Cleaning process for large-size imbricated battery piece

A battery chip, large-size technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of high cleaning cost, long cleaning time, poor effect, etc., to shorten cleaning time, increase production line productivity, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

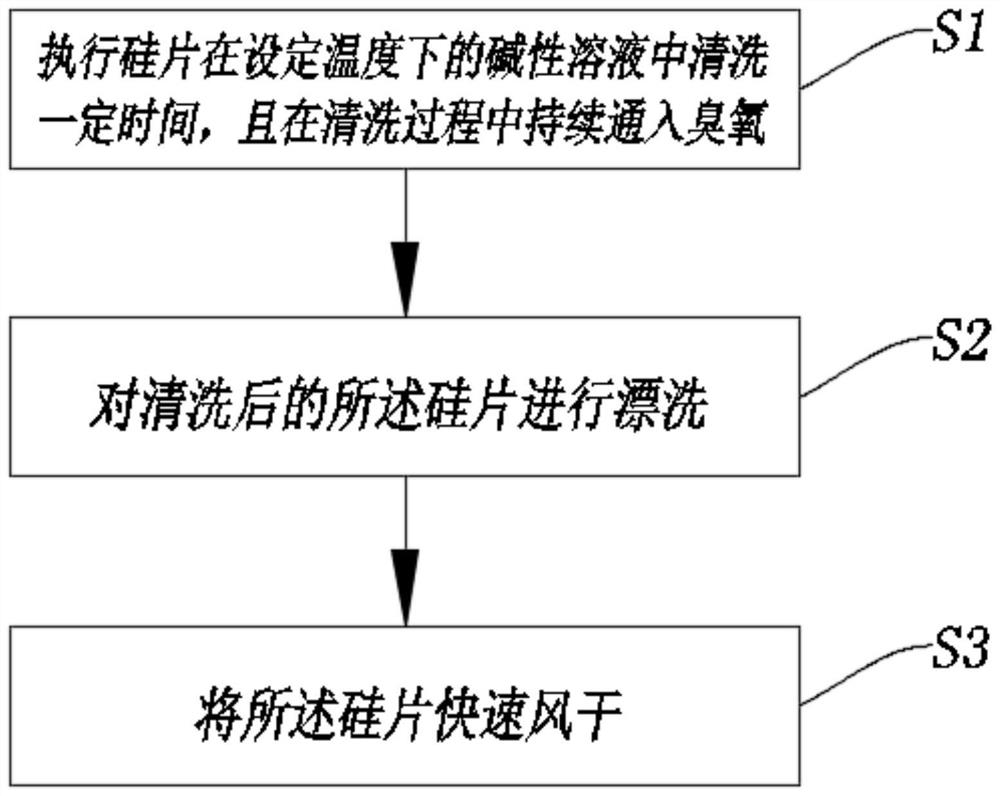

[0031] S1: The silicon wafer is cleaned in a mixed alkaline solution of sodium hydroxide and deionized water, wherein the temperature of the alkaline solution is 65° C., cleaning is performed for 5 minutes, and ozone is introduced into the entire cleaning process. The volume concentration of sodium hydroxide is 3.7%; and the flow rate of ozone is 5L / min.

[0032] S2: Put the cleaned silicon wafer into deionized water for rinsing, and the rinsing temperature is 85°C; the rinsing time is 3 minutes.

[0033] S3: the rinsed silicon wafer is quickly air-dried, and the air-drying time is 2 minutes.

Embodiment 2

[0035] S1: The silicon wafer is cleaned in a mixed alkaline solution of sodium hydroxide and deionized water, wherein the temperature of the alkaline solution is 70° C., cleaning is performed for 4 minutes, and ozone is introduced into the entire cleaning process. The volume concentration of sodium hydroxide is 3.7%; and the flow rate of ozone is 5L / min.

[0036] S2: Put the cleaned silicon wafer into deionized water for rinsing, and the rinsing temperature is 80°C; the rinsing time is 5 minutes.

[0037] S3: the rinsed silicon wafer is quickly air-dried, and the air-drying time is 2 minutes.

Embodiment 3

[0039] S1: The silicon wafer is cleaned in a mixed alkaline solution of sodium hydroxide and deionized water, wherein the temperature of the alkaline solution is 75° C., cleaning is performed for 3 minutes, and ozone is introduced into the entire cleaning process. The volume concentration of sodium hydroxide is 3.5%; and the flow rate of ozone is 7L / min.

[0040] S2: Put the cleaned silicon wafer into deionized water for rinsing, and the rinsing temperature is 75°C; the rinsing time is 4 minutes.

[0041] S3: the rinsed silicon wafer is quickly air-dried, and the air-drying time is 2 minutes.

[0042] By using the method of the present invention, the results obtained by cleaning the silicon wafers of the same silicon wafer type through the processes in the first, second and third embodiments are compared with the texturing cleaning process in the prior art. The results of the dirt particle cleaning rate are shown in the table below:

[0043] Table 1 Comparison of test result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com