chemical solution in a container and then conveying the prepared chemical solution into an autoclave, wherein the chemical solution comprises the following components in percentage by volume: 2vol% of viscose oil, 1.5vol% of silica gel oil and the balance of water; 3, putting the modified comet fiber filtering material in the autoclave, turning on a heating power supply for increasing temperature, cutting off the power supply when the temperature rises to 110 DEG C, keeping the pressure of 0.11-0.15MPa for 2-3 minutes, then adding cooling water to the autoclave to reduce the temperature to 50 DEG C, turning on an outlet valve so that the fiber filtering material subjected to modification chemical treatment and the chemical solution flow into another container at the same time; 4, fishing out the fiber filtering material subjected to modification chemical treatment, drying in a spin dryer, taking out of the spin dryer and air-drying to obtain the finished product.

Owner:HENAN LVYUAN WATER TREATMENT TECH

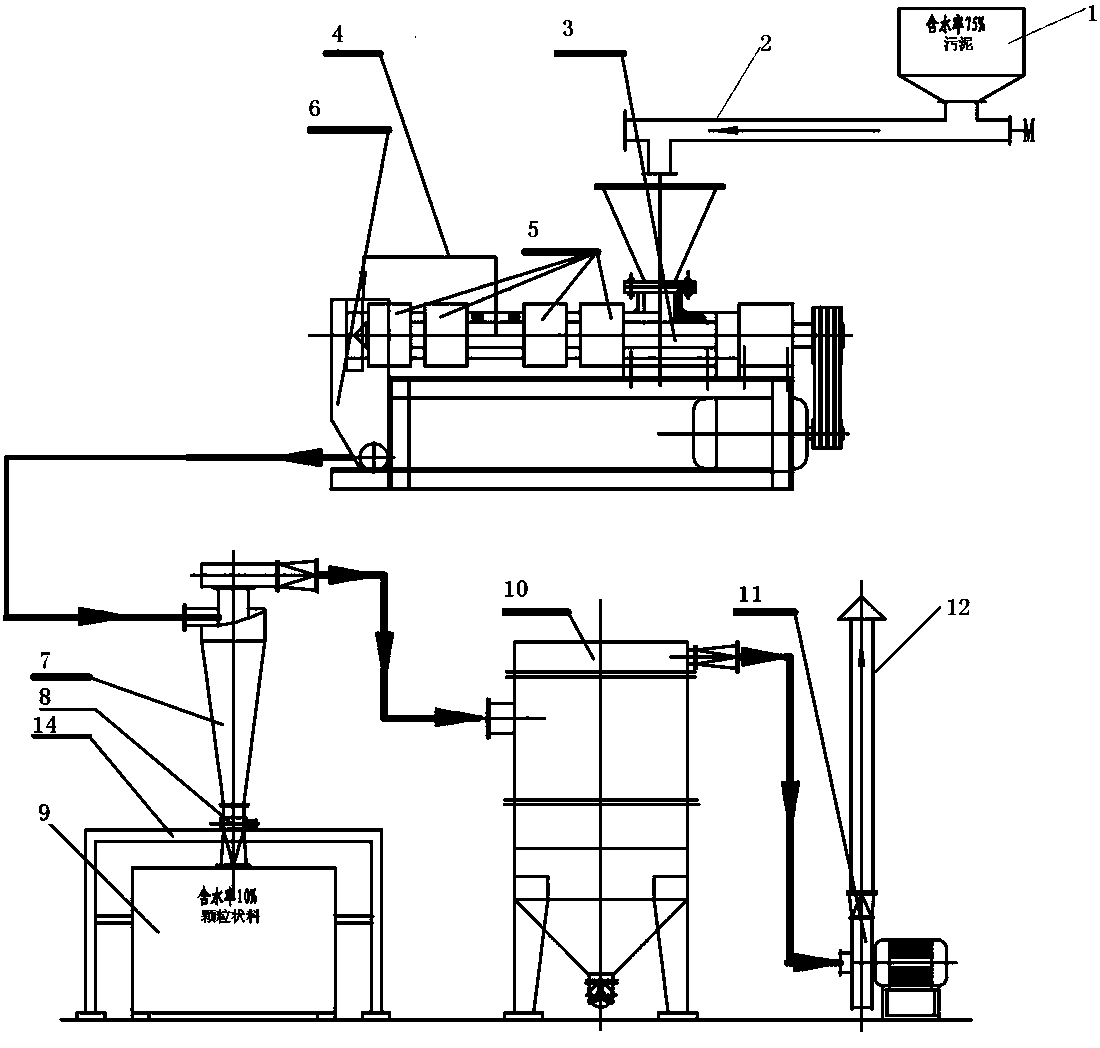

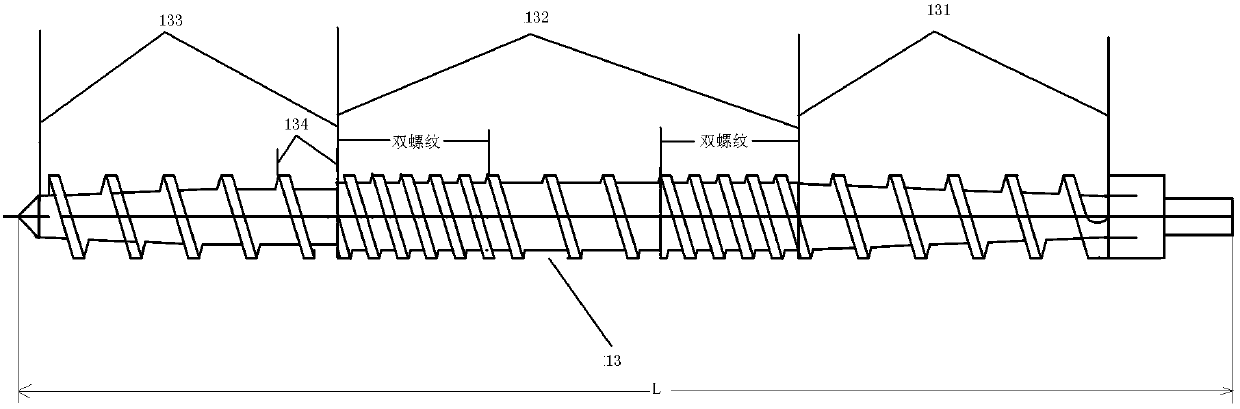

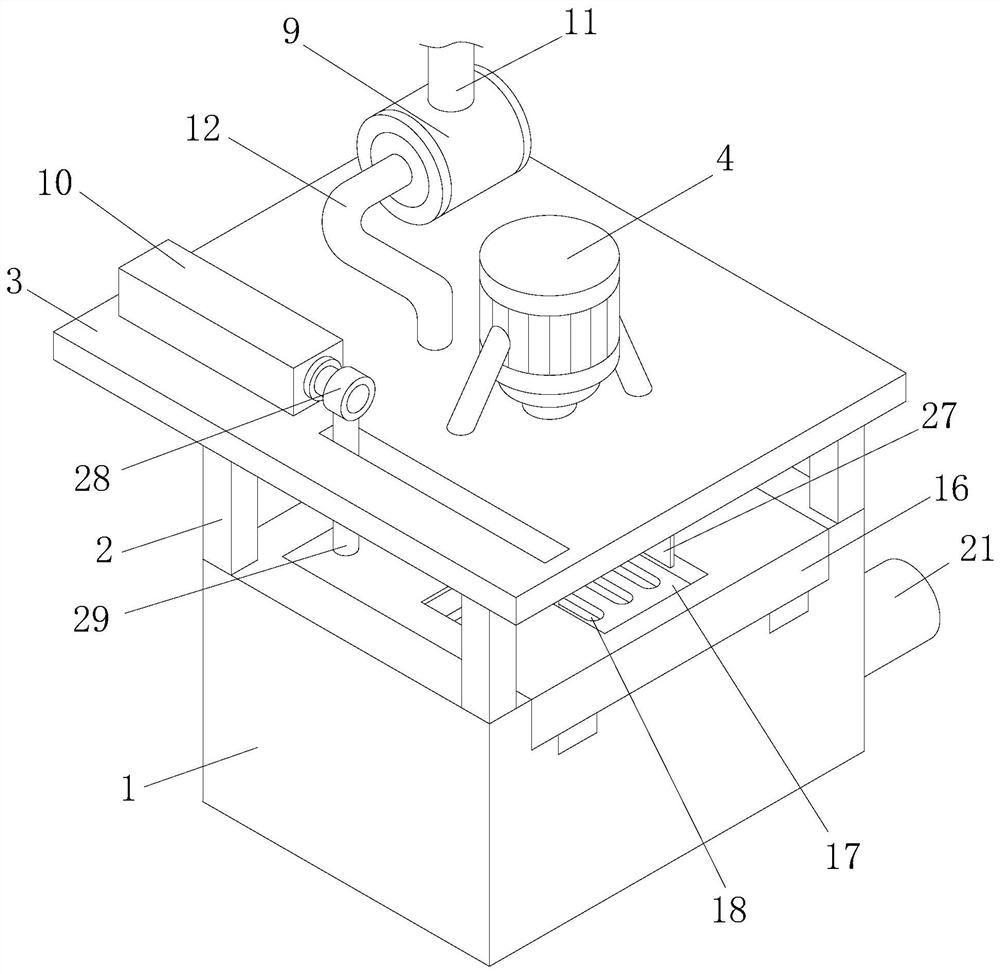

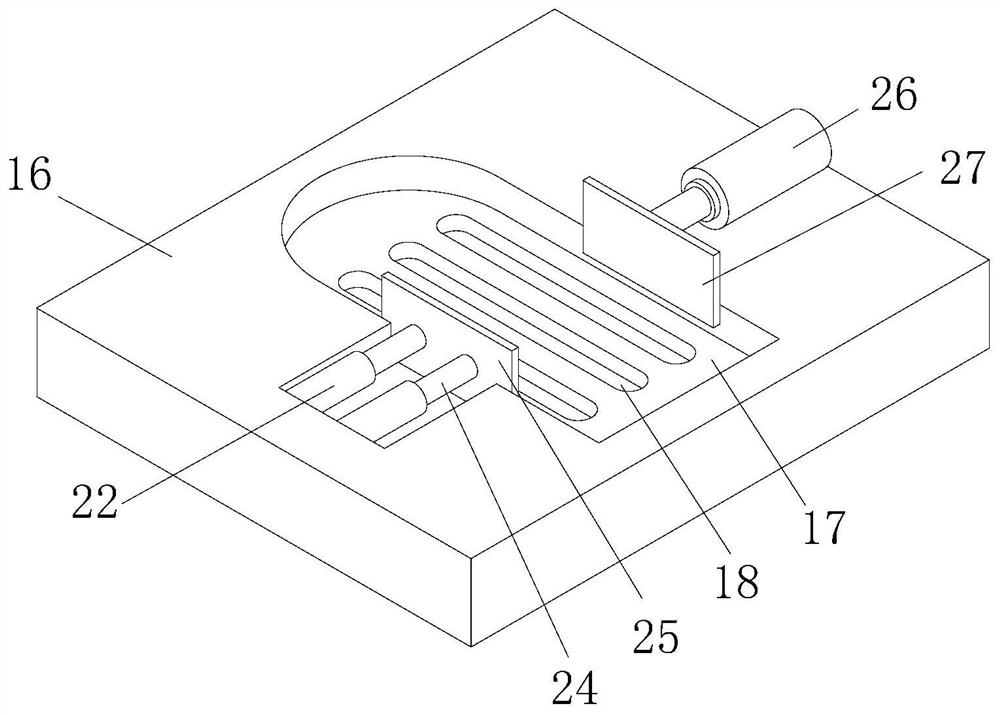

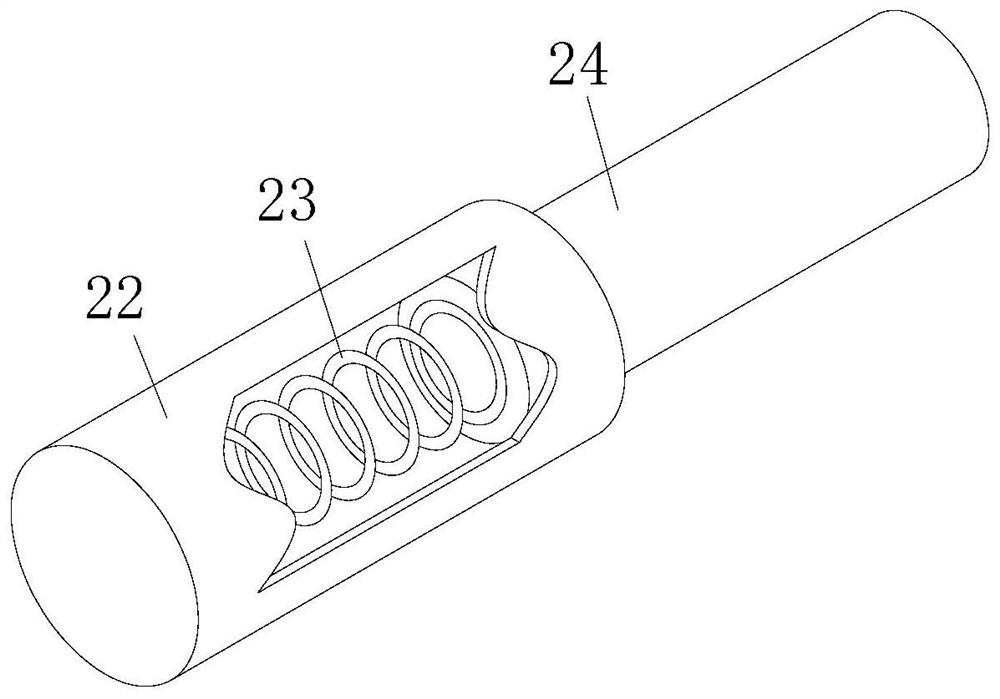

Sludge screw type direct drying device and method

ActiveCN106242230BSolve the dead angle problemGrow fastCombination devicesSludge treatment by de-watering/drying/thickeningSludge cakePulp and paper industry

The invention relates to a sludge treatment device and method, in particular to a sludge screw-type direct drying device and method and mainly aims to solve the technical problem that existing sludge treatment methods are low in treatment amount and high in cost. The sludge screw-type direct drying device comprises a feeding hopper, a screw conveyor is arranged at an outlet, a discharging port of the feeding hopper faces a feeding port of a spiral extrusion electric heating material dryer, an electric heater wraps the outside of the feeding hopper, a screw of a dryer is driven by a motor through a belt wheel, an exhaust pipe is arranged at the top of the dryer to be connected with a negative pressure material collector, and an outlet of the dryer is connected with the negative pressure material collector; an outlet of the negative pressure material collector is connected with a cyclone separator through a pipeline, the cyclone separator is fixed on a steel frame, a fan is arranged at the lower end of the cyclone separator and connected with a material bin, an air outlet of the cyclone separator is connected with a pulse deduster through a pipeline, and an air outlet of the pulse deduster is connected with a high-pressure fan and a chimney through pipelines. The sludge screw-type direct drying device and method mainly aims to dry and extrude sludge cakes formed by sludge after being mechanically press-filtered and dewatered into granular powder.

