Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Improve production line capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thick-specification pipeline steel and low-compression-ratio production process thereof

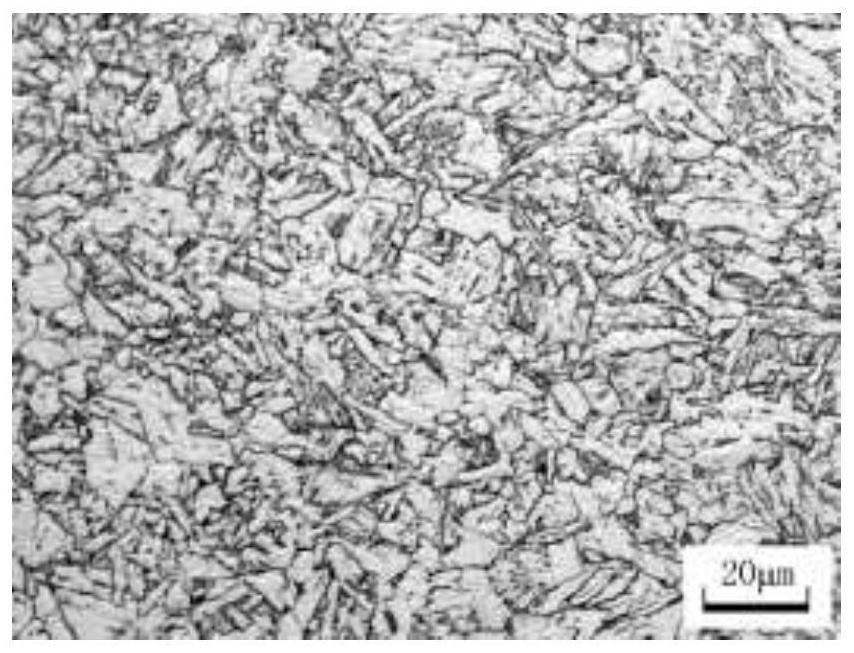

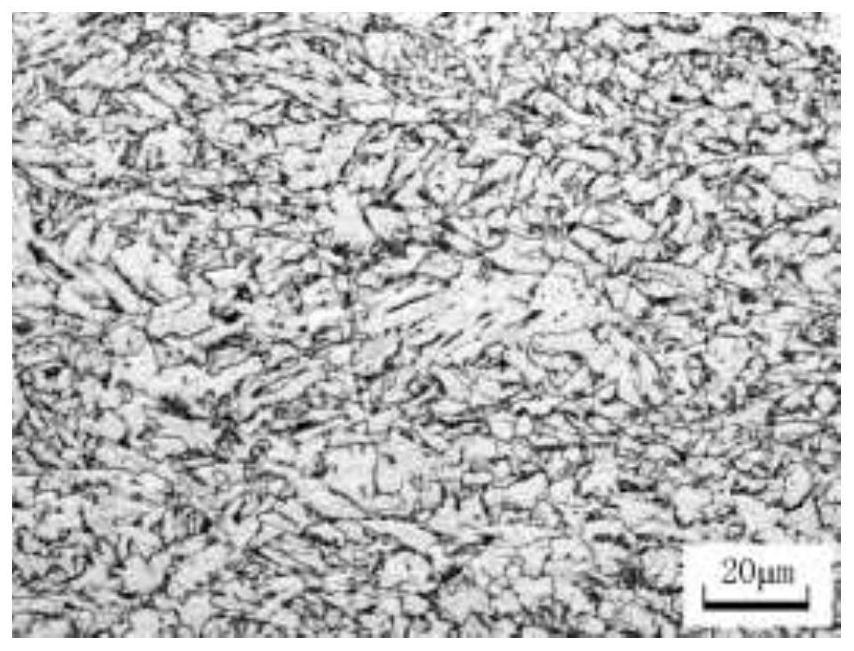

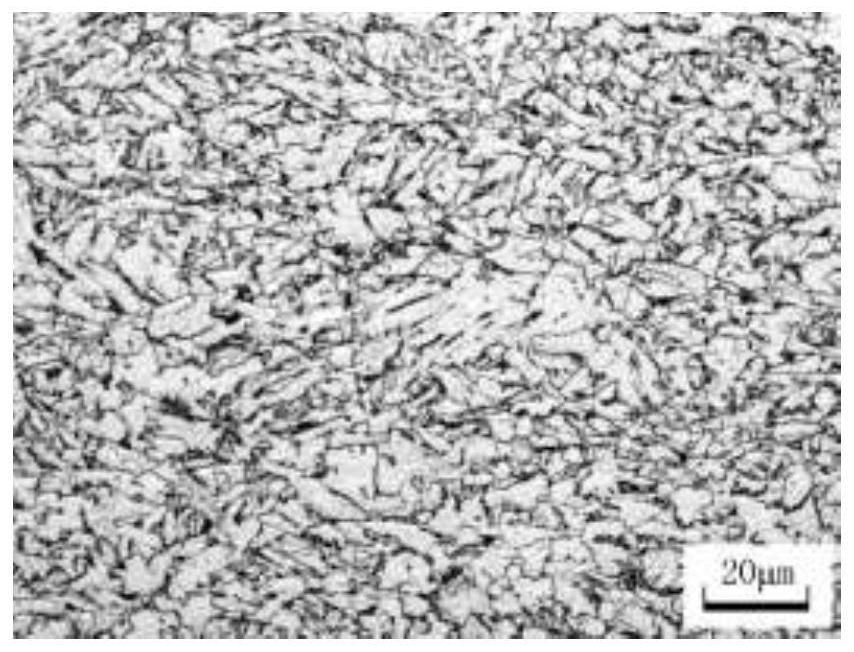

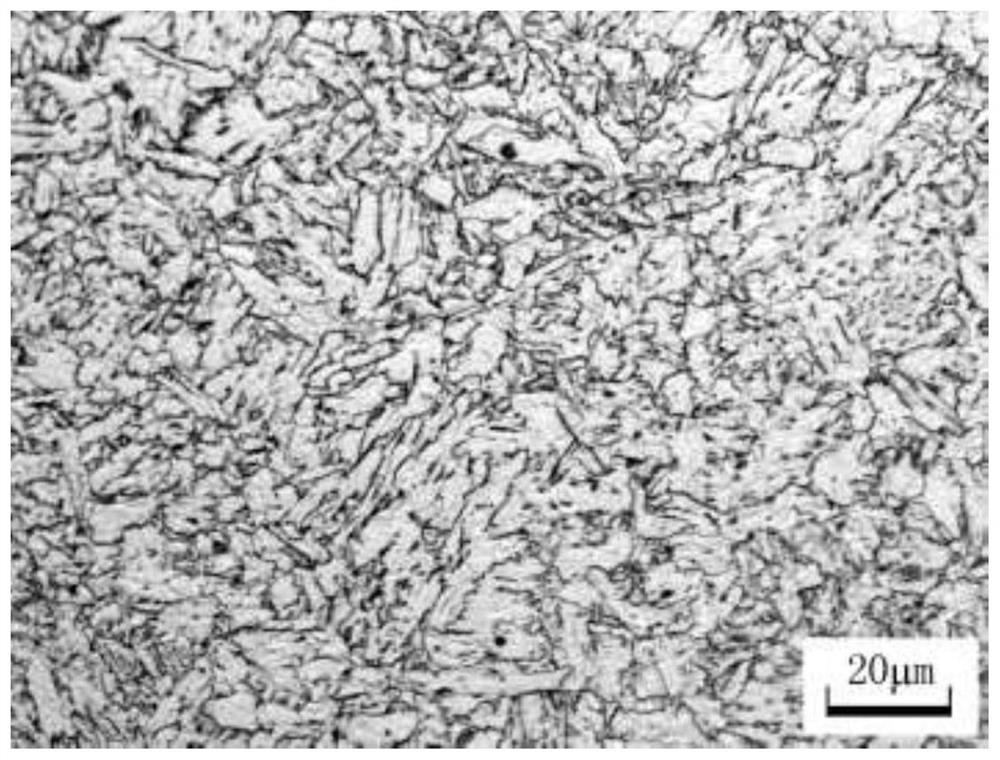

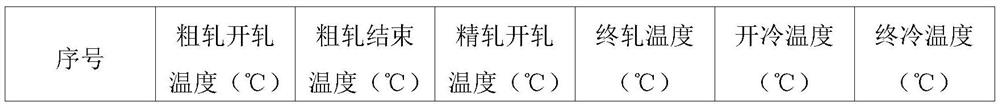

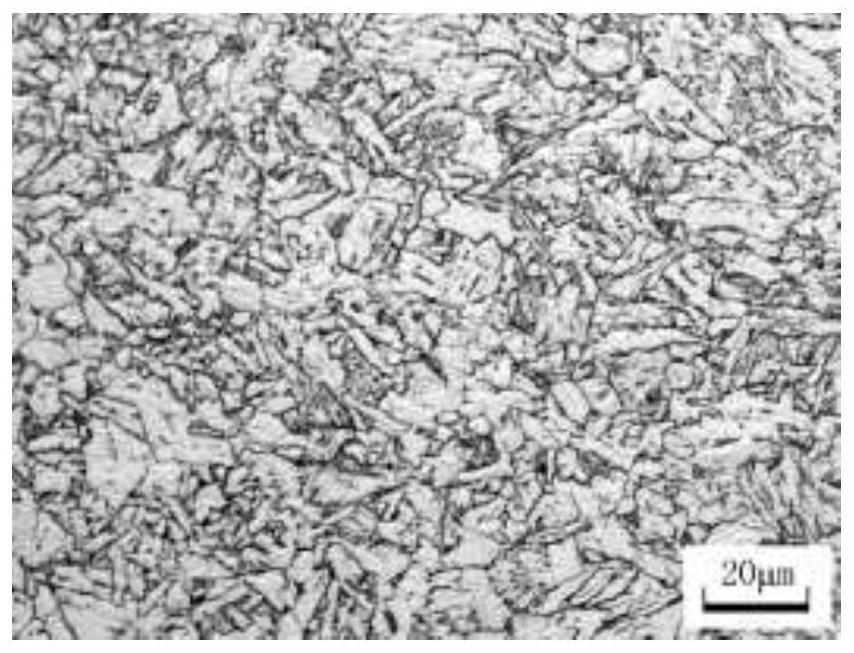

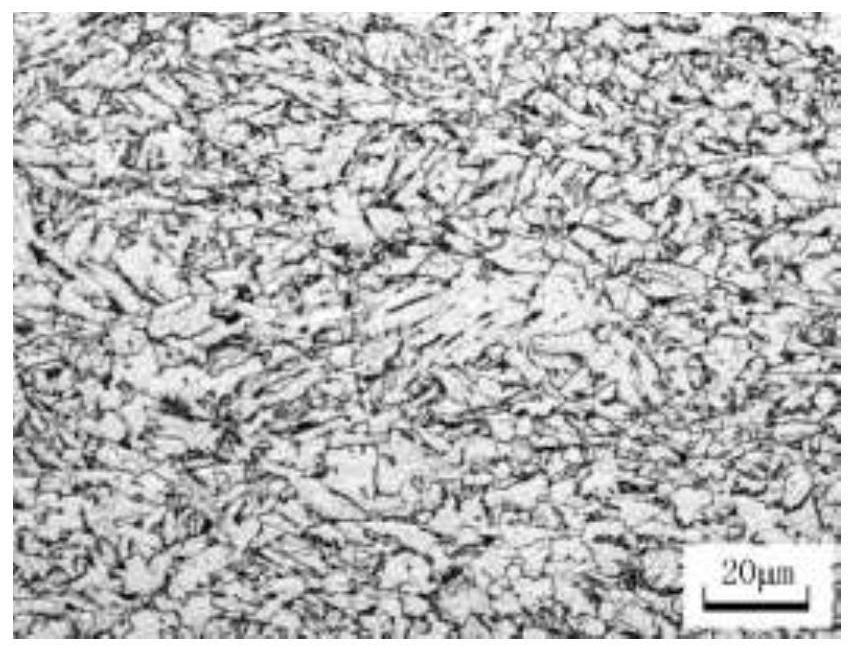

The invention discloses low-compression-ratio thick-specification pipeline steel which consists of the following chemical components in percentage by mass: 0.03-0.07% of C, 0.10-0.30% of Si, 1.1-1.6%of Mn, 0.1-0.3% of Cr, 0.1-0.4% of Ni, 0.10-0.25% of Mo, 0.04-0.07% of Nb, less than or equal to 0.03% of V, 0.01-0.025% of Ti, 0.01-0.045% of Al, and 0.002-0.0022% of Mg. The thick-specification pipeline steel is prepared from clean steel smelting, continuous casting, casting blank heating, three-stage controlled-rolling, and a super-quick cooling process. A matrix structure of an obtained steelplate is granular bainite and acicular ferrite, has better strength toughness matching and a low yield ratio, is excellent in HIC and SSCC acidic corrosion resistance, and can meet service technical requirements of pipeline steel with thickness specification yield strength greater than or equal to 485 MPa, and an anti-acid pipeline.

Owner:武汉钢铁有限公司

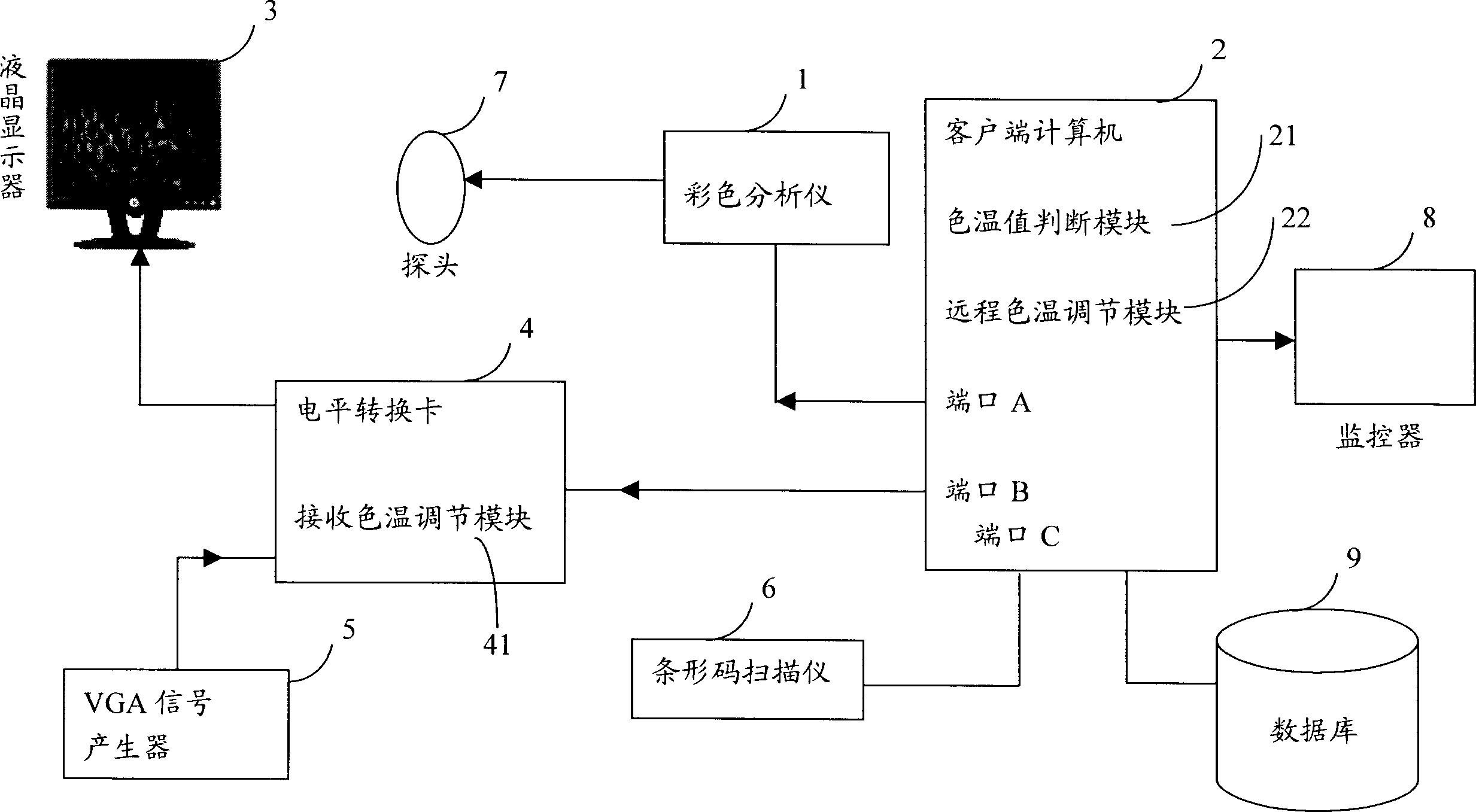

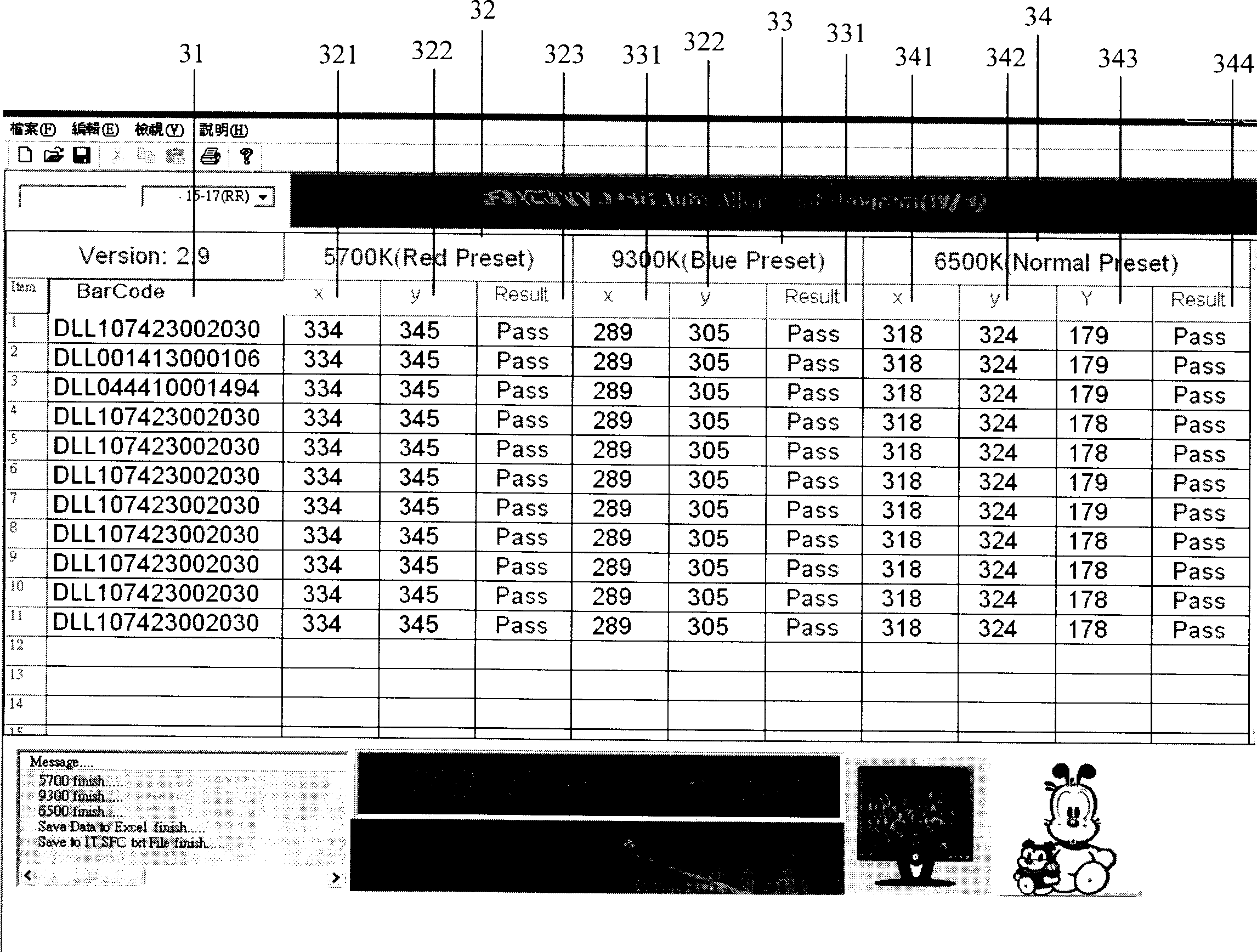

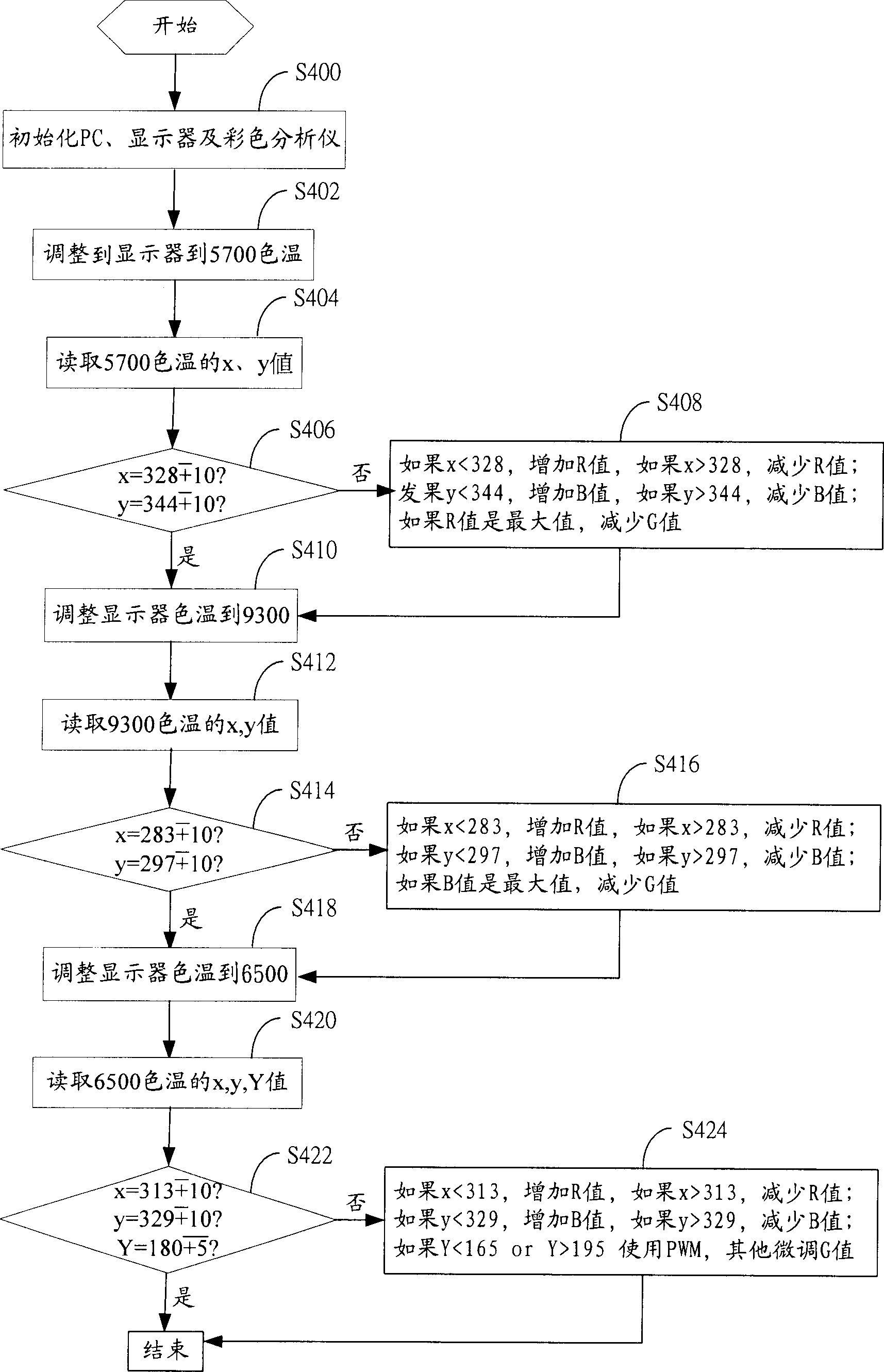

Liquid crystal display colour-temp. automatic regulation systemand method

InactiveCN1710638AImprove production line capacityStatic indicating devicesTransceiverLiquid-crystal display

