Liquid crystal panel and display device

A liquid crystal panel and liquid crystal layer technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve problems such as the lower limit of LCMargin becoming higher and affecting production line production capacity, and achieve the effect of raising the upper limit, increasing production line production capacity, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

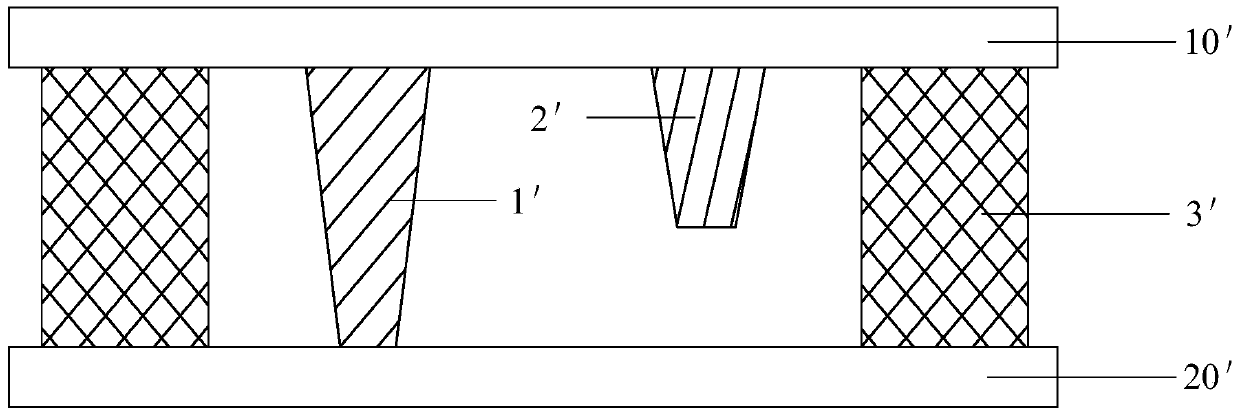

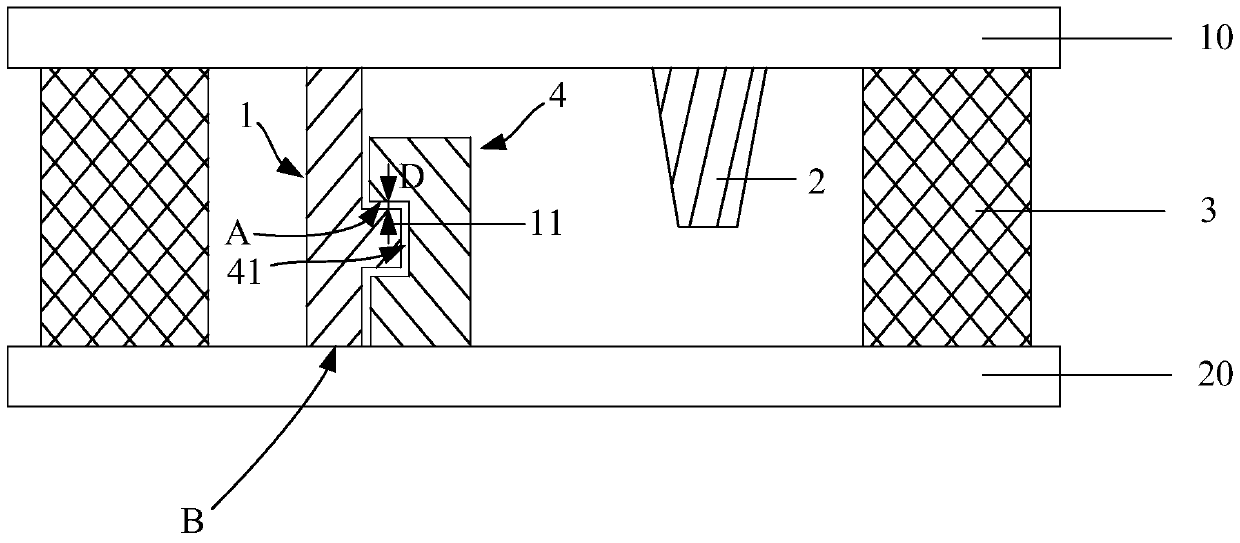

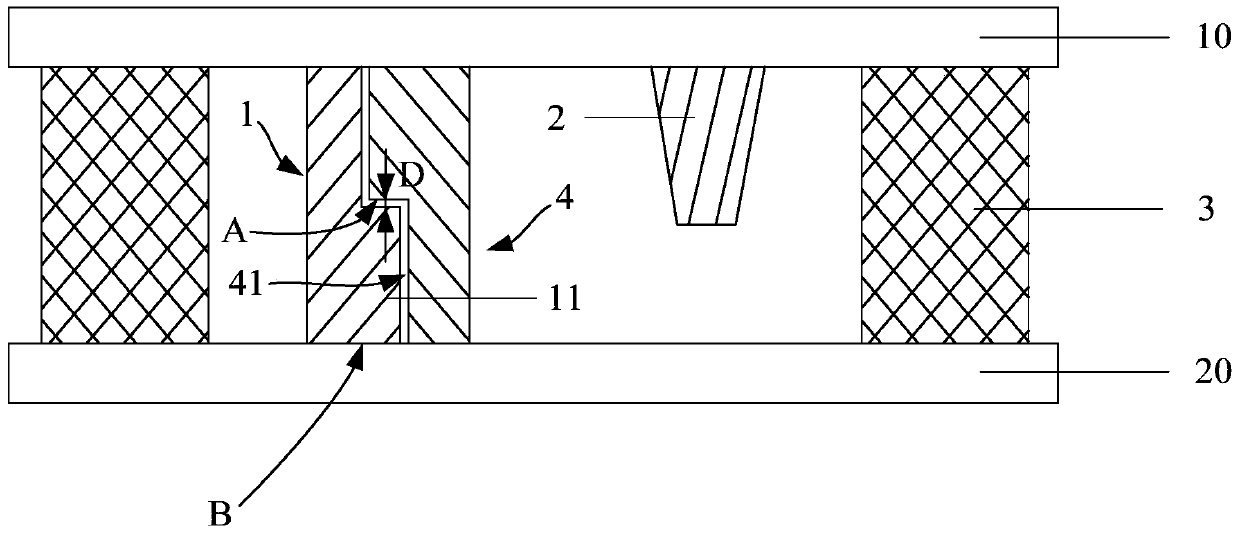

[0040] In the production line of LCD panels, the larger the range of liquid crystal filling, the greater the fluctuation of the process during mass production, and the higher the production line capacity. The liquid crystal filling range is specifically the difference between the liquid crystal filling upper limit and the liquid crystal filling lower limit. Wherein, the greater the level difference between the main spacer and the auxiliary spacer of the liquid crystal panel, the lower the lower limit of liquid crystal filling and the larger the liquid crystal filling range. However, the greater the level difference between the main spacer and the auxiliary spacer, the weaker the compression resistance of the liquid crystal panel. In the actual production process, the lower limit of liquid crystal filling is generally sacrificed for the pressure resistance, which greatly affects the production line capacity.

[0041] The present invention provides a liquid crystal panel, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com