Owner:上海朗彪环境科技有限公司

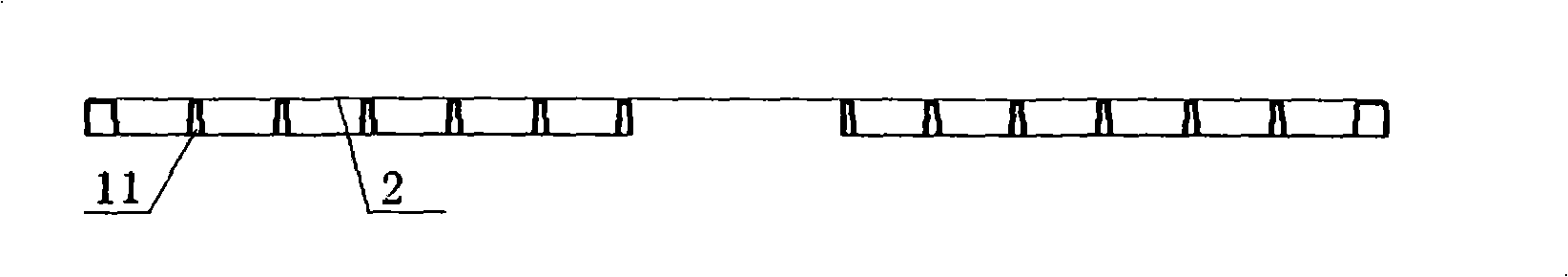

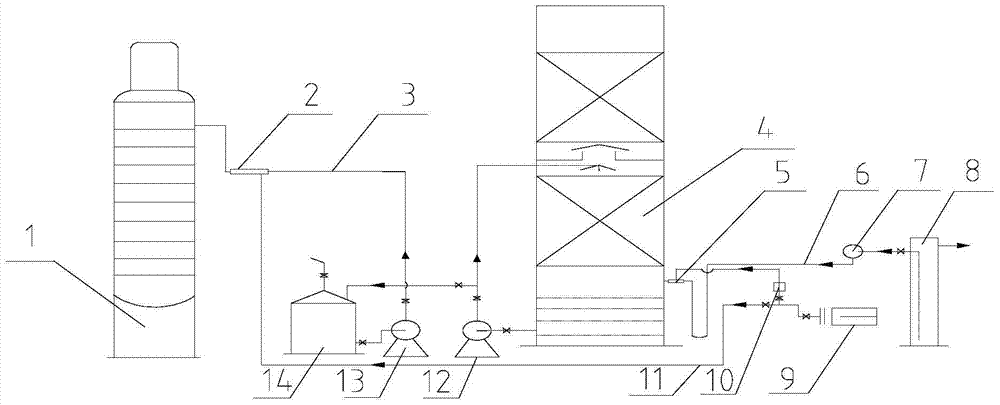

Linear feeding method for aluminum electrolysis flue gas purification system

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Anti-settling water-based quick-drying production process of pearlescent printing ink

The invention provides an anti-settling water-based quick-drying production process of a pearlescent printing ink. The production process comprises the following steps: 1) one to two days before printing, soaking a pearlescent pigment powder with a particle diameter of 5-25 [mu]m into a mixed solvent to make the pearlescent pigment powder moistened as a paste; 2), adding a thickener, and performing soaking for 3-4 hours to make the oil absorption of the pearlescent pigment reach saturation; 3), after the soaking, performing stirring dispersion at a speed of 150r / min, and performing full soaking; 4), before production use, pouring a high-concentration bright silver oil into the well soaked pearlescent pigment container while stirring, and adding a mixed solvent in an appropriate amount; 5),adding an anti-settling agent of 1%-5%, and detecting the viscosity of the printing ink after stirring for 15 minutes; and 6) in the production process, detecting the viscosity of the ink once every15-20 minutes to ensure that the viscosity is controlled in the range of 30-35 s of a No. 4 cup. According to the printing process, after printing, packaged products have a significant pearlescent effect, and the ink has a good stability on machine, not only can adapt to high-speed machine stable production, but also is easy to combine with a common solvent medium; and the operation is easy, and no pollution is brought.

Owner:ZHUHAI S E Z CHENGCHENG PRINTING

A secondary utilization device and utilization process of coking crude benzene separation water

ActiveCN104232172BReduce dosageIncrease alkalinityChemical industryCombustible gas purificationCooling towerDihydrogen oxide

The invention relates to a device and process for secondarily utilizing coked crude benzene separation water. Separation water distilled by a debenzolization tower for a crude benzene coking procedure serves as a raw material, crude benzene separation water separated by a light benzene control separator is introduced into a final cooling tower as updating supplementation water through a pipeline, and a trace amount of a NaOH solution with the concentration of 40 percent for ammonia still is supplemented into the final cooling tower, so that the separation water and the NaOH solution are mixed to form an alkaline solution; after final cooling circulation, the redundant solution is directly fed into a surplus ammonia water tank from an outlet of a circulating pump and enters an ammonia still system. The separation water serves as the supplemented water, so that a great amount of industrial new water is saved, acid mist carried in coal gas can be absorbed and neutralized by supplementing the trace amount of the NaOH solution, packing supporting of the final cooling tower is prevented, and corrosion prevention of equipment is realized; moreover, part of benzene in the separation water in contact with the coal gas is volatilized, directly enters the coal gas, and reaches a benzene washing tower, and part of light benzene in the separation water is recycled. The process is simple in operation, environmentally-friendly, energy-saving, low in investment cost, and safe and reliable to operate.