The system includes following parts: multiple liquid crystal display (LCD) to be carried out color temperature adjustment, color analyzer for converting displayed frame to specific value of color temperature, VGA signal generator for supplying normal full white frame, and a PC for analyzing information and adjusting color temperature of LCD. Probe of the color analyzer is reached to central position of LCD to be tested, and present information of color temperature is transferred to the color analyzer. Through RS-232 asynchronous transceiver, communication program at bottom layer executes data exchange and communication between LCD and PC. Data are stored in electronic spreadsheet for convenient to carried out data statistics, saving operation time and raising efficiency.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

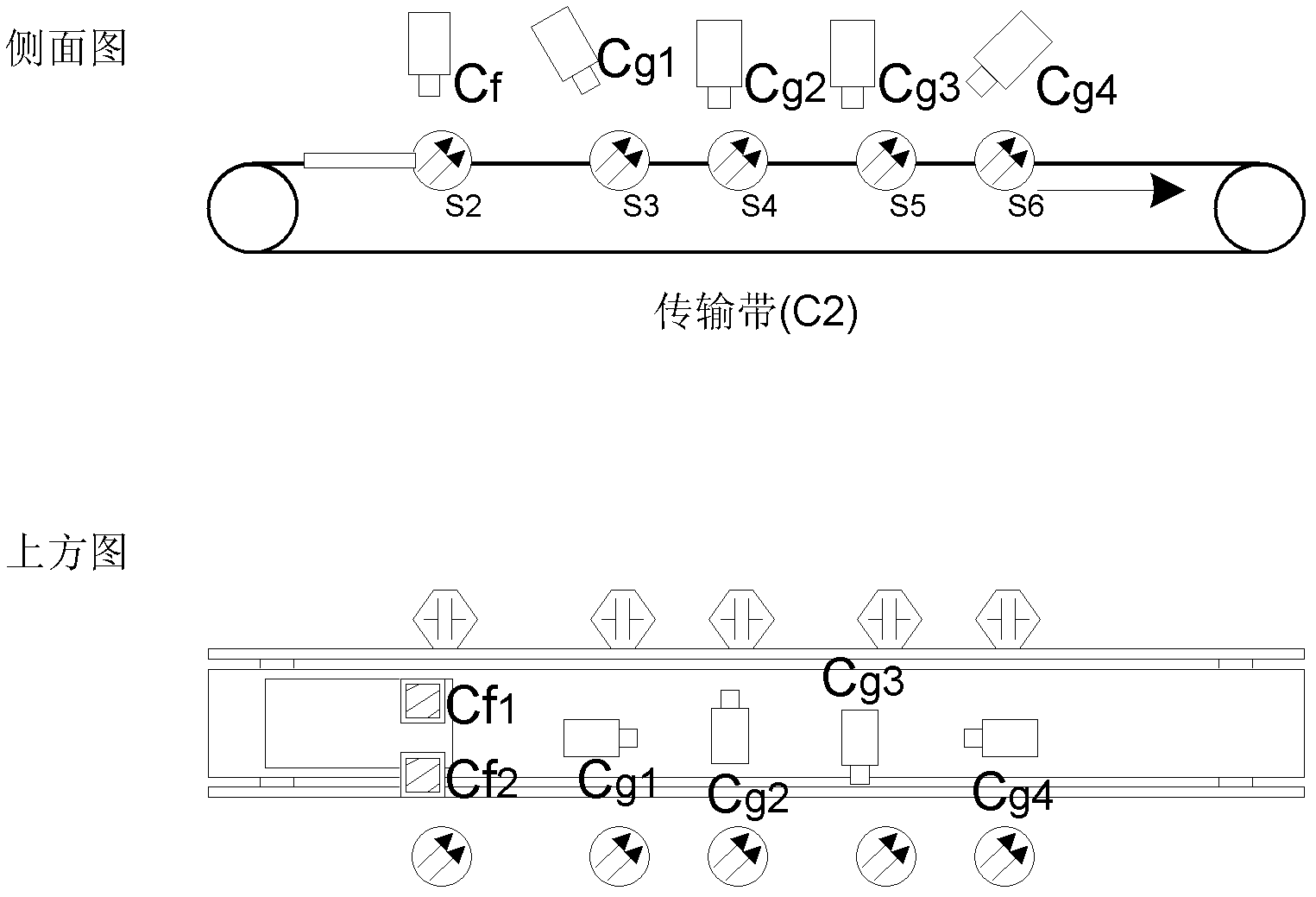

Detection device and method for appearance and assembly of electric paper book based on machine vision

ActiveCN102353683AEnsure clarity and completenessGuaranteed infallibilityOptically investigating flaws/contaminationMachine visionEconomic benefits

The invention discloses a detection device for apparent defects and an assembly of an electric paper book. Three-section type online detection is adopted in the detection process of the device and back side detection of a product is carried out in a gap of the sections; and detection for the requirements on pollution, scratches, missing parts, assembly errors and the like is carried out by detection software based on a pattern recognition algorithm. According to the electric paper book detection device defined by the invention, the position of the electric paper book is transmitted to a camera through a sensor to trigger and collect images; and then background analysis is carried out according to the collected images. The design of the device guarantees an automatic flow of the detection process and the detection state can be monitored; and then products can be processed by a qualified / unqualified classification according to a detection result. By using the electric paper book detection device disclosed by the invention, objective and accurate detection can be obtained. In addition, the operation of the device is convenient and easy to understand and the defects of the electric paper book can be accurately detected without professional skills, so that careless mistakes caused by the judgment of artificial subjective factors can be effectively prevented and the detection deviceis good for improving the work efficiency of staff and the economic benefits of enterprises.

Owner:苏州优纳科技有限公司

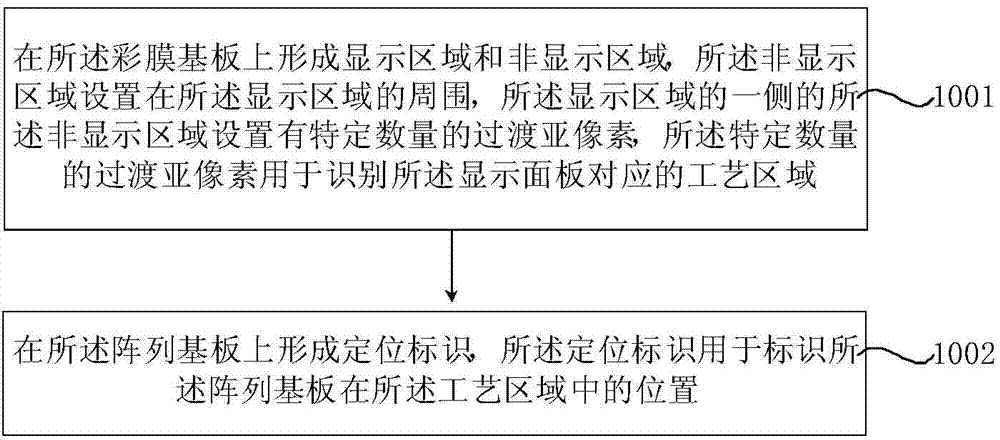

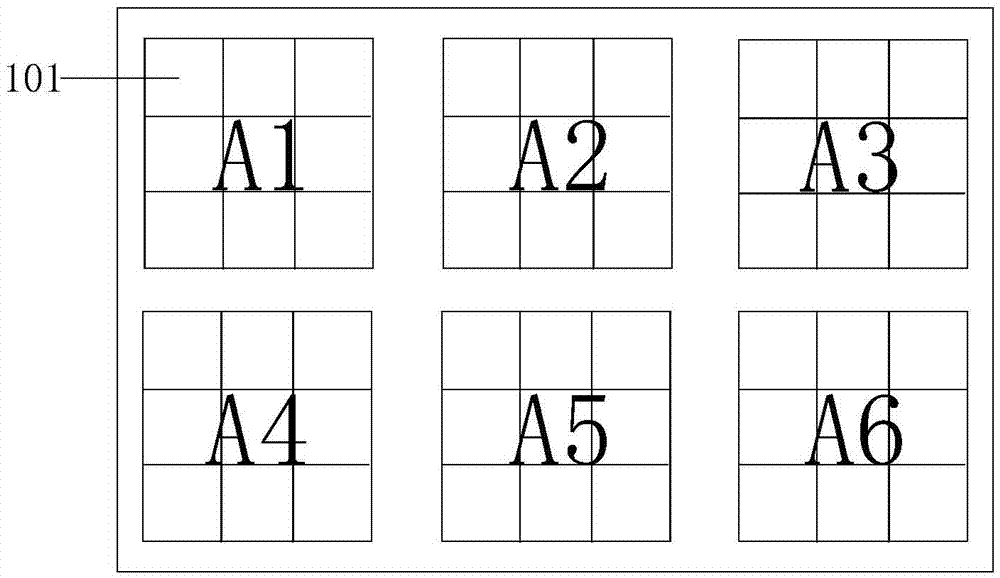

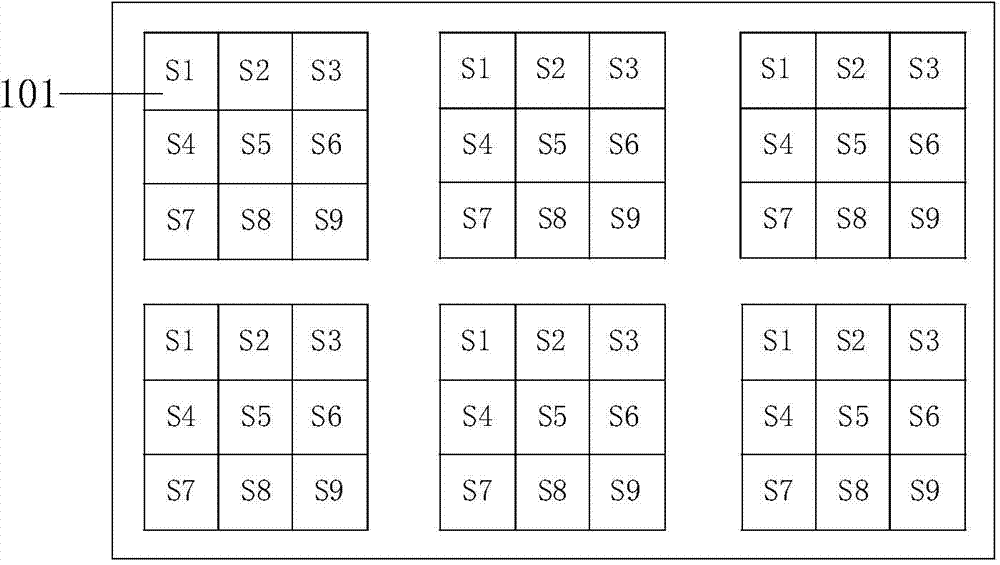

Display panel motherboard and preparation method thereof

ActiveCN104778904ARealize identificationOptimizing the Design SpaceSemiconductor/solid-state device detailsSolid-state devicesProduction lineColor film

The invention discloses a display panel motherboard and a preparation method thereof. The display panel motherboard comprises multiple process areas, each process area comprises multiple display panels, and each display panel comprises a color film substrate and an array substrate which are oppositely arranged. According to the technical scheme, the method comprises the steps that the process area to which each display panel belongs is determined through a specified amount of transition subpixels of a non-display area at one side of the display area of the color film substrate, the specific location of a display panel in the process area to which the display panel belongs is judged through a positioning mark on the array substrate, and therefore recognition of the display panels is achieved, the production line capacity is improved, and meanwhile design space of the peripheral zone of a display screen is optimized.

Owner:HEFEI BOE OPTOELECTRONIC TECH CO LTD +1

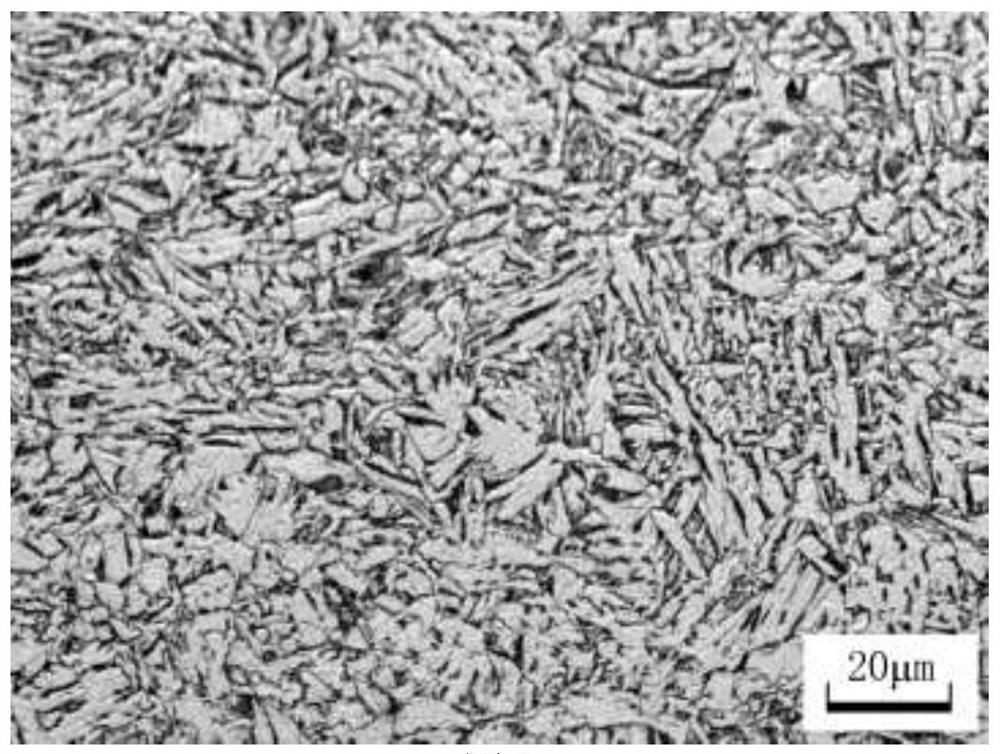

Extra-thick wall X70-grade ocean acid-resistant pipeline steel and preparation method thereof

ActiveCN111748742AImprove toughnessExcellent resistance to hydrogen sulfide corrosionThick wallToughness

The invention discloses extra-thick wall X70-grade ocean acid-resistant pipeline steel. Chemical components of the extra-thick wall X70-grade ocean acid-resistant pipeline steel comprise, by mass percent, 0.03%-0.05% of C, 0.10%-0.30% of Si, 1.0-1.3% of Mn, 0.2%-0.3% of Cr, 0.2%-0.4% of Ni, 0.10%-0.20% of Mo, 0.04%-0.07% of Nb, 0.03%-0.05% of V, 0.01%-0.02% of Ti, 0.01%-0.045% of Al and the balance Fe. The matrix structure of the obtained steel is granular bainite / acicular ferrite and a small quantity of small-size quasi-polygonal ferrite, high strength, high toughness, hydrogen sulfide corrosion resistance and stress corrosion resistance are all achieved well, and the technical index requirements of X70 MOSs with the thickness being 25 mm or above are met; and the involved preparation process is simple, energy consumption is low, and the steel is suitable for application and popularization.

