Linear feeding method for aluminum electrolysis flue gas purification system

A flue gas purification system and aluminum electrolysis technology, which is applied in the field of aluminum electrolysis and alumina feeding, can solve the problems of large amount of alumina damage, poor alumina powder fluidity, and poor use effect, so as to reduce pollutant emissions and increase reaction Time, the effect of improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

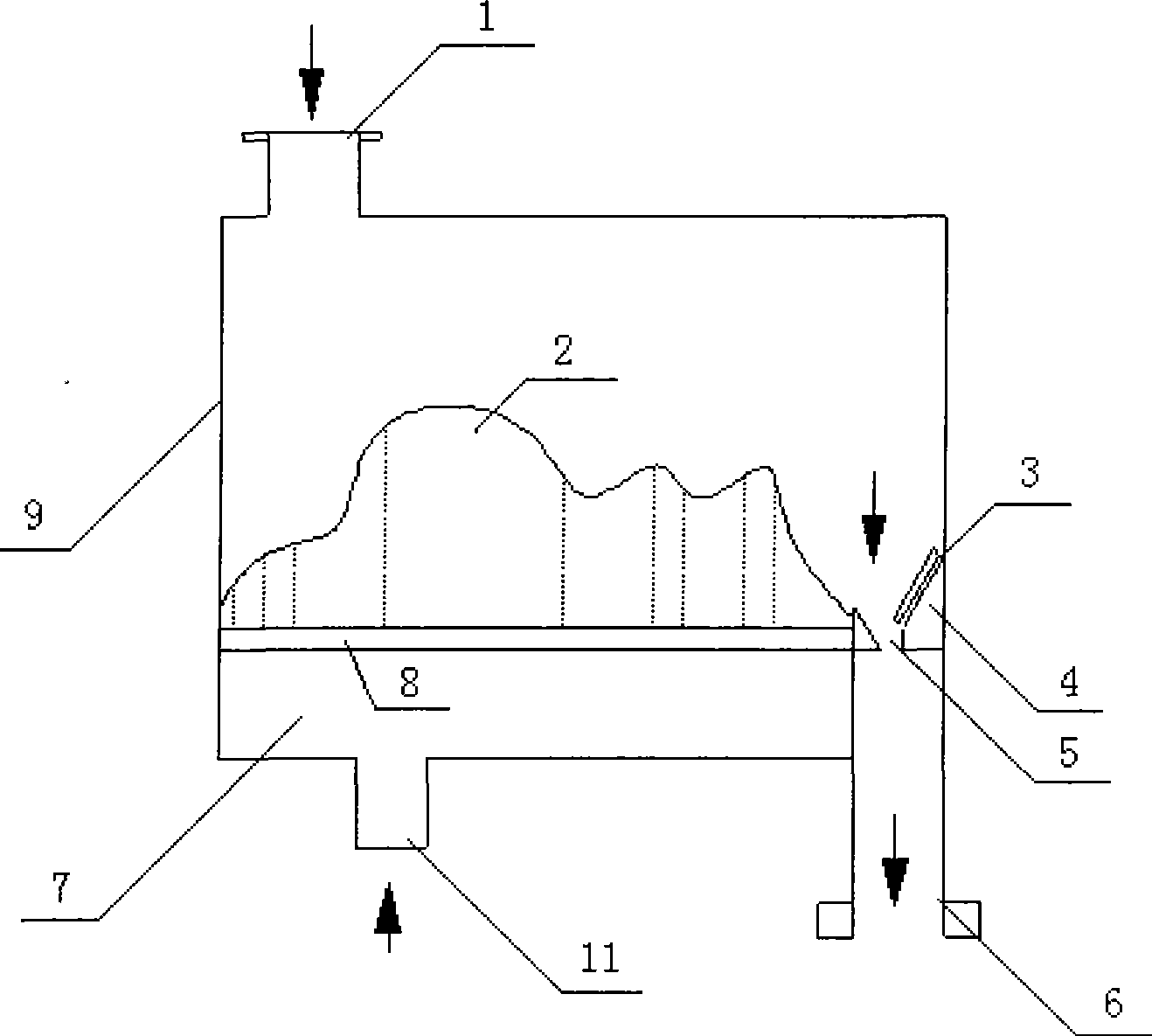

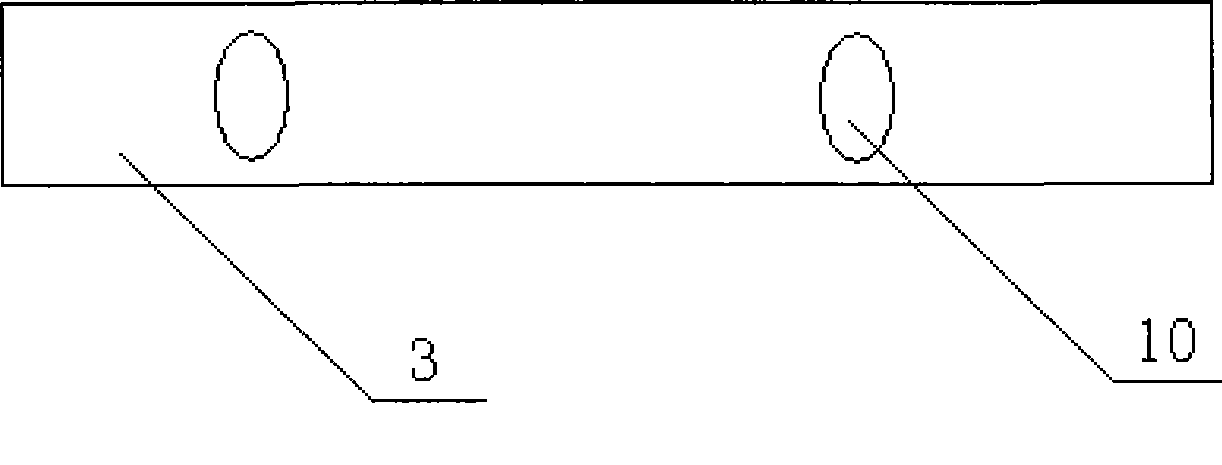

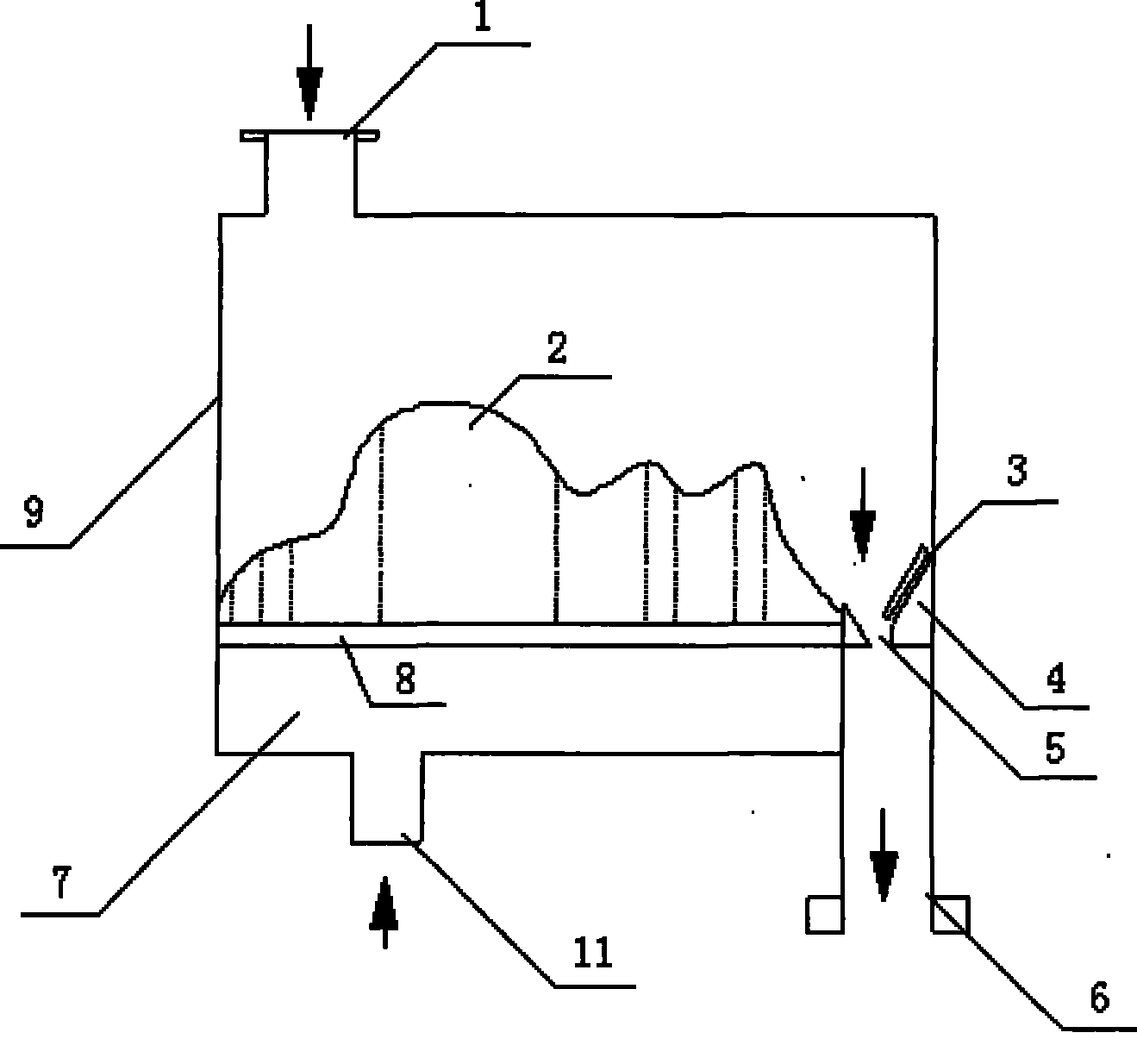

[0024] Made of steel plate as figure 1 In the box-type material chamber 9 shown, the feed inlet 1 is arranged on one side of the top of the material chamber 9 and is connected with the alumina delivery pipeline; the fluidized bed 8 is made of a breathable nylon plate, and the fluidized bed 8 is passed through the pressure iron and Bolts are horizontally fixed on the lower side wall of the material chamber 9 and the fluidized bed 8 is inclined 5° towards the direction of the discharge port 5. A long discharge port 5 is left on one side of the underground flue 6 in the material chamber 9. The discharge port 5 The