Owner:NANJING IRON & STEEL CO LTD

Snow boot processing vamp cleaning device

The invention discloses a snow boot processing vamp cleaning device which comprises a device box. Supporting columns are fixedly connected to the four corners of the top of the device box, a mounting plate is fixedly connected to the tops of the supporting columns, and a driving motor is fixedly connected to the front side of the top of the mounting plate through a support. And an output shaft of the driving motor penetrates through the mounting plate and is fixedly connected with a first gear. The supporting column is used for supporting and fixing the mounting plate so that a machine at the top of the mounting plate can stably operate, the situation that the machine at the top of the mounting plate shakes during operation and influences normal operation of the device is avoided, and the driving motor, the first gear, a rotating column and a second gear are used for driving a cleaning brush plate to rotate; and the vamps can be brushed through the cleaning brush plate so that impurities and dust on the vamps can be cleaned, and the situation that the follow-up bonding quality of the vamps is affected by the impurities and dust attached to the vamps is avoided.

Owner:杭州雪履科技有限公司

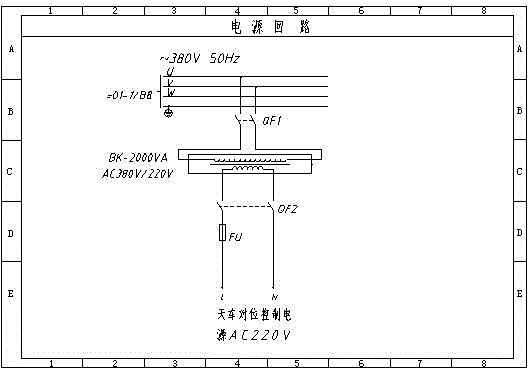

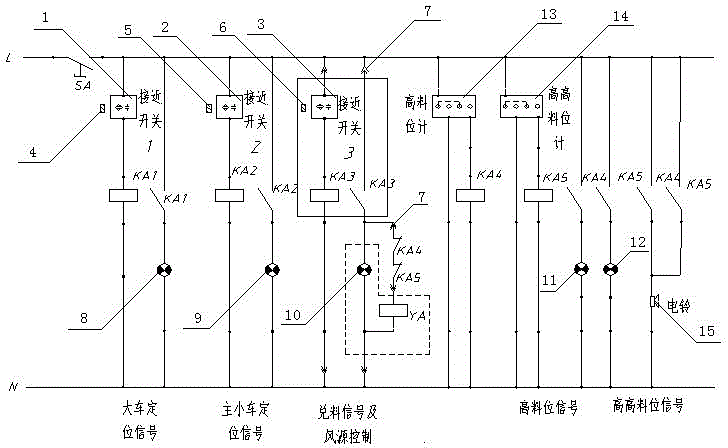

Automatic material blending control device for aluminum electrolytic bath

The invention relates to the technical field of aluminum electrolysis and particularly relates to an automatic material blending control device for an aluminum electrolytic bath. The automatic material blending control device comprises a cart locating proximity switch, a main trolley locating proximity switch, a material blending locating proximity switch, a cart locating indicator, a main trolley locating indicator, a material blending locating indicator, an aviation plug, a cart locating indication lamp, a main trolley locating indication lamp, a material blending locating indication lamp, a first material level indication lamp, a second material level indication lamp, a first material level gage, a second material level gage and an electric bell. The automatic material blending control device for the aluminum electrolytic bath has the advantages that the problems of automatic multifunctional crane cart locating, automatic main trolley aluminum oxide silo locating, automatic material blending process control, automatic material level monitoring and the like are solved, so that an automatic multifunctional crane material blending control process for aluminum electrolysis is realized; the automaticity and reliability of locating are realized; the automatic material blending process control is realized; the automatic material level indication and alarming of a crane silo are realized; and the labor intensity of operating workers is reduced, and the production cost is lowered.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Retraction structure for safety syringe

InactiveCN101927048BImprove practical progressEasy retraction actionInfusion syringesInfusion needlesSyringe needleSafety syringe

The invention provides a retraction device for a safety syringe, in particular a creative design that a syringe needle bed is stably positioned at an opening end of a barrel. A borrow locking device and a retraction embedded linkage device are arranged between needle beds mutually. Due to the creative and unique design, a pull rod head of a pull rod can be rapidly clamped to be positioned on a needle bed group by means of the borrow locking device and the retraction embedded linkage device so as to provide convenience for a user to perform the next retraction action. Meanwhile, the needle bedgroup can be stably assembled and positioned at the opening end of the barrel and hardly makes clamping and sealing functionally damaged due to external temperature change. For example, the clamping degree between the needle bed and the barrel is reduced due to steep temperature rise so as to cause the inner retraction or leakage of the needle bed in the injection process, or the needle bed and the barrel are excessively clamped due to steep temperature reduction, and the injection needle cannot retract after injection and the needle bed enters the barrel, and the like. Therefore, the retraction device for the safety syringe can improve the safety and environmental protection quality.