Owner:武汉钢铁有限公司

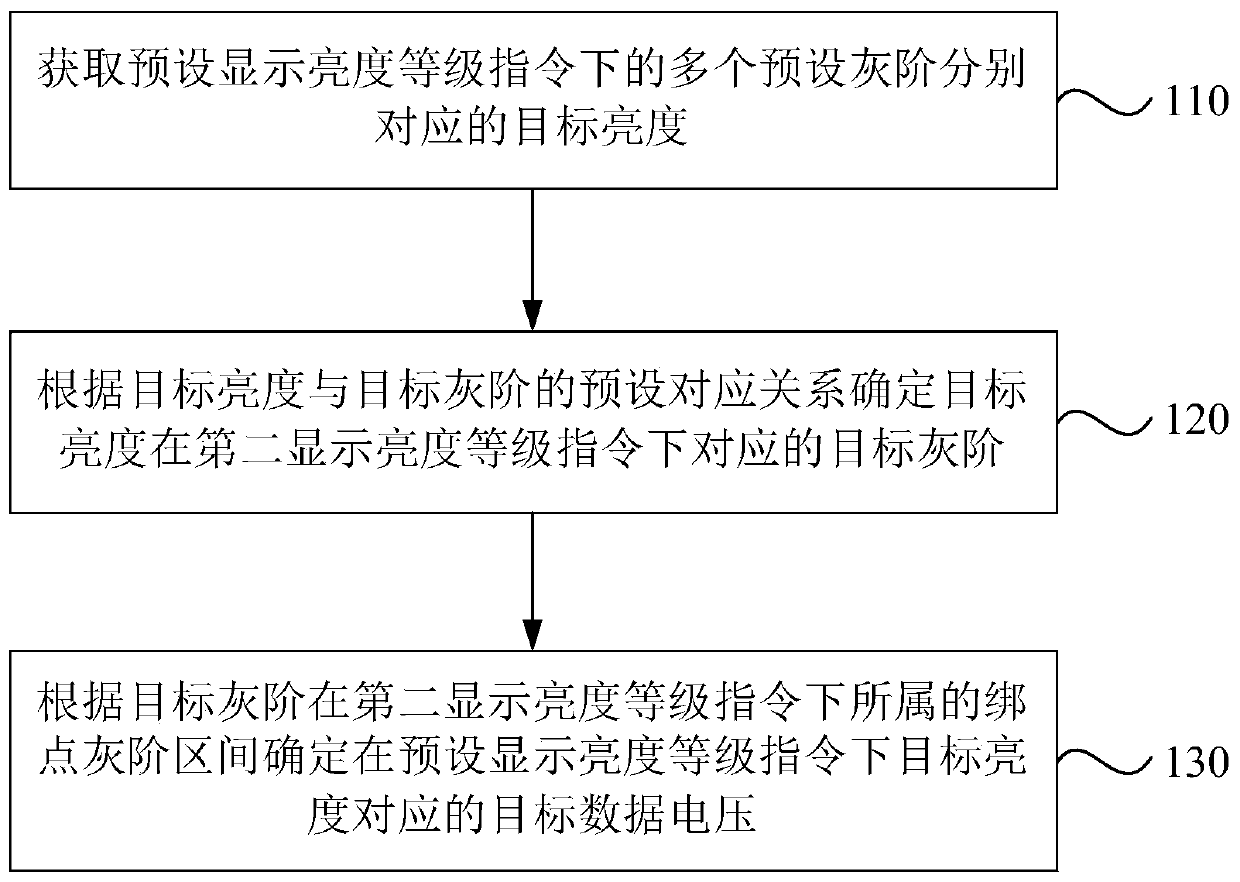

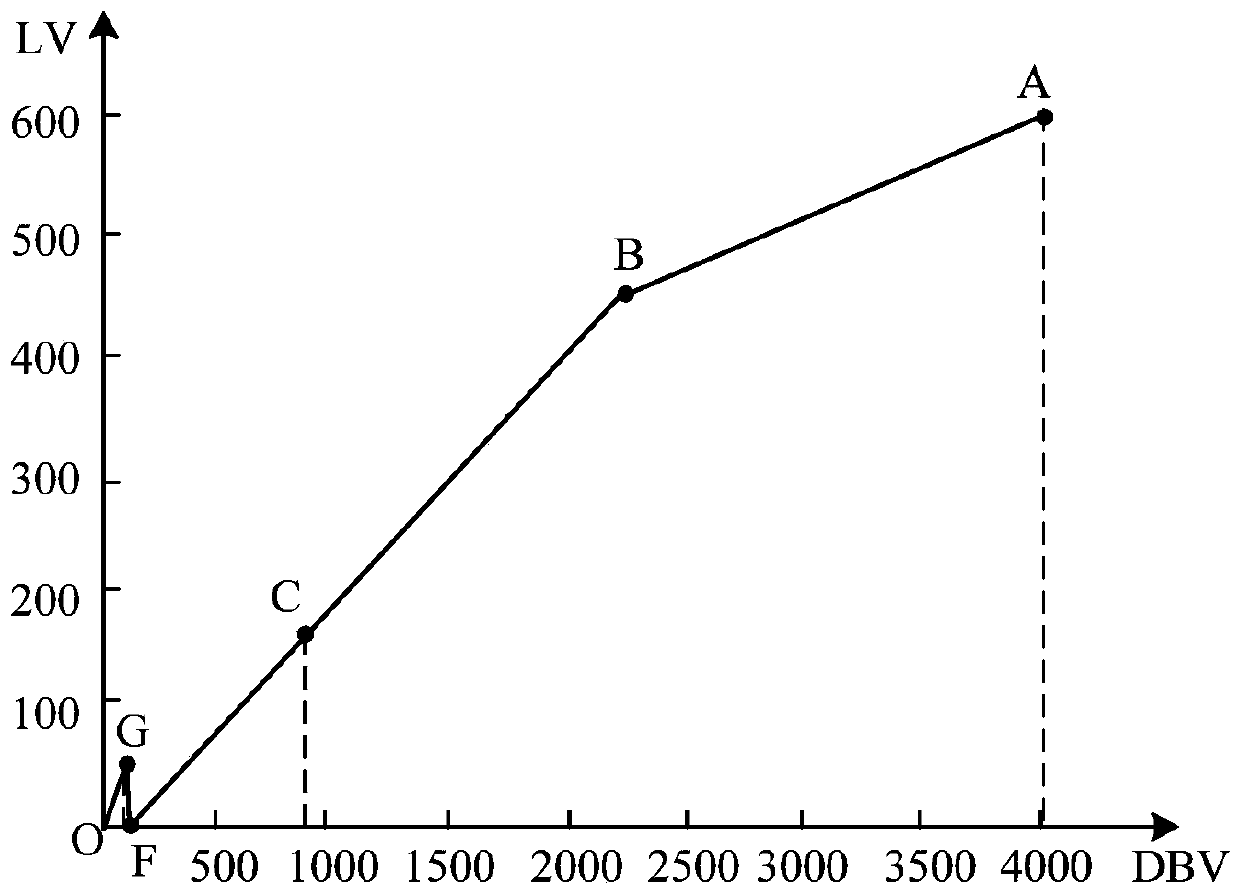

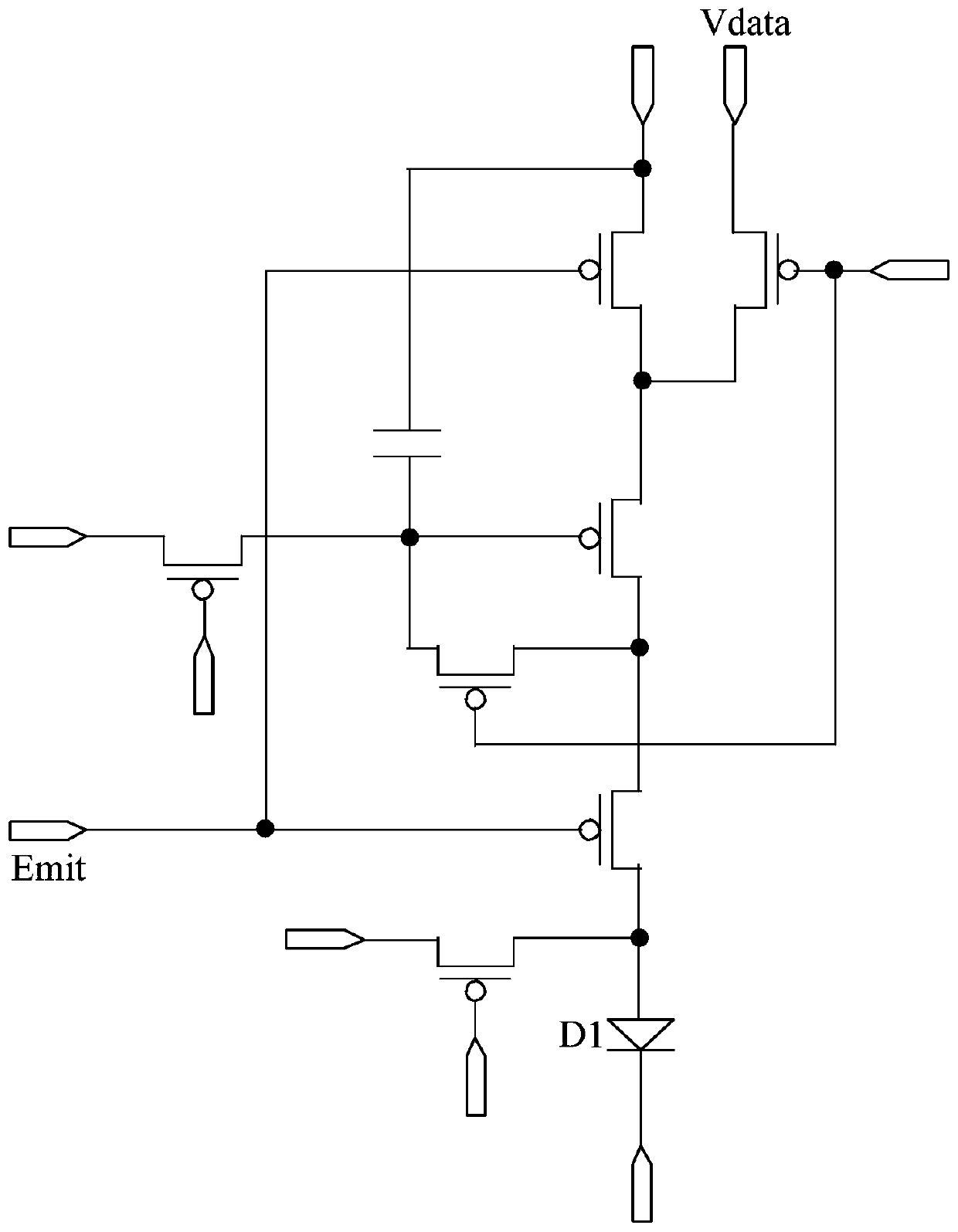

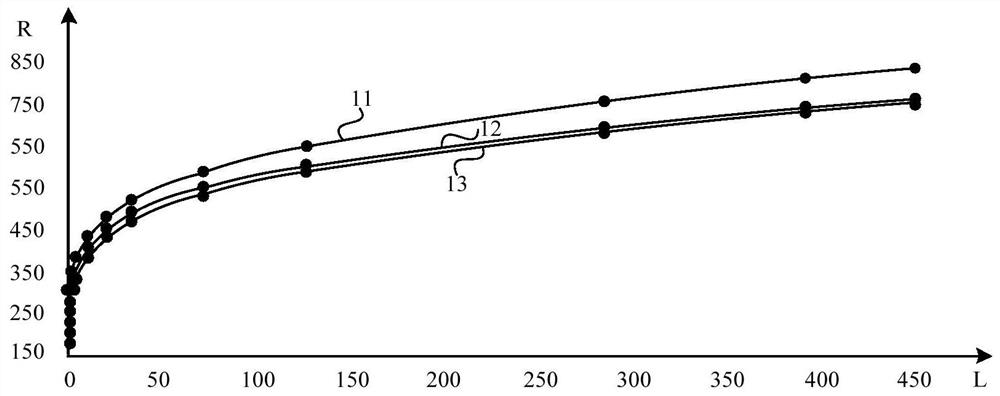

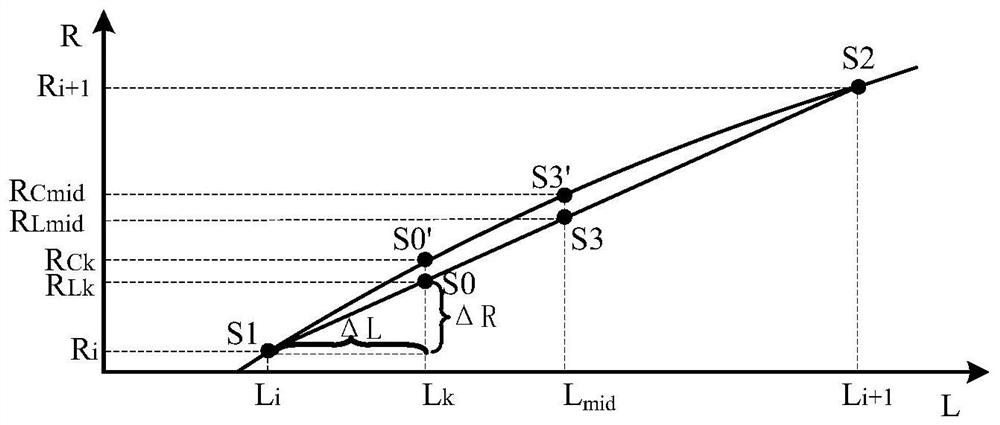

Display panel gamma adjustment method and device

ActiveCN111508414AShorten burn timeImprove production line capacityCathode-ray tube indicatorsEngineeringGrey level

The invention discloses a display panel gamma adjustment method and a display panel gamma adjustment device. The display panel gamma adjustment method is characterized by acquiring target brightness corresponding to a plurality of preset gray scales under a preset display brightness level instruction; determining a target gray scale corresponding to the target brightness under a second display brightness level instruction according to a preset corresponding relationship between the target brightness and the target gray scale; and determining a target data voltage corresponding to the target brightness under the preset display brightness level instruction according to a binding point gray scale interval to which the target gray scale belongs under the second display brightness level instruction. A group of gamma voltages under any preset display brightness level instruction in a data voltage dimming interval can be calculated according to a group of gamma voltages under a maximum display brightness level instruction in the data voltage dimming interval; only gamma debugging needs to be carried out under the maximum display brightness level instruction to obtain a group of gamma voltages under the maximum display brightness level instruction in one data voltage dimming interval, so that the time of gamma debugging and gamma voltage burning can be shortened, and the productivity of a production line is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