side wall of the material chamber 9 is provided with an adjusting plate base 4, and the adjusting plate base 4 is fixed with an adjusting plate 3 by bolts; the adjusting plate 3 is a rectangular plate made of a steel plate, and the adjusting plate 3 is provided with a long hole adjusting hole 10. The adjustment distance of the adjustment hole 10 is 10mm, such as figur...

Embodiment 2

[0027] Made of steel plate as figure 1 In the box-type material chamber 9 shown, the feed inlet 1 is arranged on one side of the top of the material chamber 9 and is connected with the alumina delivery pipeline; the fluidized bed 8 is made of a breathable nylon plate, and the fluidized bed 8 is passed through the pressure iron and Bolts are horizontally fixed on the lower side wall of the material chamber 9 and the fluidized bed 8 is inclined 8° towards the direction of the discharge port 5. A long discharge port 5 is left on one side of the underground flue 6 in the material chamber 9. The discharge port 5 The side wall of the material chamber 9 is provided with an adjusting plate base 4, and the adjusting plate base 4 is fixed with an adjusting plate 3 by bolts; the adjusting plate 3 is a rectangular plate made of a steel plate, and the adjusting plate 3 is provided with a long hole adjusting hole 10. The adjustment distance of the adjustment hole 10 is 10mm, such as figur...

Embodiment 3

[0030] Made of steel plate as figure 1In the box-type material chamber 9 shown, the feed inlet 1 is arranged on the top side of the material chamber 9 and is connected with the alumina delivery pipeline; the fluidized bed 8 is made of a breathable nylon plate, and the fluidized bed 8 is passed through the pressure iron and Bolts are horizontally fixed on the lower side wall of the material chamber 9 and the fluidized bed 8 is inclined 10° towards the direction of the discharge port 5. A long discharge port 5 is left on one side of the underground flue 6 in the material chamber 9. The discharge port 5 The side wall of the material chamber 9 is provided with an adjustment plate base 4, and the adjustment plate base 4 is fixed with an adjustment plate 3 by bolts; the adjustment plate 3 is a rectangular plate made of a steel plate, and the adjustment plate 3 is provided with a long hole adjustment hole 10. The adjustment distance of the adjustment hole 10 is 10mm, such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com