Owner:张淑茗

A regenerative braking energy feedback system

ActiveCN108215806BReduce wasteQuality improvementElectrodynamic brake systemsAc-dc conversionRegenerative brakeControl engineering

The invention discloses a regenerative braking energy feedback system. The system comprises diode rectifiers, energy feedback modules, detection loop devices and control circuit devices, a group of energy feedback modules are connected with a group of diode rectifiers in anti-parallel, the energy feedback modules are connected with the detection loop devices, and the detection loop devices are also connected with the control circuit devices. The system can leave out an additional boost transformer for controlling braking energy, effectively reduce cost, reduce energy waste, and improve environmental protection quality.

Owner:NINGBO JIANGBEI GOFRONT HERONG ELECTRIC

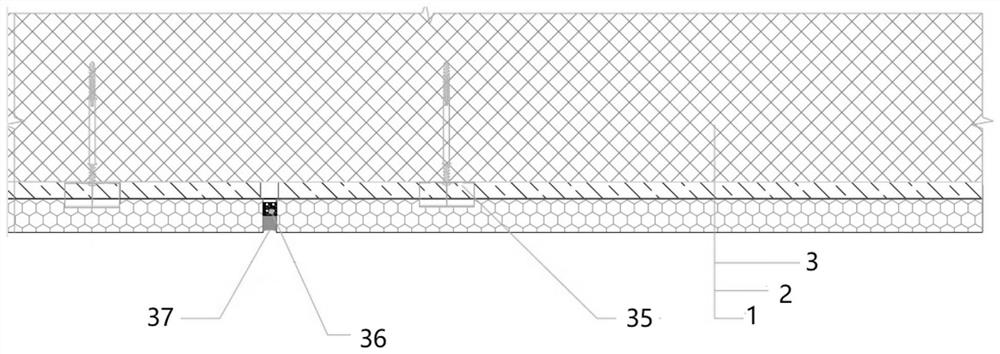

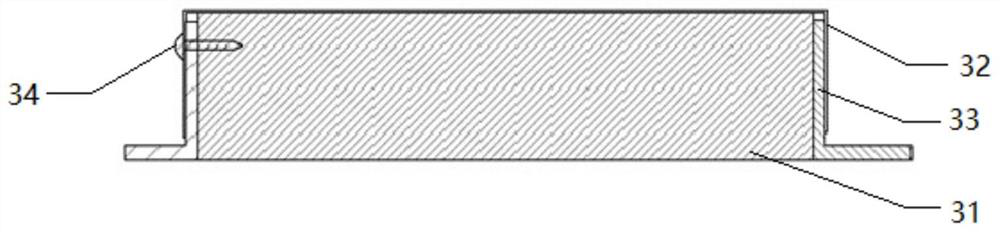

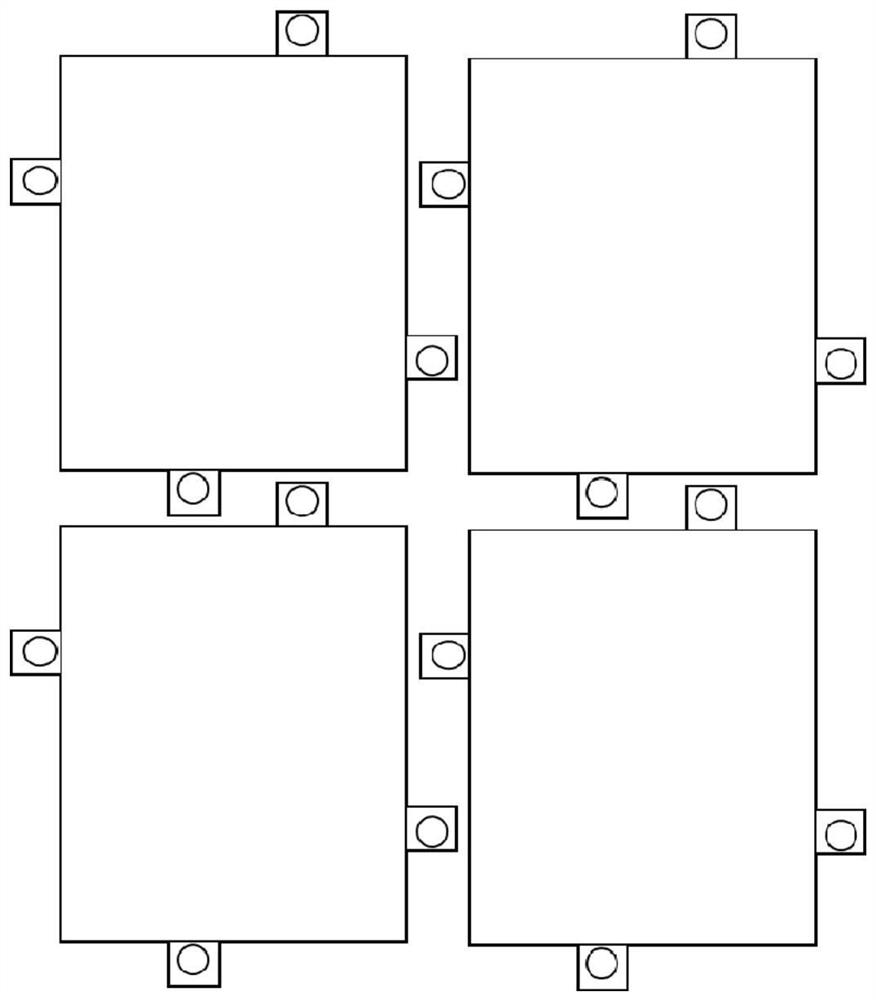

A fire-proof decoration integrated fire-proof isolation belt

The present invention provides a new type of integrated fire protection isolation belt for fire protection decoration, which is laid on the building exterior wall (1), corresponding to the height area of the floor slab between floors, and is in the shape of a belt surrounding the wall, extending from the building exterior wall (1) to the The outer layer includes a bonded mortar layer (2) and a fireproof insulation board layer (3) in sequence, and fireproof insulation boards are closely arranged in the fireproof insulation board layer (3), and the fireproof insulation board includes a heat preservation board (31), a cover layer (32) And L-shaped fixture (33), cover layer (32) is a metal plate, and insulation board (31) is the fireproof insulation board that glass fiber and water-soluble phenolic resin prepare. The fireproof isolation board layer in the fireproof isolation belt of the present invention can be prefabricated, which