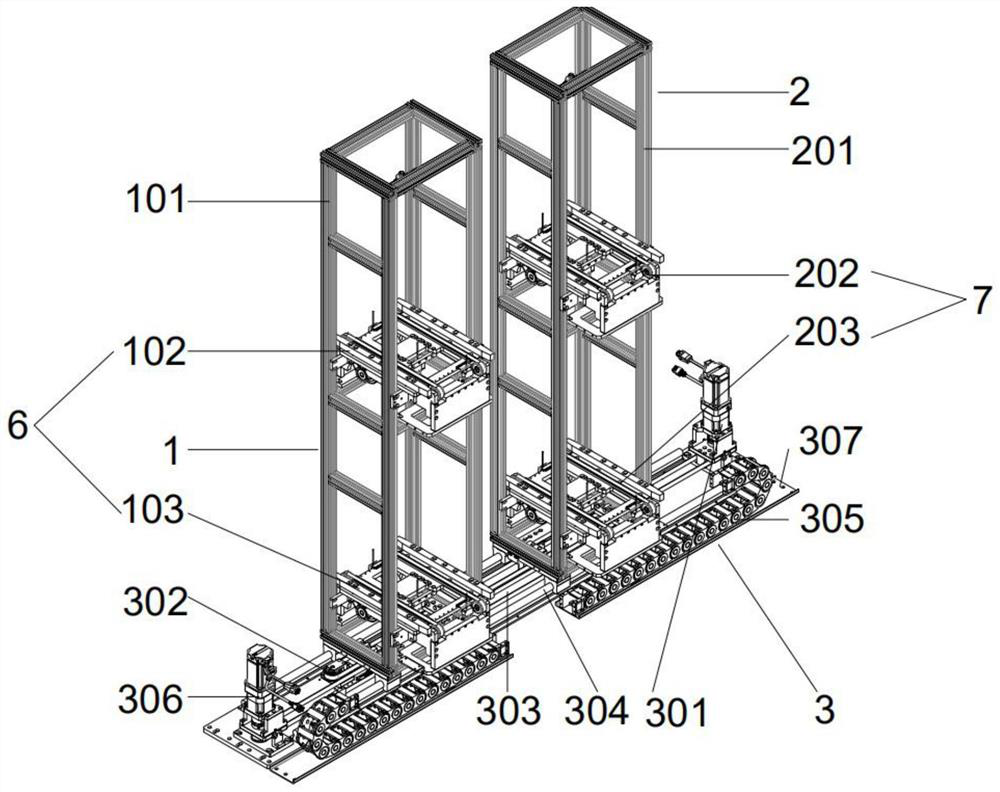

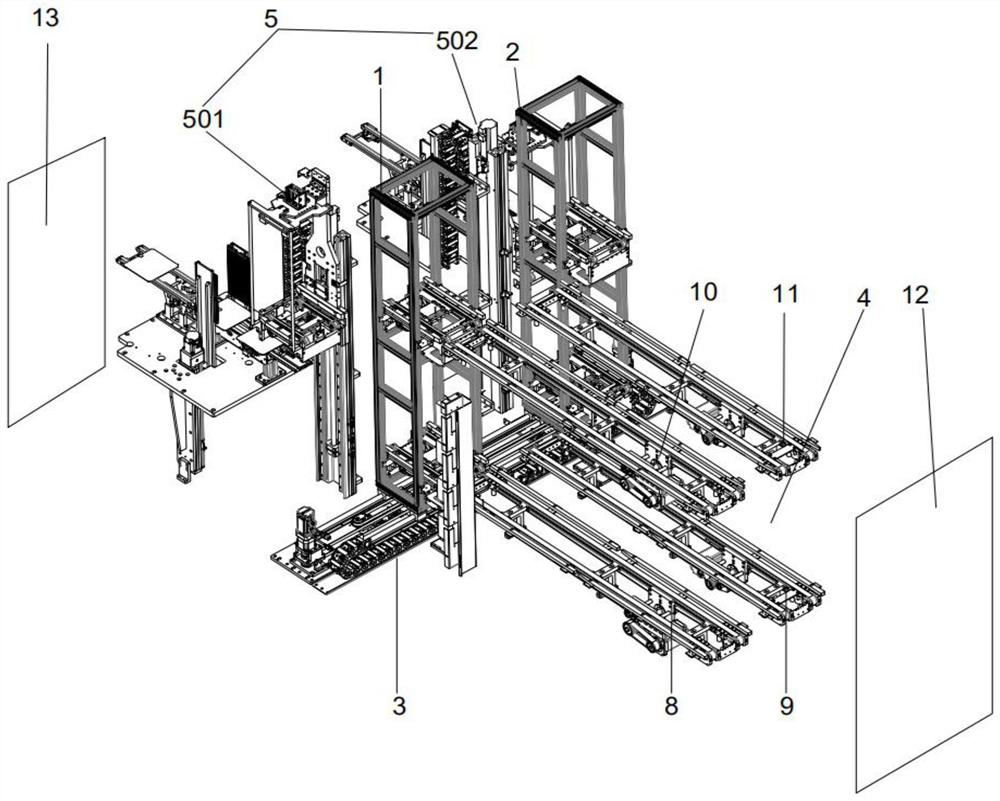

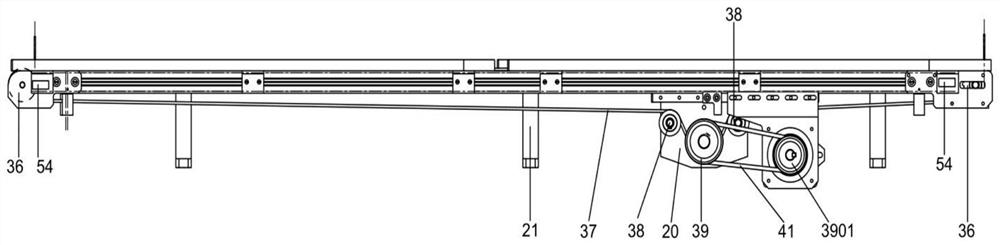

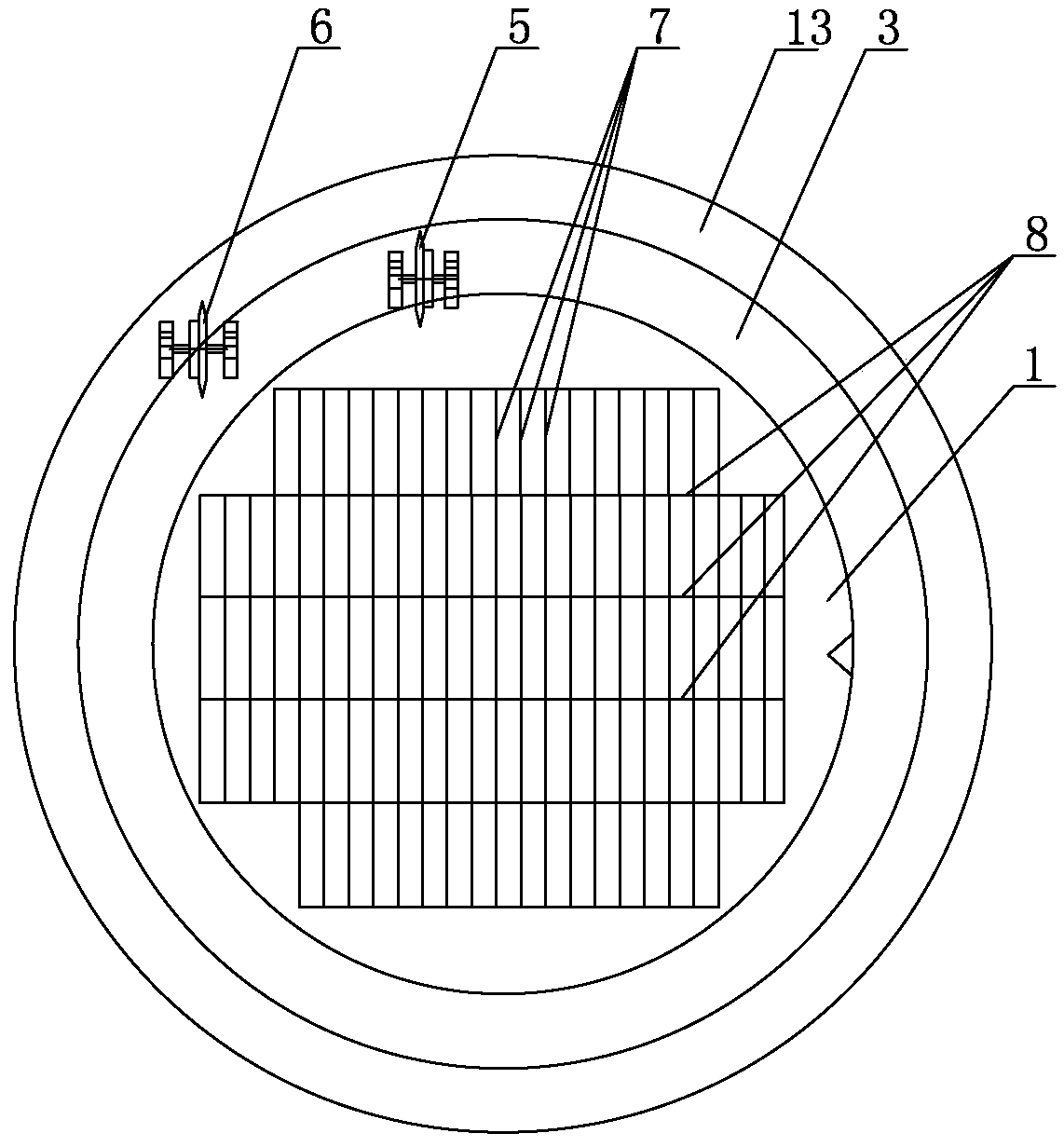

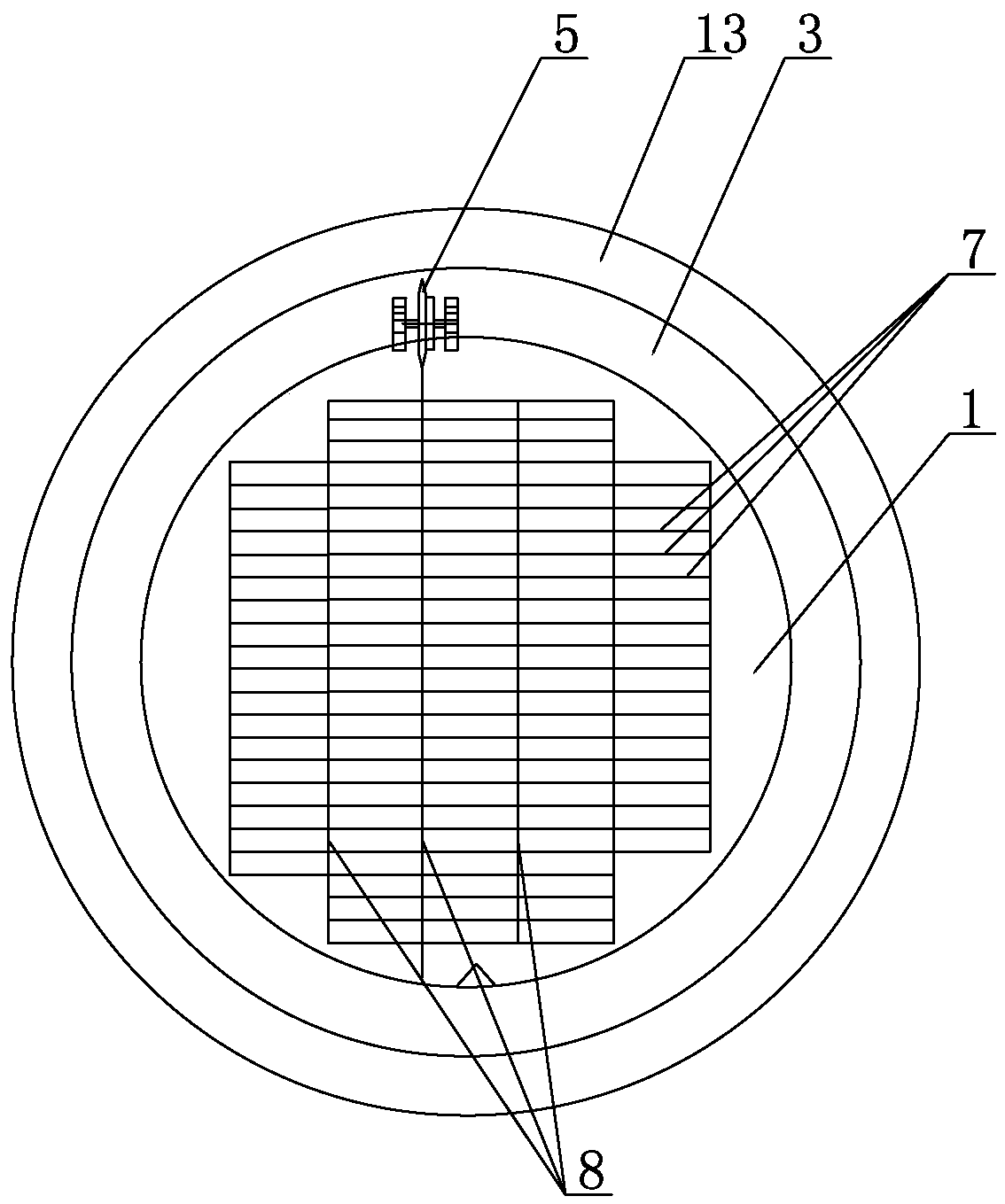

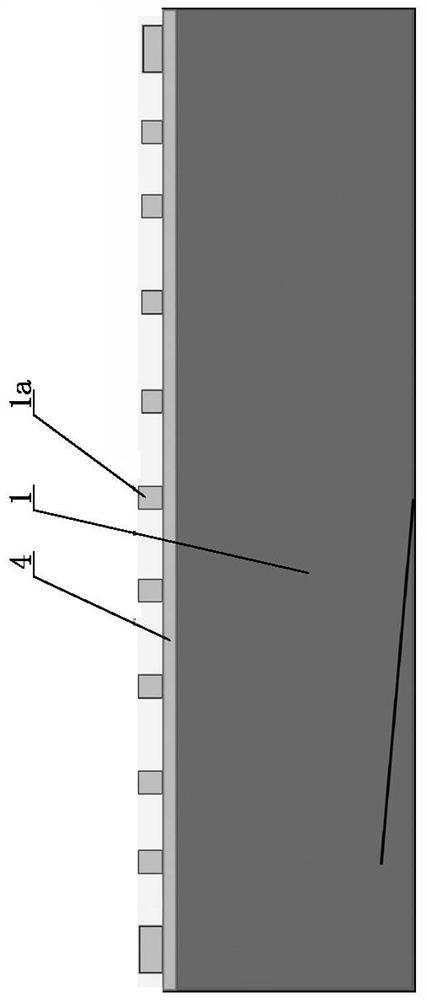

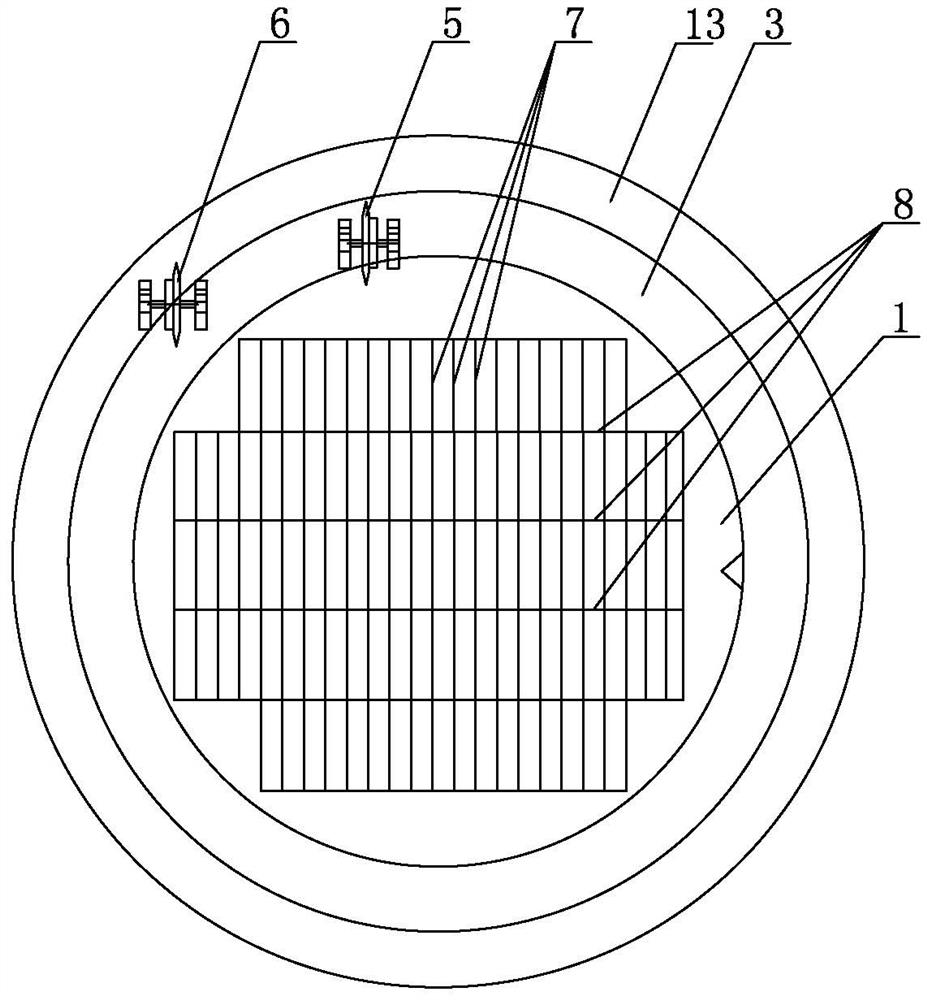

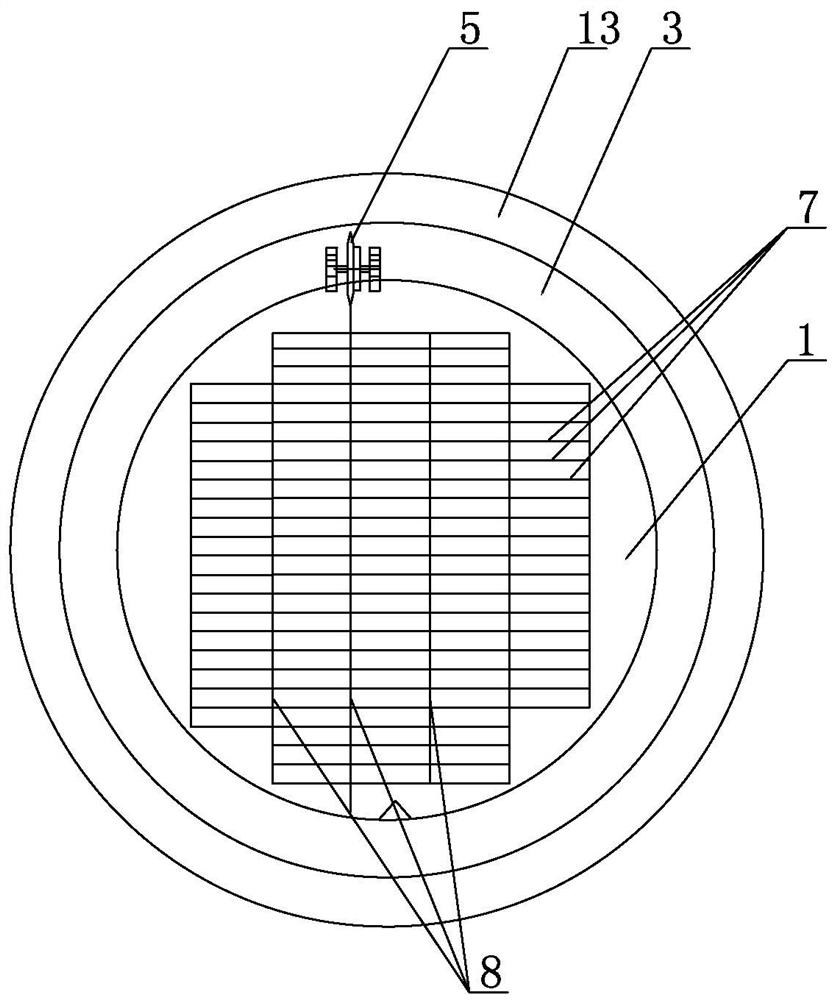

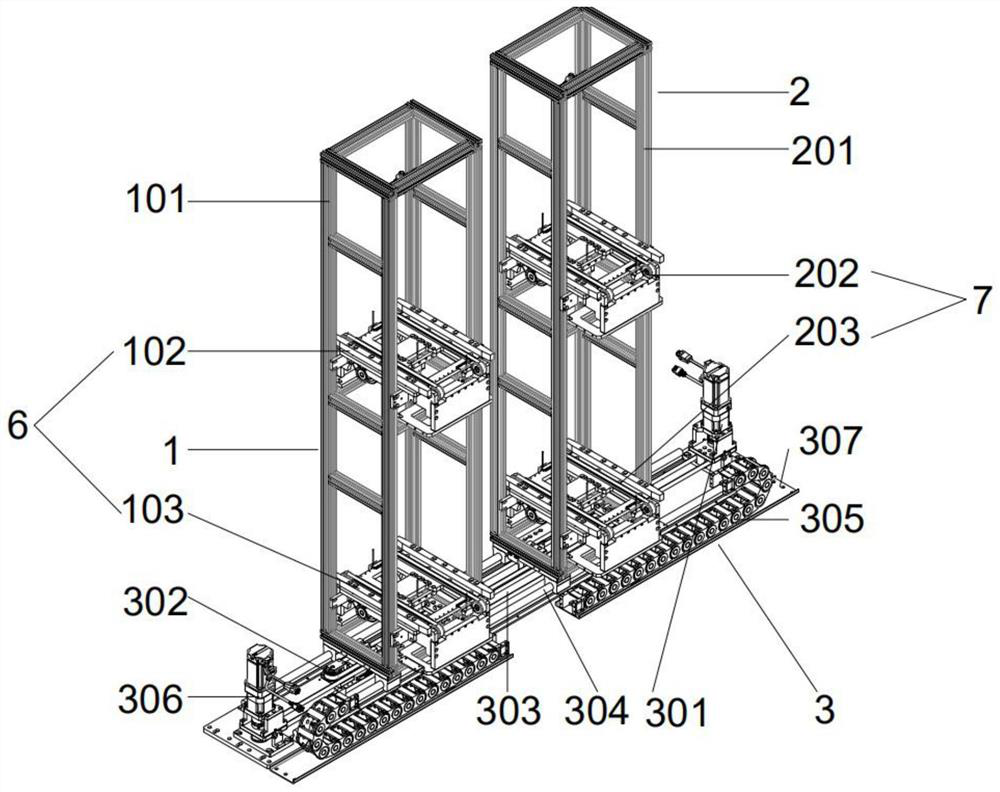

Silicon wafer carrier dispatching platform for double-track feeding

ActiveCN113035761AImprove production line capacitySemiconductor/solid-state device manufacturingConveyor partsSilicon chipMechanical engineering

The invention provides a silicon wafer carrier dispatching platform for double-track feeding. The silicon wafer carrier dispatching platform comprises a first conveying module, a second conveying module and a translation module, wherein the first conveying module and the second conveying module are horizontally and slidably arranged on the translation module, one side of the first conveying module and one side of the second conveying module are used for being in butt joint with a carrier transmission flow line, the opposite sides, in butt joint with the carrier conveying flow line, of the first conveying module and the second conveying module are in butt joint with a carrier lifting system, the carrier conveying flow line is connected with an AGV feeding position, and the carrier lifting system is connected with a discharging position. The silicon wafer carrier dispatching platform overcomes the technical problem that production efficiency is reduced since in intelligent production, AGV transferring carriers and a silicon wafer carrier feeding machine are in butt joint for feeding, carriers on two feeding flow lines need to be emptied during AGV feeding, the discharging numbers of the two feeding flow lines are different due to double-line production during discharging and AGV feeding can only by conducted when the carriers on the other feeding flow line are discharged completely although the carriers on one feeding flow line are emptied.

Owner:苏州市中辰昊科技有限公司

Gamma calculation method and device and display panel

ActiveCN111754913AShorten burn timeImprove production line capacityCathode-ray tube indicatorsEngineeringComputational physics

An embodiment of the invention discloses a gamma calculation method, a gamma calculation device, and a display panel. The gamma calculation method comprises the steps of: determining a corresponding register gain value of second binding point brightness on a straight line connecting line according to the straight line connecting line of two endpoints, in a first binding point brightness interval to which a reference curve belongs, corresponding to the second binding point brightness under a to-be-calculated display brightness level in a data voltage dimming interval; determining a target register offset value corresponding to the second binding point brightness according to a preset corresponding relationship between a target register offset value corresponding to the second binding pointbrightness and a preset midpoint offset value corresponding to the middle brightness of the two endpoints; and determining a gamma register value corresponding to the second binding point brightness under the to-be-calculated display brightness level according to the register gain value and the target register offset value. According to the gamma calculation method and the gamma calculation device, the gamma register value under any preset display brightness level in the data voltage dimming interval can be determined through calculation according to the group of gamma register values under the maximum display brightness level in a data voltage dimming interval, so that the gamma debugging time can be shortened.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

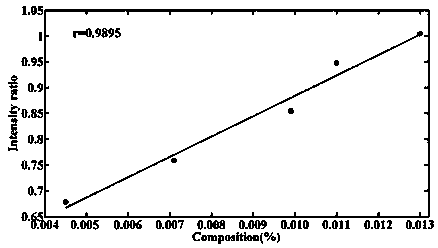

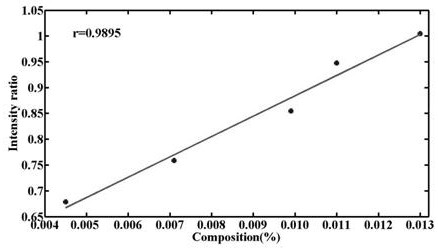

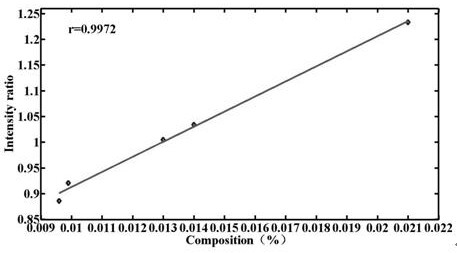

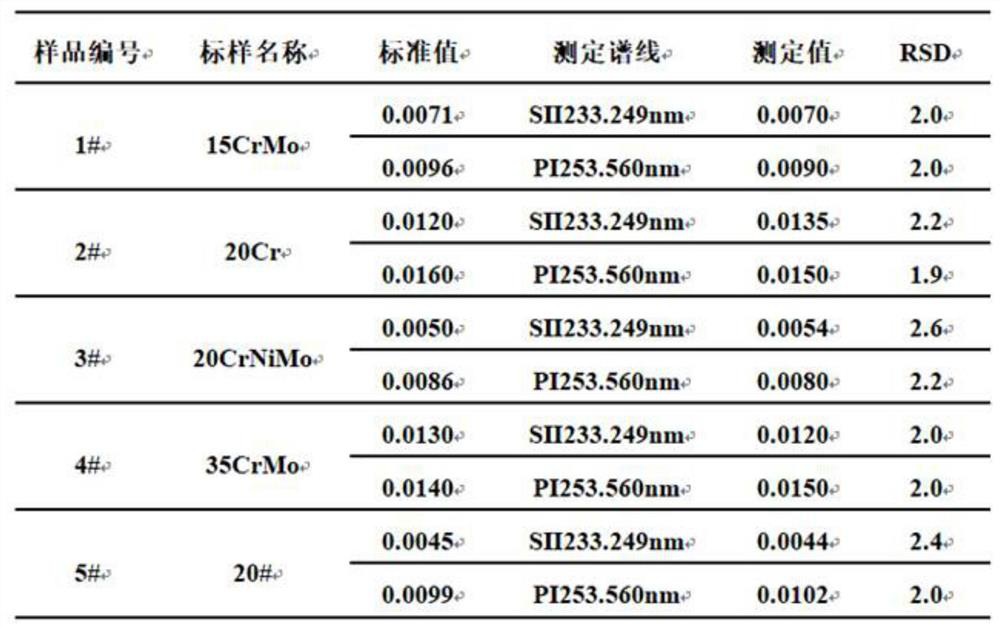

Method for quantitative analysis of sulfur and phosphorus in steel

ActiveCN108414500AReduce sample processing timeImprove production line capacityAnalysis by thermal excitationPhysicsStandard curve

The invention discloses a method for quantitative analysis of sulfur and phosphorus in steel. The method comprises the following steps: preparation of standard establishing samples; adjustment of theparameters of a laser induced breakdown system; collection of laser induced breakdown spectrum signals; establishment of standard curves for SII 233.249 nm and PI253.560 nm based on an internal standard method; collection of the signals of the sample to be tested; and acquisition of the S / P quantitative analysis result of the sample to be tested according to the standard curves. The method of theinvention integrates the internal standard method with laser induced breakdown spectroscopy and can thus rapidly detect the contents of elemental sulfur and elemental phosphorus in situ.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Wafer three-sided cutting method

ActiveCN110600372ARealize physical cuttingReduce viscositySemiconductor/solid-state device manufacturingStress concentrationEngineering

The invention discloses a wafer three-sided cutting method in the technical field of semiconductors. The method includes the following steps: providing a wafer, conveying the wafer to a rotatable wafer stage below a cutting mechanism, enabling a detection camera to perform scanning and analyzing to form a plurality of horizontal cutting channels and longitudinal cutting channels arranged at intervals, and enabling first and second cutters to cut the wafer along corresponding longitudinal cutting channels; rotating the wafer stage by 90 degrees, enabling the first cutter to cut the wafer alongthe respective horizontal cutting channels, and enabling the first cutter to cut out a groove on the wafer along the horizontal cutting channels; enabling the second cutter to the wafer along the respective horizontal cutting channels, and enabling the second cutter to through cut the wafer along the horizontal cutting channels so as to separate an IC. The method can separate the IC from the waferin three cutting steps, can reduce a risk of cracks on the back of the IC, enhances the reliability of the IC, reduce product stress concentration, and improves the quality of the cut IC product.

Owner:JIANGSU UNION SEMICON

Nickel-based positive electrode material of lithium secondary battery and preparation method of nickel-based positive electrode material

PendingCN114520319AIncrease the areaHigh purityMaterial nanotechnologySecondary cellsMetallurgyNew energy

The invention discloses a nickel-based positive electrode material of a lithium secondary battery and a preparation method of the nickel-based positive electrode material, the chemical formula of the positive electrode material is Lia (NixMy) (1-z) NzO2. Fb, M is at least one of Co, Mn, Al or Mg; n is at least one of Ba, Mo, Ce, Al, Zr, Mg, Ti, Sr, Y, W or La; f is a LiSiAlWO7 compound; wherein 0.90 < = a < = 1.20, 0.1 < = x < = 1.0, 0 < = y < = 0.9, x + y = 1, 0.001 < = z < = 0.010, and 0.001 < = b < = 0.050. The preparation process of the positive electrode material has the advantages of simple process flow, high productivity, no ammonia or alkali in raw materials, and facilitation of wastewater recovery; the product has excellent comprehensive performance and the like, and a new low-cost high-performance lithium secondary battery positive electrode material is provided for large-scale application of new energy automobiles.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

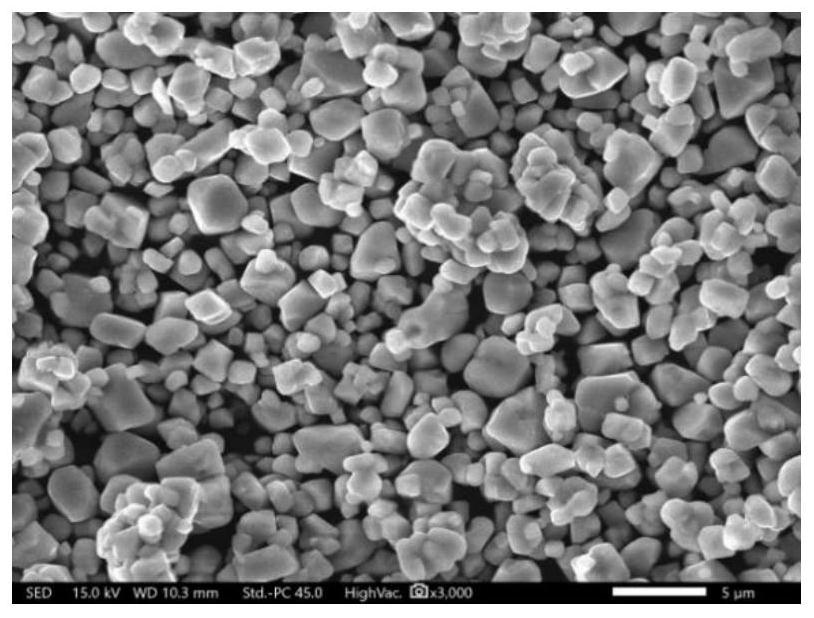

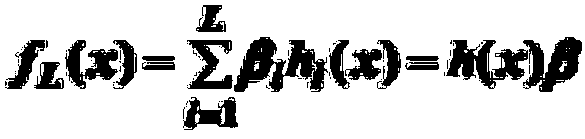

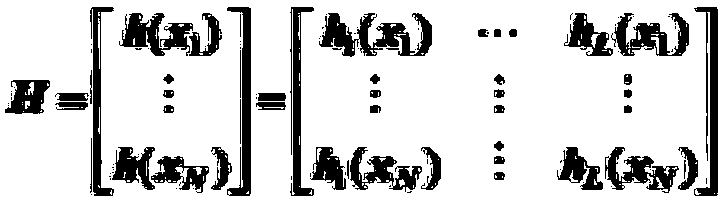

Quantitative analysis method for total iron and alkalinity in sinter

InactiveCN108267429AAccurate quantitative detectionSpeed blockPreparing sample for investigationAnalysis by material excitationAlkalinityLearning machine

The invention discloses a quantitative analysis method for total iron and alkalinity in sinter, and particularly relates to a quantitative analysis method for the total iron and alkalinity in sinter on the basis of a nuclear extreme learning machine combined with laser induced breakdown spectroscopy. The method comprises the steps of sample preparation, laser spectroscopy data obtaining, extreme learning machine correction model building, nuclear extreme learning machine model building, to-be-detected sinter sample detection and the like. The method is high in analysis speed and high in accuracy and has great significance for guidance on the steel making process.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

