Liquid crystal display colour-temp. automatic regulation systemand method

A liquid crystal display and color temperature adjustment technology, applied to static indicators, instruments, etc., can solve the problems of unsatisfactory color adjustment of liquid crystal display, narrow viewing angle of liquid crystal display, low production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

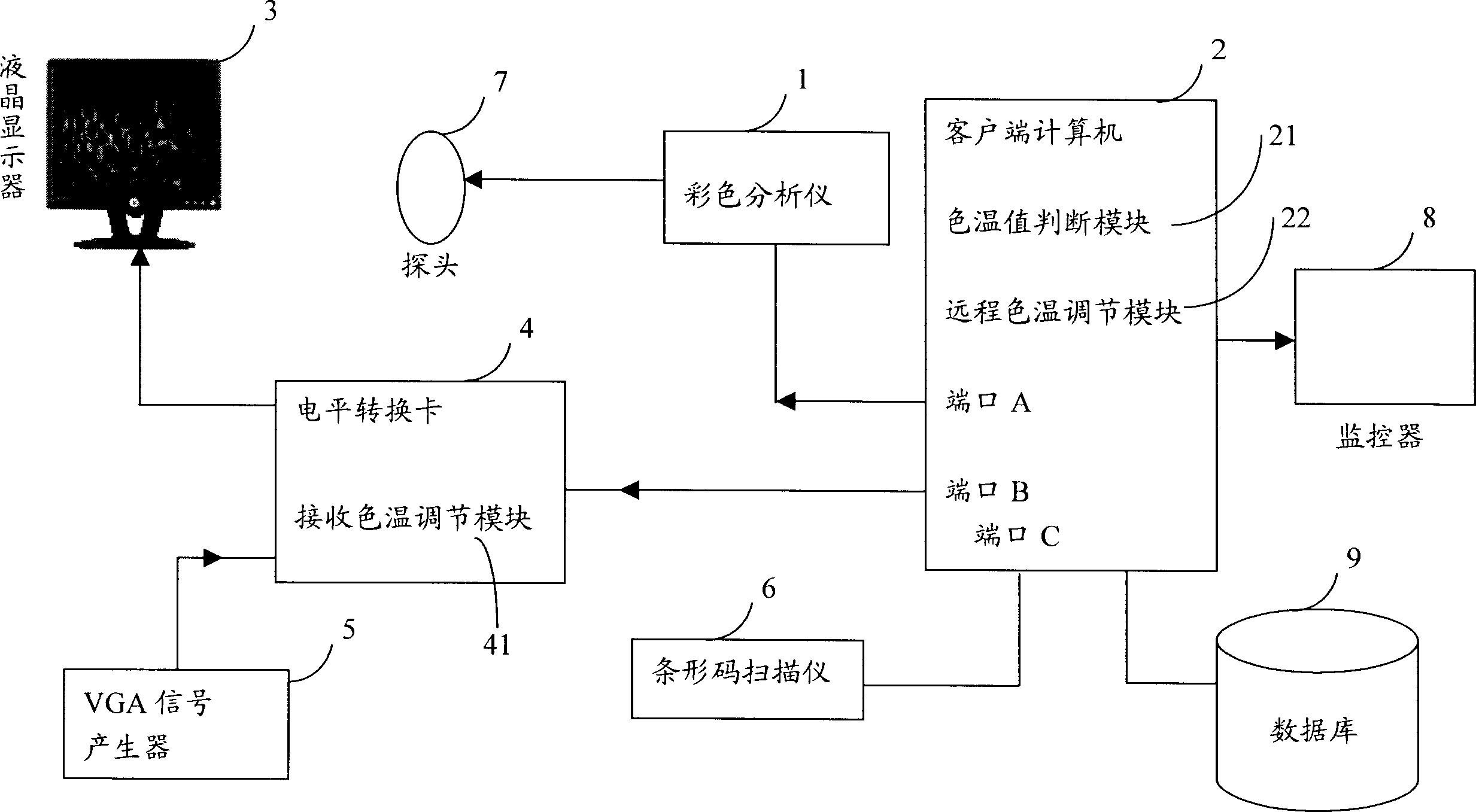

Method used

Image

Examples

Embodiment Construction

[0012] First explain the terms involved in this embodiment

[0013] R value: Red value, which is the red value of the three primary colors.

