Extra-thick wall X70-grade ocean acid-resistant pipeline steel and preparation method thereof

A pipeline steel and extra-thick technology, which is applied in the field of extra-thick-wall X70 grade marine acid-resistant pipeline steel and its preparation, can solve the problems of low strength level, difficult to control structure uniformity, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

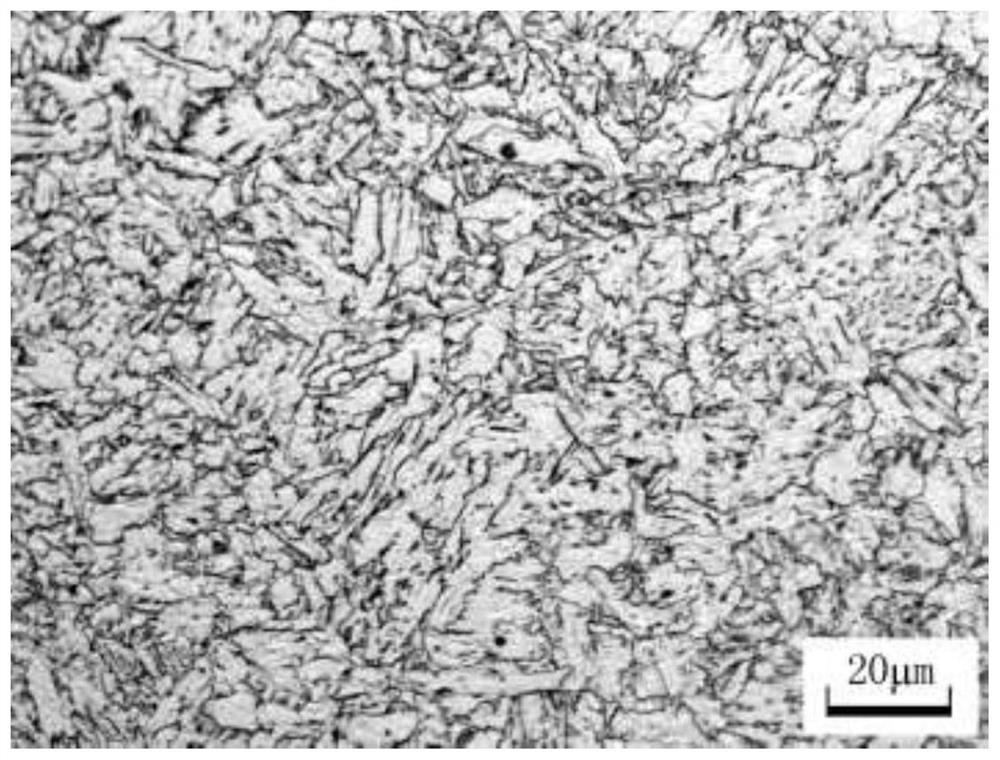

[0051] 150mm billet is used to roll 25mm thickness X70 grade seabed acid-resistant pipeline steel. The specific implementation steps are as follows:

[0052] 1) Carry out smelting according to the composition requirements stated in Table 1, and control the content of molten steel as follows: N≤0.0050%, H≤0.0002%, O≤0.0025%, P≤0.015%, S≤0.0020%; molten steel composition After qualified, add Ca to the molten steel, control the Ca / S in molten steel to 1.5-3.0, control the casting temperature at 1533-1548°C, use electromagnetic stirring and dynamic light pressure to improve the segregation of the continuous casting slab, and control the low magnification of the casting slab The rating is within C1.0;

[0053] 2) After casting into a slab with a thickness of 150mm, install a heating furnace to heat and keep it warm; the heating temperature is 1150-1180°C; according to different furnace loading temperatures, the time in the furnace is 130-230min, and the holding time at a high tempe...

Embodiment 6~10

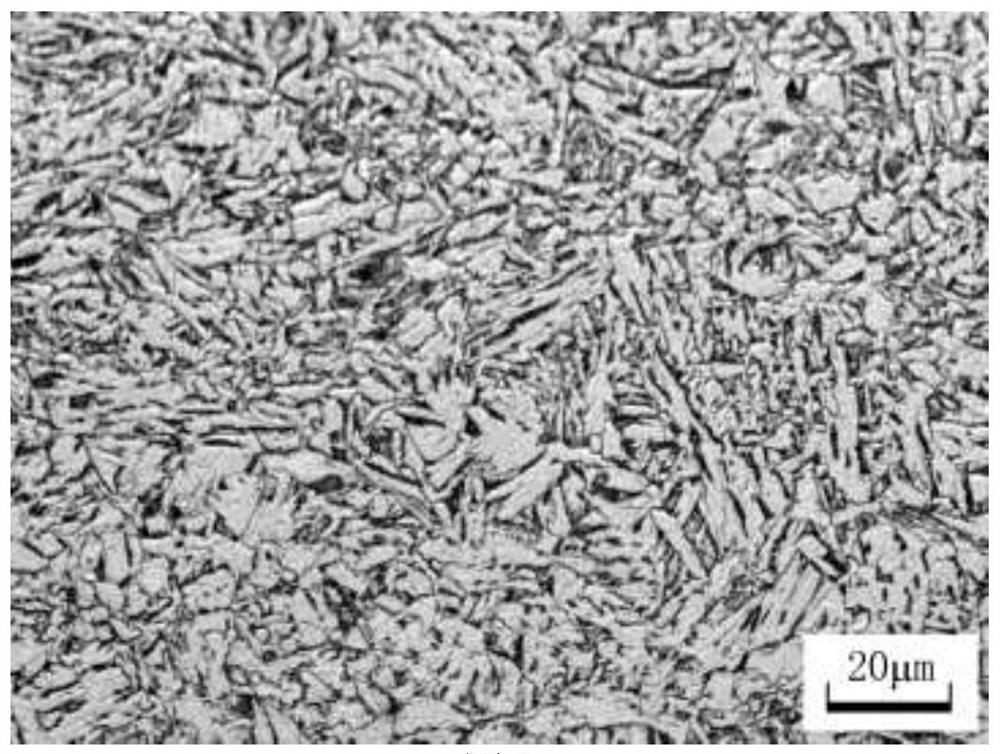

[0066] Using 230mm billet to roll 40mmX70 grade pipeline steel, the specific implementation steps are as follows:

[0067] 1) Carry out smelting according to the composition requirements stated in Table 4, and control the content of molten steel as follows: N≤0.0050%, H≤0.0002%, O≤0.0025%, P≤0.015%, S≤0.0020%; molten steel composition After passing the test, add Ca to the molten steel, control the Ca / S in the molten steel to 1.5-3.0, and control the casting temperature at 1533-1548°C. The slab low-magnification rating is within C1.0;

[0068] 2) After casting into a slab with a thickness of 230mm, install a heating furnace to heat and keep it warm; the heating temperature is 1150-1180°C; according to different furnace loading temperatures, the time in the furnace is 160min-260min, and the holding time at a high temperature of 1150-1180°C is 60-100min;

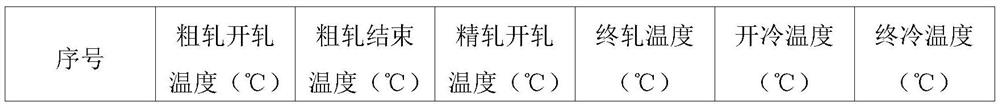

[0069] 3) Three-stage hot rolling; in the first stage, one pass of large deformation rolling is carried out in the high-temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com