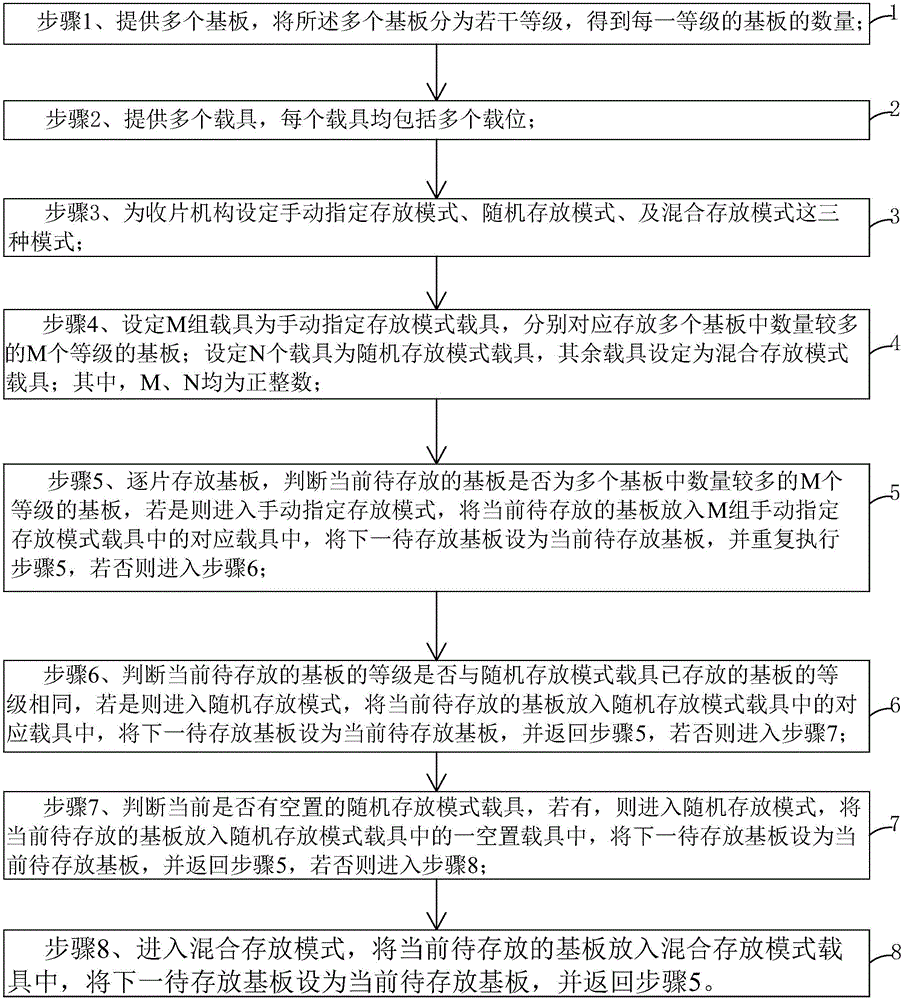

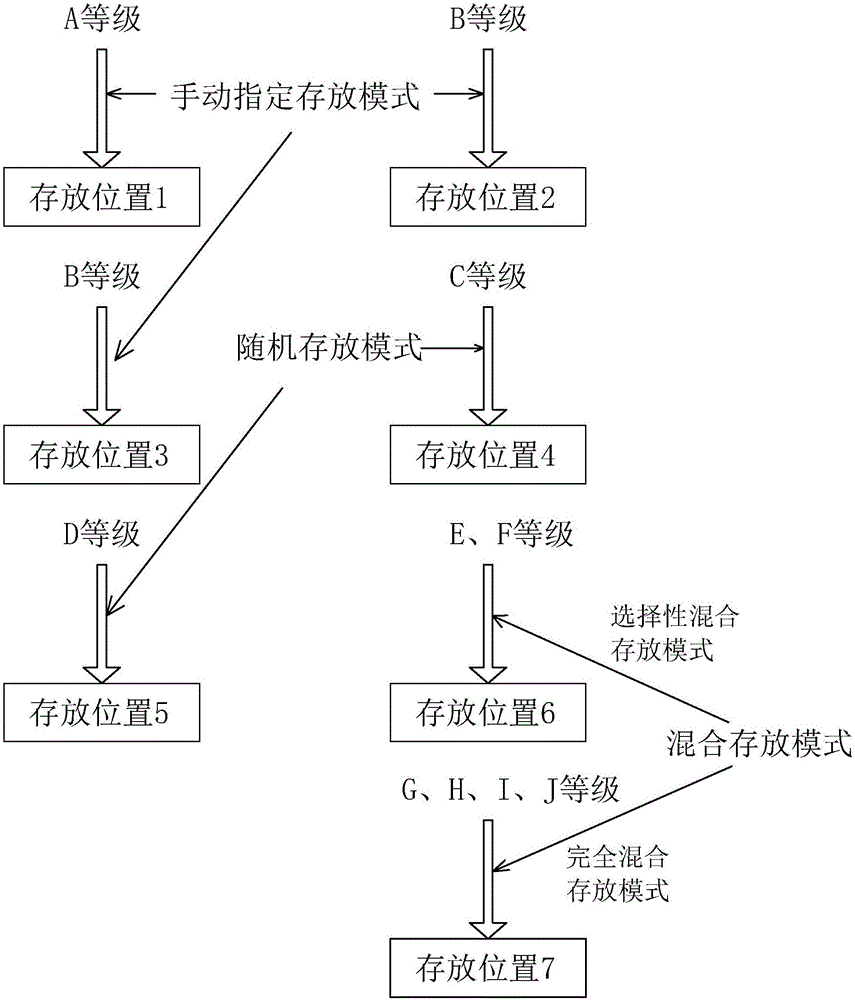

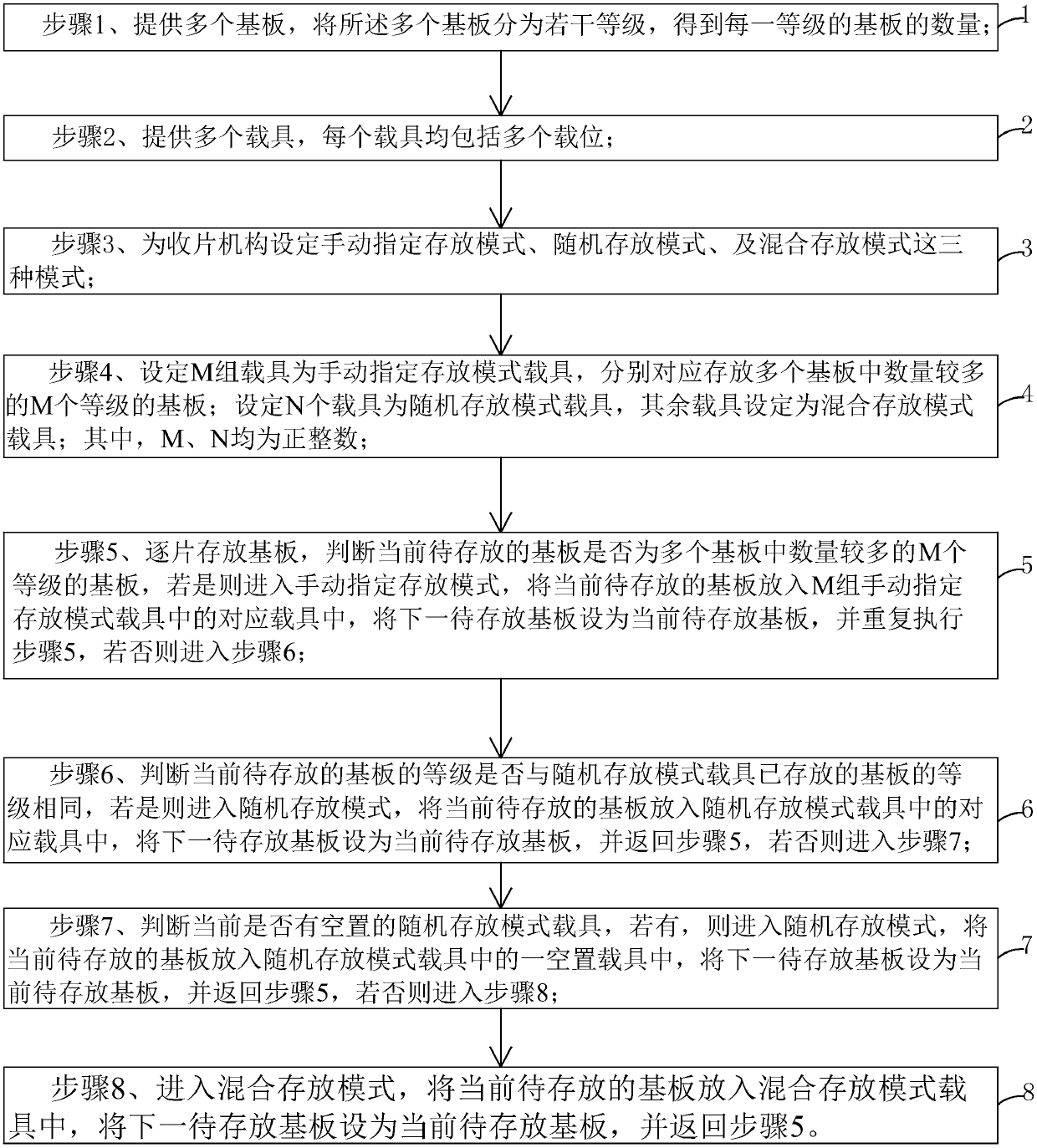

Graded storage method of substrates

ActiveCN106449495AGuaranteed full loadAvoid vacant wasteSemiconductor/solid-state device manufacturingProduction lineTransport time

The invention provides a graded storage method of substrates. A random storage mode and a mixed storage mode are additionally arranged on the basis of a manual specific storage mode. When graded storage of the substrates is performed, the substrates of large number and grade of multiple substrates are arranged in corresponding manual specific storage mode carriers so that the loading rate of the carriers can be guaranteed, and the efficiency of the corresponding grades of substrates to the next station can be enhanced; partial grades of substrates are randomly arranged in random storage mode carriers so that empty waste of the carriers caused by the fact that an operator forgets to set the grade can be prevented, and an elastic space for storing multiple grades of substrates can also be provided for machines having less storage positions; and multiple grades of substrates of less number are arranged in mixed storage mode carriers in a mixed way so that each carrier is enabled to be fully loaded as much as possible, the utilization rate of the carriers can be enhanced, the transport time can be reduced, the efficiency of later continuous classification and waiting can be enhanced and the capacity of the production line can be greatly enhanced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

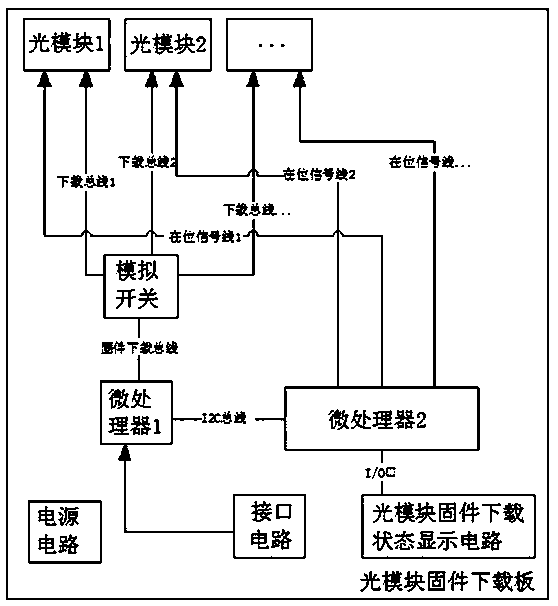

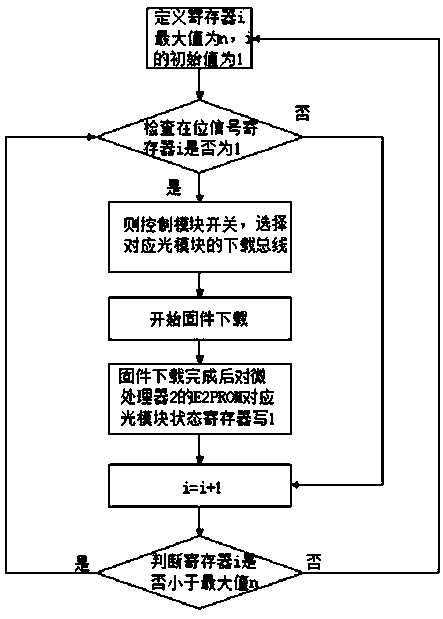

Method for quickly downloading optical module firmware

InactiveCN109802861AImprove download efficiencyImprove production line capacityData switching networksProduction lineOptical Module

The invention discloses a method for quickly downloading optical module firmware, and relates to the technical field of optical communication networks, and the optical module firmware downloading board comprises an optical module which is used for downloading optical module firmware; The analog switch is used for being communicated with an appointed optical module downloading bus; The first microprocessor is responsible for firmware downloading of all the optical modules; The second microprocessor is responsible for in-place signal detection of all the optical modules and module firmware downloading state display; The optical module firmware downloading state display circuit is used for displaying the optical module firmware downloading state; The interface circuit is used for connecting the optical module firmware downloading board and the upper computer; And the power supply circuit is used for providing a working power supply for all parts of the optical module firmware downloadingboard. According to the method for quickly downloading the optical module firmware, the optical module firmware downloading efficiency can be greatly improved, the production line capacity can be improved, the production efficiency can be improved, the labor cost can be reduced, and firmware downloading of a plurality of optical modules can be realized by using the testing device of the optical module firmware downloading plate.

Owner:泰瑞创通讯(成都)有限公司

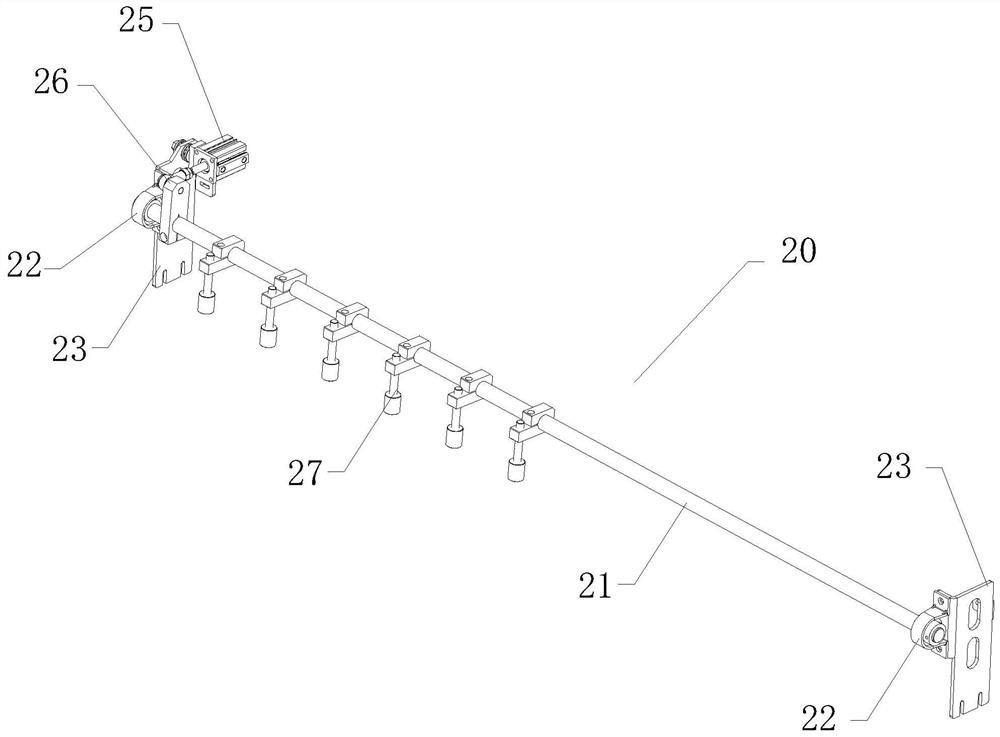

Bearing equipment and arm tooth fork thereof

InactiveCN112110206AIncrease contact areaReduce internal stressCharge manipulationNon-linear opticsProduction lineEngineering

The invention discloses bearing equipment and an arm tooth fork thereof. The arm tooth fork comprises a plurality of fork teeth and a cap frame strip fixed to at least one fork tooth in the fork teeth, the extending direction of the cap frame strip is parallel to the extending direction of the fork tooth where the cap frame strip is located, and at least the top of the cap frame strip is made of elastic materials. The bearing equipment comprises the arm tooth fork. The contact area of a mechanism and a glass substrate can be increased through the shape of the cap frame strip for bearing the glass substrate, and the internal stress of the glass substrate is reduced; and the material of the cap frame strip for bearing the glass substrate can be improved, so that the magnitude of static electricity generated by friction of the mechanism on the glass substrate is reduced. The problem of abnormal single-point alignment on the glass substrate can be effectively prevented, the ratio of abnormal single-point alignment of the glass substrate is effectively reduced, and product loss caused by abnormal single-point alignment is avoided. The product yield and the production line capacity are greatly improved, and the company income is increased.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

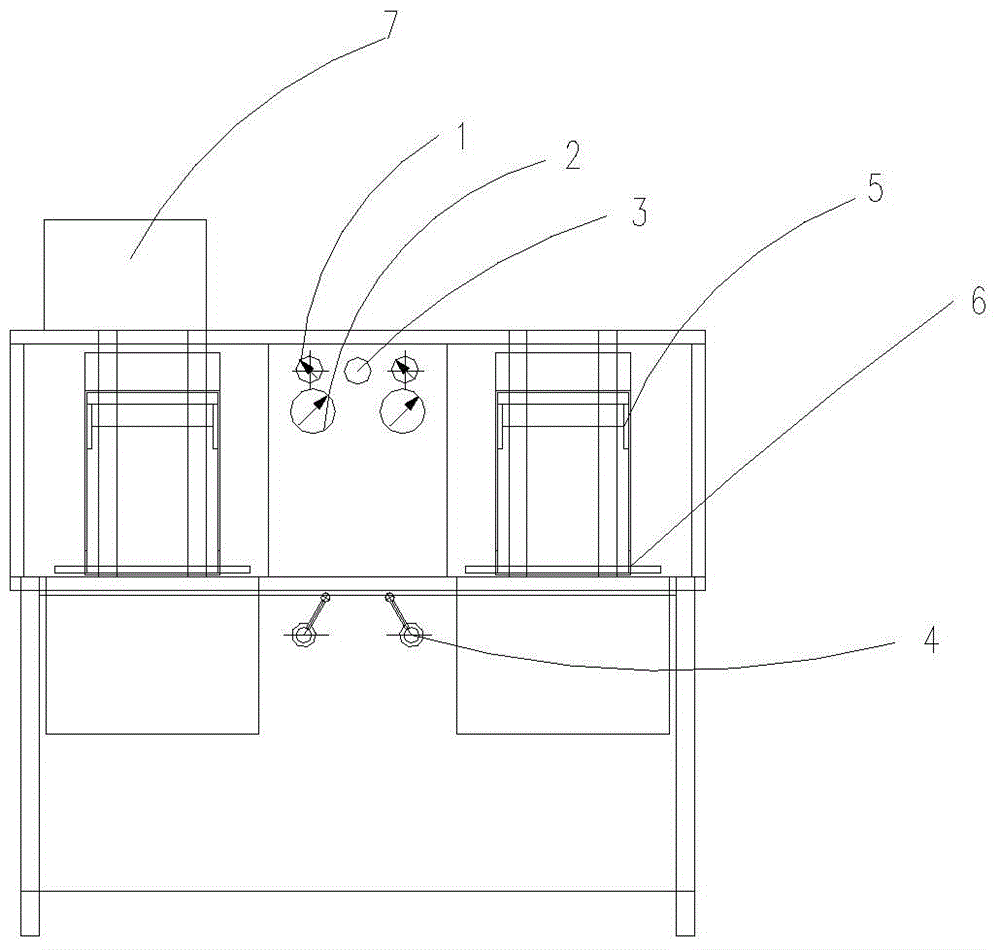

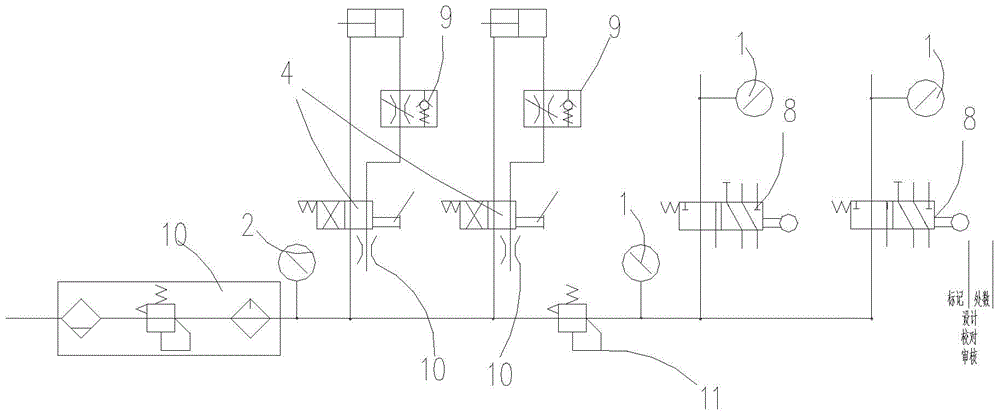

Automatic airtightness testing device

InactiveCN105784291AImprove work efficiencyImprove production line capacityMeasurement of fluid loss/gain rateTest fixtureTraining set

The invention discloses an automatic airtightness testing device. The automatic airtightness testing device comprises a housing, in which is disposed a support, and the support is provided with an operation bench. The left side and the right side of the operation bench are respectively provided with a guide rail, the bottom part of which is provided with an automatic elevating working bench. The automatic elevating working bench is disposed on the support, and a pressure adjusting valve is disposed in the operation bench. The left side and the right side of the pressure adjusting valve are respectively provided with a first pressure gauge and a second pressure gauge. The bottom part of the support is respectively provided with a first hand-operated rotating valve and a second hand-operated rotating valve. The automatic airtightness testing device is advantageous in that the airtightness testing working efficiency can be greatly improved, the production output of the production line can be improved, the labor intensity of the workers can be reduced, the production costs can be reduced, and the product quality can be guaranteed.