reduces the difficulty of on-site construction. The adhesive mortar layer covers the outer wall in an all-round way, the structure design of the fireproof isolation board and the new insulation board improve the fireproof performance. Compared with the existing The fireproof isolation system of the present invention has the advantages of simple structure, convenient construction, good fireproof and thermal insulation performance, and is beneficial to popularization in the construction field.

Owner:BEIJING SATELLITE MFG FACTORY

A gas purification device for domestic waste flash mineralization processor

ActiveCN104815503BImprove processing efficiencyQuality improvementCombination devicesPtru catalystActivated carbon filtration

The invention relates to a gas purification device for a domestic garbage flash mineralization processor. The processor includes a box body and a chimney. The box body is a closed rectangular box structure composed of an upper top plate, a side vertical plate and a bottom plate, wherein the upper top plate It is an upper arch, and a dome-shaped smoke holder is made in the center of the upper roof, and the gas mixing pipe of the chimney is fixed on the dome-shaped smoke holder. A gas purification device is fixed on the upper top plate of the side of the seat, and the total air inlet pipe and the total gas outlet pipe of the gas purification device are respectively communicated with the gas mixing pipe, and are fixed on the upper and lower gas mixing pipes of the gas mixing pipe cut-off gate. The present invention can strengthen the circulation of smoke and dust through the set external power, and can also carry out catalyst filtration, water filtration, purification agent filtration, activated carbon filtration and automatic prompting for replenishment and drainage, which greatly improves the purification level of the gas and ensures Environmental quality of the exhaust.

Owner:苑忠宝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com