[0014] G value: the Green value, which is the green value of the three primary colors.

[0015] B value: the Blue value, which is the blue value of the three primary colors.

[0016] PWM: Pulse Width Modulation.

[0017] This embodiment adopts Chroma 7120 color analyzer, but other color analyzers can also be used in actual production. Chroma 7120 is equipped with a sensor similar to the CIE1931 color matching function, which can accurately measure the light energy emitted by the LCD panel. Users can freely switch between three different chromaticity coordinate systems, including xyY (xy: chromaticity coordinate value, Y: brightness value).

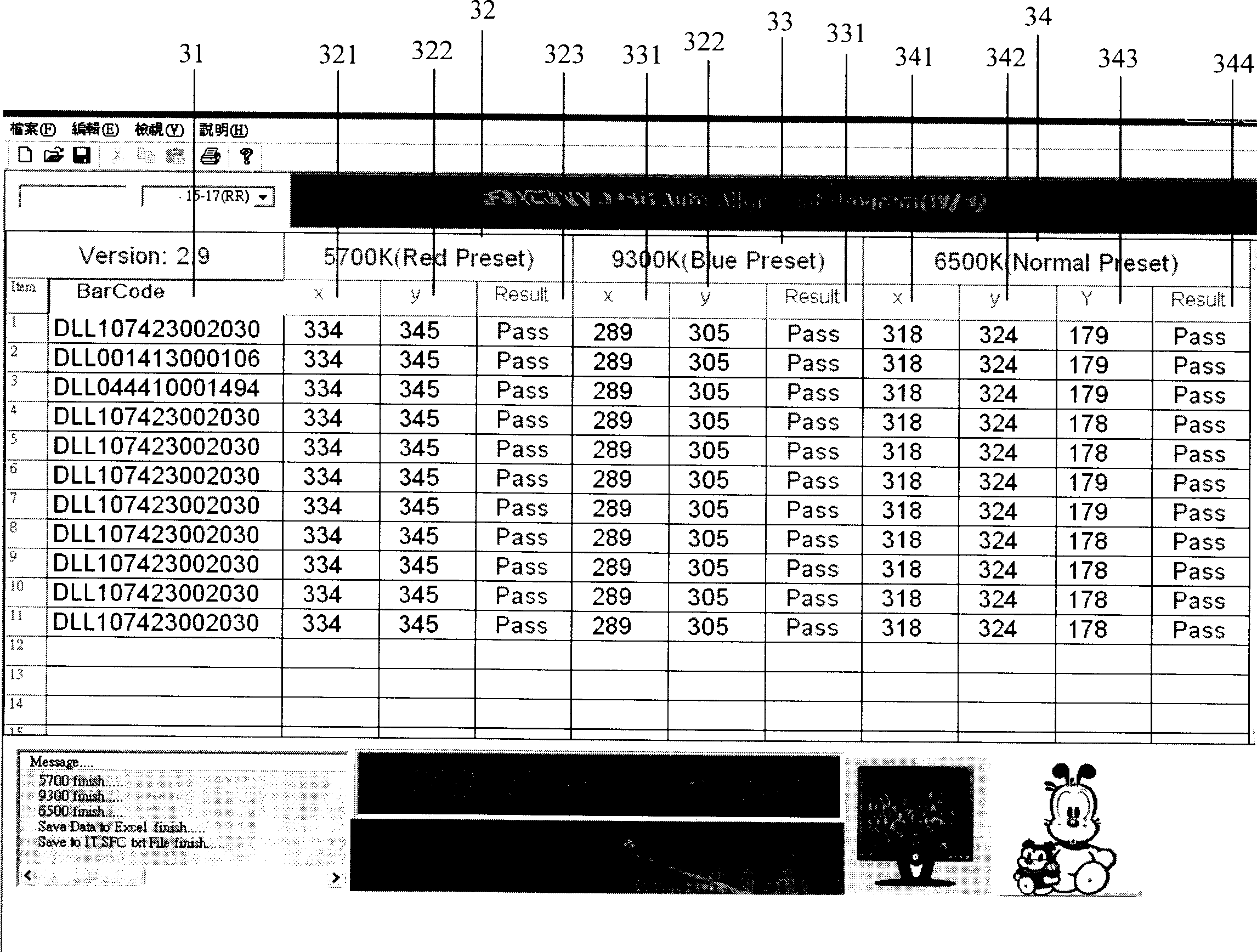

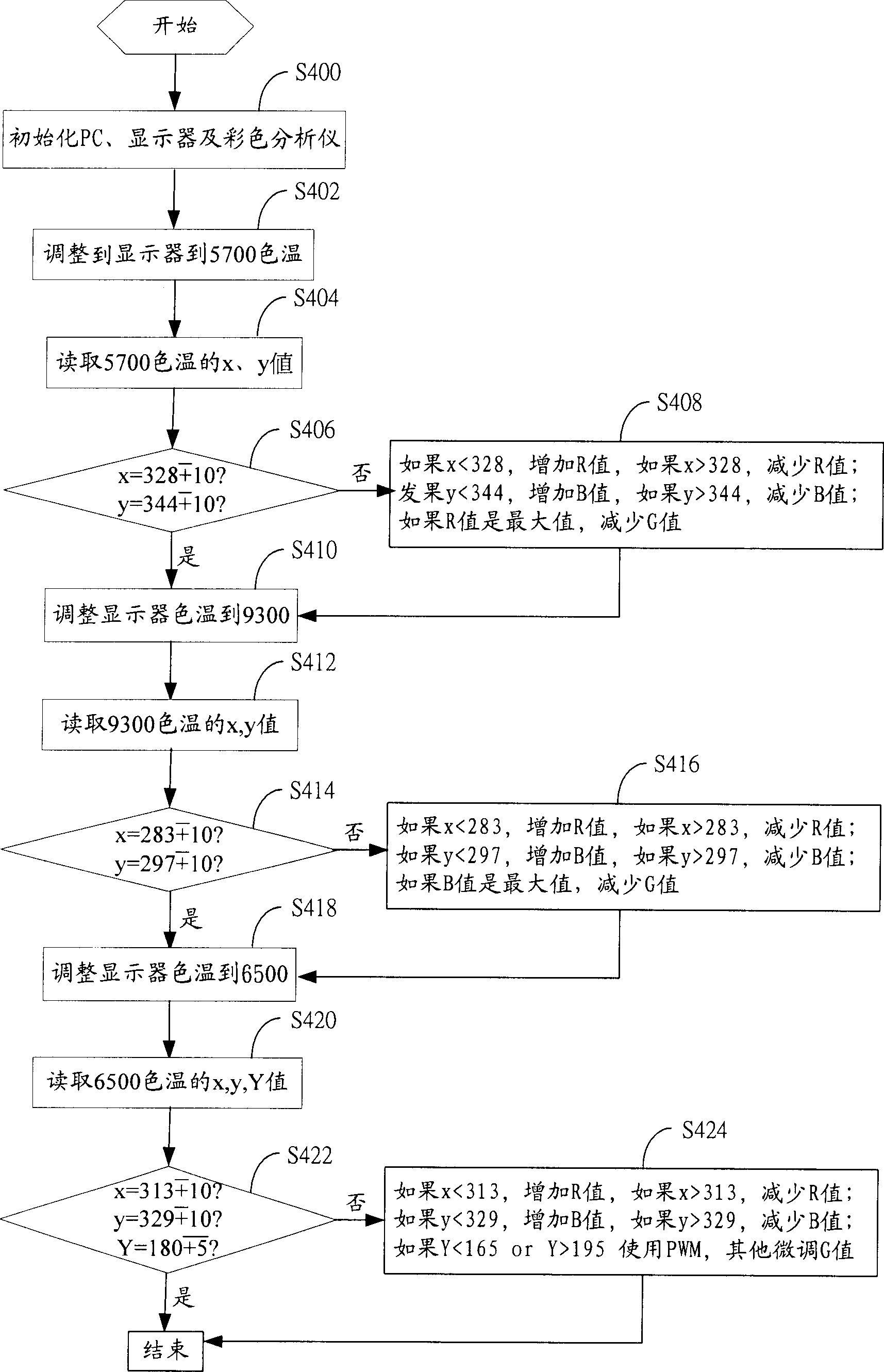

[0018] In this embodiment, the requirements 5700K, 9300K, and 6500K proposed by customers are taken as examples. For example, under the color temperature standard of TCO99, the abscissa value of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com