Owner:上海伊祥机械制造有限公司

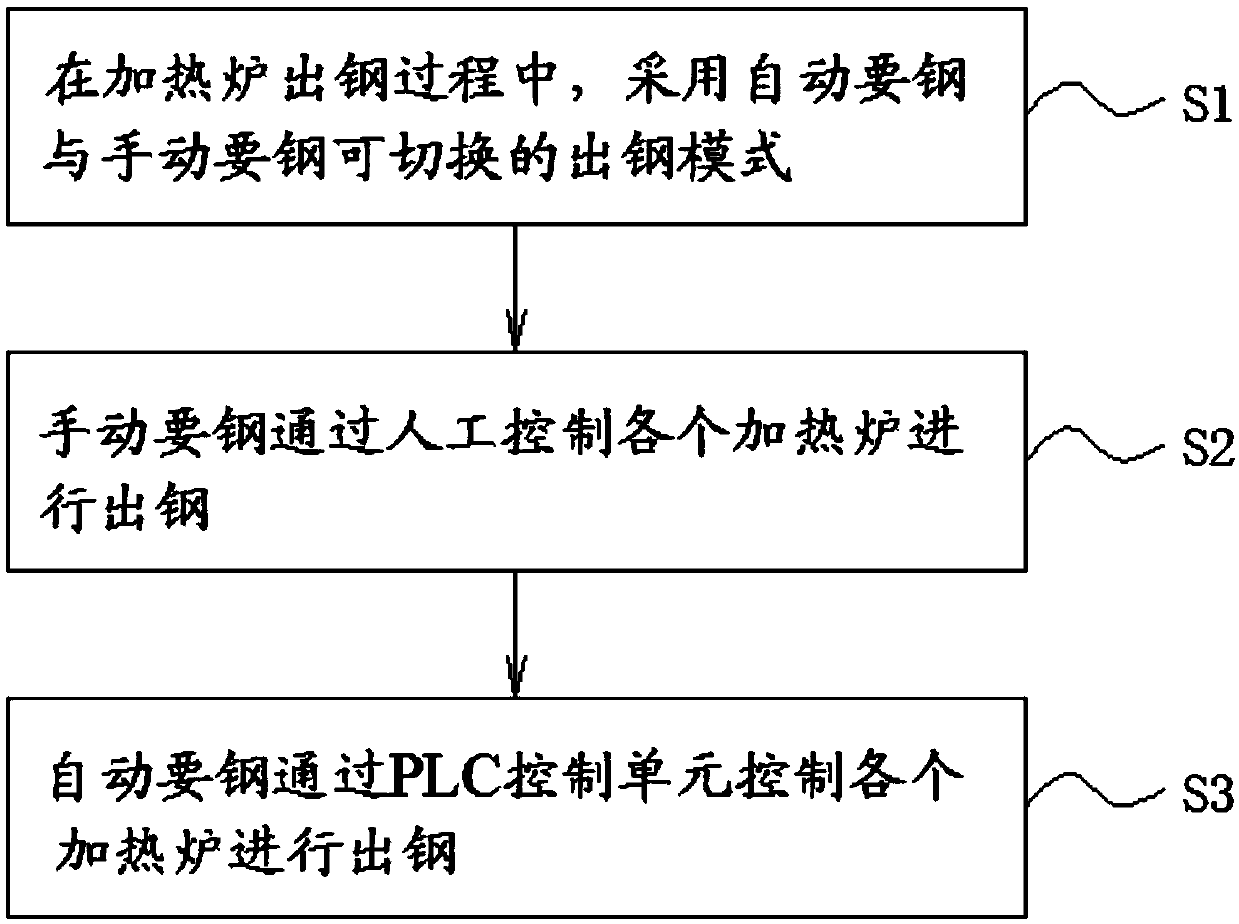

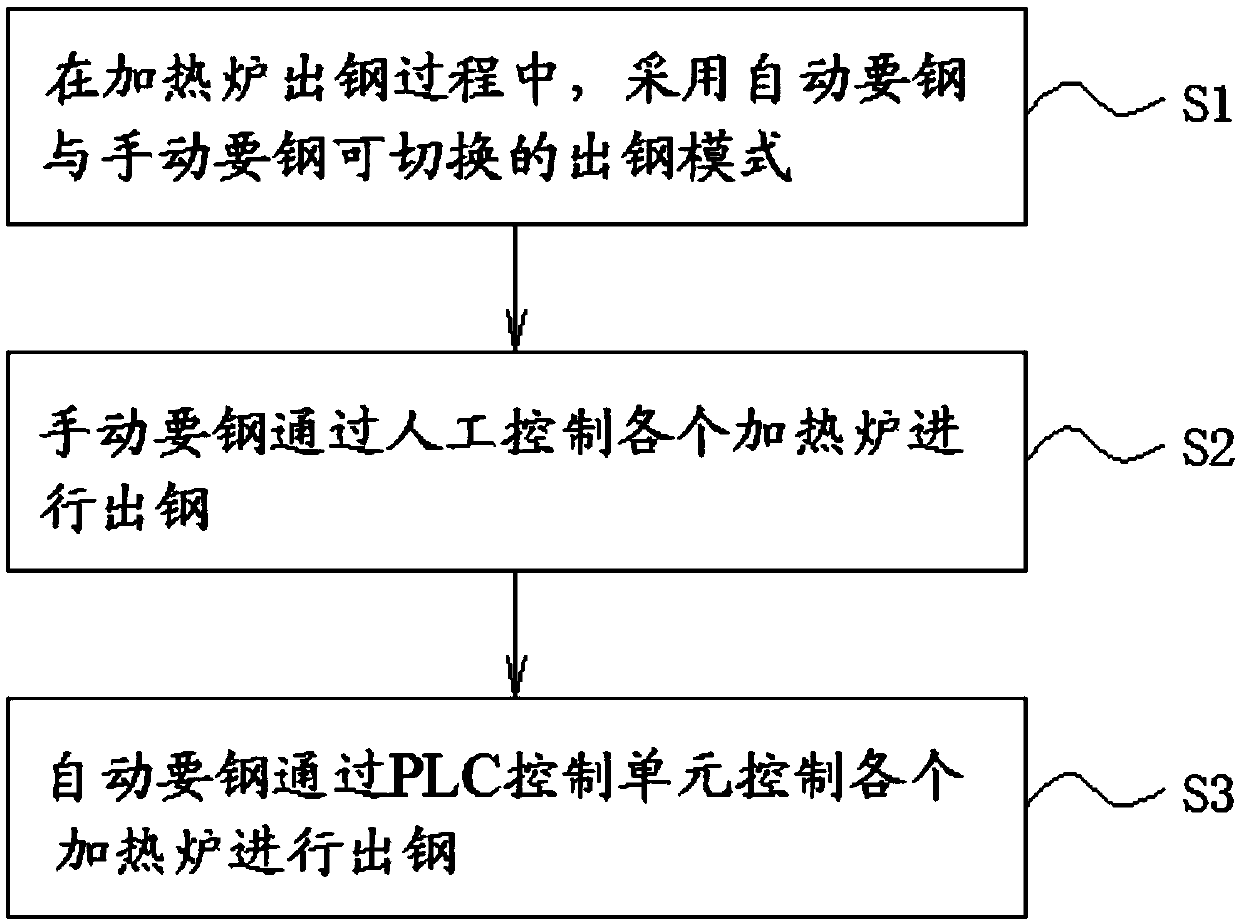

A kind of operation method of hot rolling automatic steel

ActiveCN107497851BReduce the burden onImprove rolling rhythmRoll mill control devicesMetal rolling arrangementsCommunication unitHeating furnace

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

A thick-gauge pipeline steel and its low compression ratio production process

The invention discloses a low-compression ratio thick-gauge pipeline steel, the chemical composition and mass percentage of which are: C 0.03-0.07%, Si 0.10-0.30%, Mn 1.1-1.6%, Cr 0.1-0.3%, Ni 0.1 ~0.4%, Mo 0.10~0.25%, Nb 0.04~0.07%, V≤0.03%, Ti 0.01~0.025%, Al 0.01~0.045%, Mg 0.002‑0.0022%, using clean steel smelting, continuous casting, and slab heating , Three-stage controlled rolling, and ultra-fast cooling process. The matrix structure of the obtained steel plate is granular bainite and acicular ferrite, which has good strength-toughness matching and low yield ratio, and has excellent resistance to HIC and SSCC acid corrosion, and can meet the thickness specification yield strength ≥ 485MPa pipeline steel and service technical requirements for acid-resistant pipelines.

Owner:武汉钢铁有限公司

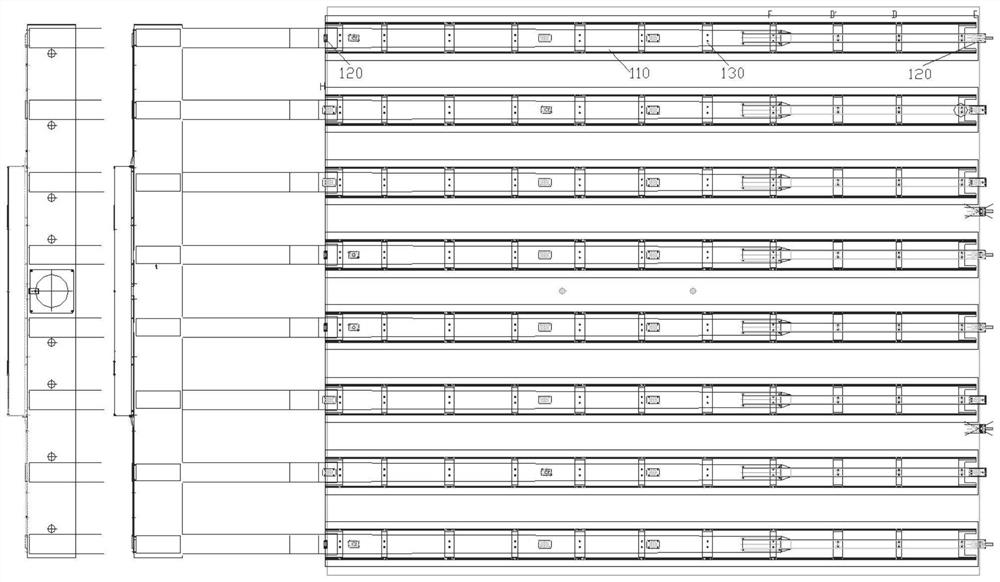

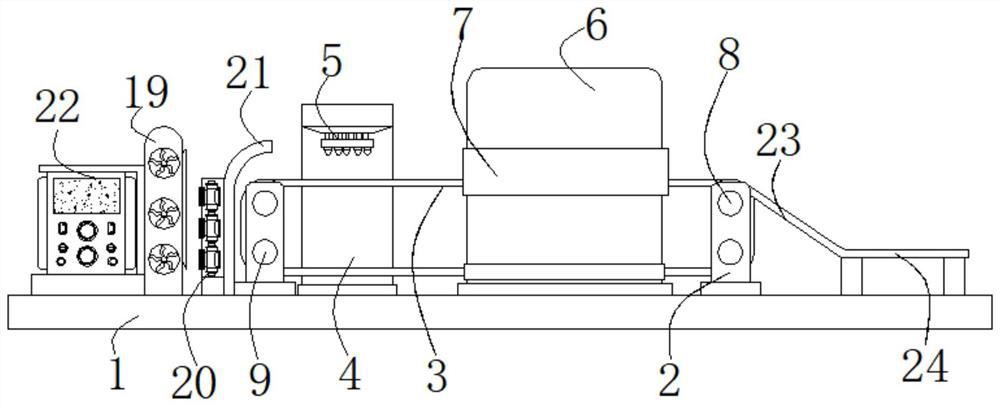

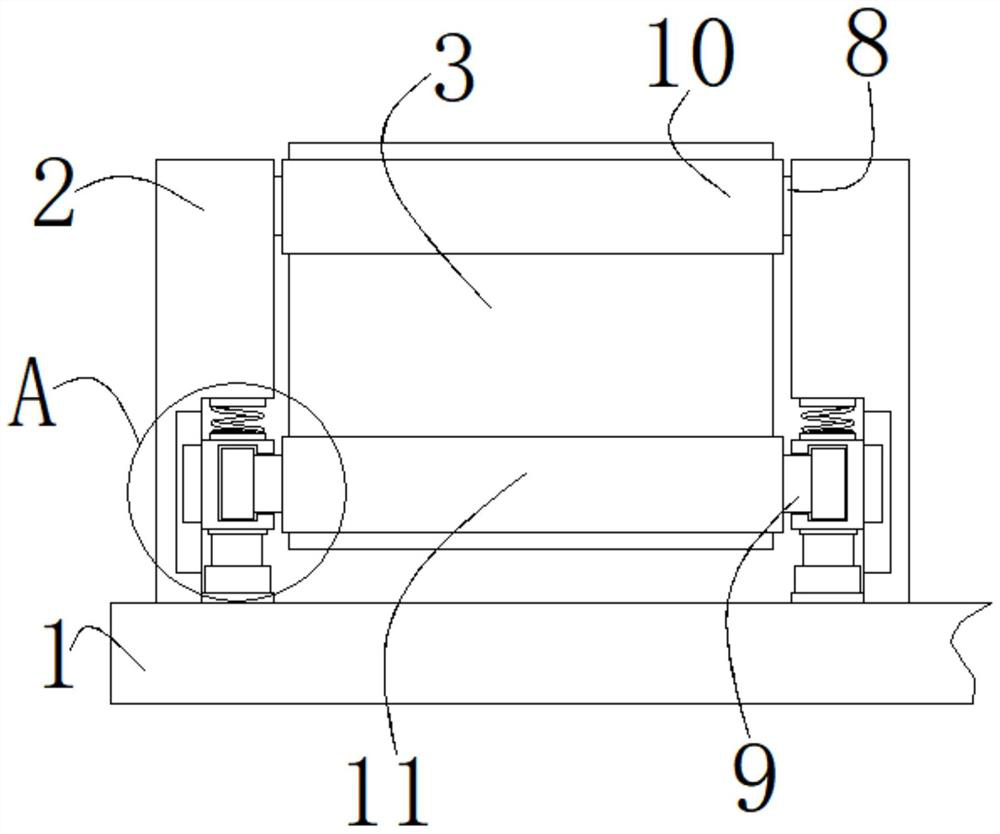

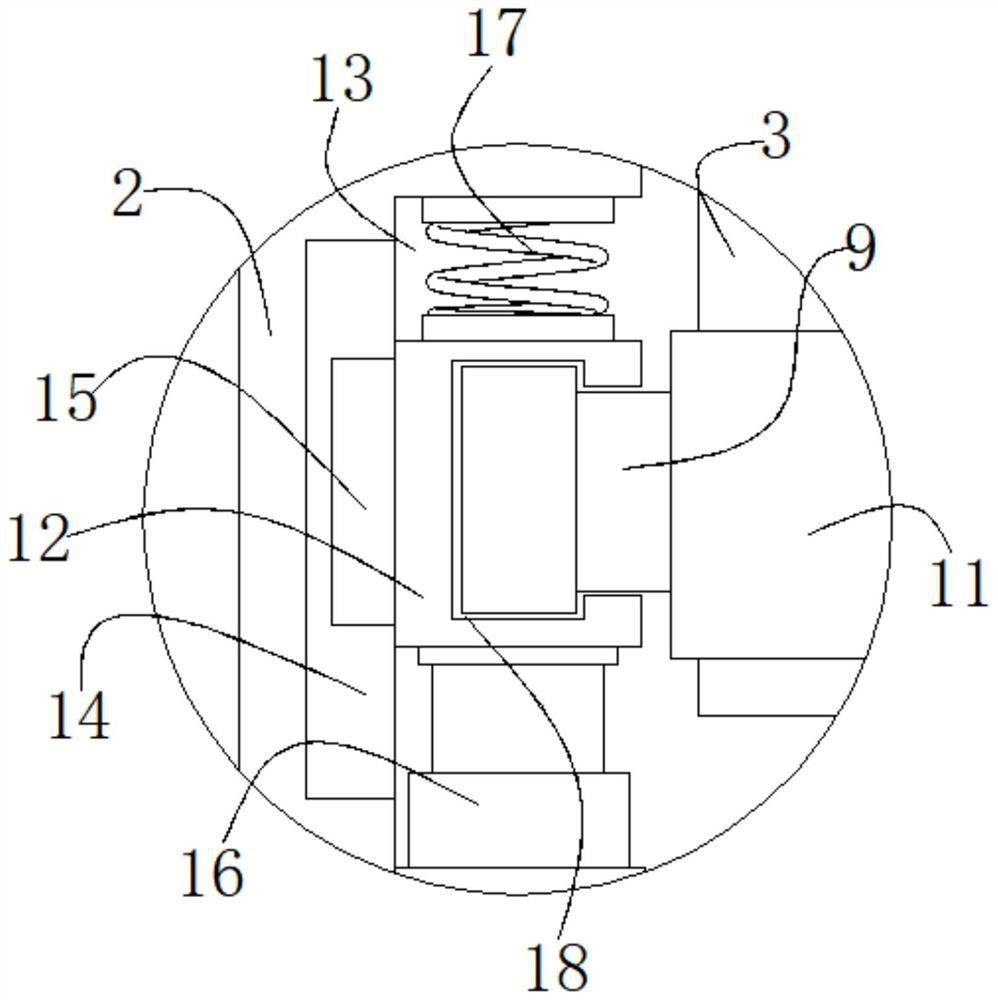

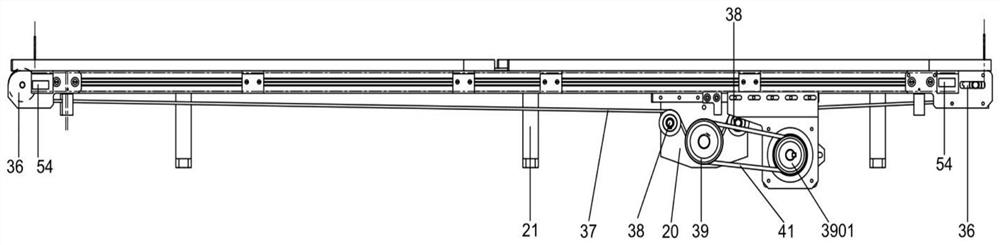

Automatic control system of large plate hot press

PendingCN114734713AImprove production line capacityReduce manual labor intensityLaminationLamination apparatusPhysicsAutomatic control

The invention discloses a large plate hot press automatic control system which comprises a bottom plate, a supporting frame is fixedly connected to the top of the bottom plate, a driving shaft and a driven shaft are arranged on the inner side of the supporting frame, a roller and a guide cylinder are fixedly connected to the surface of the driving shaft and the surface of the driven shaft respectively, and a conveying belt is wound around the surface of the roller and the surface of the guide cylinder. Connecting blocks are rotatably arranged at the two ends of the driven shaft, mounting grooves are formed in the two sides of the inner wall of the supporting frame, the connecting blocks are slidably connected with the inner walls of the mounting grooves, air cylinders are fixedly connected to the bottoms of the connecting blocks, the bottoms of the air cylinders are fixed to the bottom plate, and rotating grooves are formed in the connecting blocks; and the driven shaft is rotationally connected with the connecting block through the rotating groove. The automatic control system of the large plate hot press solves the problems that in the using process of an existing large plate hot press, a conveying belt is prone to loosening, manual adjustment is needed, and the production efficiency is affected.

Owner:ANHUI KAILE SPECIAL VEHICLES

Classified storage method for substrates

ActiveCN106449495BGuaranteed full loadAvoid vacant wasteSemiconductor/solid-state device manufacturingProduction lineTransport time

The invention provides a graded storage method of substrates. A random storage mode and a mixed storage mode are additionally arranged on the basis of a manual specific storage mode. When graded storage of the substrates is performed, the substrates of large number and grade of multiple substrates are arranged in corresponding manual specific storage mode carriers so that the loading rate of the carriers can be guaranteed, and the efficiency of the corresponding grades of substrates to the next station can be enhanced; partial grades of substrates are randomly arranged in random storage mode carriers so that empty waste of the carriers caused by the fact that an operator forgets to set the grade can be prevented, and an elastic space for storing multiple grades of substrates can also be provided for machines having less storage positions; and multiple grades of substrates of less number are arranged in mixed storage mode carriers in a mixed way so that each carrier is enabled to be fully loaded as much as possible, the utilization rate of the carriers can be enhanced, the transport time can be reduced, the efficiency of later continuous classification and waiting can be enhanced and the capacity of the production line can be greatly enhanced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

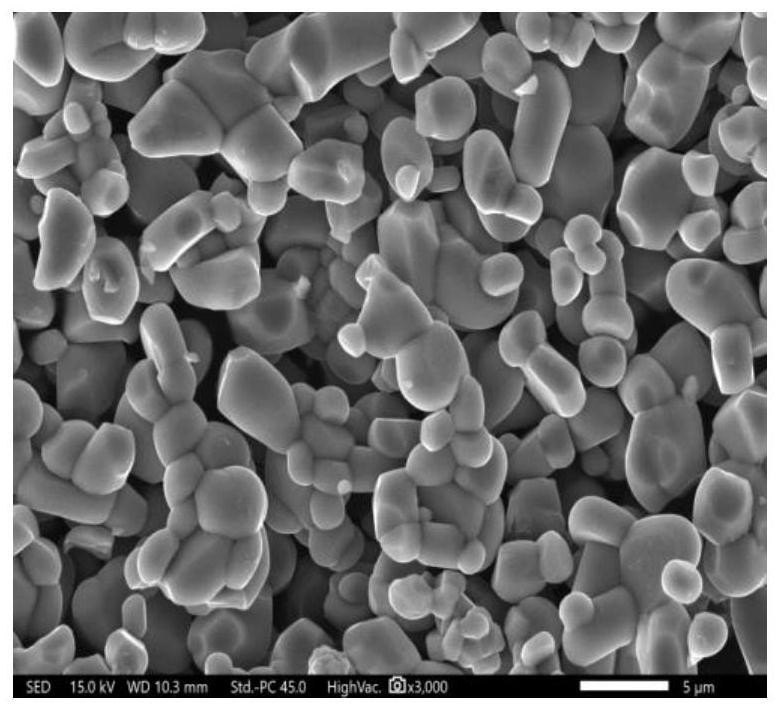

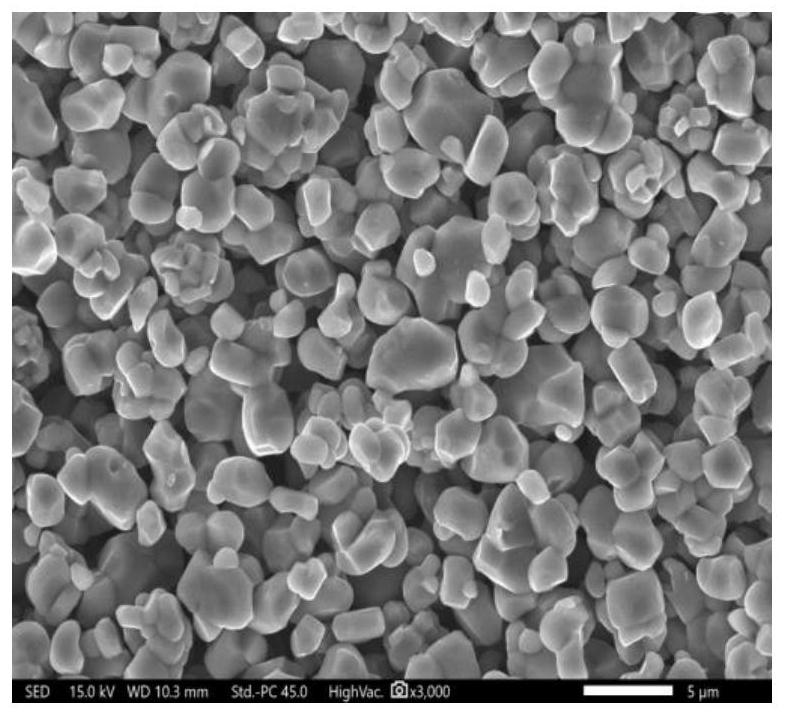

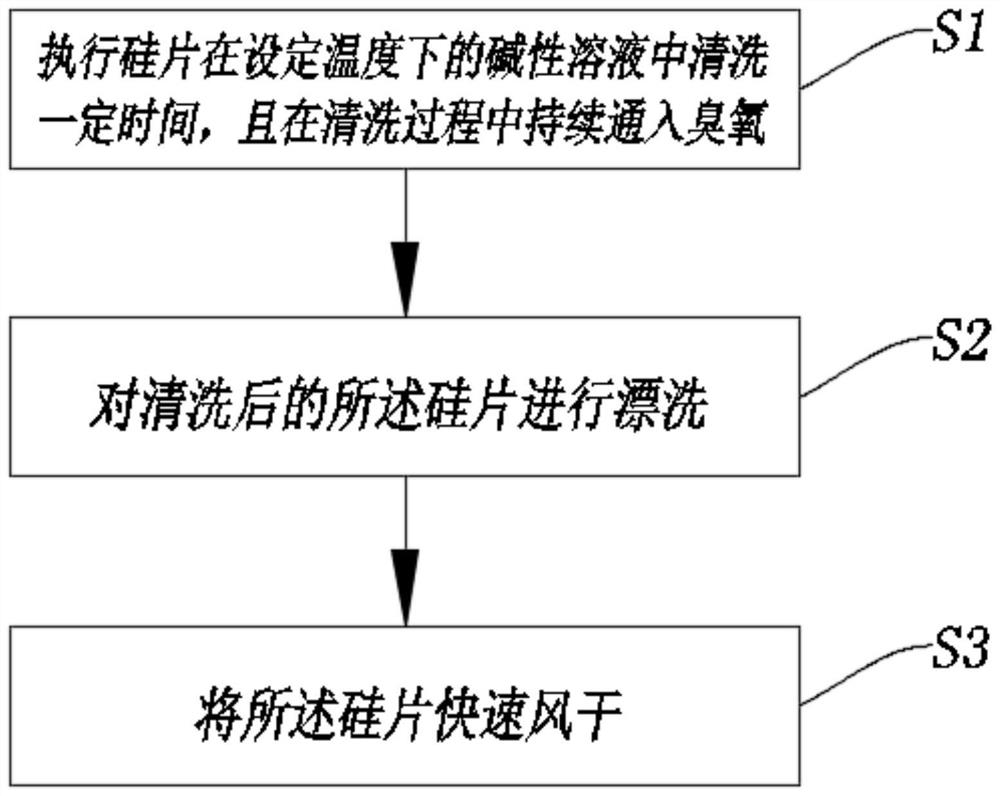

Cleaning process for large-size imbricated battery piece

PendingCN114823281AEfficient removalReduce dosageSemiconductor/solid-state device manufacturingSemiconductor devicesChemical reactionMetallurgy

The invention provides a cleaning process for a large-size imbricated battery piece, which comprises the following steps of: cleaning a silicon wafer in an alkaline solution at a set temperature for a certain time, and continuously introducing ozone in the cleaning process; and then the cleaned silicon wafer is rinsed. According to the cleaning process provided by the invention, the cleaning solution of sodium hydroxide and water in an optimal ratio is obtained, and ozone is introduced in the cleaning process, so that the surface of the silicon wafer can be subjected to complex physical and chemical reactions; organic dirt, dust, other particle dirt, metal ion dirt and the like generated in the linear cutting process of the solar silicon wafer are effectively removed, and the cleaning rate is at least 99.5% or above.

Owner:DONGFANG HUANSHENG PHOTOVOLTAIC (JIANGSU) CO LTD

A method for cutting wafers on three sides

ActiveCN110600372BRealize physical cuttingReduce viscositySemiconductor/solid-state device manufacturingWaferStructural engineering

The invention discloses a wafer three-sided cutting method in the technical field of semiconductors. The method includes the following steps: providing a wafer, conveying the wafer to a rotatable wafer stage below a cutting mechanism, enabling a detection camera to perform scanning and analyzing to form a plurality of horizontal cutting channels and longitudinal cutting channels arranged at intervals, and enabling first and second cutters to cut the wafer along corresponding longitudinal cutting channels; rotating the wafer stage by 90 degrees, enabling the first cutter to cut the wafer alongthe respective horizontal cutting channels, and enabling the first cutter to cut out a groove on the wafer along the horizontal cutting channels; enabling the second cutter to the wafer along the respective horizontal cutting channels, and enabling the second cutter to through cut the wafer along the horizontal cutting channels so as to separate an IC. The method can separate the IC from the waferin three cutting steps, can reduce a risk of cracks on the back of the IC, enhances the reliability of the IC, reduce product stress concentration, and improves the quality of the cut IC product.

Owner:JIANGSU UNION SEMICON

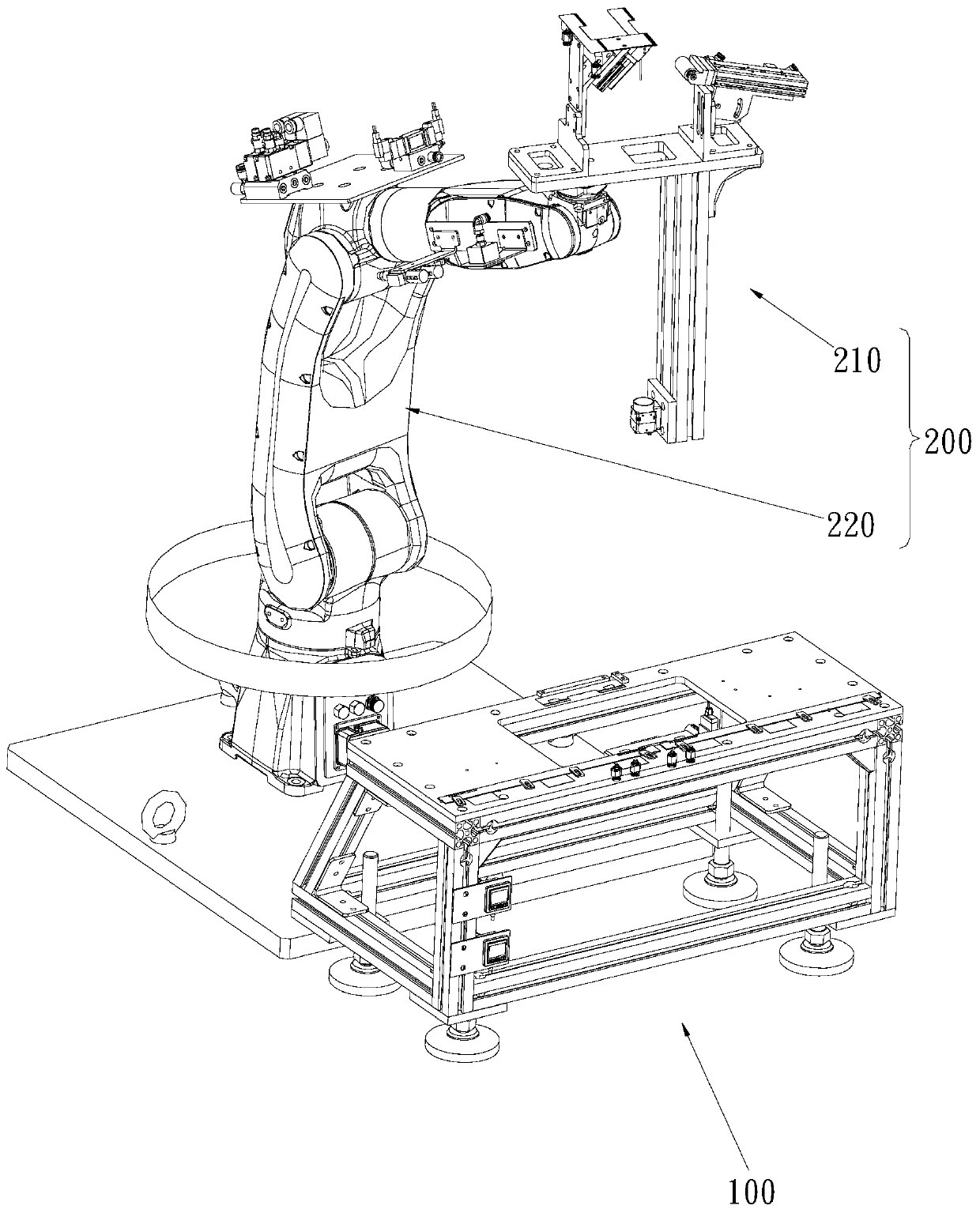

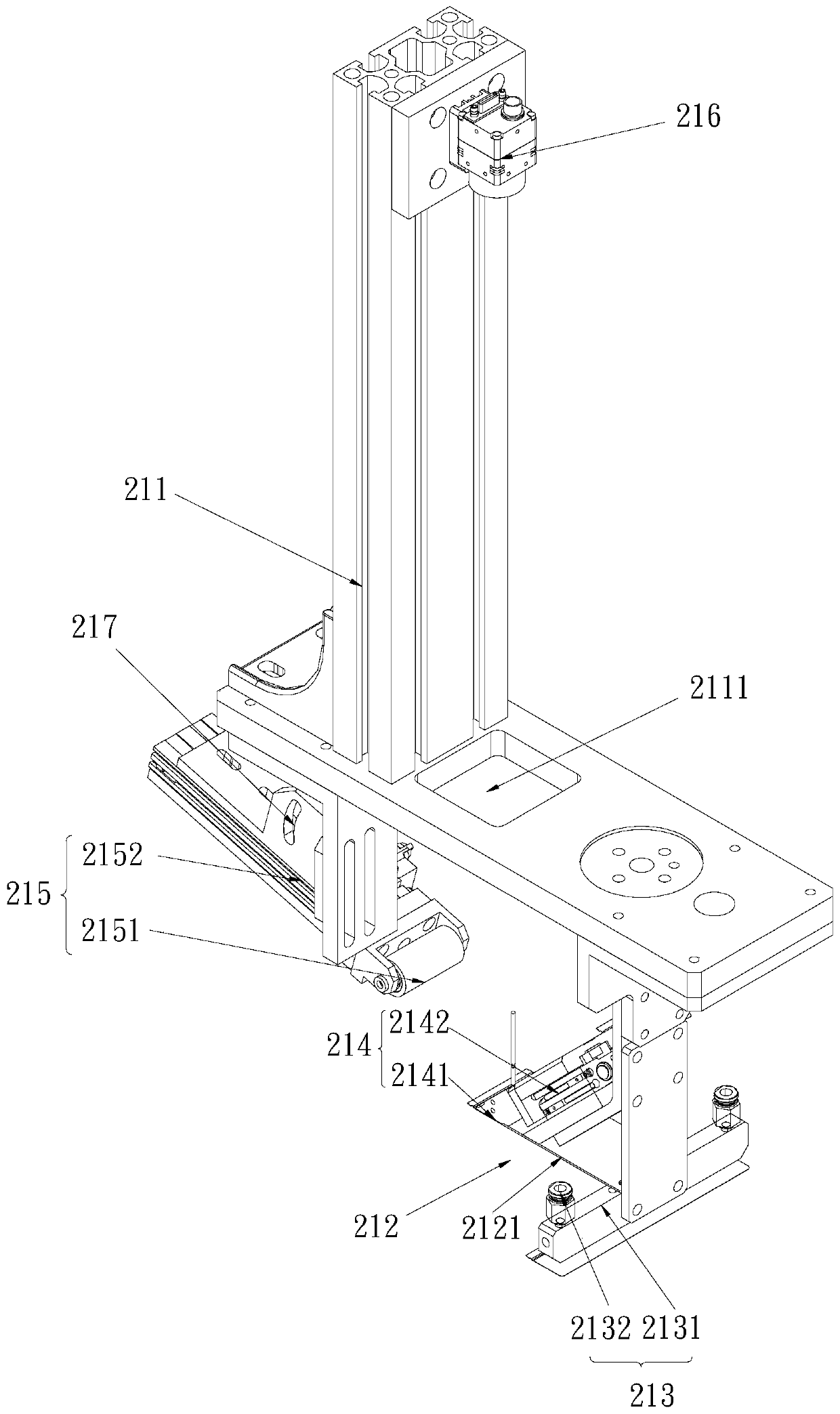

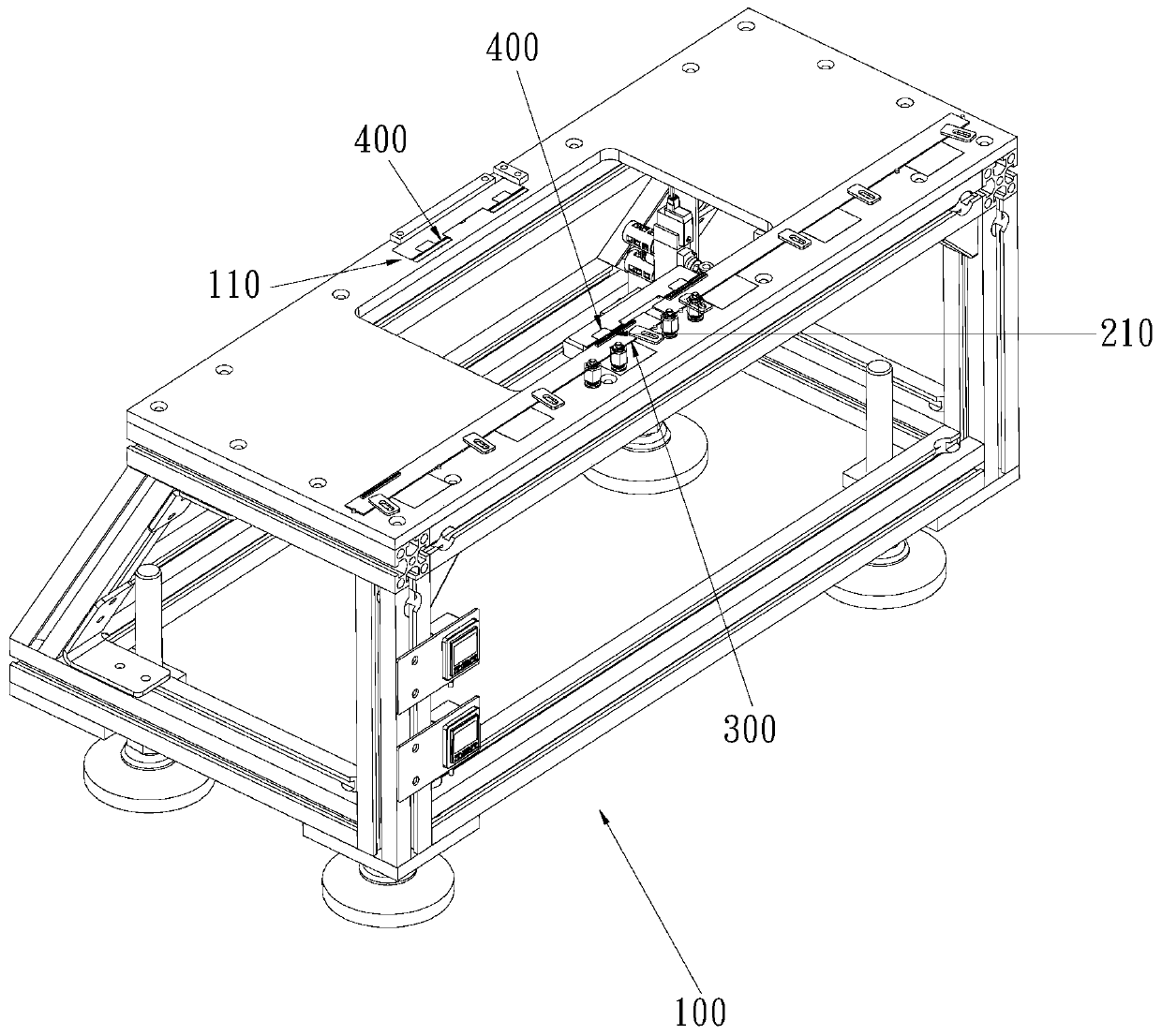

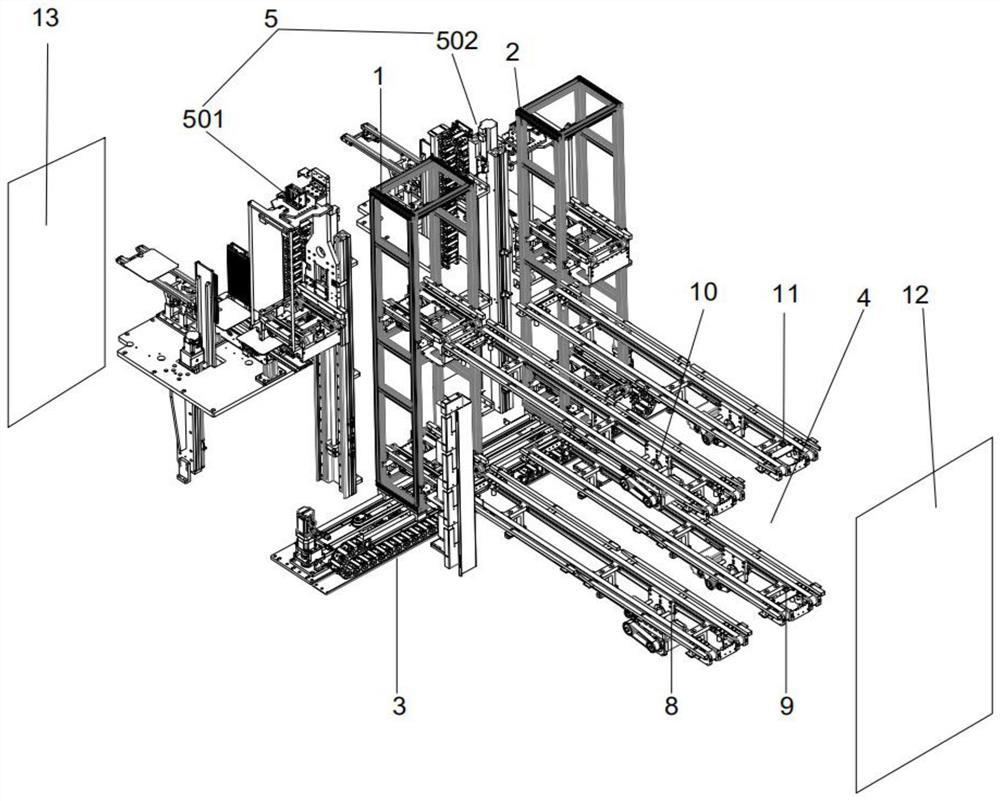

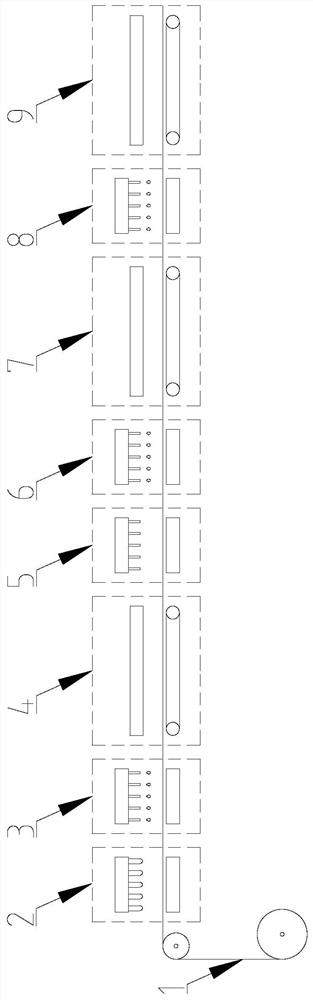

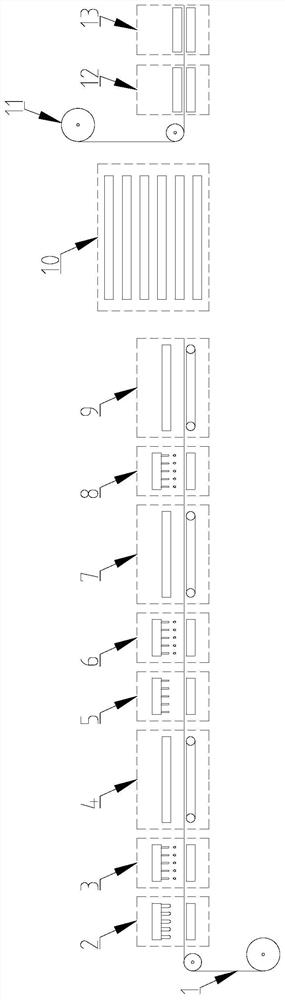

Automatic plug device

PendingCN110191595AImprove production line capacityRealize automated productionPrinted circuit assemblingNon-linear opticsLiquid-crystal displayLiquid crystal

The present invention relates to the assembling technology field of control panels of liquid crystal display panels, and discloses an automatic plug device. The automatic plug device comprises a workbench and a plug mechanism, the workbench is arranged to fix a first circuit board and a second circuit board, the first circuit board is provided with at least one cover plate capable of opening and closing; the plug mechanism is arranged at the side portion of the workbench, the plug mechanism comprises a plug tool and a drive piece configured to drive movement of the plug tool, the plug tool comprises a cover lifting component arranged at a fixed mount, an absorption component, a clamping component and a gland component, the cover lifting component is configured to be inserted between the cover plate and the first circuit board; the absorption component is configured to absorb the second circuit board; the clamping component is configured to abut against the second circuit board on the cover lifting component; and the gland component is configured to push the cover plate to cover the first circuit board. The automatic plug device can automatically connect an FPC onto a PCB to save manpower and improve the efficiency.

Owner:旭东机械(昆山)有限公司

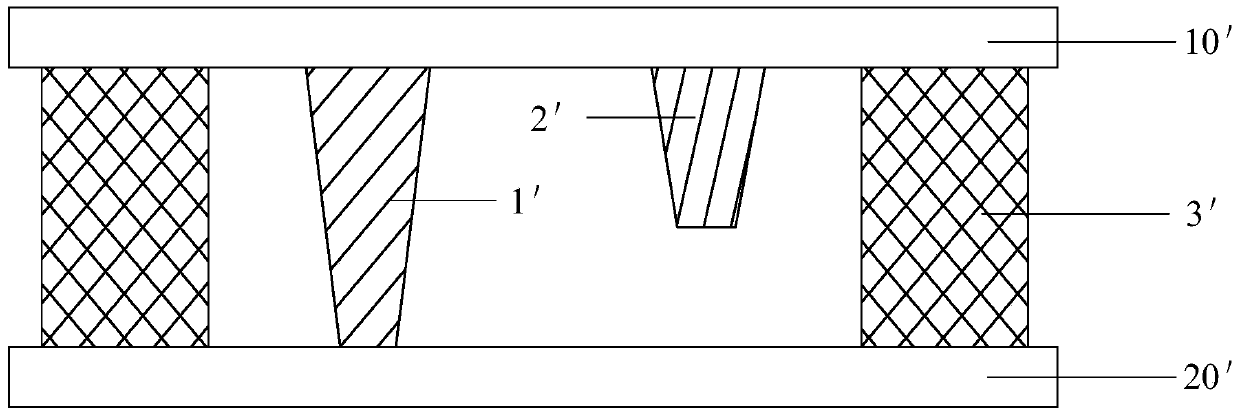

Liquid crystal panel and display device

ActiveCN104635384BRaise the upper limit of paddingThe problem of overcoming the gravitational muraNon-linear opticsLiquid-crystal displayDisplay device

The present disclosure relates to the technical field of liquid crystal display. A liquid crystal panel and a display panel are provided. A main post spacer of the liquid crystal panel is arranged on a first substrate. A stopping structure used to stop the main post spacer from moving in a direction away from a second substrate is arranged on the second substrate. Hence, even if lots of liquid crystals are filled, the main post spacer and the second substrate may be kept in a seamless state due to the stopping structure.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

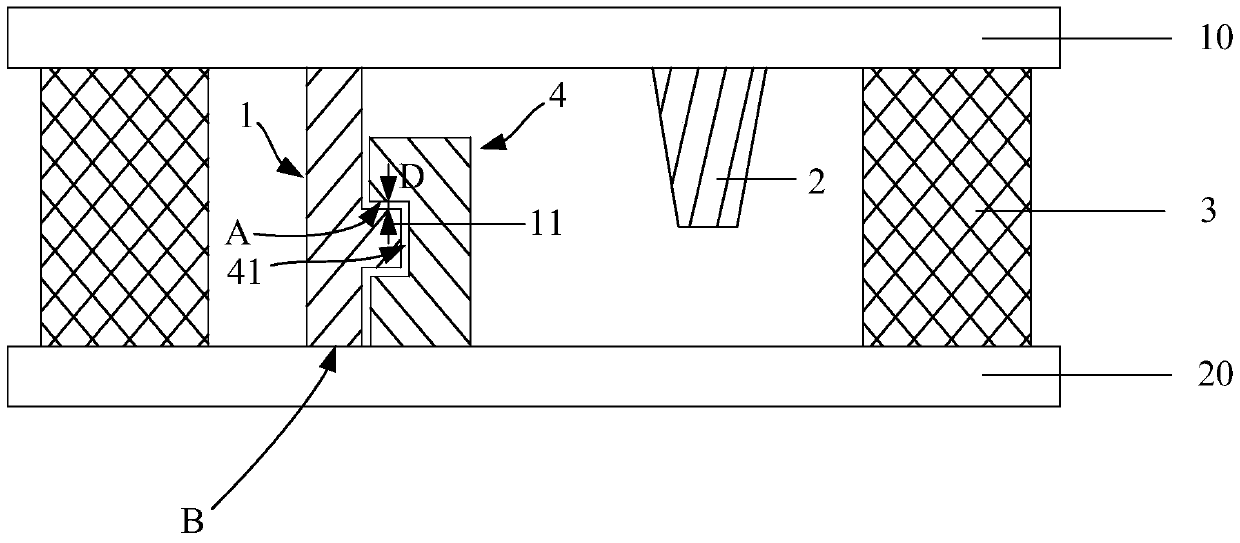

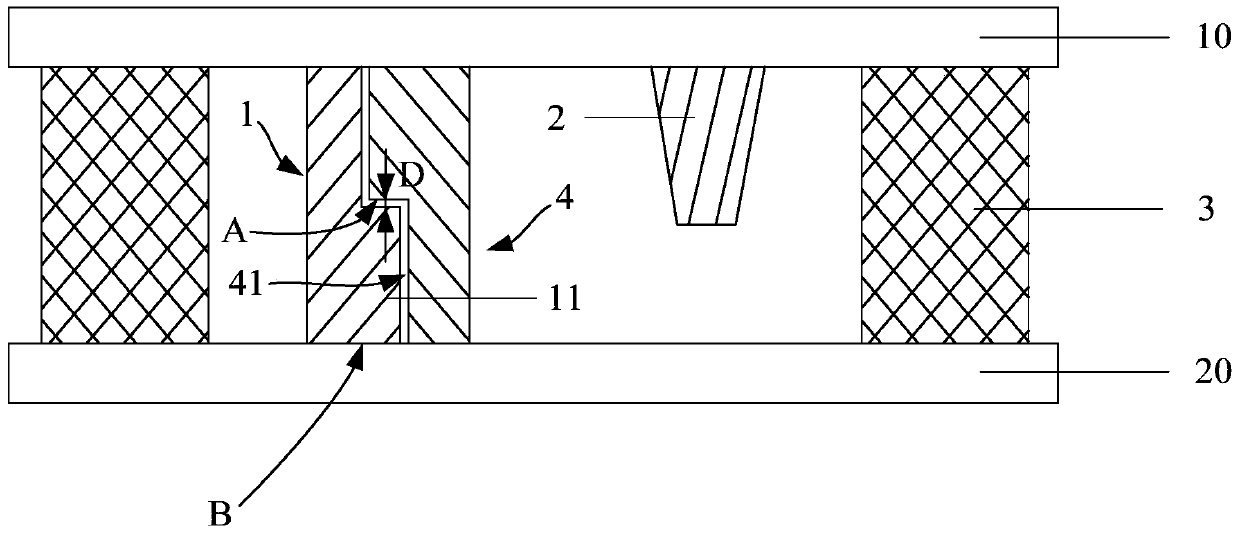

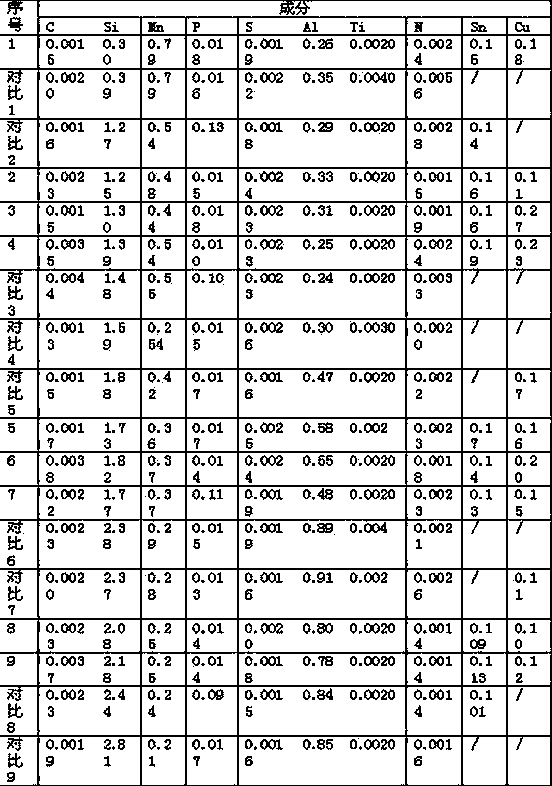

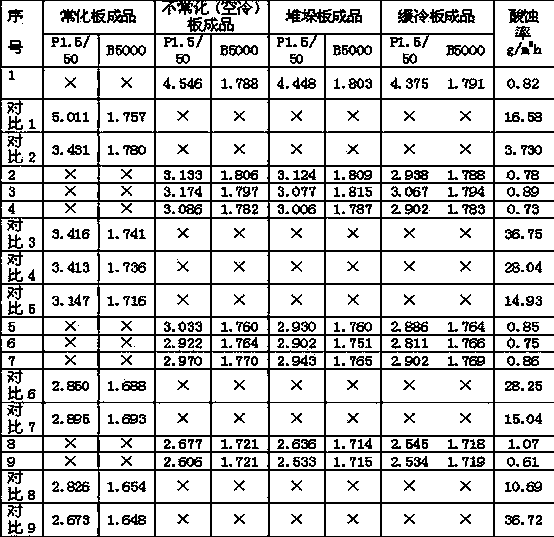

Normalization-free high-magnetic induction low-iron loss acid etching-resistant non-oriented silicon steel and production method thereof

The invention relates to a normalization-free high-magnetic induction low-iron loss acid etching-resistant non-oriented silicon steel and a production method thereof. The normalization-free high-magnetic induction low-iron loss acid etching-resistant non-oriented silicon steel comprises the following components in percentage by weight: C less than or equal to 0.0050%, 0.30-2.50% of Si, 0.15%-0.80% of Mn, 0.25-0.80% of Al, P less than or equal to 0.050%, S less than or equal to 0.0050%, N less than or equal to 0.0050%, Ti less than or equal to 0.0050% and 0.20-0.45% of Sn+Cu, wherein Sn and Cu are not equal to 0.The production method comprises the following steps of: smelting and casting into a blank; heating and soaking the cast blank to 1080-1150 DEG C; carrying out conventional hot rolling; rolling; pickling; carrying out one-time cold rolling to the thickness of a finished product; and annealing. The normalization-free high-magnetic induction low-iron loss acid etching-resistant non-oriented silicon steel disclosed by the invention is low in Si alloying degree, achieves the P 1.5 / 50 to the level of medium-high grade non-oriented silicon steels and the magnetic induction B 5000 higher than that of common non-oriented silicon steels by more than 0.08 T and equivalent to that of high-magnetic induction non-oriented silicon steels with same iron loss grades, is very conductive to enhancing the stability of a motor operated in a harsh environment for a long time and prolonging the service life of the motor and can also reduce the rusting loss in producing, storing, transporting and using processes.

Owner:武汉钢铁有限公司

A method for quantitative analysis of sulfur and phosphorus in iron and steel

ActiveCN108414500BRapid content detectionReduce processing timeAnalysis by thermal excitationSulfurInternal standard

The invention discloses a method for quantitative analysis of sulfur and phosphorus in steel. The method comprises the following steps: preparation of standard establishing samples; adjustment of theparameters of a laser induced breakdown system; collection of laser induced breakdown spectrum signals; establishment of standard curves for SII 233.249 nm and PI253.560 nm based on an internal standard method; collection of the signals of the sample to be tested; and acquisition of the S / P quantitative analysis result of the sample to be tested according to the standard curves. The method of theinvention integrates the internal standard method with laser induced breakdown spectroscopy and can thus rapidly detect the contents of elemental sulfur and elemental phosphorus in situ.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

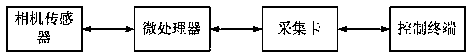

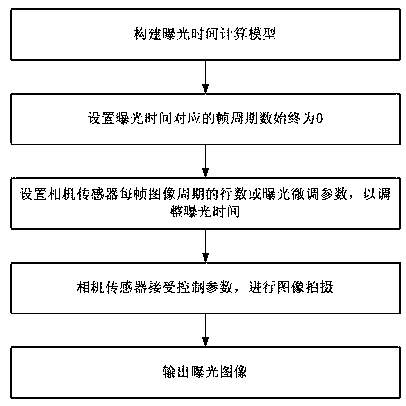

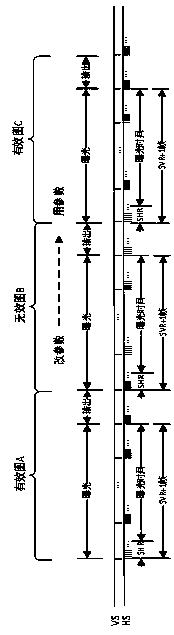

Camera image capturing method and system

ActiveCN110753189AImprove acquisition speedImprove production line capacityTelevision system detailsColor television detailsCamera imageComputer graphics (images)

The invention provides a camera image capturing method and system. The system suitable for the method comprises a control terminal, an acquisition card, a microprocessor and a camera sensor, wherein the control terminal, the acquisition card, the microprocessor and the camera sensor are electrically connected in sequence. The method comprises the following steps: constructing an exposure time calculation model; setting the frame period number corresponding to the exposure time to be always 0; setting the line number or exposure fine adjustment parameters of each frame image period of the camera sensor to adjust the exposure time; enabling the camera sensor to receive the control parameters and perform image shooting; and outputting exposed images. The method and system have an obvious effect on the scene of switching the exposure time to photograph and shortening the image capturing time.

Owner:WUHAN JINGLI ELECTRONICS TECH +1

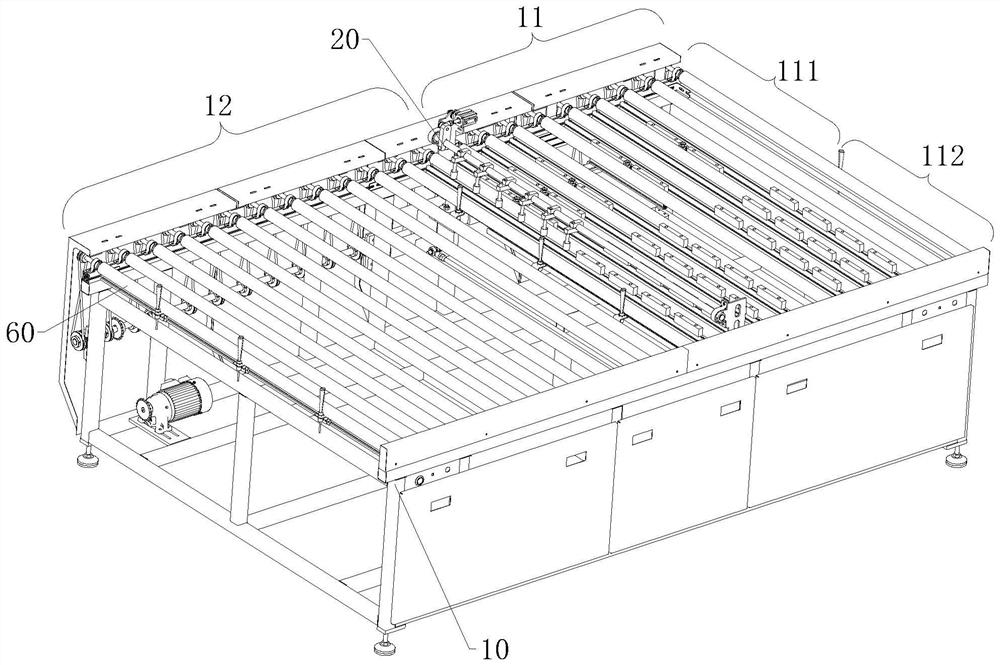

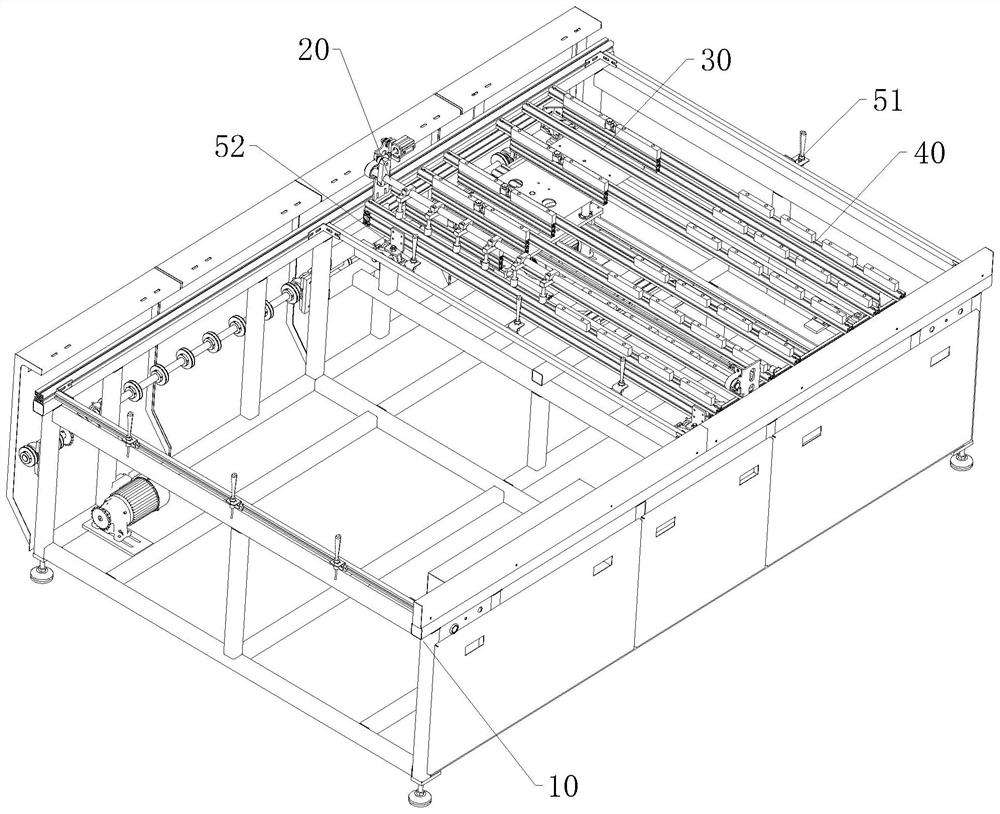

Chip arranging machine and control system thereof

PendingCN114104594AAvoid Force Inconsistency ProblemsImprove efficiencyConveyorsControl devices for conveyorsProduction lineControl system

The invention relates to the technical field of production line equipment, and provides a sheet arranging machine and a control system thereof in order to solve the technical problems of low efficiency and low productivity caused by manual material arranging and sheet arranging in the prior art. A material blocking mechanism for dividing the sheet arranging machine into a front area and a rear area is arranged on a rack, and the front area comprises a material blocking area and a waiting area; a material sheet transferring device is arranged on the lower portion of the front area and moves between the material blocking area and the waiting area, the material sheet transferring device is provided with a first jacking mechanism for jacking material sheets, a discharging platform is arranged on the lower portion of the front area, a strip-shaped supporting block of the discharging platform is located in the waiting area, and the discharging platform is provided with a second jacking mechanism. The second jacking mechanism drives the strip-shaped supporting block to ascend and descend between the rubber rollers. Through cooperation of all the mechanisms, the material sheets in the waiting area stay according to needs or directly flow to the rear area or flow out along with the next material sheet, different combinations of the multiple material sheets can be achieved according to actual needs, efficiency and precision are improved, and the productivity of a production line is increased.

Owner:SHENZHEN CHNTOP SCREEN PRINTING MACHINERY

A silicon wafer flower basket scheduling platform for double-track feeding

ActiveCN113035761BImprove production line capacitySemiconductor/solid-state device manufacturingConveyor partsProcess engineeringMechanical engineering

The invention provides a silicon wafer flower basket dispatching platform for double-track feeding, which includes a first delivery module, a second delivery module and a translation module, the first delivery module and the second delivery module are horizontally slidably arranged on the translation module, and the One side of the delivery module 1 and the delivery module 2 is used for docking with the flower basket transmission line, the opposite side of the delivery module 1 and the delivery module 2 is connected to the flower basket transmission line and the flower basket lifting system, and the flower basket transmission line The AGV loading level is connected, and the flower basket lifting system is connected with the lowering level, which solves the problem of using the AGV transfer flower basket and the silicon wafer flower feeding machine for docking and loading in intelligent production, and the AGV loading must ensure two The flower baskets on the feed flow line are empty. Due to the double-line production, there will be different output quantities of the two feed flow lines, so the flower baskets on one feed flow line will be emptied and the other feed flow line will be empty. The AGV can only load the material after the flower basket is discharged, which reduces the technical problem of production efficiency.

Owner:中辰昊智能装备(江苏)有限公司

Low-temperature coating equipment and production process

PendingCN113730247AGuaranteed activityImprove functionalityPharmaceutical product form changeFood coatingProduction lineProcess engineering

The invention relates to low-temperature coating equipment and a production process, and belongs to the technical field of pharmaceutical equipment. The coating equipment comprises a first forming device, a first filling device, a first quick-freezing device, a second forming device, a second filling device, a second quick-freezing device, a third filling device and a third quick-freezing device which are sequentially arranged above a packing material conveying mechanism. In the whole coating process, the active ingredient liquid can be always kept in a low-temperature state, the activity of the active ingredients sensitive to the temperature is effectively guaranteed, and the functional effect of the active ingredients is improved; a streamlined operation mode is adopted, manual interference is avoided, the efficiency is high, and the productivity is large; the productivity of a production line can be easily improved according to the productivity requirement; compared with conventional large-batch coating, the effect of single coating can be ensured; according to the invention, a final coating finished product is directly formed from a packing material, and other extra granulation equipment and the like are not needed; and the problems that in the existing coating process, the product activity is reduced, consumed time is long, and coating is not uniform are solved.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com